Electrolyte pulse type electrolytic machining device and method

A processing device and processing method technology, applied in electric processing equipment, electrochemical processing equipment, accessories and other directions, can solve the problems of large impact force of machine tools, large inertia of mechanical vibration mechanism, reducing the life of main shaft and transmission mechanism, etc. cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the drawings.

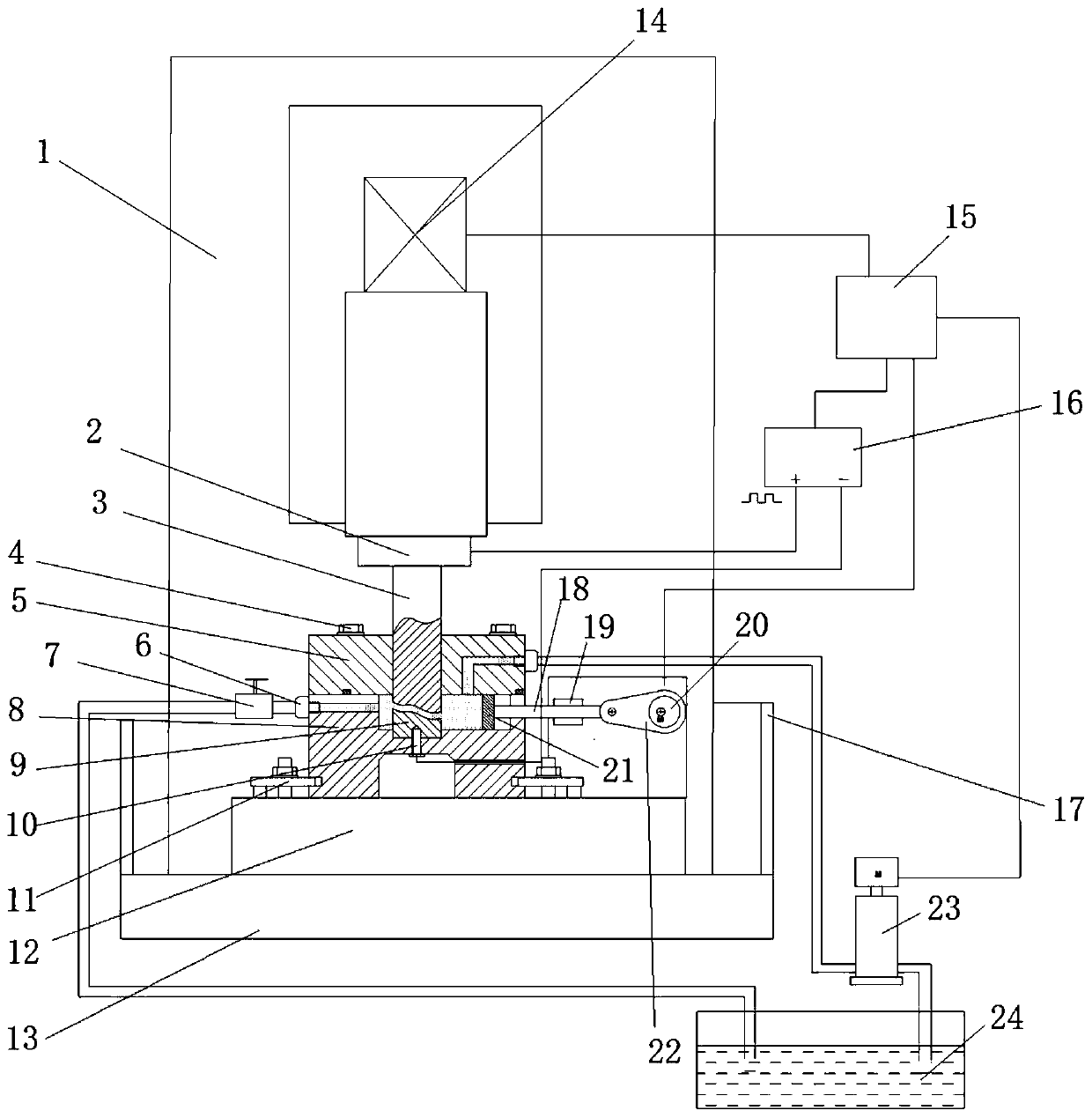

[0020] The present invention provides a figure 1 The shown electrolyte pulse type electrochemical machining device includes a Z-axis feed system 14, an eccentric cam vibration mechanism, a control system 15, an electrochemical machining power supply 16, and an electrolyte supply system. When the anode of the workpiece is close to the cathode of the workpiece, and the machining gap is small enough, under the action of the electric field and the flow field, the anode workpiece is electrochemically dissolved and processed away, while the cathode is not processed but remains as it is. With the continuous feeding of the anode, Finally, the contour of the tool cathode is approximately copied.

[0021] The Z-axis feed system is a numerical control feed system that includes a spindle, a servo motor, a ball screw, a guide rail, and a position sensor. It is installed on the machine too...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com