Multi-degree-of-freedom 3D printer of fiber reinforced composite material and printing method thereof

A 3D printer and composite material technology, applied in the field of fiber reinforced composite material multi-degree-of-freedom 3D printer, can solve the problems of raising the price of composite material parts, difficult to manufacture three-dimensional complex structure composite material parts, and complicated fiber laying equipment, etc. Achieve the effect of reducing manufacturing cost and production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

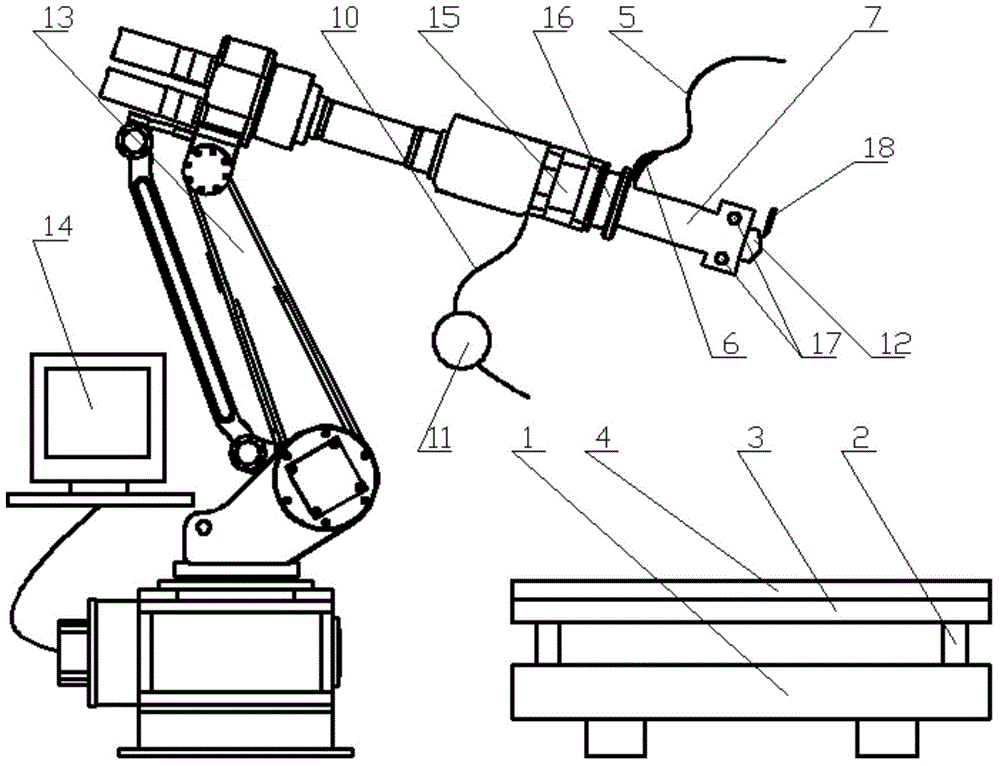

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0020] refer to figure 1 , a fiber-reinforced composite material multi-degree-of-freedom 3D printer, comprising a 3D printing head 7, the 3D printing head 7 is connected to a six-degree-of-freedom manipulator 13, the six-degree-of-freedom manipulator 13 is connected to a computer 14, and the 3D printing head 7 is provided with scissors Cutting device 18, the cutting device 18 is connected with the computer 14, a movable workbench 1 is provided under the 3D printing head 7, and the movable workbench 1 is connected with the heating base plate 3 through the leveling screw 2 on it, and the heating base plate 3 is connected There is a printing platform 4;

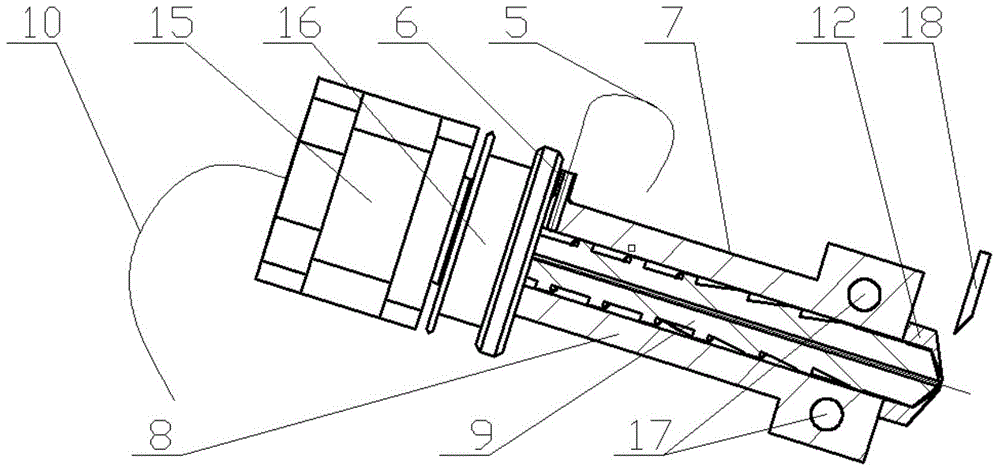

[0021] refer to figure 2 , the 3D printing head 7 includes a screw 9, the screw 9 is provided with a hollow channel, the screw 9 is connected with a screw housing 8, the end of the screw 9 and the screw hous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com