Polymer composite grinding wheel substrate and preparation method thereof

A technology of composite materials and polymers, which is applied in the composite material matrix of superabrasive grinding wheels and its preparation field, can solve the problems of large thermal deformation, uneven density, poor heat resistance of bakelite matrix, etc., and achieve high impact toughness and rigidity The effect of low requirements and not easy to break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] A preparation method of a polymer composite material grinding wheel matrix, comprising the following steps:

[0042] (1) Preparation of resin liquid reinforced fiber mesh cloth

[0043] Modified polyester fibers and polyimide fibers were made into 60-mesh mesh cloth, soaked in 70% acetic acid solution for 2 hours to set the shape, and then air-dried; the air-dried mesh cloth was soaked in Immerse in the mixture of alcohol-based phenolic resin solution and polyurethane resin solution for 5 minutes, then take out the impregnated grid cloth and place it in a glass tray, and dry and cure it in an oven at 100°C for 2 hours;

[0044] (2) Preparation of molding materials

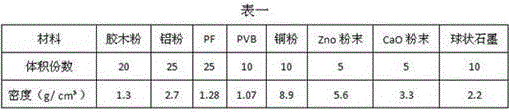

[0045]According to the parts by volume of each component, bakelite powder 15-25, aluminum powder 20-30, phenolic resin 25-40, polyvinyl butyral 10-20, copper powder 8-15, zinc oxide powder 3-8, calcium oxide Powder 3-8, spherical graphite 8-15 Weigh the filling material, mix the filling material in a ball ...

Embodiment 1

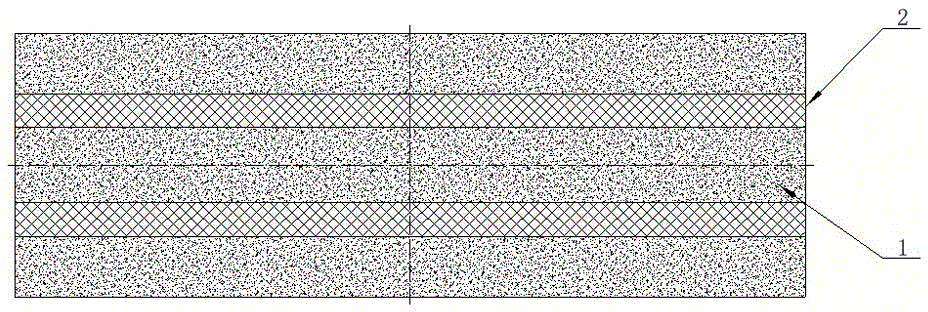

[0049] A polymer composite material grinding wheel matrix, which is formed by pressing and solidifying resin liquid reinforced fiber mesh cloth and filling material, and the composition of each raw material in the filling material is shown in Table 1.

[0050]

[0051] A preparation method of a polymer composite material grinding wheel matrix, comprising the following steps:

[0052] (1) Preparation of resin liquid reinforced fiber mesh cloth

[0053] Modified polyester fibers and polyimide fibers were made into 60-mesh mesh cloth, soaked in 70% acetic acid solution for 2 hours to set the shape, and then air-dried; the air-dried mesh cloth was soaked in Immerse in the mixture of alcohol-based phenolic resin solution and polyurethane resin solution for 5 minutes, then take out the impregnated grid cloth and place it in a glass tray, and dry and cure it in an oven at 100°C for 2 hours;

[0054] (2) Preparation of molding materials

[0055] Weigh the filling materials of eac...

Embodiment 2

[0059] A polymer composite material grinding wheel matrix, which is formed by pressing and solidifying resin liquid reinforced fiber mesh cloth and filler, and the filler is composed of the following raw materials in parts by volume: bakelite powder 15, aluminum powder 30, phenolic resin 39, polyvinyl butyral 20, copper powder 15, zinc oxide powder 3, calcium oxide powder 3, spherical graphite 15.

[0060] A preparation method of a polymer composite material grinding wheel matrix, comprising the following steps:

[0061] (1) Preparation of resin liquid reinforced fiber mesh cloth

[0062] Modified polyester fibers and polyimide fibers were made into 60-mesh mesh cloth, soaked in 70% acetic acid solution for 2 hours to set the shape, and then air-dried; the air-dried mesh cloth was soaked in Immerse in the mixture of alcohol-based phenolic resin solution and polyurethane resin solution for 5 minutes, then take out the impregnated grid cloth and place it in a glass tray, and dr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com