Foamed reinforced composite material structure vacuum co-injection integral forming method

A composite material, vacuum injection technology, applied in the field of composite materials, can solve the problems of looseness or air bubbles, easy to produce dry spots, complicated penetration, etc., to ensure stability, avoid the bonding process, and simplify the process operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below through specific embodiments and accompanying drawings.

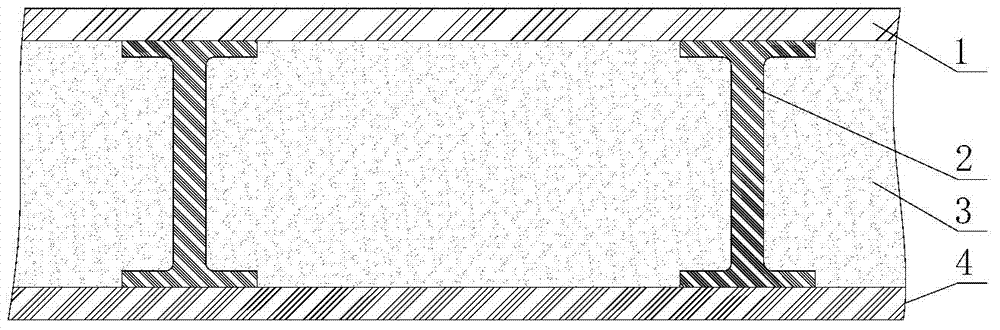

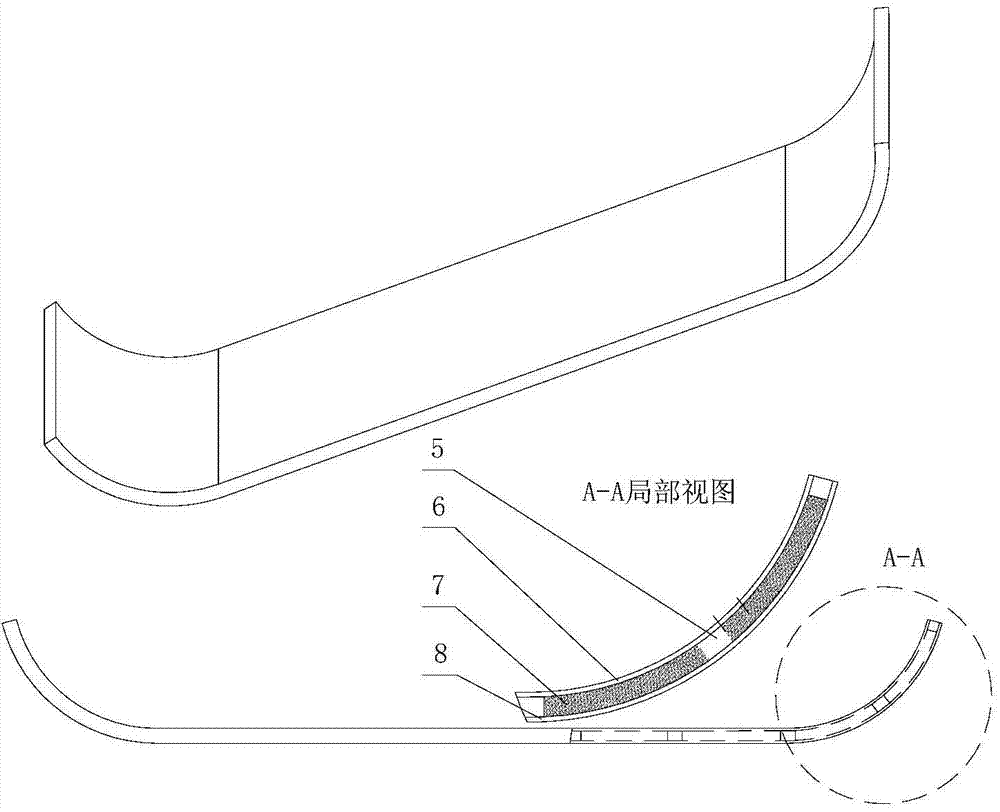

[0030] figure 1 It is a structural schematic diagram of the foam reinforced composite material of the present invention, which includes an upper skin 1 , a reinforcement 2 (that is, a reinforcing rib), a foam interlayer 3 and a lower skin 4 . The steps of the vacuum co-injection integral molding method of the material are as follows: figure 2 As shown, a single-sided mold with a frame is used to form the lower skin by vacuum injection, and the foam interlayer and reinforced prefabricated parts are directly laid on the lower skin without demoulding, and then the upper skin prefabricated parts are laid, and after vacuum sealing The injection resin is integrally molded, and the product can be obtained after demoulding after curing. The upper skin and the lower skin referred to in the present invention can also be called inner skin and outer skin respectively. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com