Composite components with integral protective casings

a technology of composite components and protective casings, applied in the field of structural composite components, can solve the problems of low densities of polymer composites, harsh environmental conditions during use of rockets, missiles and other similar airborne structures that move through the air at very high speeds, and limit the feasibility of using materials such as metals and metal alloys

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

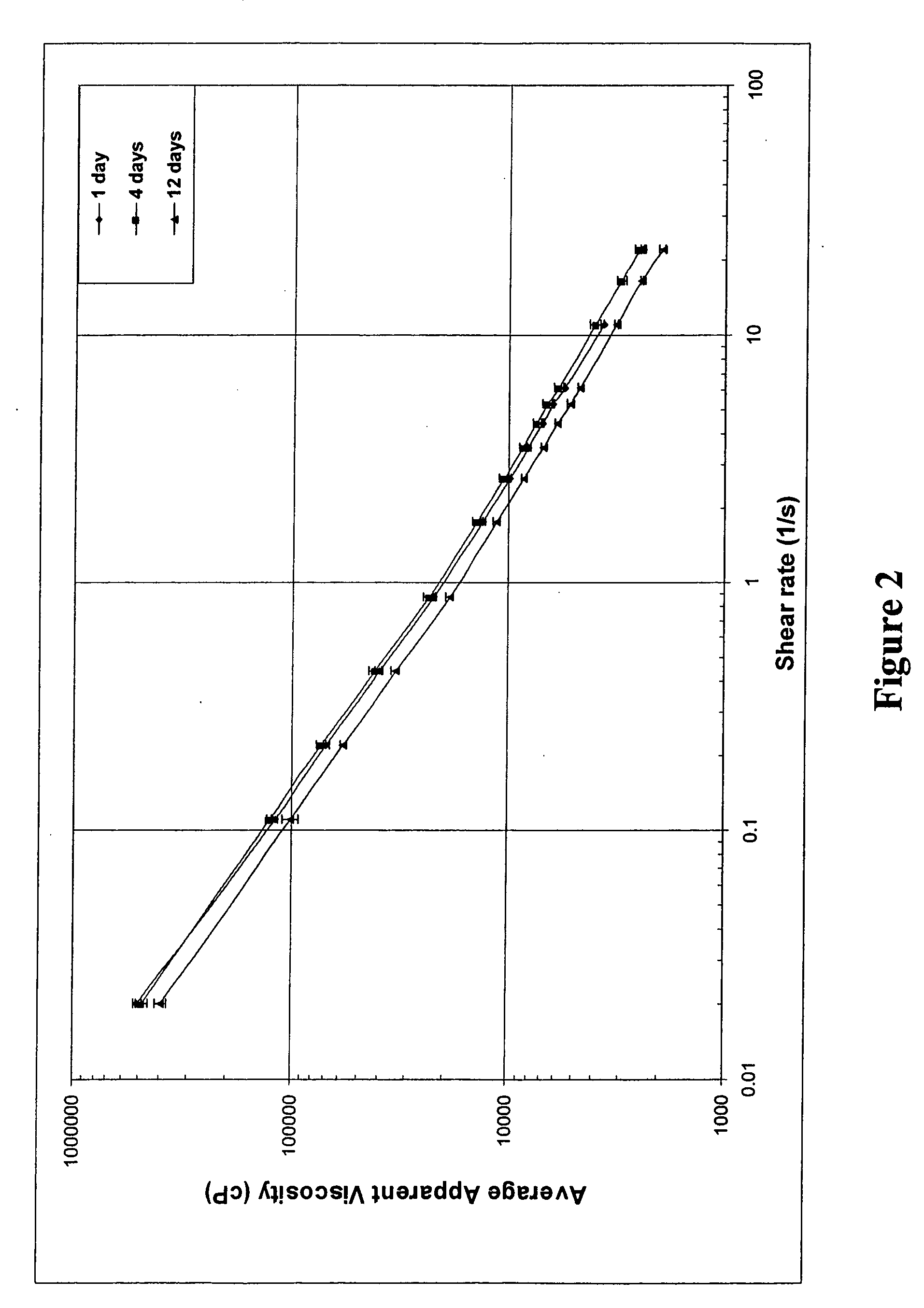

Slurry Evaluation

[0038]The following Si3N4 slurries were evaluated:[0039](1) Ceramic slurry made from a premixed blend of UBE E-5 and E-10 Si3N4 powder, commercially available from UBE Industries, Tokyo, Japan, and ceria-based sintering aids (53 vol % solids loading);[0040](2) Ceramic slurry made from a premixed blend of UBE E-5 and E-10 Si3N4 powder and added ceria-based sintering aids (50 vol % solids loading);[0041](3) Ceramic slurry of UBE E-5 and E-10 Si3N4 powder and aluminum nitride and alumina and yttria sintering aids (52.18 vol % solids loading);[0042](4) Ceramic slurry made from Stark M-11 Si3N4 powder, commercially available from H. C. Starck Inc., Newton, Mass., and alumina and yttria sintering aids, commercially available from Malakoff Industries, Malakoff, Tex., and Molycorp Inc., Mountain Pass, Calif., respectively (52 vol % solids loading);[0043](5) Ceramic slurry made from Stark M-11 Si3N4 powder and alumina and yttria sintering aids (42 vol % solids loading); and[...

example 2

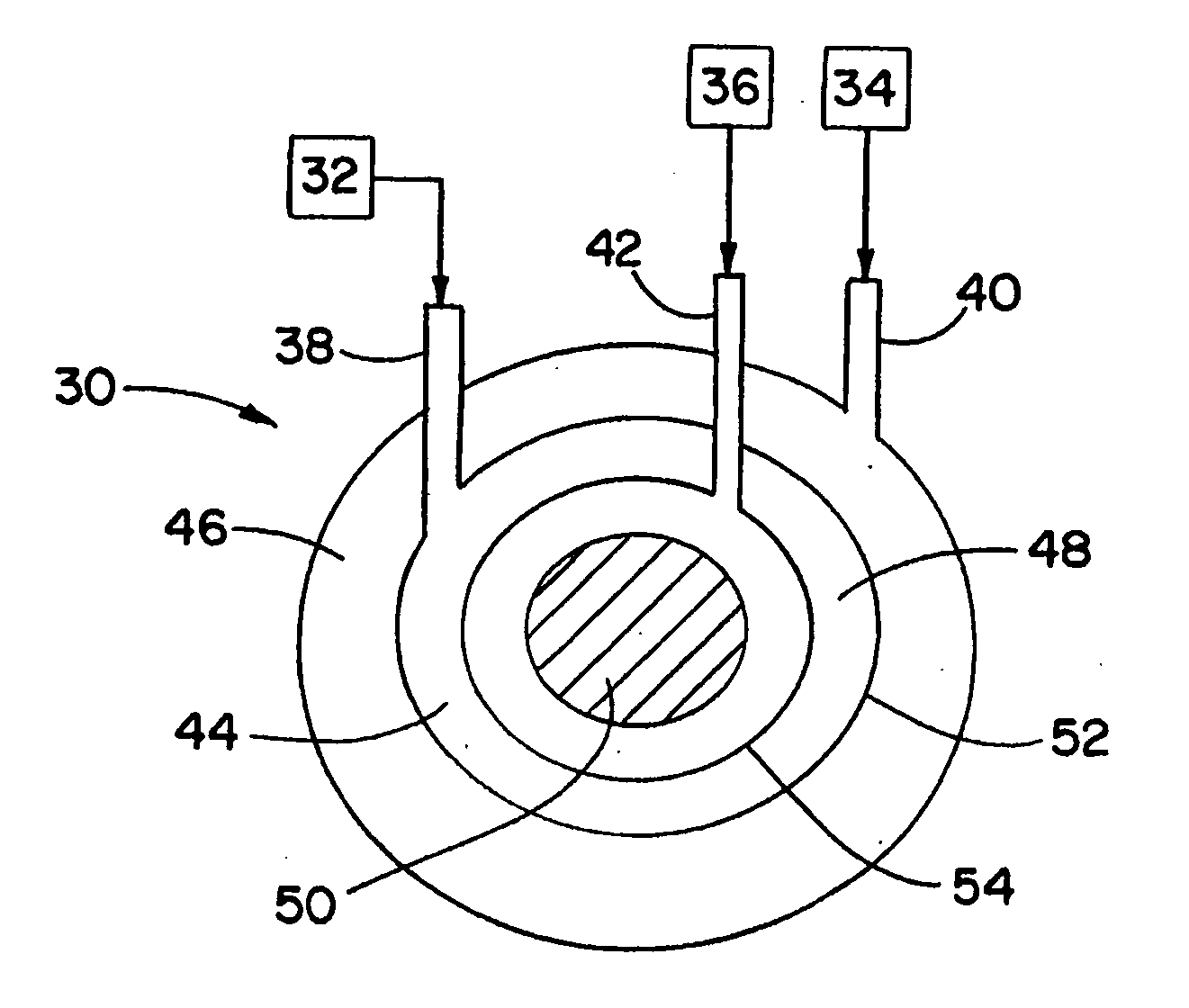

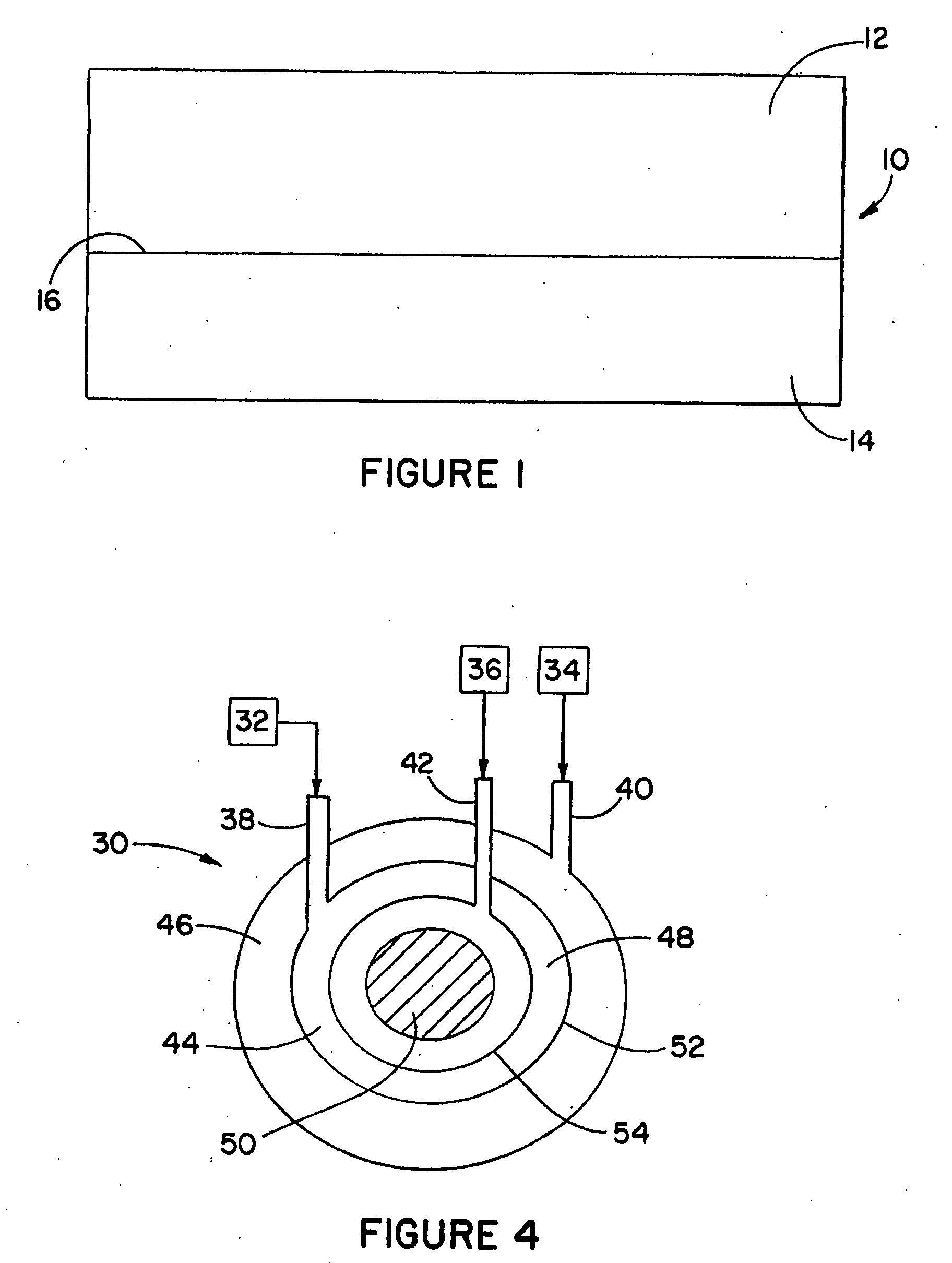

CITRM of Composite Panels with Integral Heat Shields

[0048]Composite panels were fabricated using a CIRTM process. Epoxy resin and silicon nitride ceramic slurry were co-injected into a two-dimensional, 50% by volume porous fiber preforms to produce integral composite panels. A polysulfone layer was included as an intermediate layer for the epoxy resin and ceramic slurry to diffuse into and create a strong bond between the two layers after final curing. A 24-oz. S2 glass fabric was used as the preform. Initial co-injection tests were used to evaluate slurry rheology and whether the slurries were capable of being effectively co-injected with the polymer composite resins.

[0049]Once the co-injection process was complete, the composite panels were allowed to self-cure for several hours during the exothermic portion of the curing cycle. To accelerate the final stages of the endothermic curing cycle, the panels were placed in a 350° F. oven for 2 hours. The following 6″×6″ panels were prod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameters | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com