Nanocrystal magnetically soft alloy with high processing property and high saturation magnetic induction strength, and preparation method therefor

A nanocrystalline soft magnetic and magnetic induction technology, applied in magnetic materials, magnetic objects, electrical components, etc., can solve the problems of low heating rate of nanocrystalline alloys, increase melting cost, etc., and achieve low coercivity, high practicability, good reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

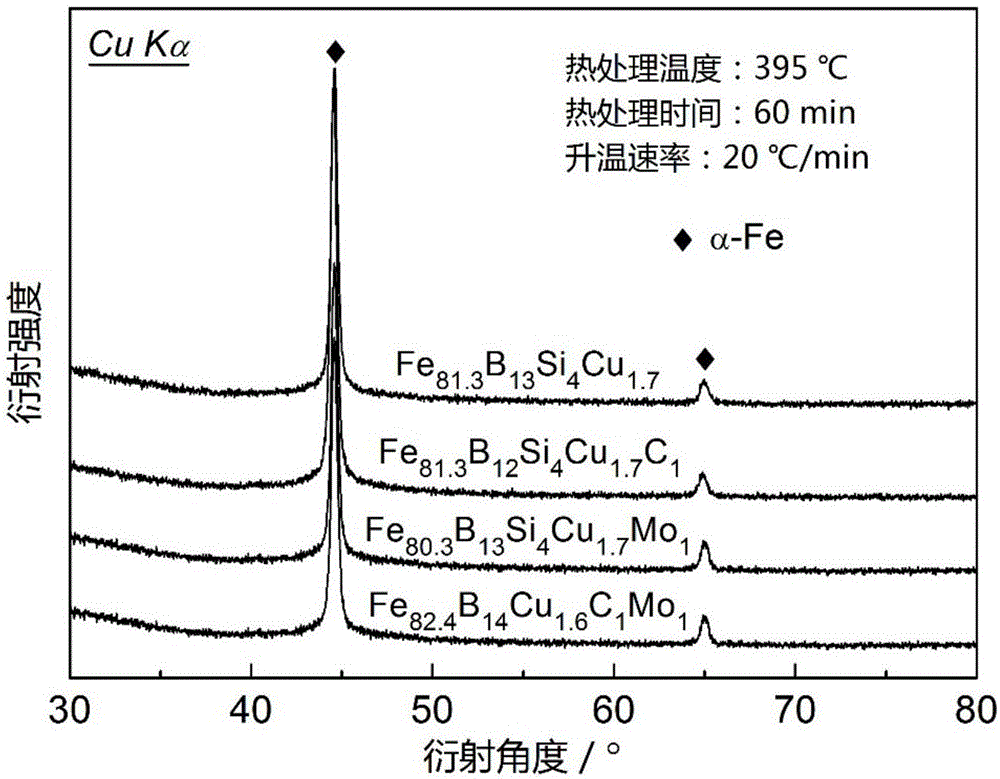

[0029] Example 1Fe 81.3 B 13 Si 4 Cu 1.7

[0030] Step 1, using Fe, B, Si and Cu raw materials with a mass percentage greater than 99% to carry out weighing and batching according to the designed alloy composition;

[0031] Step 2. Prepare the master alloy ingot in a non-consumable electric arc furnace under an Ar gas atmosphere, and the alloy is repeatedly smelted 4 times to ensure that the composition of the master alloy ingot is uniform;

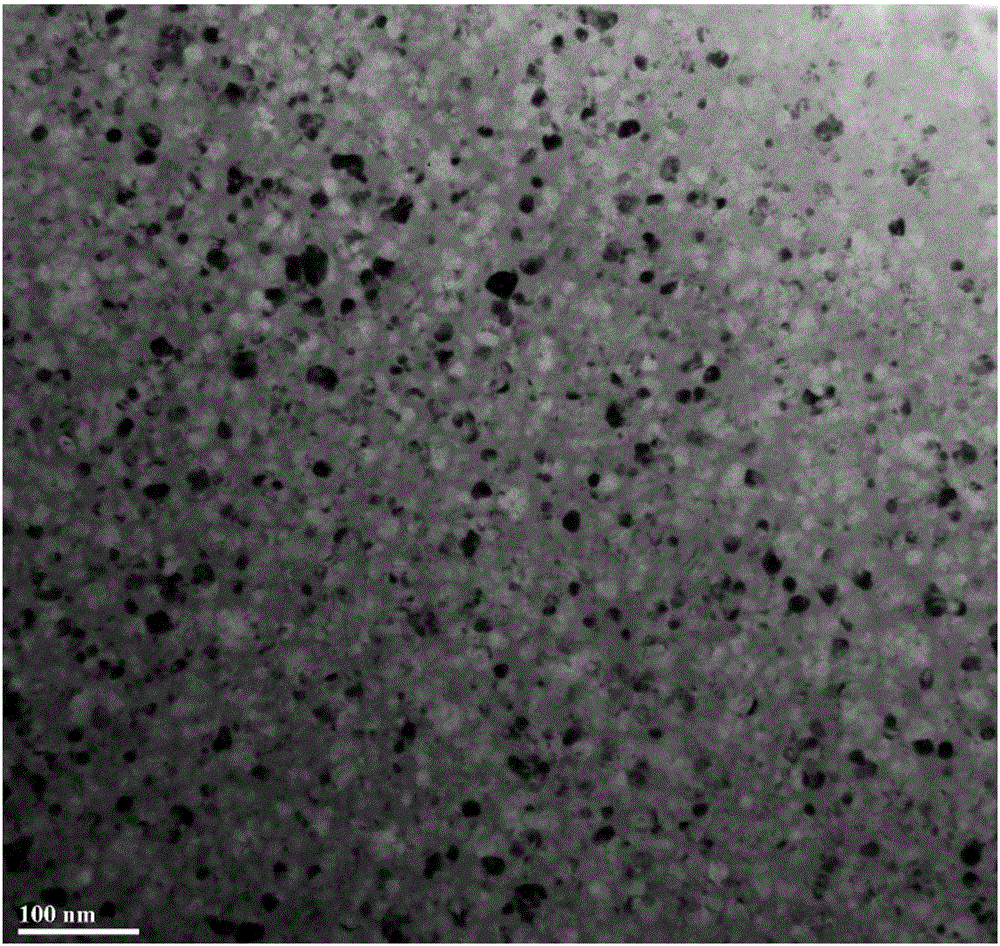

[0032] Step 3: crush the master alloy ingot and put it into a quartz tube, and use a single-roll strip stripping process at a speed of 30m / s to produce an amorphous alloy strip with a width of 2-3mm and a thickness of 20-25μm ;

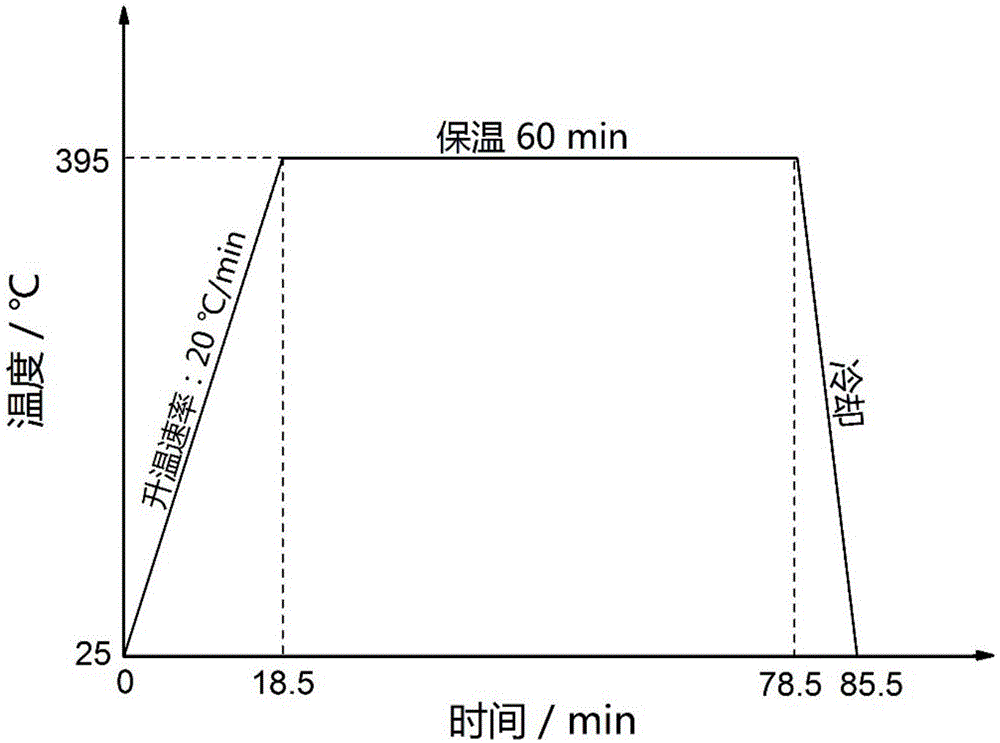

[0033] Step 4: Heat treatment of multiple batches of amorphous alloy strips in a vacuum heat treatment furnace with different processes: in the temperature range of 365-425 ° C, every 15 ° C is used as a holding temperature, and the temperature is raised to 20 ° C / min. After each holding temperature, it w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com