Plasma processing apparatus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033]Hereinafter, embodiments of the present invention will be described with reference to the accompanying drawings which form a part hereof.

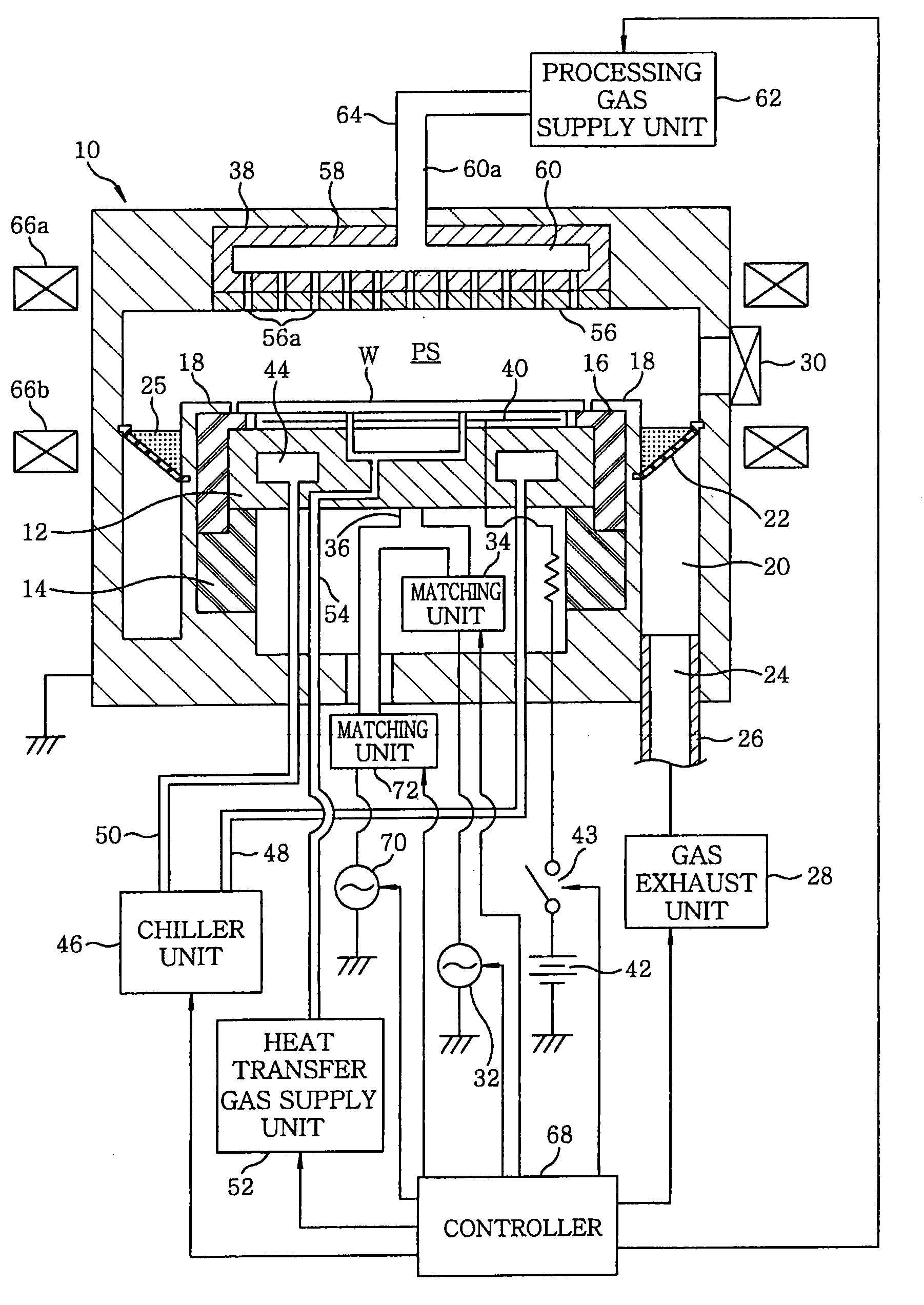

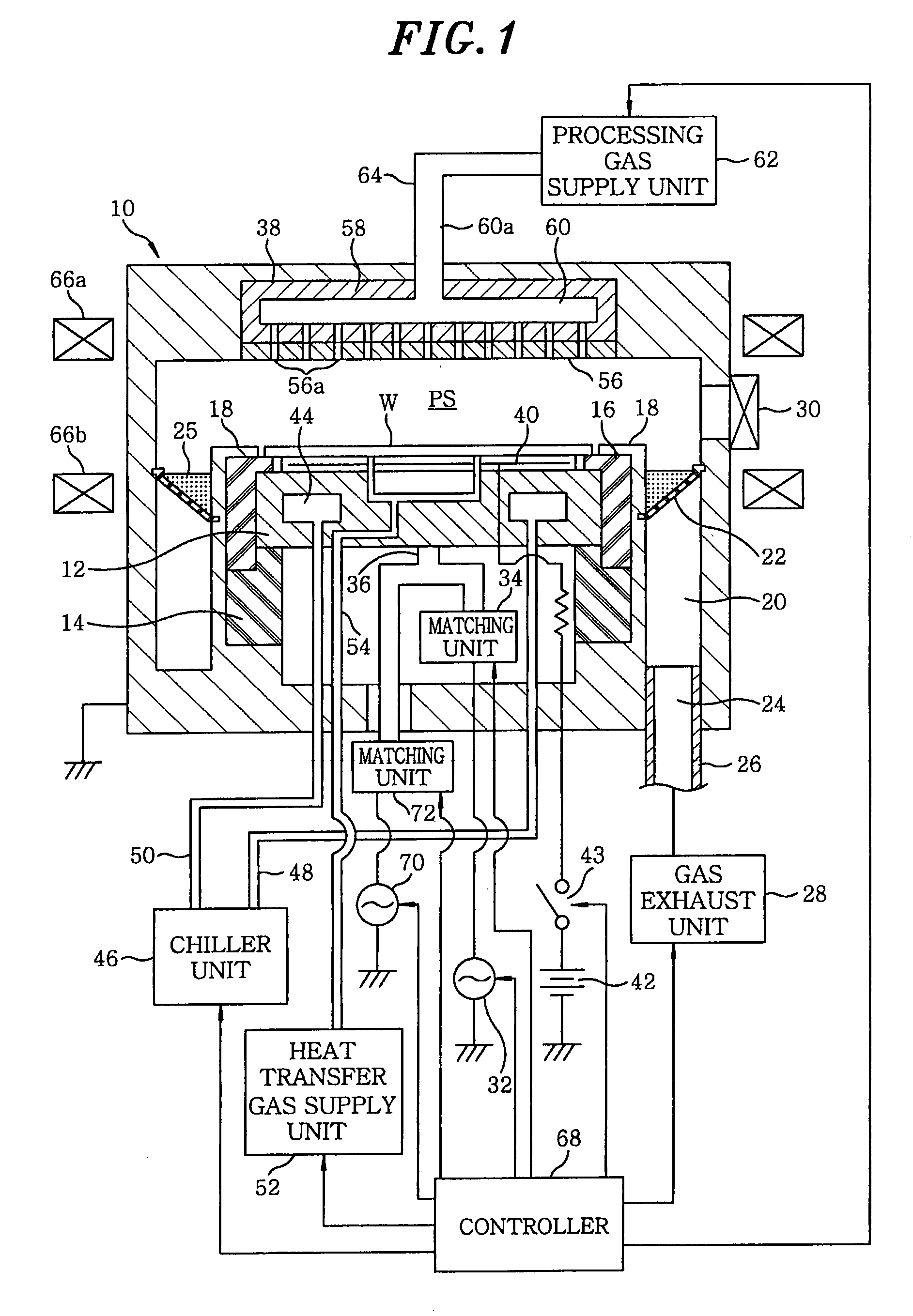

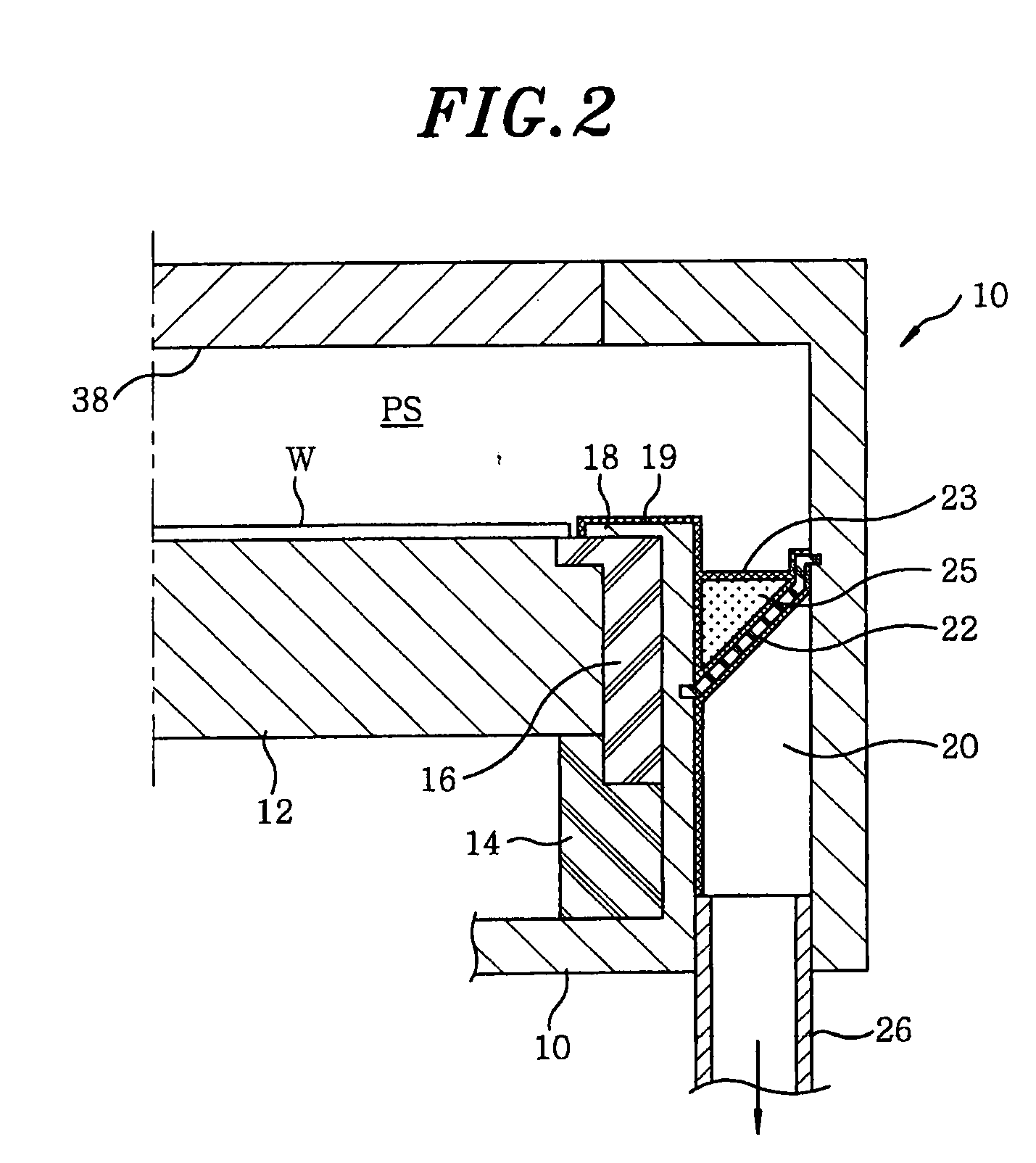

[0034]FIG. 1 shows a configuration of a plasma etching apparatus in accordance with an embodiment of the present invention. The plasma processing apparatus is configured as a capacitively coupled plasma etching apparatus of a cathode coupling type (lower electrode dual frequency application type) in which dual radio frequency (RF) powers are applied to a lower electrode, and includes a cylindrical chamber (processing chamber) 10 made of metal such as aluminum, stainless steel or the like. The chamber 10 is frame grounded.

[0035]A circular plate-shaped lower electrode or a susceptor 12 for mounting thereon a substrate to be processed, e.g., a semiconductor wafer W, is installed in the chamber 10. The susceptor 12 is made of a conductive material, e.g., aluminum, and is supported by the bottom wall of the chamber 10 through a cylindrical support...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Frequency | aaaaa | aaaaa |

| Dielectric polarization enthalpy | aaaaa | aaaaa |

| Electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com