Production method for 2 or multi-halohydrocarbon crosslinked polybenzimidazole crosslinked membrane

A technology of polybenzimidazole and aminopolybenzimidazole, which is applied in the field of chemical materials, can solve the problems of easy volatilization loss of crosslinking agent and difficulty in precise control of crosslinking density, and achieve excellent mechanical properties, simple method and mild reaction conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Preparation of amino-containing polybenzimidazole homopolymers from 5-aminoisophthalic acid and 3,3',4,4'-tetraaminobiphenyl:

[0035] Add 5mmol (1.071g) of 3,3',4,4'-tetraaminobiphenyl and 5mmol (0.905g) of 5-aminoisophthalic acid into 20g of polyphosphoric acid containing 70-90wt% phosphorus pentoxide , Under the condition of mechanical stirring under the protection of nitrogen, first react at 150°C for 2 hours, then react at 190°C for 20 hours, and pour into water after cooling down. First neutralize to weak acidity with sodium hydroxide, then neutralize to neutral with sodium bicarbonate, filter, put the collected polymer in ammonia water at 80°C and stir for 12 hours, filter, wash the sample to neutral, 100 °C for 24 hours in vacuum to obtain a homopolymer of amino-containing polybenzimidazole.

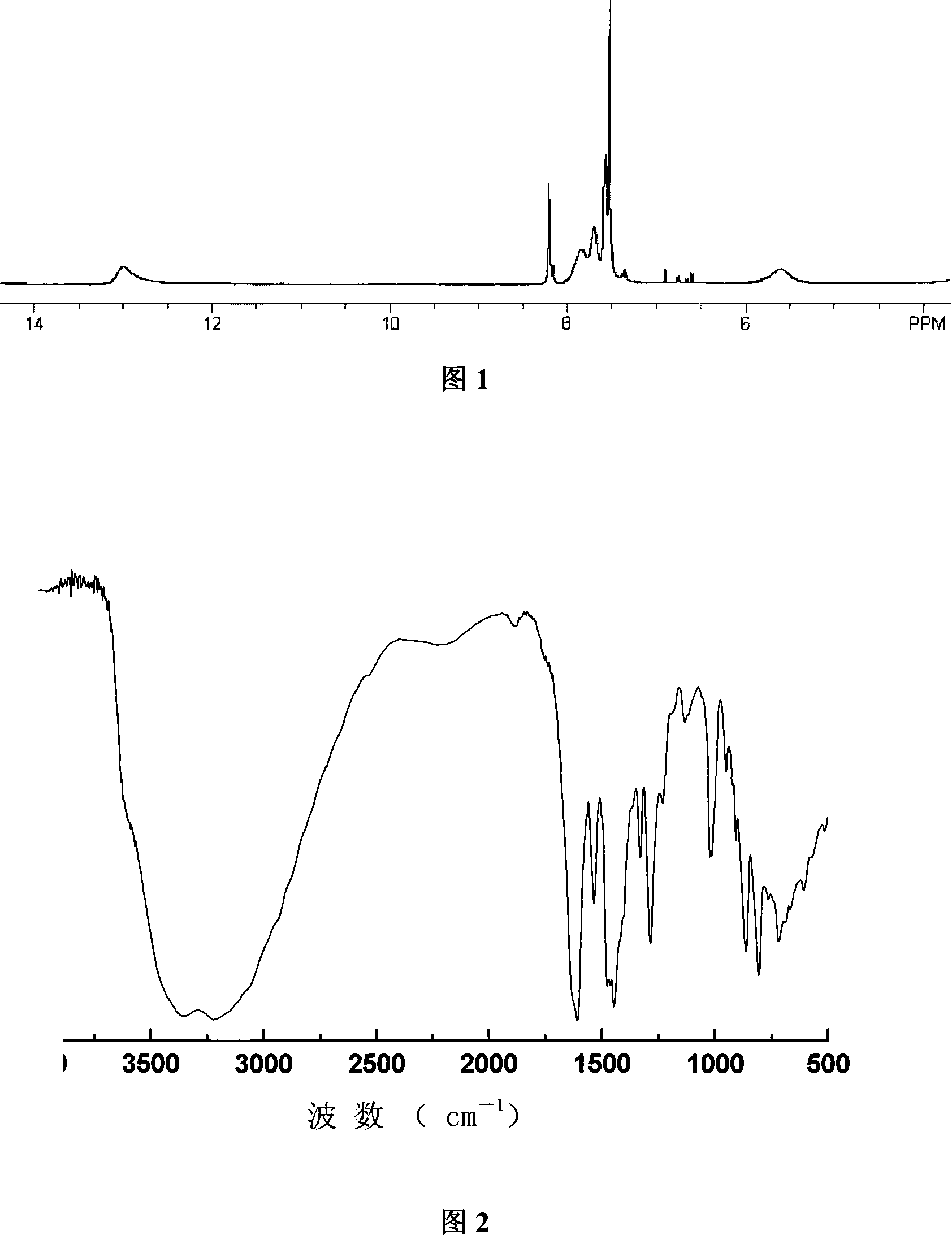

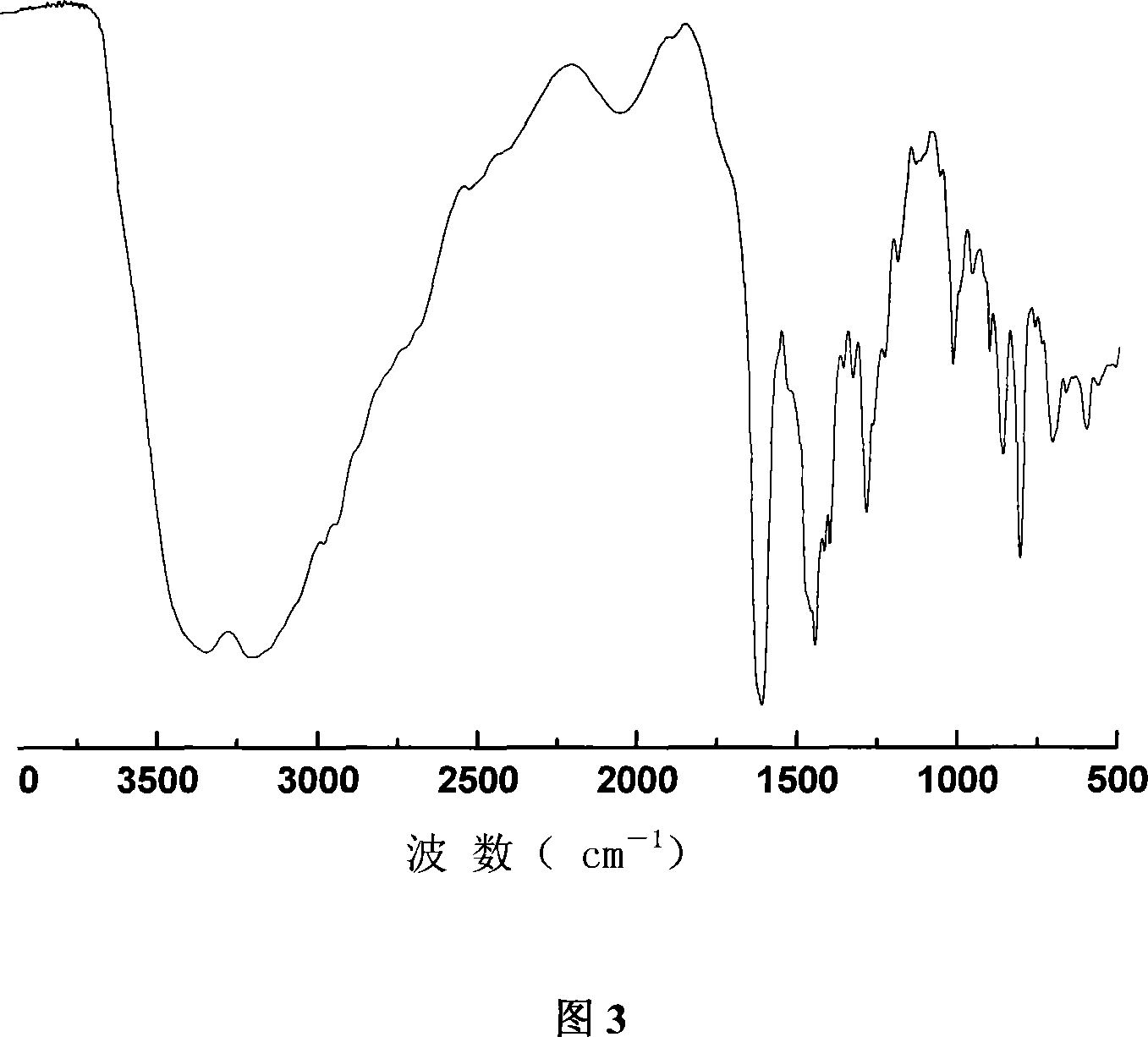

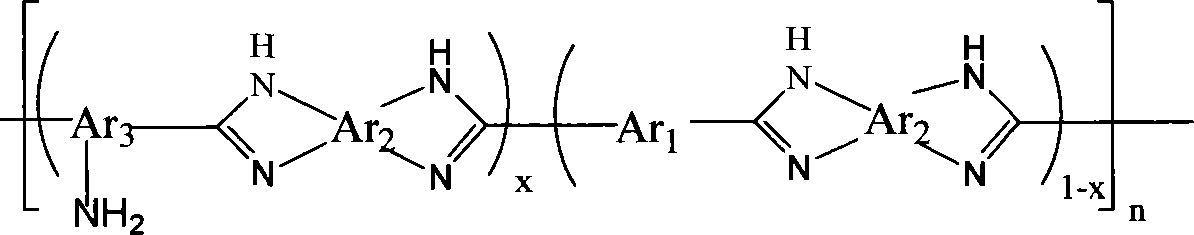

[0036] Its intrinsic viscosity is 0.64dL / g, Fig. 1 is its nuclear magnetic resonance spectrum, Fig. 2 is its infrared spectrum.

[0037] Preparation of 1,3-dibromopropan...

Embodiment 2

[0041] The amino-containing polybenzimidazole copolymer was prepared from 5-aminoisophthalic acid, isophthalic acid and 3,3',4,4'-tetraaminobiphenyl.

[0042]Add 6mmol (1.2856g) 3,3',4,4'-tetraaminobiphenyl, 3mmol (0.4984g) isophthalic acid and 3mmol (0.543g) 5-aminoisophthalic acid to 20g containing 70-90wt % phosphorus pentoxide polyphosphoric acid, under the condition of mechanical stirring under the protection of nitrogen, first react at 150°C for 2 hours, then react at 190°C for 20 hours, and pour it into water after cooling down to room temperature. First neutralize to weak acidity with sodium hydroxide, then neutralize to neutral with sodium bicarbonate, filter, put the collected polymer in ammonia water at 80°C and stir for 12 hours, filter, wash the sample to neutral, 100 °C for 24 hours in vacuum to obtain a copolymer containing amino polybenzimidazole. Its intrinsic viscosity is 0.36dL / g.

[0043] Preparation of polybenzimidazole cross-linked film cross-linked wit...

Embodiment 3

[0046] The amino-containing polybenzimidazole copolymer was prepared from 5-aminoisophthalic acid, isophthalic acid and 3,3',4,4'-tetraaminobiphenyl.

[0047] 6mmol (1.2856g) 3,3',4,4'-tetraaminobiphenyl, 4mmol (0.6645) isophthalic acid and 2mmol (0.362g) 5-aminoisophthalic acid were added to 20g containing 70-90wt% In the polyphosphoric acid of phosphorus pentoxide, under the condition of nitrogen protection and mechanical stirring, first react at 150°C for 2 hours, then react at 190°C for 20 hours, and pour it into water after cooling down to room temperature. First neutralize to weak acidity with sodium hydroxide, then neutralize to neutral with sodium bicarbonate, filter, put the collected polymer in ammonia water at 80°C and stir for 12 hours, filter, wash the sample to neutral, 100 °C for 24 hours in vacuum to obtain a copolymer containing amino polybenzimidazole. Its intrinsic viscosity is 1.40dL / g.

[0048] Preparation of 1,3-dibromopropane crosslinked polybenzimidaz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com