FeNi-based amorphous soft magnetic alloy and preparation method of soft magnetic alloy

A soft magnetic alloy and soft magnetic alloy ribbon technology, applied in the direction of magnetic materials, magnetic objects, electrical components, etc., can solve the problems of low content of ferromagnetic element FeNi, low alloy forming ability, low saturation magnetic induction intensity, etc., to achieve excellent soft Magnetic and mechanical properties, high amorphous forming ability, large critical size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

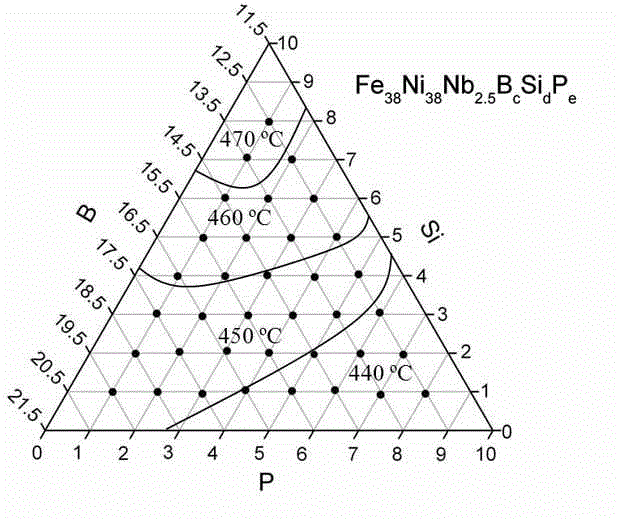

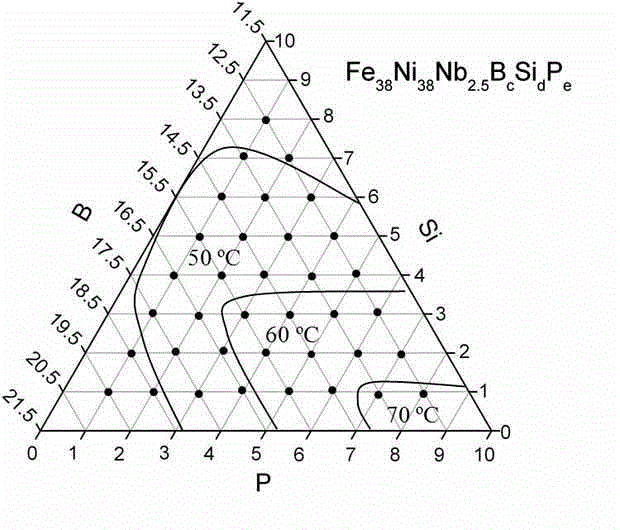

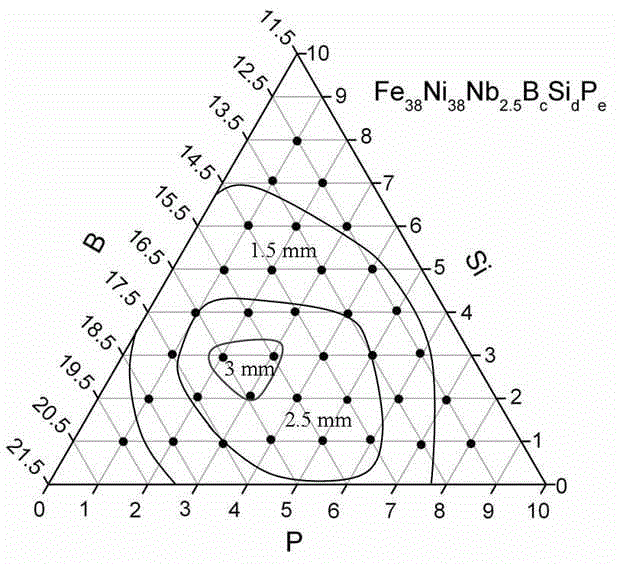

[0071] Melting composition is Fe 38 Ni 38 B 21.5-d-e Si d P e Nb 2.5 The alloys were prepared by copper mold casting method to prepare amorphous alloy rods with different diameters, the critical diameter of the alloy was determined, and the amorphous forming ability of the alloy was calibrated. Specifically, by calculating the critical diameter of an amorphous rod, the larger the critical diameter, the amorphous structure can be obtained even at a slow cooling rate, which means that it has a high ability to form amorphous. Amorphous alloy strips with different B, P and Si contents were prepared by single-roll rapid quenching method, and the thermophysical parameters of the amorphous alloy were tested by DSC. Put the strip into the tube furnace at T g Heat treatment at -50°C for 10 minutes, and test the magnetic properties of the strip after heat treatment. The test performance is shown in Table 1.

[0072]

[0073]

[0074]Table 1 Properties of amorphous alloys w...

Embodiment 2

[0084] Smelting of different Fe and Ni total contents (Fe 0.5 Ni 0.5 ) a+b (B 0.646 Si 0.125 P 0.125 Nb 0.104 ) 100-a-b Alloy, using the copper mold casting method to prepare amorphous alloy rods with different diameters, determine the critical diameter of the alloy, and calibrate the forming ability of the alloy. The amorphous strips with different Fe and Ni total contents were prepared by single-roll rapid quenching method, and the thermal physical parameters of the amorphous alloy were tested by DSC, and the strips were put into the tube furnace at T g Heat treatment at -50°C for 10 minutes, and test the magnetic properties of the strip. The test performance is shown in Table 2:

[0085]

[0086] Table 2 Properties of amorphous alloys with different Fe and Ni total contents

[0087] The increase of the total content of Fe and Ni leads to the decrease of the content of amorphous forming elements, but the alloy composition is closer to the eutectic point, the role...

Embodiment 3

[0094] Melting Fe with different Ni content a Ni 78-a B 14.2 Si 2.75 P 2.75 Nb 2.3 Alloy, prepare amorphous alloy rods with different diameters by copper mold casting method, determine the critical diameter of the alloy, and calibrate the amorphous forming ability of the alloy. Amorphous strips with different Ni content were prepared by single-roll rapid quenching method, and the thermal physical parameters were tested by DSC. The strips were put into the tube furnace at T g Heat treatment at -50°C for 10 minutes, and test the magnetic properties of the strip. The test performance is shown in Table 3:

[0095]

[0096] Table 3 Properties of amorphous alloys with different Ni contents

[0097] In this system, the physical and chemical properties of Fe and Ni are similar, they are the same kind of atoms, and their atomic radii are similar, 0.124 and 0.125 respectively; The content of Ni does not obviously affect the close-packed structure of the system, and the format...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Coercivity | aaaaa | aaaaa |

| Coercivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com