Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

103results about How to "Reduce rigidity requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

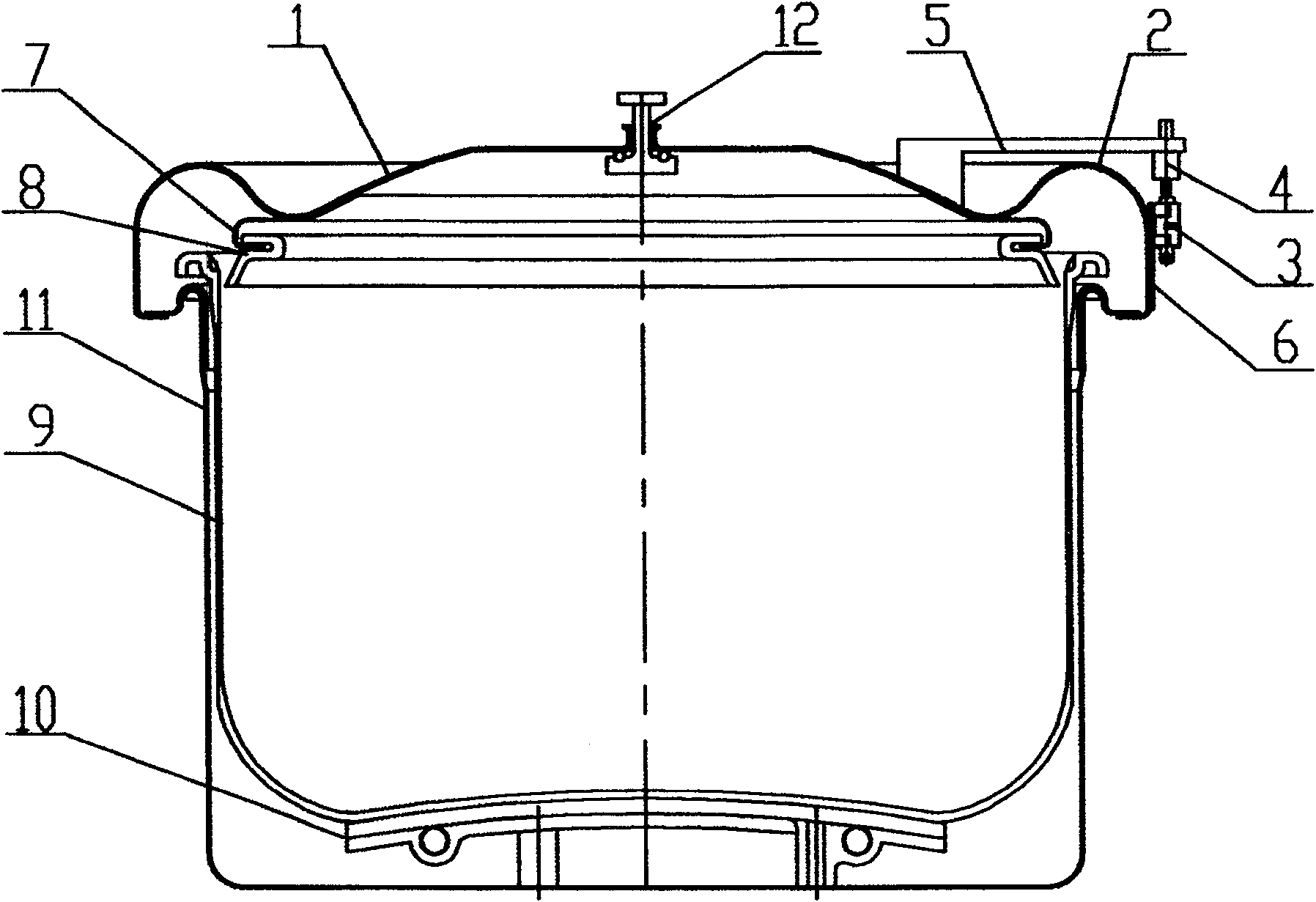

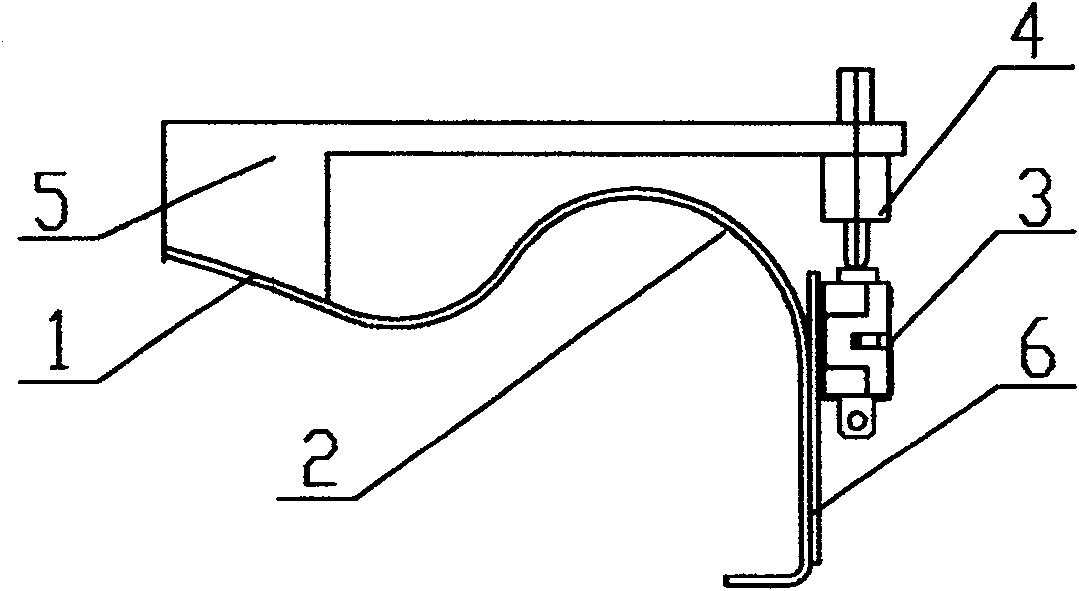

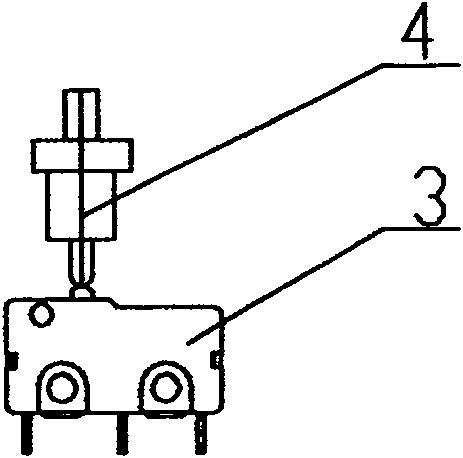

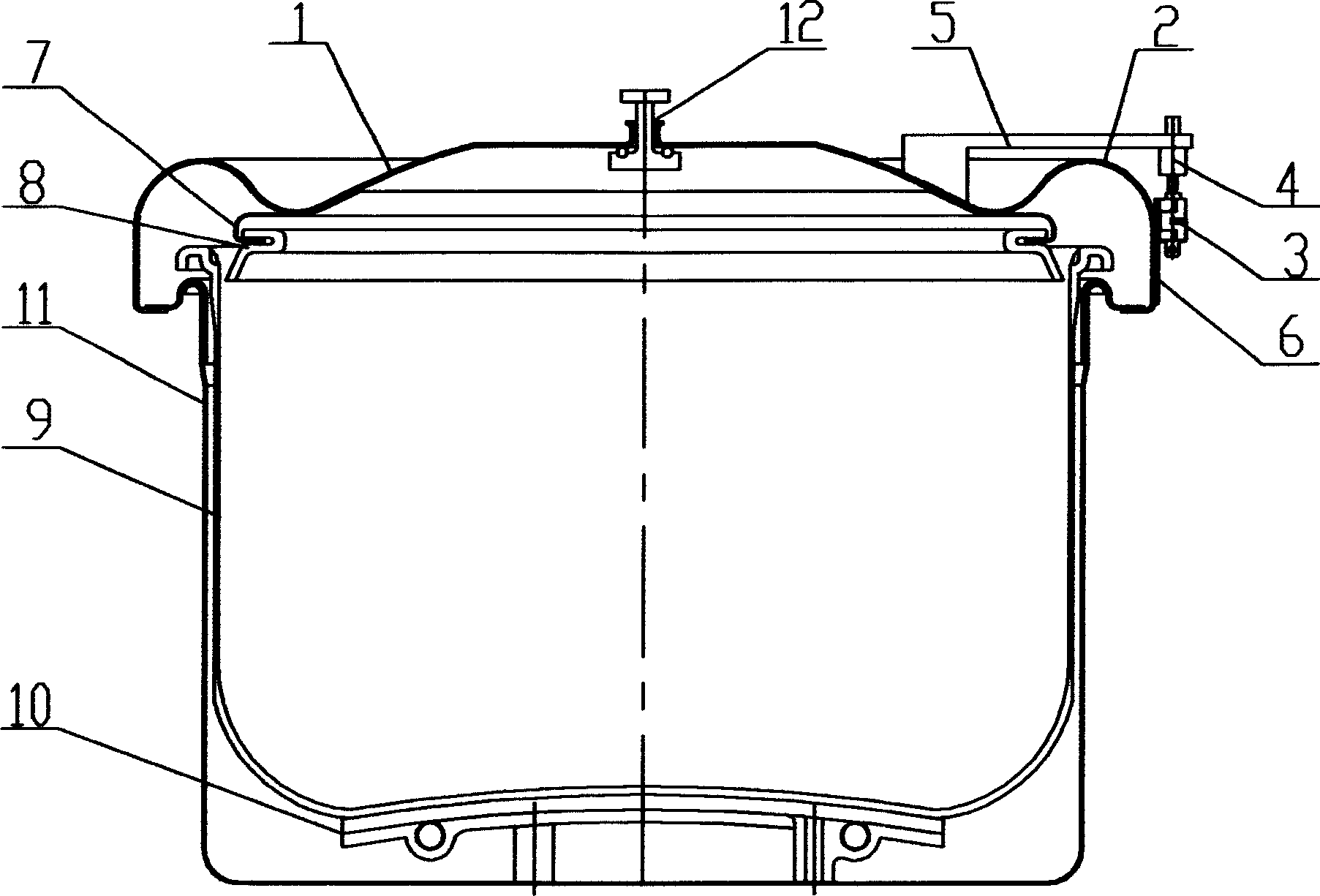

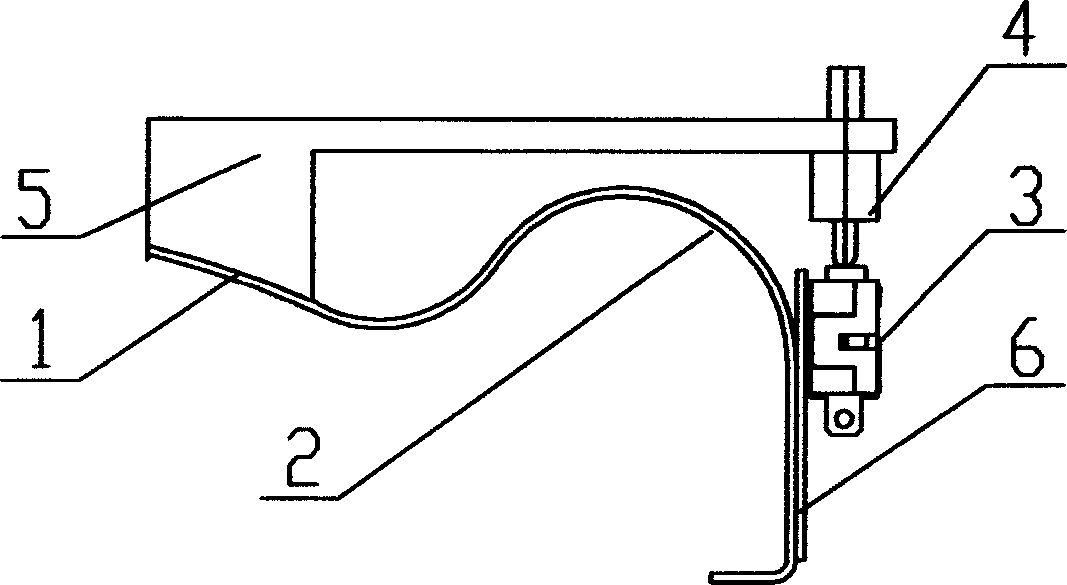

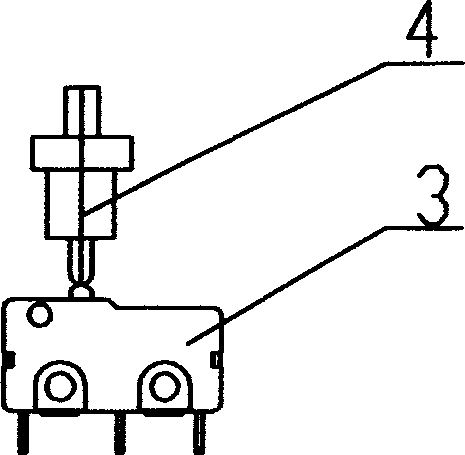

Moving-cover type electric pressure cooker

The invention relates to a movable cover electric pressure cooker, which belongs to kitchen electric appliances, and is a patented technology of electric rice cooker pressurization that controls and limits the pressure inside the cooker through an elastic cooker cover. It includes a pot cover, an elastic element, a switch, a sealing ring, an inner pot, an electric heater, and an outer pot; the edge of the inner pot sits on the edge of the outer pot; The outer pot is movable and rigidly connected; the elastic element controls the on-off of the switch by the elastic displacement generated under the pressure in the pot, and the elastic displacement is transmitted to the corresponding device through the transmission part arranged at the displacement or static position of the elastic element. on the switch. The invention can solve the problems in the integrated design and mechanical connection of the elastic element and other parts in the prior art, improve the utilization rate of materials, simplify the production process and reduce the production cost.

Owner:王永光

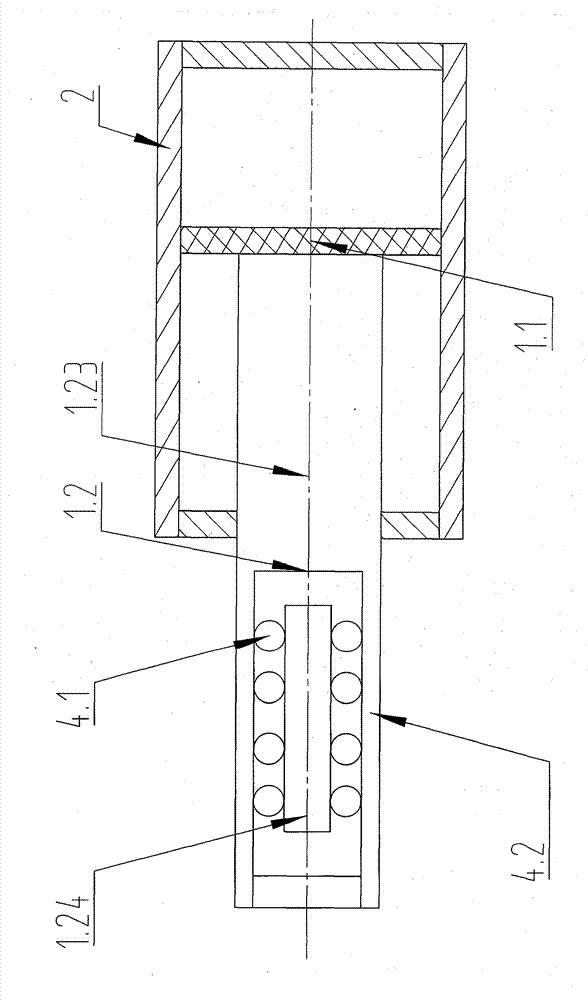

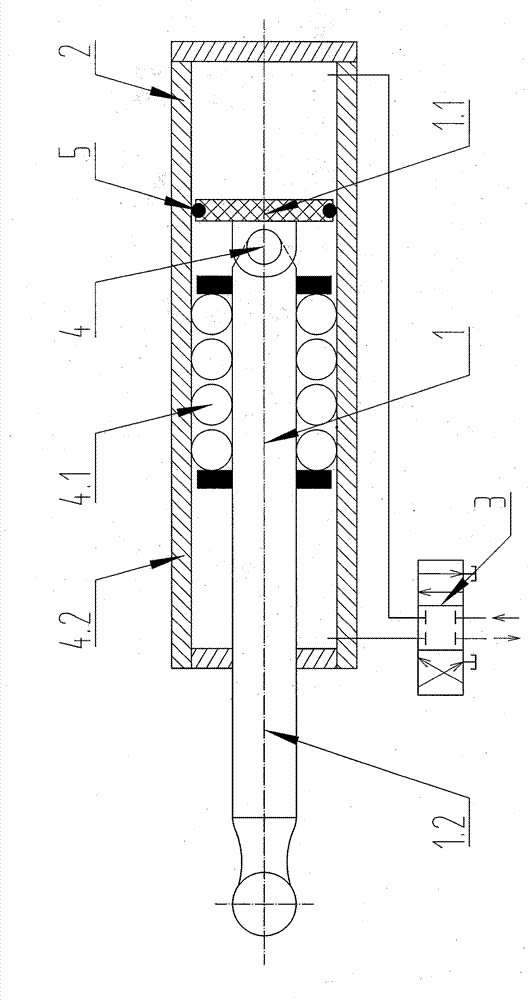

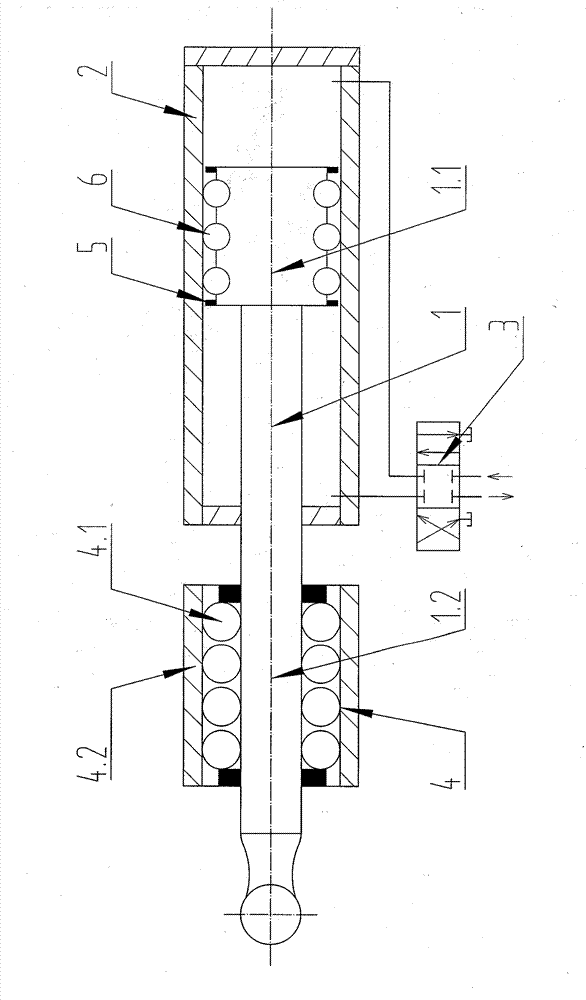

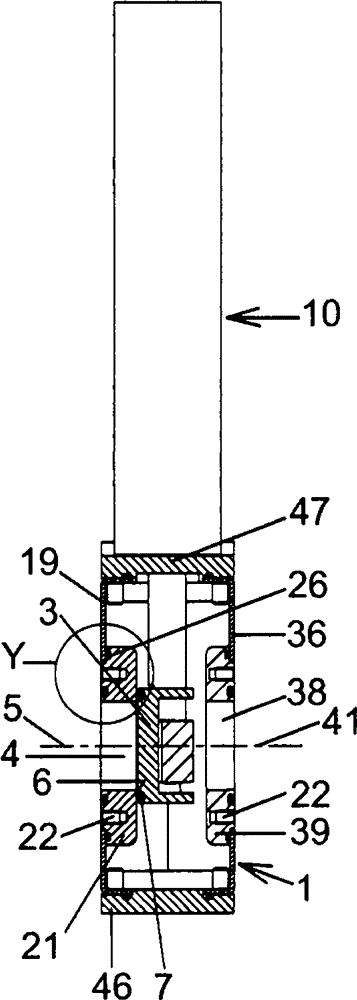

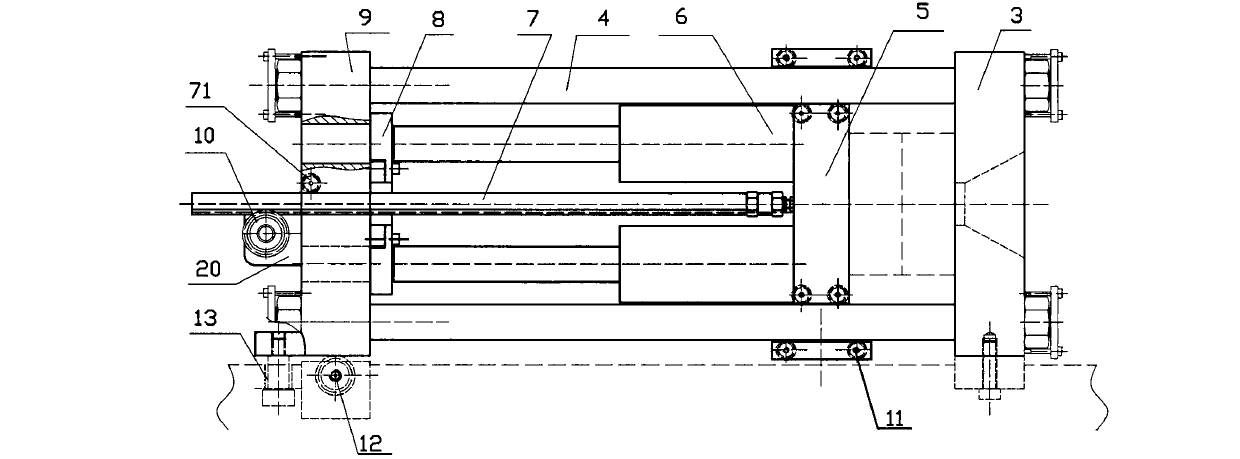

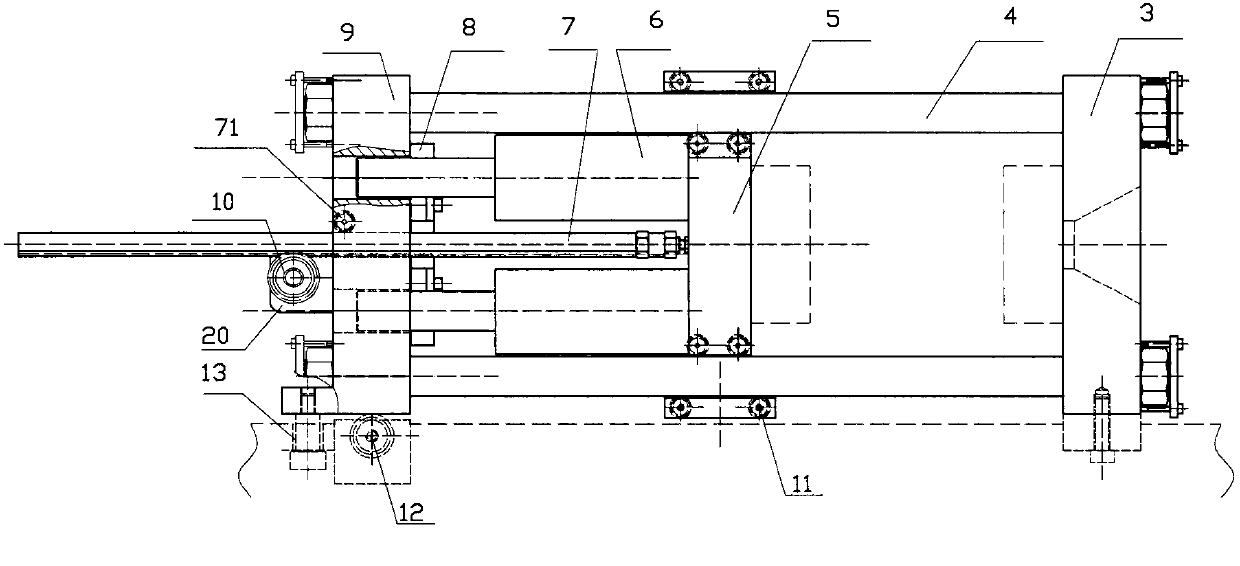

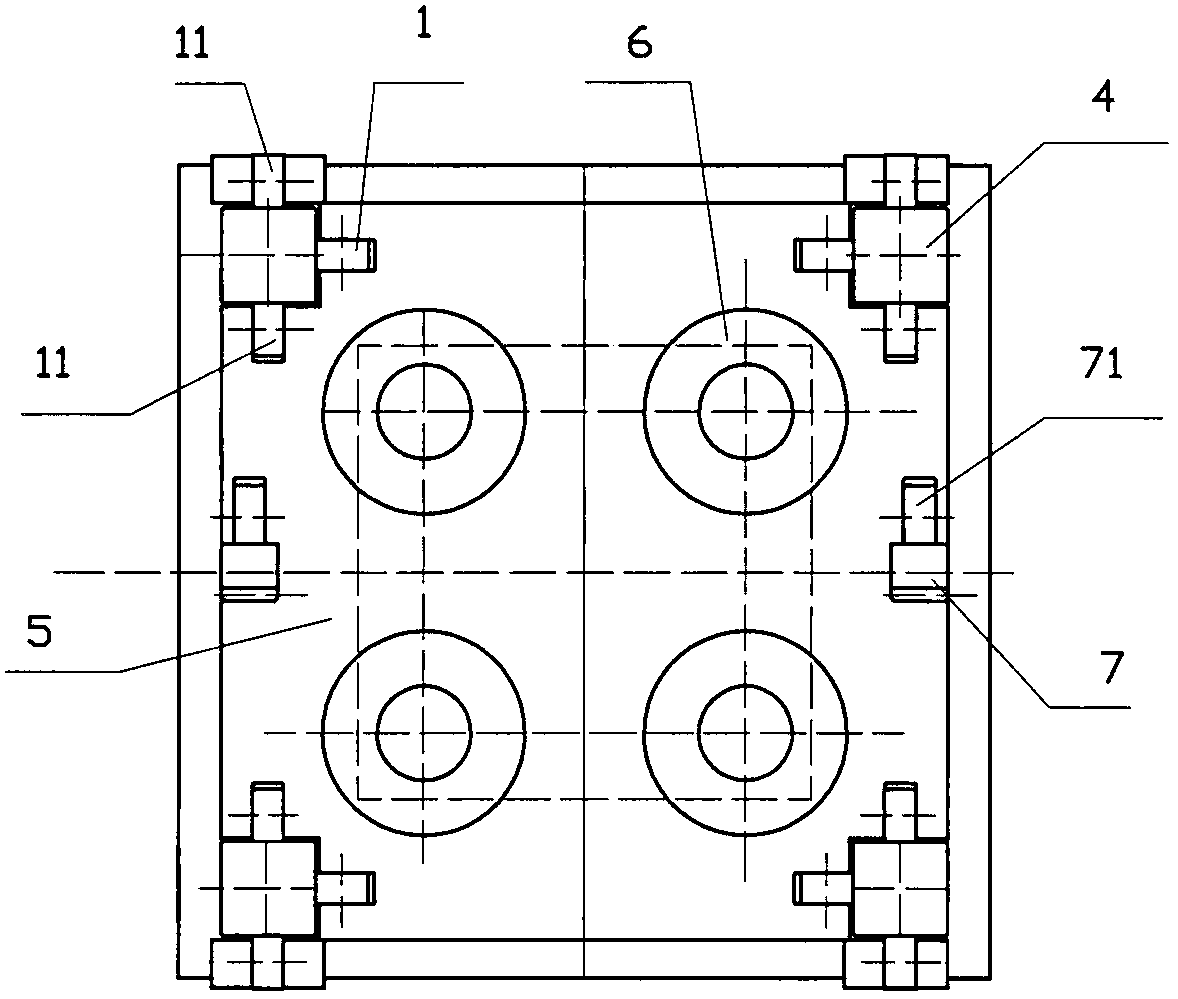

Method for utilizing rolling friction to centralize piston rod to do reciprocating motion and actuating device for utilizing rolling friction to centralize piston rod to do reciprocating motion through implementing method

InactiveCN103291683AReduce twistReduce friction lossFluid-pressure actuatorsReciprocating motionPressure.drive

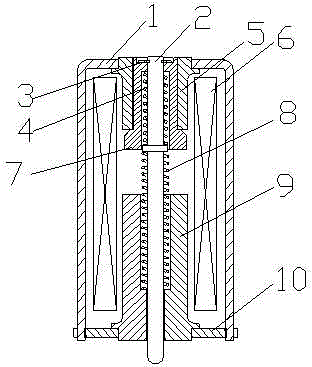

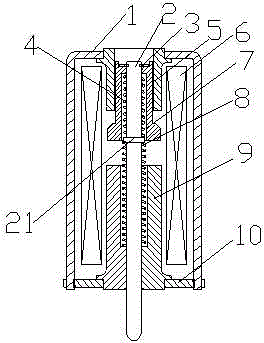

The invention belongs to the field of machinery, and relates to a hydraulic drive, gas drive or solid flowing pressure drive device and equipment, particularly to a method for utilizing rolling friction to centralize a piston rod to do reciprocating motion and an actuating device for utilizing rolling friction to centralize the piston rod to do reciprocating motion through implementing the method. The actuating device comprises a piston rod, a cylinder body, a controlling piece and a centralizer, wherein the piston rod comprises a piston and a cylinder rod; the centralizer comprises a guiding rolling element and a guiding rolling element supporting piece; the guiding rolling element is arranged between the guiding rolling element supporting piece and the cylinder rod; the controlling piece controls flow of liquid, gas or solid; the piston drives the cylinder rod to do reciprocating motion; and the guiding rolling element fits the guiding rolling element supporting piece and the cylinder rod to rotate and centralizes the motion direction of the cylinder rod through the rolling friction.

Owner:刘素华

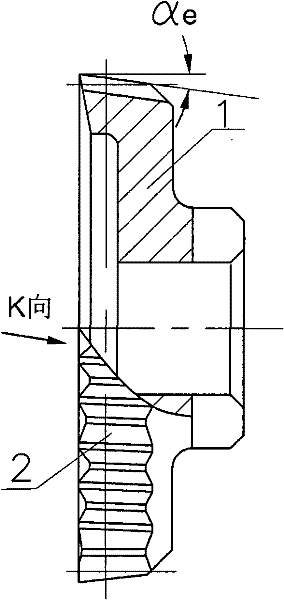

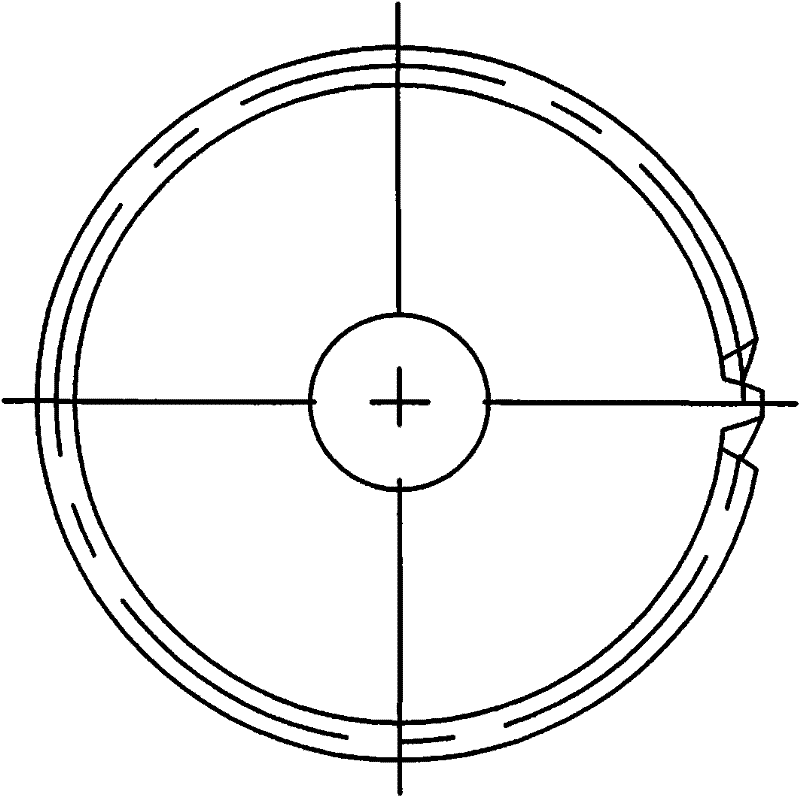

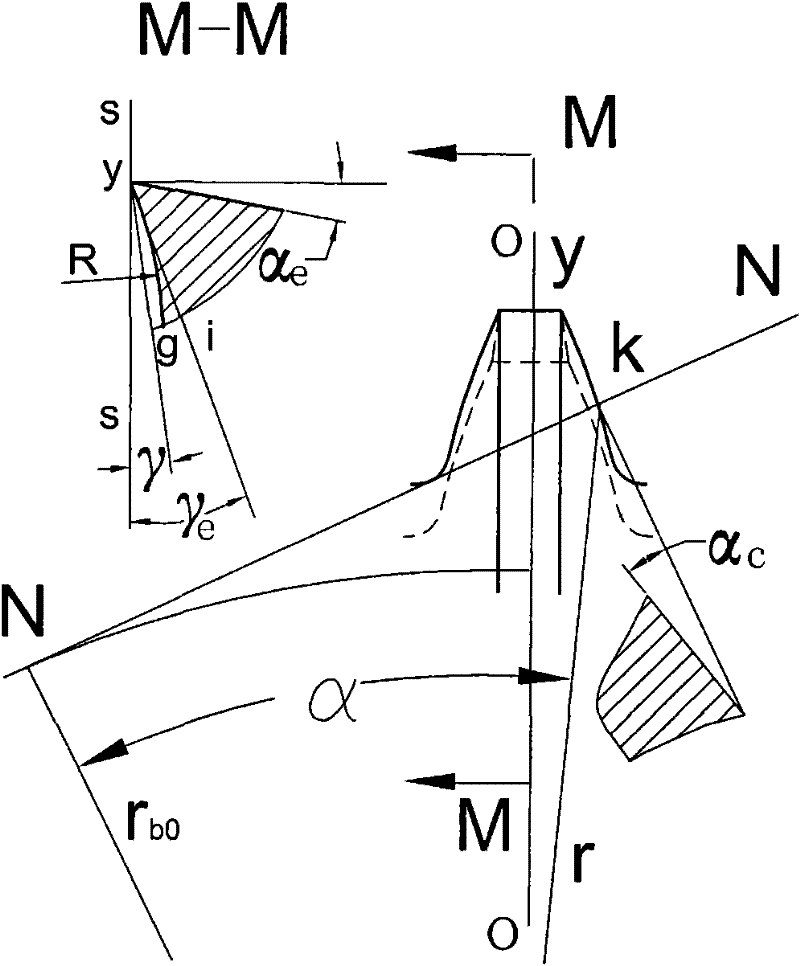

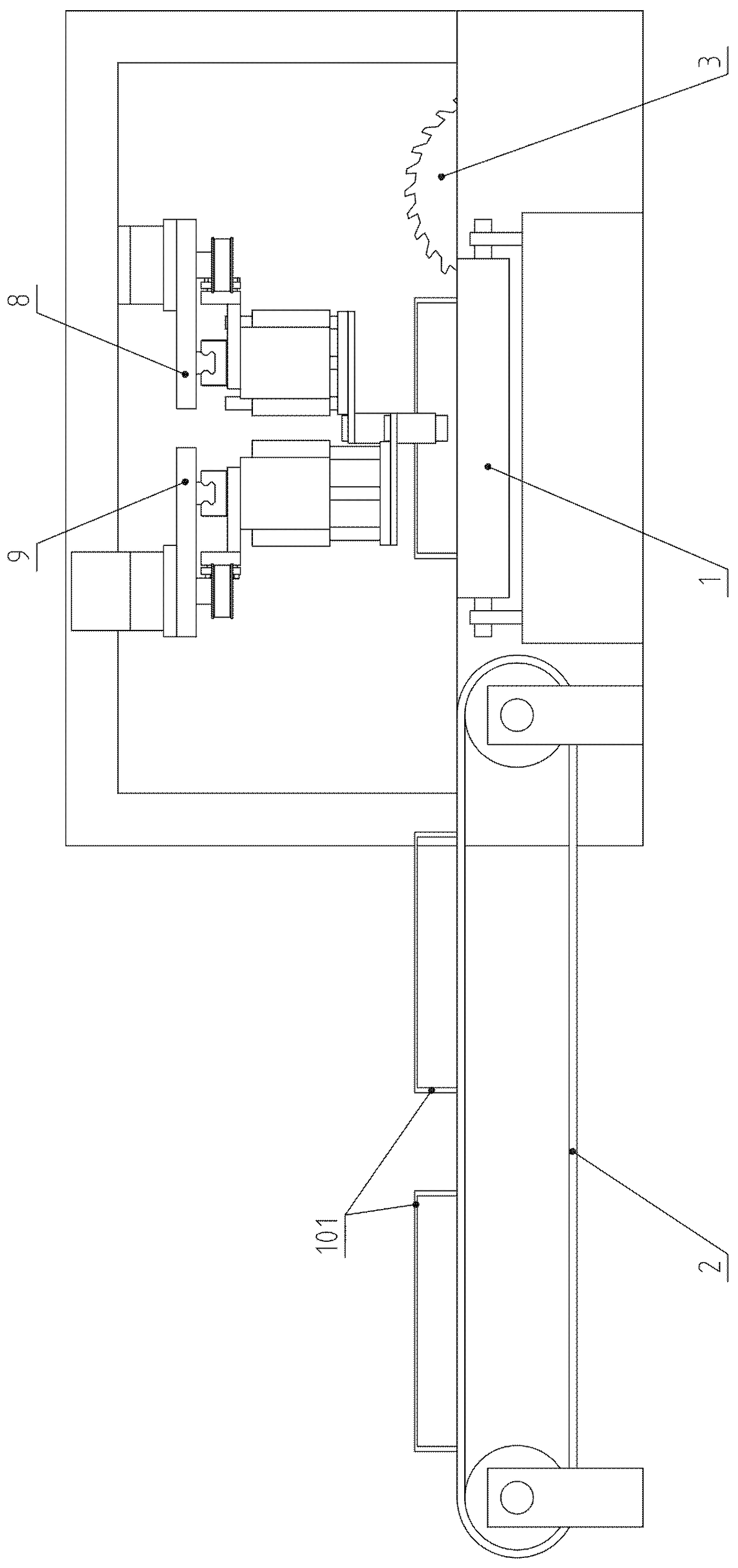

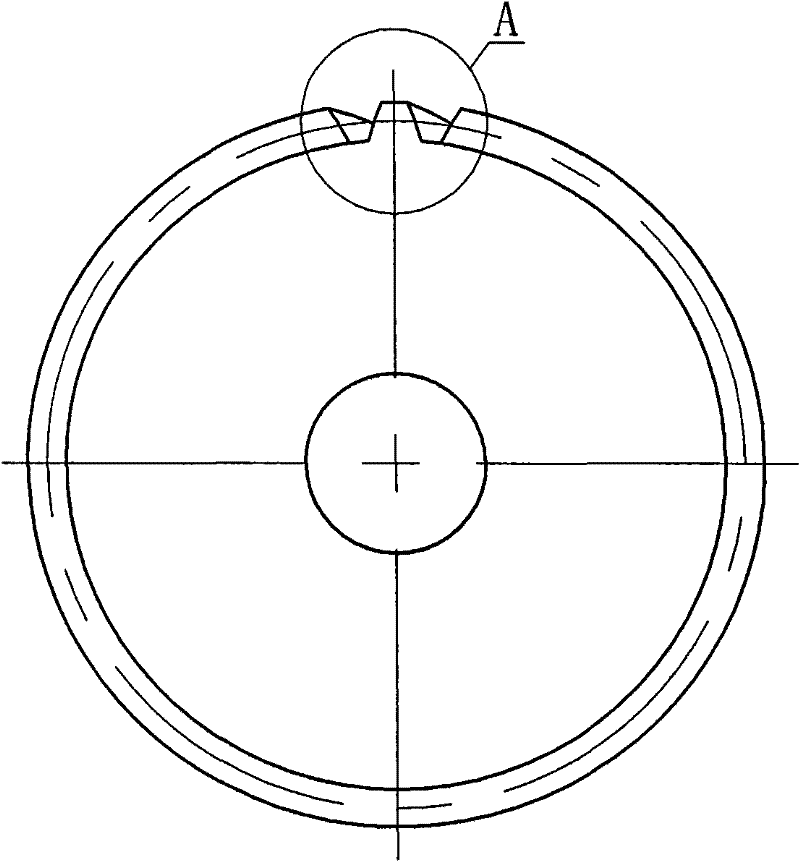

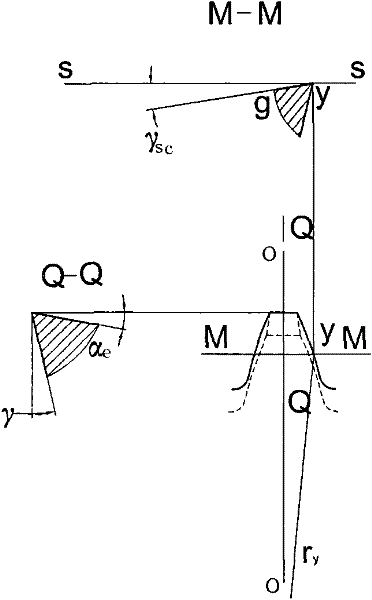

Double-side edge tooth cutting tool for cylindrical gear

InactiveCN102441712AReduce pollutionImprove efficiencyGear teeth manufacturing toolsGear teethEngineeringMiddle line

The invention discloses a double-side edge tooth cutting tool for a cylindrical gear. The double-side edge tooth cutting tool comprises a cutter tooth disc, wherein the cutter tooth disc is provided with a circle of cutter teeth having a conjugated tooth shape with a workpiece gear set; the normal modulus of the double-side edge tooth cutting tool for the cylindrical gear is identical with that of a workpiece; and the cutter teeth comprise a front angle gamma, a tooth top rear angle alpha e, a side-edge rear angle alpha c and a spiral angle. The double-side edge tooth cutting tool is characterized in that each cutter tooth is also provided with a side-edge front angle gamma sc; the side-edge front angle gamma sc is an intersection angle between an intersection line y1g1 of a plane M1-M1 and the front cutter surface of the cutter teeth and the normal plane S-S of the cutter teeth, wherein the plane M1-M1 passes any point y1 on the side edge of the cutter teeth, is tangent to a circle passing the point y1 on the cutter tooth disc and is simultaneously parallel to the axis of the cutter tooth disc; and the inclined directions of the side-edge front angles gamma sc corresponding to the toothed surfaces at two sides of each cutter tooth are opposite and inclined from the side edges of the cutter teeth to the midlines of the cutter teeth and the inside of a cutter body respectively. The double-side edge tooth cutting tool disclosed by the invention has reasonable cutting parameters in the processing process, optimized cutting states and formed favorable cutting precision and surface quality.

Owner:长沙机床有限责任公司 +1

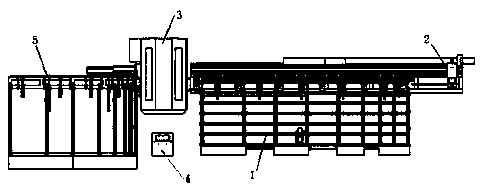

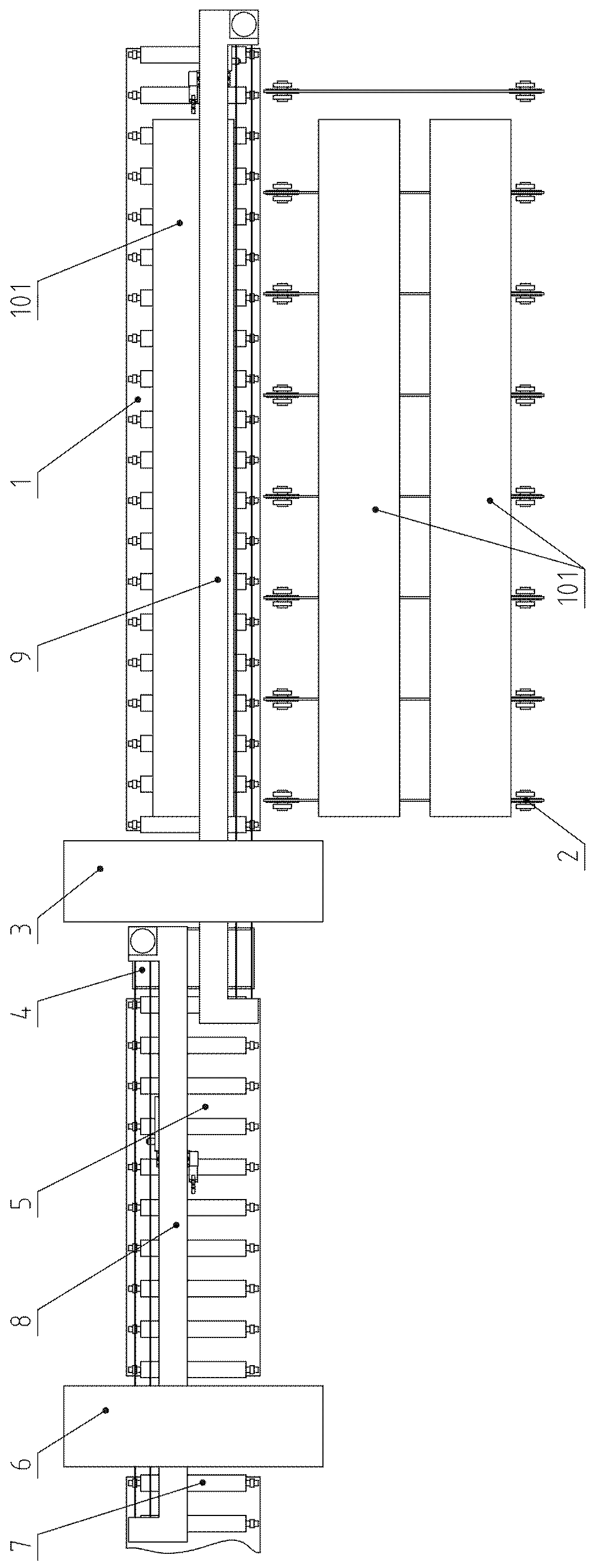

Machining center for automatically cutting single-branch door and window aluminum plastic profile at 45-degree angle

PendingCN110587023AReduce vibrationGuaranteed cutting stabilityMetal sawing devicesMetal working apparatusEngineeringMechanical engineering

The invention relates to a machining center for automatically cutting a single-branch door and window aluminum plastic profile at a 45-degree angle. The machining center comprises a console and a cutting mechanism; a cutting platform of the cutting mechanism is provided with two cutting openings which are arranged back and forth in the feeding direction and are perpendicular to the feeding direction; the cutting platform is provided with a first saw blade and a second saw blade, wherein the first saw blade and the second saw blade can perform reciprocating cutting movements in the cutting openings separately through cutting work-in assemblies; the cutting platform is provided with a tail material opening between the two cutting openings; a positioning plate used for limiting an aluminum plastic profile during cutting is vertically fixed on the cutting platform, and a pressing assembly guided through a guide rail and used for limiting the aluminum plastic profile during cutting is arranged between the positioning plate and the cutting platform; and the cutting platform is provided with a material-taking hand assembly for dragging a finished product after cutting out of the cutting mechanism in the discharging direction. The machining center is high in cutting precision, and functions of automatic feeding, automatic cutting, discharging, waste collecting and the like can be achieved.

Owner:JINAN SHITONG CNC MACHINERY CO LTD

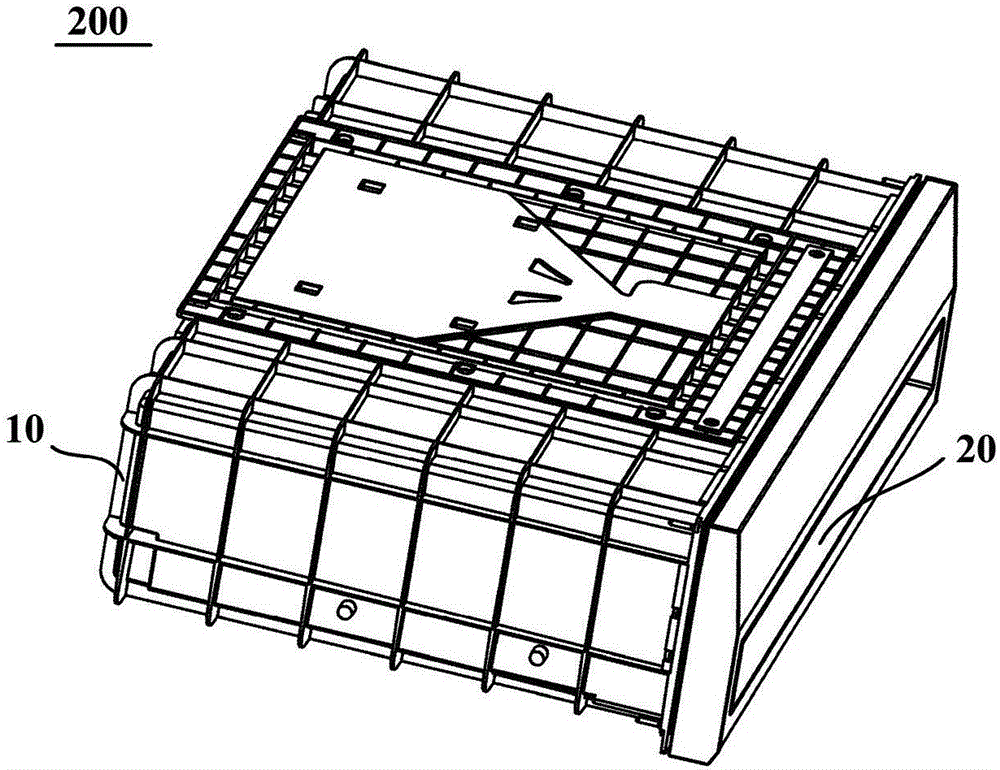

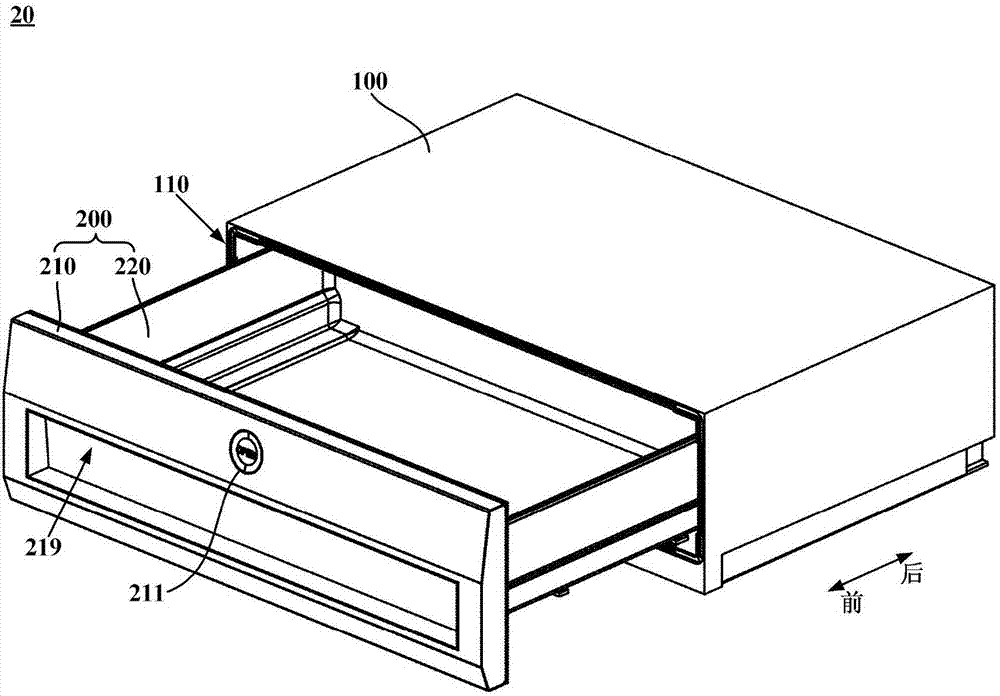

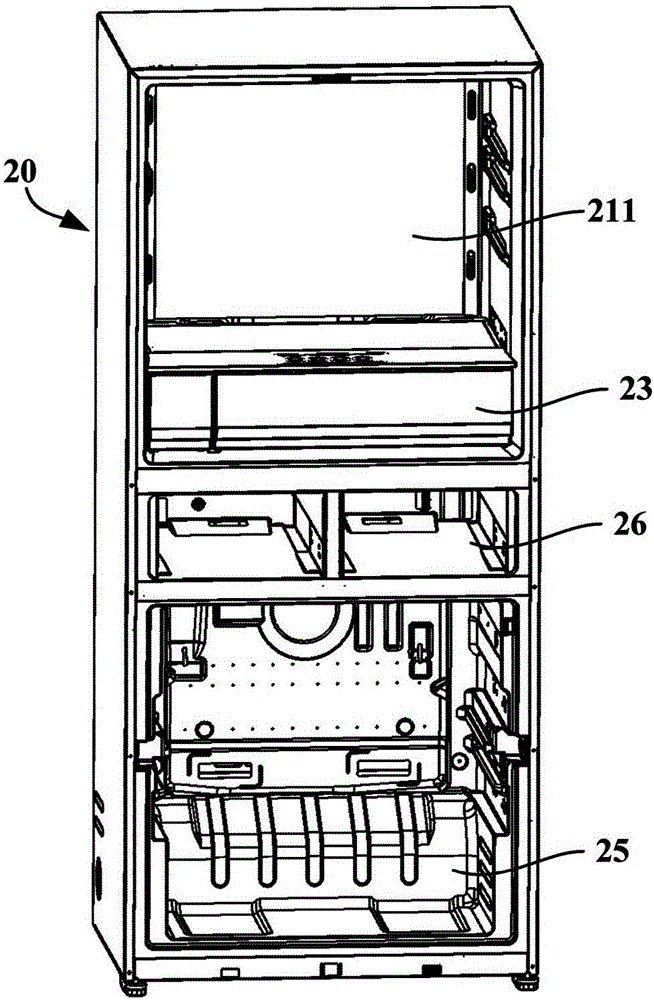

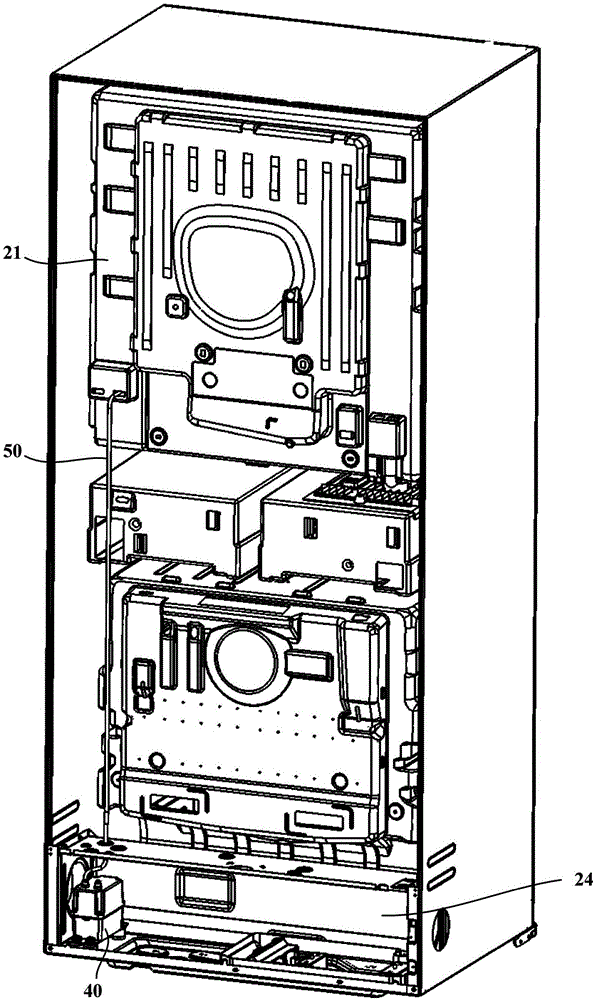

Drawer module and refrigerating and freezing device with drawer module

ActiveCN106766622AReduce the intensity of aerobic respirationReduce intensityLighting and heating apparatusDomestic refrigeratorsAnaerobic respirationNO storage

The invention relates to a drawer module and a refrigerating and freezing device with the drawer module. The drawer module comprises a cylinder and a controlled atmosphere membrane module, wherein drawer space is limited in the cylinder; an accommodating cavity is limited in the top wall of the cylinder, and is communicated with the drawer space; the controlled atmosphere membrane module is mounted in the accommodating cavity, and has a controlled atmosphere membrane and an oxygen-enriched gas collecting cavity; and the controlled atmosphere membrane module is configured to enable more oxygen in the accommodating cavity to enter the oxygen-enriched gas collecting cavity through the controlled atmosphere membrane compared with nitrogen in the accommodating cavity. The drawer module can form rich nitrogen and lean oxygen in the drawer space to facilitate a gas atmosphere for food preservation, reduces the aerobic respiration strength of fruits and vegetables, and meanwhile, guarantees basic breathing effect to prevent anaerobic respiration of the fruits and the vegetables so as to achieve the purpose of long-time preservation of the fruits and the vegetables. The drawer module occupies no storage space, and can prevent collision from damaging the controlled atmosphere membrane module.

Owner:HAIER SMART HOME CO LTD

One-way damping hinge device and method for controlling passive vibration of structure by using same

ActiveCN109826480AImproved Vibration Control EfficiencySmooth transmissionProtective buildings/sheltersShock proofingVibration controlControl theory

The invention discloses a one-way damping hinge device, which comprises an upper connecting support, a lower connecting support and a hinge shaft, wherein the hinge shaft is fixedly connected with theupper connecting support; the hinge shaft is rotatably connected with the lower connecting support; a gear rack transmission mechanism, a damper mounting frame and a U-shaped transmission curved rodwhich is fixedly connected with an input rod of a damper are arranged on the lower connecting support; the gear rack transmission mechanism comprises a driving gear and a driven gear rack which are meshed with each other; the driving gear is fixedly connected with the hinge shaft; the driven gear rack is fixedly connected with the U-shaped transmission curved rod; and rollers are arranged betweenthe damper mounting frame and the U-shaped transmission curved rod. In addition, the invention also provides a method for controlling passive vibration of a structure by using the one-way damping hinge device. According to the one-way damping hinge device, the gear transmission principle is utilized, so that the capability of the building structure to resist vibration load can be effectively improved, the vibration control efficiency of the building structure is improved, and a new and effective method is provided for the vibration control of the structure in the field of civil engineering.

Owner:CHANGAN UNIV

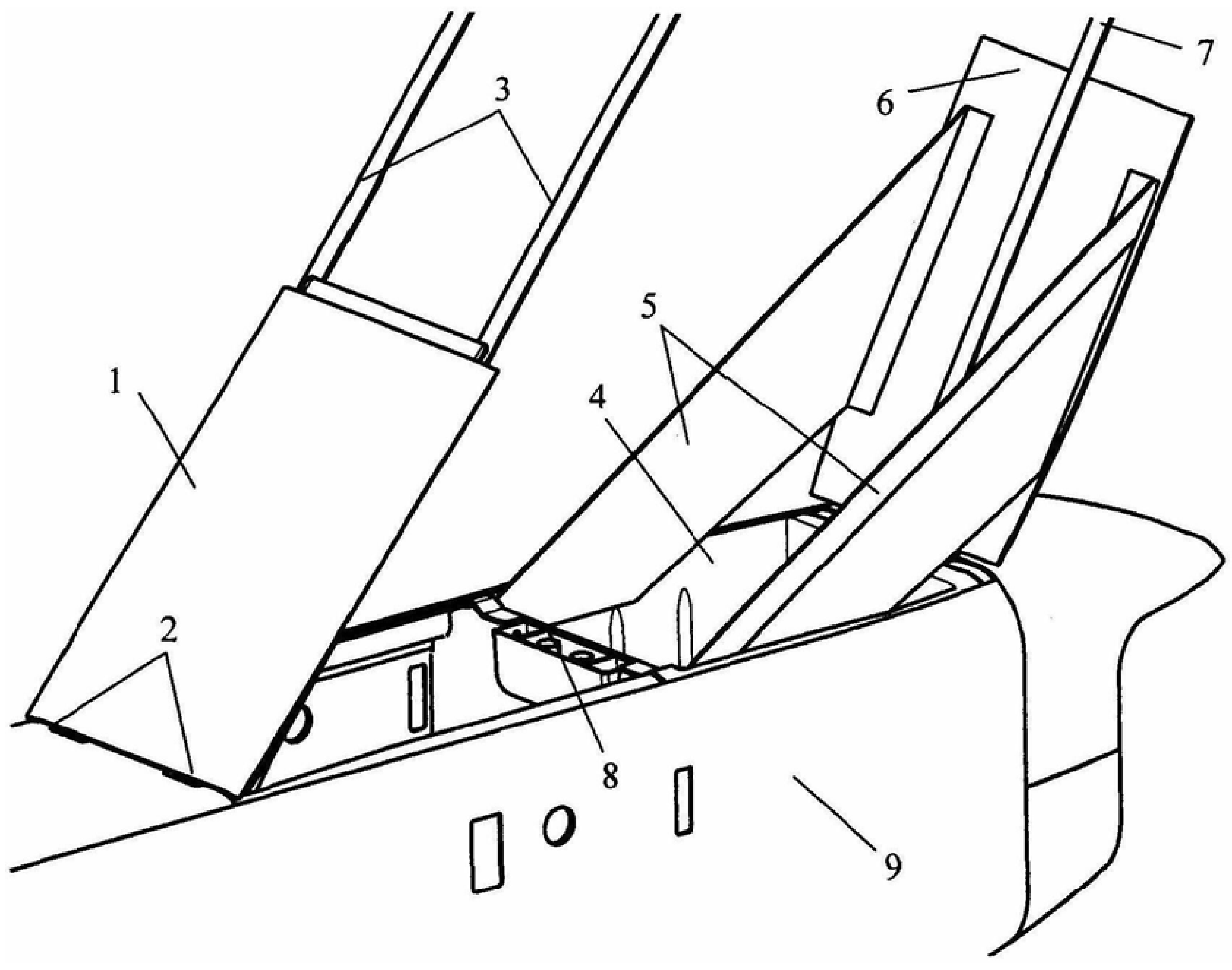

Small UAV canopy

The invention discloses an umbrella hatch cover of a small unmanned aerial vehicle parachute recovery system. The umbrella canopy is composed of a front cover of the umbrella canopy and a rear cover of the umbrella canopy. The open double umbrella canopy makes the front and rear umbrella hanger joints all placed inside the fuselage, and the rear cover of the umbrella canopy uses a limit cloth to limit the opening angle and reduce the flight resistance. The split double umbrella canopy reduces the rigidity requirements for the umbrella canopy. The umbrella canopy is made of carbon fiber composite material with a honeycomb sandwich structure, which can reduce the weight by 60% compared with the aluminum alloy canopy canopy.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

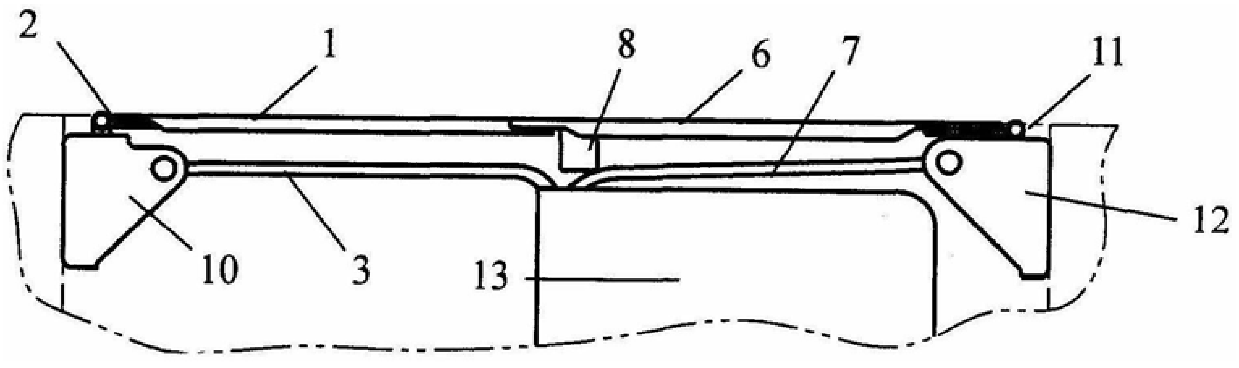

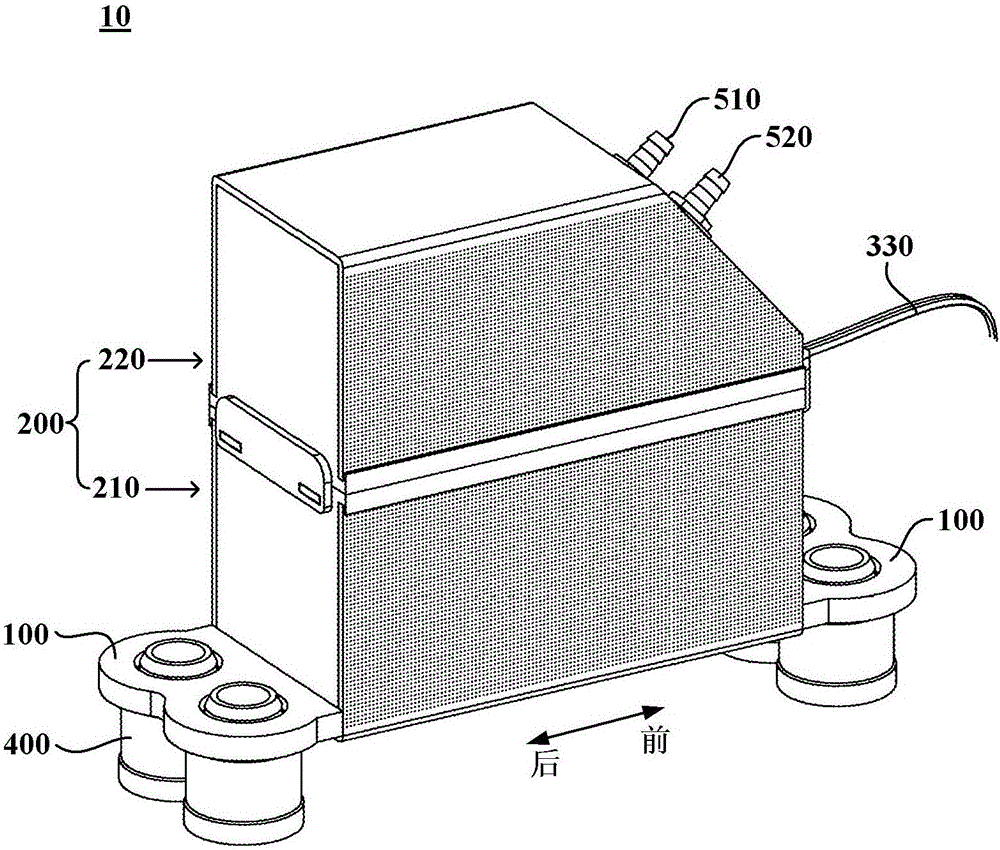

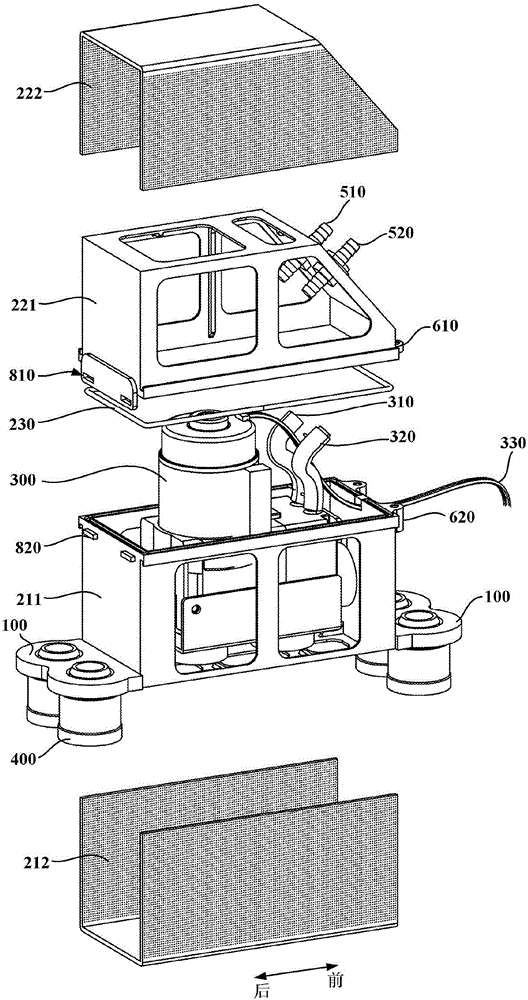

Refrigerator and drawer assembly thereof

ActiveCN107062781AAvoid interfering with tanglesImprove protectionLighting and heating apparatusDomestic refrigeratorsIceboxCoil spring

The invention provides a refrigerator and a drawer assembly thereof. The drawer assembly for the refrigerator comprises a box provided with a forward opening, a drawer arranged in the box in a front-back push-pull manner and provided with a front end plate used for sealing the forward opening, and a transmission cable assembly. The transmission cable assembly comprises a wiring rod and a spiral spring cable, wherein the front end of the wiring rod is fixedly connected to the rear surface of the front end plate and arranged in the front-back direction, the spiral spring cable is arranged on the wiring rod in a sleeving manner, the end portion of the spiral spring cable is fixedly connected to the front end plate so that electric power or signals can be transmitted to a power utilization component on the front end plate, and the spiral spring cable is arranged to be subjected to elastic and telescopic deformation along with front-back movement of the front end plate.

Owner:HAIER SMART HOME CO LTD

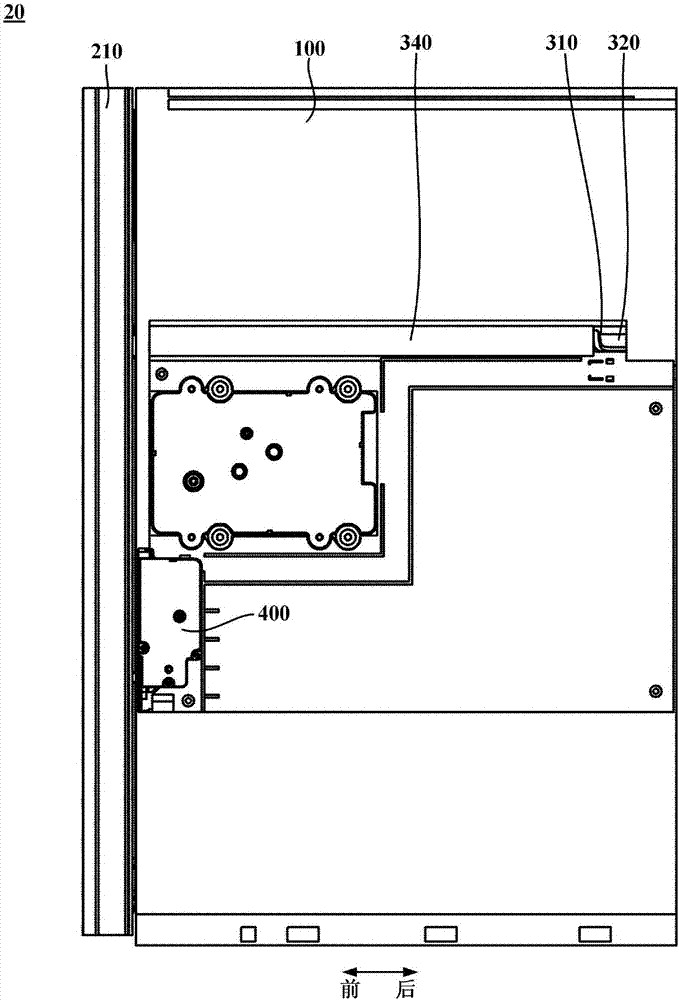

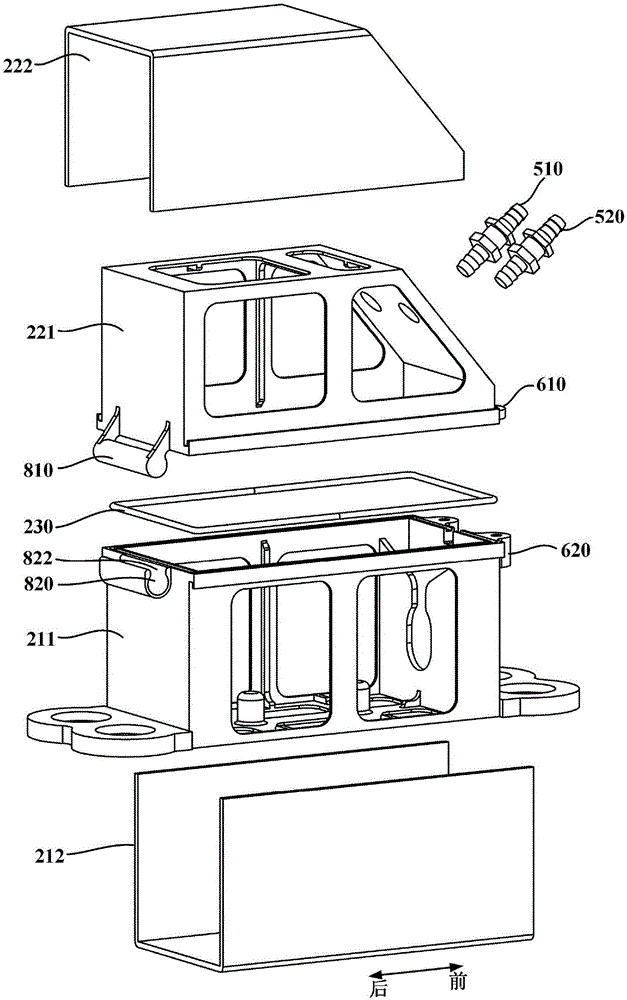

Gas suction pump assembly and cold storage and freezing device

ActiveCN106593819AReduce outward spreadImprove sound absorptionPositive displacement pump componentsLighting and heating apparatusAir pumpEngineering

The invention relates to a gas suction pump assembly and a cold storage and freezing device. The gas suction pump assembly comprises an installing box and a gas suction pump; a containing space is defined in the installing box; at least part of the box wall of the installing box is made from a micro-porous silencing plate; the surface of the micro-porous silencing plate is provided with a plurality of silencing through holes; the gas suction pump is arranged in the installing box; and the micro-porous silencing plate is arranged to absorb noise generated by the gas suction pump when the gas suction pump runs. By means of the micro-porous silencing plate, the gas suction pump assembly reduces outward spreading of the noise when the gas suction pump runs.

Owner:HAIER SMART HOME CO LTD

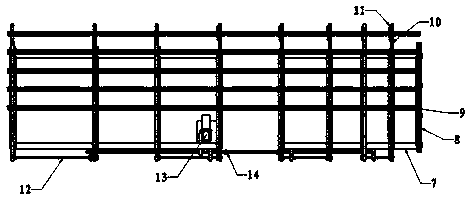

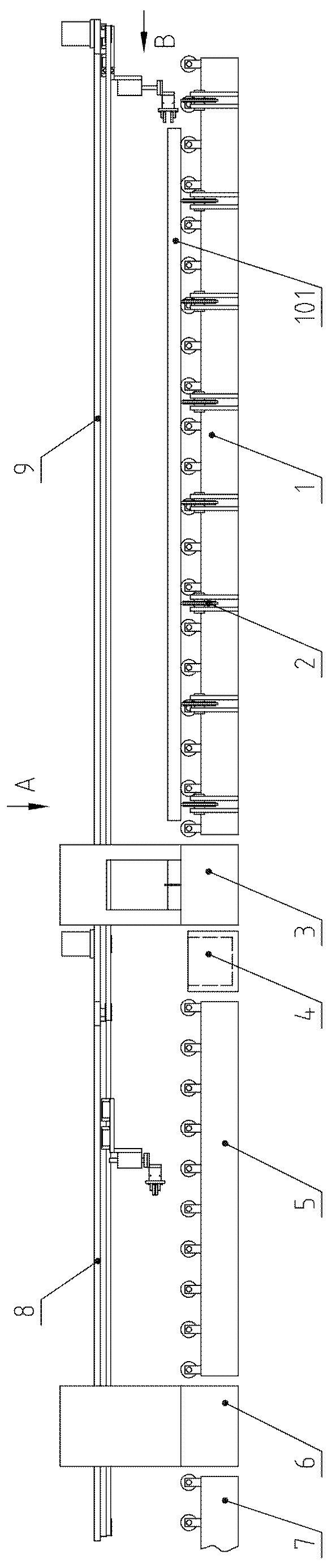

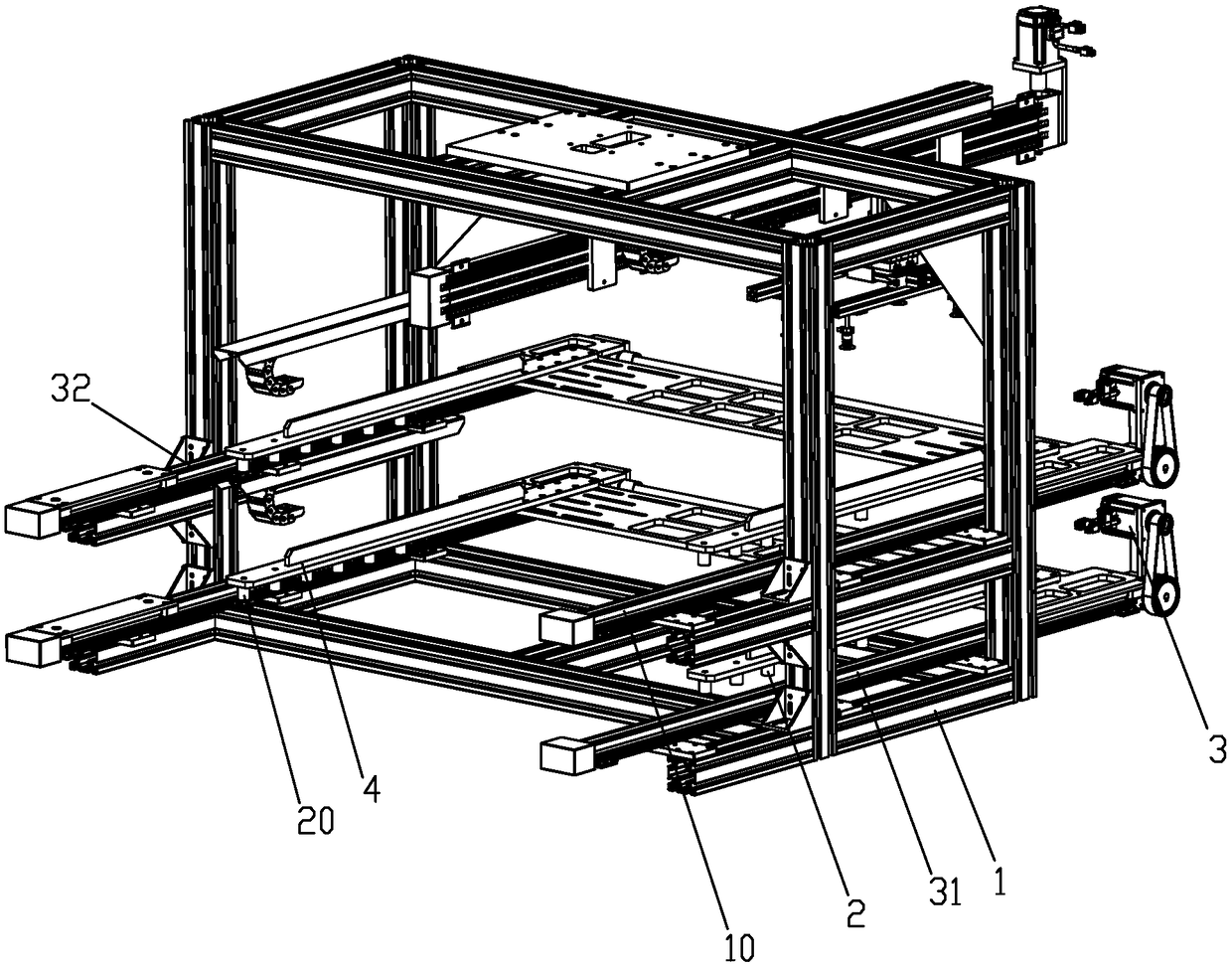

Material delivery mechanism of aluminum template automatic blanking production line

InactiveCN108857449AReduce production processLower manufacturing requirementsOther manufacturing equipments/toolsMetal working apparatusProduction linePunch press

The invention belongs to the technical field of aluminum template manufacturing equipment and relates to blanking equipment of aluminum template blank materials and specifically relates to a materialdelivery mechanism of an aluminum template automatic blanking production line. a drive device I is electrified to rotate to drive a translation component I to translate forward along a linear guide rail; a guide rod type lifting air cylinder I drives a pneumatic finger I to descend; the pneumatic finger I clamps an aluminum template blank. A drive device II is electrified to rotate to dive a translation component II to translate forward along a linear guide rail II; a guide rod type lifting air cylinder II drives a pneumatic finger II to descend; the pneumatic finger II clamps an aluminum template. A sawing machine feeder and a punching machine feeder can realize relay delivery. The material delivery mechanism provided by the invention has the following beneficial effects: the delivery mechanism is remarkably simplified, and requirements on the manufacturing technology and machining accuracy are lowered while the feeding accuracy still can reach the using requirements and the manufacturing cost of the whole equipment is substantially reduced.

Owner:杜宗英

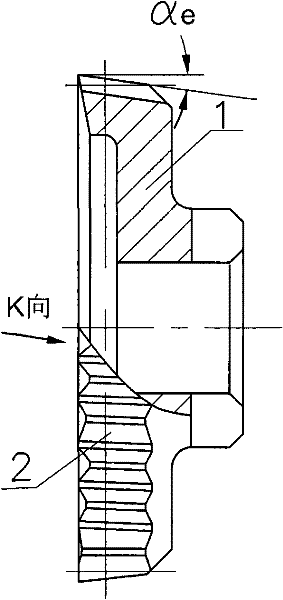

Single-side edge tooth cutting tool for cylindrical gear

InactiveCN102441711AReduce pollutionImprove efficiencyGear teeth manufacturing toolsGear teethEngineeringMiddle line

The invention discloses a single-side edge tooth cutting tool for a cylindrical gear. The edge tooth cutting tool for a cylindrical gear comprises a cutter tooth disc, wherein the cutter tooth disc is provided with a circle of cutter teeth having a conjugated tooth shape with a workpiece gear set; the normal modulus of the single-side edge tooth cutting tool for the cylindrical gear is identical with that of a workpiece; the cutter teeth comprise a front angle gamma, a tooth top rear angle alpha e, a side-edge rear angle alpha c and a spiral angle; each cutter tooth is also provided with a side-edge front angle gamma sc; the side-edge front angle gamma sc is an intersection angle between an intersection line gy of a plane M-M of and a front cutter surface of the cutter teeth and a normal plane S-S of the cutter tooth disc, wherein the plane M-M passes any point y on the side edge of a cutter outline of the cutter teeth, is perpendicular to a midline o-o of a front cutter surface of the cutter teeth and is parallel to the axis of the cutter tooth disc; and the inclined directions of the side-edge front angles gamma sc on two adjacent cutter teeth are symmetrically distributed with the midlines of the two cutter teeth as the axes. The single-side edge tooth cutting tool disclosed by the invention has reasonable cutting parameters in the processing process, optimized cutting states and formed favorable cutting precision and surface quality.

Owner:长沙机床有限责任公司 +1

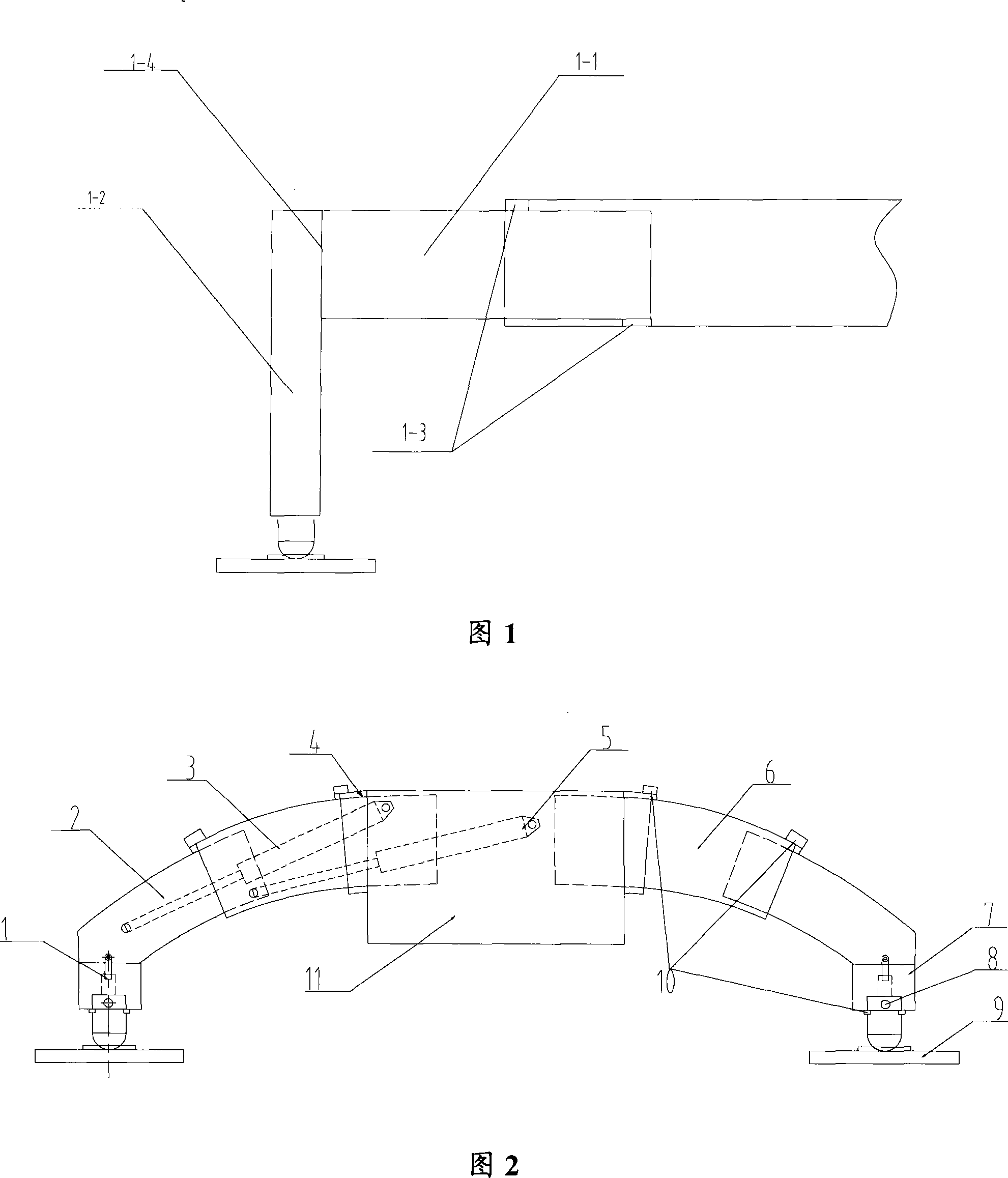

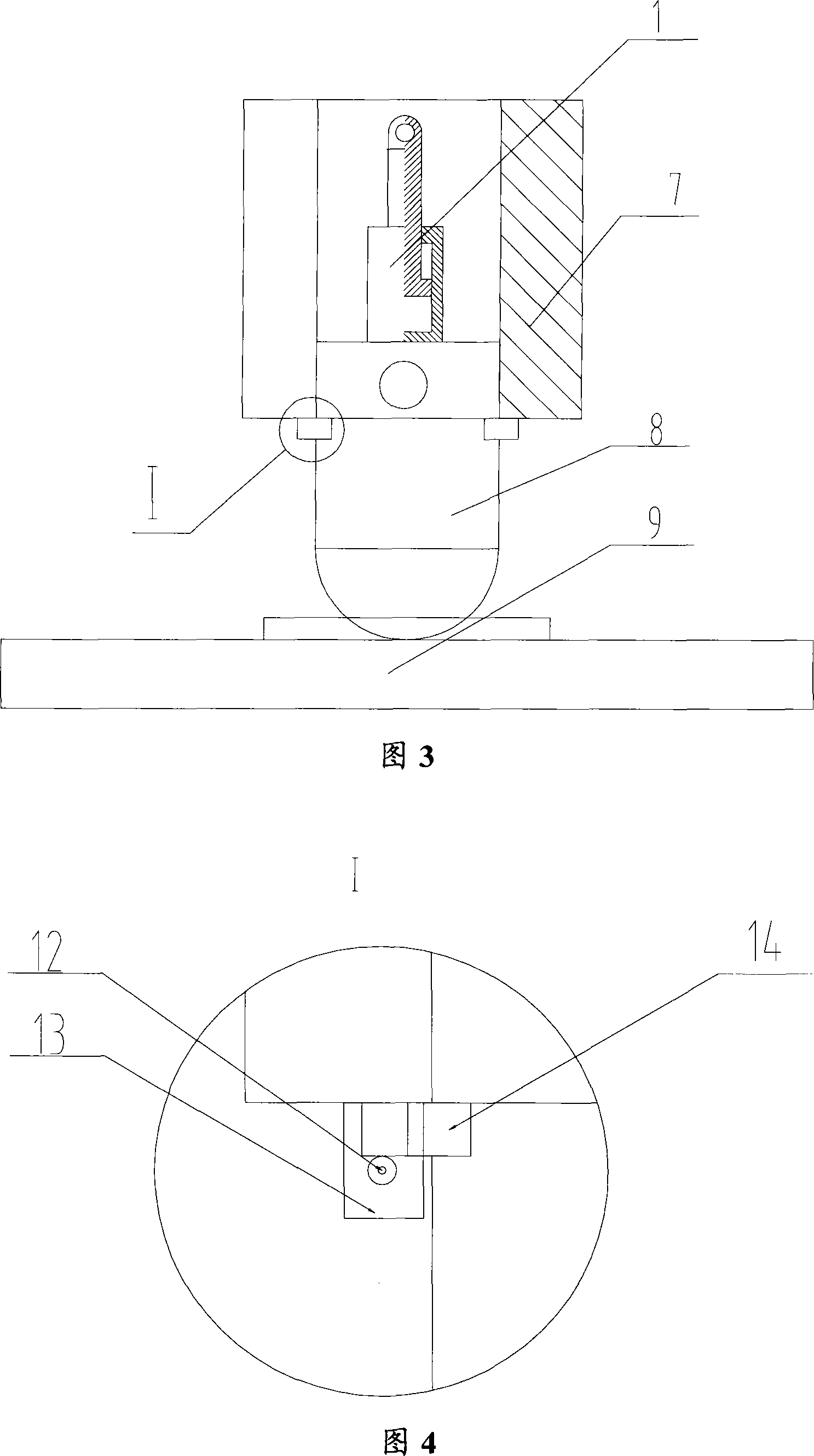

Movable hoisting device supporting leg and movable hoisting device with the supporting leg

InactiveCN101219757AReduce saggingAvoid vertical stress concentrationCranesIndustrial engineeringLifting equipment

Owner:SANY AUTOMOBILE HOISTING MACHINERY

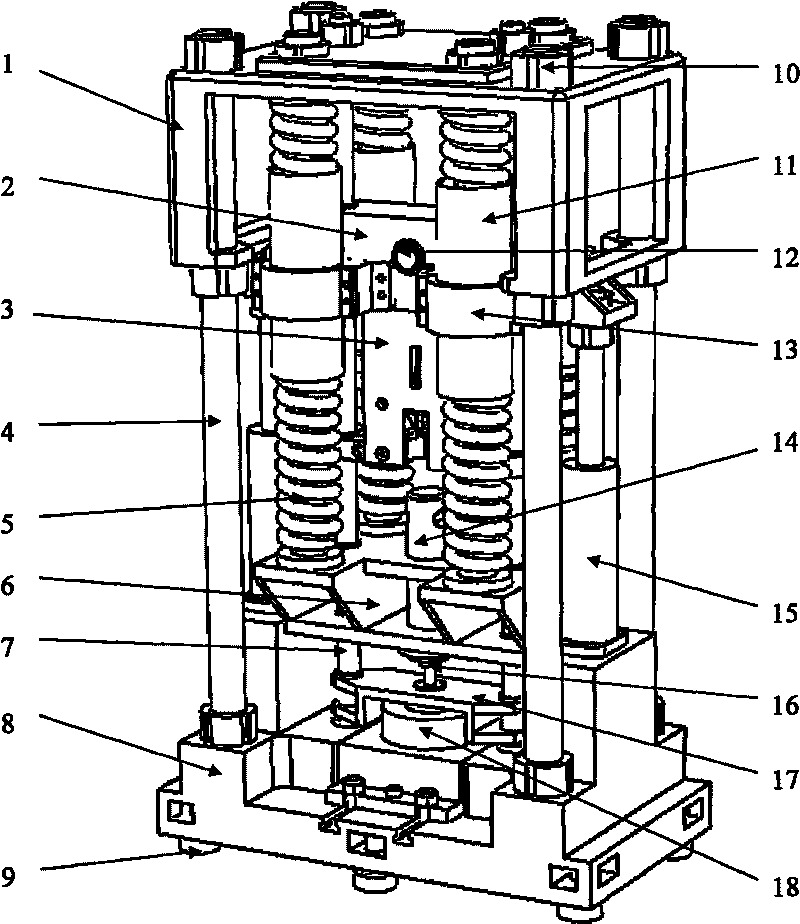

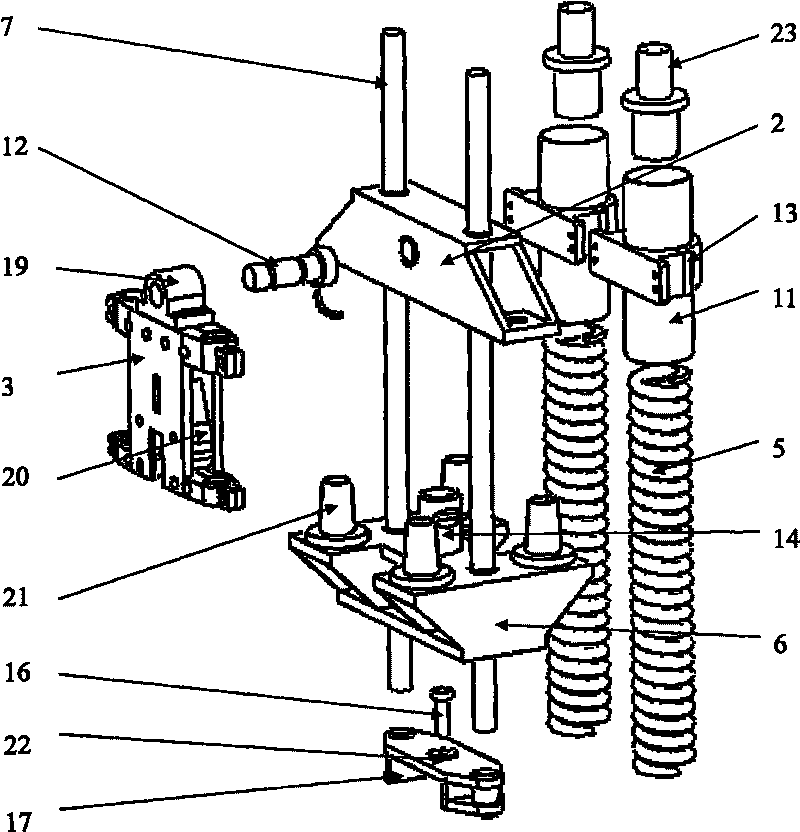

Press for high-speed pressing of powder metallurgy on basis of mechanical spring energy storage

The invention discloses a press for high-speed pressing of powder metallurgy on the basis of mechanical spring energy storage. The press comprises a press body frame, a heavy hammer lifting mechanism, a heavy hammer impact mechanism, a hammer handle locking and releasing mechanism, a mechanical spring, a suspension part thereof, a spring sleeve, a fastener thereof, an upper die punching and supporting table and a power mechanism, wherein the heavy hammer lifting mechanism sliding along a straight line, the hammer handle locking and releasing mechanism, the heavy hammer impact mechanism and the upper die punching and supporting table are successively connected on a guide rod in series; in the direction vertical to the guide rod, two ends of a shaft pin type sensor pass through and are clamped into the through holes of a suspension part frame; and the middle part passes through to be clamped in a hanger through hole. The high-speed press for powder metallurgy of the invention is suitable for producing powder metallurgy high-speed pressing parts with smaller volume, has small volume, small weight, simple structure, convenient assembly and reliable performance, overcomes the problems of complex structure and high manufacturing cost of the existing hydraulic high-speed pressing equipment, and is easy to popularize and apply in the powder metallurgy industry.

Owner:SOUTH CHINA UNIV OF TECH

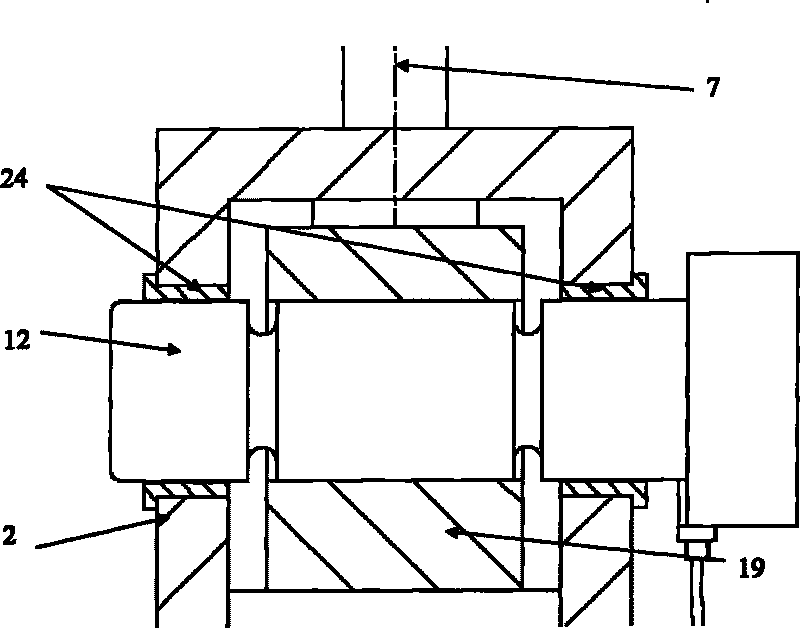

Electromagnet with buffer structure

ActiveCN104485195AReduce rigidity requirementsMiniaturizationElectromagnets with armaturesDriving currentMiniaturization

The invention relates to an electromagnet with a buffer structure. The electromagnet comprises a magnetic yoke, a static end magnetic pole, a coil, a jacking rod and a movable end magnetic pole, wherein the movable end magnetic pole is glidingly arranged in a center hole of the movable end magnetic yoke, one end, facing the static end magnetic pole, of the jacking rod extends through the center hole of the static end magnetic pole and then extends out to be used as a thrust output end, and in addition, a reset spring acts between the jacking rod and the static end magnetic pole. The electromagnet is characterized in that one end, facing the movable end magnetic yoke, of the jacking rod extends to pass through the inner hole of the movable end magnetic pole, a buffer spring also acts between the jacking rod and the movable end magnetic pole, and the jacking rod moves towards the static end magnetic pole side relative to the movable end magnetic pole through the elasticity of the buffer spring, so that a blocking part is matched with the movable end magnetic pole. The electromagnet has the advantages that under the condition of the same requirements, the rigidity requirement on the electromagnet per se is relatively reduced, the miniaturization of the electromagnet is favorably realized, in addition, the driving current is small, and the energy is saved.

Owner:CHANGSHU SWITCHGEAR MFG CO LTD (FORMER CHANGSHU SWITCHGEAR PLANT)

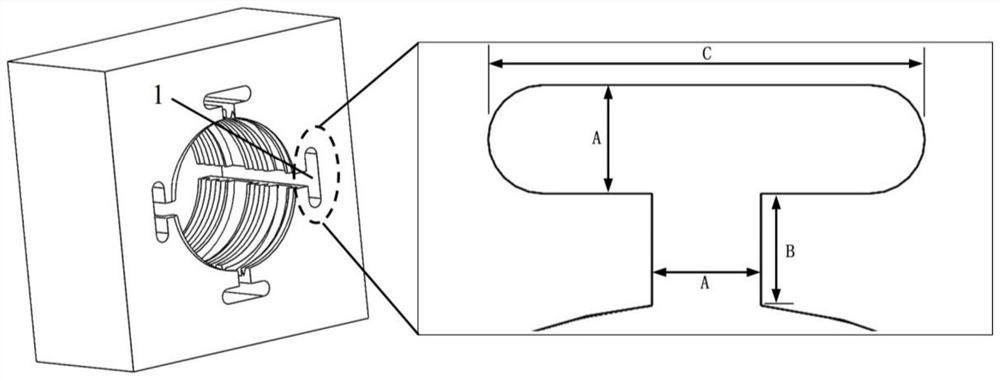

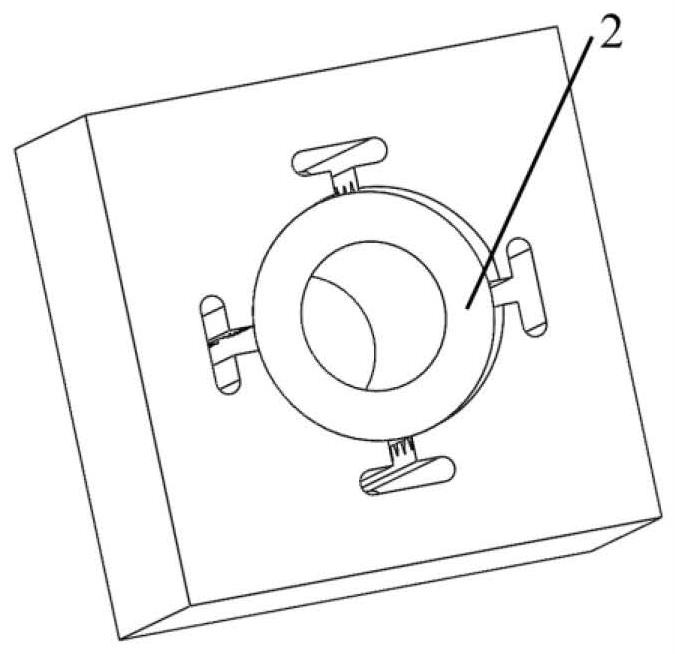

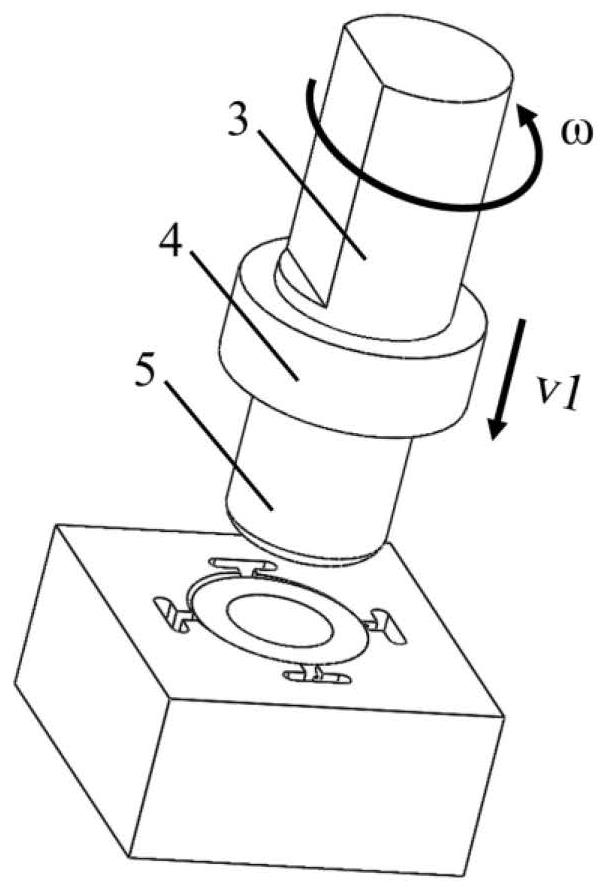

Electrolyte pulse type electrolytic machining device and method

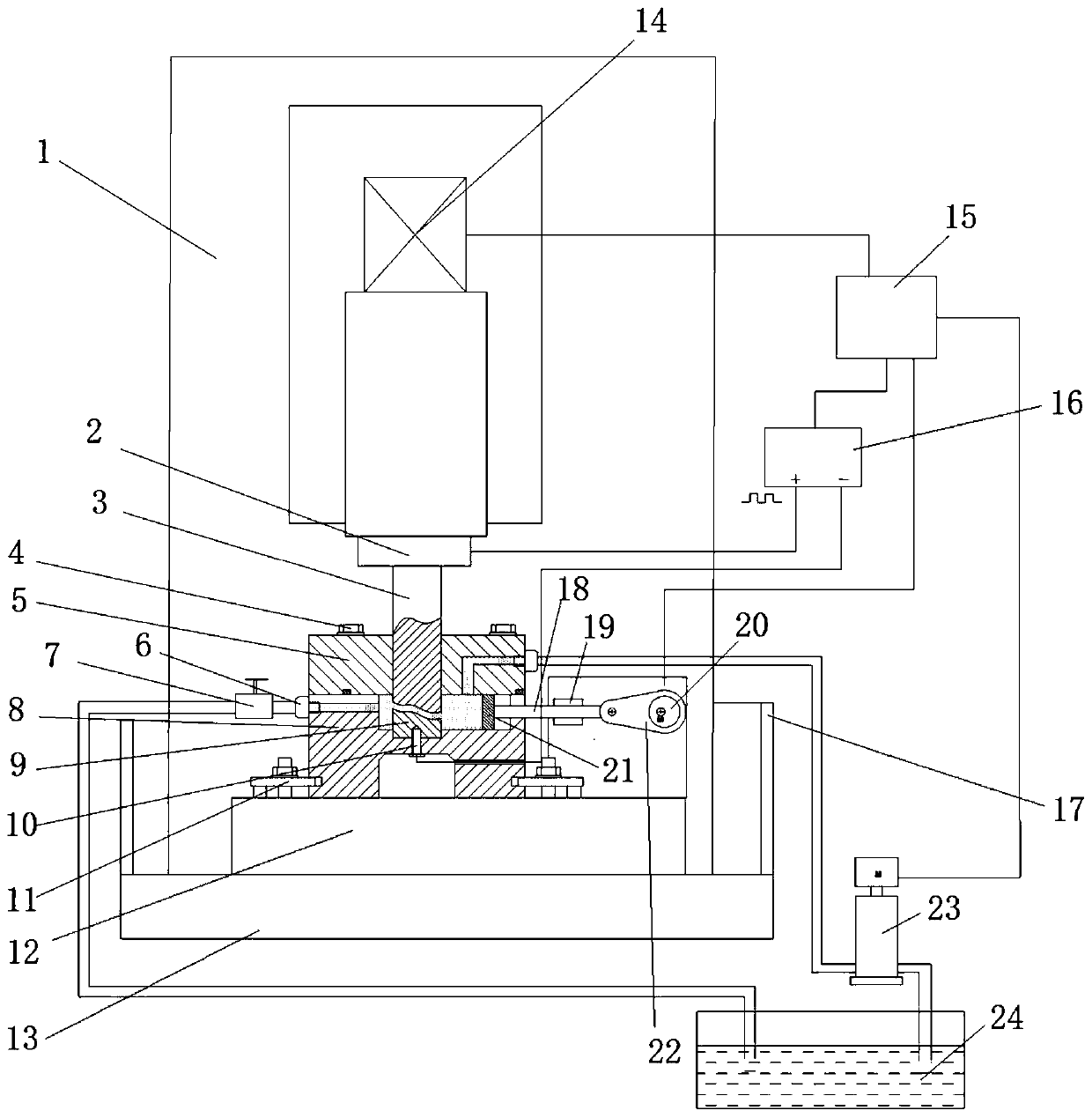

ActiveCN111185641AAmplitude position is not requiredReduce rigidity requirementsMachining working media supply/regenerationElectrical-based auxillary apparatusElectrolytic agentControl system

The invention discloses an electrolyte pulse type electrolytic machining device and method. The electrolyte pulse type electrolytic machining device comprises a Z-axis feeding system, an eccentric camvibration mechanism, a control system, an electrolytic machining power source and an electrolyte supply system; the eccentric cam vibration mechanism comprises a motor, an eccentric cam, a connectingrod, a guide rail, a piston rod and a piston, the motor is connected with the eccentric cam, the connecting rod movably sleeves the eccentric cam, and the piston rod transversely runs along the guiderail under the action of the connecting rod to push the piston to push the electrolyte from one side of a machining gap to the other side; and the electrolyte makes pulsating motion under the assistance of the eccentric cam vibration mechanism, and when a workpiece anode gets close to a workpiece cathode and the machining gap is small enough, under the action of an electric field and a flow field, the anode workpiece is electrochemically dissolved and machined to approximately copy the outline of the tool cathode. The requirements for the amplitude position of the vibration mechanism and therigidity of the mechanism are not high, the cost is reduced, small-gap machining in electrolytic machining can also be achieved, and in other words, high-precision electrolytic machining is achieved.

Owner:上海蓝长自动化科技有限公司

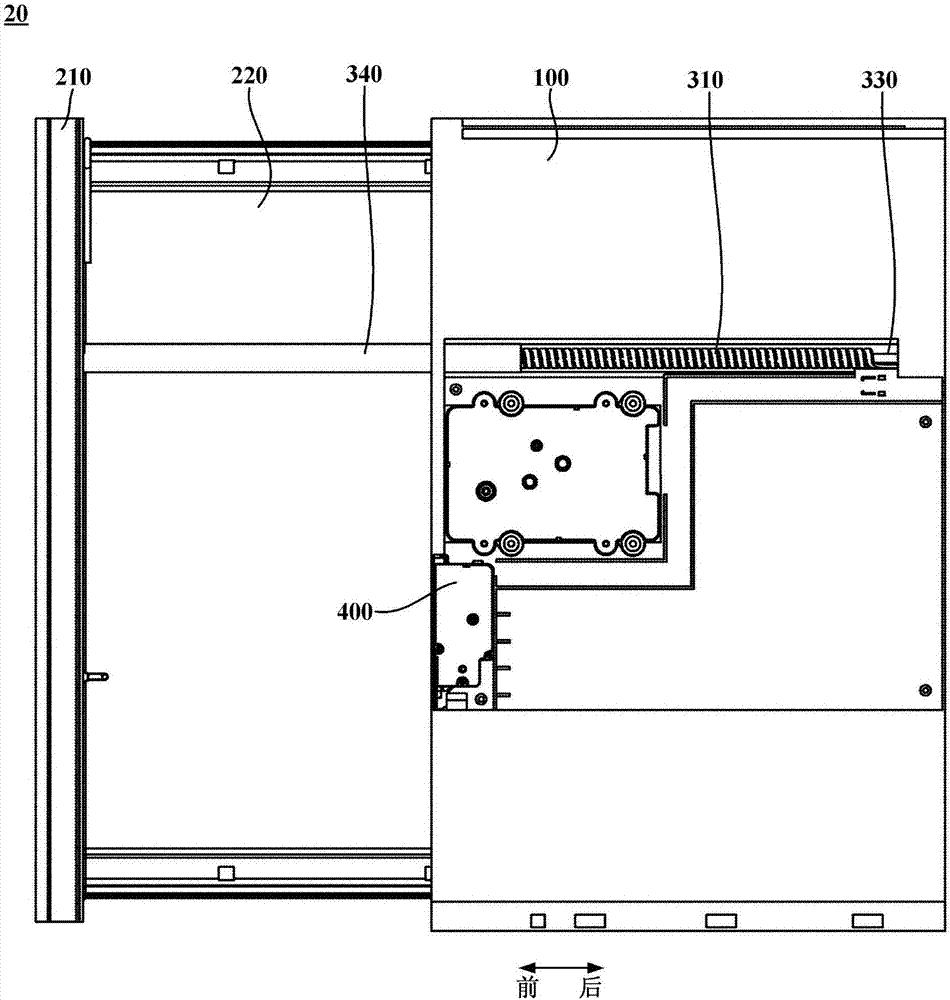

Air extracting pump assembly and refrigerating and freezing device

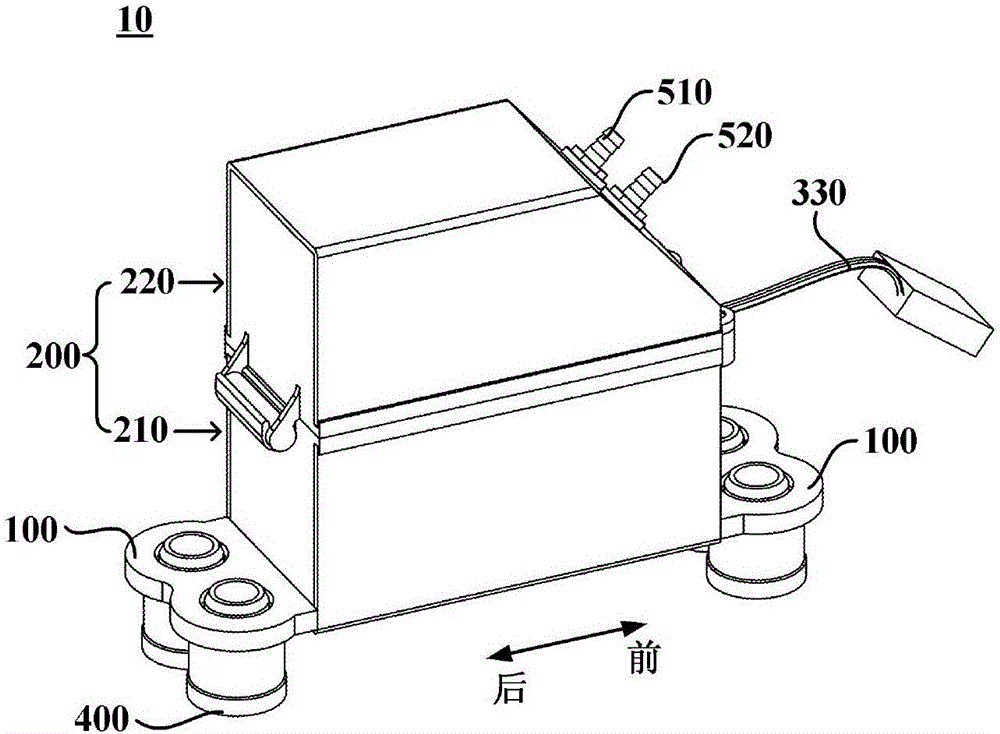

ActiveCN106593823AEasy to operateEasy to take outPositive displacement pump componentsLighting and heating apparatusMechanical engineeringEngineering

The invention relates to an air extracting pump assembly and a refrigerating and freezing device. The air extracting pump assembly comprises a sealing box where a sealing space is defined, and an air extracting pump arranged in the sealing box. The sealing box comprises a lower box body with the upper side opened, and an upper box body with the lower side opened. A sealing cover of the sealing box is buckled on the upper side of the lower box body so that the sealing space of the sealing box can be defined by the sealing cover and the lower box body together. The rear end of the upper box body is hinged to the rear end of the lower box body. The front end of the upper box body is fastened at the front end of the lower box body in a thread connection manner. By means of the air extracting pump assembly, outward propagation of the noise of the air extracting pump can be reduced, and the air extracting pump is convenient to disassemble and assemble.

Owner:HAIER SMART HOME CO LTD

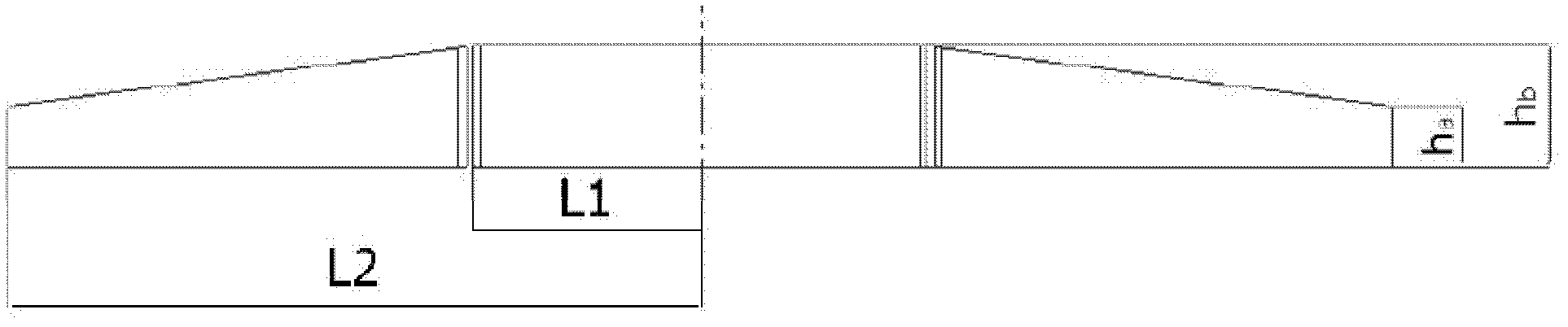

Flexible automobile radiator system

ActiveCN102493864AAdapt to DistortionReduce stress concentrationMachines/enginesEngine cooling apparatusDistortionHeat spreader

The embodiment of the invention discloses a flexible automobile radiator system comprising an upper supporting board, a lower supporting board, an external left supporting framework, an external right supporting framework, a core body, an upper main piece and a lower main piece. The upper main piece is arranged between the core body and an upper water chamber. The lower main piece is arranged between the core body and a lower water chamber. Reinforcing plates are arranged at the left side and right side of the core body. The reinforcing plates are in a variable cross-section structure. The middle thickness of the reinforcing plates is more than the edge thickness of the reinforcing plates. Each reinforcing plate is provided with flexible grooves which transversely extend, pass through thethickness direction of the reinforcing plate and are symmetrical to the middle point of the reinforcing plate. Each one of the upper main piece and the lower main piece comprises a left piece and a right piece. The inner ends of the left and right pieces are fixedly connected. The flexible automobile radiator system provided by the invention limits the distortion flexibility of the core body on the premise of ensuring the structure stability of the flexible automobile radiator system, so that the flexible automobile radiator system has the advantages of higher anti-vibration strength and longer service life.

Owner:WEICHAI POWER CO LTD

Precision injection molding machine clamping mechanism

InactiveCN103286928BImprove mechanical propertiesImprove efficiencyRolling resistanceInjection molding machine

Owner:上海云静企业发展有限公司

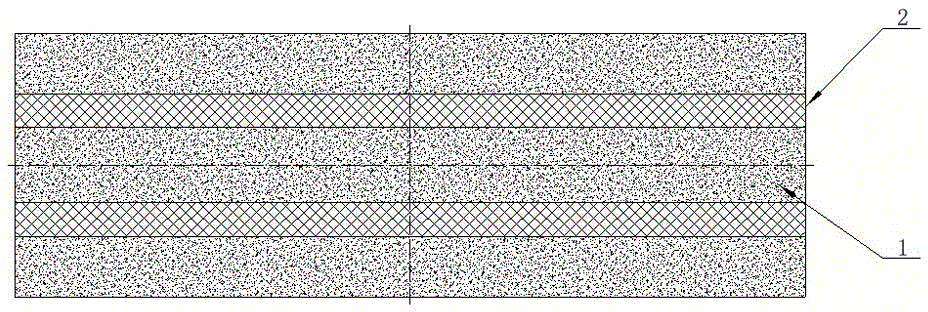

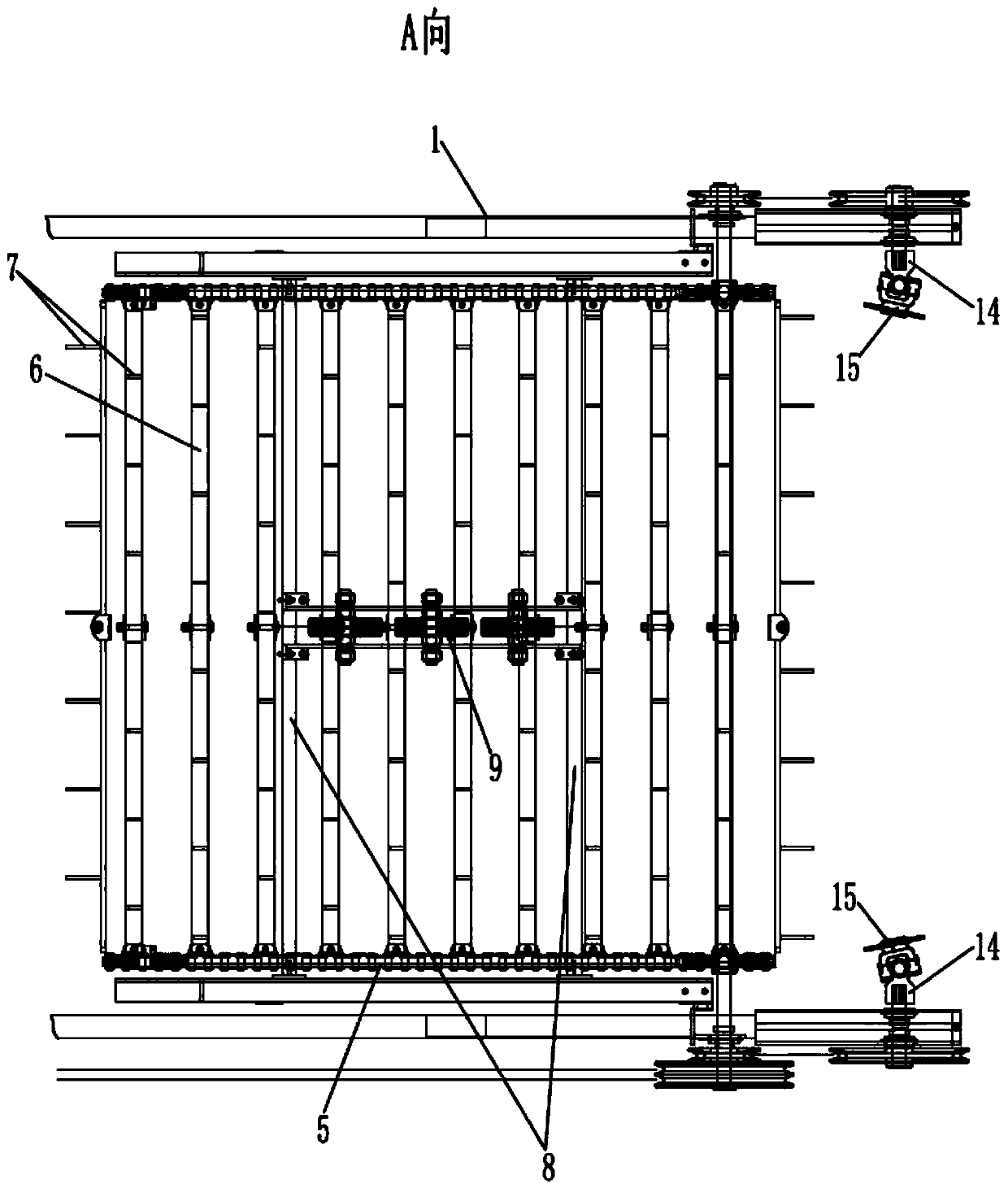

Polymer composite grinding wheel substrate and preparation method thereof

ActiveCN105538175AHigh strengthHigh speed grindingAbrasion apparatusGrinding devicesPolyvinyl butyralFiber

The invention discloses a polymer composite grinding wheel substrate. The polymer composite grinding wheel substrate is prepared by pressing liquid resin reinforced fiber gridding cloth and a filler to obtain a semi-finished substrate and conducting curing molding on the semi-finished substrate to obtain the finished substrate. The filler comprises the following ingredients in parts by volume: 35-55 parts of bakelite powder and aluminium powder, 35-60 parts of an adhesive, and 22-46 parts of a functional filler, wherein the adhesive is a mixture of modified thermosetting phenol resin powder and thermoplastic polyvinyl butyral with elasticity, and the volume ratio of the modified thermosetting phenol resin powder to thermoplastic polyvinyl butyral is (2-4) to 1; and the functional filler is a mixture of copper powder, calcium oxide powder, zinc oxide powder and spheroidal graphite, and the volume ratio of the copper powder to the calcium oxide powder to the zinc oxide powder to spheroidal graphite is (1-5) to 1 to 1 to (1-5). Through the addition of modified reinforced fibers, resin with toughness, and the filler, the polymer composite grinding wheel substrate has certain elasticity and high strength, is higher in impact toughness, can be matched with a fine-grained polishing grinding wheel, can be used for high-speed grinding, and is not prone to breakage, and besides, the safe grinding speed of the polymer composite grinding wheel substrate can be up to 70 m / s; and compared with an aluminum substrate and a steel substrate, the polymer composite grinding wheel substrate is low in density and light in mass, and can be applicable to a common resin grinding wheel, a common super-abrasive grinding wheel and a common elastic polishing grinding wheel.

Owner:ZHENGZHOU RES INST FOR ABRASIVES & GRINDING CO LTD

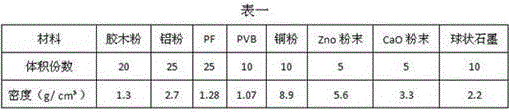

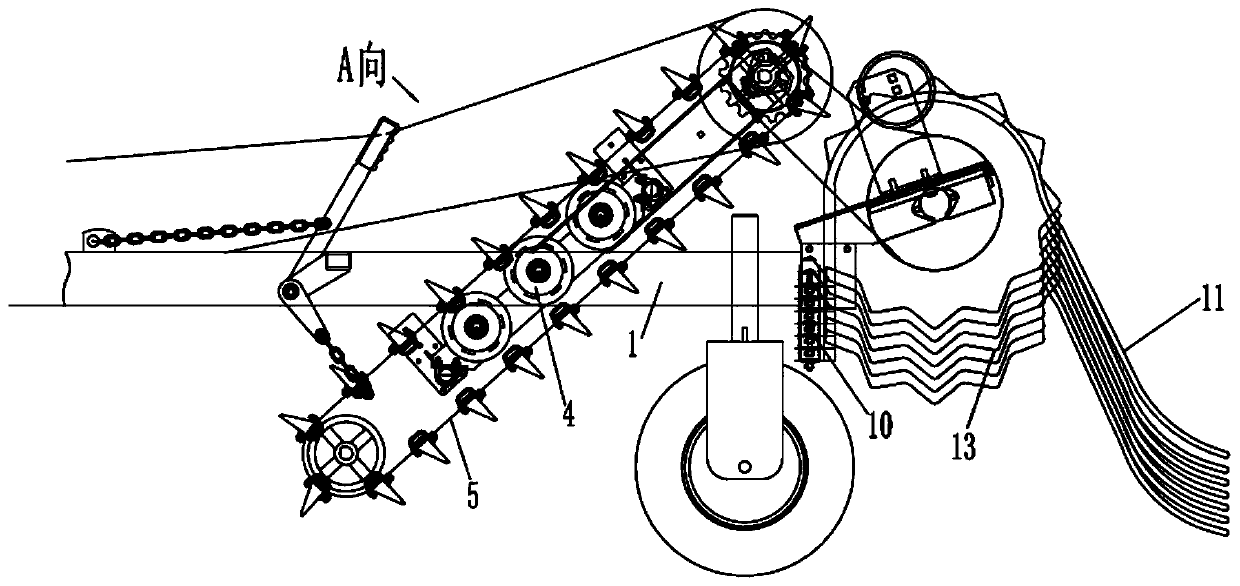

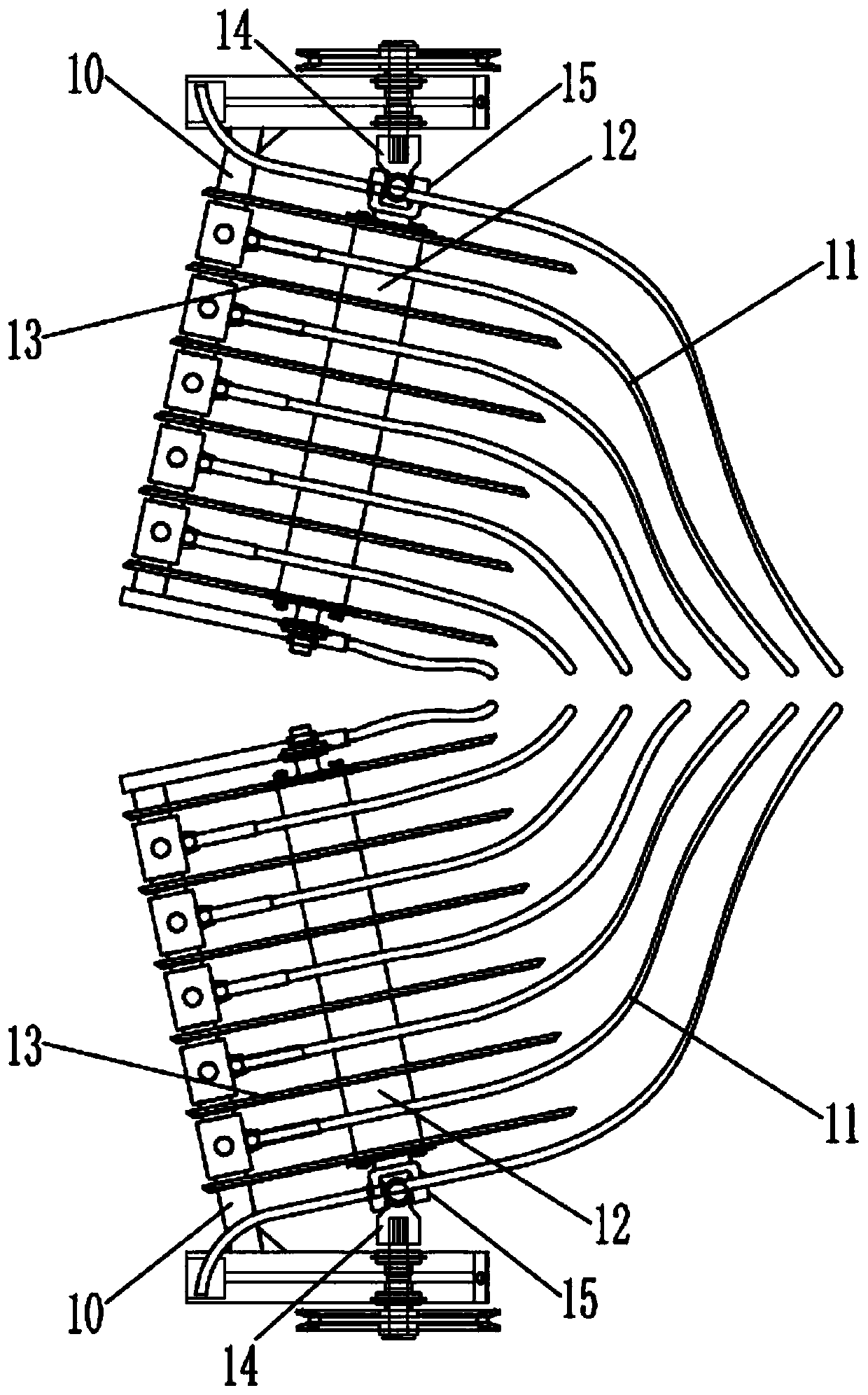

Peanut vine soil removing conveying and back laying device for peanut digging and back-laying machine

The invention discloses a peanut vine soil removing conveying and back laying device for a peanut digging and back-laying machine and belongs to the technical field of peanut harvesting machinery. Thepeanut vine soil removing conveying and back laying device comprises a suspended type rack equipped with supporting wheels, wherein a peanut vine soil removing conveying device and a peanut vine backlaying device are sequentially arranged on the rack from front to back; the peanut vine soil removing conveying device comprises a peanut vine conveying device and a vibrating device; the vibrating device comprises at least one roller train; the peanut vine back laying device comprises a left-side peanut vine back laying structure and a right-side peanut vine back laying structure, the left-sidepeanut vine back laying structure and the right-side peanut vine back laying structure are arranged in bilateral symmetry and are the same in structure, and each of the left-side peanut vine back laying structure and the right-side peanut vine back laying structure comprises a bar fixing bracket fixed to the rack and bars which are fixed to the corresponding bar fixing bracket at intervals. According to the peanut vine soil removing conveying and back laying device for the peanut digging and back-laying machine, peanut vines dug out from a field can be subjected to peanut vine soil removing and are conveyed to the peanut vine back laying device so as to carry out back laying and regular piling on the peanut vines, and thus, sun-curing of peanuts and processing of a peanut-vine separator are facilitated.

Owner:河北永发鸿田农机制造有限公司 +1

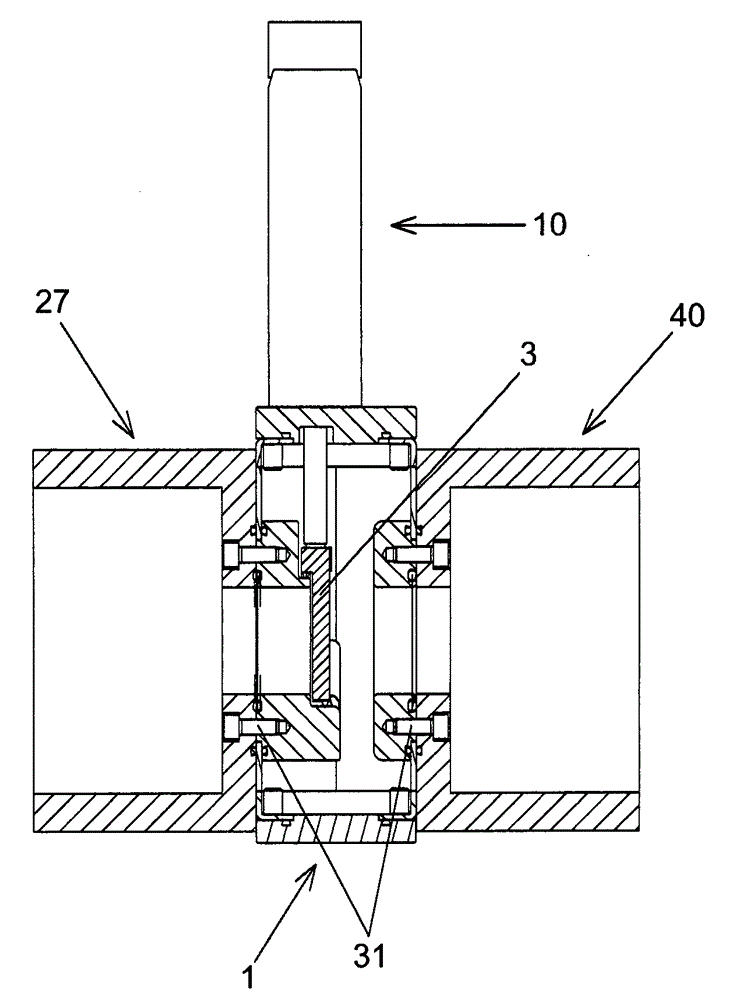

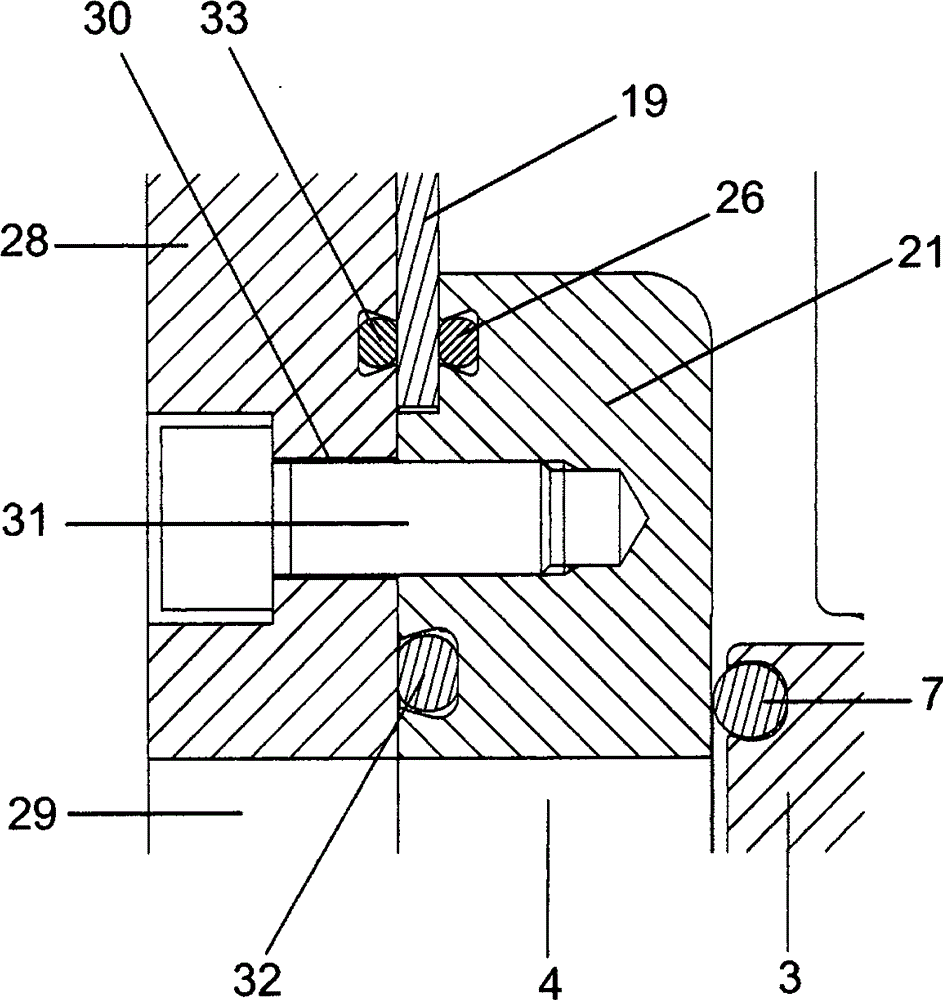

Vacuum valve

InactiveCN104838189ASave materialReduce rigidity requirementsSlide valveThin material handlingValve openingEngineering

The valve has a closure element (3) that is arranged in an interior (2) of a valve housing (1). The closure element surrounding a valve opening (4) is mounted in a valve seat (6) in a closed state.The valve housing has a housing wall (19) made of sheet metal, for delimiting the interior. A flange ring (21) is connected to a connection flange (28) of a vacuum unit (27) by a screw connection. The interior of the vacuum unit is attached to the valve housing.The closure element is placed over the valve seat in the closed state by the flange ring.

Owner:VAT HLDG AG

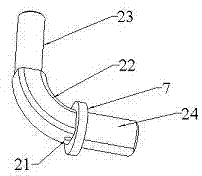

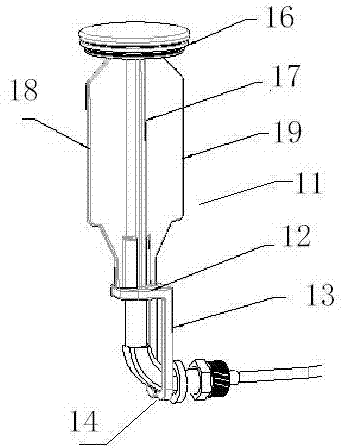

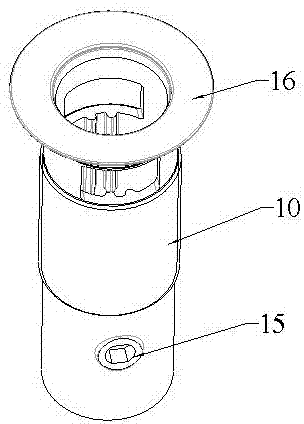

A pull-type drainage control device

The invention relates to a drainer, in particular to a lift-draw type drainage control device for kitchen and bathroom. The lift-draw type drainage control device comprises: a housing that is suitable for the installation in the drainhole of a pool; a piston slidingly matched with the housing; and a steel wire actuating device which is provided with a steel wire and a sleeving having a flexible sleeve and limited axial compression; the actuating end of the steel wire stretches into the housing and is combined with the lower part of the piston, and the controller of the steel wire actuating device is arranged outside the housing. The drainage control device is convenient for installation, and prevents blockage.

Owner:贝朗(中国)卫浴有限公司

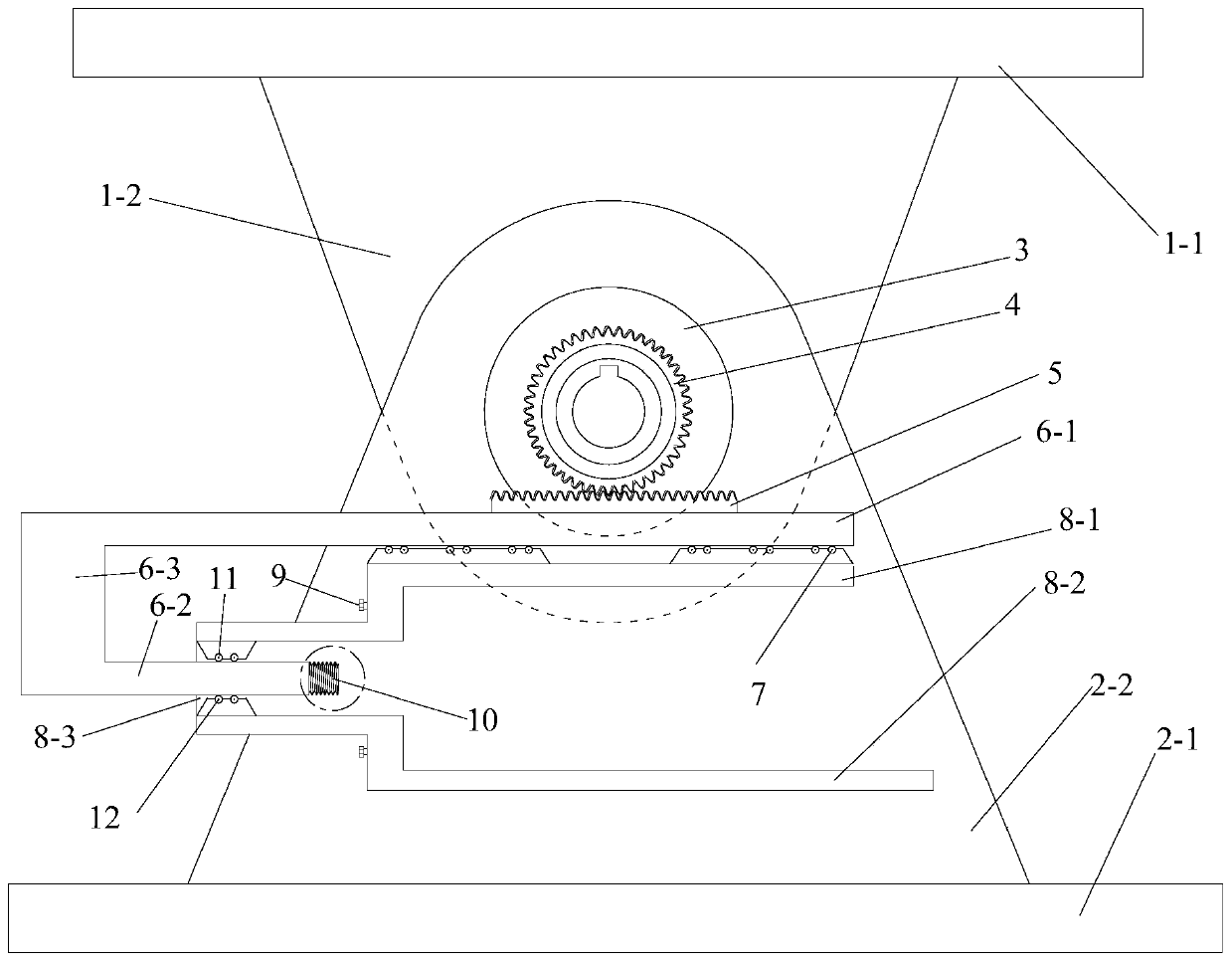

Clamping mechanism for precision injection molding machine

The invention relates to a clamping mechanism for a precision injection molding machine. The clamping mechanism comprises a structure frame composed of a fixed die plate, a movable die plate, a rear die plate and a guide column, a movable die plate fast moving mechanism and a clamping cylinder structure; the section of the guide column on the structure frame is rectangular, four corner parts of the movable die plate are provided with rollers on the upper column surface, the lower column surface and the inner side of the guide column; the movable die plate fast moving mechanism is composed of a motor reduction gear, a pair of engaged gears and rack and a guide wheel; the clamping cylinder structure is composed of four cylinders, a clamping support plate and a transmission mechanism, and the rear die plate has a through hole through which a cylinder piston rod is capable of passing. The clamping mechanism provided by the invention has the advantages that the friction between the movable die plate and the guide column is changed as the rolling friction from the sliding friction, the fit clearance is adjustable, the movement precision is improved, the movement resistance is decreased, and the energy consumption is reduced; through the rotation of the clamping support plate, the length of the guide column required for die closing is greatly shortened through the support or discharging provided for the cylinder piston rod, the whole machine body is reduced, and the control is simplified.

Owner:上海云静企业发展有限公司

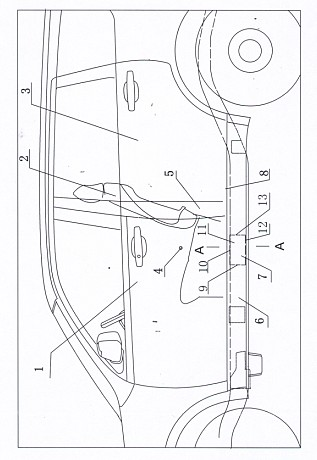

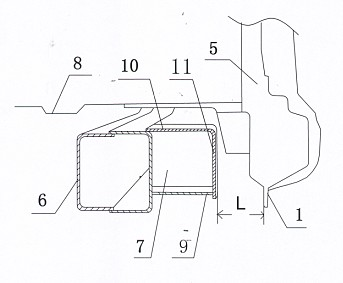

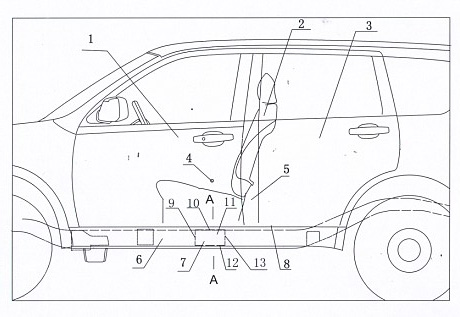

Frame side-impact limiting device for SUVs (sport utility vehicles)

The invention discloses a frame side-impact limiting device for SUVs (sport utility vehicles), which comprises a frame longitudinal beam and a body B pillar. The limiting device disclosed by the invention is characterized in that a steel side-impact limiting box consisting of a top plate, a left side plate, a bottom plate, a right side plate and an outer plate is fixed on the external sidewall ofthe frame longitudinal beam in front of the body B pillar, under a driver seat, and at a position close to a point R so as to improve the rigidity of the side-impact limiting box. The side-impact limiting box can participate in the absorption of impact energies during the early and middle periods of impact, thereby reducing the requirements on the quantity of absorbed impact energies of body parts such as the body B pillar, a body floor and a side body, and the like, namely, correspondingly reducing the rigidity demands for the body parts, reducing the complexity of the body structure, and lowering the process requirements of the body. By using the side-impact limiting device disclosed by the invention, when a side impact occurs to vehicles, impact energies can be transferred to the framelongitudinal beam as many as possible and then absorbed efficiently so as to reduce the damages to a body passenger cabin; and the side-impact limiting device has the advantages of less investment and low cost, therefore, the side-impact limiting device is suitable for non-stressed SUVs.

Owner:JIANGLING HLDG

Moving-cover type electric pressure cooker

The present invention relates to a movable lid type electric pressure cooker. It is characterized by utilizing elastic lid to control and limit interior pressure of cooker. Said movable lid type electric pressure cooker includes the following several portions: lid, elastic element, switch, sealing ring, inner pot, electric heater and outer pot. Besides, said invention also provides the connection mode of all the above-mentioned portions and the working principle of said electric pressure cooker.

Owner:王永光

Cold storage refrigerating device

ActiveCN106766510AReduce contentReduce the intensity of aerobic respirationLighting and heating apparatusDomestic refrigeratorsNitrogenEngineering

The invention provides a cold storage refrigerating device which comprises a cabinet body, an air adjusting film assembly and an air extractor. A first storage space is defined in the cabinet body. A storage container is arranged in the first storage space. The storage container is provided with a cylinder body and an air adjusting preserving space located in the cylinder body. The air adjusting film assembly is installed on the cylinder body, and space around the air adjusting film assembly communicates with the air adjusting preserving space. The air adjusting film assembly is provided with at least one air adjusting film and an oxygen enrichment gas collecting cavity and arranged to enable more oxygen in air flow in the space around the air adjusting film assembly to penetrate the air adjusting films relative to nitrogen in air flow in the space around the air adjusting film assembly to enter the oxygen enrichment gas collecting cavity. The air extractor communicates with the oxygen enrichment gas collecting cavity through a pipeline to extract and pump the gas penetrating into the oxygen enrichment gas collecting cavity out of the storage container. The cold storage refrigerating device is good in preserving effect, moreover, the requirements for rigidity and strength of the cabinet body and the like are low, the achievement requirement is low, and the cost is low. Moreover, the size is small, the noise is low, and cold storage refrigerating device is particularly applicable to families and individuals.

Owner:HAIER SMART HOME CO LTD

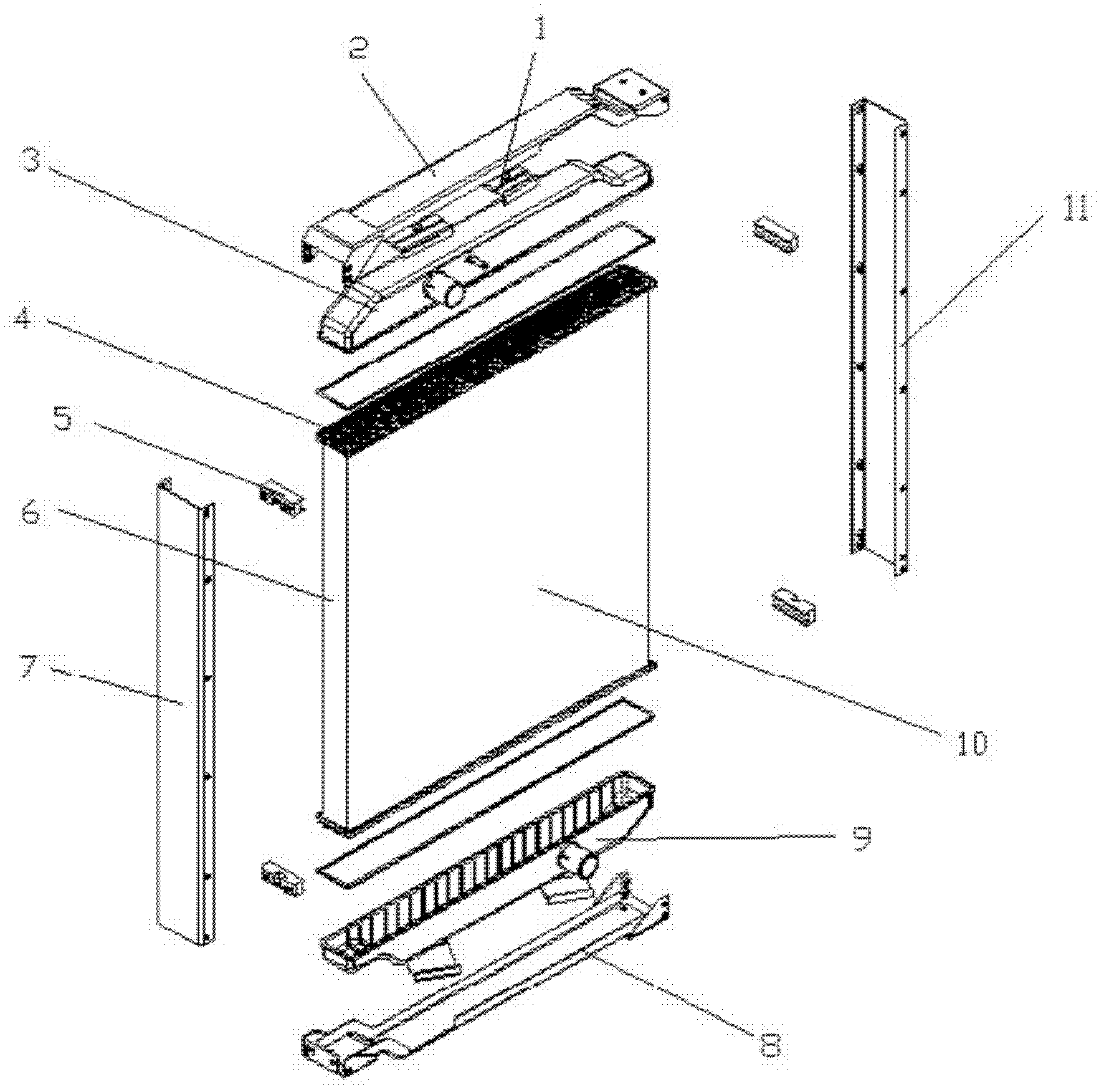

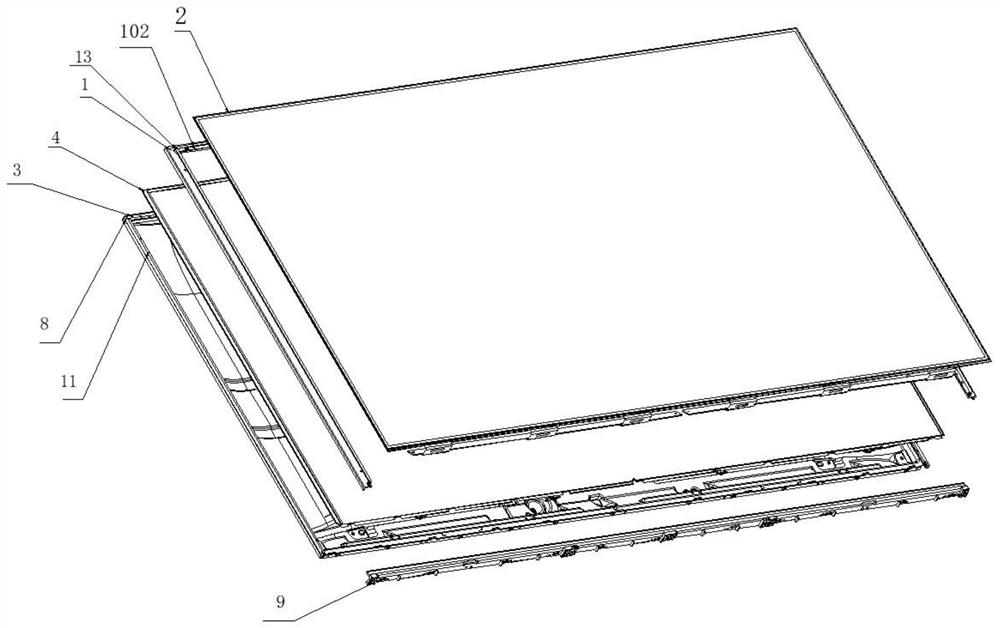

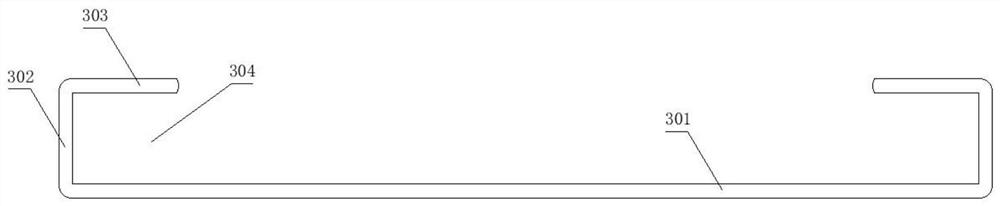

Display device

InactiveCN111816061AReduce rigidity requirementsImprove interchangeabilityNon-linear opticsIdentification meansDisplay deviceStructural engineering

The invention provides a display device, which comprises a back plate, an optical assembly, a middle frame and a display panel, wherein the back plate is of a rectangular structure and comprises a bottom plate and side edges, the three side edges of the back plate are provided with bending structures, each bending structure comprises a first bending part perpendicular to the bottom plate and a second bending part parallel to the bottom plate, the bottom plate, the first bending part and the second bending part are encircled to form an accommodating groove, the optical assembly is positioned inthe accommodating groove, the middle frame comprises a first side plate and a second side plate of which the edges are vertically connected, one side portion, close to the second side plate, of the first side plate is fixedly connected with the second bending part, one side portion, far away from the second side plate, of the first side plate is fixedly connected with the display panel, and one side portion, close to the first side plate, of the second side plate is fixedly connected with the first bending part. The display device provided by the invention is good in appearance effect and lowin cost.

Owner:HISENSE VISUAL TECH CO LTD

Friction stir welding repair method for threaded hole

ActiveCN114406605AImprove restoration qualityReduce resistanceNon-electric welding apparatusScrew threadMaterials science

The invention provides a friction stir welding and mechanical self-locking repair method for a threaded hole, and aims to improve the repair quality and repair efficiency of the threaded hole. The groove is machined in the to-be-repaired threaded hole, so that mechanical self-locking is generated while metallurgical bonding of the filling material and the to-be-repaired area is achieved, and the bearing capacity of the repaired threaded hole is improved through the dual effects of mechanical self-locking and metallurgical bonding. And the adopted filling material is in a circular ring shape, so that the repairing efficiency is improved, and the rigidity requirement of the used equipment is reduced.

Owner:国营四达机械制造公司

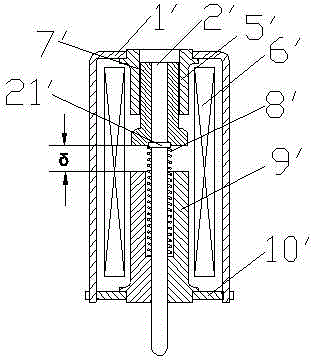

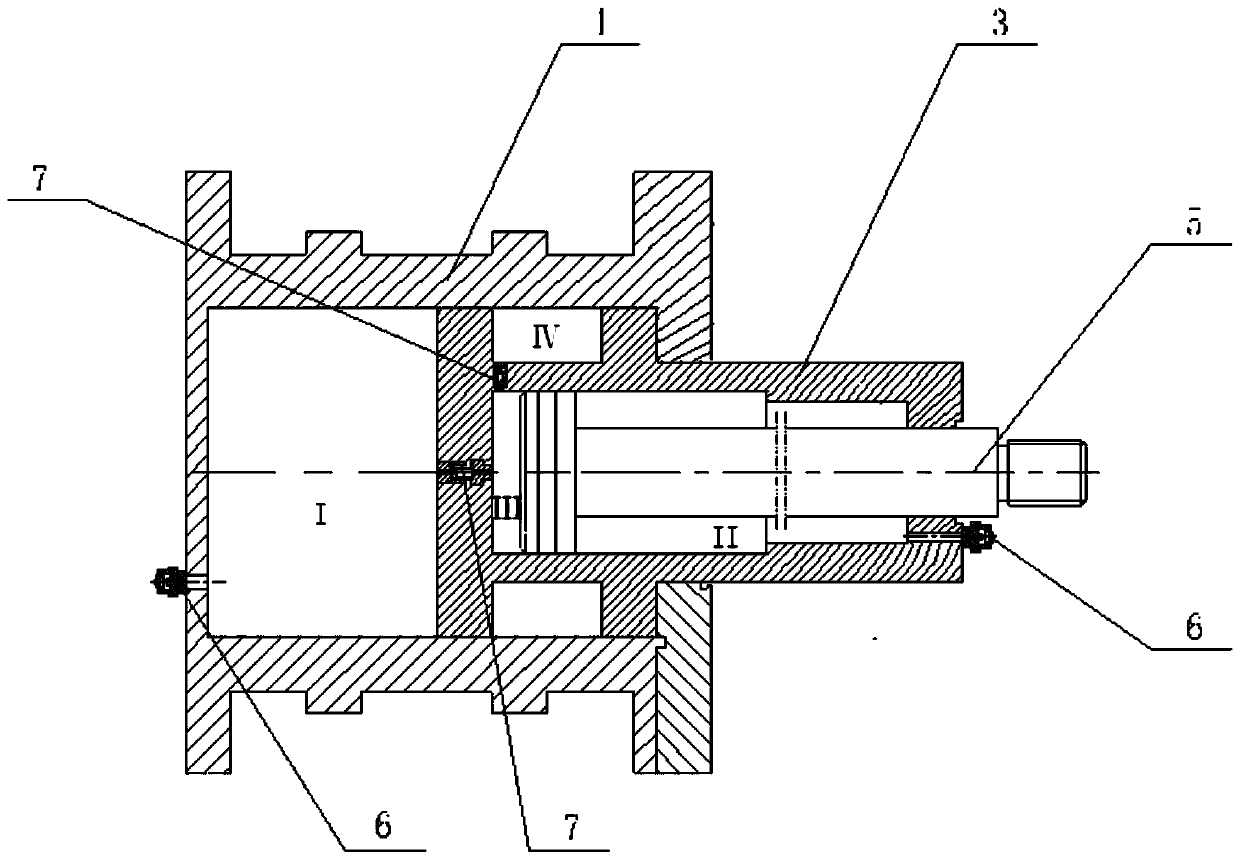

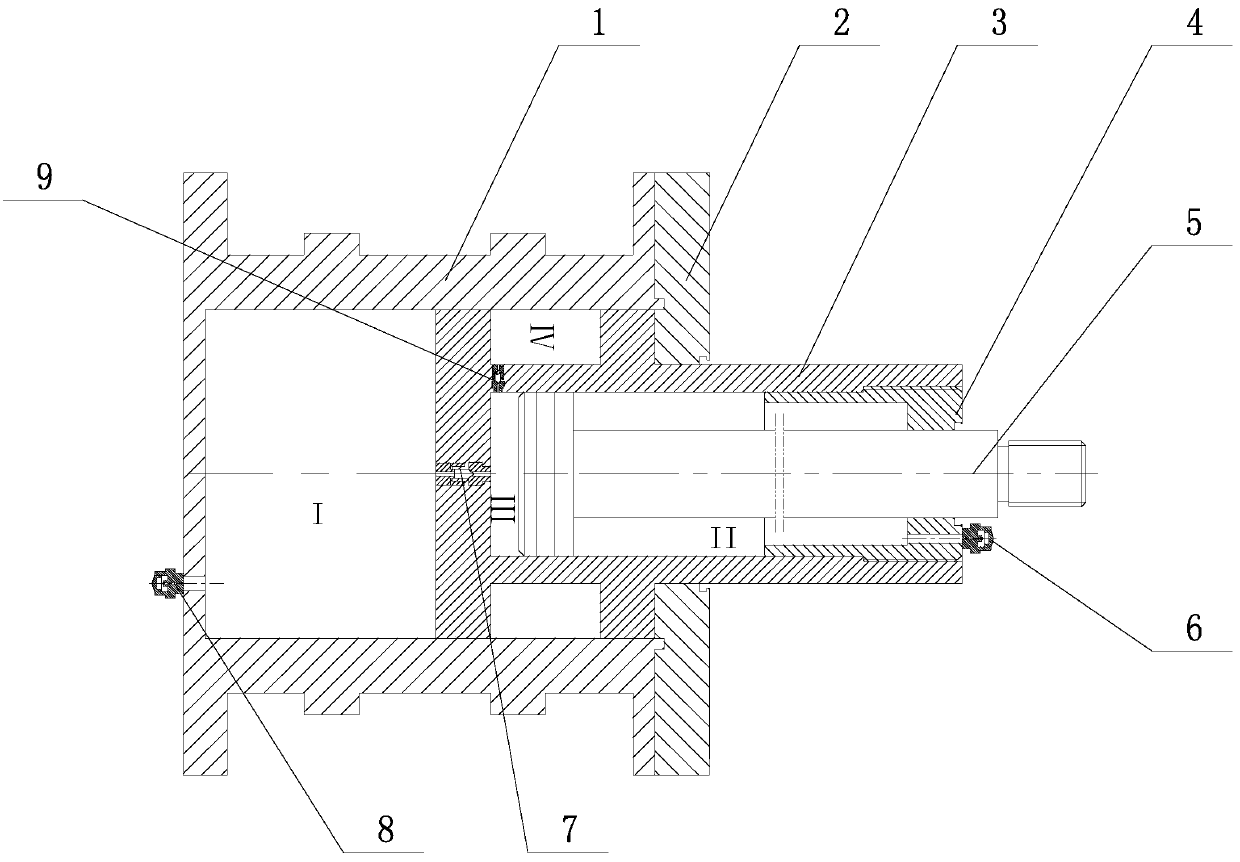

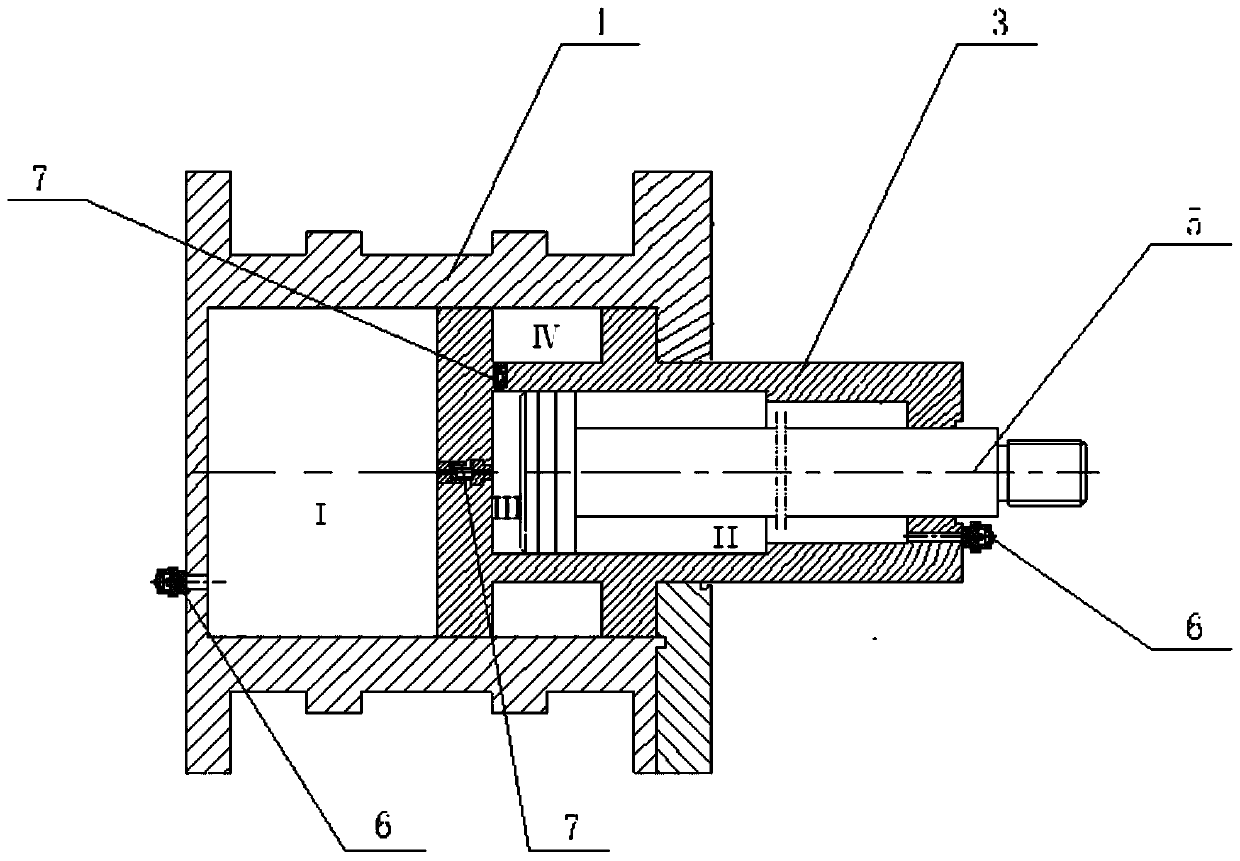

Multistage gas gun anti-recoil device

ActiveCN109855471AReduced bearing strengthReduce rigidity requirementsCompressed gas gunsReturn zeroEngineering

The invention relates to a multistage gas gun anti-recoil device and belongs to the technical field of mechanical machining. The multistage gas gun anti-recoil device comprises a cylinder block I (1),a cylinder block II (3), a buffer rod (5), a gas injection valve (6) and a balance valve (7). The cylinder block I is fixedly connected with a gun piece. The cylinder block II is fixedly connected tothe cylinder block I. One end of the buffer rod is movably connected with the cylinder block II. One end of the buffer rod is connected with the gun piece. Cavities of the cylinder block I and the cylinder block II are filled up with gas at different pressures through the gas injection valve. The cavities communicate through the balance valve. At different stages of the gas gun shooting process,the pressures of the cavities are adjusted through the balance valve to implement buffering on recoil force and forward impact force. Compared with the prior art, the multistage gas gun anti-recoil device can accurately return zero to shifting generated under different working conditions within short time in the gas gun shooting process, gently absorb peak stress generated in different stress directions and reduce the requirements for rigidity and strength and the foundation load bearing strength, is simple in structure and achieves the combined operation effect of multiple recoil mechanisms and counter-recoil mechanisms of an original gas gun.

Owner:SHANXI NORTH MACHINE BUILDING

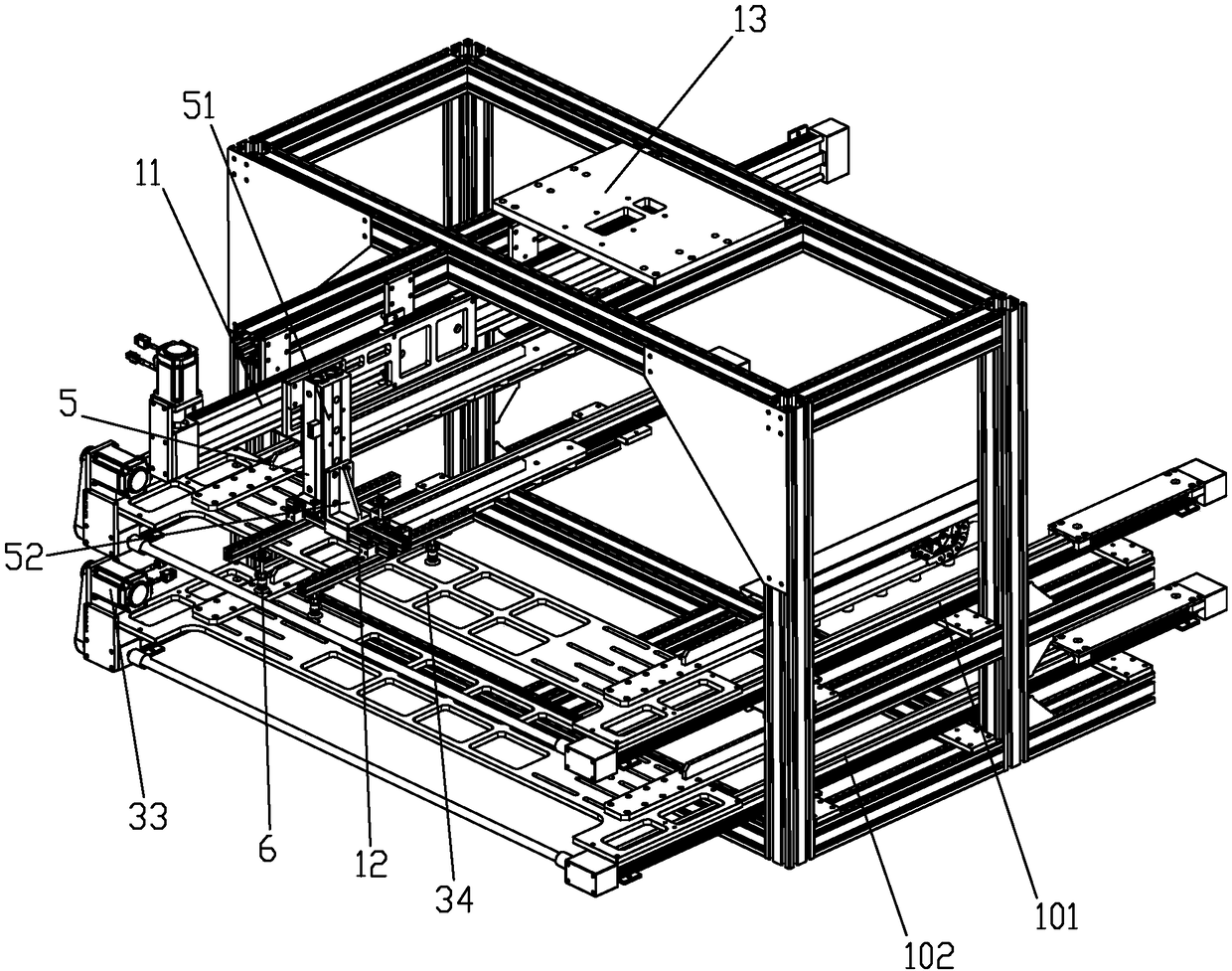

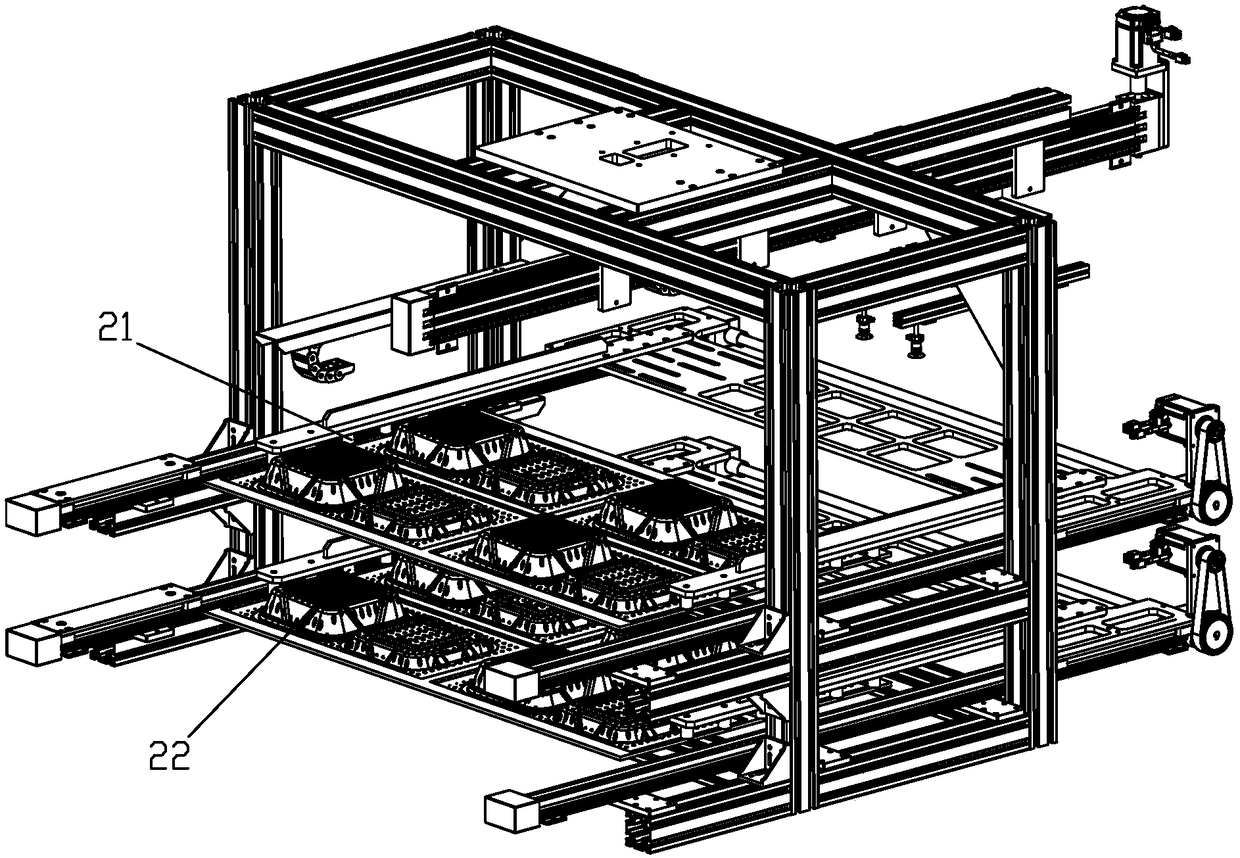

Full-automatic intelligent forming technology for paper matrixes

InactiveCN108547181AReduce rigidity requirementsImprove stabilityTextiles and paperPulp and paper industryElectromagnet

Owner:GUANGDONG CLAW ROBOT CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com