Flexible transfer film and manufacture method thereof

A manufacturing method and transfer film technology, applied in chemical instruments and methods, synthetic resin layered products, lamination devices, etc., can solve the problems of industrial rigid objects, weak adhesion on the surface of objects, and easy deformation of patterns, etc. Achieve the effects of reducing pollution and human injury, low transfer temperature, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

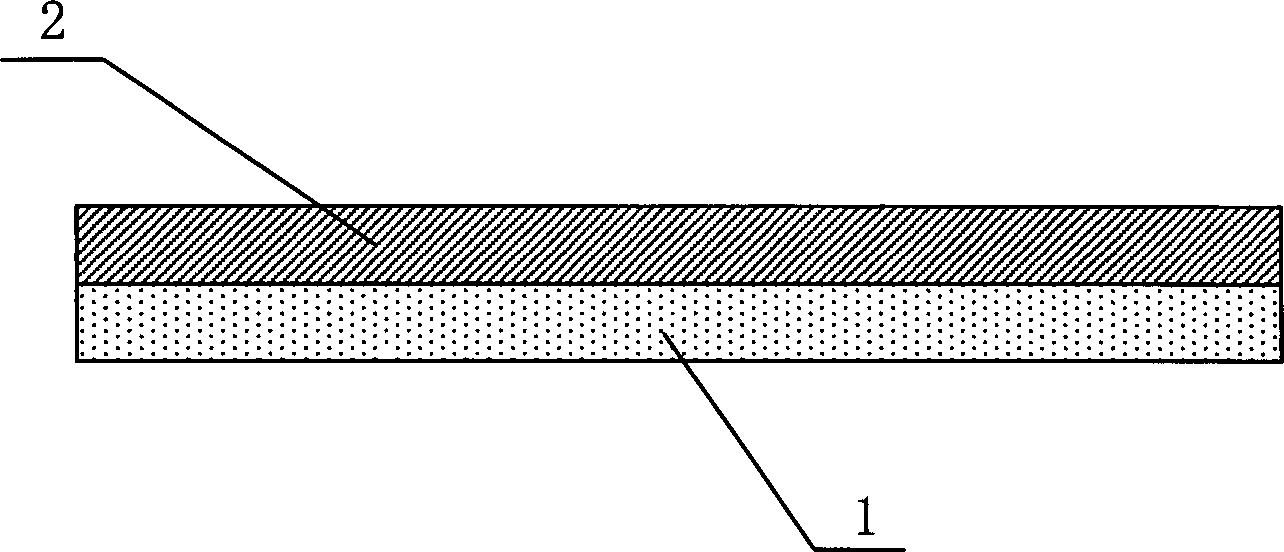

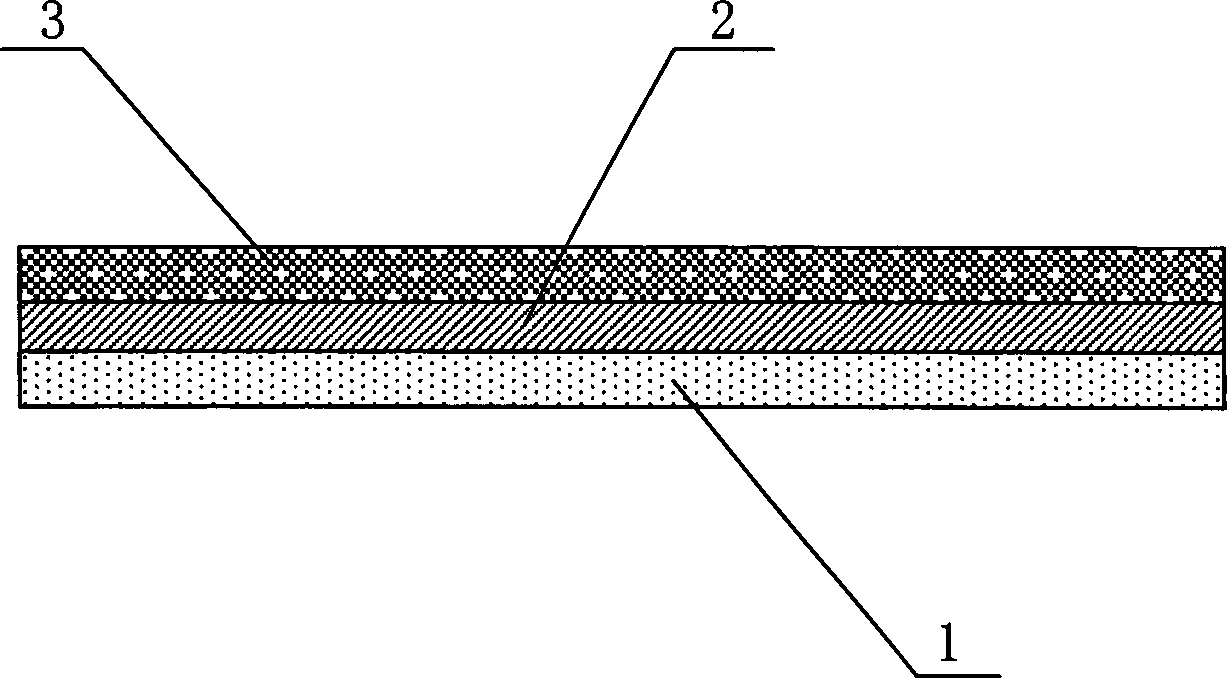

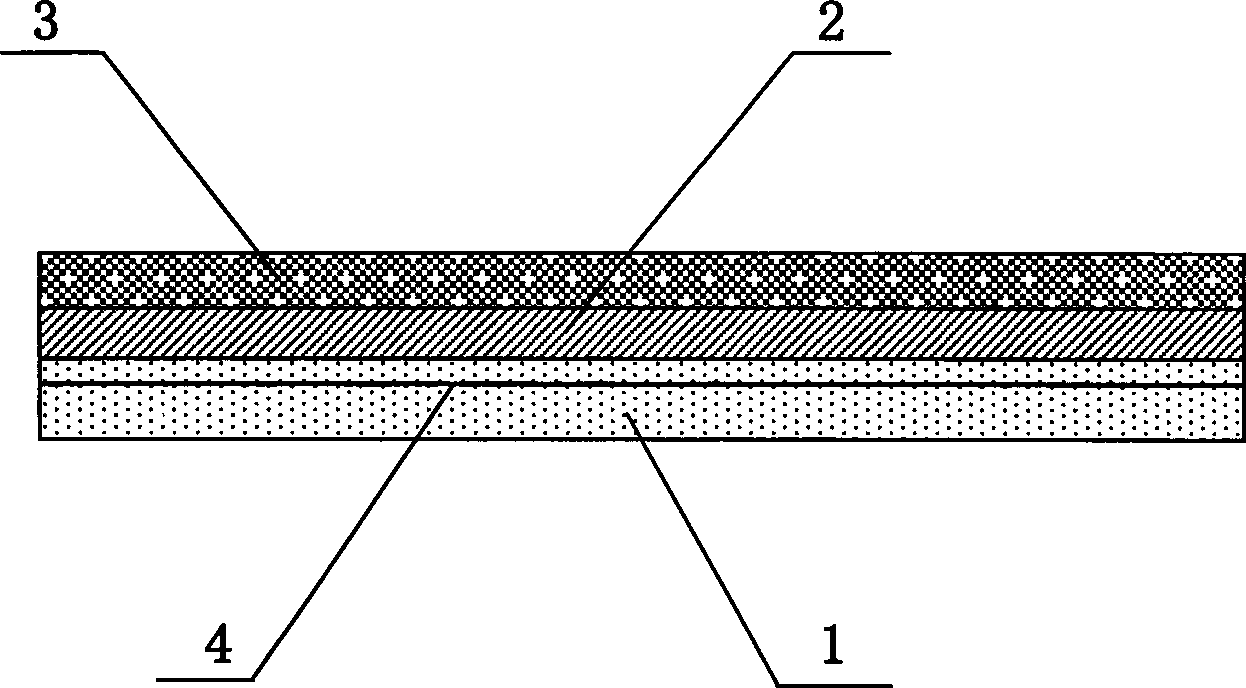

[0035] Such as figure 1 As shown, a flexible transfer film includes a stretchable flexible film 1 and a stretchable pattern layer 2 . The flexible film 1 can be stretched and attached to the surface of irregular objects. The material of the flexible film 1 is usually TPU (Thermoplastic polyurethanes, thermoplastic polyurethane) film, PVC (polyvinyl chloride) film and PE (English full name Polyethylene) film. one of a kind. The pattern layer 2 is attached to the surface of the flexible film 1, and can be attached to the surface of irregular objects along with the extension of the flexible film 1. Of course, in this embodiment, in order to protect the pattern layer 2, the other side of the pattern layer 2 can be provided with a release film 3 (such as figure 2 shown), or in order to facilitate the practical application of peeling off the flexible film 1, a release layer 4 is provided between the flexible film 1 and the pattern layer 2 (such as image 3 shown).

Embodiment 2

[0037] Such as Figure 4 Shown, a kind of method for manufacturing flexible transfer film, comprises the following steps:

[0038] ① Prepare a rigid PET base film, and print the ductile pattern layer on the rigid base film evenly by printing equipment;

[0039] ② Select commonly used coating equipment (in this case, the coating machine manufactured by Xudeng New Materials (Shenzhen) Co., Ltd. is preferred) to coat the glue layer on the other side of the pattern layer;

[0040] ③Choose composite equipment (in this case, the composite machine manufactured by Xudeng New Materials (Shenzhen) Co., Ltd. is preferred) to composite the TPU flexible film on the surface of the glue layer to form a composite film;

[0041] ④ After the glue layer is dry, peel off the rigid PET base film to obtain a flexible transfer film.

[0042] The flexible transfer film manufactured by the above method has the characteristics of smooth surface, not easy to deform and convenient printing of the rigid...

Embodiment 3

[0044] Such as Figure 5 Shown, a kind of method for manufacturing flexible transfer film, comprises the following steps:

[0045] ① Prepare a rigid PET base film, and print the ductile pattern layer on the rigid PET base film evenly by hot stamping, electroplating or aluminum plating;

[0046] ②Heat the rigid PET base film with hot-stamped stretchable pattern layer to 90-110 degrees Celsius, and compound the stretchable TPU flexible film on the pattern layer through a compound machine; of course, you can also choose PVC or PE flexible film;

[0047] ③Peel off the rigid PET base film to obtain a TPU flexible transfer film.

[0048] The flexible transfer film manufactured by the above method has the characteristics of smooth surface, not easy to deform, and convenient hot stamping printing of the rigid PET film. The pattern layer is compositely printed on the rigid PET base film, and then the pattern layer on the PET is transferred to the TPU flexible transfer film by heating....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com