Method for preparing lactic acid fermentation beverage by using yellow wine lees

A technology of lactic acid fermentation and lactic acid bacteria fermentation, which is applied in the field of preparing lactic acid fermented beverages, can solve problems such as lactic acid fermented beverages that have not yet been seen, and achieve the effects of promoting sustainable and healthy development, scientific and reasonable production technology, and improving flavor and health care effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

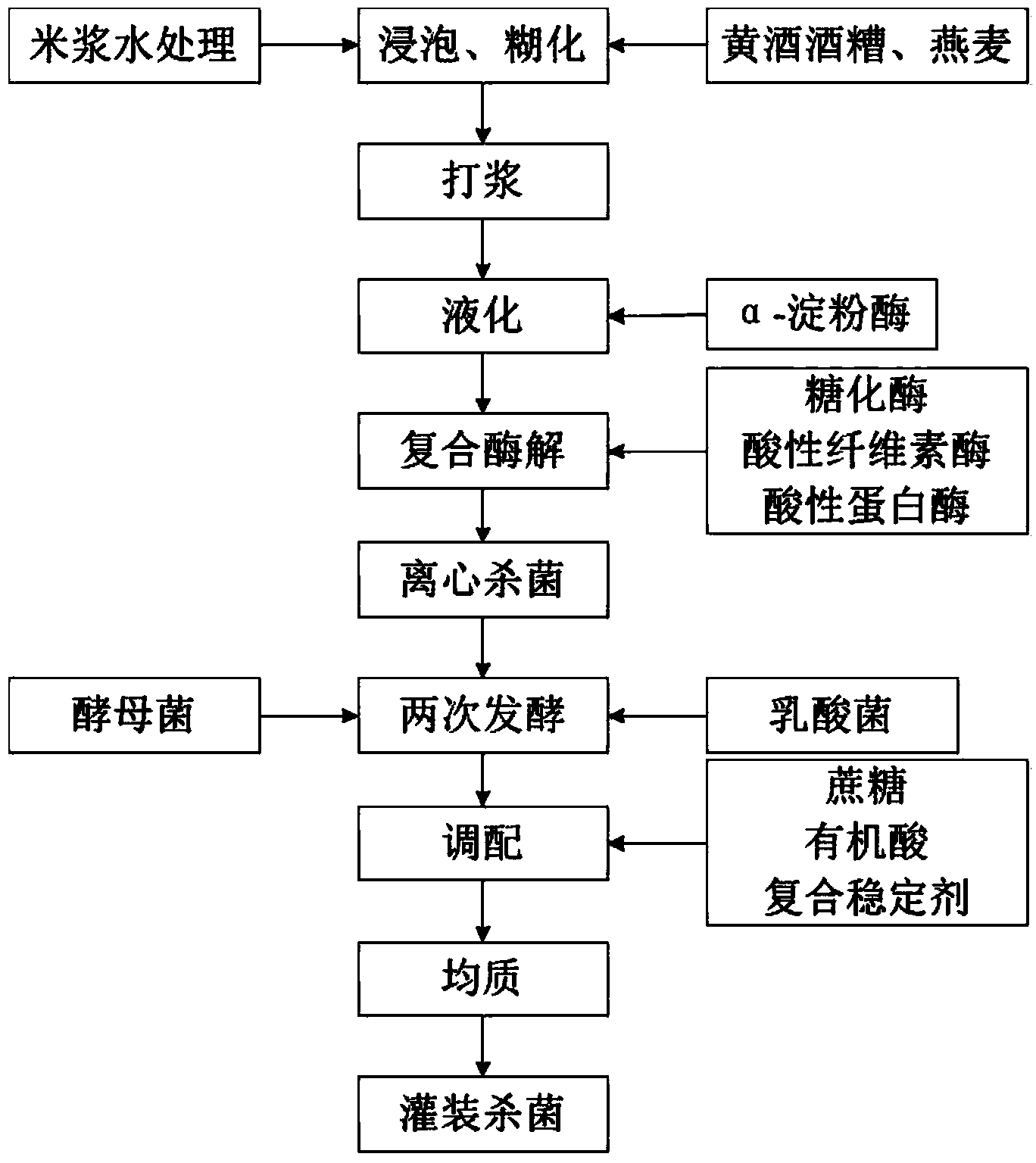

Method used

Image

Examples

Embodiment 1

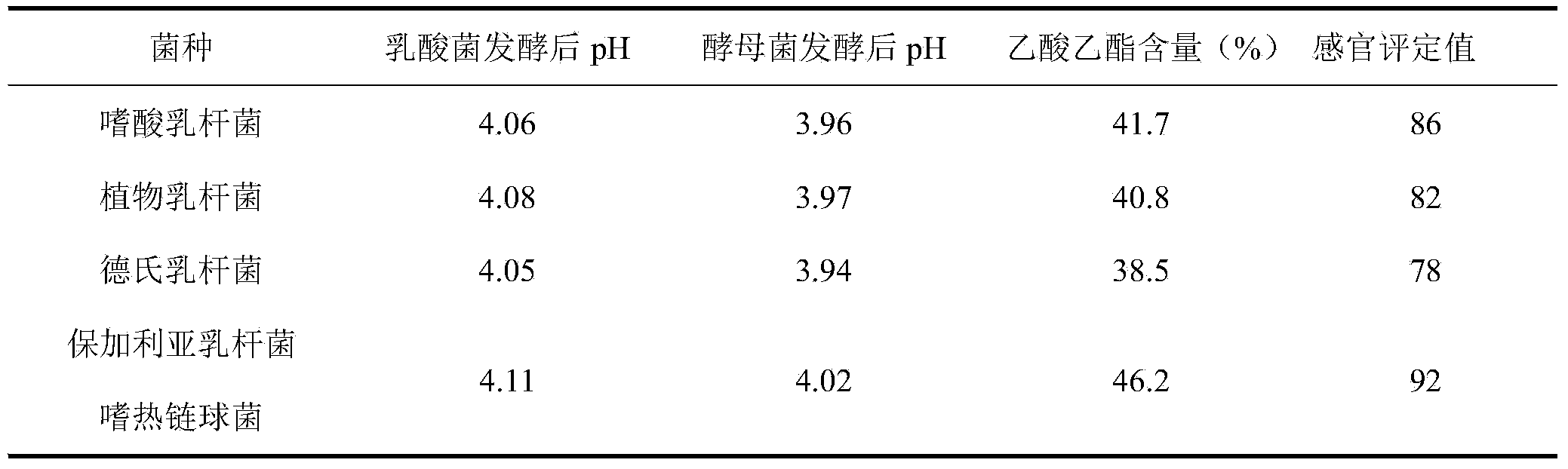

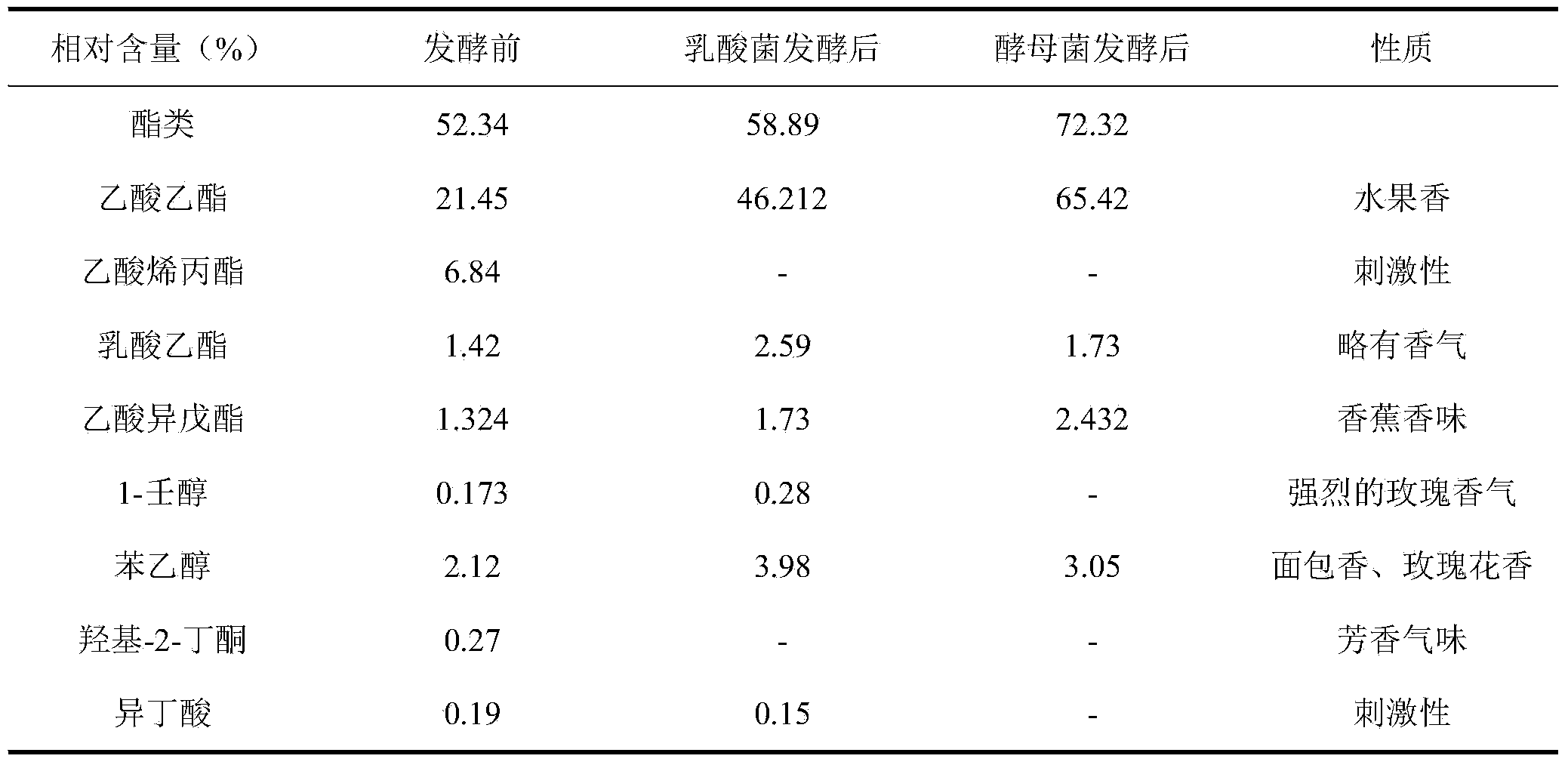

[0036] A yellow distiller's grain lactic acid fermented beverage and a preparation method thereof, comprising the following steps:

[0037] 1) Rice milk water treatment: use lime milk to adjust the pH of rice milk water to 8.0, add diatomaceous earth to 6.0g / L, add activated carbon to 8.0g / L, let the adsorption time stand for 30min, and treat the adsorbed The rice milk water is sterilized at 121°C for 15 minutes;

[0038] 2) Gelatinization: mix rice distiller's grains and oats in a mass ratio of 7:3, soak in water for 8 hours at a weight ratio of 1:15, and boil for 15 minutes to fully gelatinize;

[0039] 3) Beating: the gelatinized distiller's grains oats were beaten with water at a solid-to-liquid ratio of 1:5 for 6 minutes at a beating temperature of 50°C, and finely ground in a colloid mill for 5 minutes to make a distiller's grains oat slurry;

[0040]4) Liquefaction: Add 0.2% α-amylase (4000 U / g) of distiller's grain oat slurry to distiller's grain oat slurry with a pH ...

Embodiment 2

[0048] A yellow distiller's grain lactic acid fermented beverage and a preparation method thereof, comprising the following steps:

[0049] 1) Rice milk water treatment: use lime milk to adjust the pH of rice milk water to 7.8, add diatomaceous earth to 5.8g / L, add activated carbon to 7.8g / L, let the adsorption time stand for 35min, and treat the adsorbed The rice milk water is sterilized at 121°C for 20 minutes;

[0050] 2) Gelatinization: mix rice distiller's grains and oats in a mass ratio of 7:5, soak in water for 10 hours at a mass ratio of 1:15, and boil for 15 minutes to fully gelatinize;

[0051] 3) Beating: the gelatinized distiller's grains oats were beaten with water at a mass ratio of 1:4 for 7 minutes at a beating temperature of 50°C, and finely ground in a colloid mill for 4 minutes to make distiller's grains oat slurry;

[0052] 4) Liquefaction: Add 0.1% α-amylase (4000 U / g) of distiller's grain oat slurry to distiller's grain oat slurry with a pH of 6.0, and l...

Embodiment 3

[0060] A yellow distiller's grain lactic acid fermented beverage and a preparation method thereof, comprising the following steps:

[0061] 1) Rice milk water treatment: use lime milk to adjust the pH of rice milk water to 7.9, add diatomaceous earth to 5.5g / L, add activated carbon to 7.9g / L, and let the adsorption time to stand for 38 minutes. The rice milk water is sterilized at 121°C for 18 minutes;

[0062] 2) Gelatinization: mix rice distiller's grains and oats in a mass ratio of 7:4, soak in water for 10 hours at a mass ratio of 1:12, and boil for 16 minutes to fully gelatinize;

[0063] 3) Beating: the gelatinized distiller's grains oats were beaten with water at a solid-to-liquid ratio of 1:5 for 5 minutes at a beating temperature of 50°C, and finely ground in a colloid mill for 5 minutes to make a distiller's grains oat slurry;

[0064] 4) Liquefaction: Add 0.3% α-amylase (4000 U / g) of distiller's grain oat slurry to distiller's grain oat slurry with a pH of 7.0, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com