Material delivery mechanism of aluminum template automatic blanking production line

A transmission mechanism and production line technology, applied to other manufacturing equipment/tools, metal processing, manufacturing tools, etc., can solve the problems of increasing the complexity of the equipment manufacturing process, requiring high machining accuracy, and complex structure of the lifting device, etc., to achieve structural The effect of simplicity, low inertia, and low consumption of mechanical materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

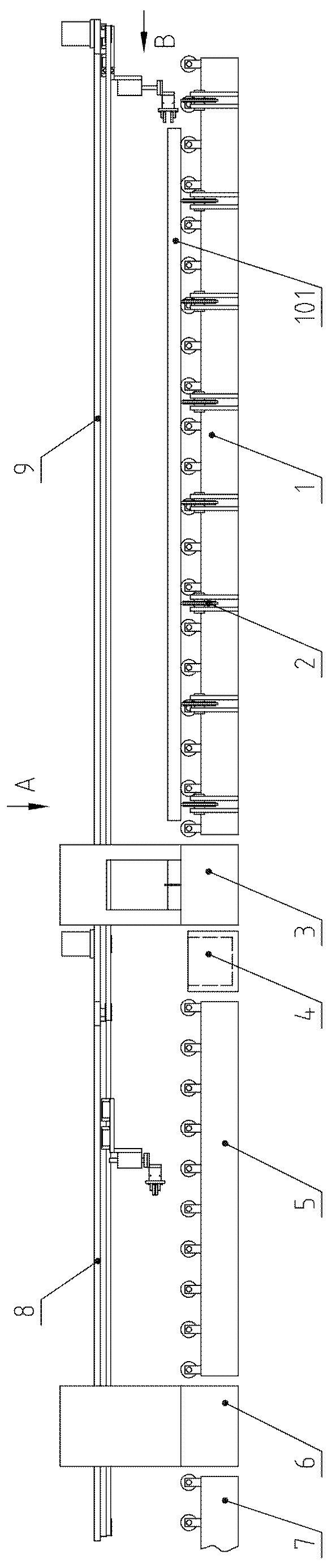

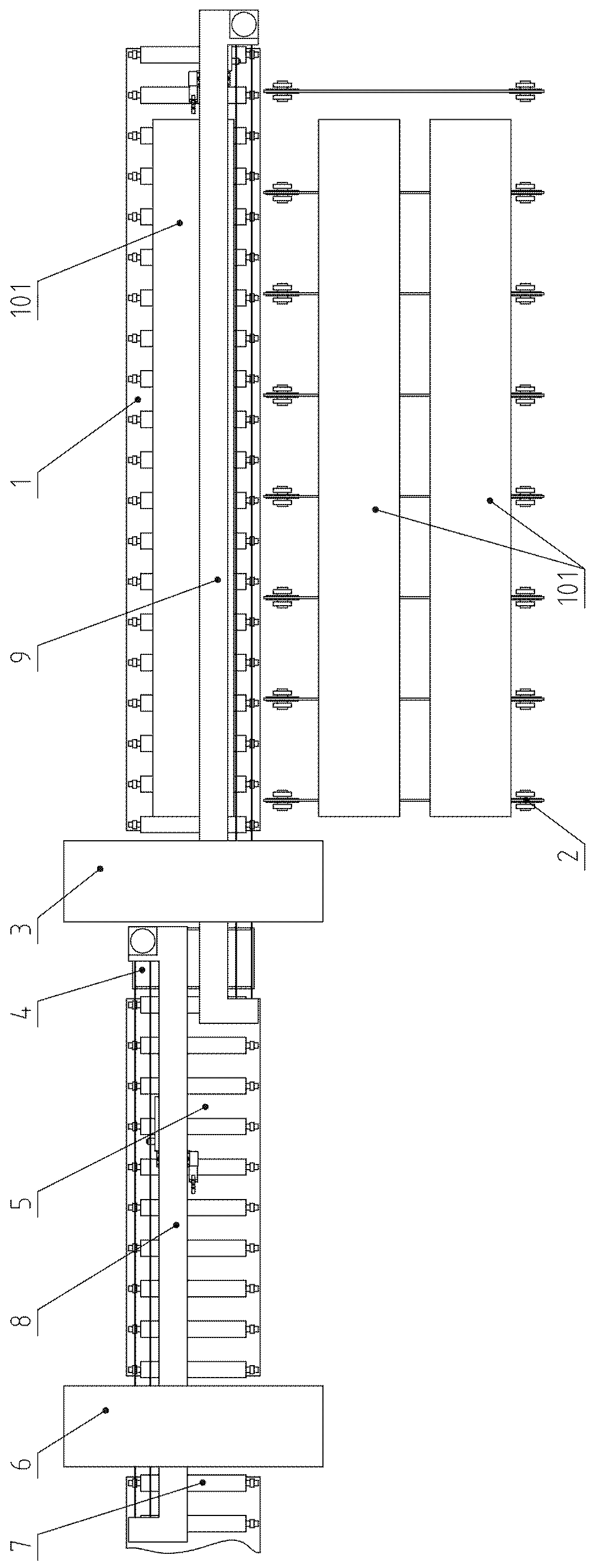

[0058] Example: see Figure 1 to Figure 15 .

[0059] A material conveying mechanism for an automatic blanking production line of aluminum templates, including a feeder 8 for a sawing machine and a feeder 9 for a punching machine;

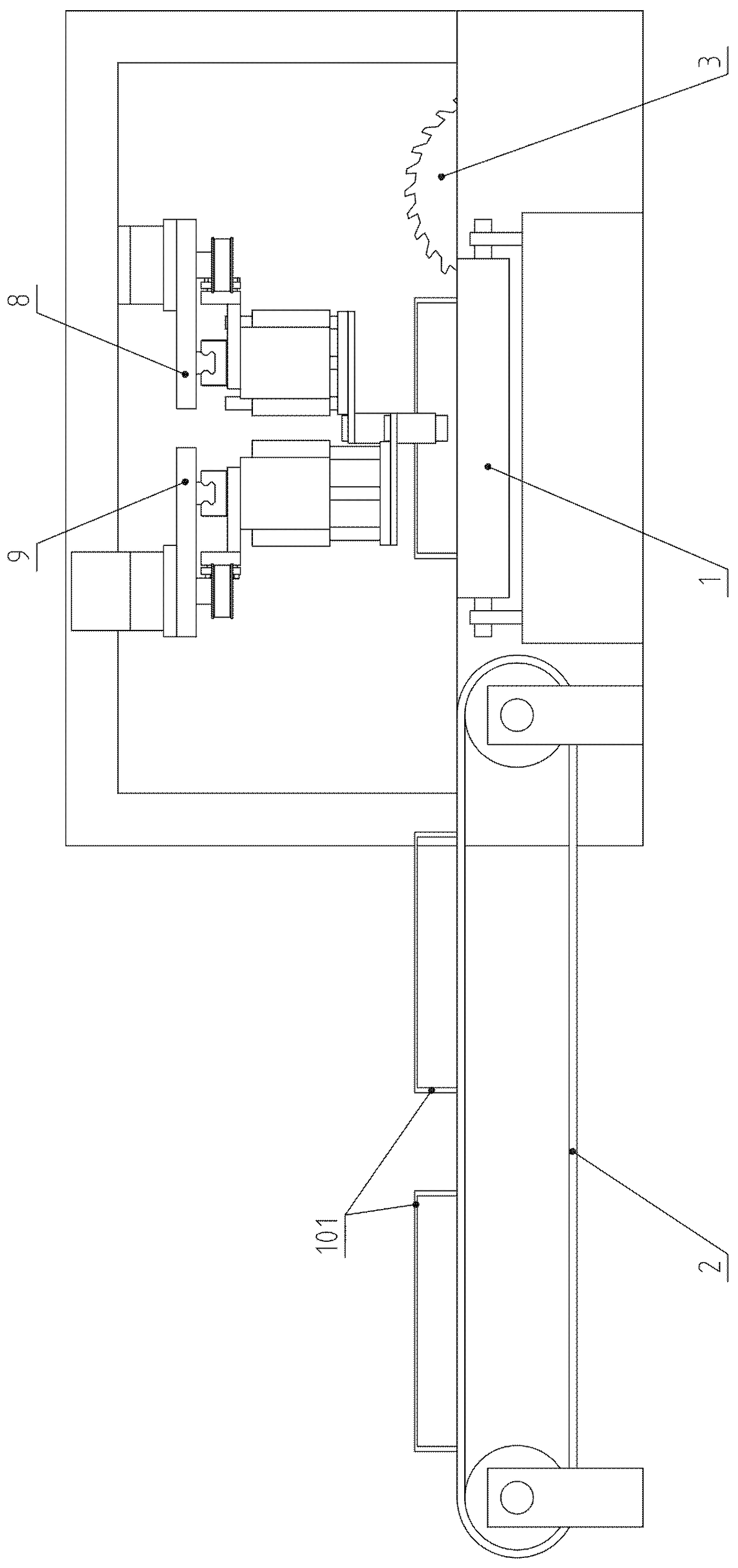

[0060] Such as Figure 12 , 13 As shown in and 14, the saw machine feeder 8 includes a support plate-81, a driving device-82, a driving synchronous wheel-83, a synchronous belt-84, a passive synchronous wheel-85, a translation assembly-86, and a guide rod type lifting cylinder- 87. Pneumatic finger one 88 and linear guide rail one 89; support plate one 81 is connected to the frame; driving device one 82 is a combination of servo motor one and reducer one; linear guide rail one 89 is fixedly installed on the lower part of support plate one 81, The linear guide rail one 89 is arranged in the front and rear horizontal direction; the passive synchronous wheel one 85 is connected with the support plate one 81 through the rotating pair, and the passiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com