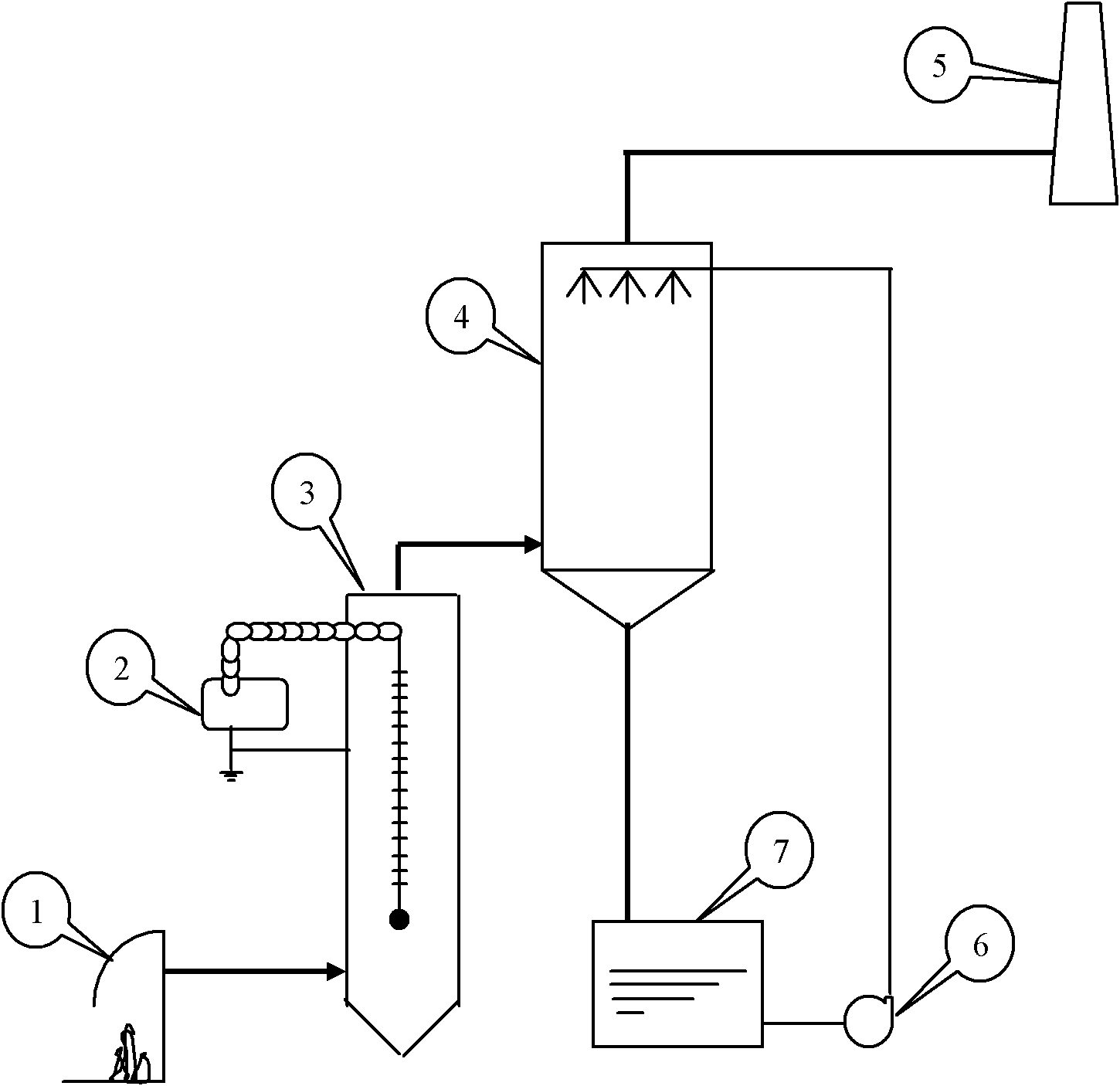

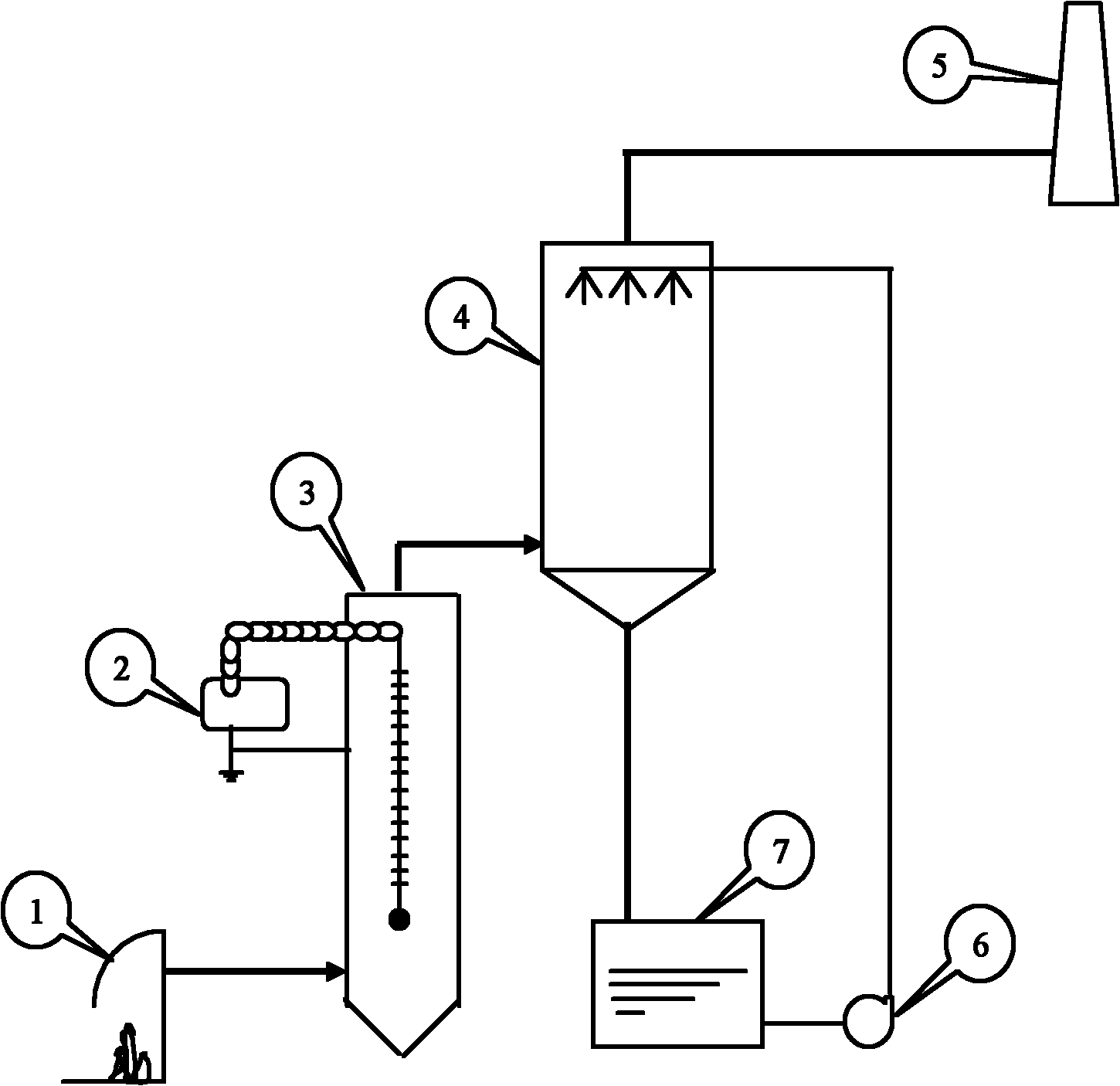

Method and device for treating nondegradable organic waste gas by combining low-temperature plasma with organisms

A low-temperature plasma, organic waste gas technology, applied in the field of environmental pollution control, can solve problems such as inability to apply, incomplete degradation, and a large number of harmful by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Wet coke quenching waste gas temperature is 50°C, contains volatile phenol 249mg / m 3 And benzene 84mg / m 3 , the flow rate is 280m 3 / h, formic acid, acetic acid and oxalic acid were not detected. The injected energy is 66kJ / m 3 After treatment in a low-temperature plasma reactor, the concentrations of volatile phenol and benzene in the gas were reduced to 18mg / m 3 and 8.2mg / m 3 , at the same time, the measured gas contains formic acid 17mg / m 3 , Acetic acid 61mg / m 3 and oxalic acid 53mg / m 3 , indicating that after the organic waste gas is treated by a low-temperature plasma reactor, some substances in the organic waste gas are oxidized to form easily degradable organic products such as formic acid, acetic acid and oxalic acid. The gas discharged from the low-temperature plasma reactor directly enters the biological scrubber, and the concentrations of volatile phenol and benzene after treatment are 12mg / m3 3 and 5.4mg / m 3 , no formic acid, acetic acid and oxalic...

Embodiment 2

[0031] The temperature of spray paint exhaust gas is 21°C, and the benzene content is 84mg / m 3 , toluene 143mg / m 3 And xylene 185mg / m 3 , the flow rate is 120m 3 / h, formic acid, acetic acid and oxalic acid were not detected. The injected energy is 58kJ / m 3 After treatment in a low-temperature plasma reactor, the concentrations of benzene, toluene and xylene in the gas were reduced to 12mg / m 3 , 11mg / m 3 and 19mg / m 3 . At the same time, the measured gas contains formic acid 62mg / m 3 , Acetic acid 97mg / m 3 and oxalic acid 37mg / m 3 . The gas discharged from the low-temperature plasma reactor directly enters the biological trickling filter tower, and the concentrations of benzene, toluene and xylene are reduced to 8mg / m3 after treatment 3 , 8mg / m 3 and 15mg / m 3 , formic acid, acetic acid and oxalic acid were not detected. After low-temperature plasma combined with biological treatment, the total removal rates of benzene, toluene and xylene were 90.5%, 94.4%, and 91....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com