Iron-based bio-char material, preparation process thereof, and application thereof in soil pollution treatment

一种生物炭、铁基的技术,应用在污染的土壤的复原、应用、土壤调节材料等方向,能够解决降低有效性等问题,达到保持有效性、减少土壤镉砷吸收、生产成本低的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

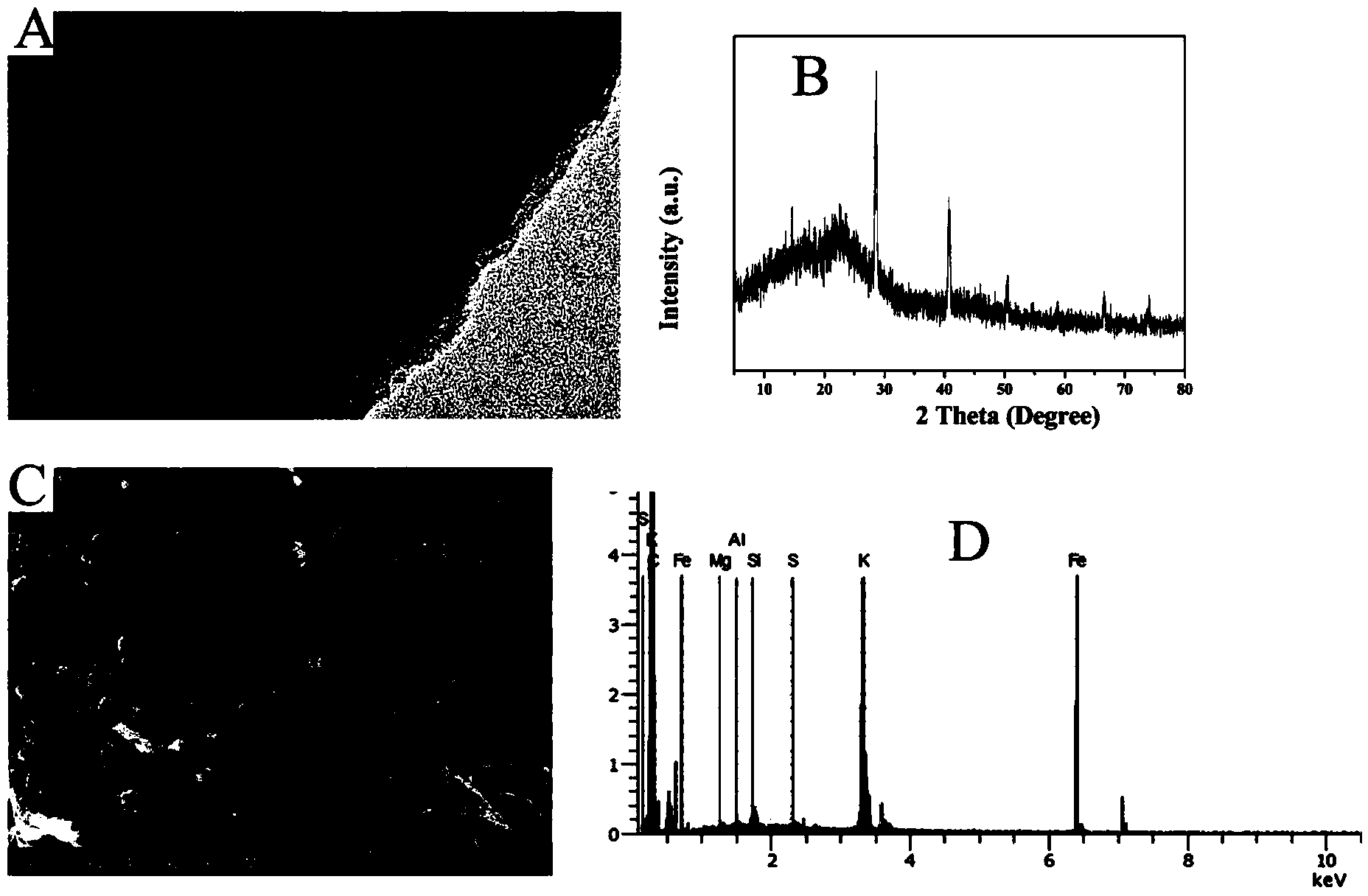

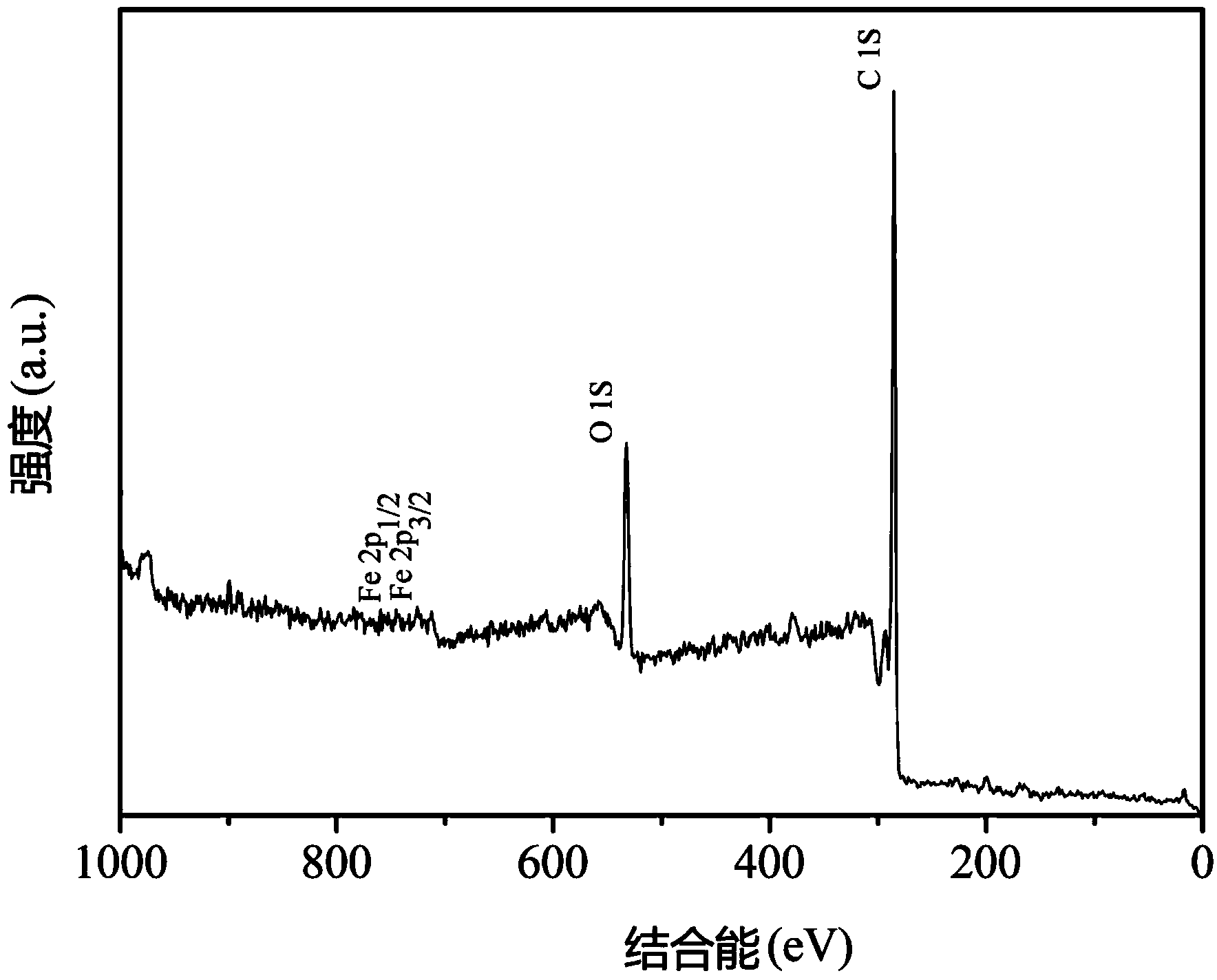

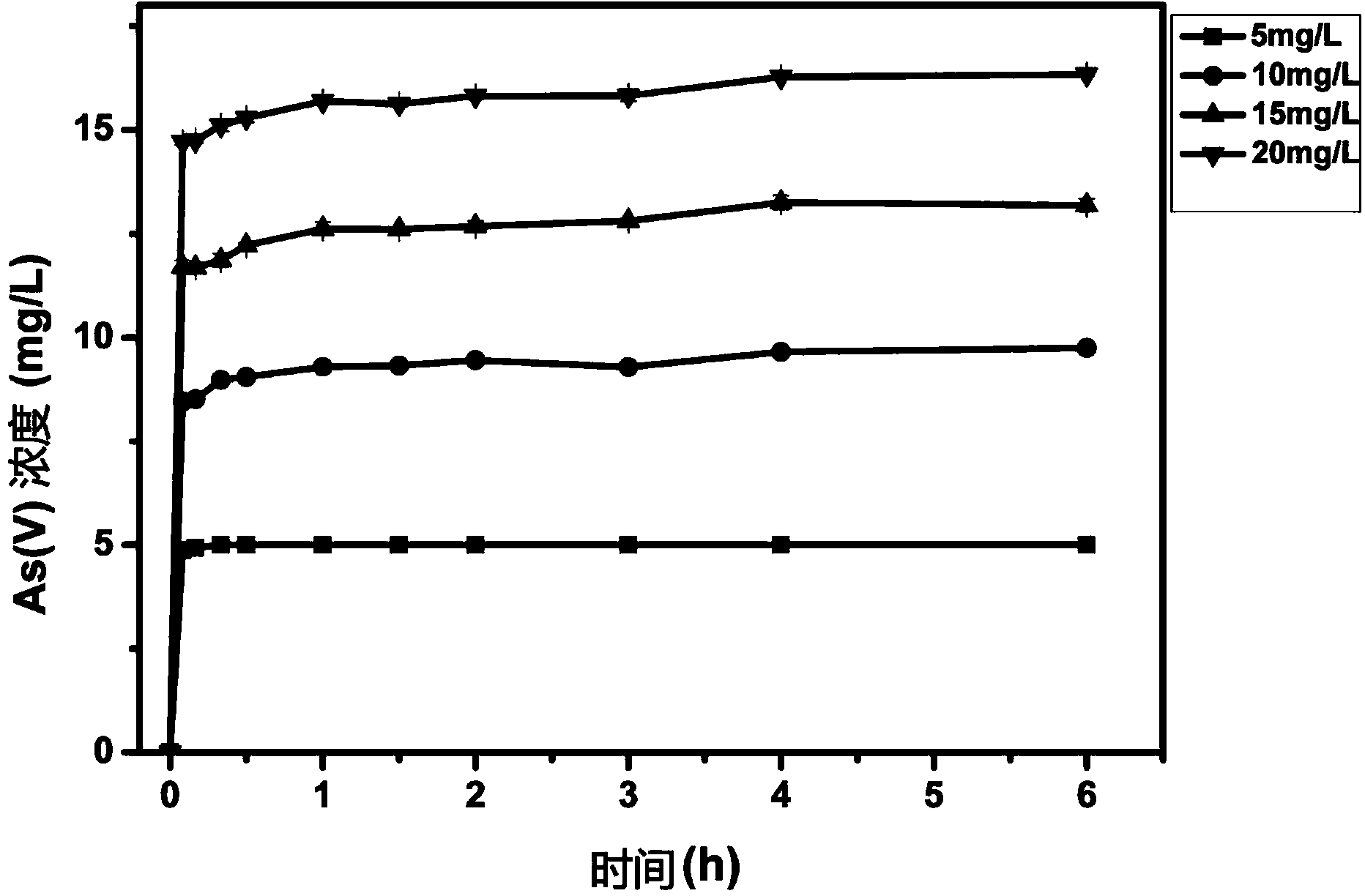

[0039] Embodiment 1 Preparation of iron-based biochar material sample 1

[0040] 1. Preparation of biochar materials

[0041] Dry the palm, weigh 10kg and crush it, place it in a high-temperature furnace, slowly heat it to 200°C, keep the temperature constant for 2 hours, raise the temperature at a rate of 5°C / min, then heat it to 800°C, and keep it at this temperature for 3 hours. Stop heating and prepare biochar material.

[0042] 2. Preparation of Iron and Biochar Mixture

[0043] Weigh 2500g of ferrous sulfate solid, and add it to the biochar material prepared in Example 1 under stirring condition to obtain a mixture of iron and biochar, wherein the mass percentage of carbon:iron is 9:1, and stir for 1 hour.

[0044] 3. Activation of biochar materials

[0045] Weigh 500 g of sodium borohydride, dissolve it in 500 mL of purified water, and prepare a sodium borohydride reducing agent solution with a mass percentage of 1%.

[0046] Slowly add the above-mentioned sodium bo...

Embodiment 2

[0051] Embodiment 2 Preparation of iron-based biochar material sample 2

[0052] 1. Preparation of biochar materials

[0053] Dry the palm, weigh 10kg and crush it, place it in a high-temperature furnace, slowly heat it to 200°C, keep the temperature constant for 2 hours, raise the temperature at a rate of 5°C / min, then heat it to 300°C, and keep it at this temperature for 12 hours. Stop heating and prepare biochar material.

[0054] 2. Preparation of Iron and Biochar Mixture

[0055] Weigh 1250g of ferric nitrate solid, and add it to the biochar material prepared in step 1 under stirring condition to obtain a mixture of iron and biochar, wherein the mass percentage of carbon:iron is 9:1, and stir for 1 hour.

[0056] 3. Activation of biochar materials

[0057] Weigh 50 g of sodium borohydride, dissolve it in 250 mL of pure water, and prepare a sodium borohydride reducing agent solution with a mass percentage of 0.2%.

[0058] Slowly add the above-mentioned sodium borohydr...

Embodiment 3

[0063] Embodiment 3 Preparation of iron-based biochar material sample 3

[0064] 1. Preparation of biochar materials

[0065] Dry the chaff, weigh 10kg and break it, place it in a high-temperature furnace, slowly heat it to 200°C, keep the temperature constant for 2 hours, raise the temperature at a rate of 5°C / min, then heat it to 500°C, and keep it at this temperature for 9 hours , stop heating, and prepare biochar material.

[0066] 2. Preparation of Iron and Biochar Mixture

[0067] Weigh 250g of ferric sulfate solid, and add it to the biochar material prepared in step 1 under stirring condition to obtain a mixture of iron and biochar, wherein the mass percentage of carbon:iron is 50:1, and stir for 1 hour.

[0068] 3. Activation of biochar materials

[0069] Weigh 5 g of sodium borohydride, dissolve it in 500 mL of purified water, and prepare a sodium borohydride reducing agent solution with a mass percentage of 0.01%.

[0070] Slowly add the above-mentioned sodium bo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com