Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

100 results about "Plastic object" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

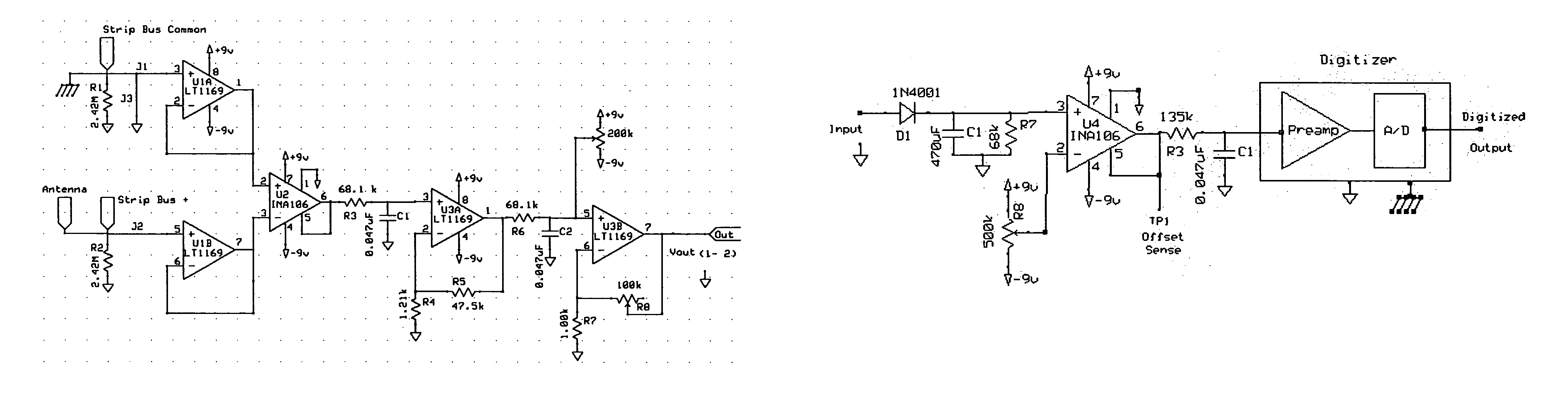

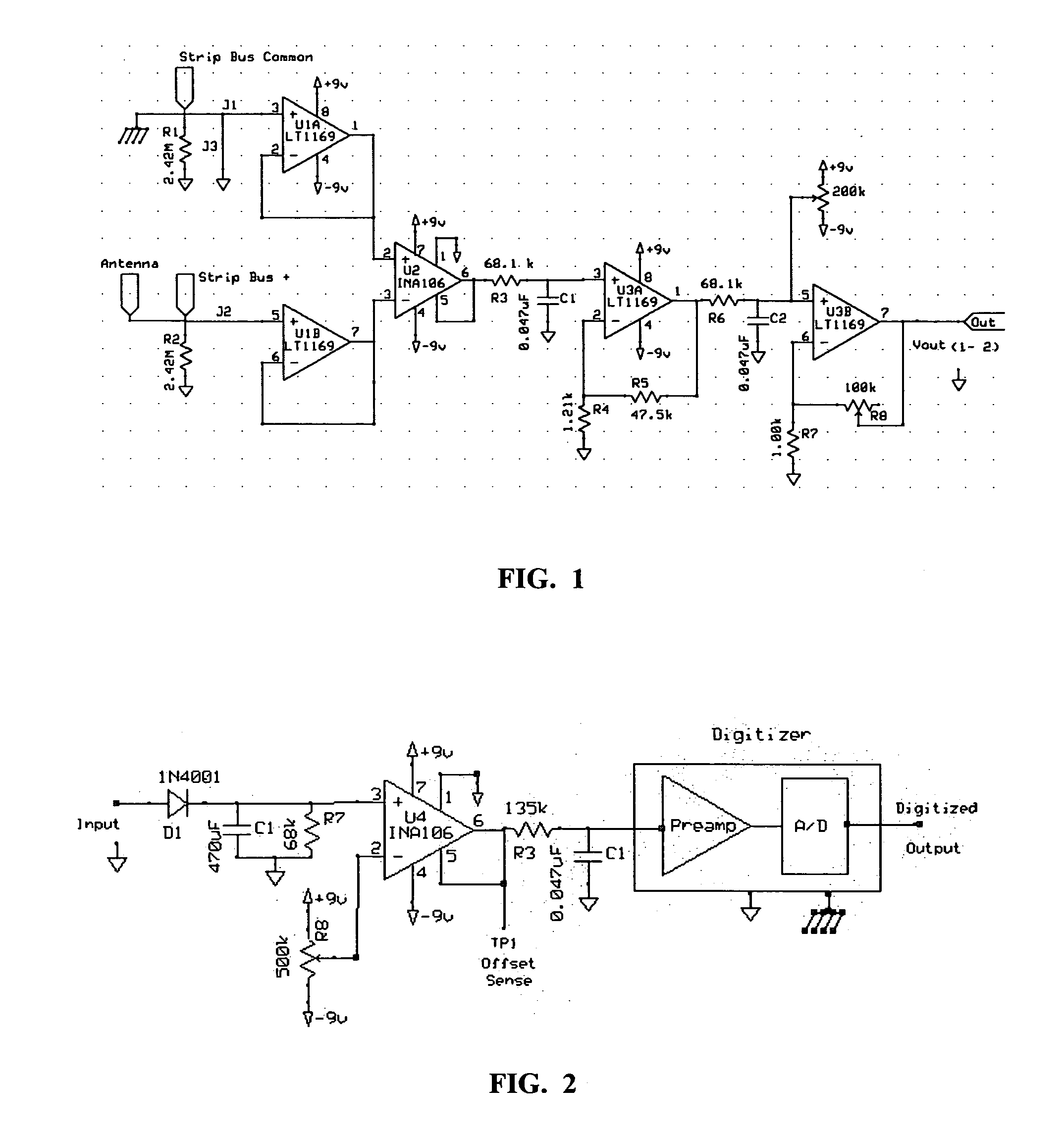

Method and apparatus for detecting charge and proximity

InactiveUS20060092022A1Possible to detectInput/output for user-computer interactionResistance/reactance/impedenceEngineeringObstacle avoidance

A method and apparatus is invented that provides unambiguously detection of the charge and proximity to an object. The method and apparatus are passive and function by using the background electric fields from electrical power wiring and equipment. The invention is useful for detecting plastic and other charged objects concealed by nonconductive covering materials. Applications of this lead to plastic detectors to scan people and cargo for dangerous dielectric items similar to metal detectors. It is also useful to warn of hazards due to static electricity buildup on objects or individuals. The technology also offers touchless control capability of computers, apparatus, and games, with plastic objects such as pointers, styluses, swords, sticks, and wands. The sensors are able to detect motion while discerning between proximity to bodies with dielectric or plastic objects. It is also useful for providing people, robots, and machines with obstacle avoidance, and vision capabilities. Medial imaging possibilities also exist with the technology of this invention.

Owner:CEHELNIK THOMAS G

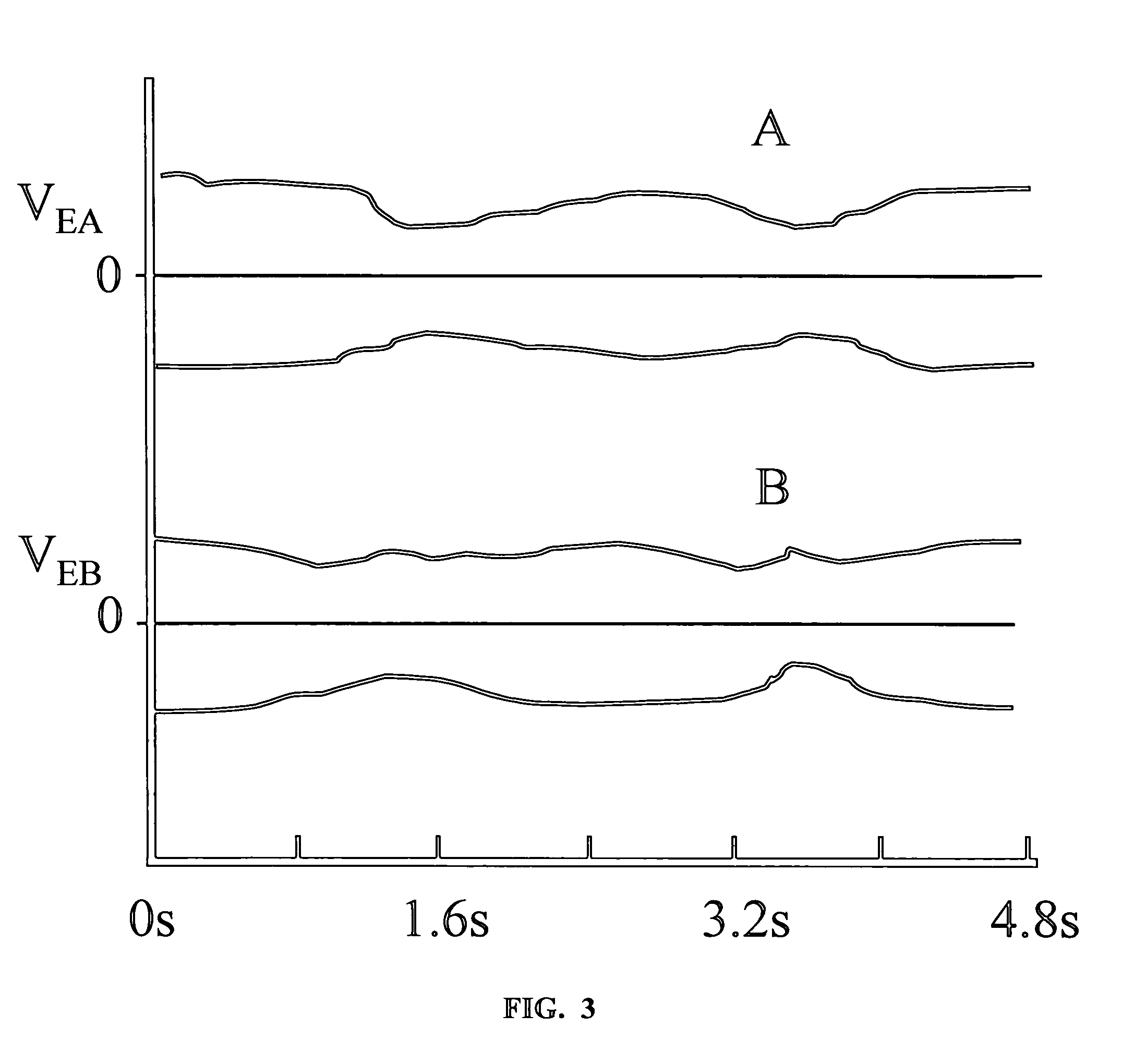

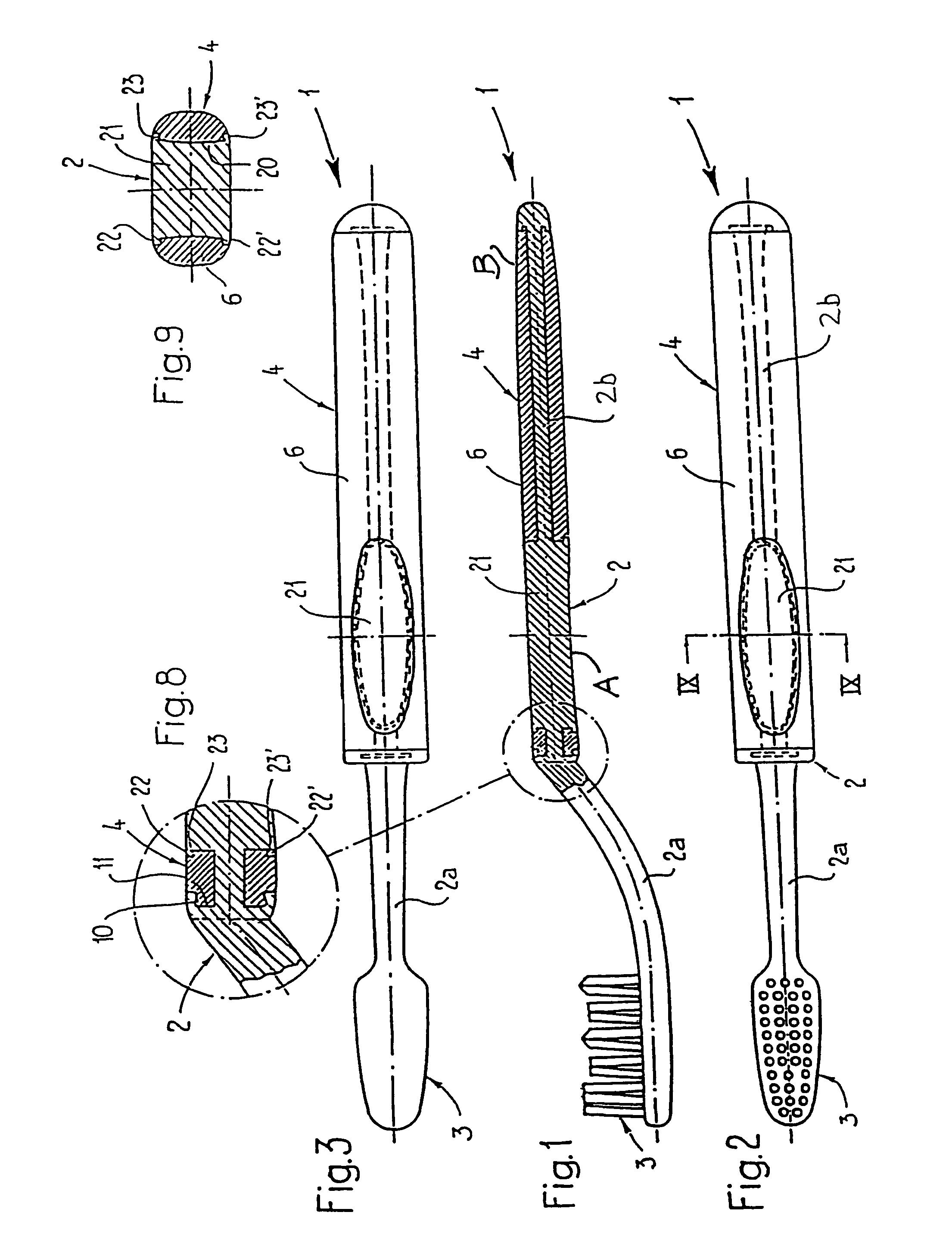

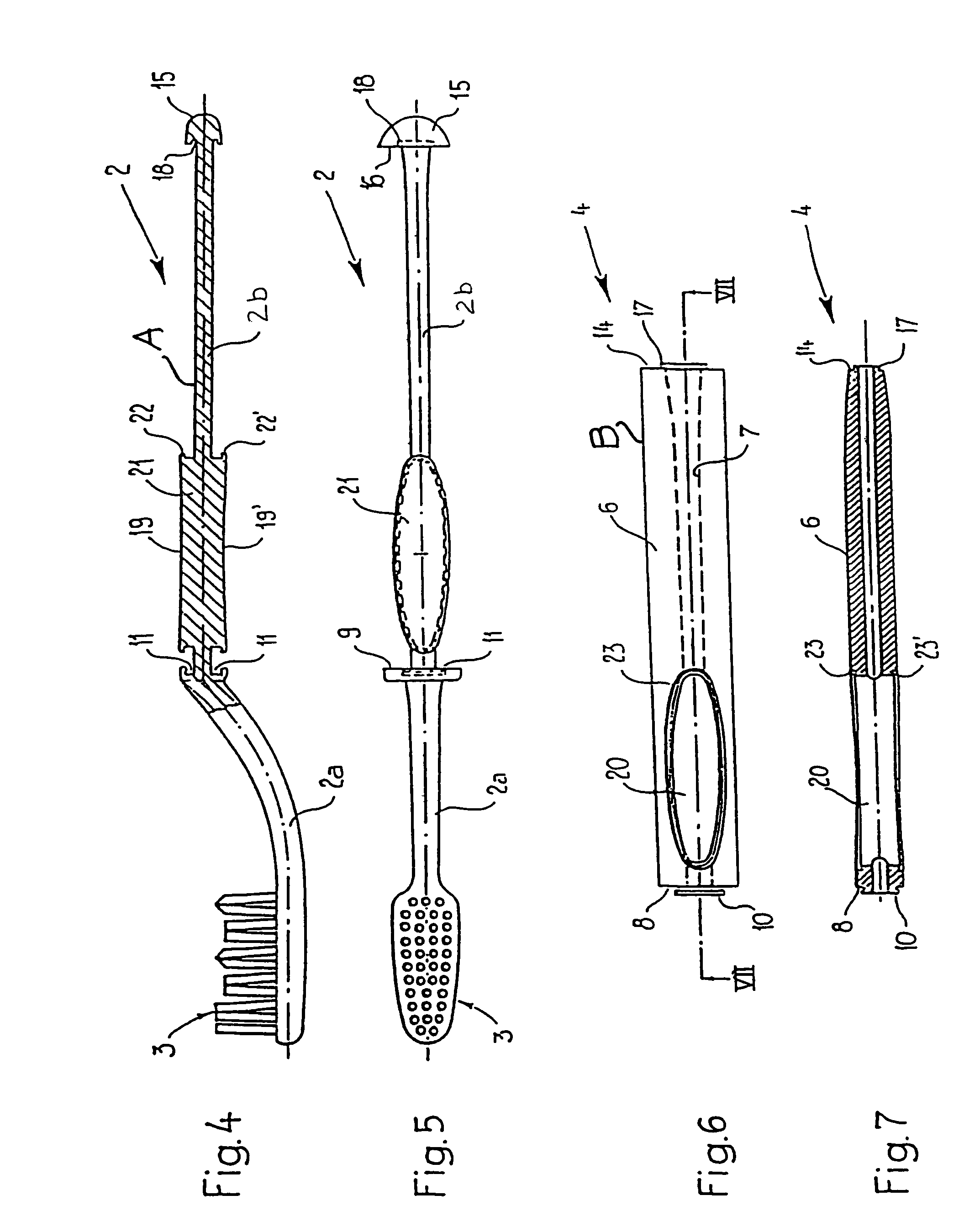

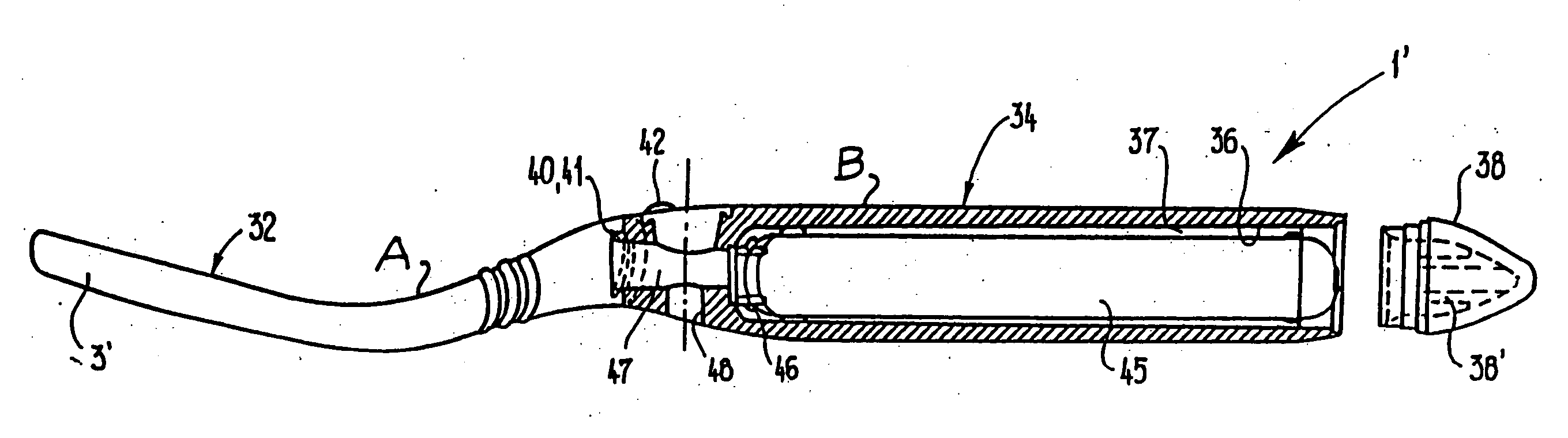

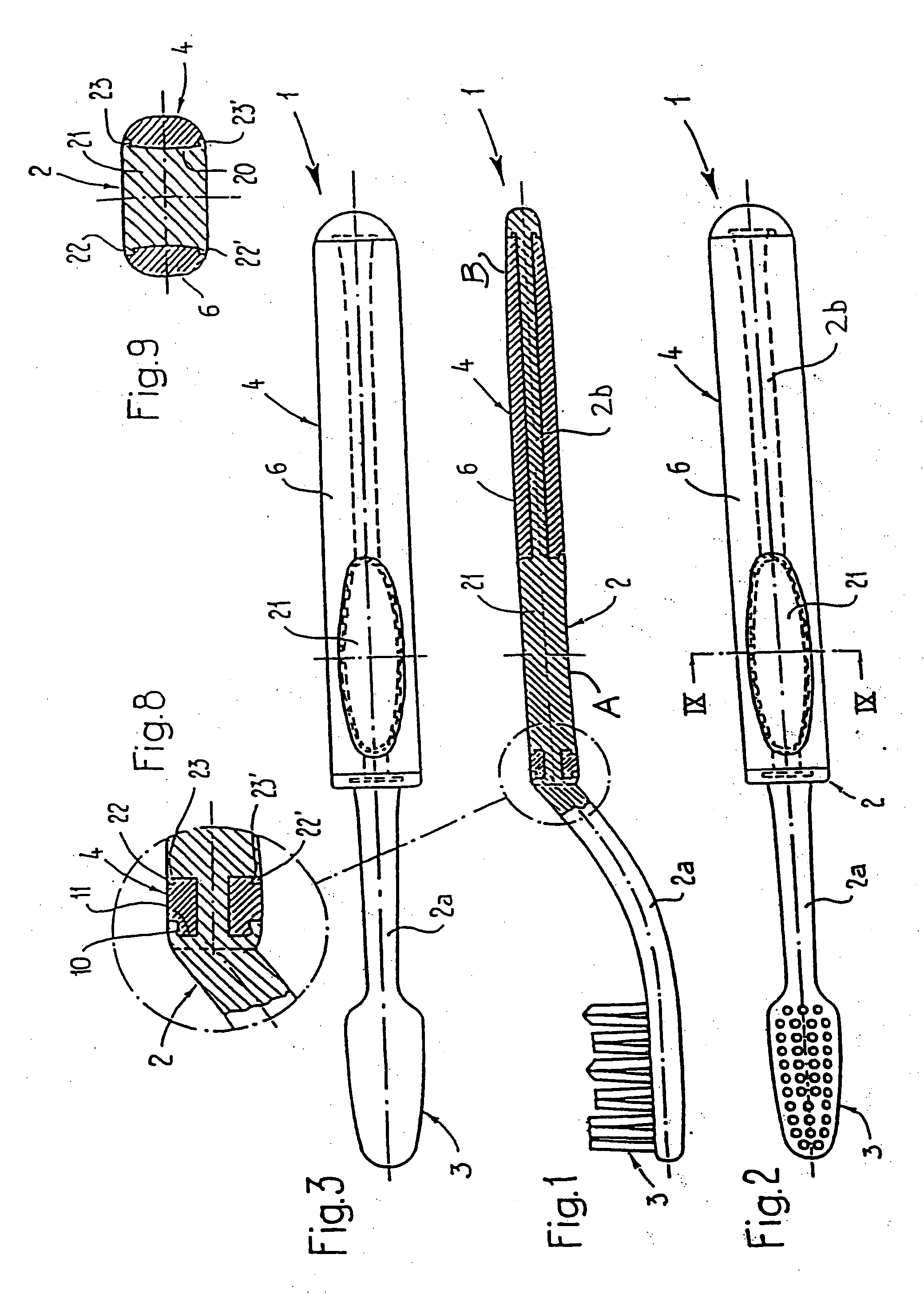

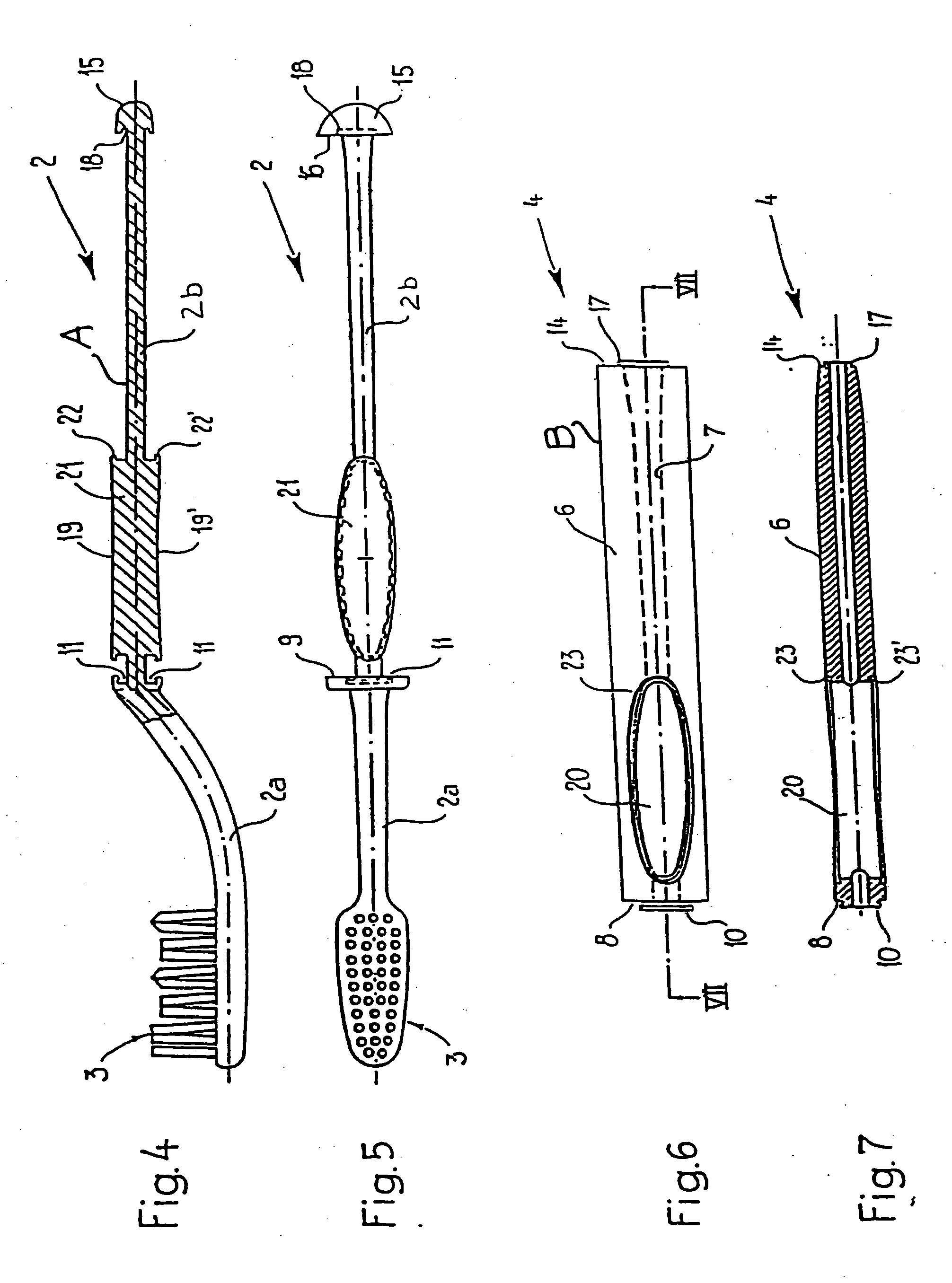

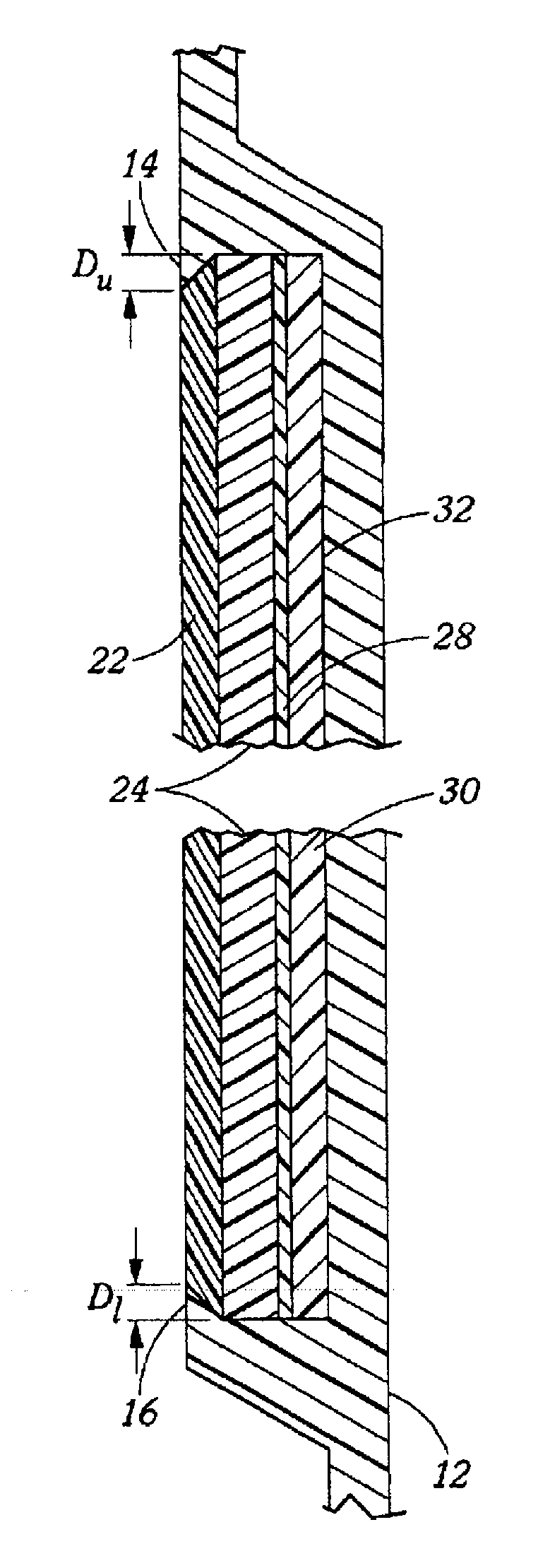

Plastic object for use in personal hygiene

InactiveUS6972106B2Sufficient forceDifferent shrinkage behaviorBrush bodiesMouldsPlastic materialsEngineering

A unitary two component article for personal hygiene, as a toothbrush, wherein the same is formed by injection molding of two differing plastic materials, which plastics do not adhesively or chemically bond to each other, thereby facilitating the manufacturing process. The two differing plastic parts of the toothbrush are mechanically connected, as by interfitting portions of the two plastic components and as by shrinking one plastic component about the other.

Owner:TRISA HLDG AG

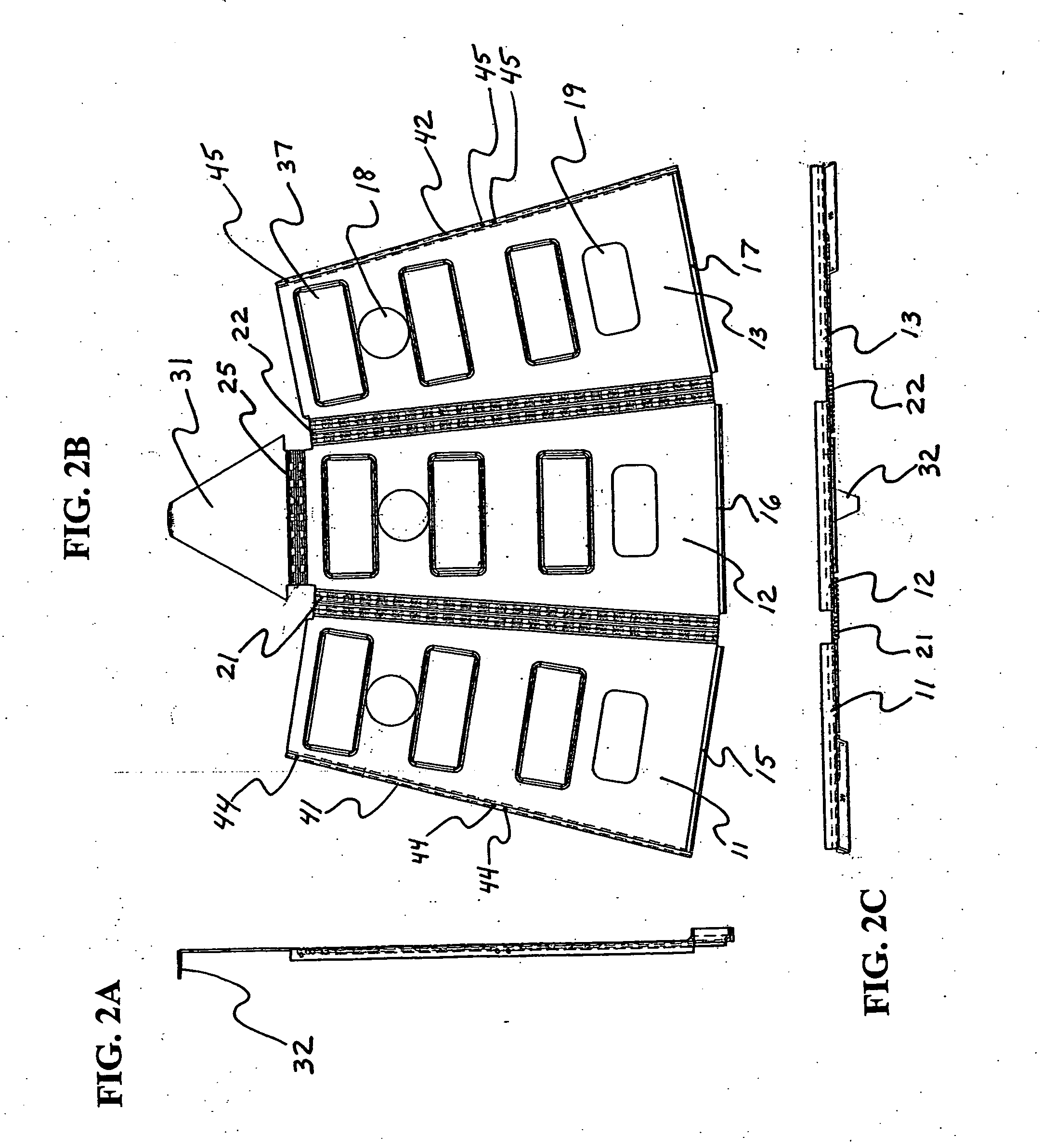

Plastic object for use in personal hygiene

InactiveUS20060021173A1Sufficient forceDifferent shrinkage behaviorCarpet cleanersBrush bodiesPlastic materialsEngineering

A unitary two component article for personal hygiene, such as a toothbrush, wherein the same is formed by injection molding of two differing plastic materials. The plastics do not adhesively or chemically bond to each other. The two differing plastic parts of the toothbrush are mechanically connected, such as by interfitting portions of the two plastic components or by shrinking one plastic component about the other.

Owner:TRISA HLDG AG

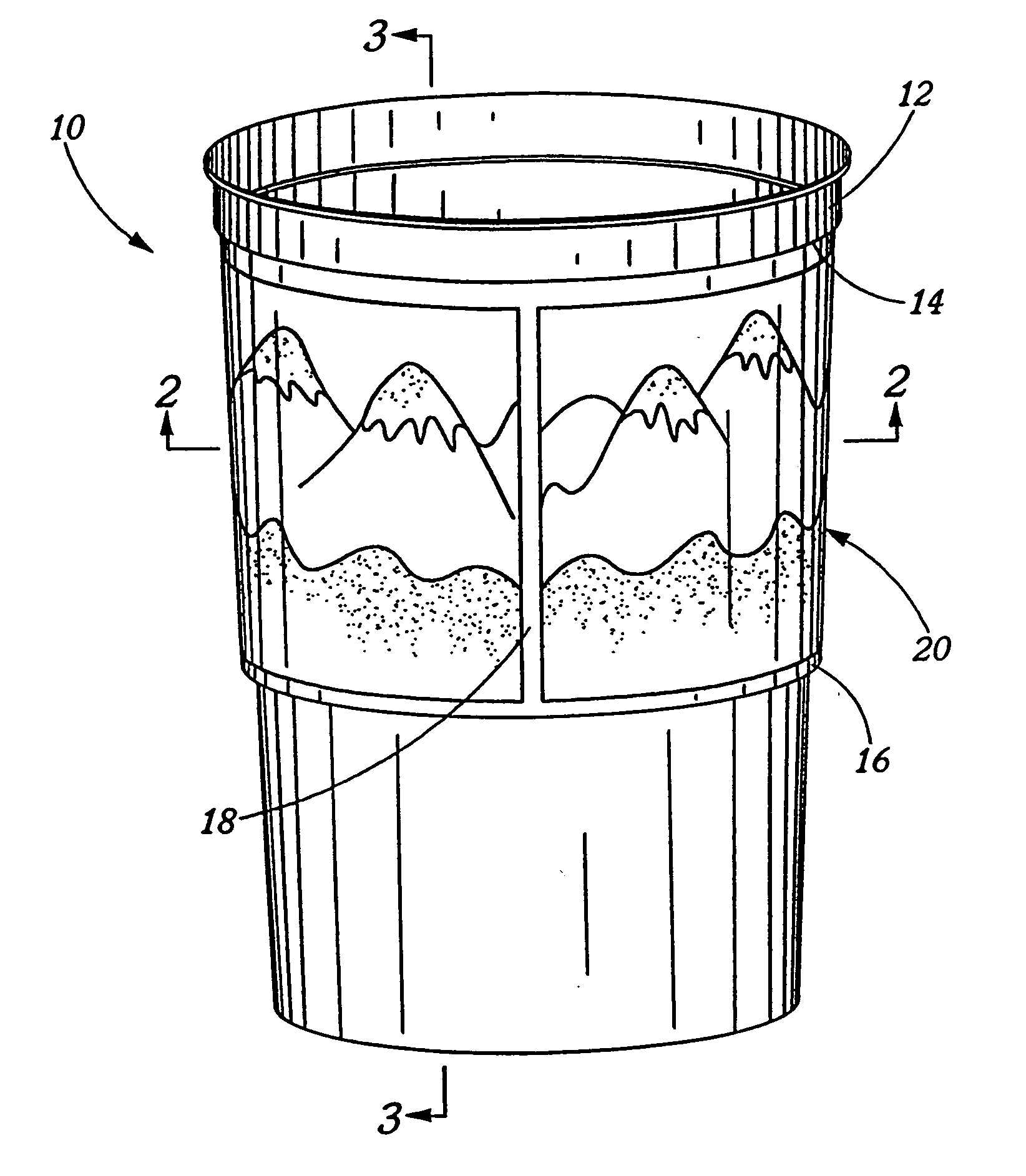

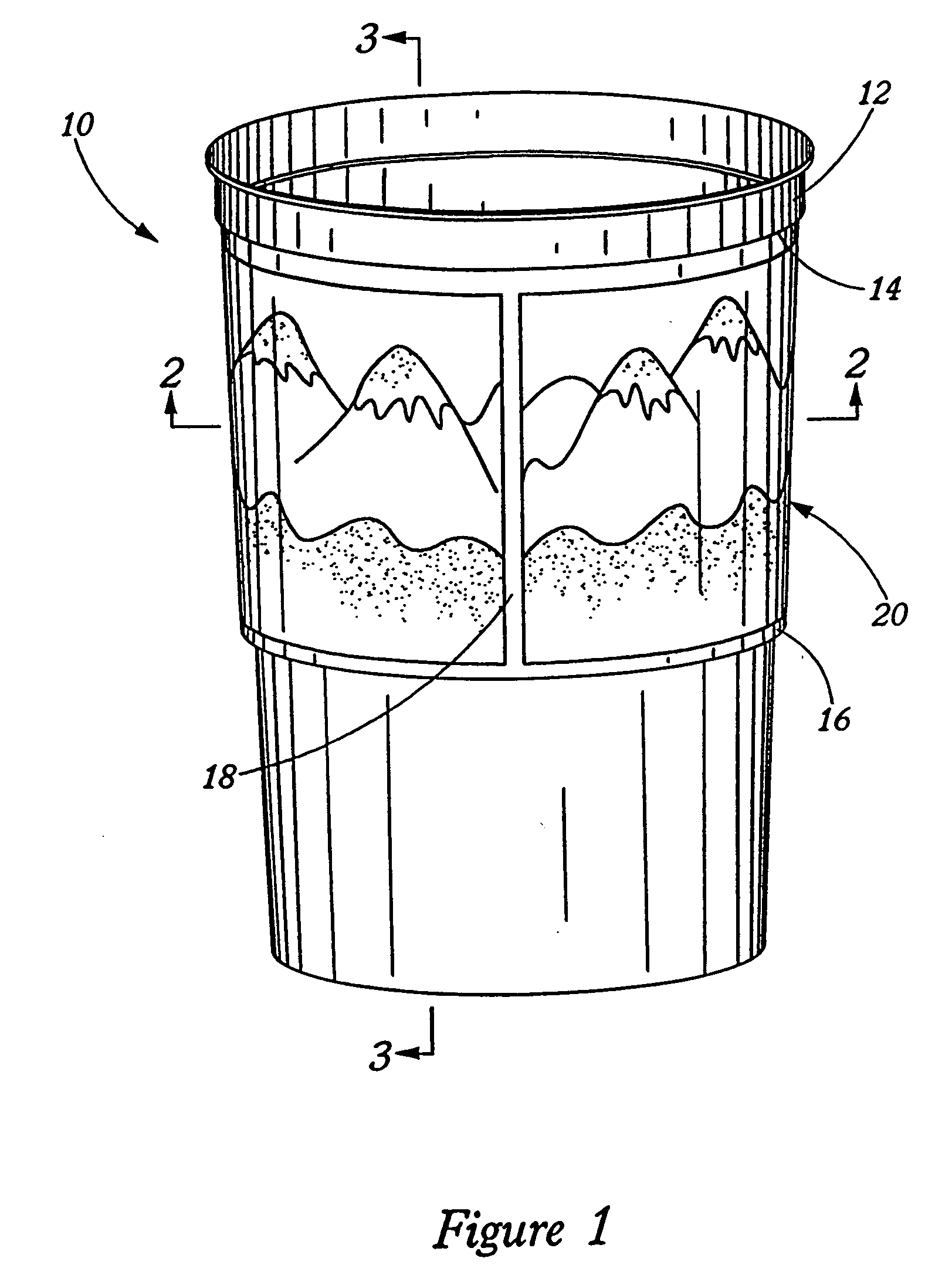

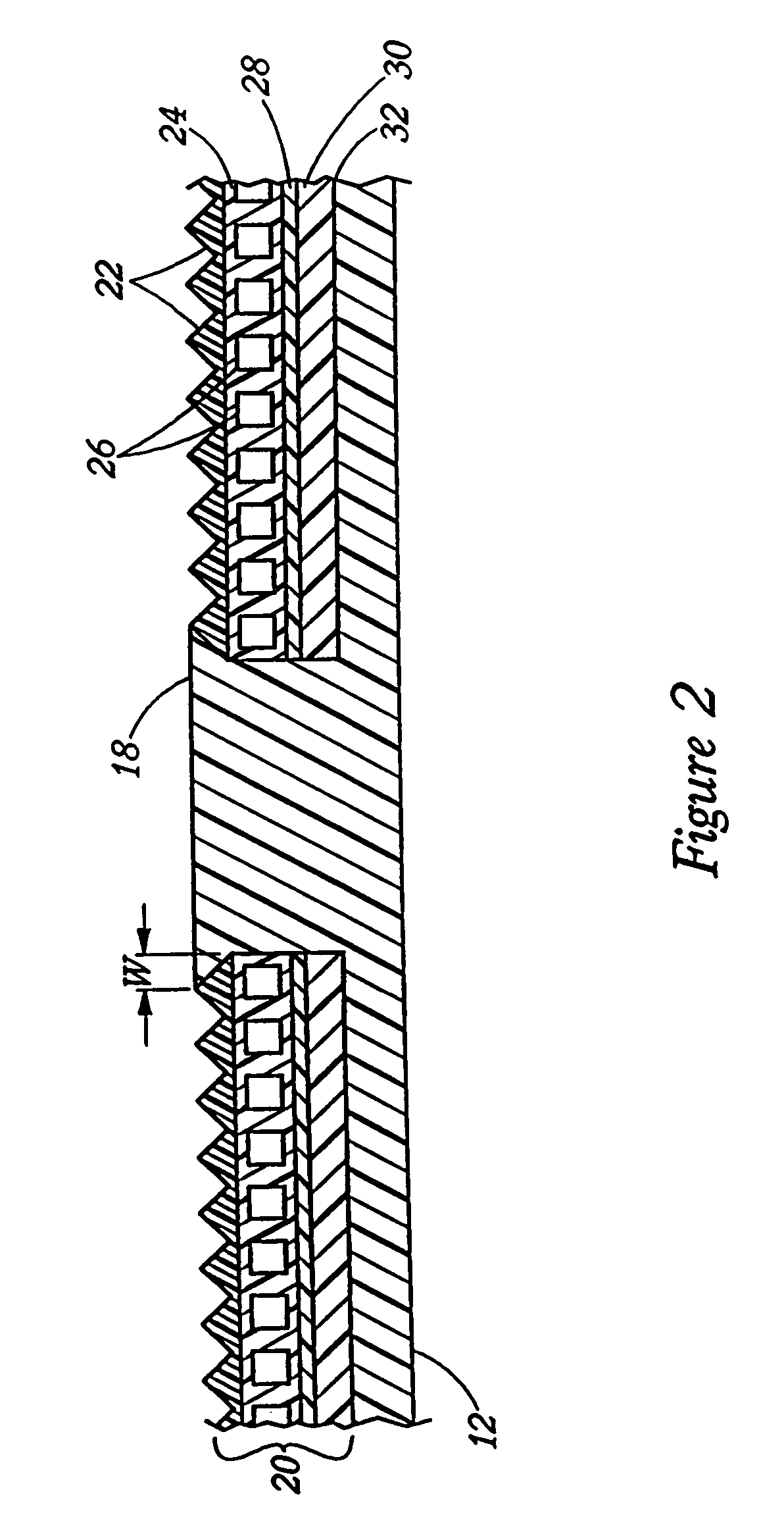

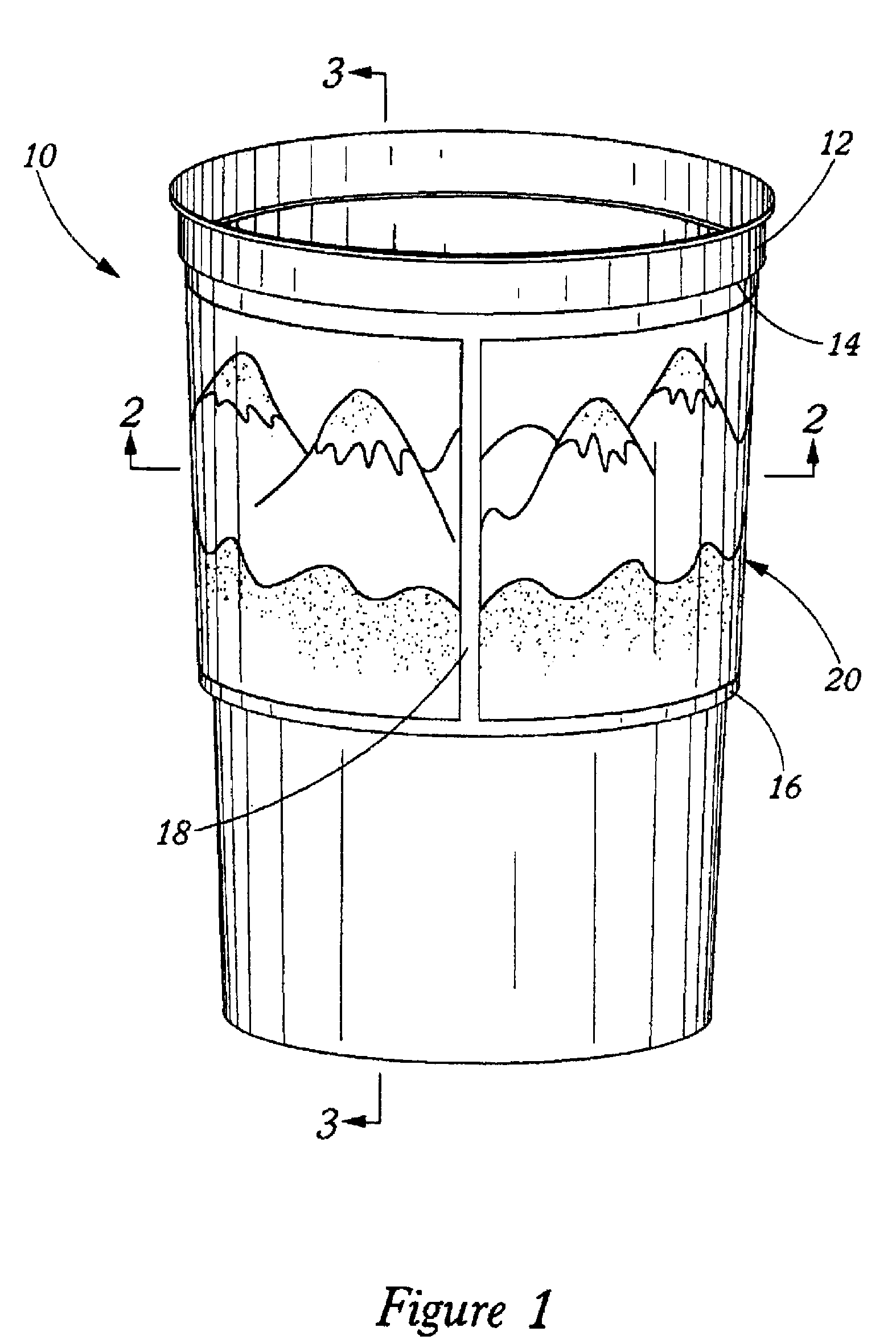

Method of bonding a lenticular lens sheet to plastic objects and objects made from same

InactiveUS20050053737A1Efficient and economicalQuality improvementEnvelopes/bags making machineryContainer decorationsPolyesterBond interface

A method of fabricating plastic objects having an insert of Lenticular lens material integrally bonded or otherwise attached therein. In one embodiment, the method is used to fabricate a container, such as a conical cup, by first manufacturing or providing a sheet of Lenticular material comprising layers of lens material and optical ridges and grooves and an ink layer printed on the flat side of the lens material. To protect the ink from the heat of molten or moldable plastic during later plastic processing, a thermally protective substrate is attached or bonded to the ink layer by using adhesives to attach a plastic substrate or by coating the ink with coating materials that thermally protect the ink from high temperatures. In one embodiment, the protective substrate is applied in a two step process of first placing a plastic hot melt onto a polyester or other material release liner and, after cooling of the hot melt, using heat and pressure to laminate or bond the hot melt plastic to the ink and then removing the liner. Lenticular inserts are cut out of the Lenticular material sheets and the inserts are positioned within a mold where the container is formed by injection, blow, or other molding process. In this step, the substrate acts as a bonding surface as it contacts the molten plastic, melts, and then cools forming a bonding interface with the plastic used to form the container.

Owner:TRAVEL TAGS

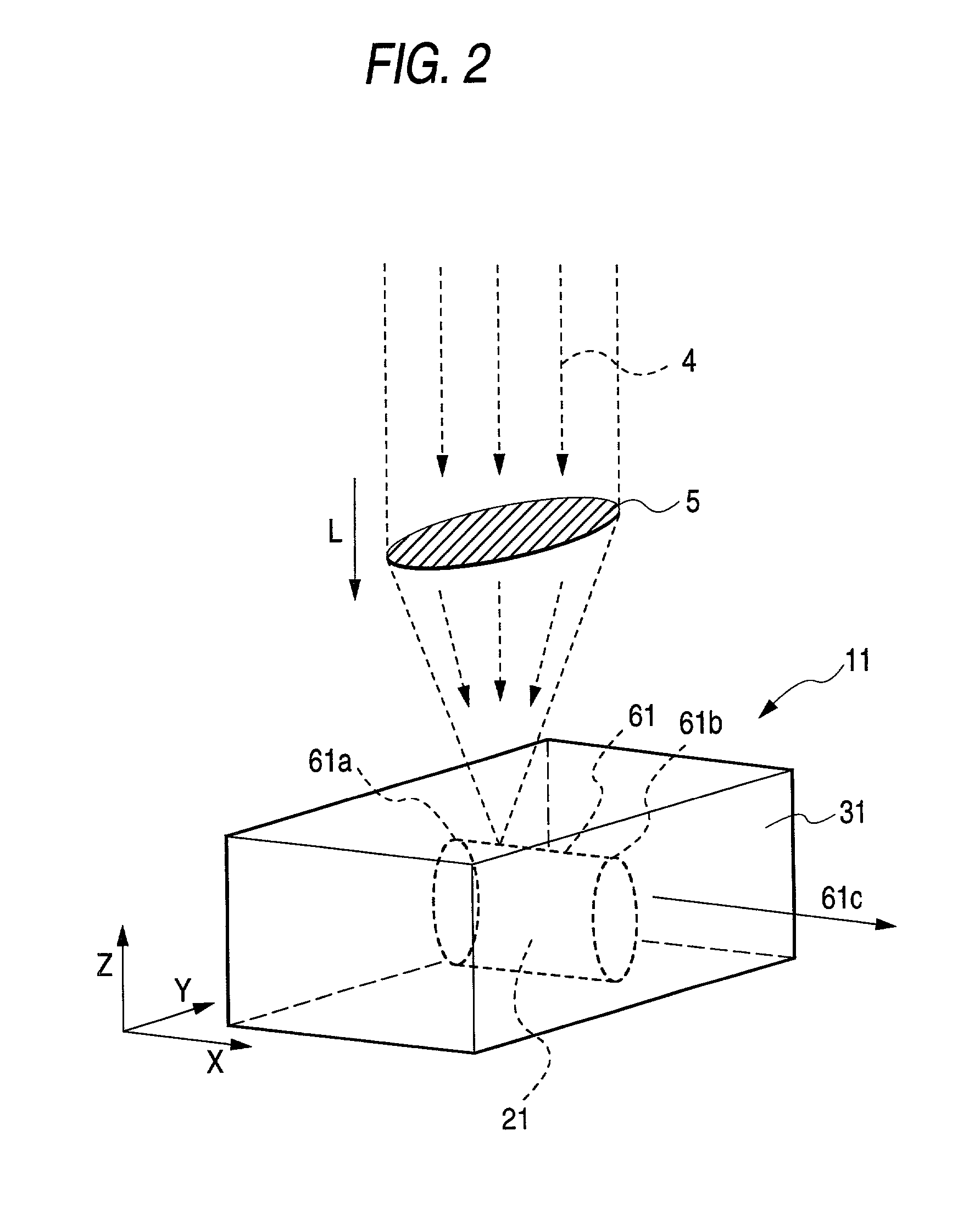

Plastic object

A plastic object having a part whose structure has been modified by irradiation with a laser light having an ultrashort pulse duration of 10-12 second or shorter. The plastic object has a structurally modified part whose structure has been modified by irradiation with a laser light having a pulse duration of 10-12 second or shorter. The laser light having a pulse duration of 10-12 second or shorter may have an irradiation energy of 500 mW or lower. The plastic object may have the structurally modified part in an inner portion thereof. The structurally modified part preferably extends in a direction parallel or perpendicular to the direction of the laser light irradiation.

Owner:NITTO DENKO CORP

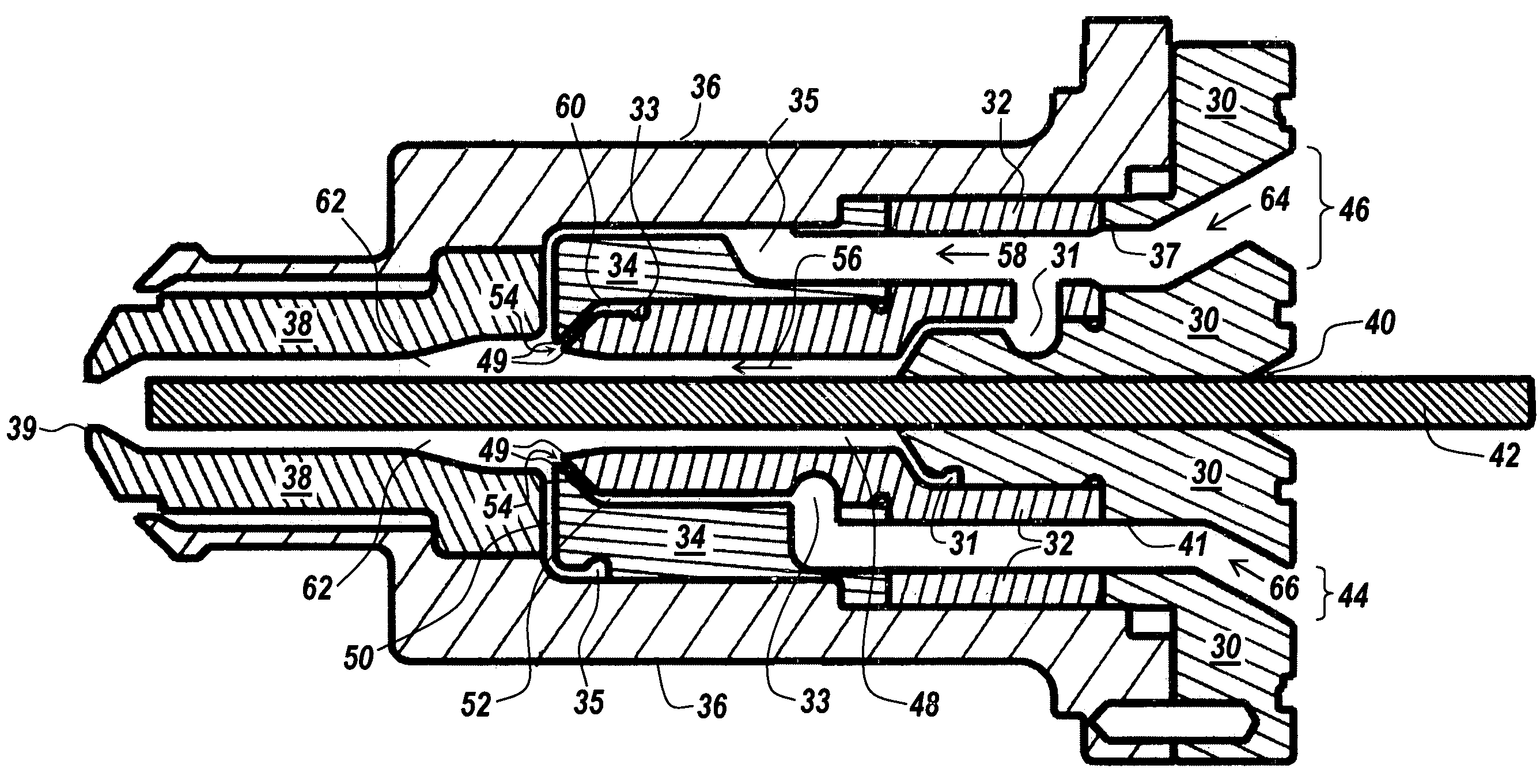

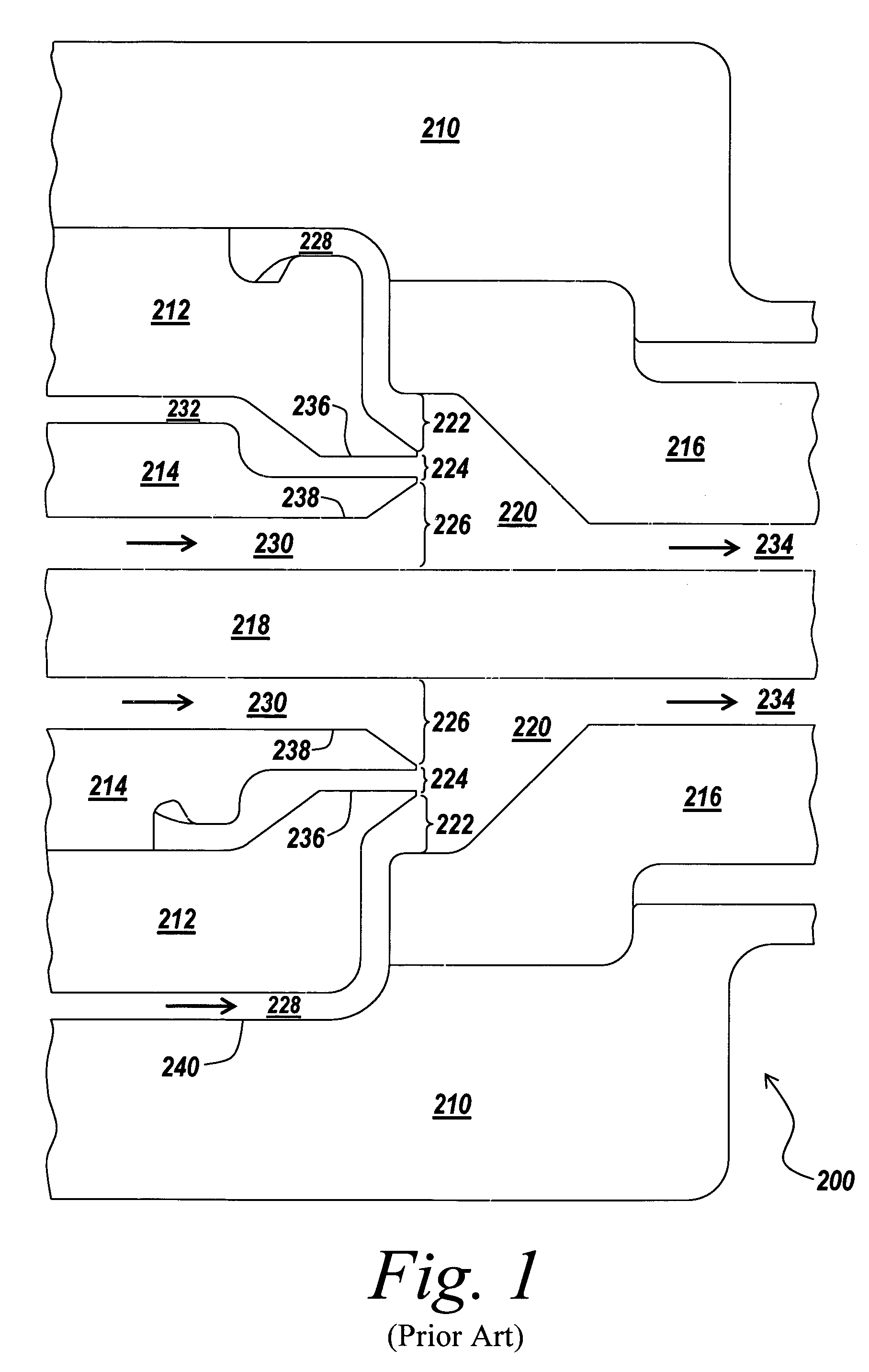

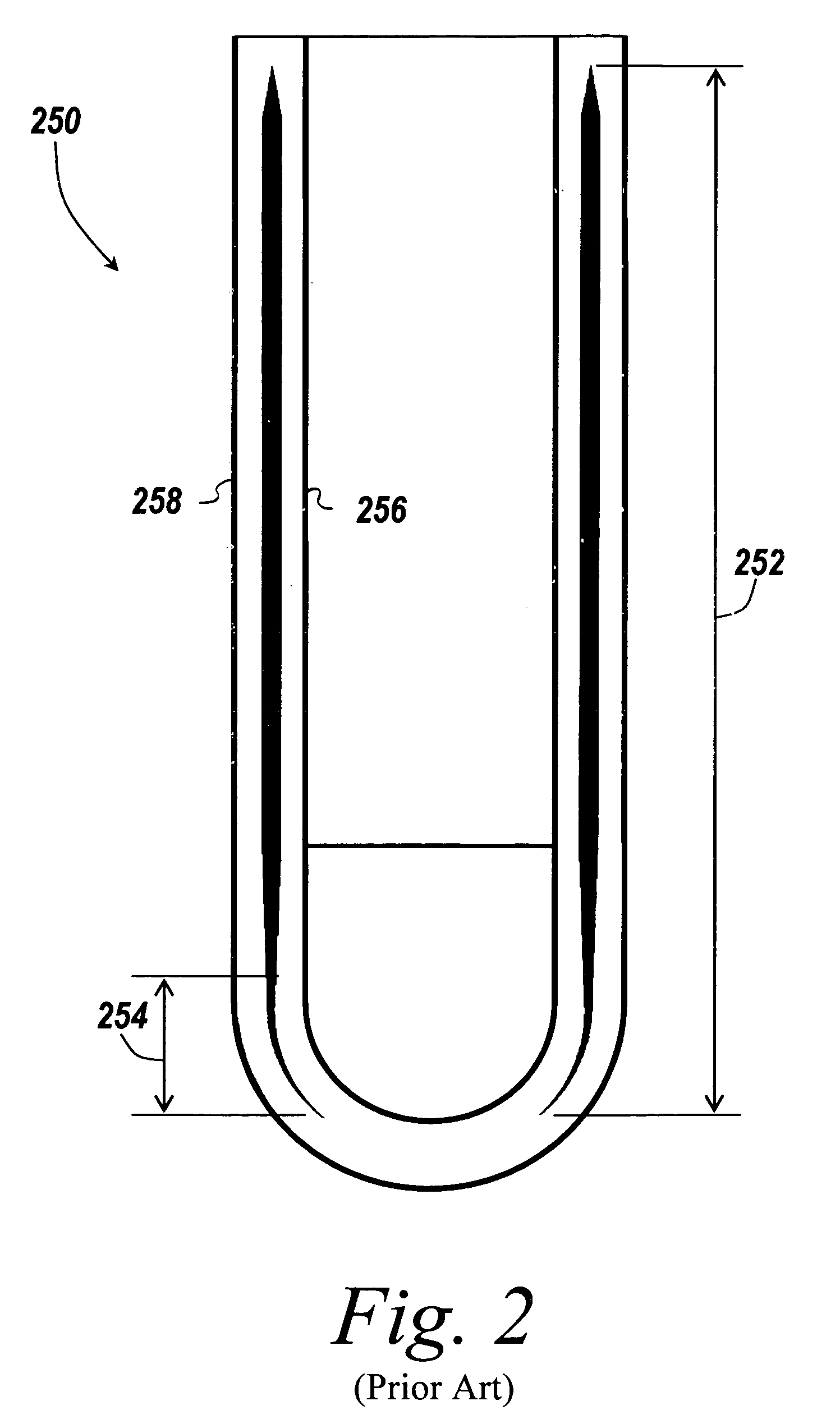

Co-injection nozzle with improved interior layer termination

ActiveUS7306446B2Easy to controlImproved barrier layer protectionButtonsRecord carriersEngineeringCo injection

Disclosed herein are a method and apparatus for combining two or more streams of a polymeric material to form a plastic object. The method and apparatus are capable of ending an interior layer of the plastic object at a desired length to avoid the need to clean selected surfaces of components used to form the plastic object. The method and apparatus increase the velocity of the polymeric material used to form the plastic object in certain components used to form the plastic object. The increase in the velocity of the polymeric material facilitates the ending of the interior layer of the plastic object.

Owner:CINCINNATI MILACRON INC

Process and materials for marking plastic surfaces

InactiveUS20050195260A1High to chemical damageGood chemical resistanceDuplicating/marking methodsPrinting after-treatmentHigh resistanceHydrophilic polymers

A method of producing ink-jet printed images with high resistance to physical and chemical damage on plastic surfaces, by coating the plastic object with an inkjet receptive layer comprising a mixture of hydrophilic polymers and UV curable pre-polymers deposited from an emulsion, ink-jetting an image onto the coating using ink-jet ink comprising a colorant and aqueous carrier, warming the printed surface to drive part of the water in the ink into the surface coating and to evaporate the other part of the water, UV curing the dried surface and over-coating the UV cured surface with lacquer or with lamination material.

Owner:KODAK IL

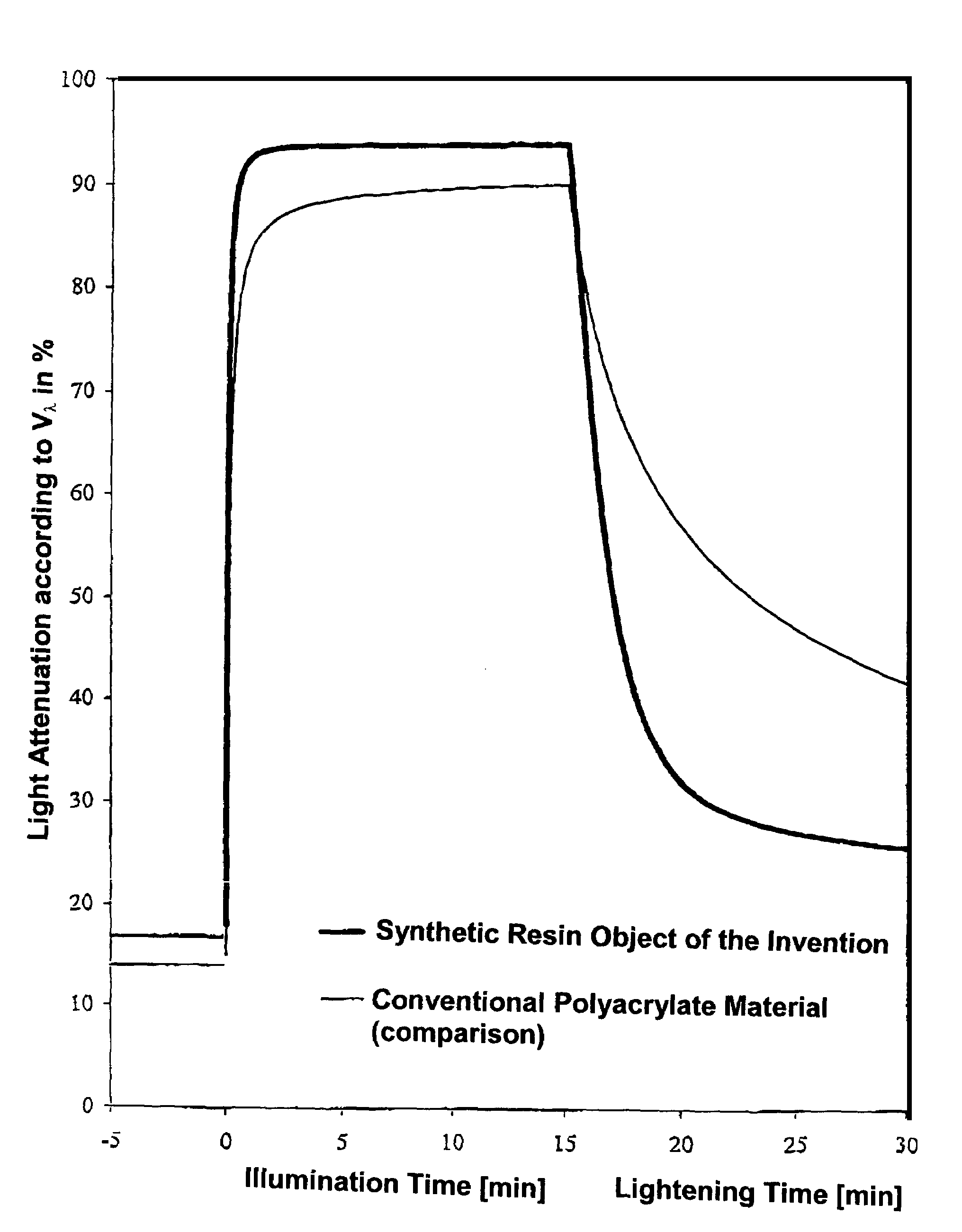

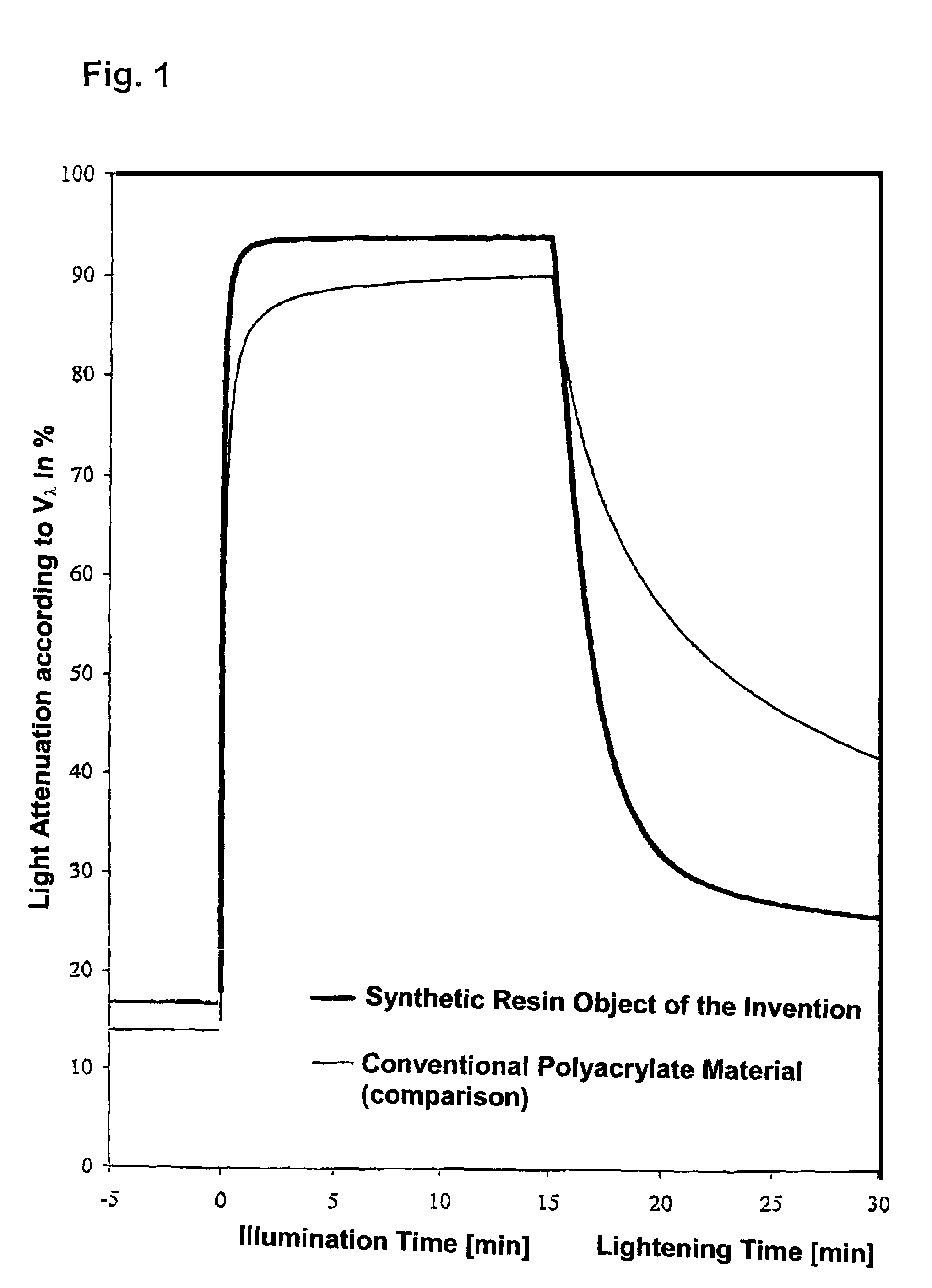

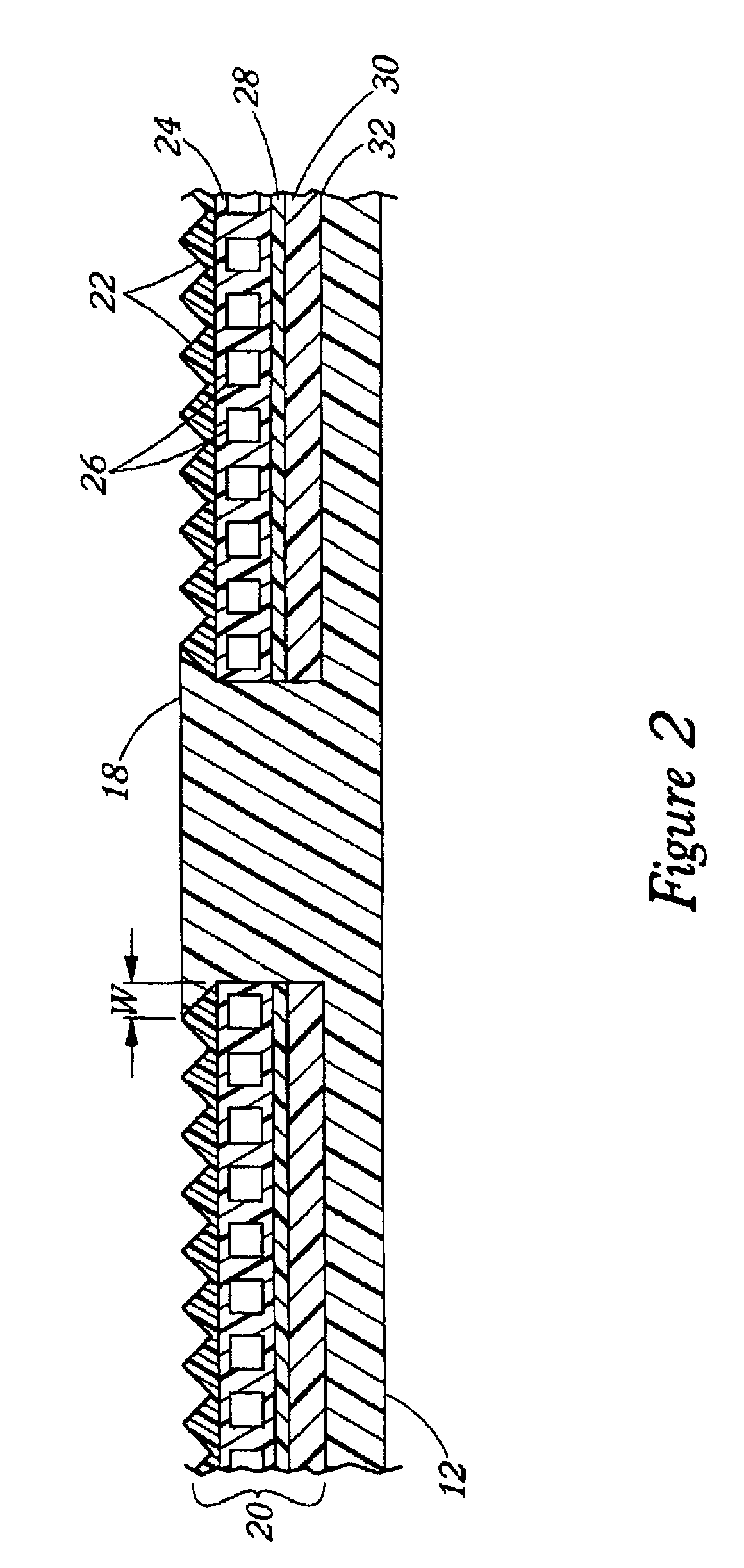

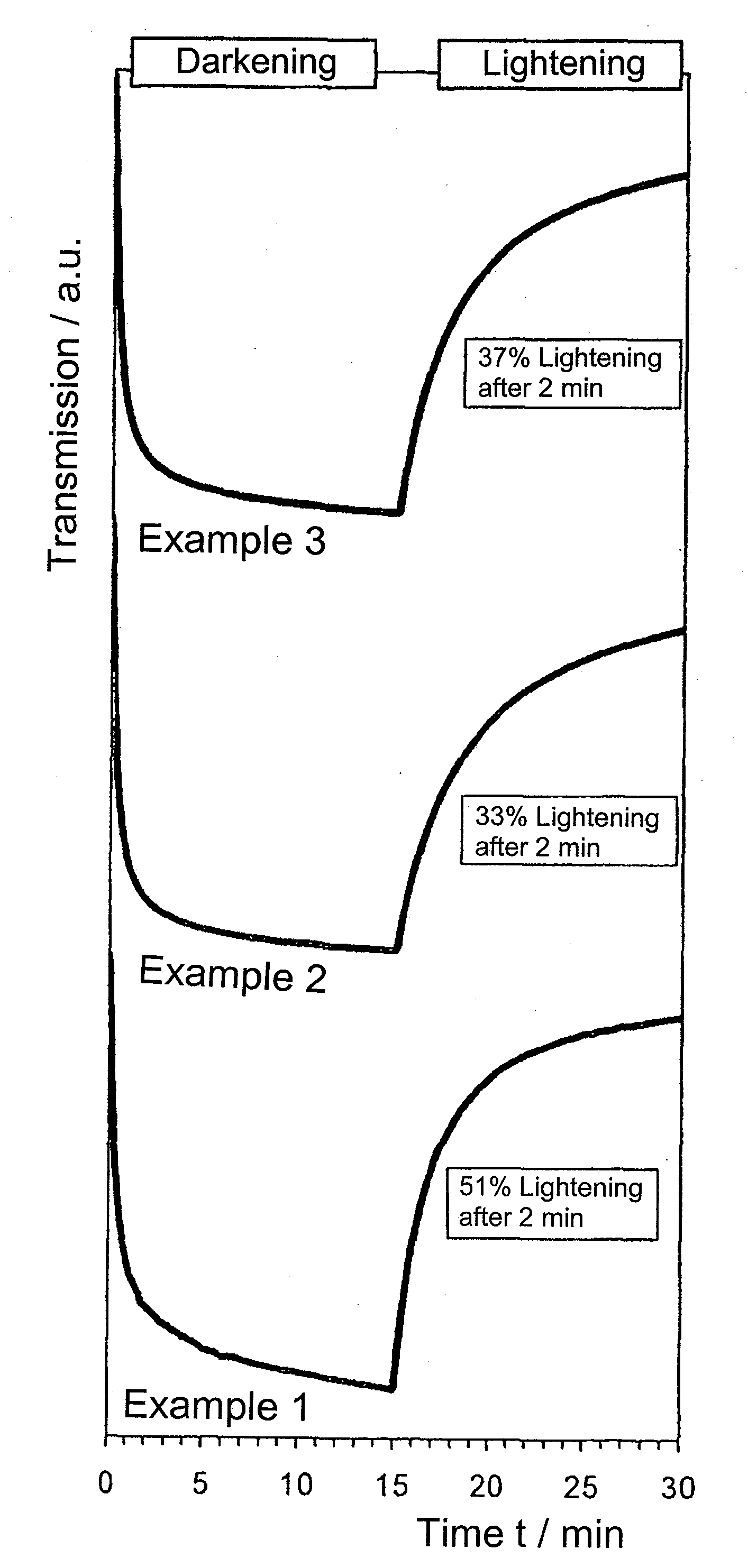

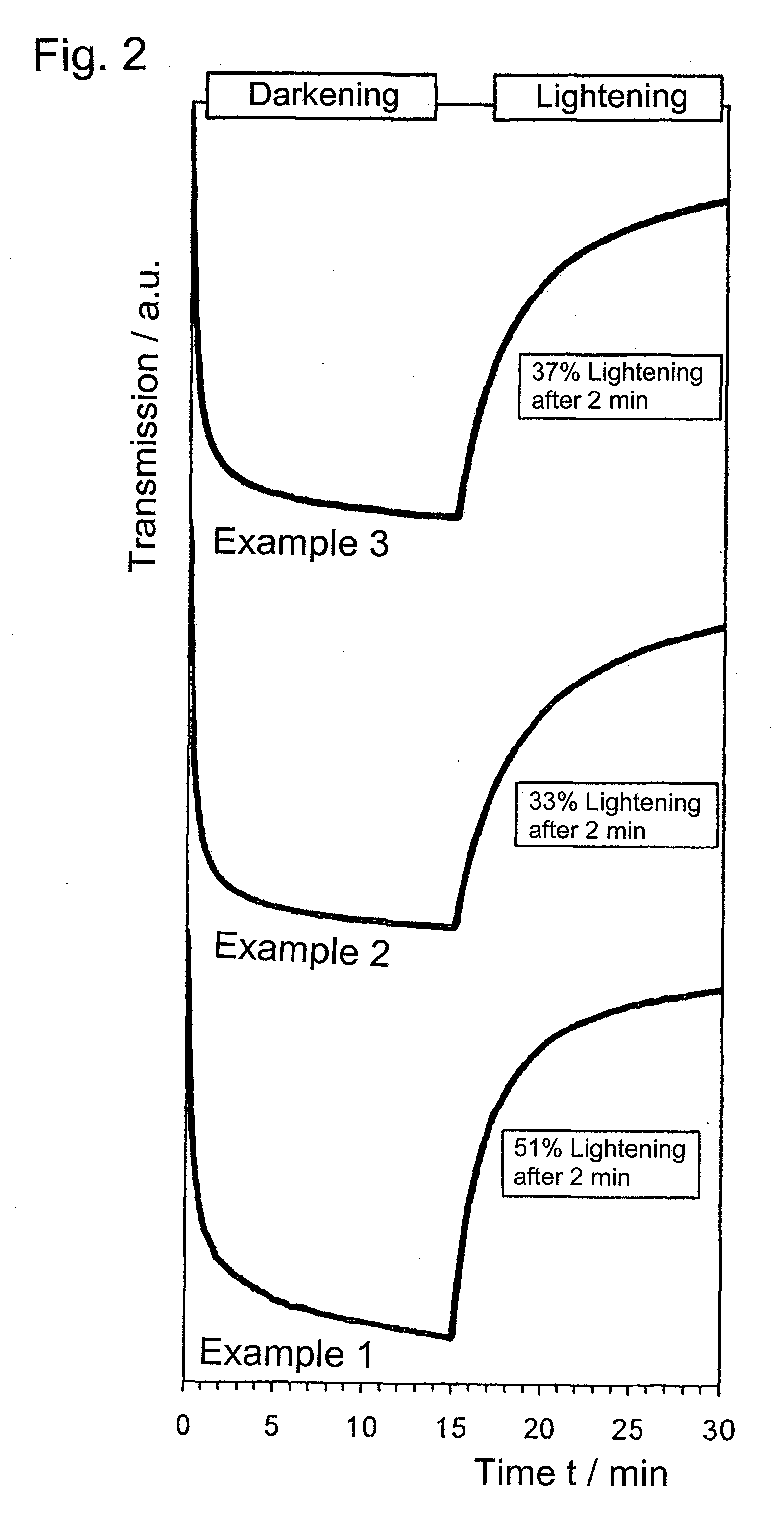

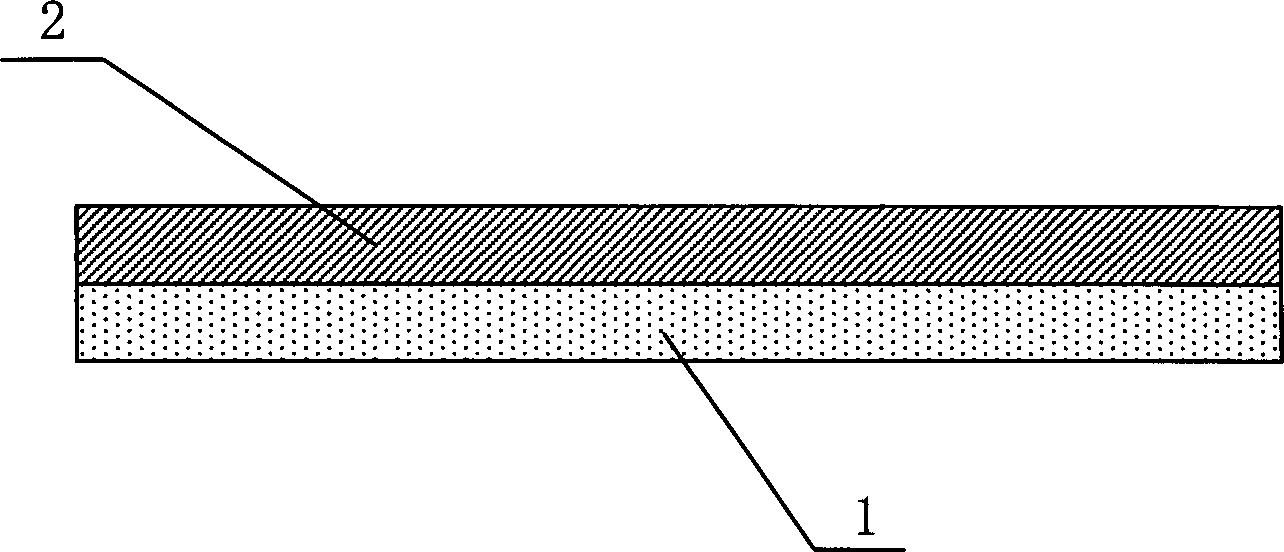

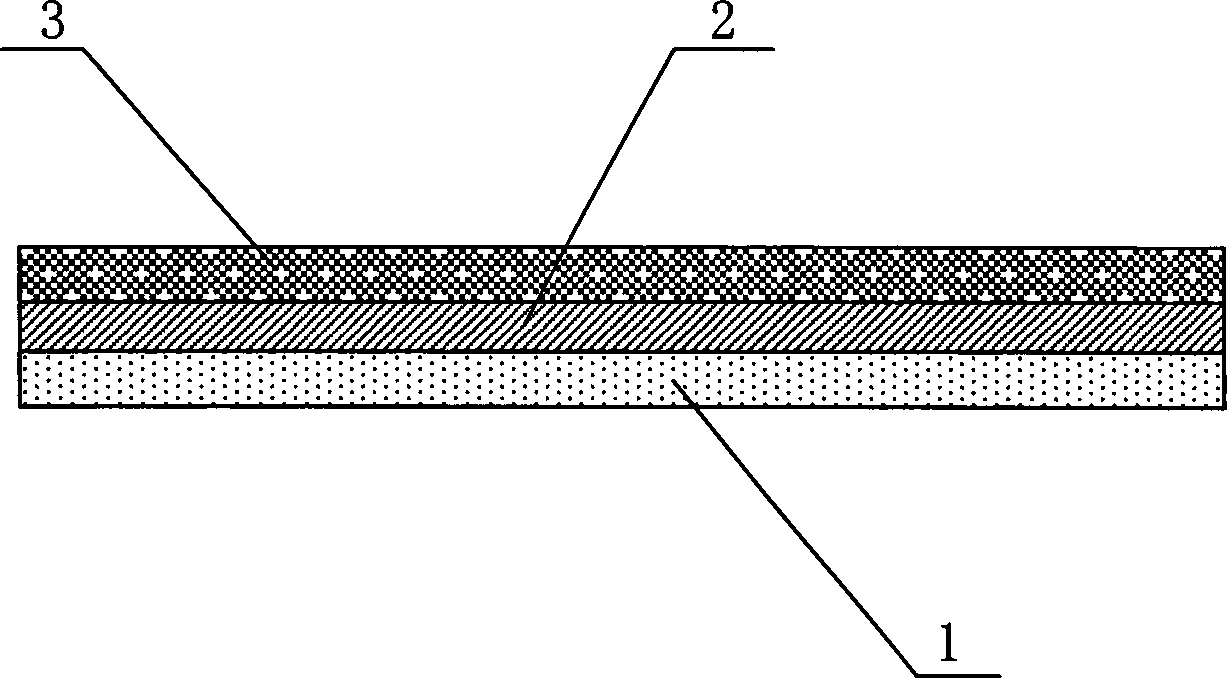

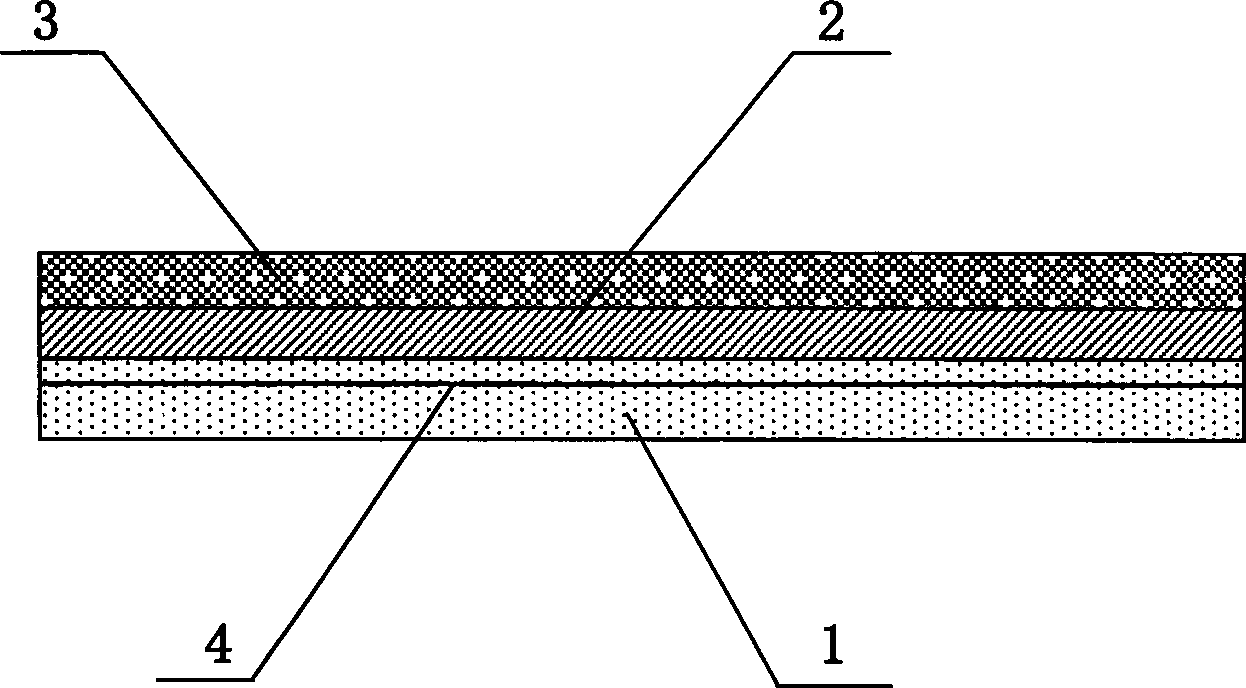

Photochromic plastic object

A photochromic plastic object made of a transparent synthetic resin material composed of at least two mutually penetrating polymer networks of different polymer materials and containing at least one photochromic dye homogeneously distributed therein, and a method for producing such a photochromic object.

Owner:JOBST LA DOUS

Methods of manufacturing plastic objects having bonded lenticular lens-sheets

InactiveUS20070132122A1Quality improvementEfficient and economicalOptical articlesContainer/bottle contructionPolyesterBond interface

A method of fabricating plastic objects having an insert of Lenticular lens material integrally bonded or otherwise attached therein. In one embodiment, the method is used to fabricate a container, such as a conical cup, by first manufacturing or providing a sheet of Lenticular material comprising layers of lens material and optical ridges and grooves and an ink layer printed on the flat side of the lens material. To protect the ink from the heat of molten or moldable plastic during later plastic processing, a thermally protective substrate is attached or bonded to the ink layer by using adhesives to attach a plastic substrate or by coating the ink with coating materials that thermally protect the ink from high temperatures. In one embodiment, the protective substrate is applied in a two step process of first placing a plastic hot melt onto a polyester or other material release liner and, after cooling of the hot melt, using heat and pressure to laminate or bond the hot melt plastic to the ink and then removing the liner. Lenticular inserts are cut out of the Lenticular material sheets and the inserts are positioned within a mold where the container is formed by injection, blow, or other molding process. In this step, the substrate acts as a bonding surface as it contacts the molten plastic, melts, and then cools forming a bonding interface with the plastic used to form the container.

Owner:TRAVEL TAGS

Photochromic Plastic Object

ActiveUS20080251772A1Improve scratch resistanceMaterial nanotechnologyPhotosensitive materialsOrganic dyeSynthetic resin

A photochromic plastic object which is composed of a transparent polymeric synthetic resin material, into or onto which at least one substantially mesoporous inorganic host structure is introduced or applied containing one or more embedded organic photochromic dye molecules so as to form a photochromic nanocomposite material. In contrast to prior techniques of adding or applying the photochromic organic dyes to the monomer mixture or prepolymer of a transparent synthetic resin material in a molecular form, in the photochromic plastic article of the present invention color is generated by using the photochromic nanocomposite particles or photochromic nanocomposite structures.

Owner:RODENSTOCK GMBH

Flexible transfer film and manufacture method thereof

InactiveCN102729549AReduce energy consumptionLow transfer temperatureSynthetic resin layered productsLaminationSurface patternHigh rate

The invention discloses a flexible transfer film. The flexible transfer film includes a malleable flexible film, which can be extendedly attached to a surface of an irregular object, and a malleable patterned layer, which is attached to the surface of the flexible film and can be extendedly attached to the surface of the irregular object with the flexible film. Through the malleable flexible film and the patterned layer, the flexible transfer film of the invention is attached to an inner surface of a molding die for a rigid object in stretching and adsorption modes, and is molded with the rigid object together; the patterned layer of the flexible transfer film is transferred to the surface of the object through temperature and viscosity in molding of the plastic object; so that surface pattern transfer process can be accomplished even on the surface of the irregular object. The flexible transfer film of the invention can reduce pollution, energy consumption, environmental pollution and harm on human body, and has low transfer temperature, low energy consumption and high rate of finished product, so as to greatly reduce the cost of production. At the same time, the invention discloses the manufacturing method of the flexible transfer film.

Owner:杨子德

Process and materials for marking plastic surfaces

InactiveUS7275818B2High to damageIncrease resistanceDuplicating/marking methodsPrinting after-treatmentHigh resistanceHydrophilic polymers

A method of producing ink-jet printed images with high resistance to physical and chemical damage on plastic surfaces, by coating the plastic object with an inkjet receptive layer comprising a mixture of hydrophilic polymers and UV curable pre-polymers deposited from an emulsion, ink-jetting an image onto the coating using ink-jet ink comprising a colorant and aqueous carrier, warming the printed surface to drive part of the water in the ink into the surface coating and to evaporate the other part of the water, UV curing the dried surface and over-coating the UV cured surface with lacquer or with lamination material.

Owner:KODAK IL

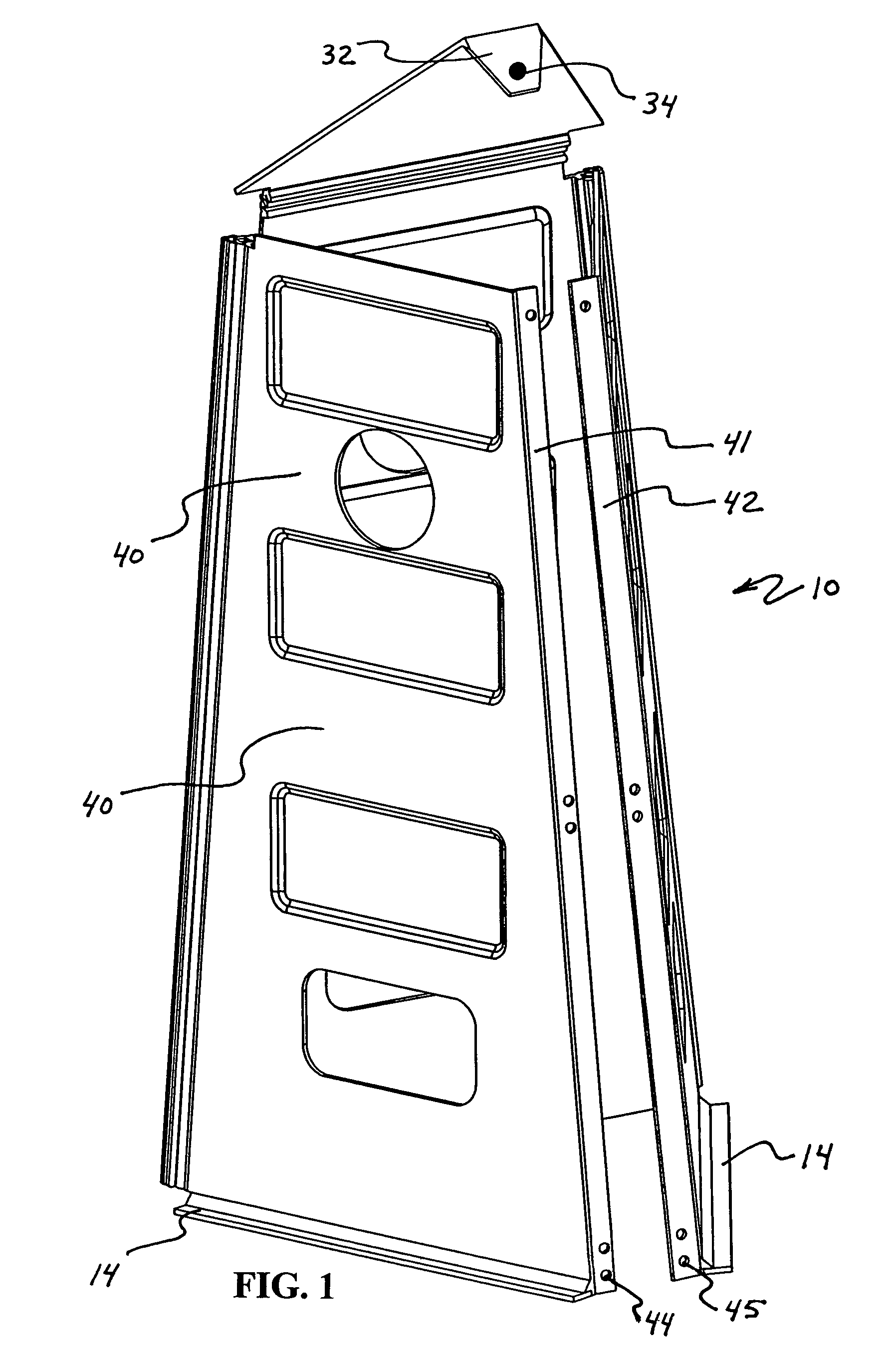

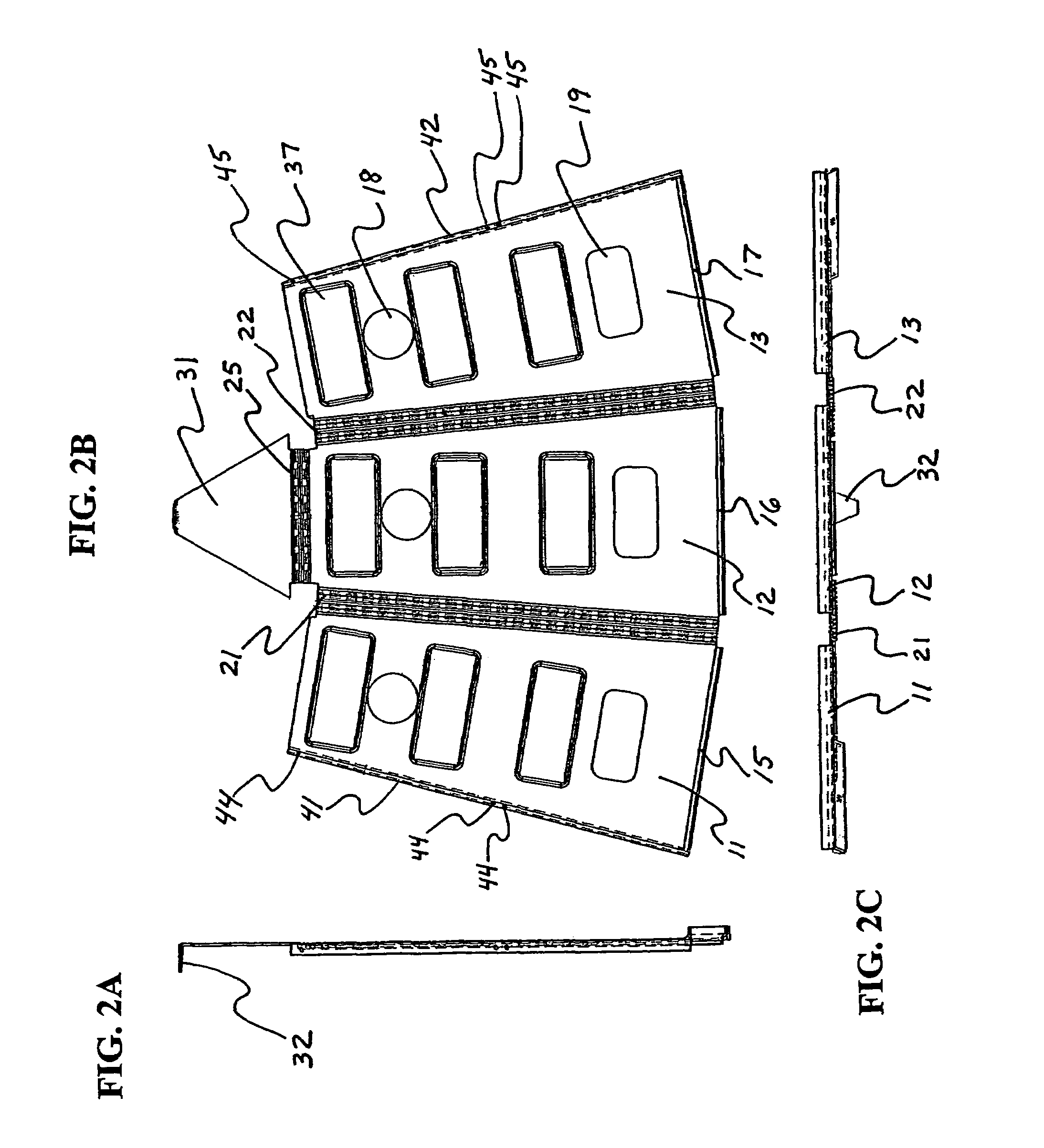

Collapsible construction barrier

InactiveUS7690321B2Durable and strongTraffic signalsPinless hingesMechanical engineeringLiving hinge

Owner:KAROW MARK P +1

Formation of hydrophilic polysaccharide coatings on hydrophobic substrates

InactiveUS7052776B2Good biocompatibilityReduce static chargeSynthetic resin layered productsCellulosic plastic layered productsDye absorptionHydrophobic polymer

Articles produced from hydrophobic polymers (e.g., polyethylene) are surface-coated with thin films of starch in order to render the surfaces hydrophilic. The thin coatings form on the surfaces of plastic objects when the objects are placed in contact with hot, aqueous solutions of starch. These starch coatings are adherent to the hydrophobic plastic surfaces under both wet and dry conditions, and they permit the surfaces to be uniformly wet with water. The coatings may be rendered even more adherent when wet by graft polymerizing the starch with a synthetic monomer. Resultant products have the potential for improved biocompatibility, improved compatibility with hydrophilic reagents, reduced build-up of electrostatic charge, reduced blocking, reduced friction, improved absorption of water-based dyes, and improved adhesion properties. The starch coatings are non-toxic, inexpensive and biodegradable.

Owner:US SEC AGRI

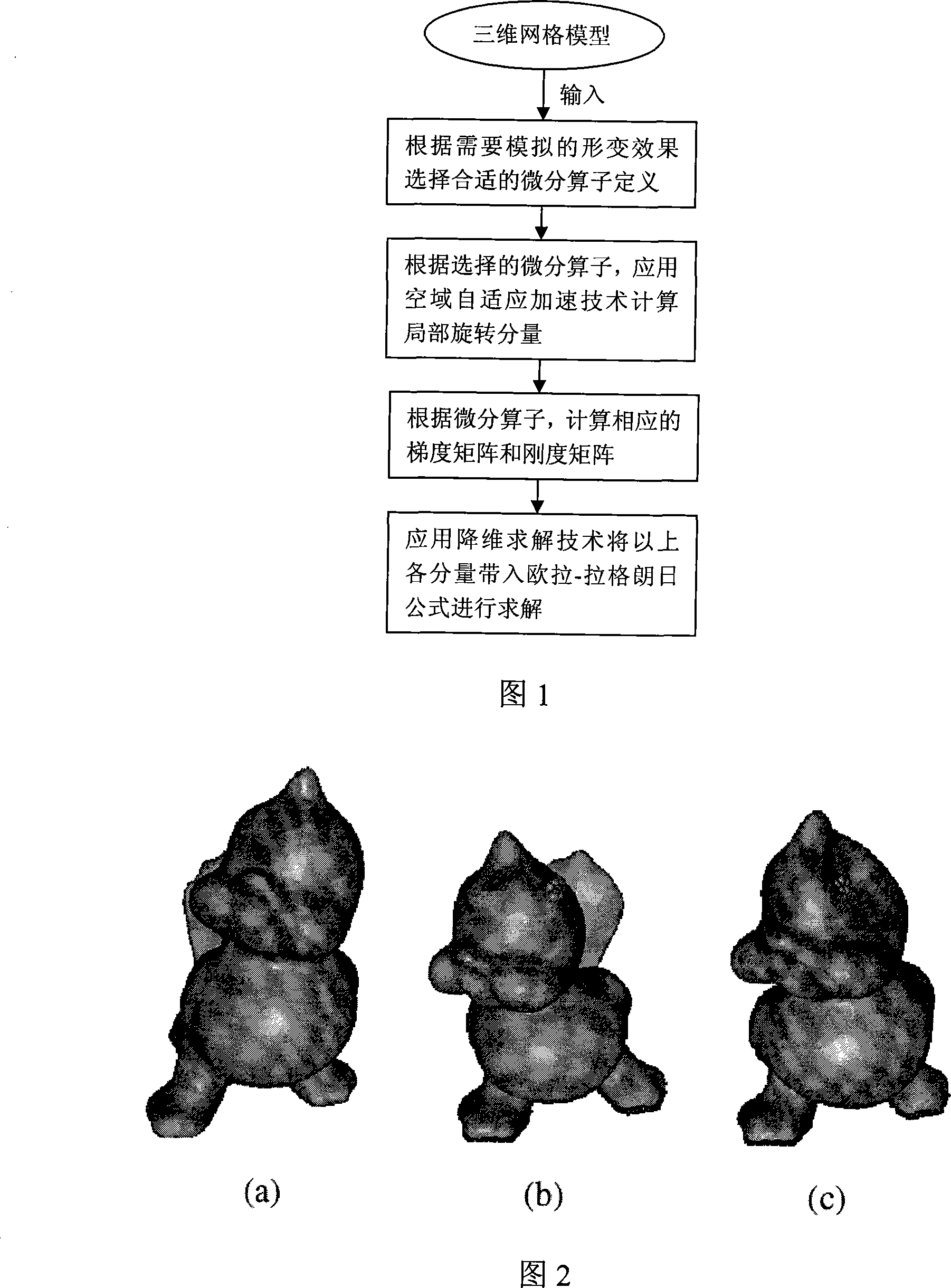

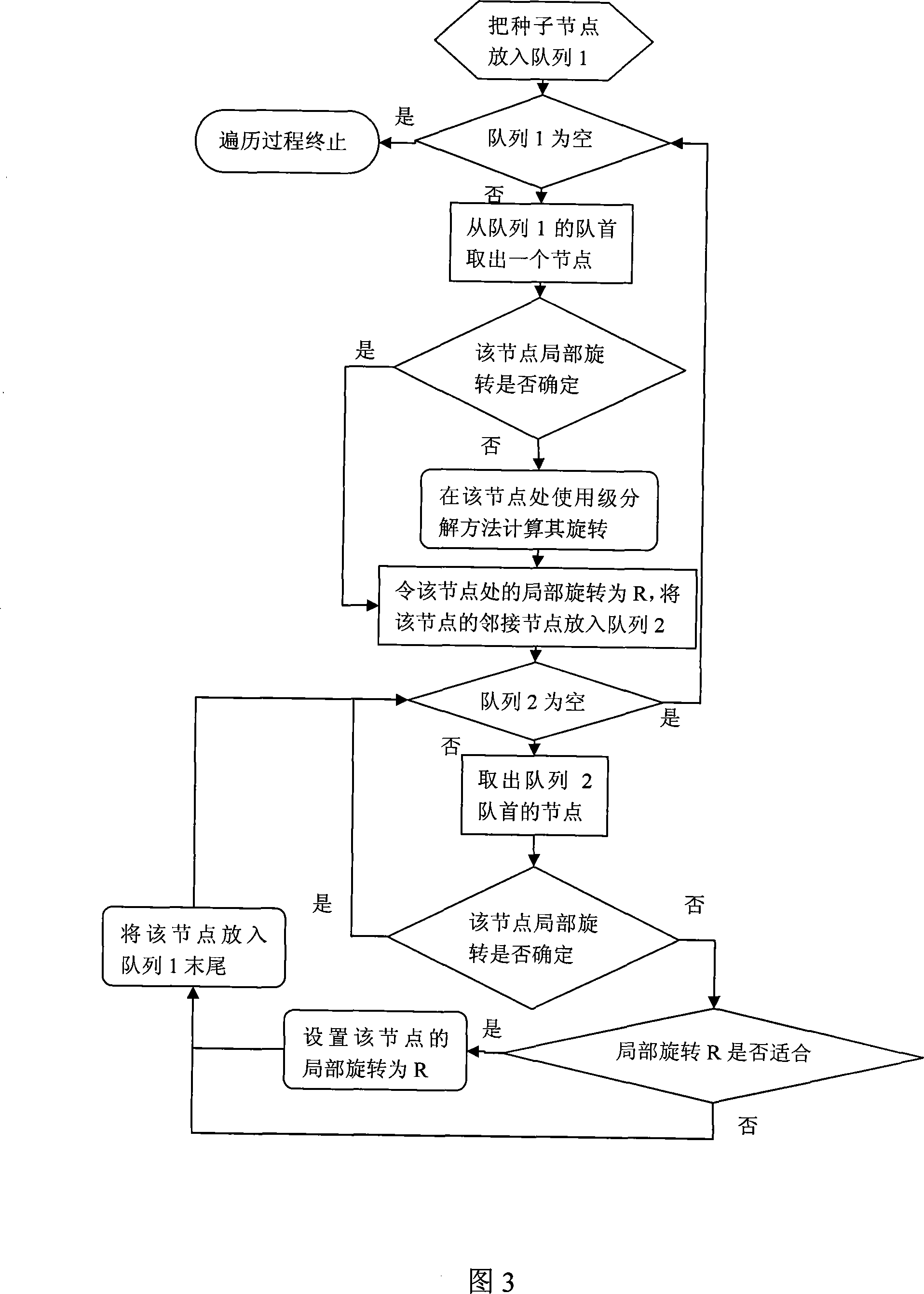

An elastic deformation simulation method based on linear differential operator

InactiveCN101216950ATroubleshooting Fast Simulation ProblemsReduce complexityAnimation3D-image renderingEuler–Lagrange equationComputation process

The invention discloses an elastic deformation simulation method based on a linear differential operator. The invention comprises the following steps of using elastic energy based on the linear differential operator defined on the geometric attribute of a deformation gridding model to replace the traditional nonlinear energy based on continuum mechanics, carrying out modeling computation using Euler-Lagrange equation to compute the deformation process of the elastic object in the computer. Meanwhile, according to the calculation model, the invention optimizes the calculation process via further using the techniques of dimension reduction solution, airspace adaptive acceleration, etc, which allows the modeling process to reach the mutual or even real time efficiency and can simulate the elasticity of different materials and the deformation process of plastic objects. The invention reduces the calculation complexity, improves the calculation efficiency of the modeling solution, and keeps the living simulating effect via the model of transform solution based on the deformation energy form of the linear differential operator. The invention solves the rapid simulating problem in the deformation process of the elastic object in the real time or in a mutual virtual simulation system.

Owner:ZHEJIANG UNIV

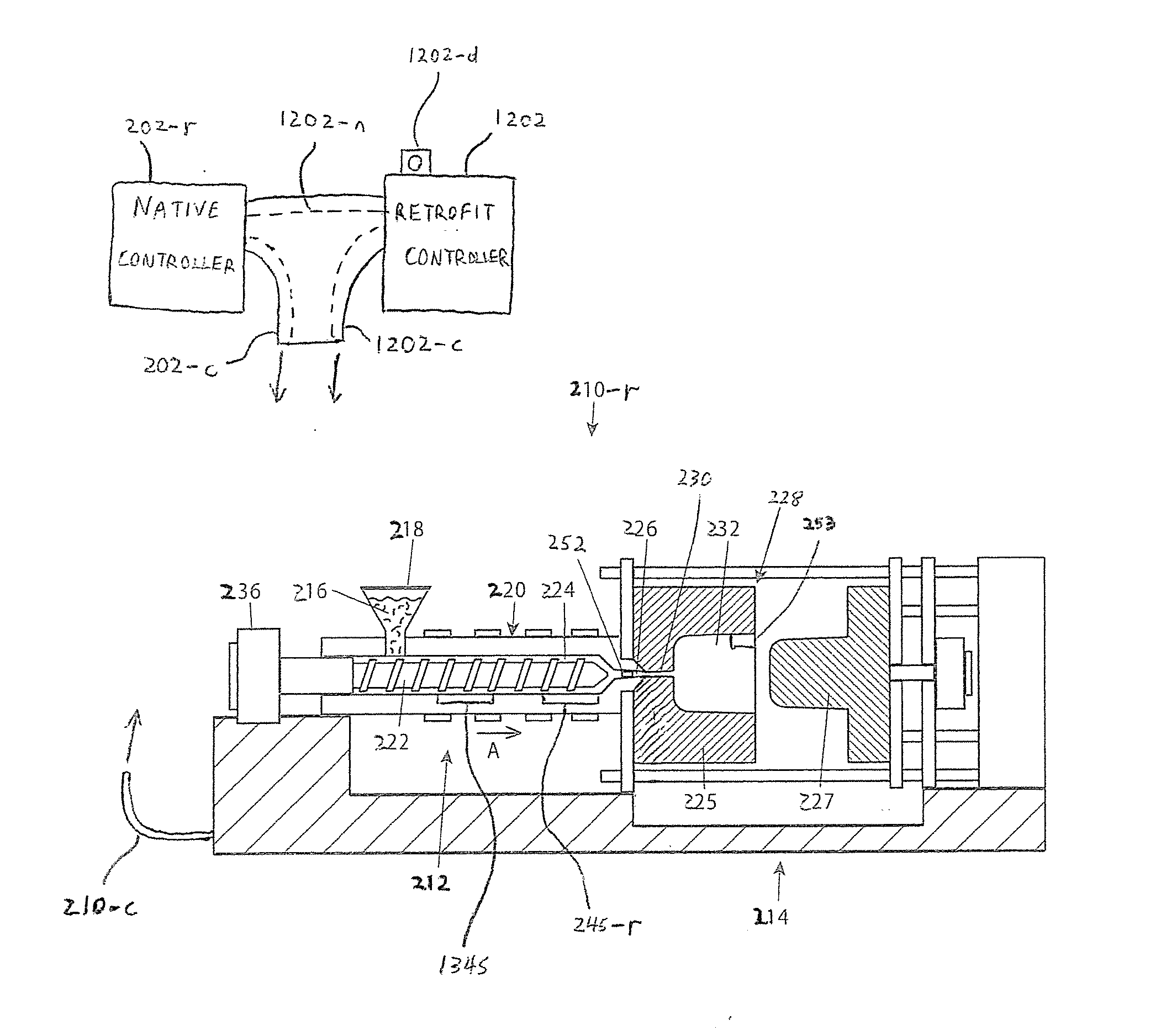

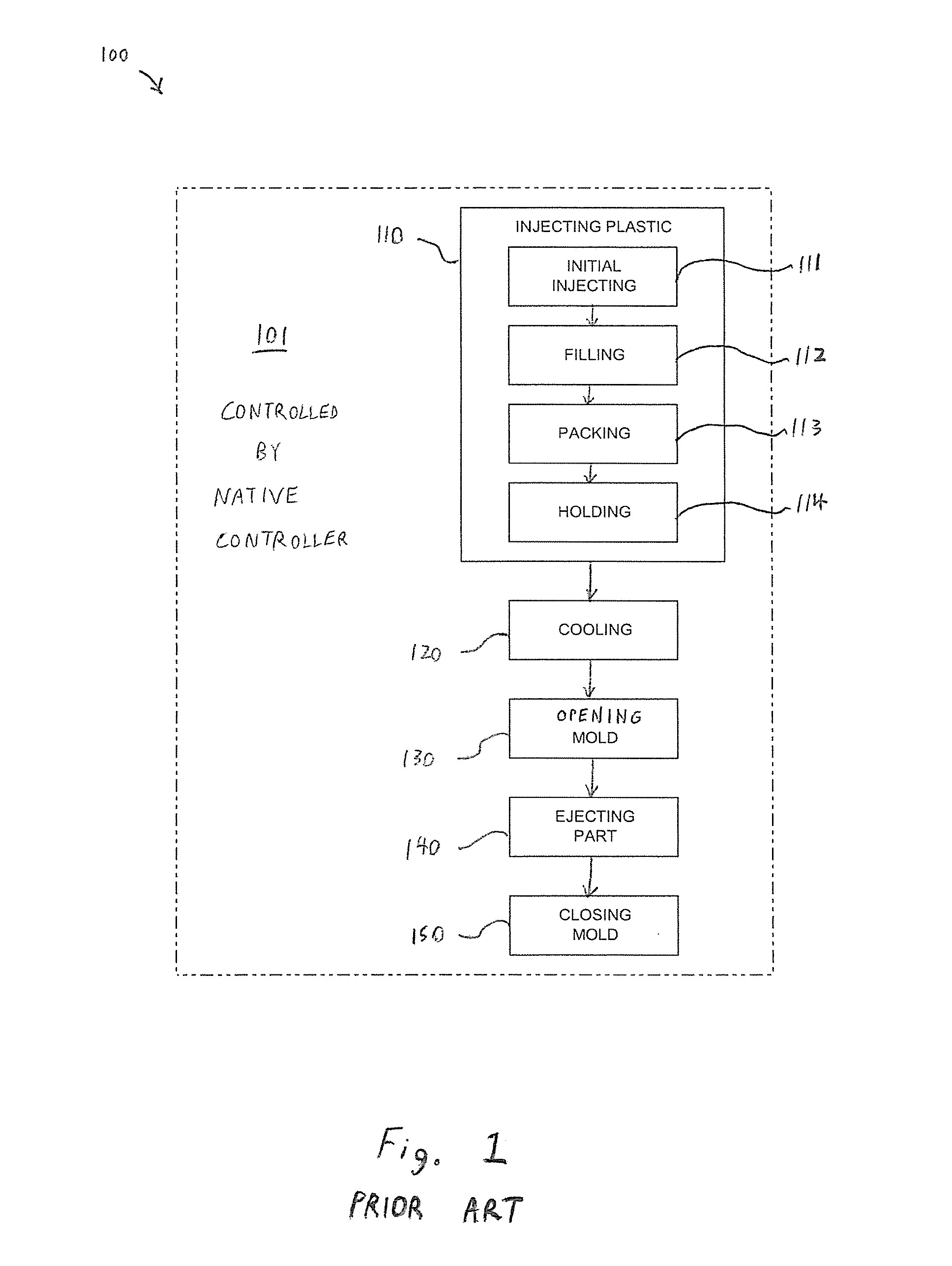

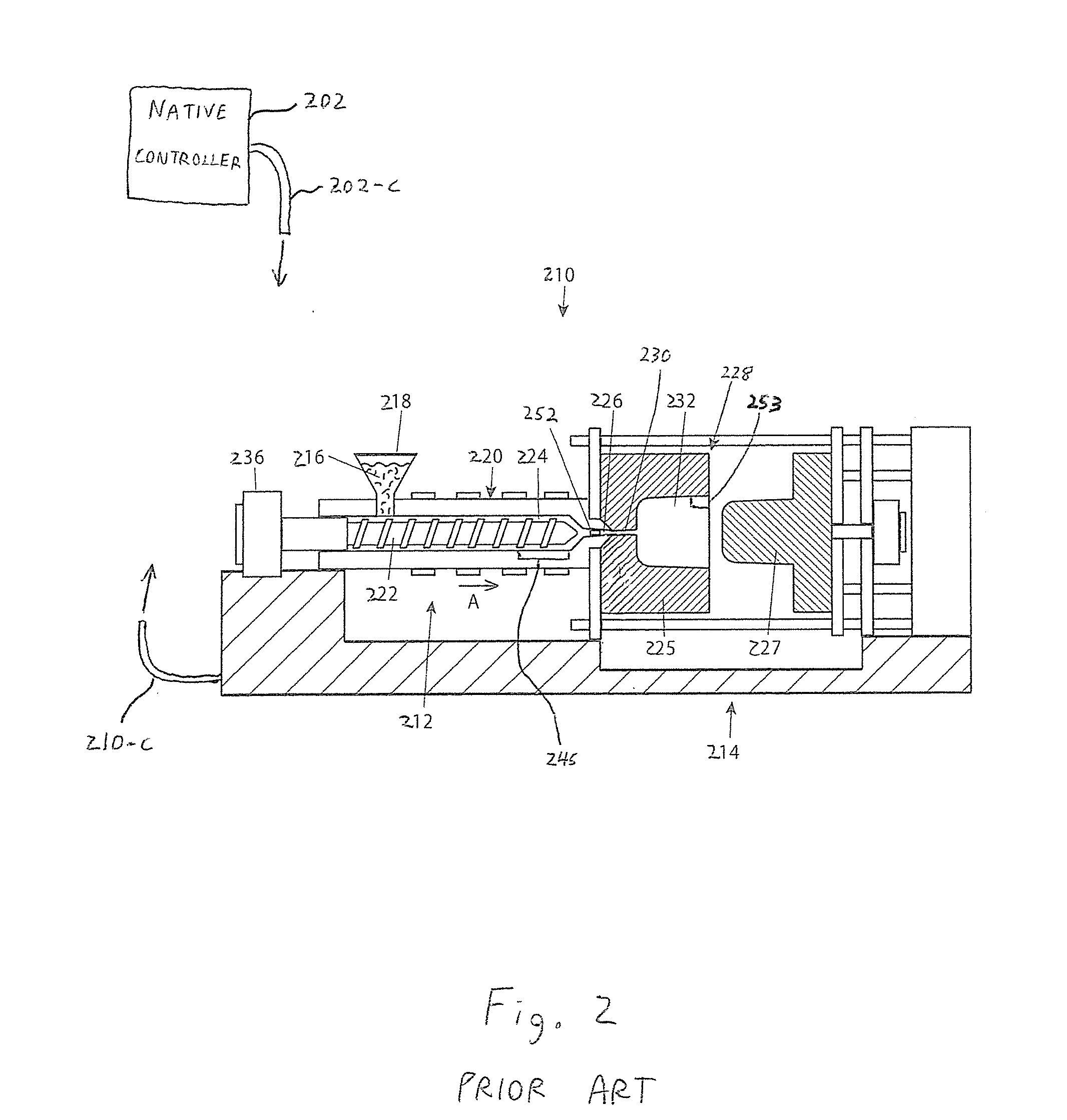

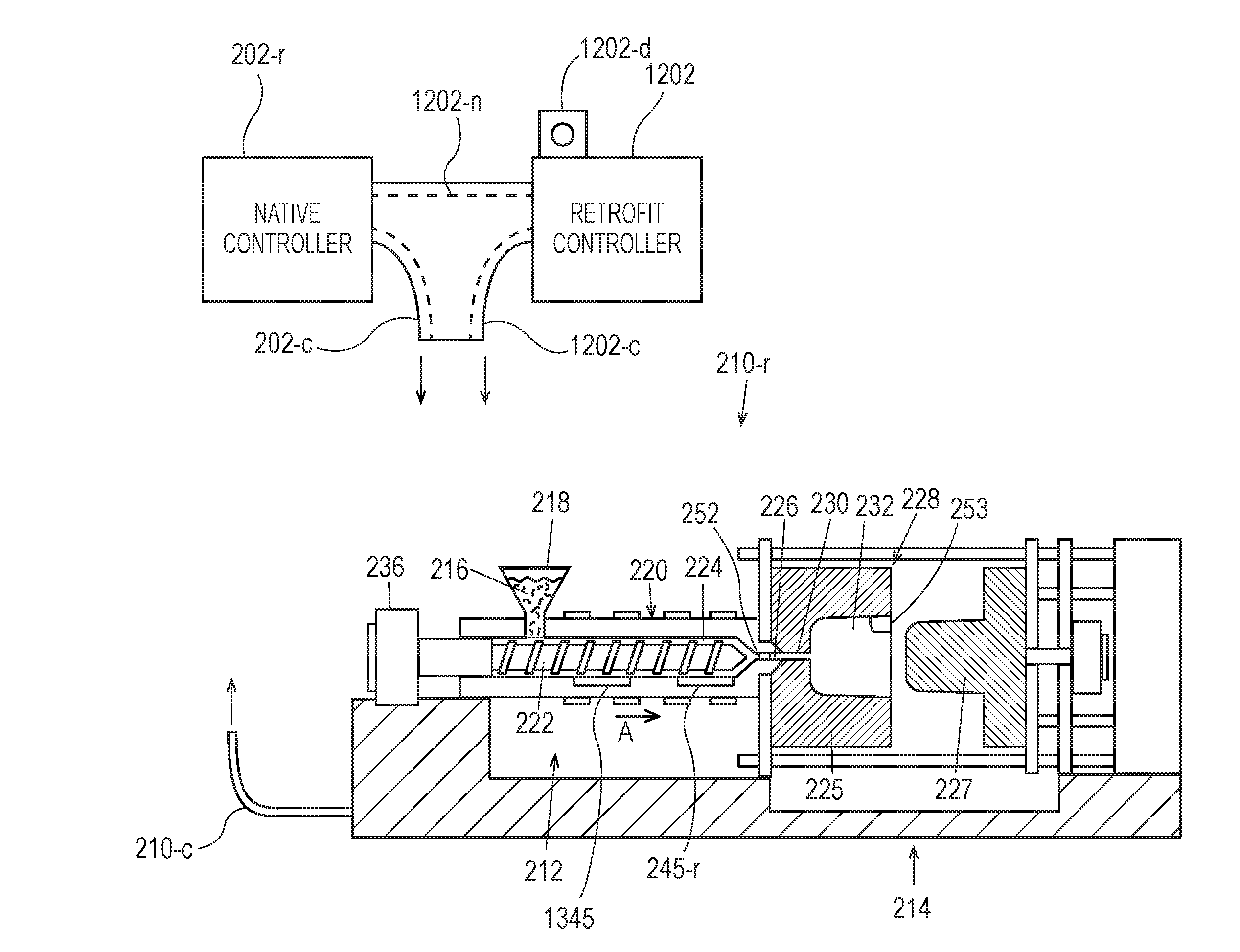

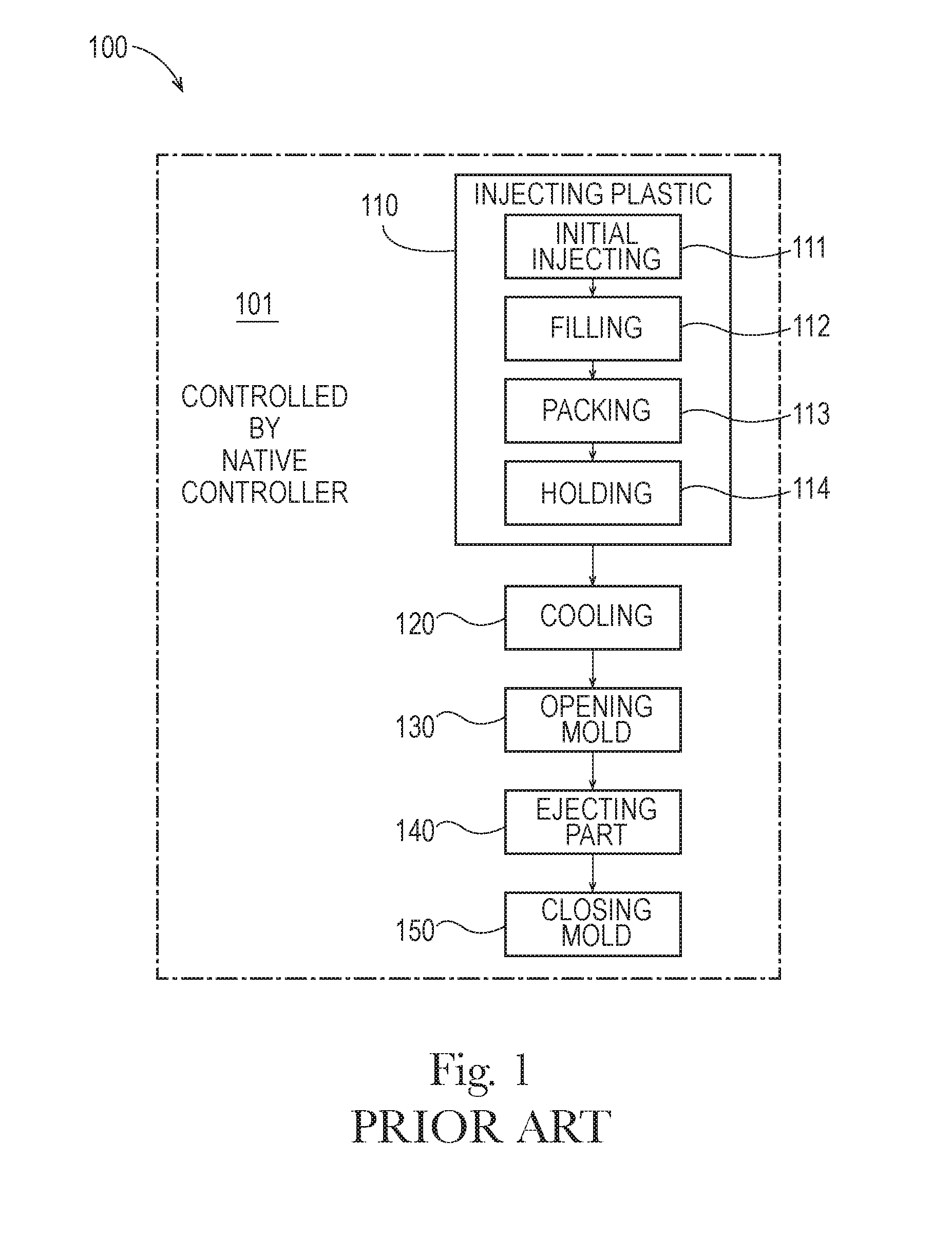

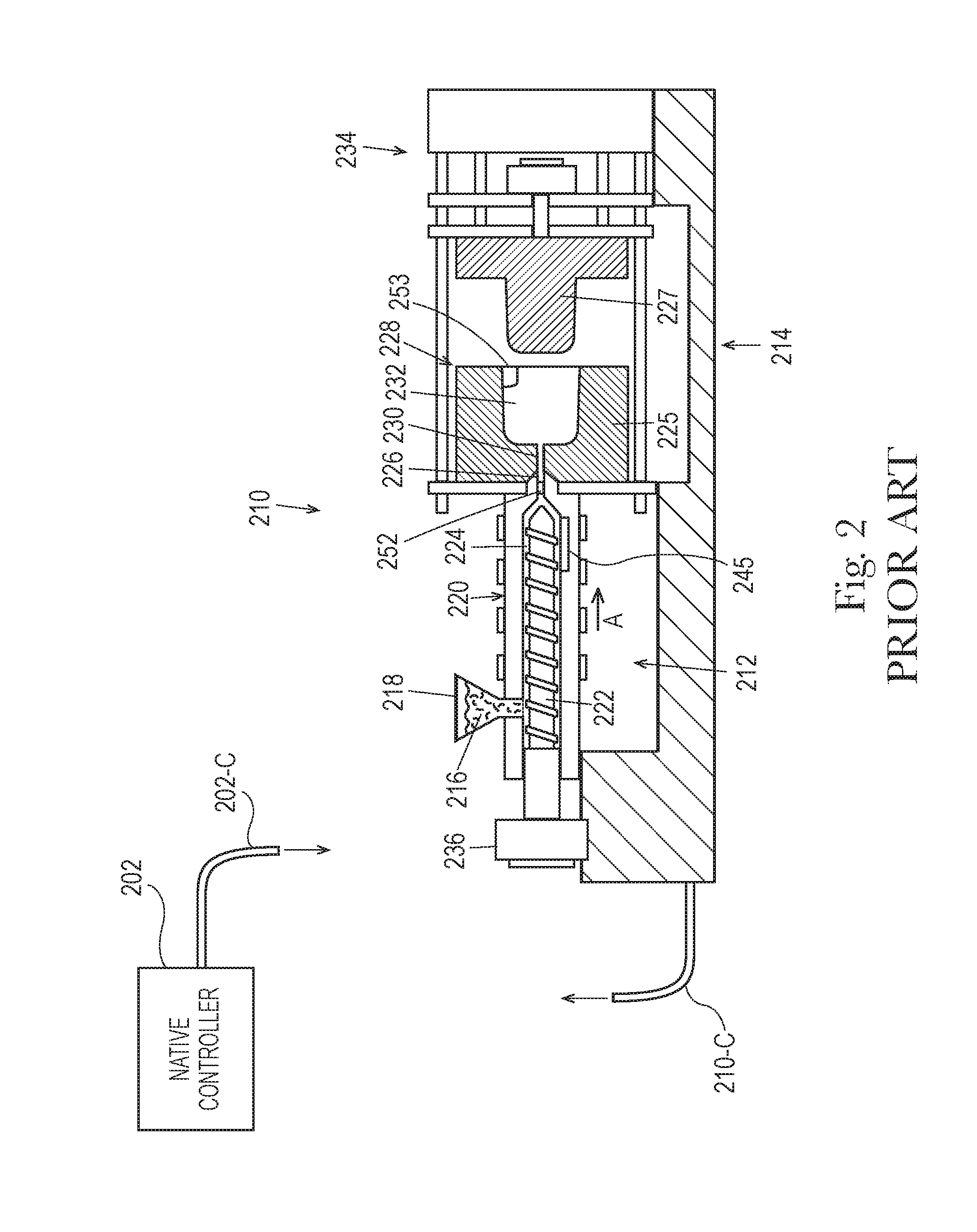

Methods of Using Retrofitted Injection Molding Machines with Reduced Pressures

An injection molding machine that uses a mold and a native controller to operate according to an original mold cycle to mold plastic objects is retrofitted with a retrofit controller; the retrofitted machine uses the mold and the retrofit controller to operate according to a retrofit mold cycle to mold plastic objects. The retrofit mold cycle has a maximum injection pressure that is less than a maximum injection pressure of the original mold cycle. The retrofit mold cycle can also have more constant injection pressures than the original mold cycle.

Owner:IMFLUX INC

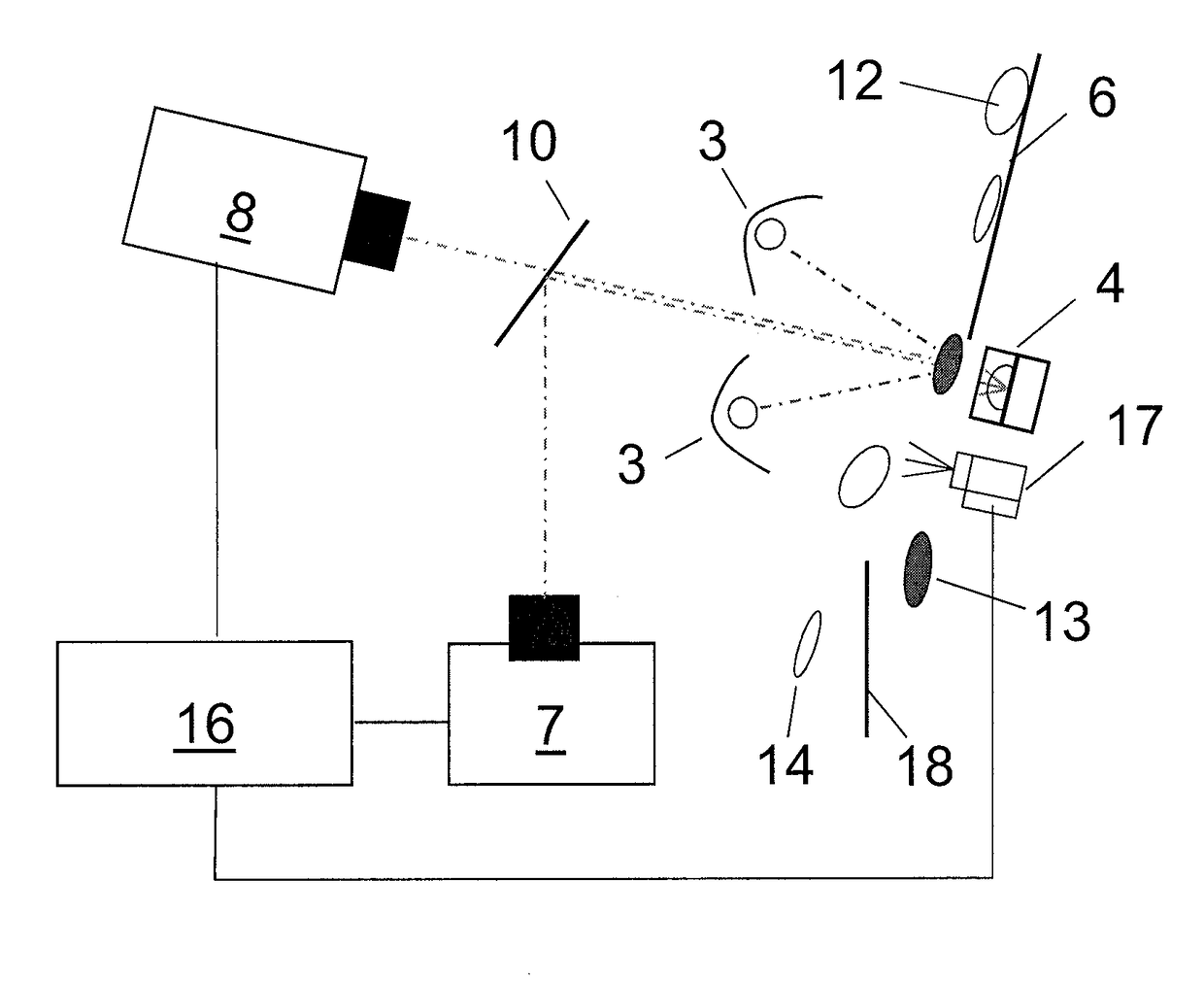

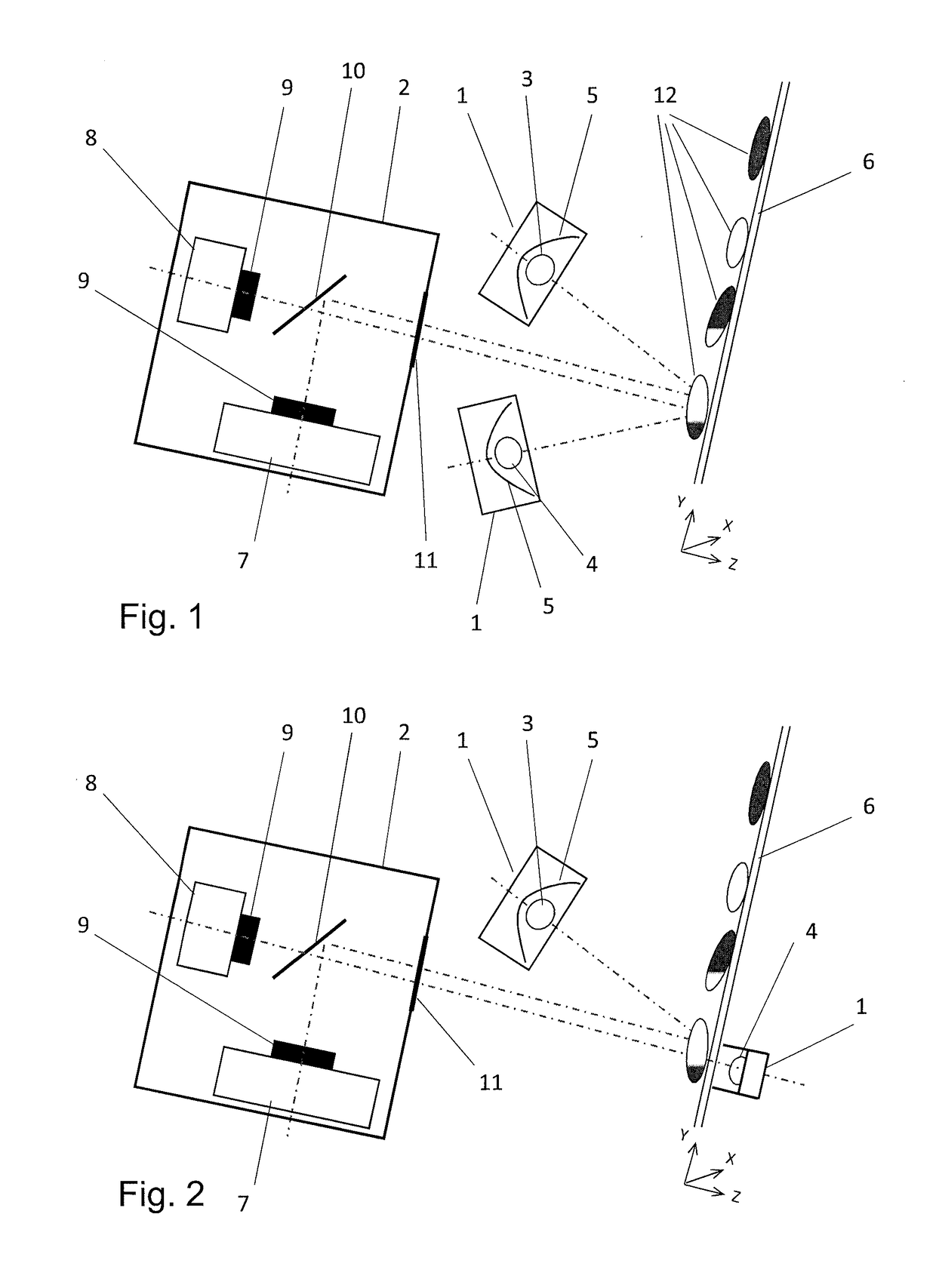

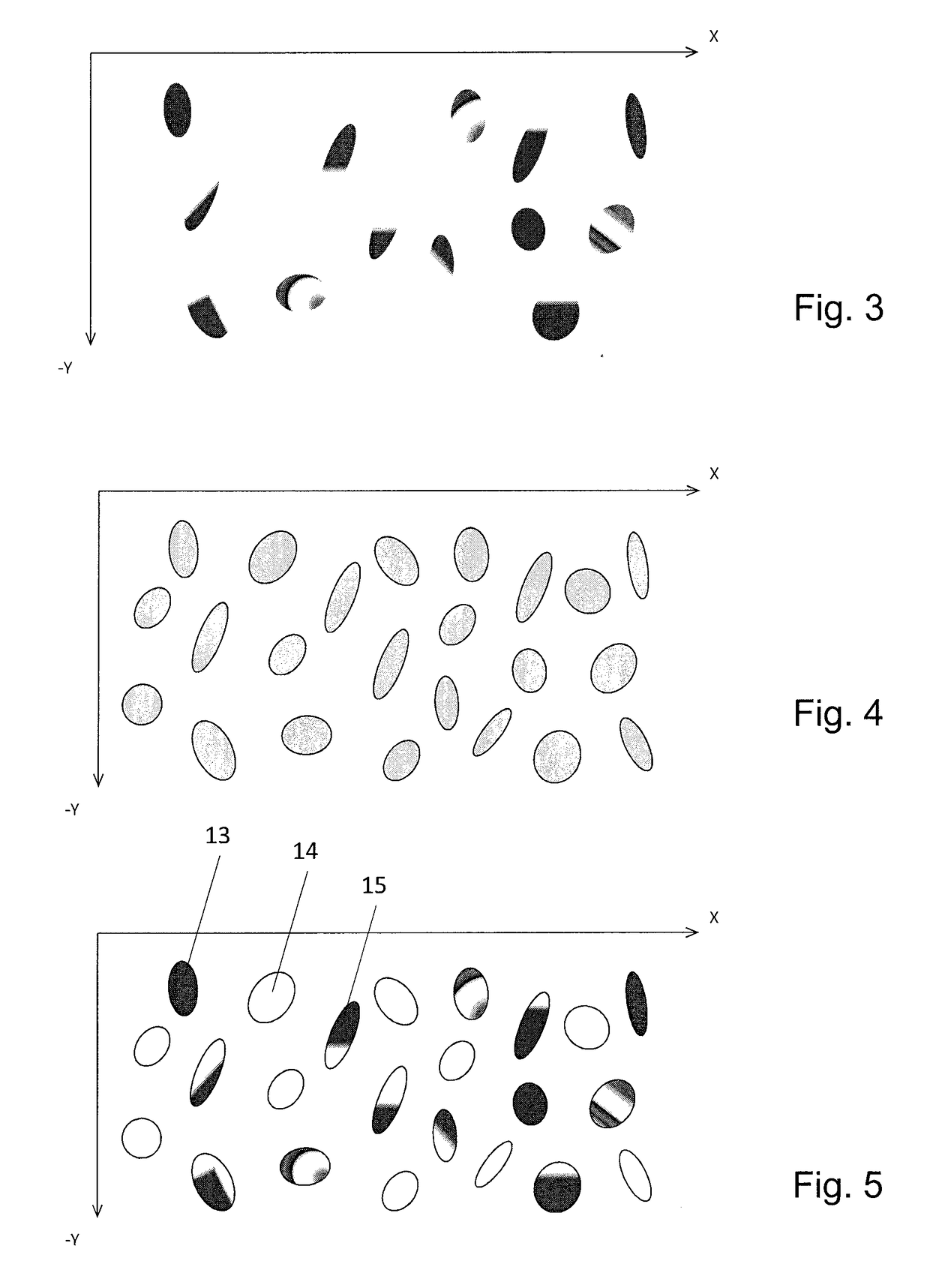

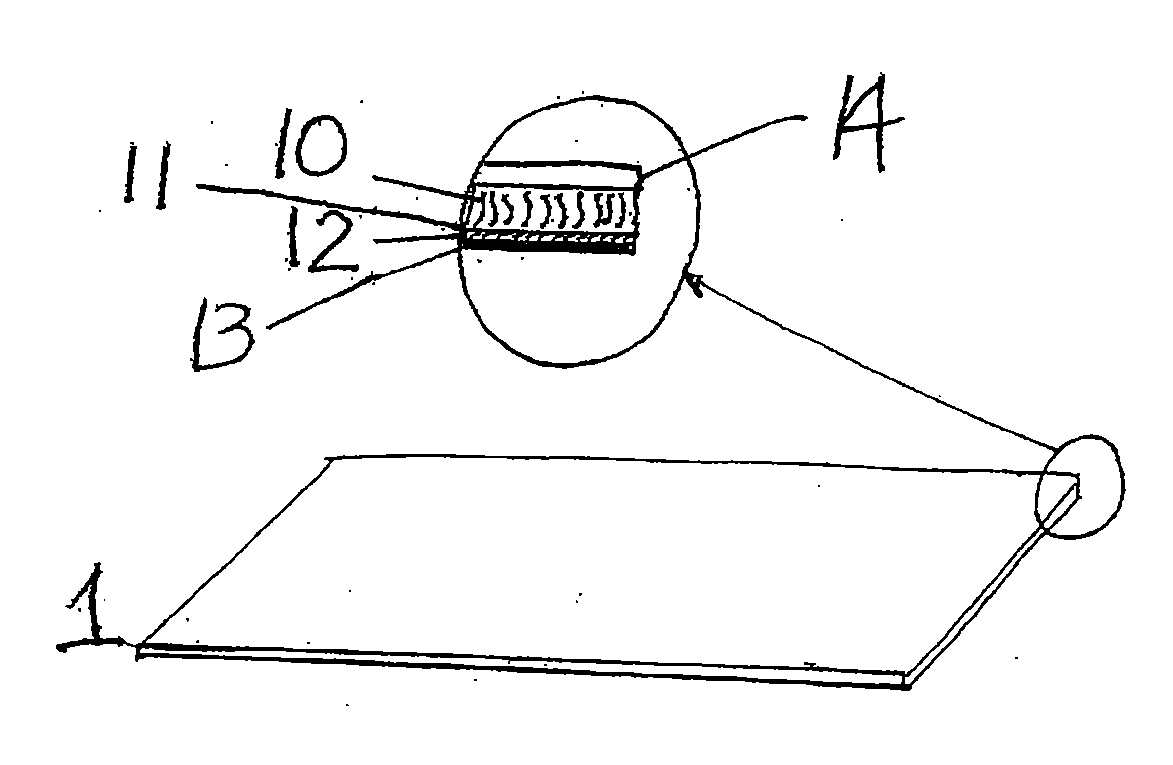

Sorting out mineral-containing objects or plastic objects

ActiveUS20180001352A1Inexpensively detectingFluorescence/phosphorescenceSortingUltimate tensile strengthFluorescent light

A method and a sorting plant for sorting out mineral-containing objects or plastic objects from a single layer material stream is shown. Here it is provided thatobjects (12) of the material stream are irradiated with stimulating light and the resulting fluorescent light is detected in the form of an image of the fluorescent points,the objects of the material stream are irradiated with object detection light outside the fluorescent light, and the transmitted light after passage between the objects or the reflected light of the objects is detected in the form of an image of the individual objects,an object is then defined as containing at least one specific mineral or one specific plastic if the fluorescent light of said object lies in a predetermined intensity range for at least one predetermined wavelength range, andthe so defined objects are separated from other objects of the material stream.

Owner:BINDER

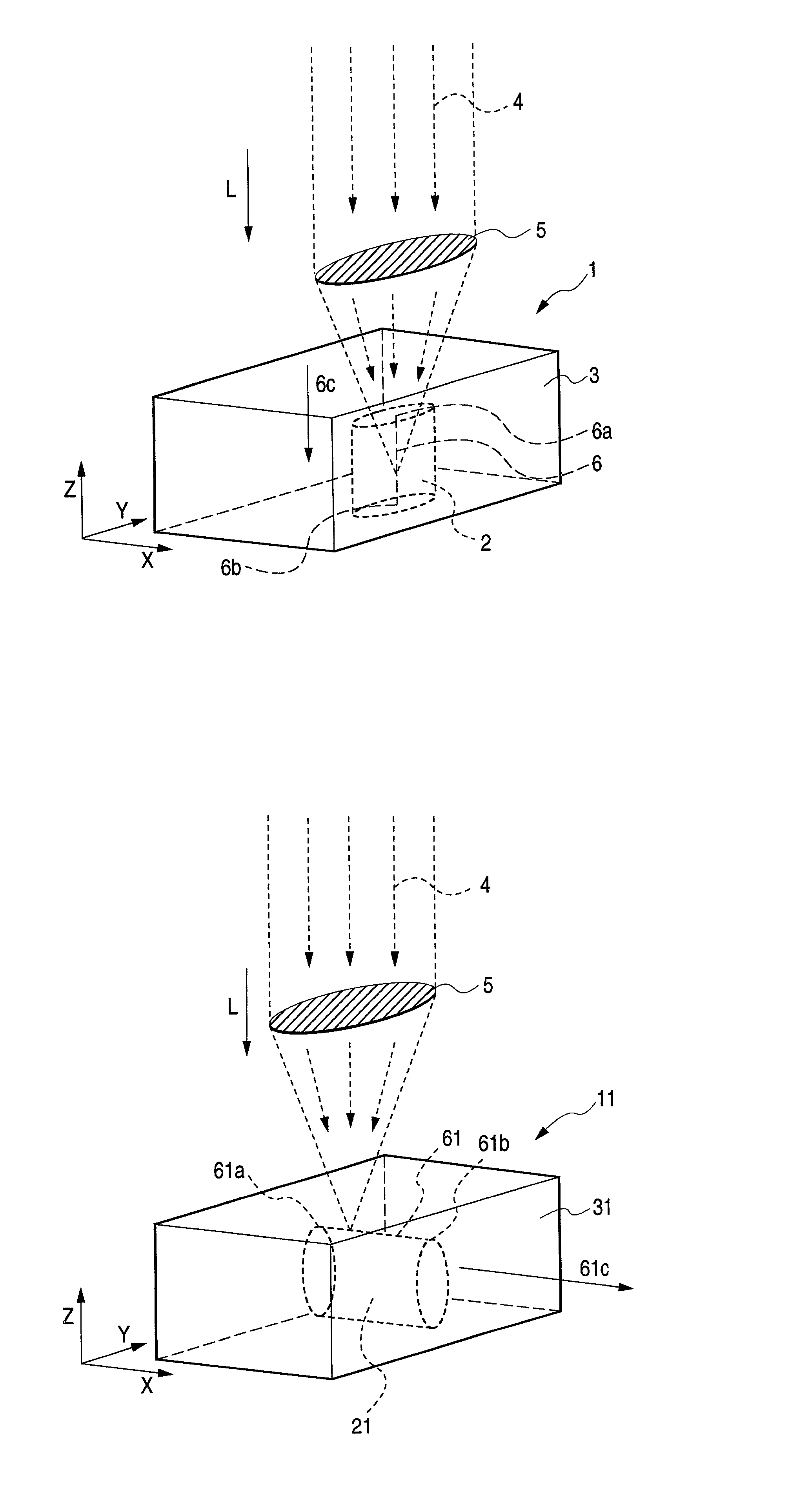

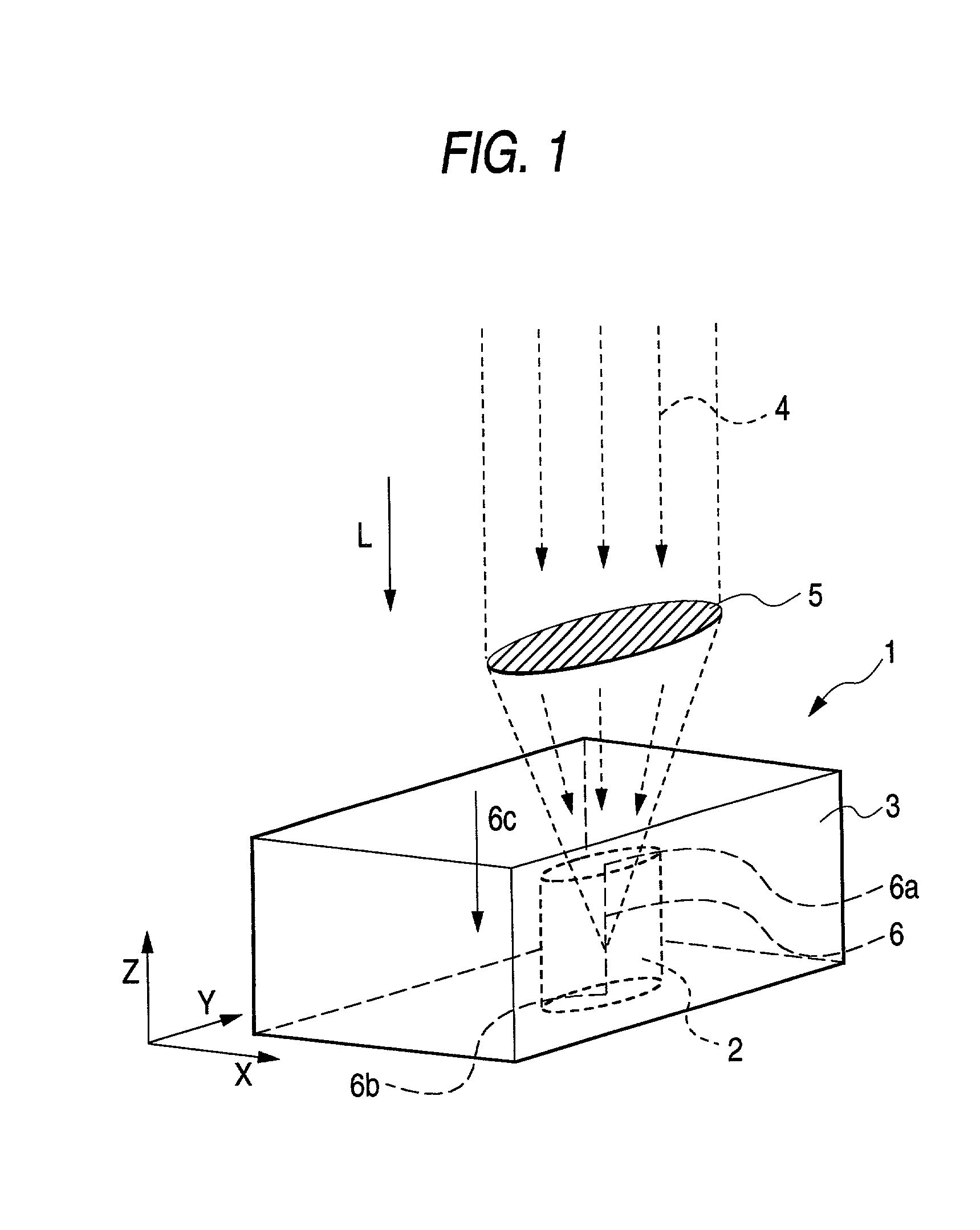

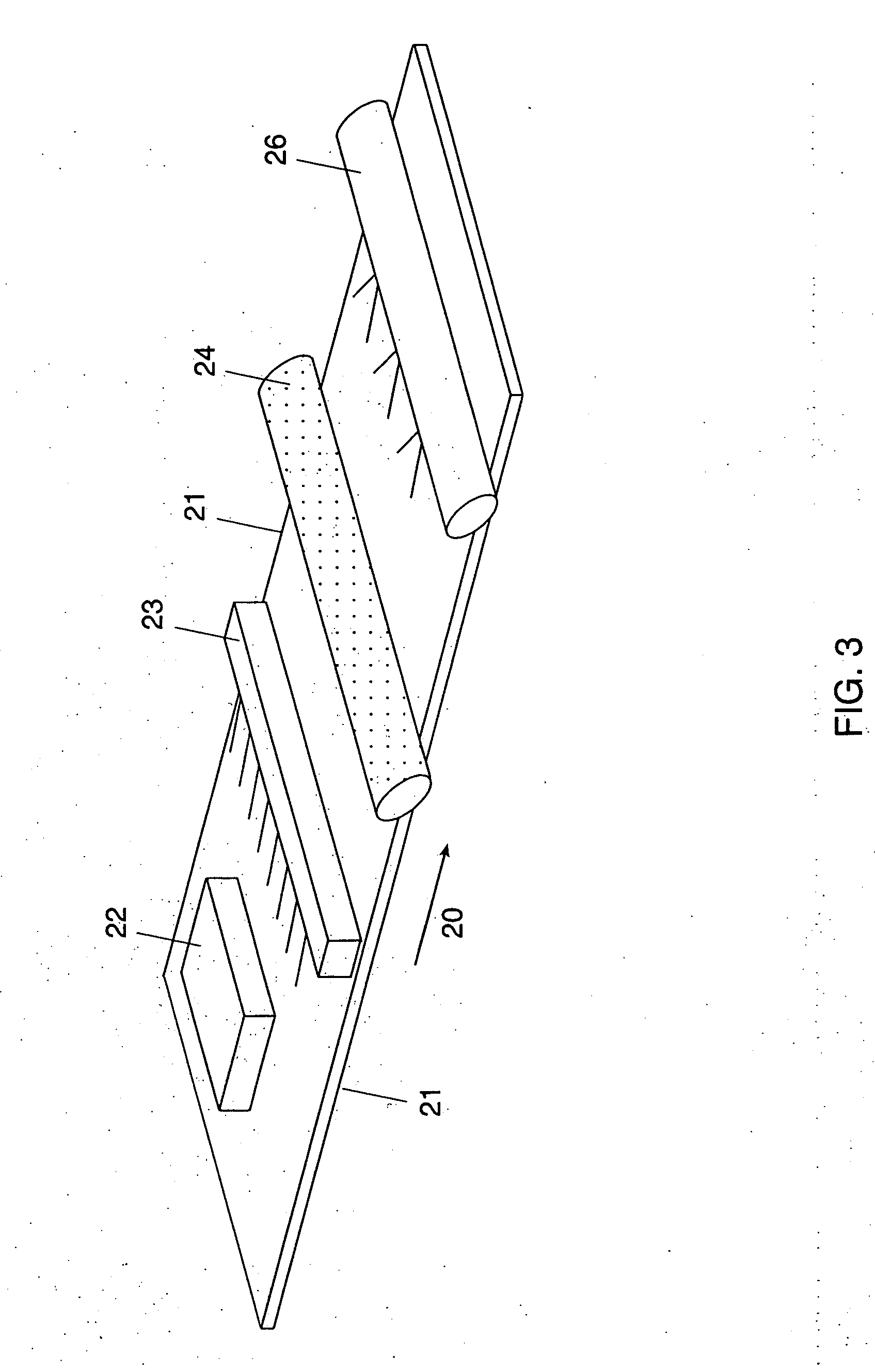

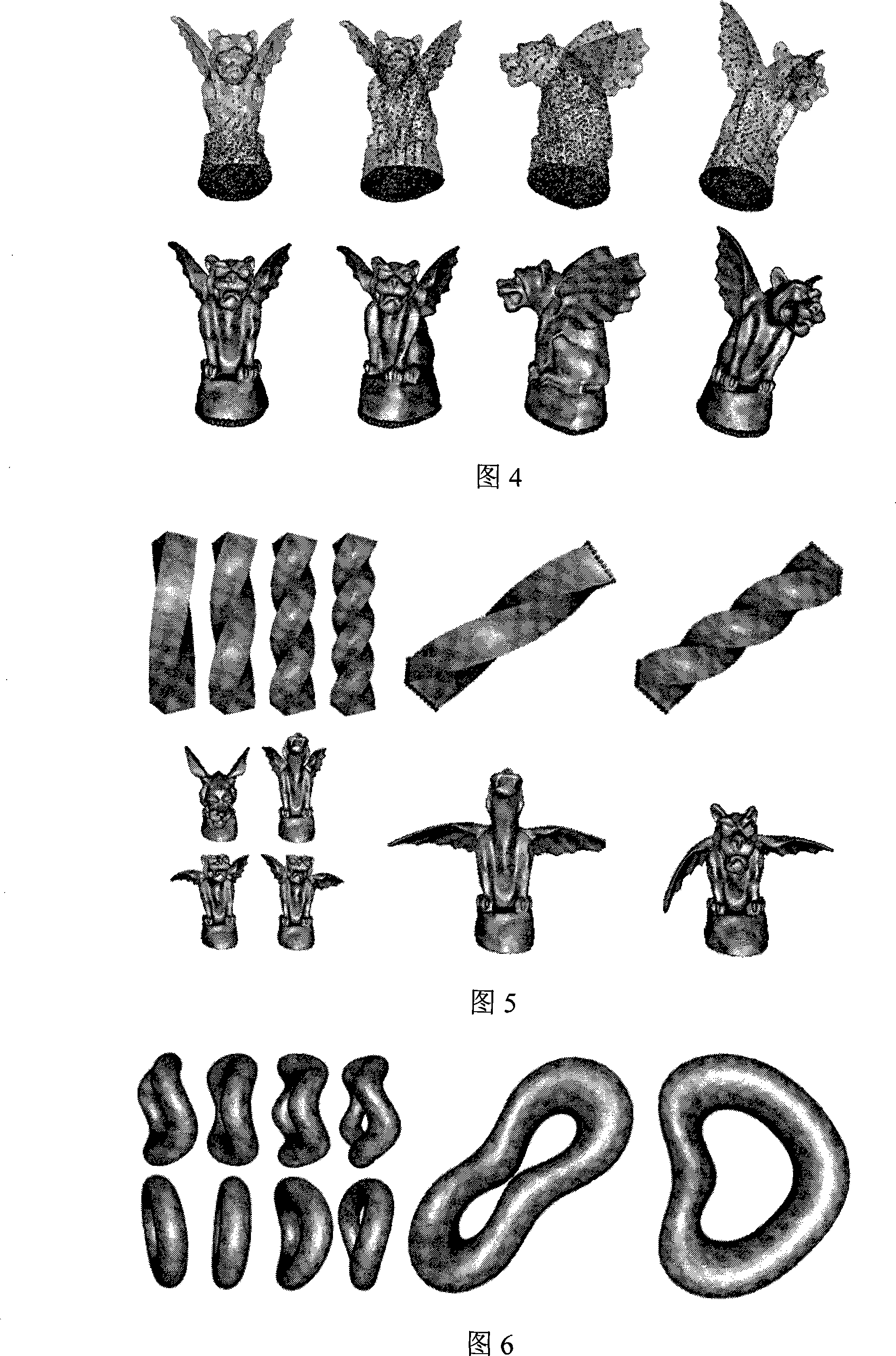

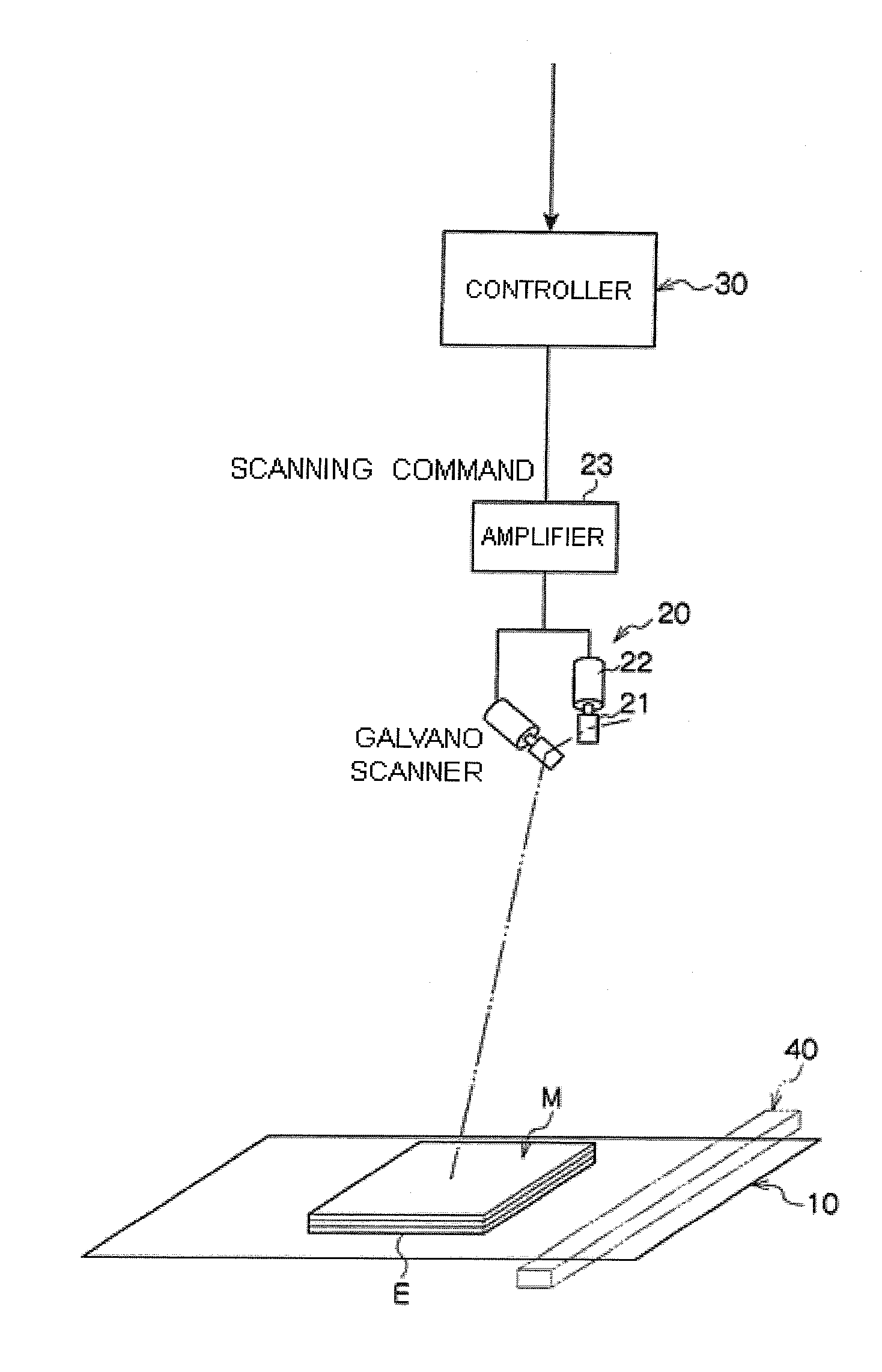

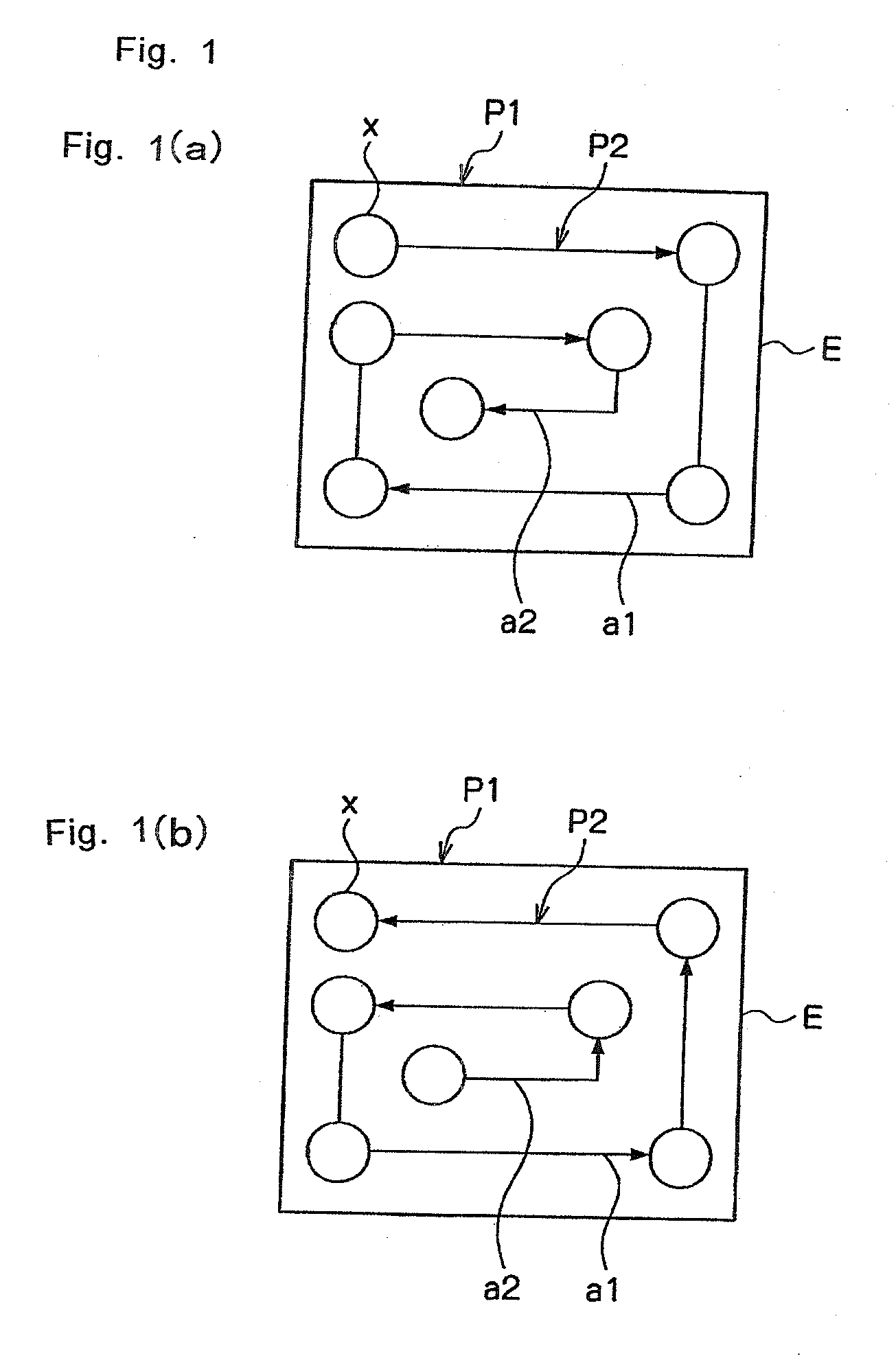

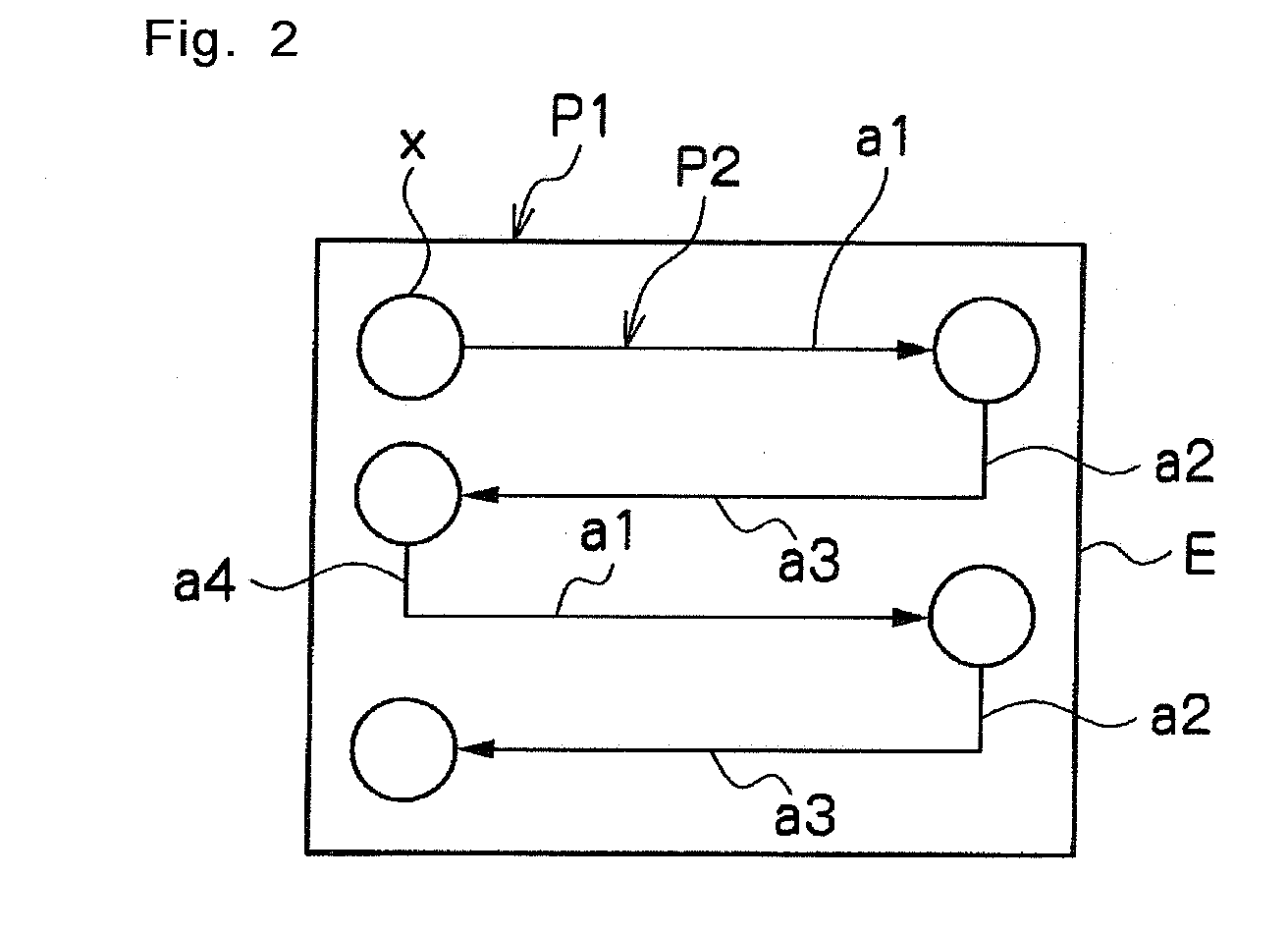

Three-Dimensional Molding Equipment and Manufacturing Method For Three-Dimensional Shape Plastic Object

InactiveUS20150283762A1Improve molding efficiencyAvoid it happening againAdditive manufacturing apparatusAuxillary shaping apparatusLight beamBeam scanning

Three-dimensional molding equipment includes powder supply equipment which forms powder layer in a laminating process; and a beam scanning unit which radiates a light or electron beam to the powder layer and moves a radiated location of the beam to sinter the powder layer, wherein the laminating and sintering processes alternately repeat, a molding path to be a scanning route of the beam on the inside of an object to be molded is preliminarily set as a continuous route which does not pass a same line and does not form any intersection, and the beam is continuously radiated along the molding path, wherein two molding paths adjacent each other formed of two straight or curve lines are set, and a distance between the adjacent scanning routes is formed larger than a radiation diameter of the beam and not larger than ten-times the radiation diameter of the same.

Owner:MATSUURA MACHINERY

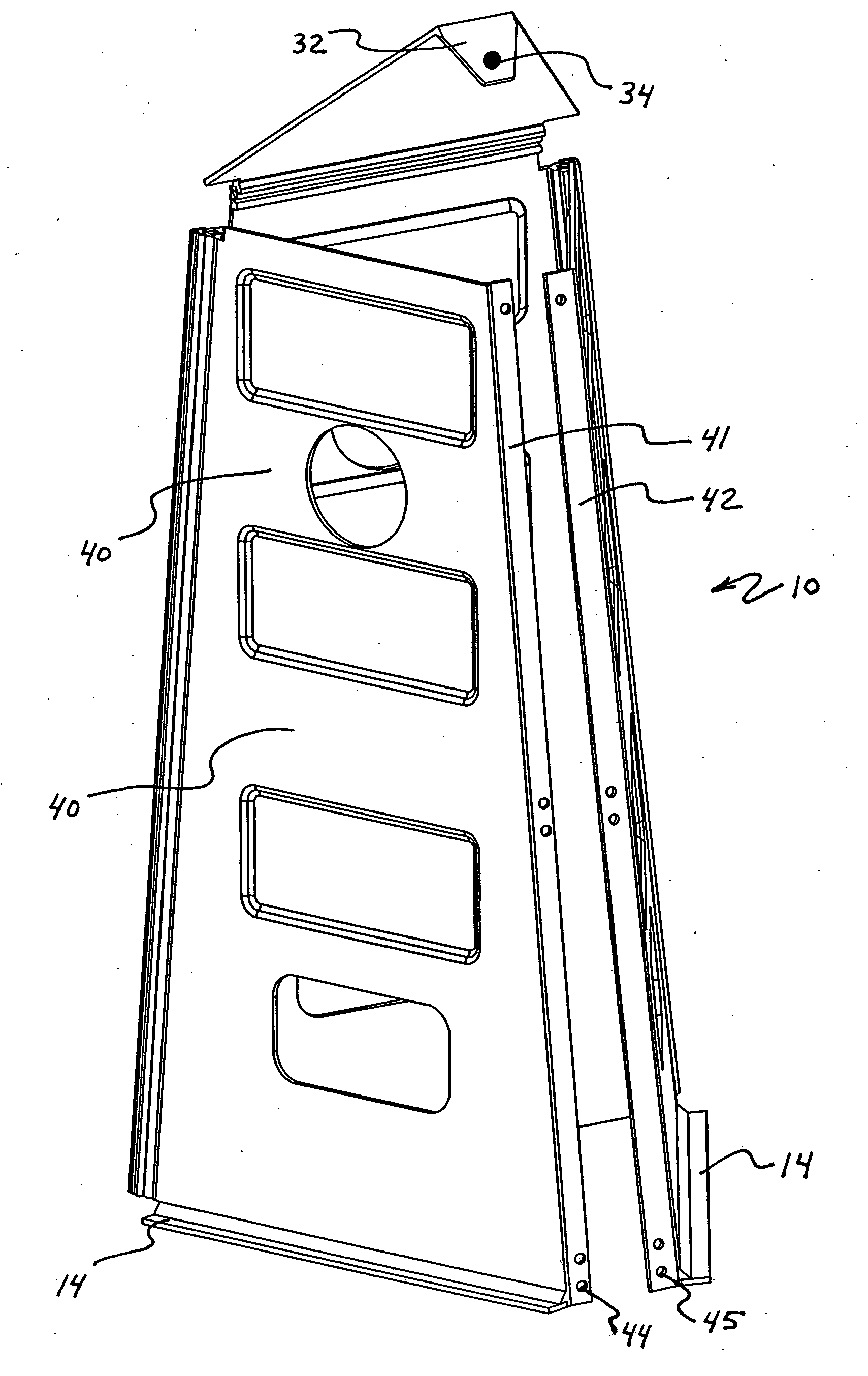

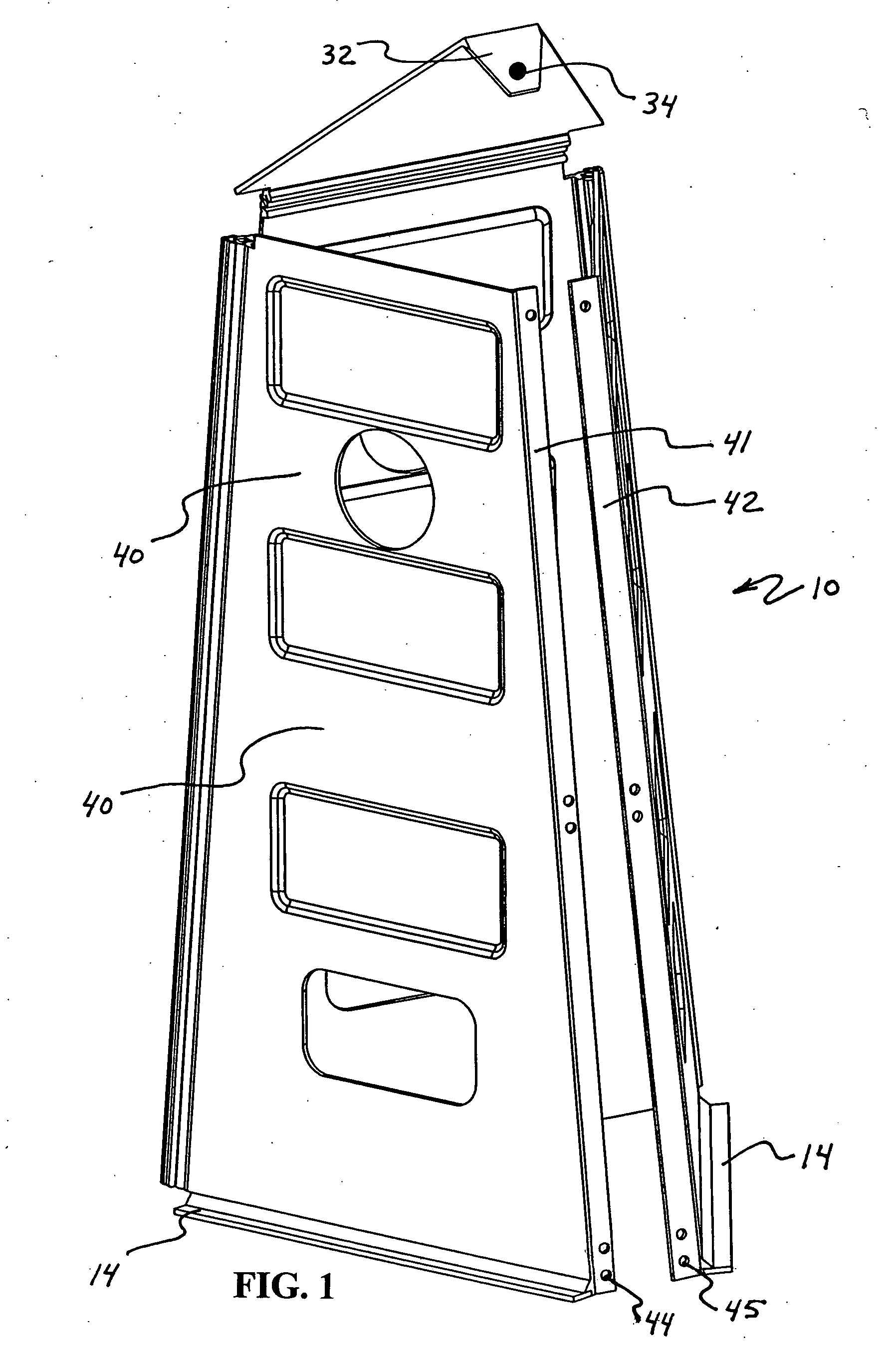

Collapsible construction barrier

InactiveUS20060124642A1Process safety and stabilityEasy to holdContainer/bottle contructionTraffic signalsEngineeringMechanical engineering

A collapsible path barrier has at least three integrally-formed wall sections with a plurality of living hinges, as a series, joining each adjacent pair of wall sections, the at least three wall sections including two endmost wall sections joinable to form an upright structure. A collapsible path barrier may include a plurality of interconnected wall sections each having a top-facing side, where one of the top-facing sides has a pocket adapted for securely holding a light. A thermoformed unitary plastic object may include at least two wall sections, at least one hinge member connecting adjacent interior ones of the wall sections' longitudinal sides, the hinge member comprising a plurality of interconnected living hinges, where a nominal thickness of the at least one hinge members of the thermoformed unitary plastic object approximates 0.100 inch.

Owner:KAROW MARK P +1

Plastic products with high strength and flexibility

The invention relates to plastic products with high strength and flexibility, characterised in comprising 10 to 50 mass % of at least one cross-linked thermoplast and 90 to 50 mass % of at least one cross-linked melamine resin ether. The invention further relates to a method for production of such a plastic product. The aim of the invention is the production of plastic objects in thermoplastics and duroplastics which can be produced by thermoplastic methodology and which have improved material properties.

Owner:AMI AGROLINZ MELAMINE INT

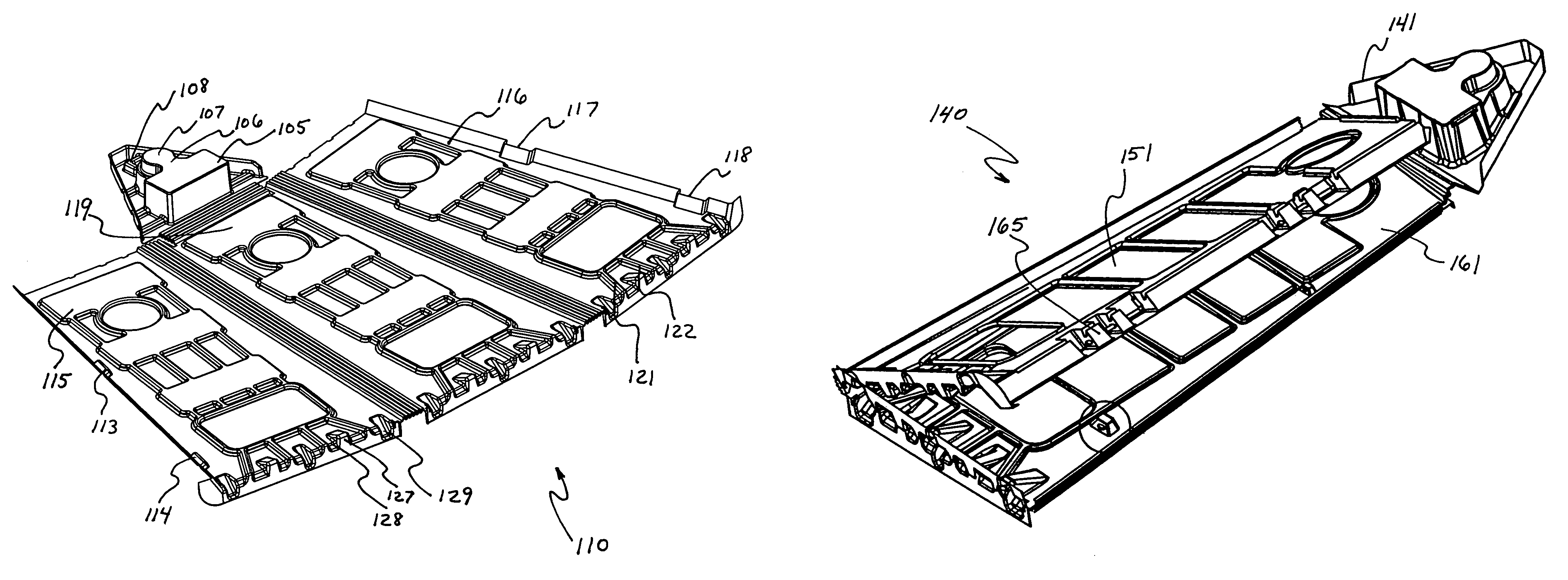

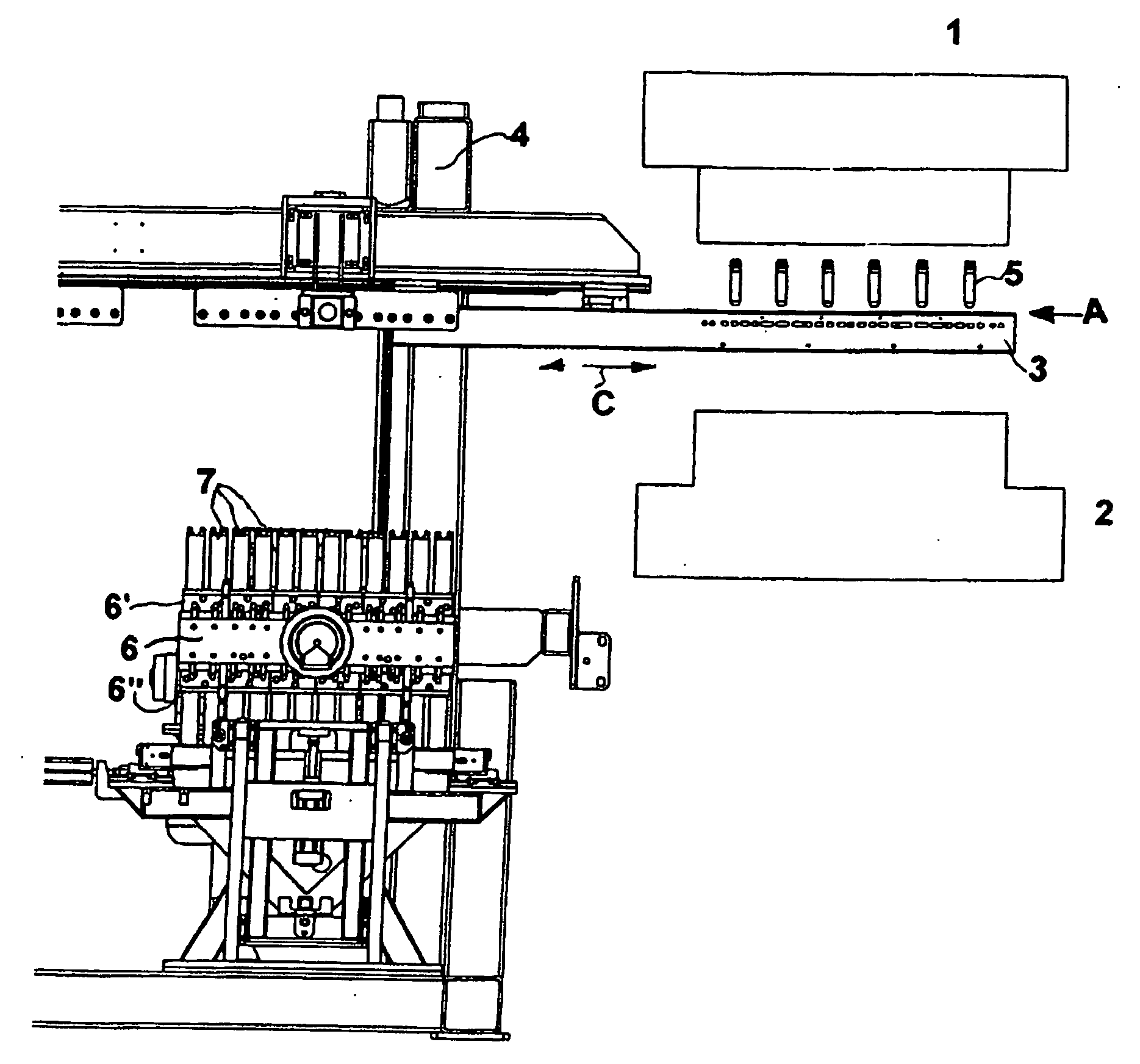

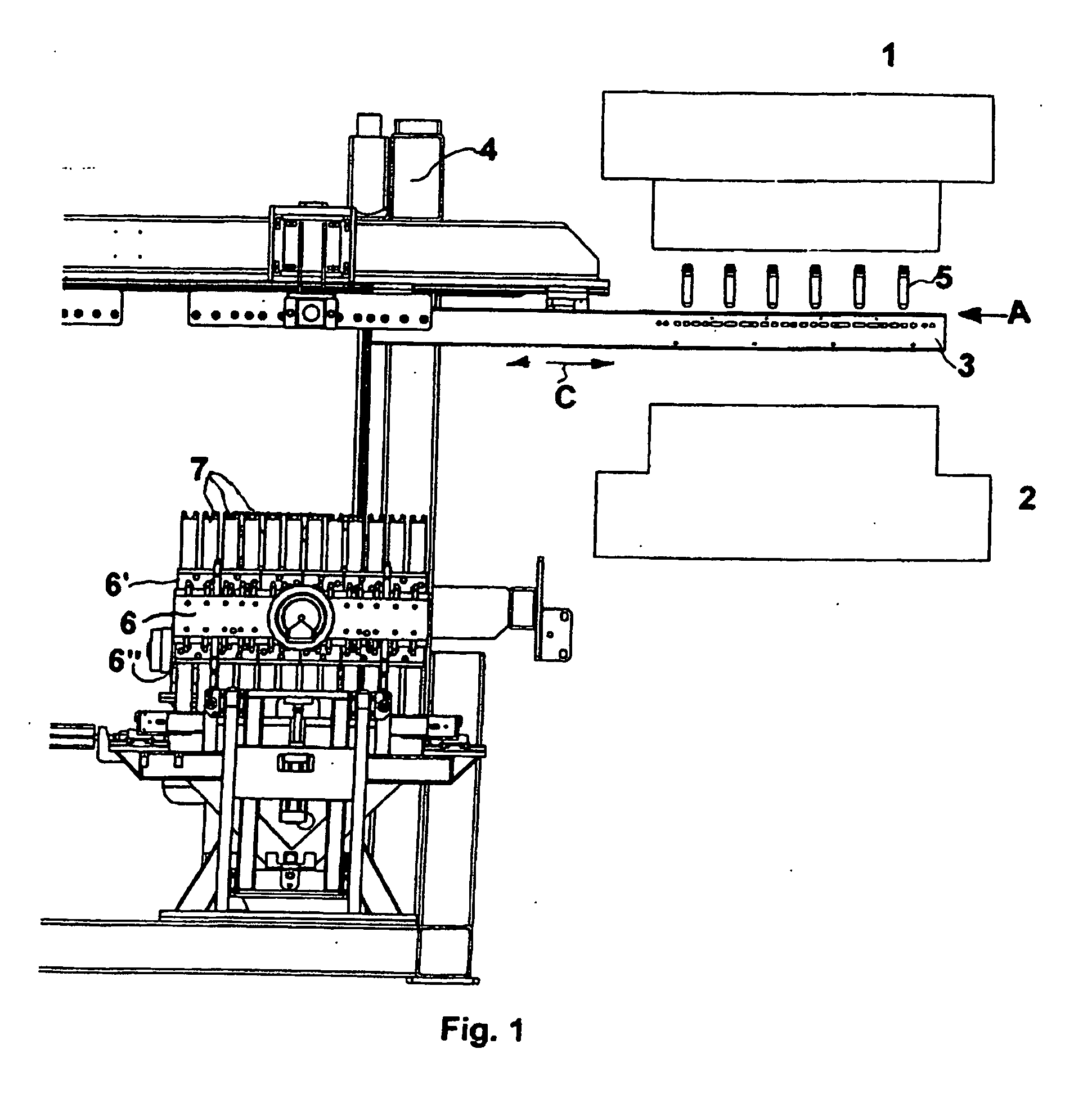

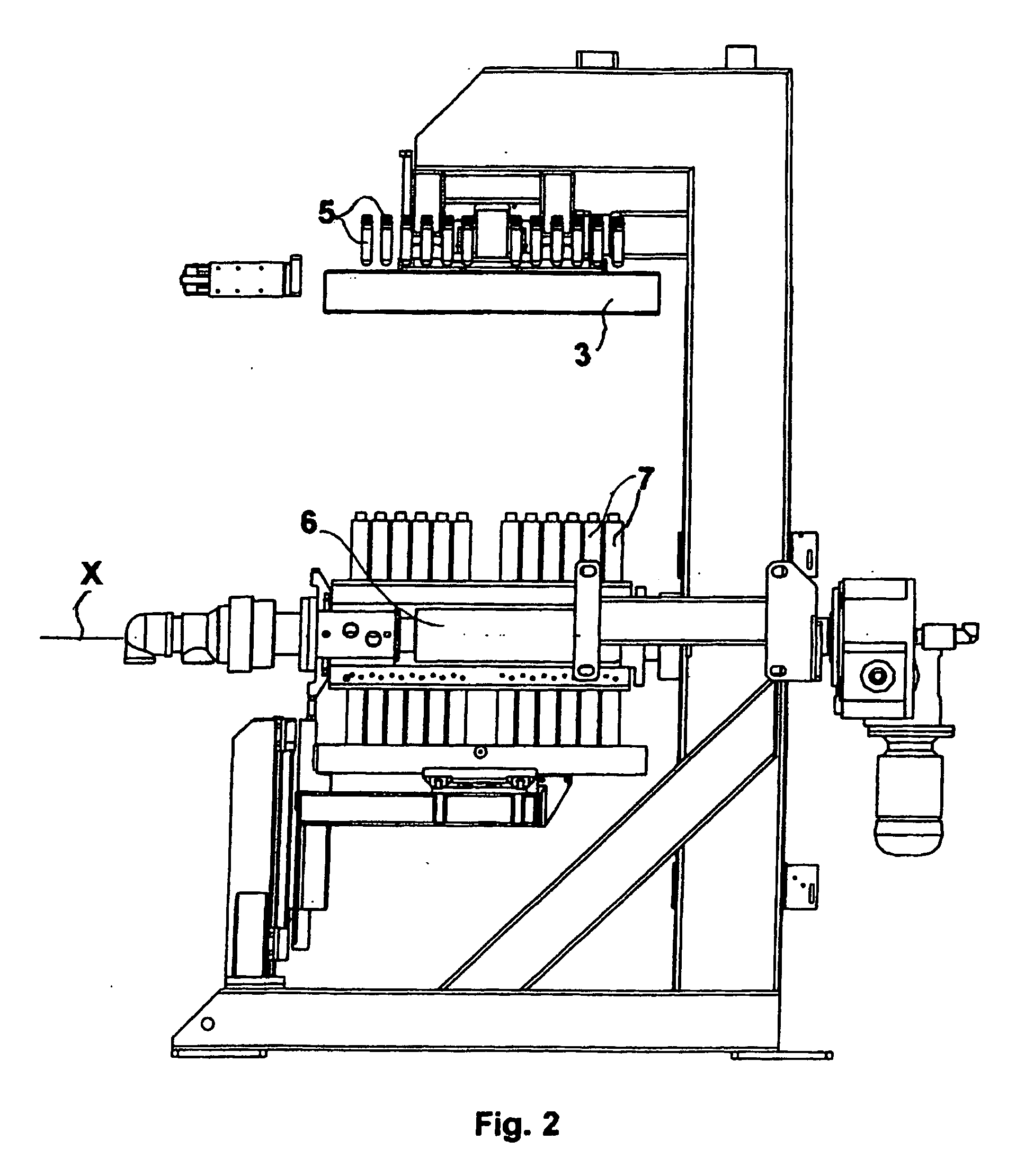

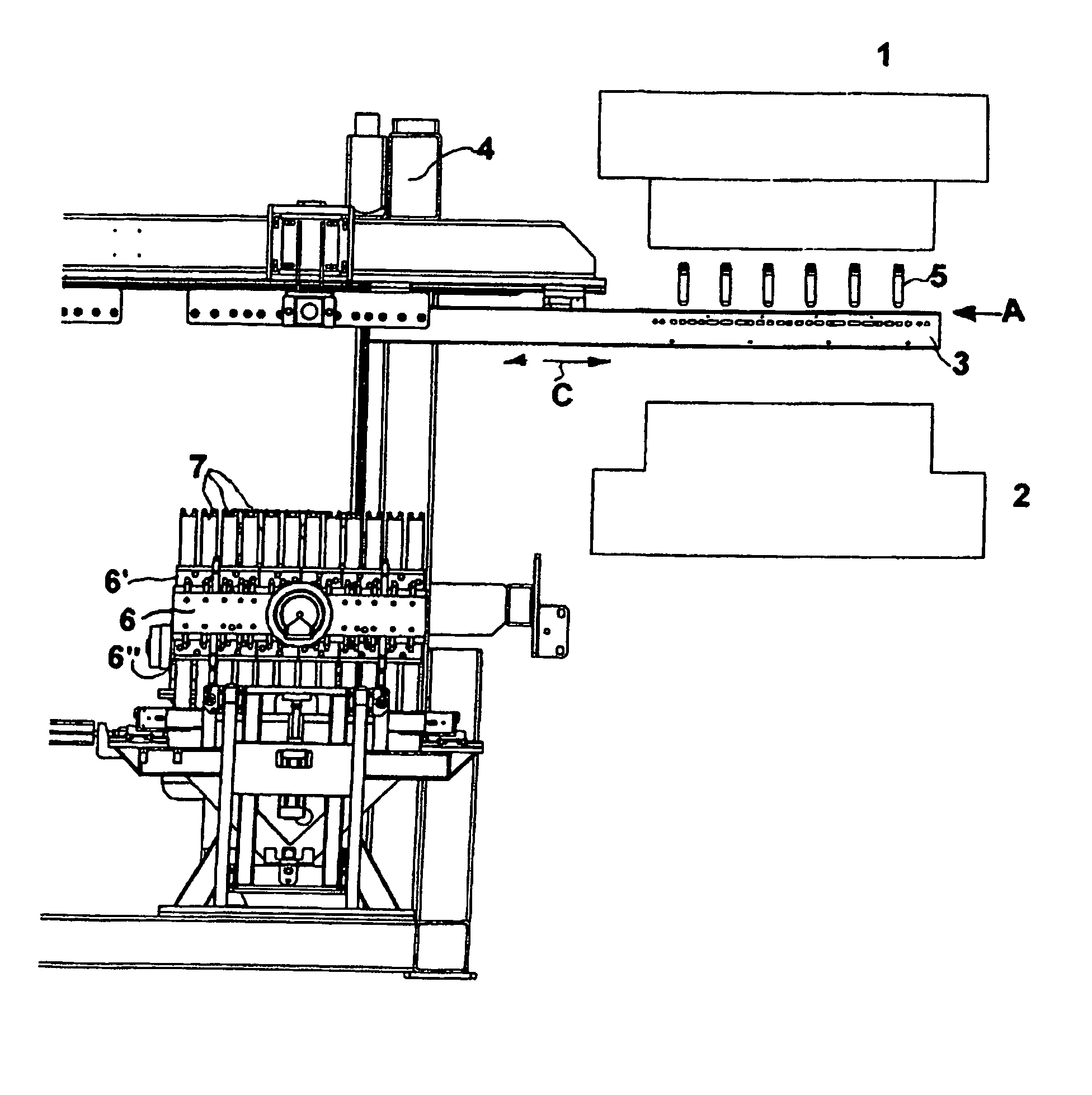

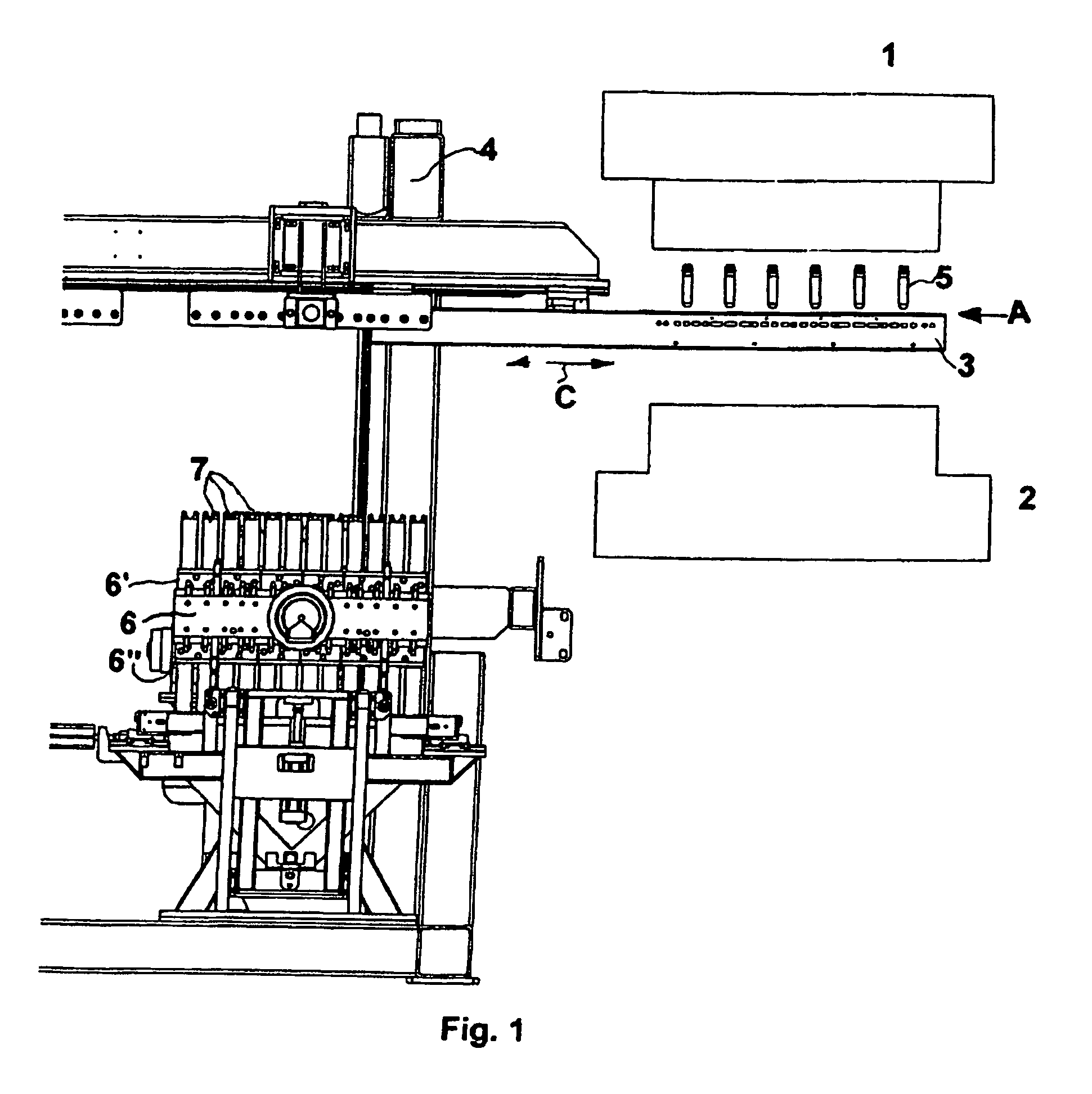

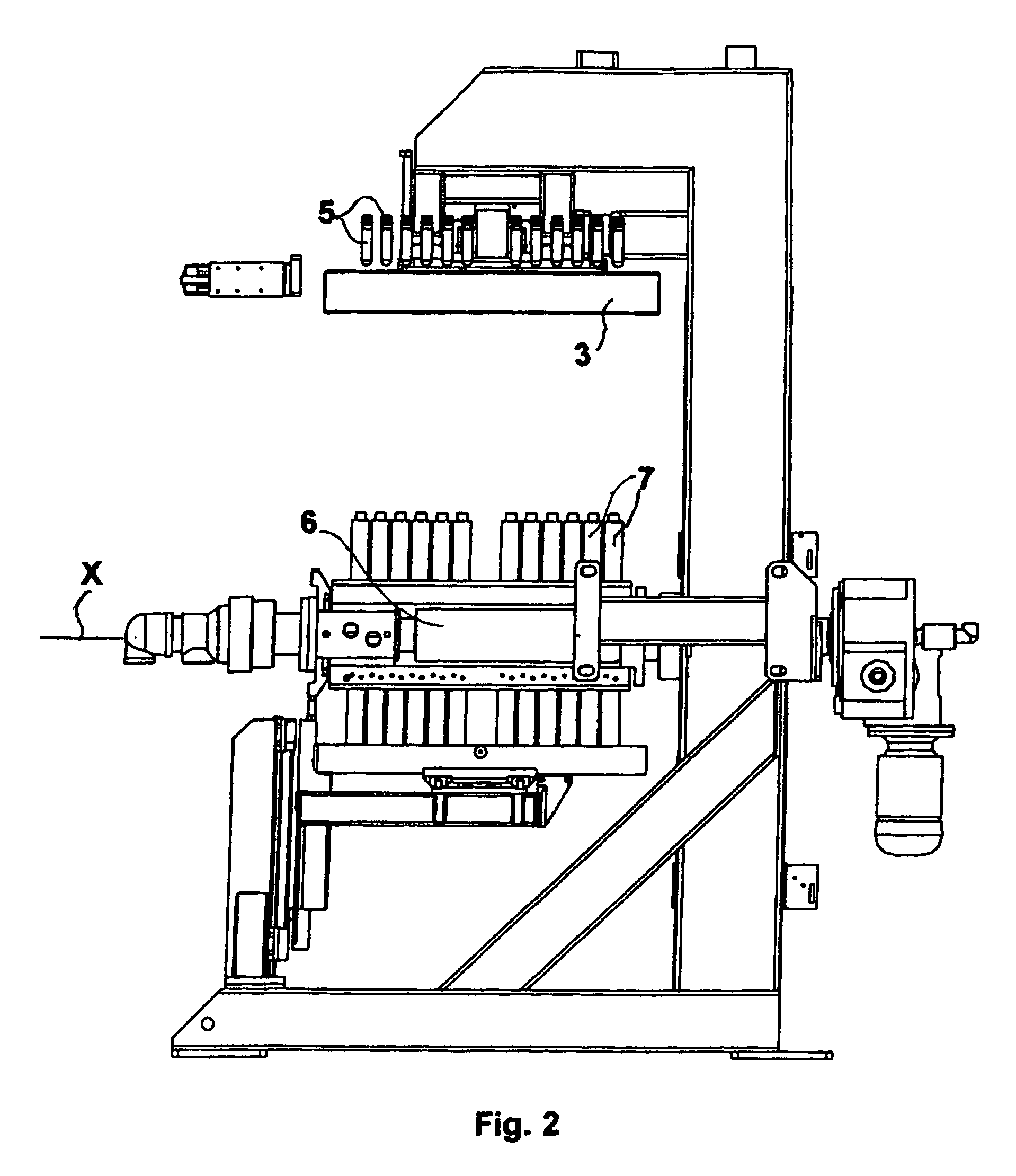

Injection device and process for plastic objects

InactiveUS20070157545A1High level of productivityReduce manufacturing costRoof toolsBuilding material handlingHorizontal axisEngineering

A plastic preforms (5) moulding device and process comprising an injection mould, containing a plurality of injection cavities, an arm (3) for extracting the preforms (5) from the mould, equipped with guillotine-like gripping elements, which moves between the existing space between the half moulds when in the open position in order to grasp the preforms and the external position, a cooling turret (6), with the faces housing a group of cups (7) for the conditioning of the preforms (5), which effects a rotational movement around a horizontal axis and a vertical translation movement between the high position under the extraction arm to receive the preforms and the low position corresponding to the extraction table of the preforms (5), on which are indented longitudinal slots with teeth shaped constrictions in order to grasp the preforms under the ring (9) and to extract them from the cups (7).

Owner:SIPA SOCIETA INDUSTRIALIZZAZIONE PROGETTAZIONE E AUTOMAZIONE SPA

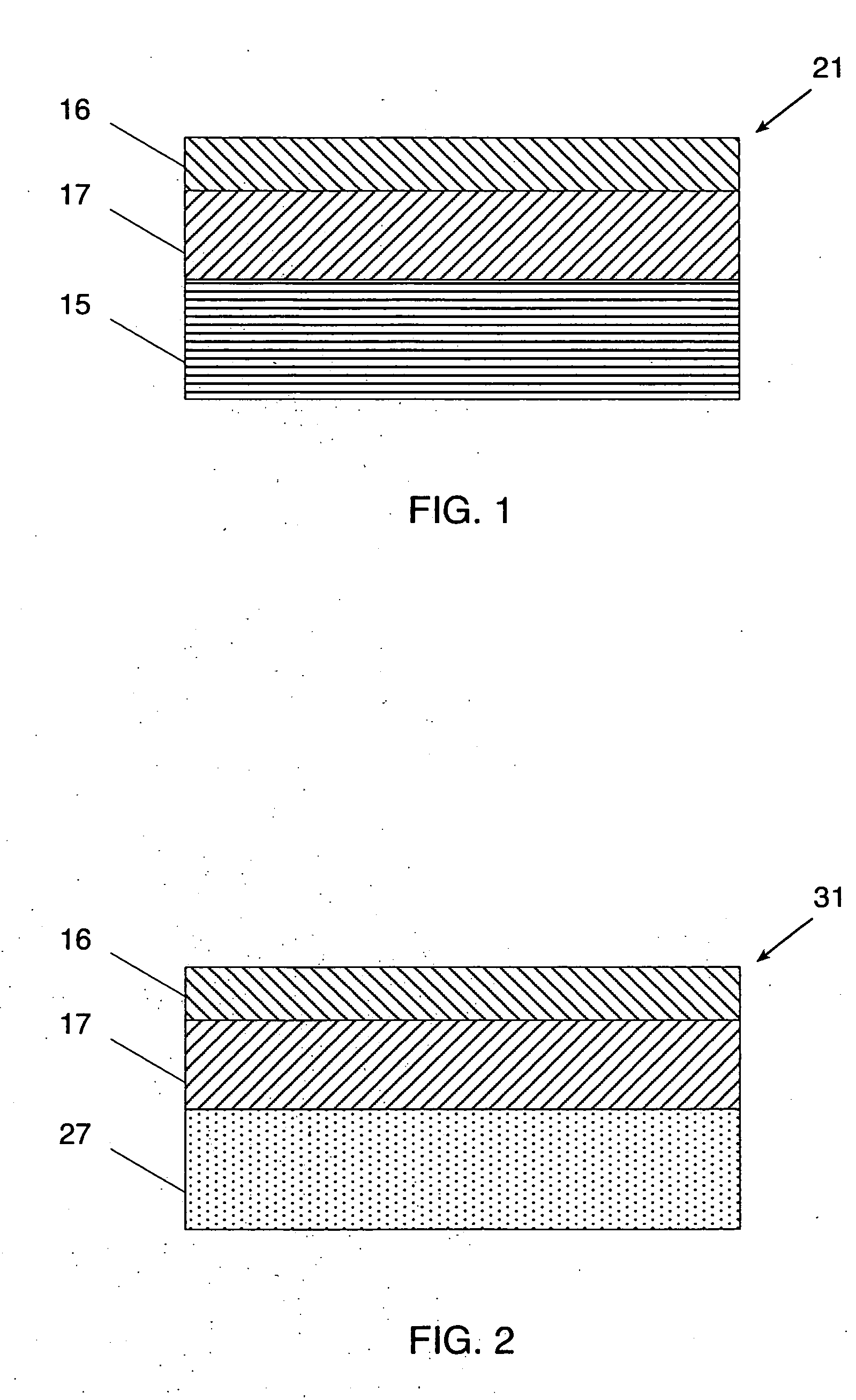

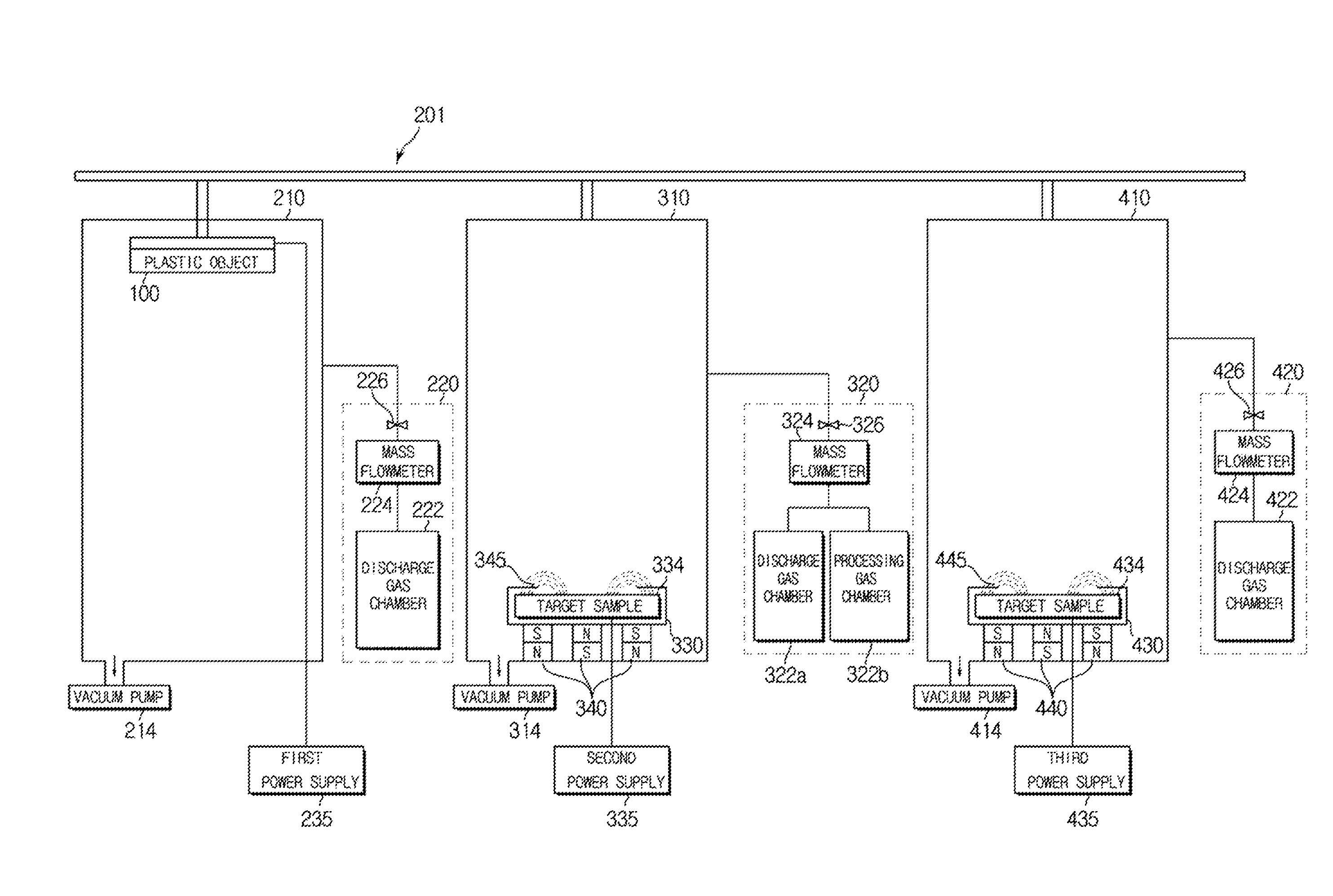

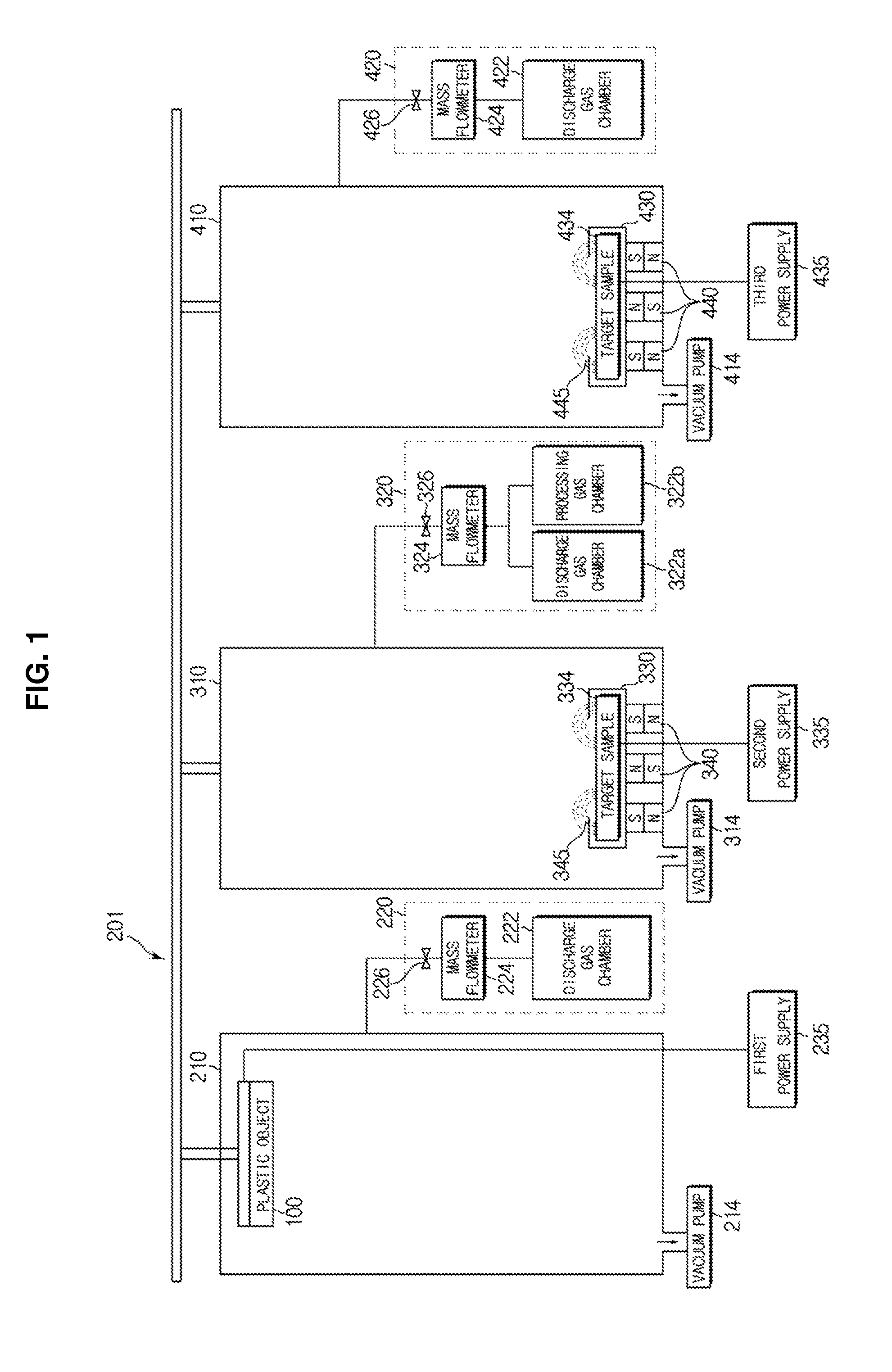

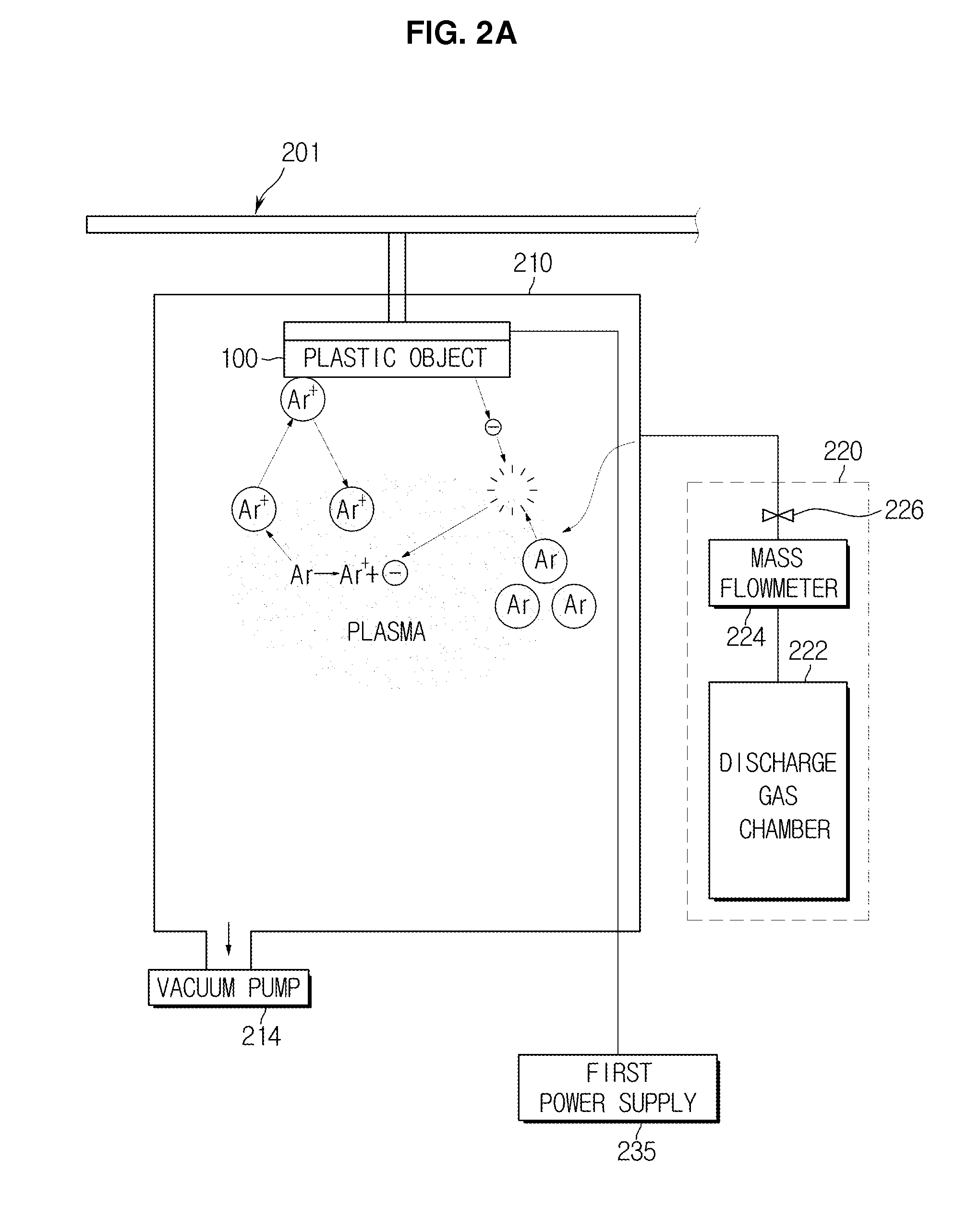

Method of manufacturing multi-layer thin film, member including the same and electronic product including the same

InactiveUS20140355183A1High surface hardnessBeautiful textureSynthetic resin layered productsVacuum evaporation coatingHardnessOptoelectronics

A method of manufacturing a multi-layer thin film is provided. The method includes modifying a surface of a plastic object by plasma treatment, depositing at least one hardness-enhancing layer on the plastic object, and depositing a color layer on the hardness-enhancing layer. The method may further include depositing a protective layer on the color layer.

Owner:SAMSUNG ELECTRONICS CO LTD

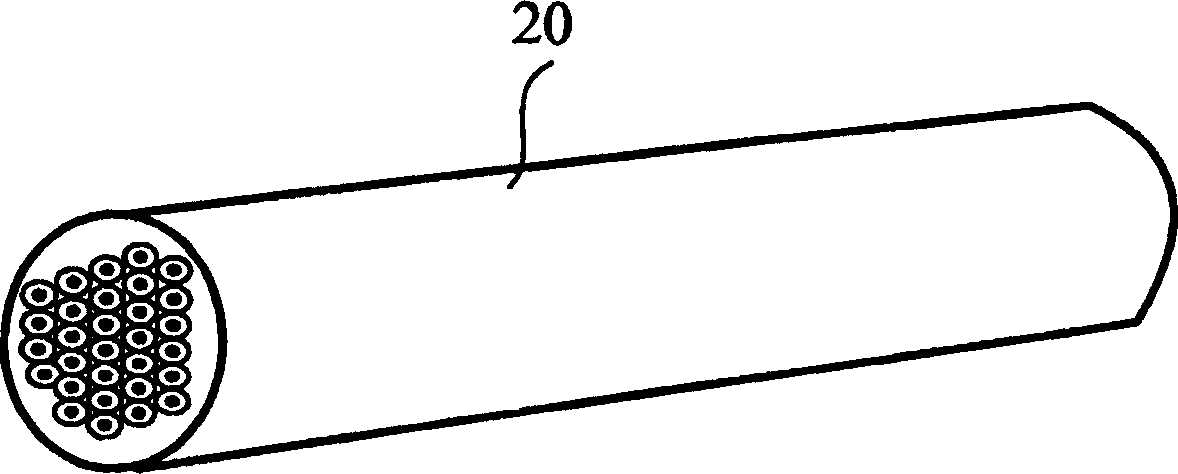

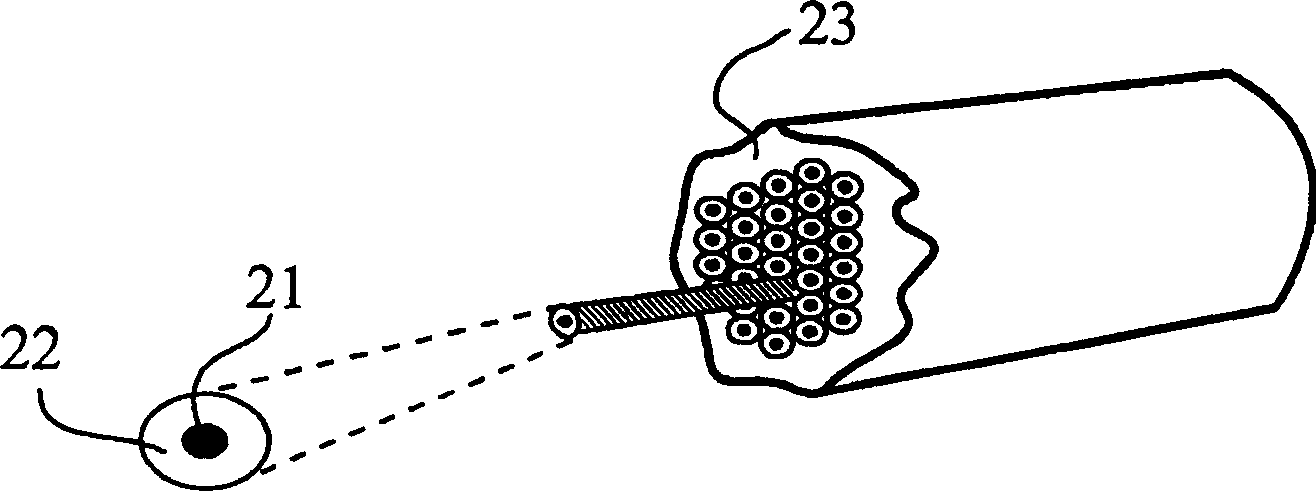

Granular composite material containing metal fiber and its mfg. method

InactiveCN1415649AEvenly dispersedOverlap phenomenon is obviousElectromagnetic shieldingMetal fibers

A granular polymer composition contains a bundle of metallic fibres parallel to each other, the first high-molecular material used as the first coated layer of each metallic fibre, and the second high-molecular material used as the second coated layer of each metallic fibre. It car be used as the raw material of plastic objects for low cost and higher antistatic and electromagnetic sheiding effect.

Owner:KINGS METAL FIBER TECH

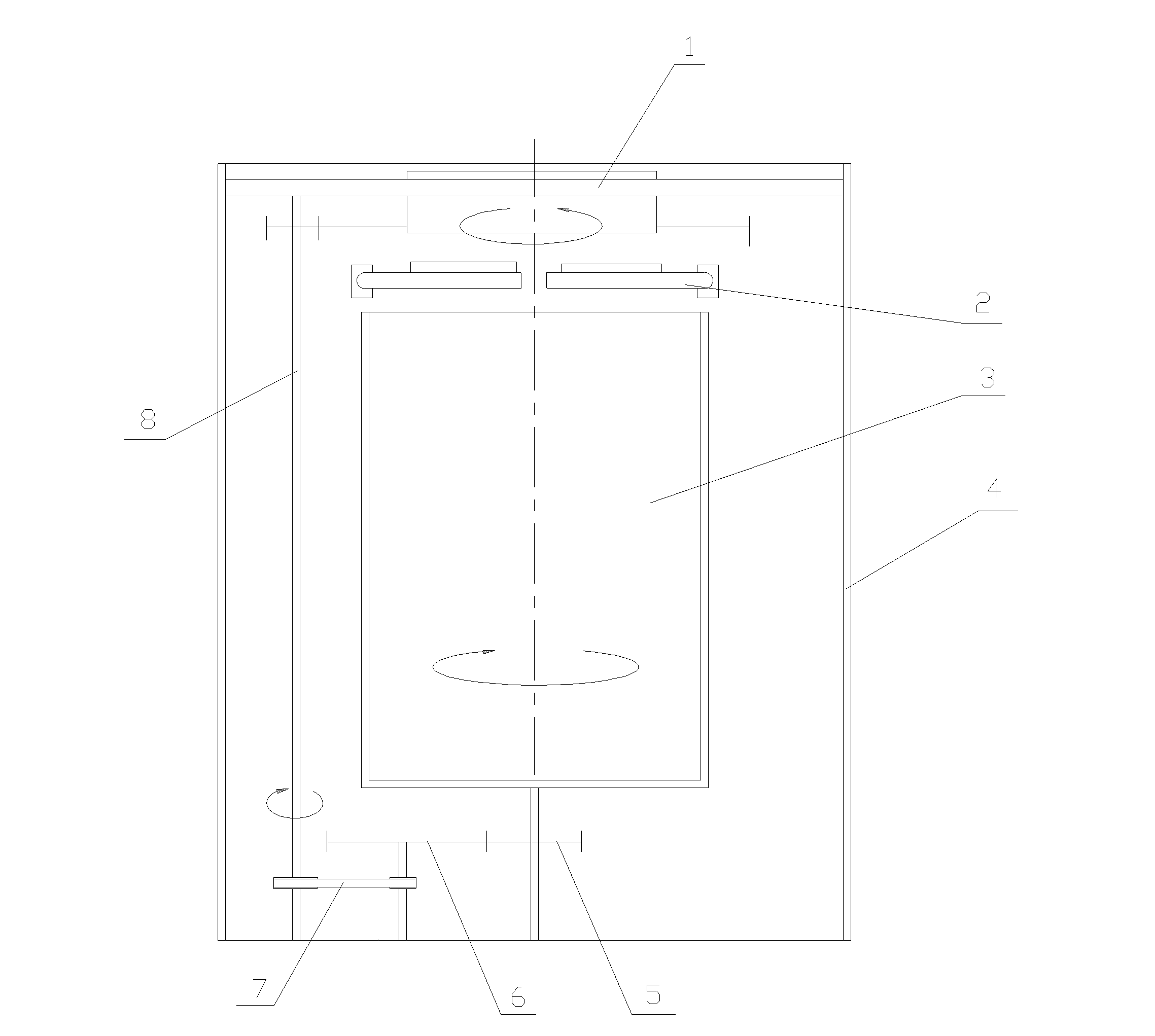

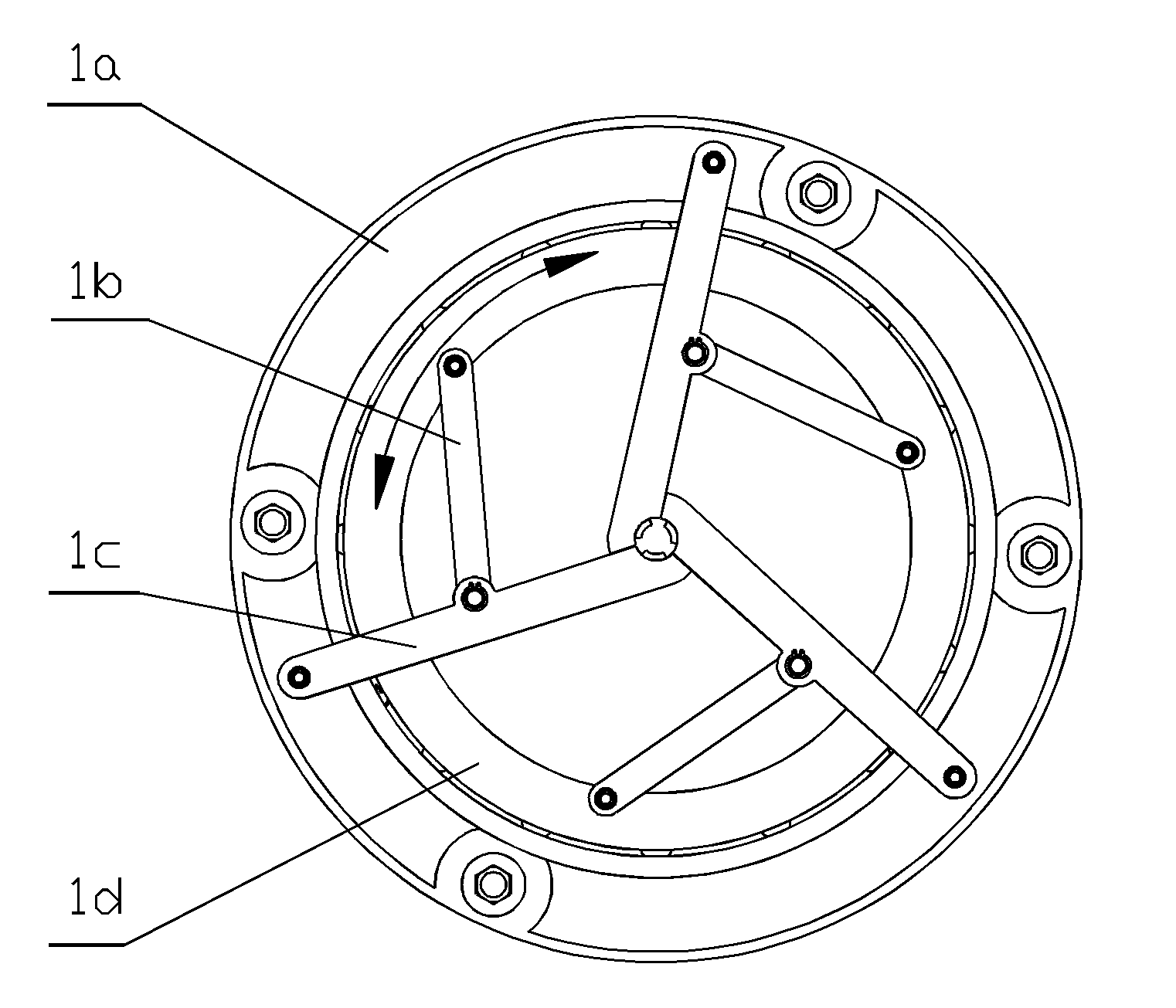

Closing and sealing device of plastic object bags

The invention belongs to items collection devices for environment protection and relates to a closing and sealing device of plastic object bags. A rotary rotating drum (3) is arranged at the center of a fixed machine frame (4), and a driving wheel (6) is arranged at the bottom of the machine frame (4), transmits power to the rotating drum (3) through a gear (5) or a belt and a belt pulley, transmits power to a vertical transmission shaft (8) disposed on the lateral portion of the machine frame (4) through the gear or the belt (7) and the belt pulley and transmits rotating power to an inner ring (1d) of a closing mechanism (1) disposed above the machine frame (4). A sealing mechanism (2) in horizontal reciprocating rectilinear motion is arranged below the closing mechanism (1) and formed by a left push plate and a right push plate which slide on two left-right parallel sliding rails. Mechanical devices are adopted so that the closing and sealing device can achieve closing, sealing, cutting off and operating of the plastic bags after object collection conveniently. Operation speed and efficiency are improved, operation is standardized, operation environment is improved, physical health of operators is benefited, and sanitary level can be improved.

Owner:SHANGHAI UNIV OF ENG SCI

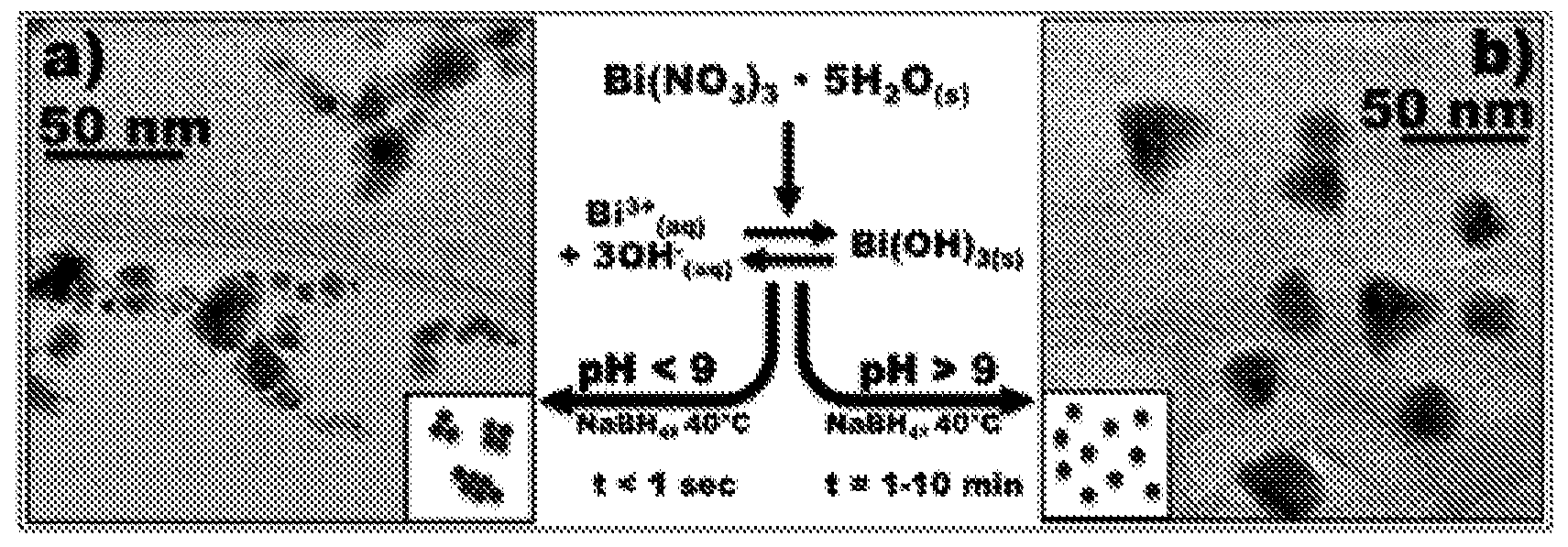

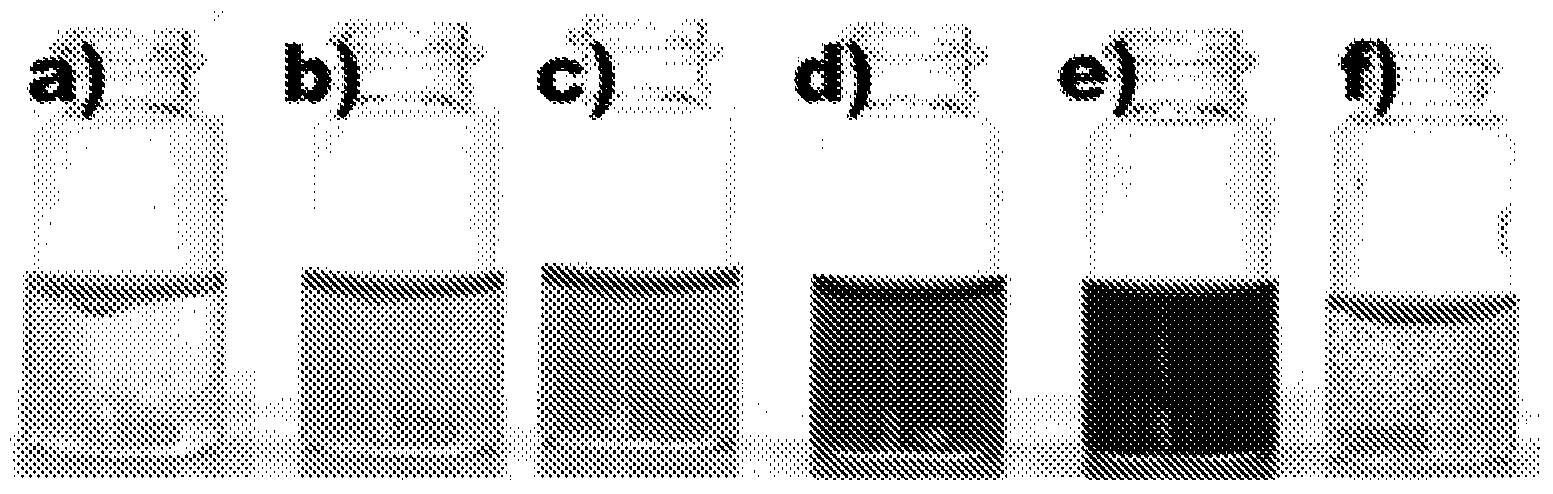

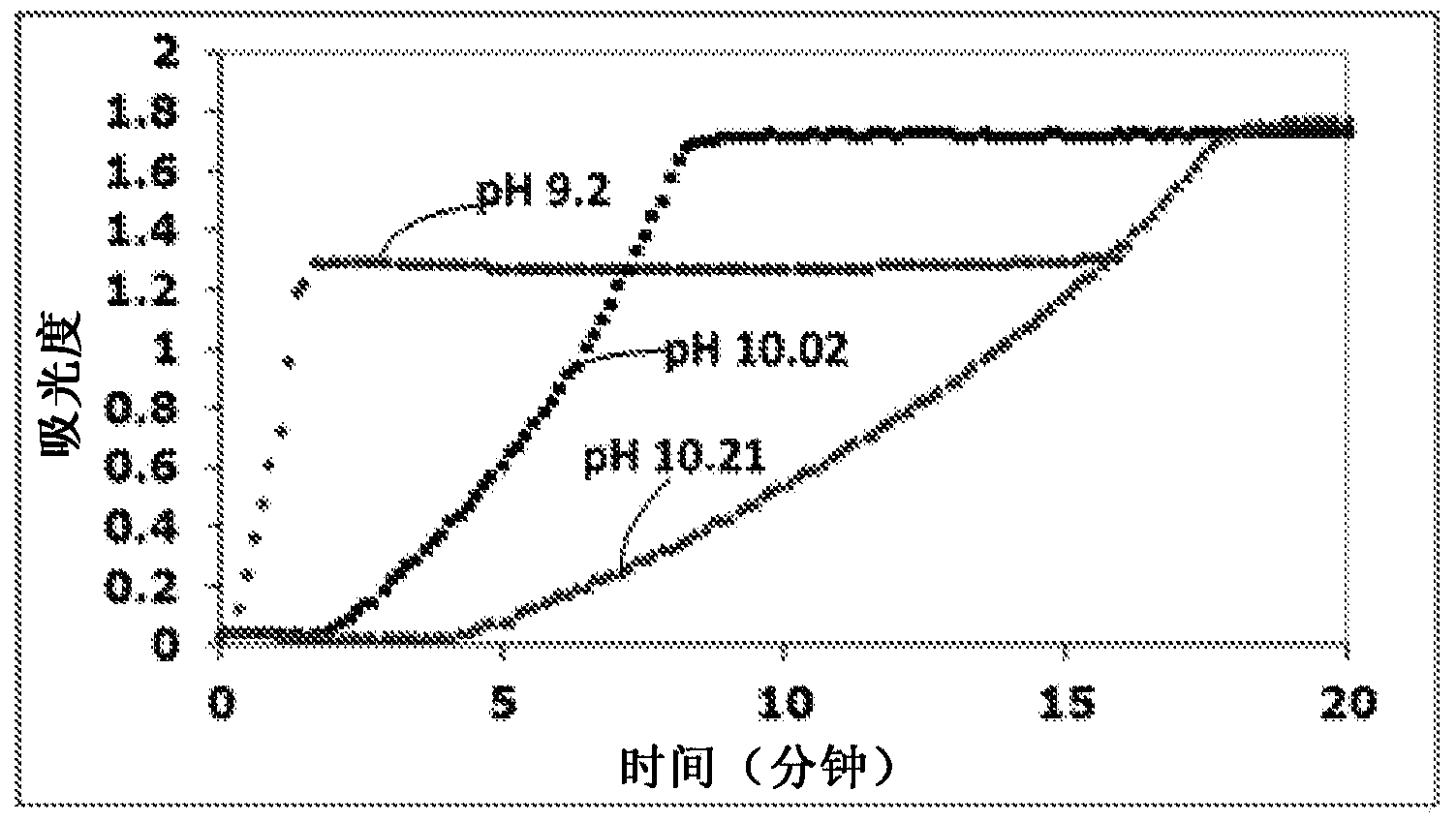

Bismuth particle X-ray contrast agents

Radiopaque bismuth particles and methods of making and using the radiopaque bismuth particles are disclosed. The radiopaque bismuth particles include an elemental bismuth core and an outer coating comprising one or more coating agents. Disclosed radiopaque bismuth particles are suitable for use in surgical sponges and plastic objects.

Owner:THE STATE OF OREGON ACTING BY & THROUGH THE OREGON STATE BOARD OF HIGHER EDUCATION ON BEHALF OF OREGON STATE UNIV

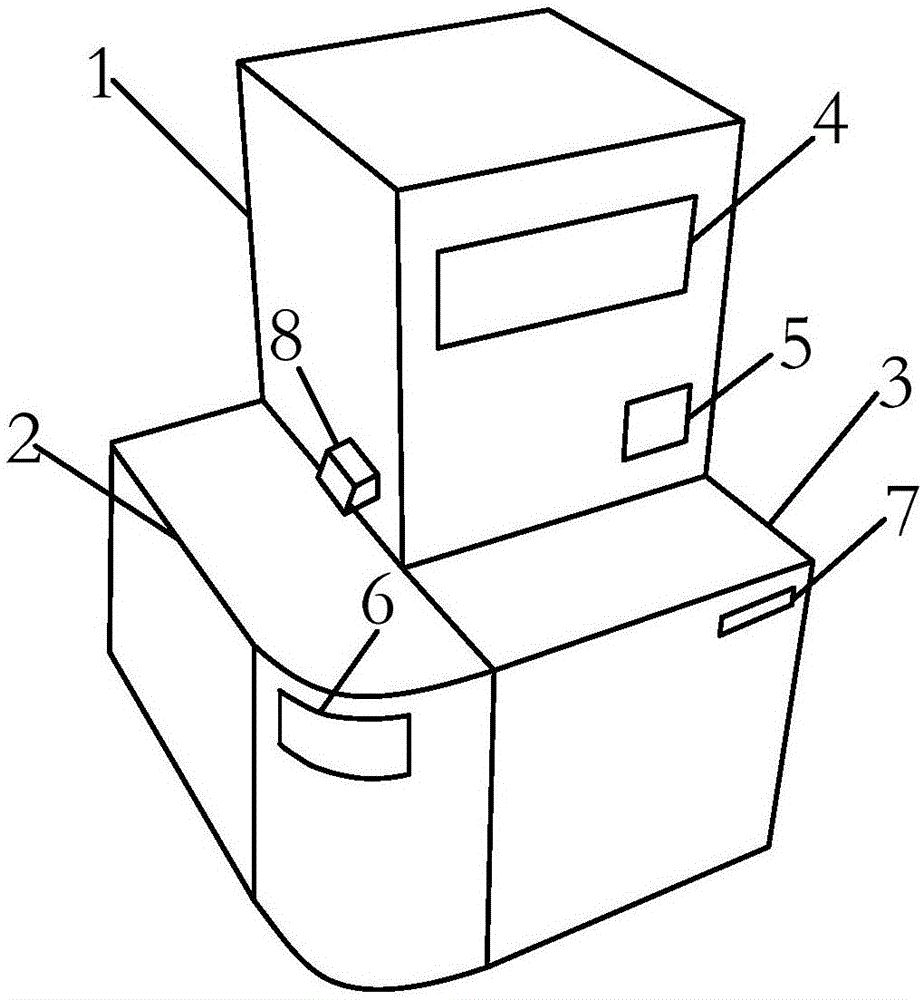

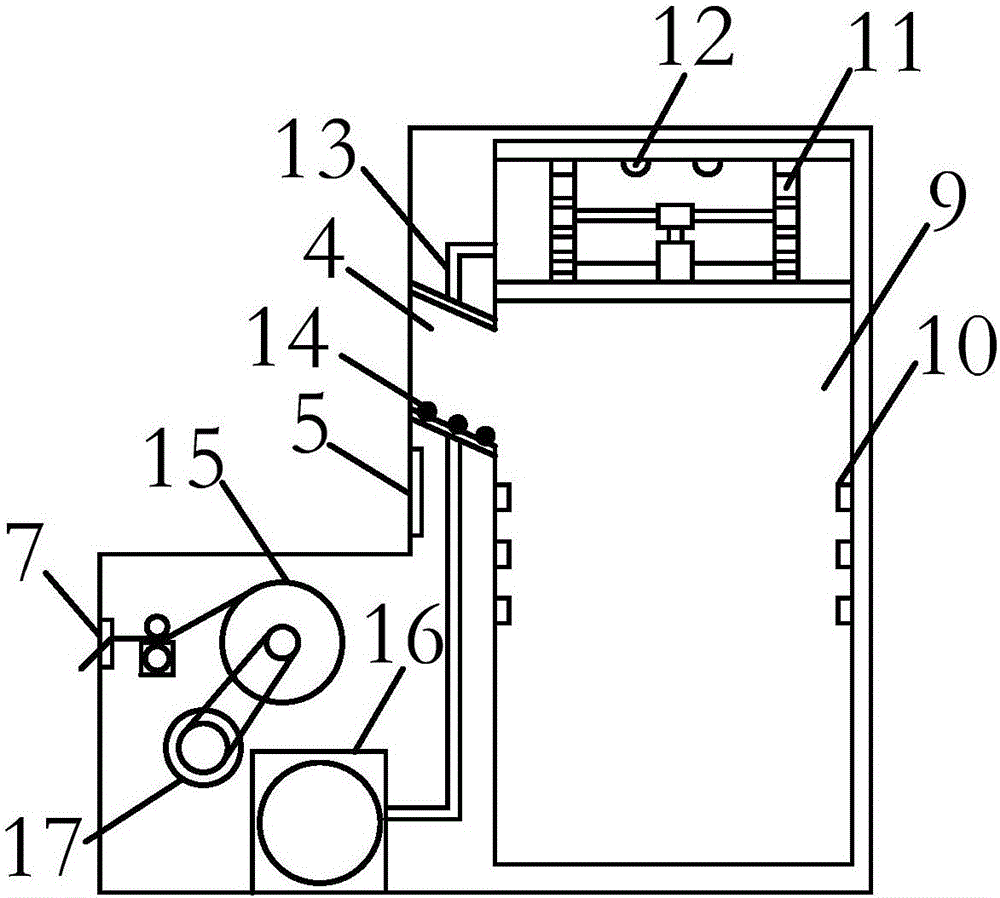

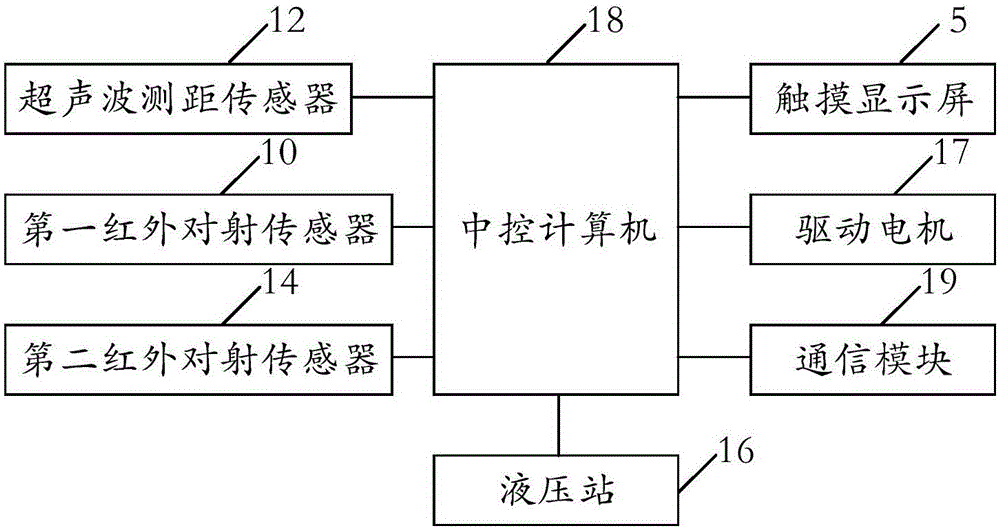

Device for recycling express trash

InactiveCN106564716AReduce resource drainImprove recycling ratesRefuse receptaclesEngineeringPollution

The invention relates to the field of trash recycling and discloses a device for recycling express trash. An outer shell of the device for recycling the express trash is composed of a first rectangular frame body (1), a second rectangular frame body (2) and a third rectangular frame body (3). The second rectangular frame body (2) and the third rectangular frame body (3) are the same in height and jointed together, the first rectangular frame body (1) is arranged on the upper portion of the third rectangular frame body (3), a trash inlet (4) is formed in the obverse side of the first rectangular frame body (1), and a touching display screen (5) is arranged on the obverse side of the first rectangular frame body (1). A fixed blade (8) is arranged on the side face of the first rectangular frame body (1), a plastic object throwing port (6) is formed in the end face of the second rectangular frame body (2), and a hop-pocket outlet (7) is formed in the third rectangular frame body (3). Resource loss of the express trash is effectively reduced, the recycling rate of the express packages is increased, trash pollution is reduced, and environment protection is facilitated.

Owner:BEIJING UNIV OF CIVIL ENG & ARCHITECTURE

Injection device and process for plastic objects

InactiveUS7879281B2Reduce manufacturing costSimple and reliable processDischarging arrangementMouldsShell moldingHorizontal axis

A plastic preforms (5) molding device and process comprising an injection mold, containing a plurality of injection cavities, an arm (3) for extracting the preforms (5) from the mold, equipped with guillotine-like gripping elements, which moves between the existing space between the half molds when in the open position in order to grasp the preforms and the external position, a cooling turret (6), with the faces housing a group of cups (7) for the conditioning of the preforms (5), which effects a rotational movement around a horizontal axis and a vertical translation movement between the high position under the extraction arm to receive the preforms and the low position corresponding to the extraction table of the preforms (5), on which are indented longitudinal slots with teeth shaped constrictions in order to grasp the preforms under the ring (9) and to extract them from the cups (7).

Owner:SIPA SOCIETA INDUSTRIALIZZAZIONE PROGETTAZIONE E AUTOMAZIONE SPA

Methods of Retrofitting Injection Molding Machines

ActiveUS20160096303A1Easy to operateReduce injection pressureMouldsShell moldingInjection molding machine

An injection molding machine that uses a mold and a native controller to operate according to an original mold cycle to mold plastic objects is retrofitted with a retrofit controller; the retrofitted machine uses the mold and the retrofit controller to operate according to a retrofit mold cycle to mold plastic objects.

Owner:IMFLUX INC

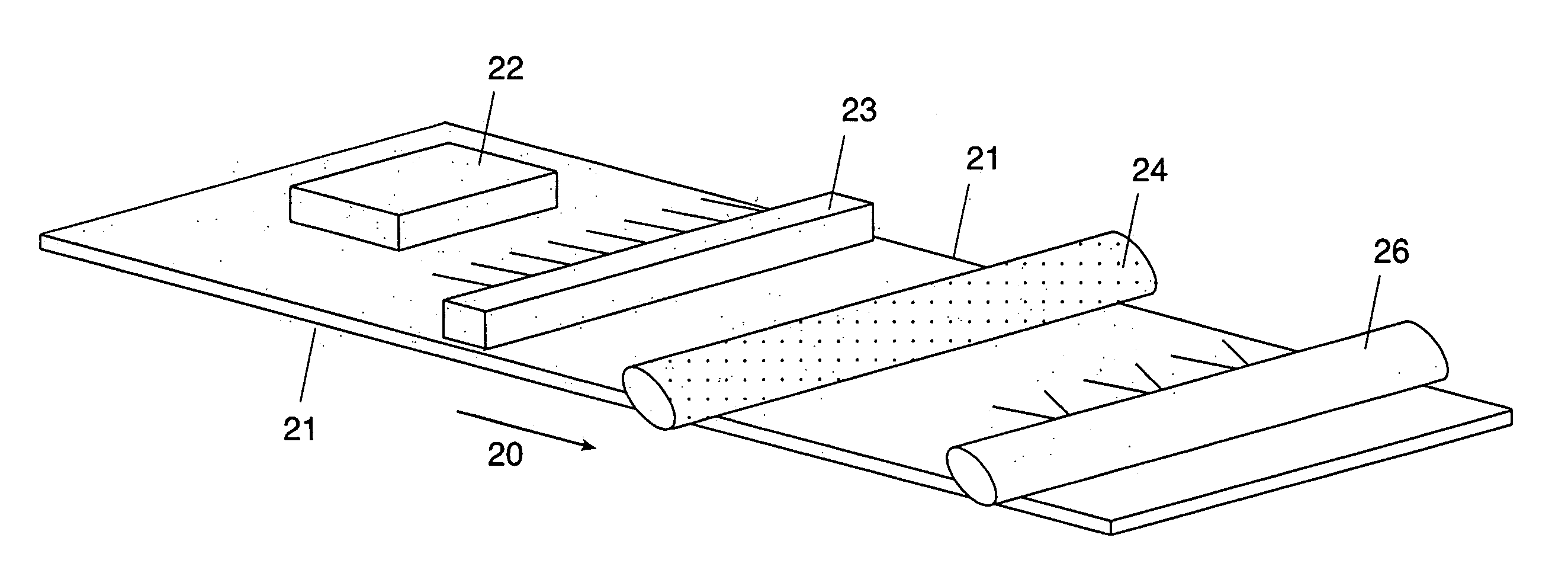

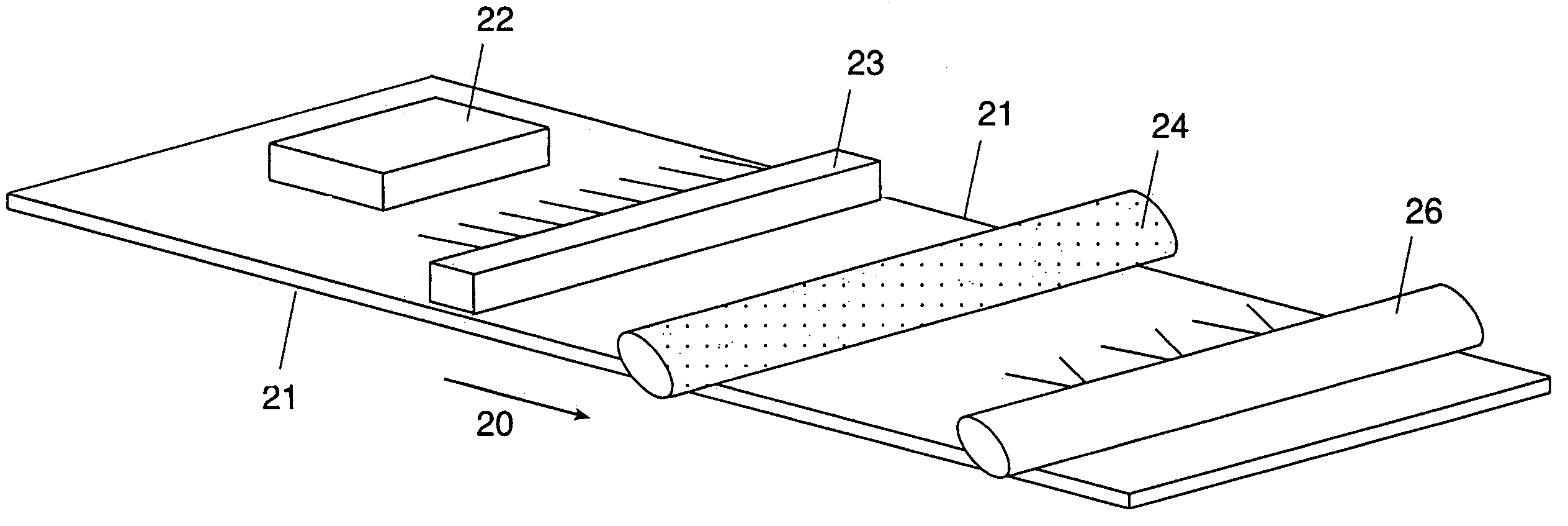

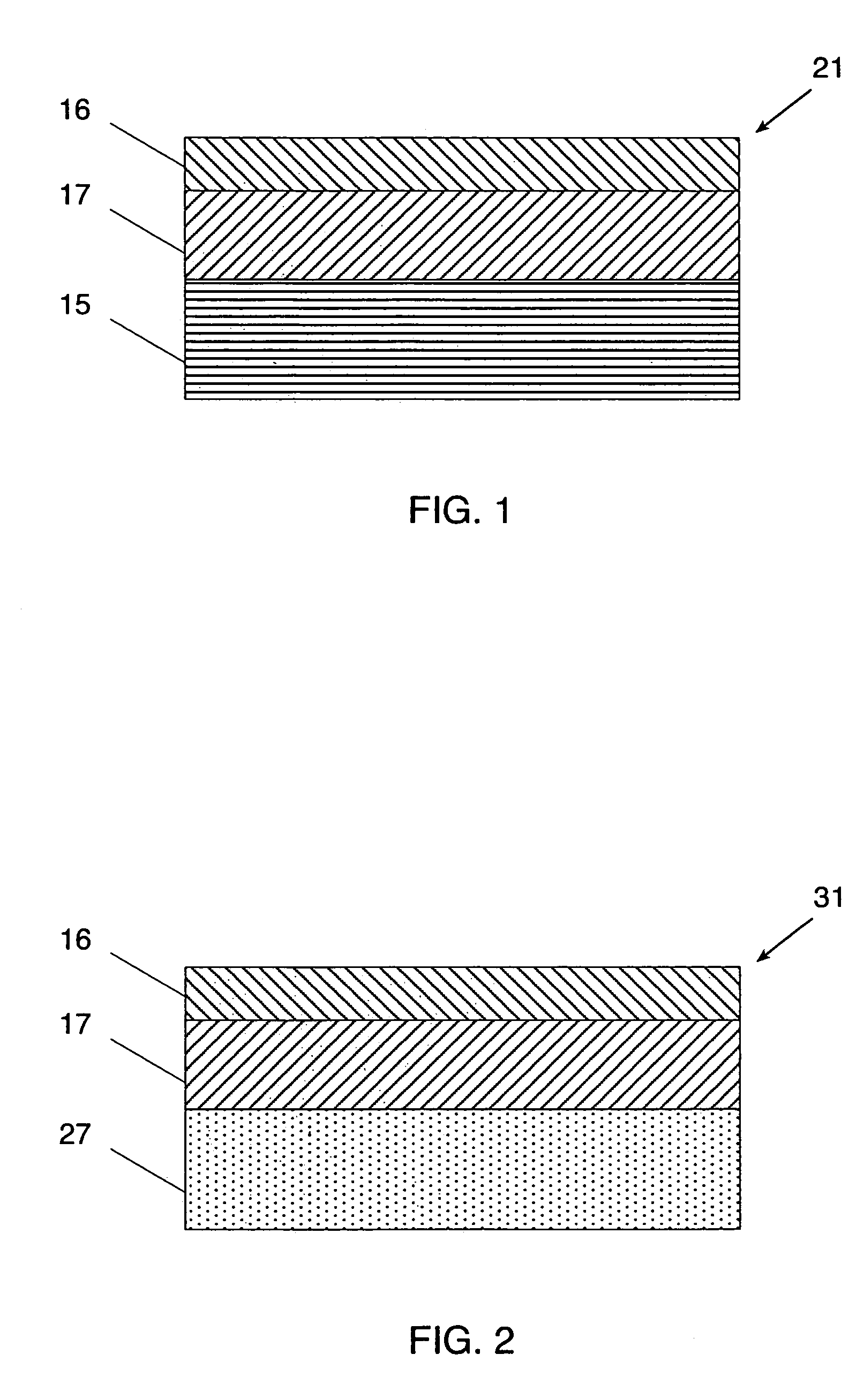

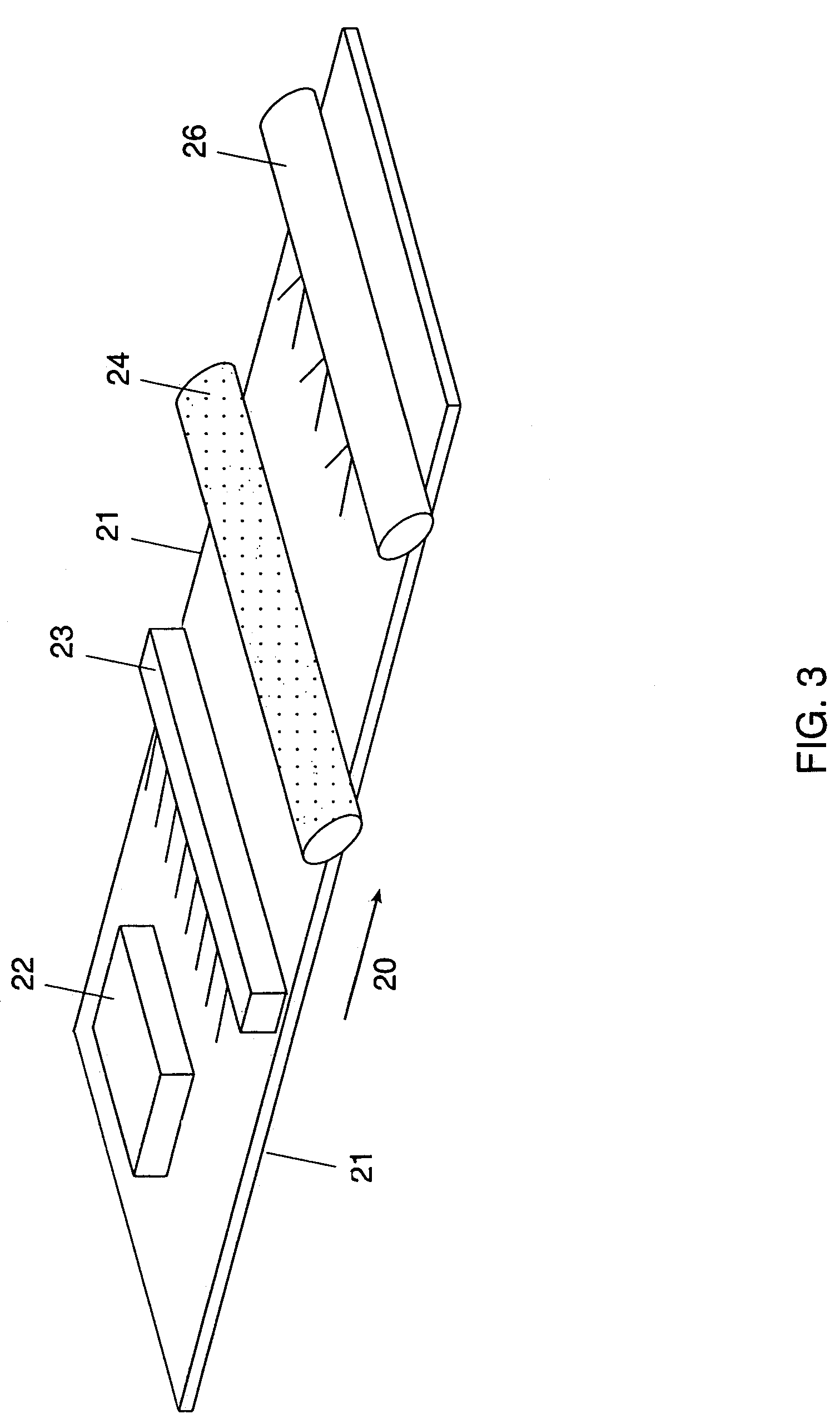

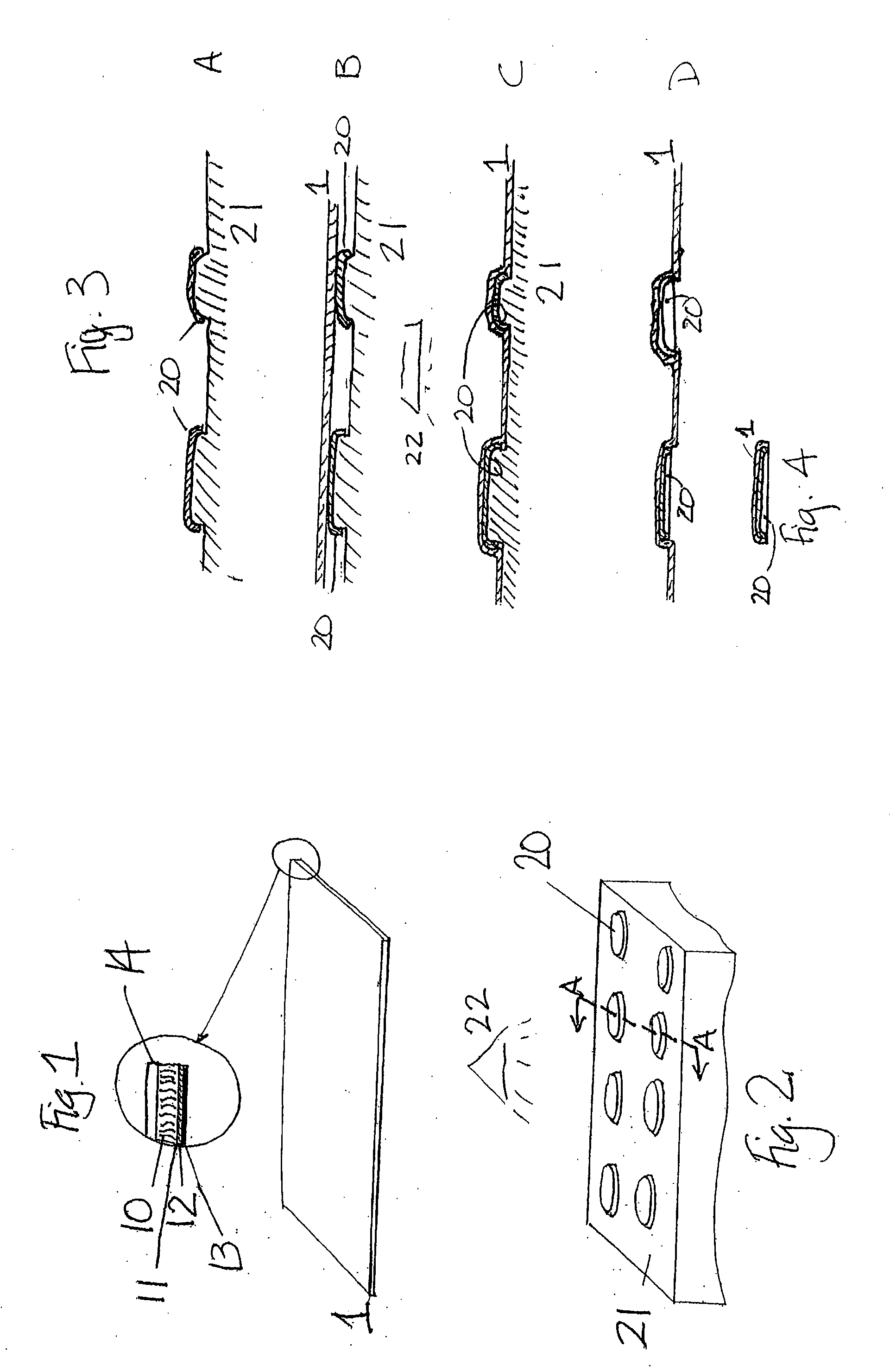

Method for applying web material to a molded plastic object

A method for applying web material to a substrate object. Web material on a thermoformable sheet can be adhered to the shaped object with a heat-actuated adhesive in a vacuum thermoforming process.

Owner:ALCAN PACKAGING BEAUTY SERVICES

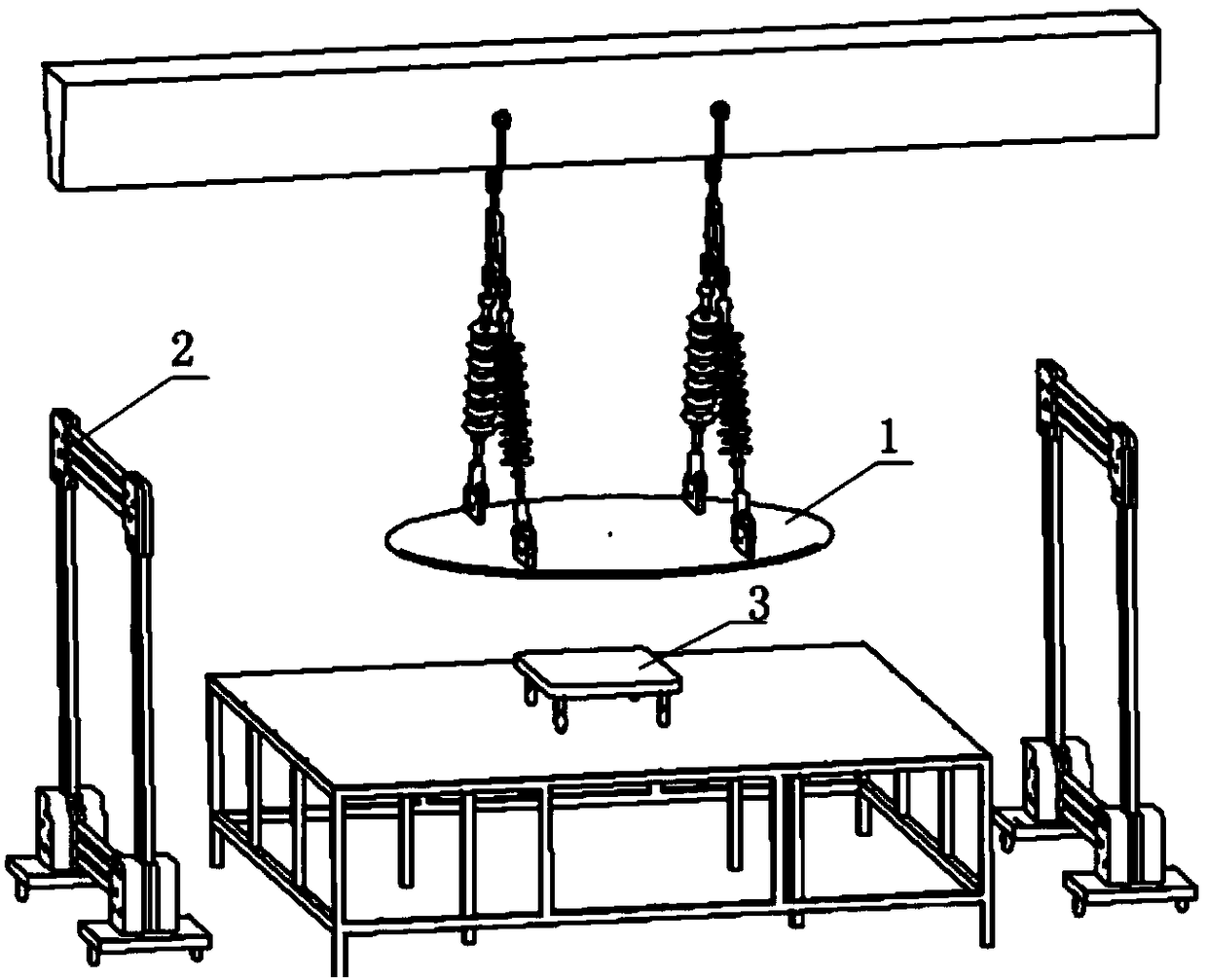

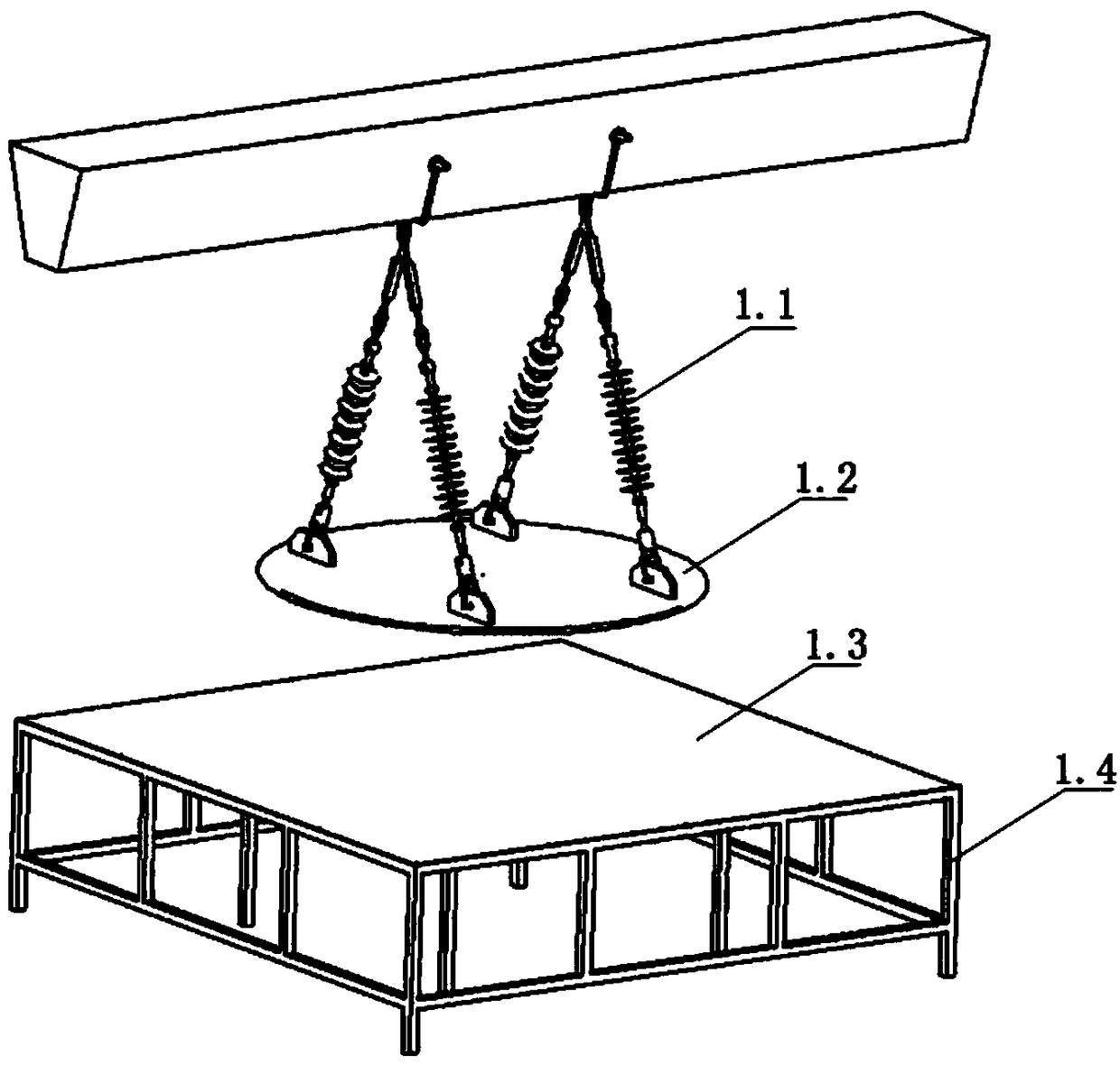

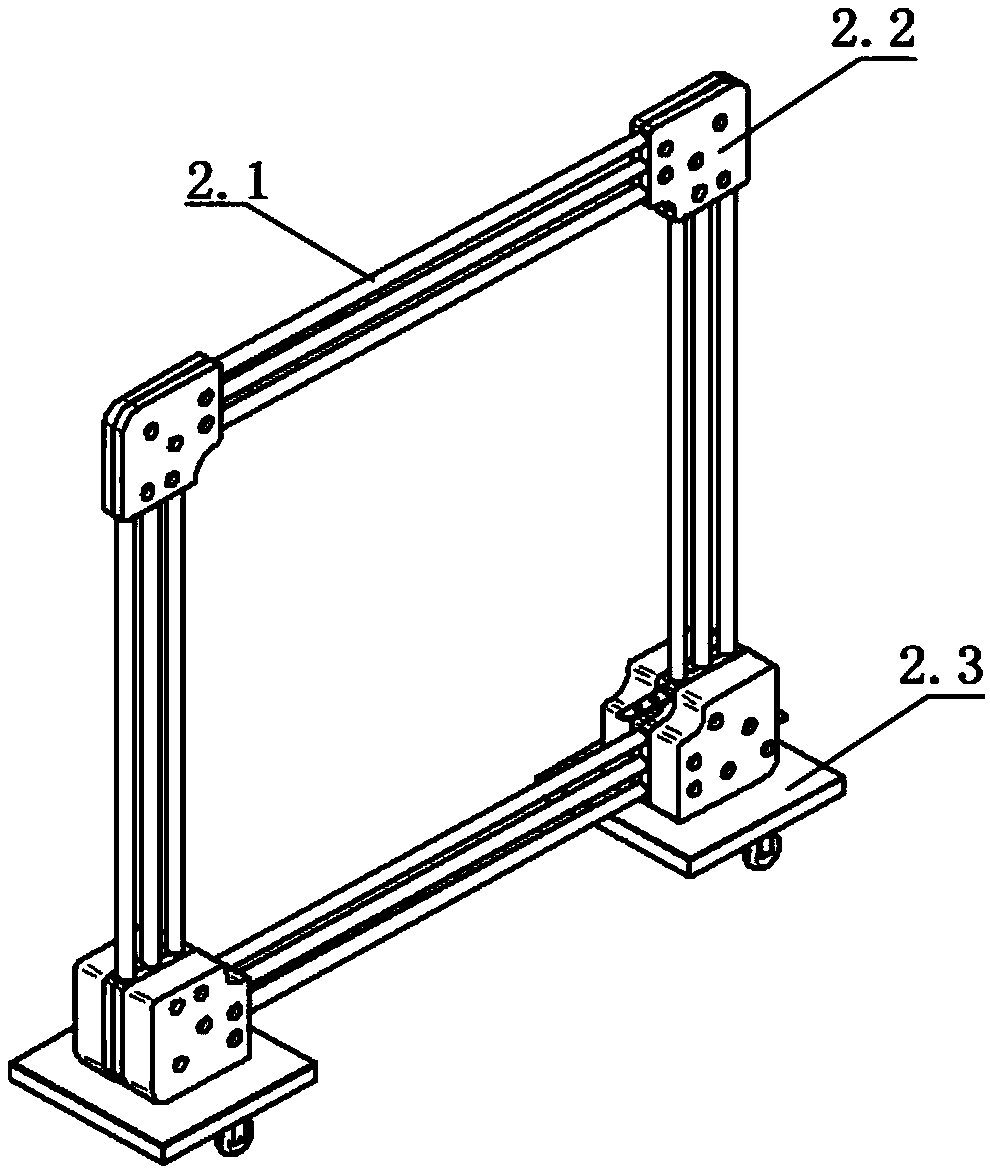

Power frequency electromagnetic field generation platform used for simulating site of substation

PendingCN108761369ASatisfied with simultaneous outputContinuously adjustable electric field strengthElectrical measurementsLower poleElectromagnetic field

The invention provides a power frequency electromagnetic field generation platform used for simulating a site of a substation. The power frequency electromagnetic field generation platform comprises an electric field generation apparatus, a magnetic field generation apparatus and a movable plastic object-placing vehicle, the electric field generation apparatus comprises an insulator, an electric field generation apparatus upper pole plate, an electric field generation apparatus lower pole plate and a support frame, the electric field generation apparatus upper pole plate is vertically suspended on a top beam of a laboratory through the insulator by employing an laboratory top beam hoisting mode, the electric field generation apparatus lower pole plate is horizontally arranged on the support frame and parallel to the upper pole plate and used for generating an electric field in a vertical direction, the magnetic field generation apparatus comprises magnetic field generation coils arranged at the left side and the right side of the electric field generation apparatus with an equal interval in a vertical manner and is used for generating a magnetic field in a horizontal direction, andthe movable plastic object-placing vehicle is arranged at the very center of the electric field generation apparatus lower pole plate and used for placing test equipment. According to the power frequency electromagnetic field generation platform, simultaneous output of the power frequency electric field and the magnetic field of the site of the substation can be simulated, and a laboratory powerfrequency electromagnetic field environment is provided for the metering characteristic research of various high-voltage test devices such as live detection / online monitoring devices in a high power frequency electromagnetic field environment of the site of the substation.

Owner:STATE GRID HUBEI ELECTRIC POWER RES INST +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com