Multistage winnowing-high voltage electrostatic separation method

A high-voltage electrostatic, multi-stage air technology, applied in electrostatic effect separation, chemical instruments and methods, solid separation and other directions, can solve the problems of dust, large output, increase the workload of electrical separators, etc., to solve the problem of low output and improve Yield, solve the effect of low separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

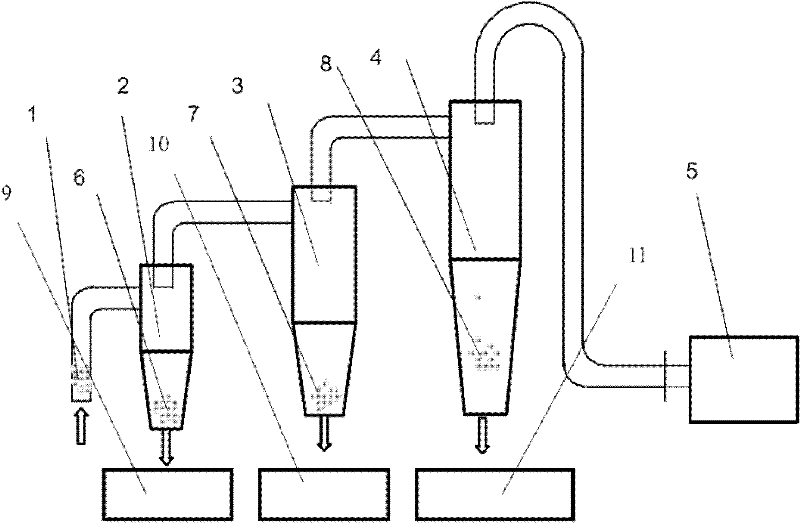

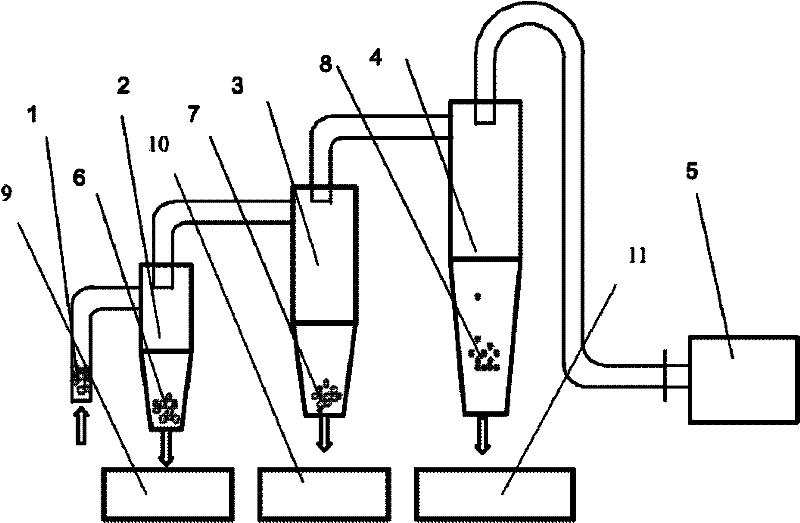

[0015] Take three-stage wind separation-two-stage high-voltage electrostatic separation as an example:

[0016] The mixed material of crushing waste circuit boards is conveyed by wind power, and the whole system is carried out under sealed conditions. The air volume of the multi-stage wind separation system is 3500m 3 / h, the wind pressure is 7000Pa; the voltage of the electric separator is 25000V.

[0017] In this embodiment, after connecting the multi-stage air separators in series, the output end of the multi-stage air separators is connected with the electric separator and the non-metallic collector, and the metal and non-metallic parts of the broken waste circuit boards to be separated are transported by wind force. The granular mixed materials with a size of 1.20mm-0.02mm are subjected to multi-stage wind separation, in which: the mixed metal and non-metallic mixed materials obtained by the first and second air separators are respectively sent to the corresponding elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com