Method of preparing nano powderusing liquid nitrogen low temperature ball mill

A low-temperature ball milling and nano-powder technology, which is applied in the field of liquid nitrogen low-temperature ball milling to prepare nano-powders with high thermal stability, can solve the problems of unfavorable environmental protection, high manufacturing costs, and limit the feasibility of the application of nano-structured materials, etc. The effect of crystal formation composition range and high solid solubility expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

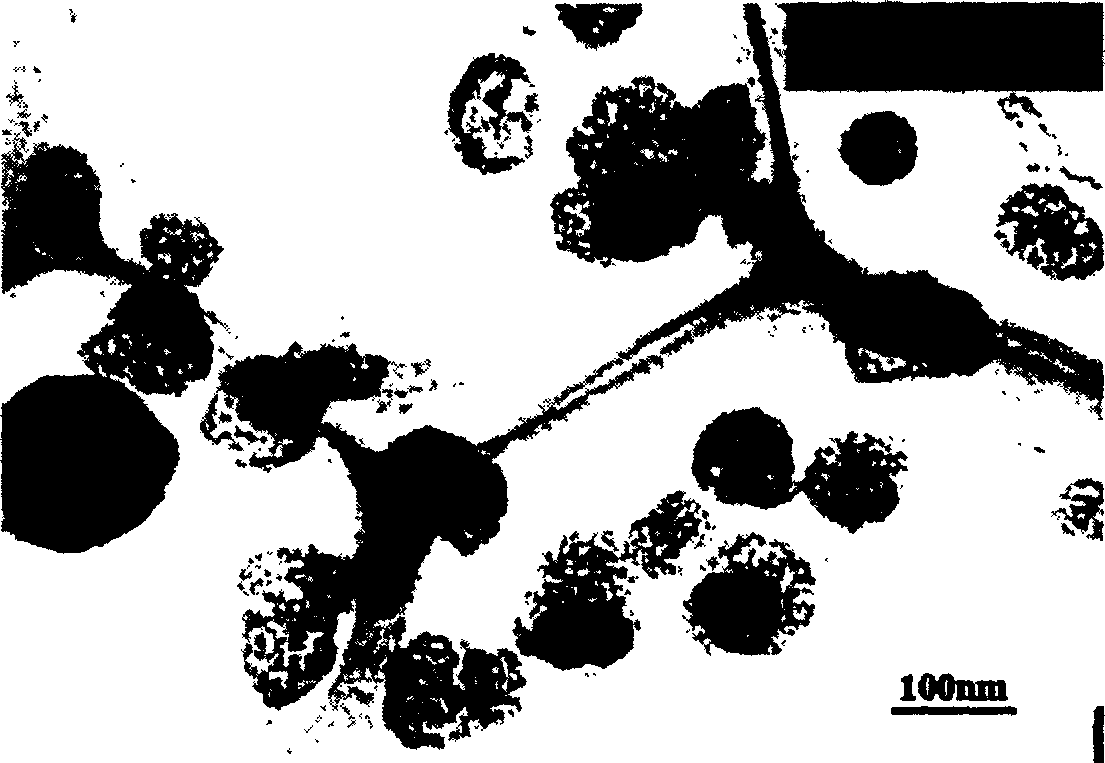

[0026] The average particle size of the original Ni powder is 232.4nm. The vertical rotor ball mill and stainless steel balls and tanks are selected. The ball-to-material ratio is 40:1. pink( figure 1 ). After being kept at 900°C (about 0.6Tm) for 1 hour, the average grain size of the nanopowder only grows up to 50.62nm.

Embodiment 2

[0028] The average particle size of the original Ni powder is 232.4nm. A vertical rotor ball mill and stainless steel balls and tanks are selected. The ball-to-material ratio is 45:1. The ball milling temperature is -112°C. After 7 hours of ball milling, Ni powder with an average grain size of 28.19nm is formed. pink. After being kept at 600°C for 1 hour, the average grain size of the nano-powder only grows up to 34.92nm.

Embodiment 3

[0030] The average particle size of the original Ni powder is 232.4nm. A high-energy horizontal rotor ball mill and stainless steel balls and tanks are selected. The ball-to-material ratio is 40:1. The ball milling temperature is -128°C. After 9.5 hours of ball milling, an average grain size of 10.78nm is formed. Ni powder. After being kept at 600°C for 3 hours, the average grain size of the nano-powder only grows up to 52.64nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com