Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

203results about How to "Stable recovery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for processing radio signals that are subject to unwanted change during propagation

InactiveUS6208295B1Acquisition stableStable captureSpatial transmit diversityRadio wave direction/deviation determination systemsRadio signalTransmitter

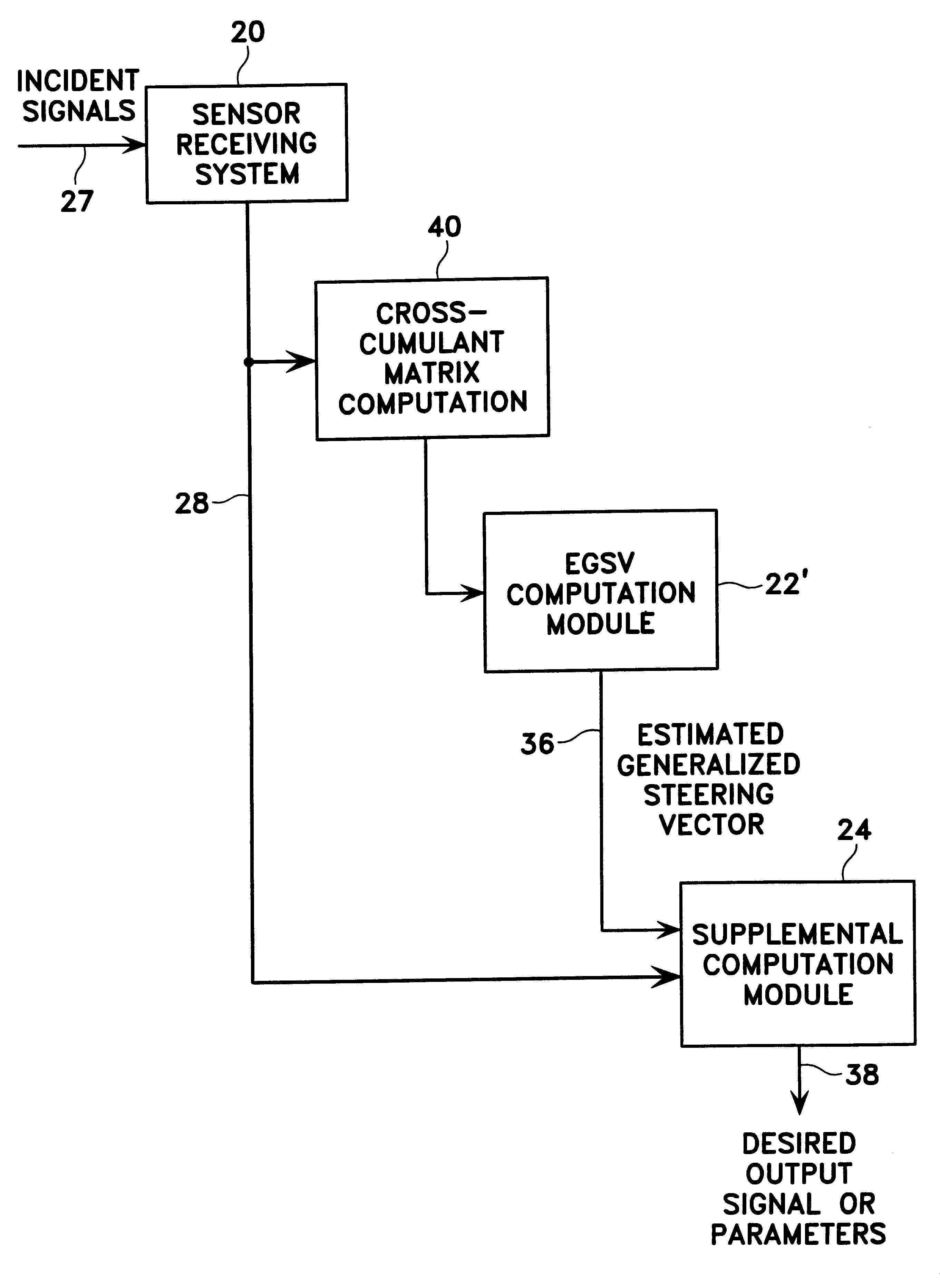

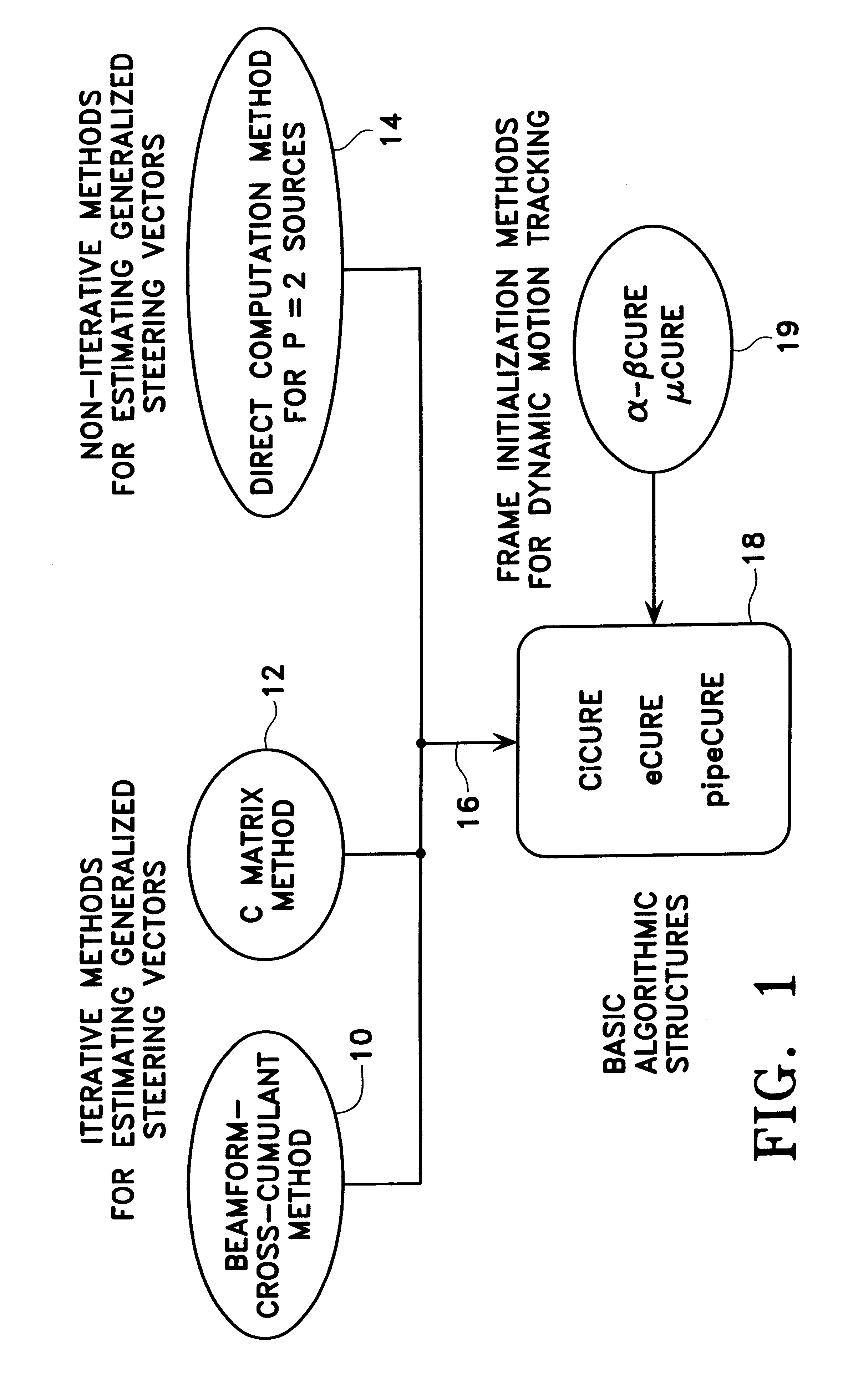

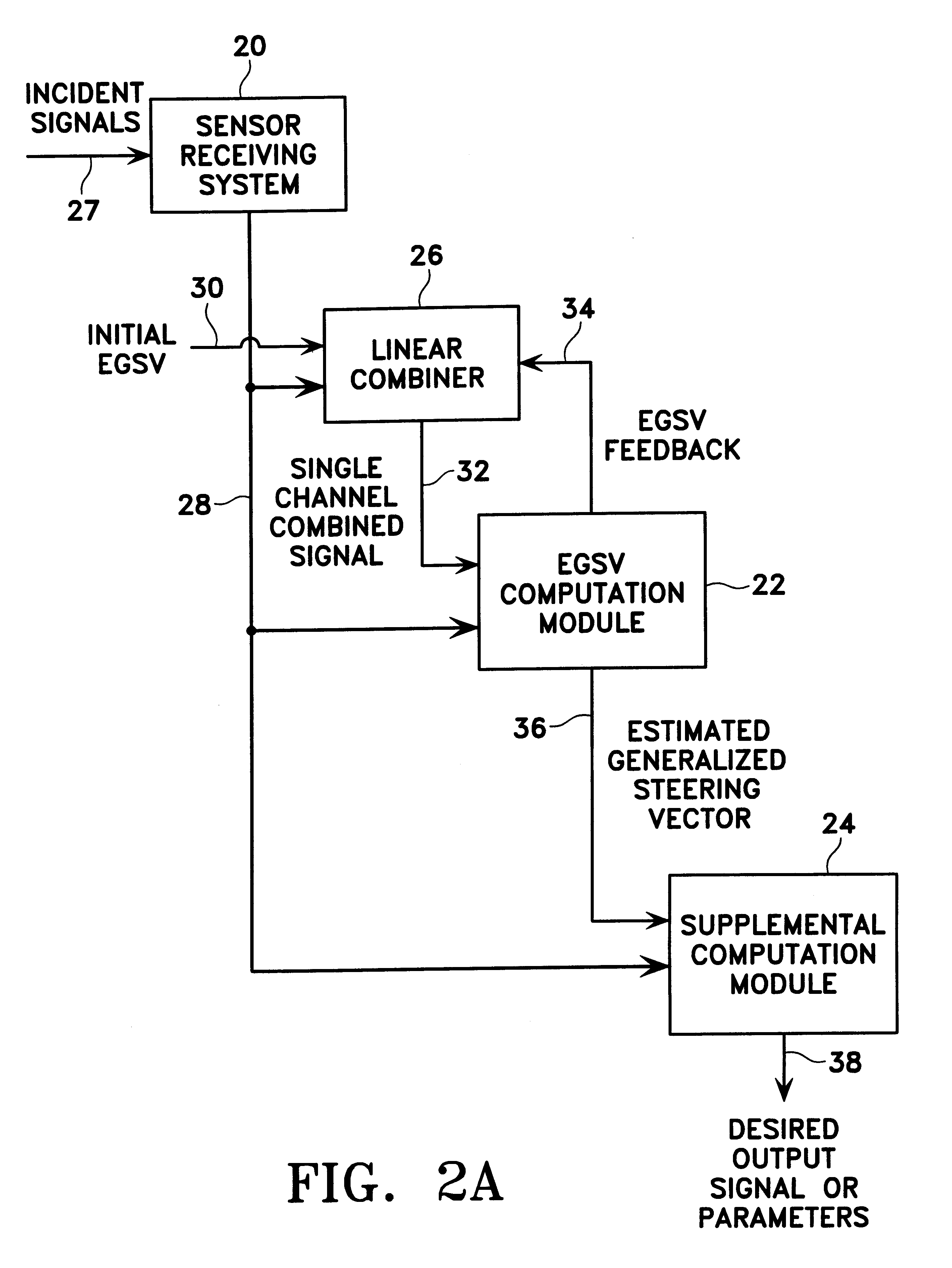

A method for processing received radio signals that are subject to unwanted change during propagation through the atmosphere, from a transmitter to a receiver array. The multiple signals are received as cochannel signals at the antenna array, and are processed to eliminate the effects of modification of the signals during propagation, wherein the processing step includes cumulant-based signal recovery without regard for the geometrical properties of the antenna array. In the invention as disclosed, two different information signals having two different polarization states are transmitted, and at least one of the transmitted signals is subjected to an unwanted change of its polarization state. The received signals are processed to separate and recover the two information signals without regard to their polarization states.

Owner:NORTHROP GRUMMAN SYST CORP

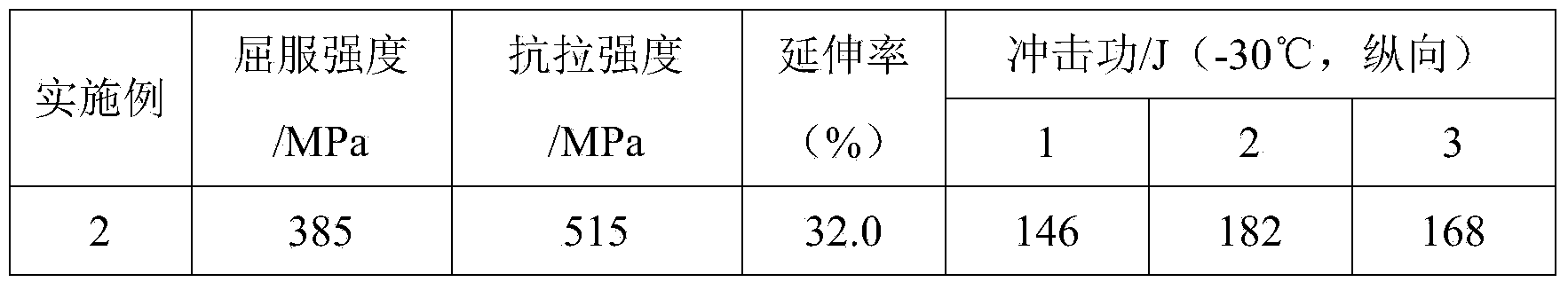

Clothes drier

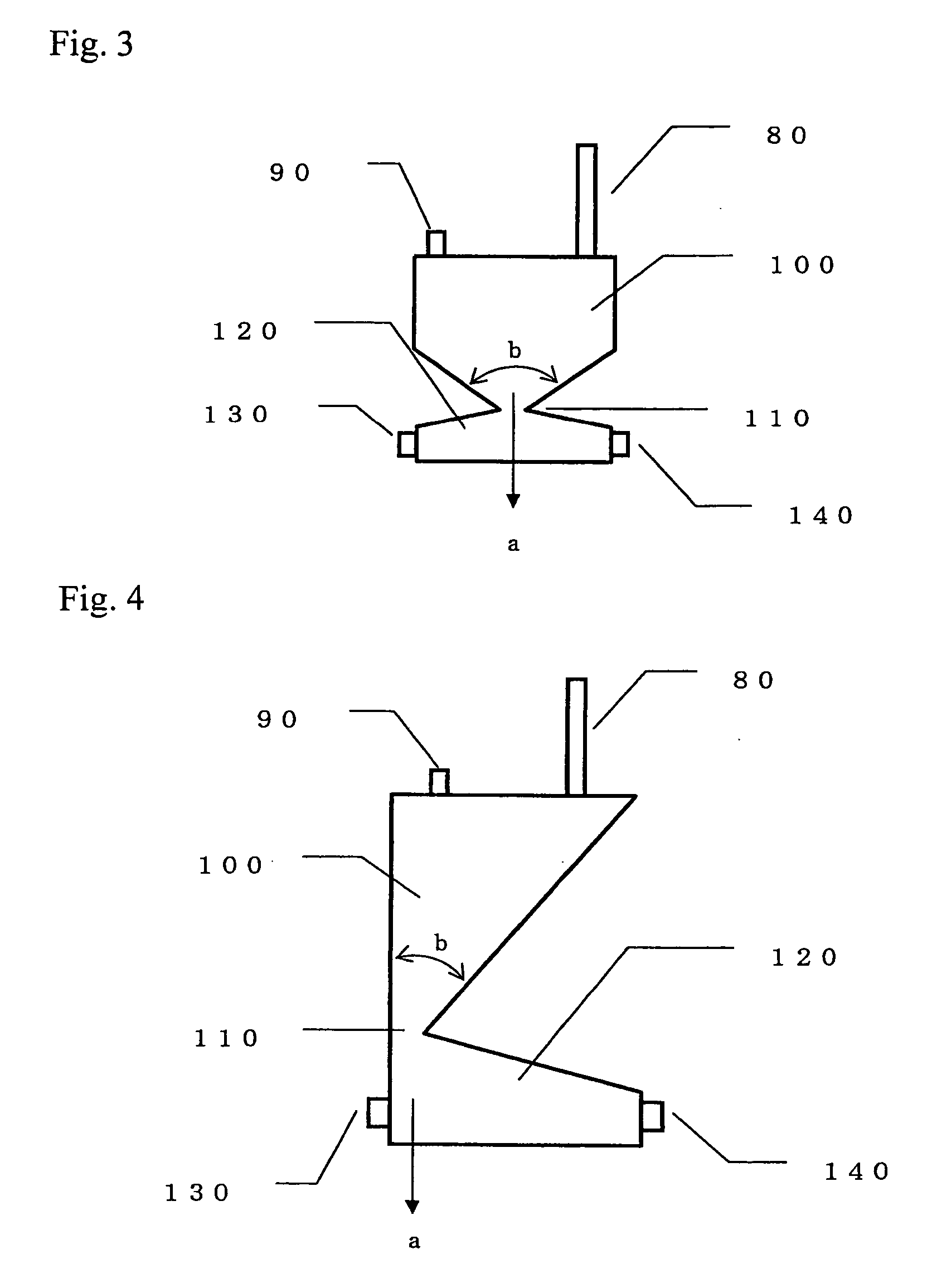

ActiveCN1626724AReduce the burden onSuppress pressure riseTextiles and paperLaundry driersThermodynamicsEngineering

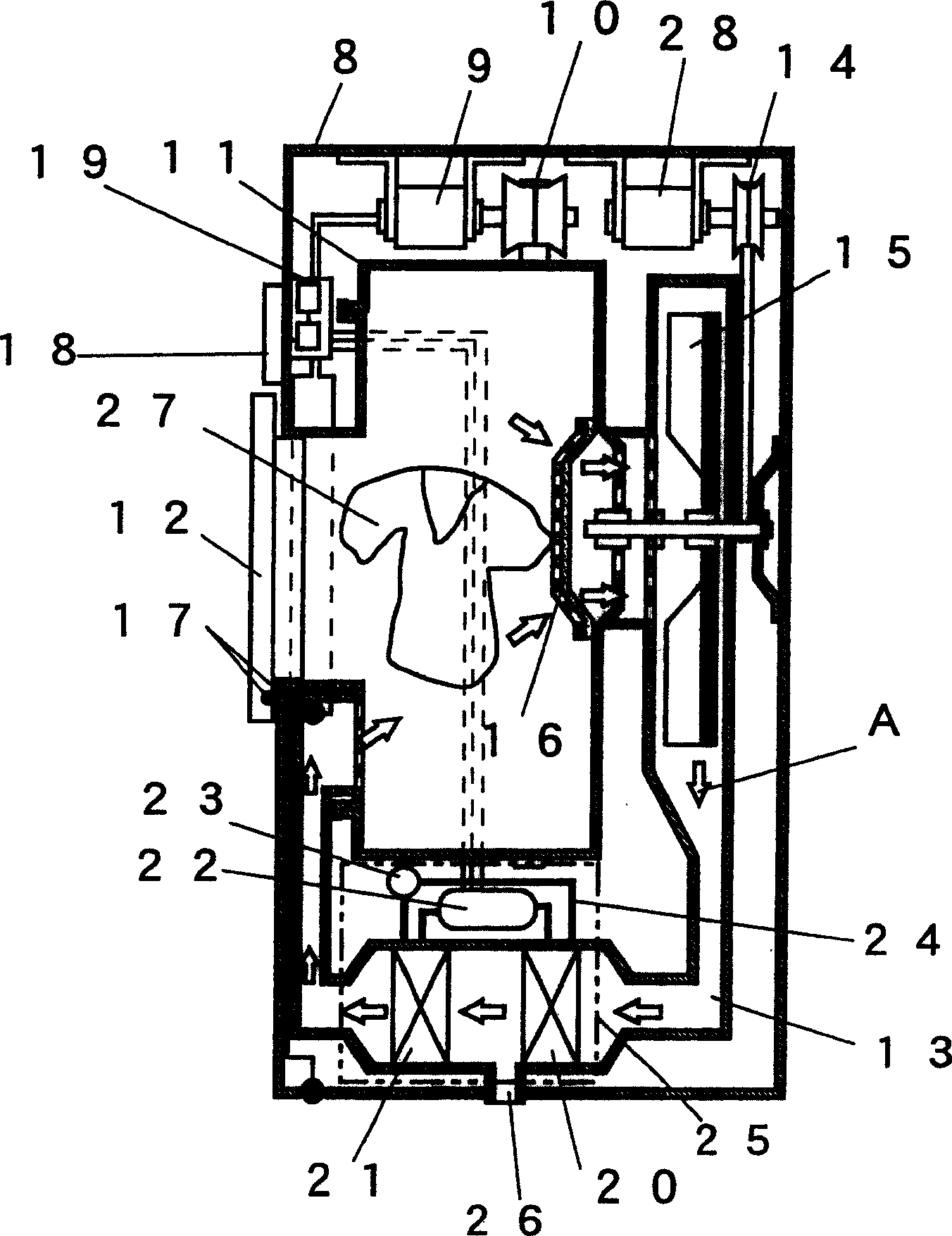

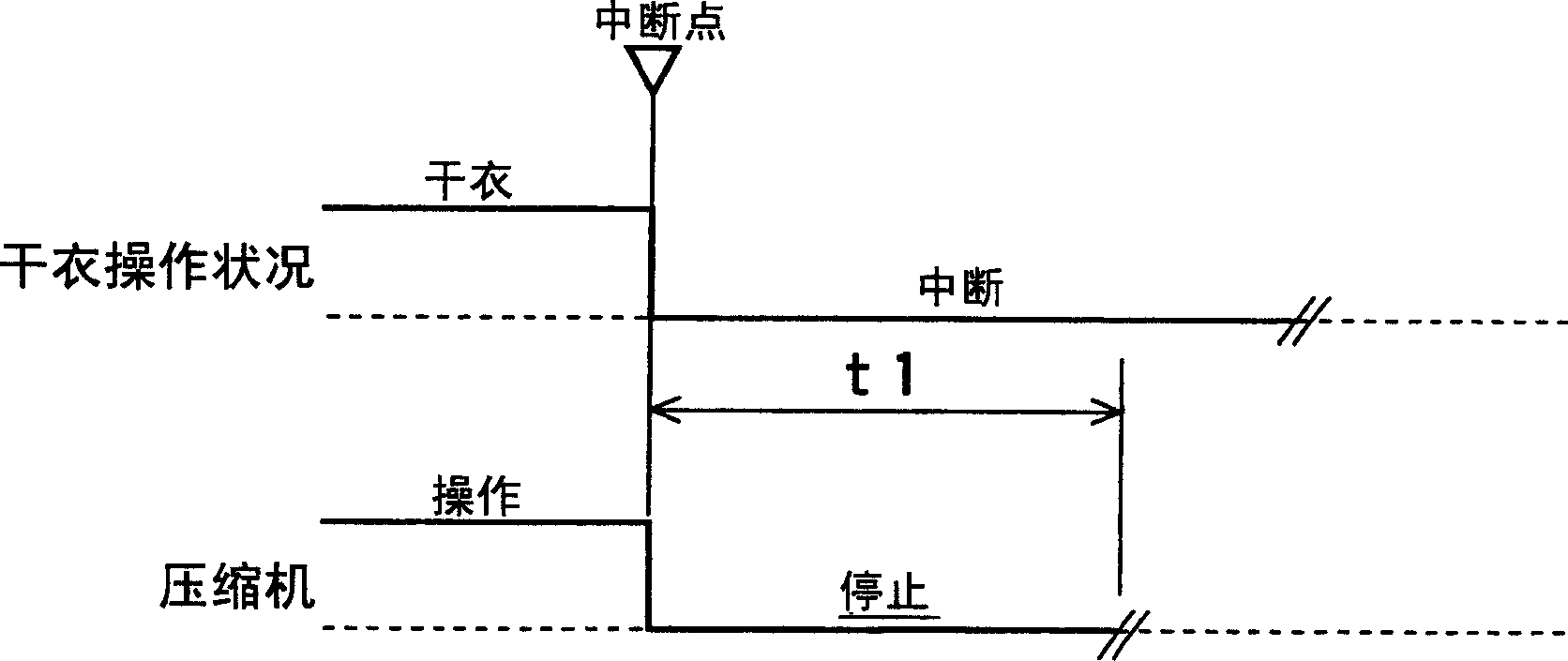

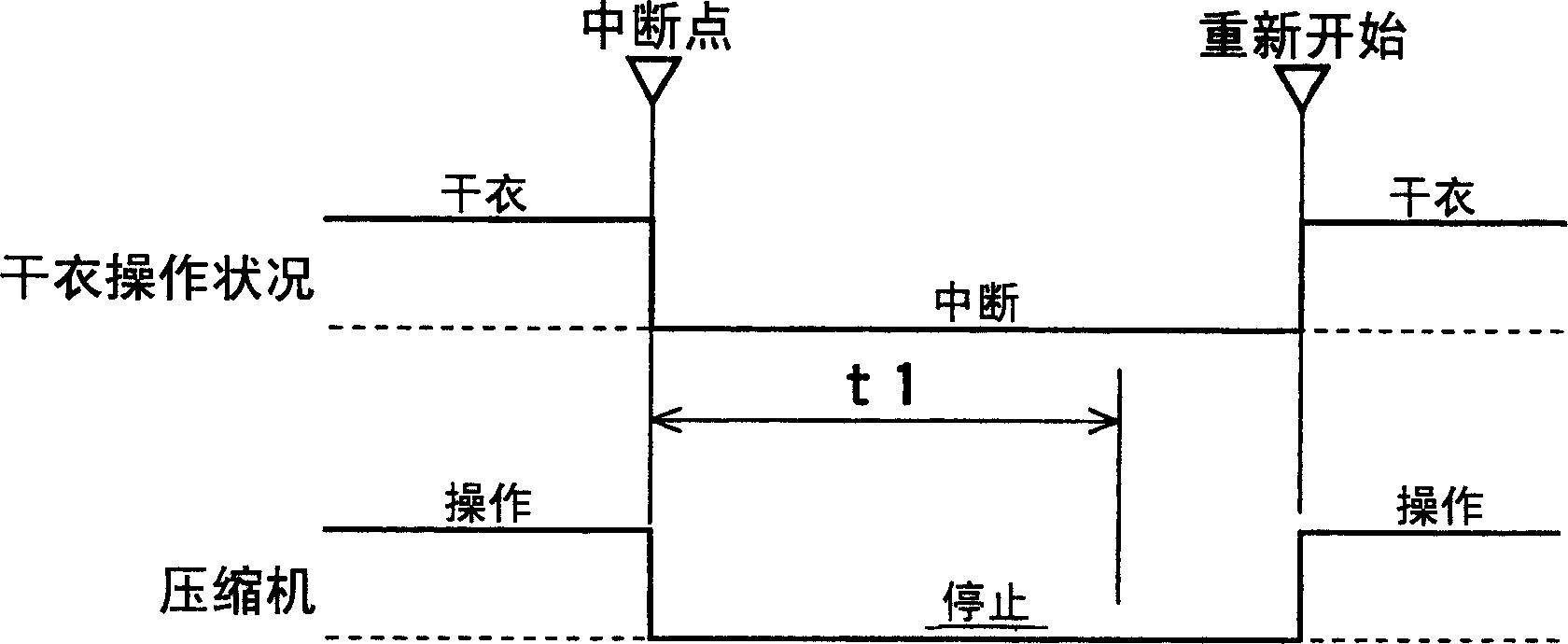

A clothes drying apparatus includes a heat pump mechanism (25), an air path (13) for guiding drying air into a drying drum (11) accommodating therein clothes (27), a blower (15) for supplying drying air to the air path (13), and a controller for controlling a driving of a compressor (22), wherein the controller operates the blower (15) and the compressor (22) during a drying operation; stops the compressor (22) in case the drying operation is suspended; and operates, in case the drying operation is resumed, the compressor (22) after a certain time period has elapsed since the compressor (22) had stopped. In case employing the heat pump mechanism (25) having the compressor (22) as a heat source, it is possible to reduce a load on the compressor (22) and allow temperature of warm air to rapidly return by using the heat pump mechanism (25). <IMAGE>

Owner:PANASONIC CORP

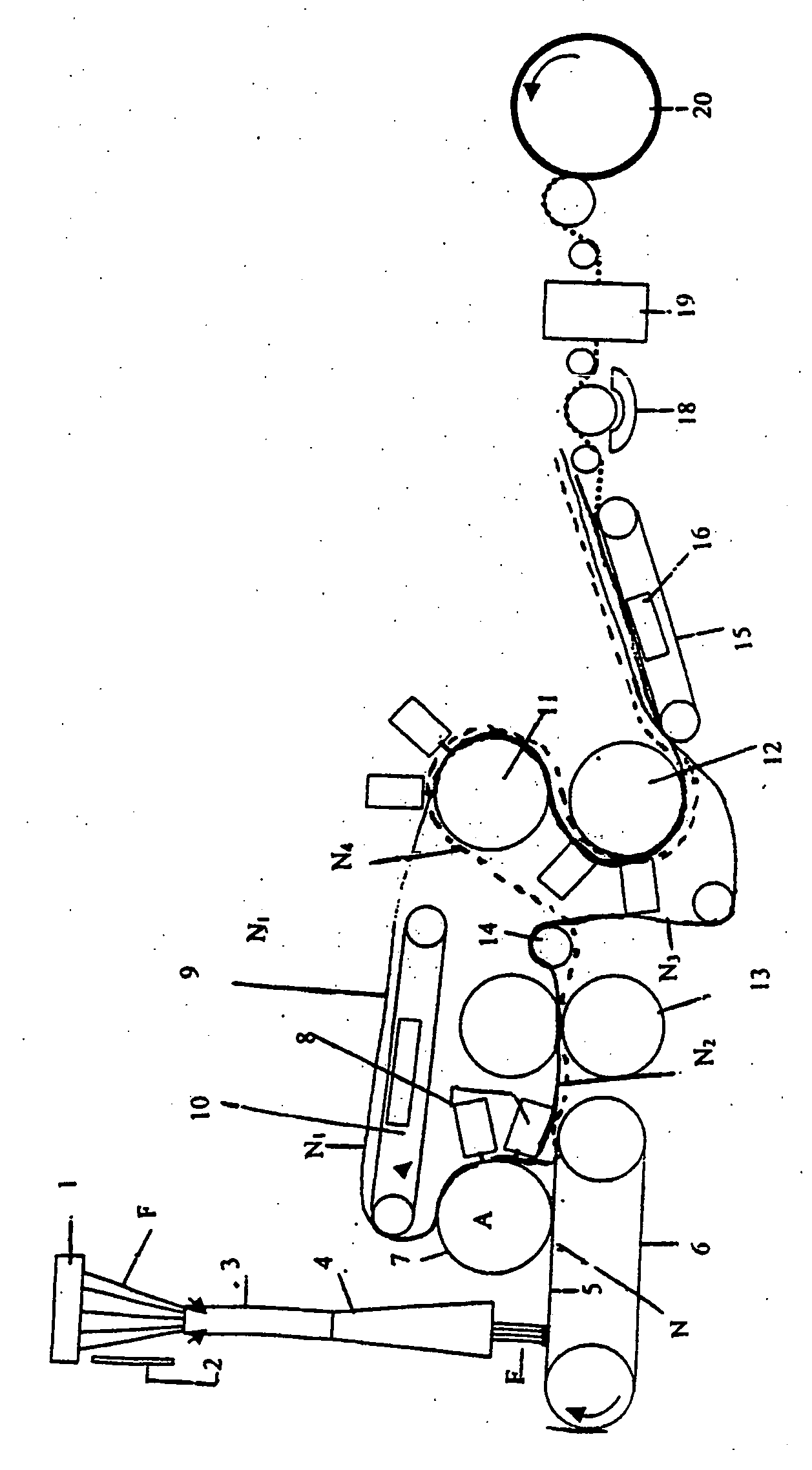

Steel plate and method thereof used for producing water heater linear enamel by flexible thin slab rolling line

ActiveCN102181805AStable recoveryExcellent anti-scale explosion performanceRoll mill control devicesMetal rolling arrangementsThin slabManganese

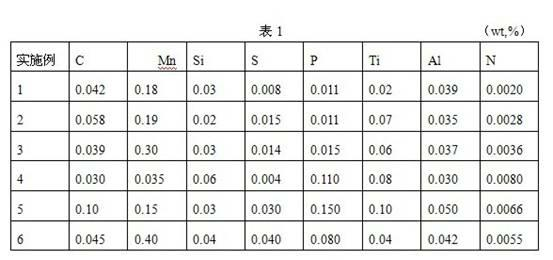

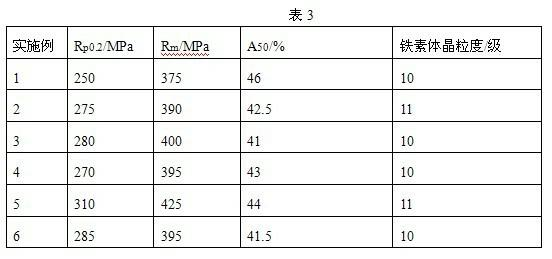

The invention relates to a steel plate and a process method thereof used for producing water heater linear enamel by a flexible thin slab rolling line (FTSR), belonging to the production field of enamel steel plates. The steel plate comprises the following chemical components in percentage by weight: 0.03-0.10wt% of carbon, 0.15-0.40wt% of manganese, less than or equal to 0.06wt% of silicon, 0.004-0.040wt% of sulphur, less than or equal to 0.15wt% of phosphorus, 0.03-0.05wt% of aluminum, 0.002-0.008wt% of nitrogen, 0.02-0.10wt% of titanium and the balance of ferrum and inevitable impurities. The tissue of the water heater linear enamel contains fine grain ferrite and a small quantity of pearlite tissues, and the granularity level of the water heater linear enamel is more than or equal to 10 levels. According to reasonable ingredient design and the FTSR process, steel for manufacturing water-storage water heater linear enamel for home appliances is produced; the steel plate has good enamel adhesion and scaling resistance, and also has the characteristics of few added alloy elements, few production working procedures, low production cost and the like; and a hot rolling scouring plate is used for replacing a cold rolling annealing plate.

Owner:HEBEI IRON AND STEEL

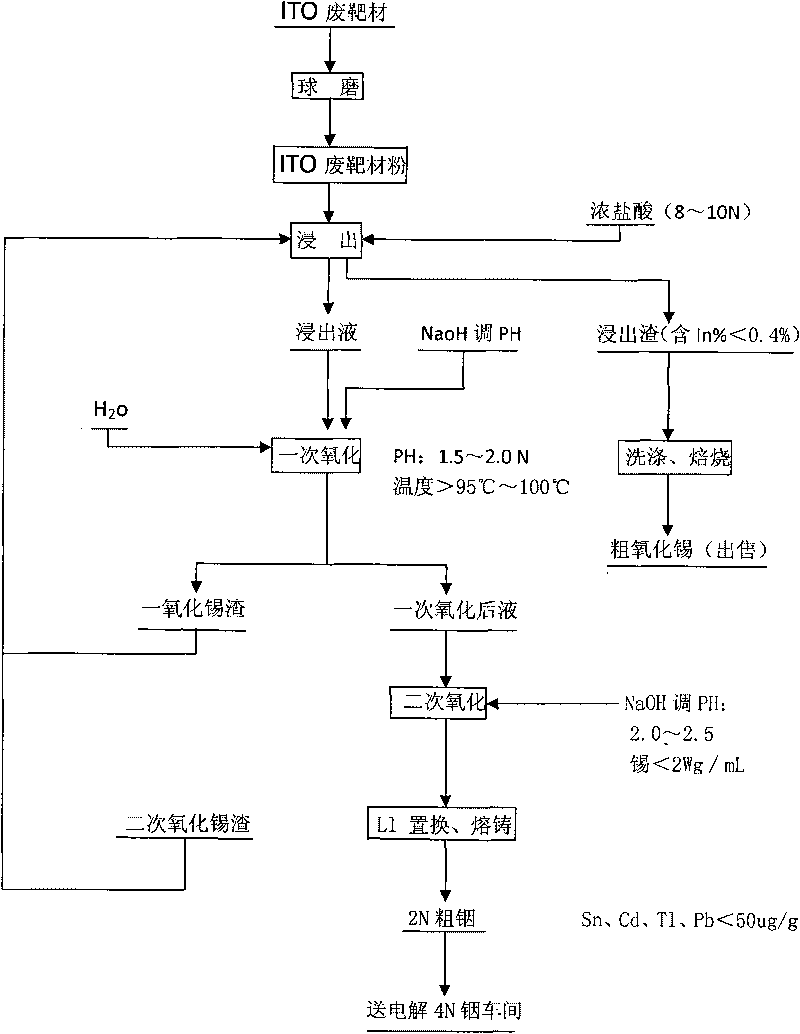

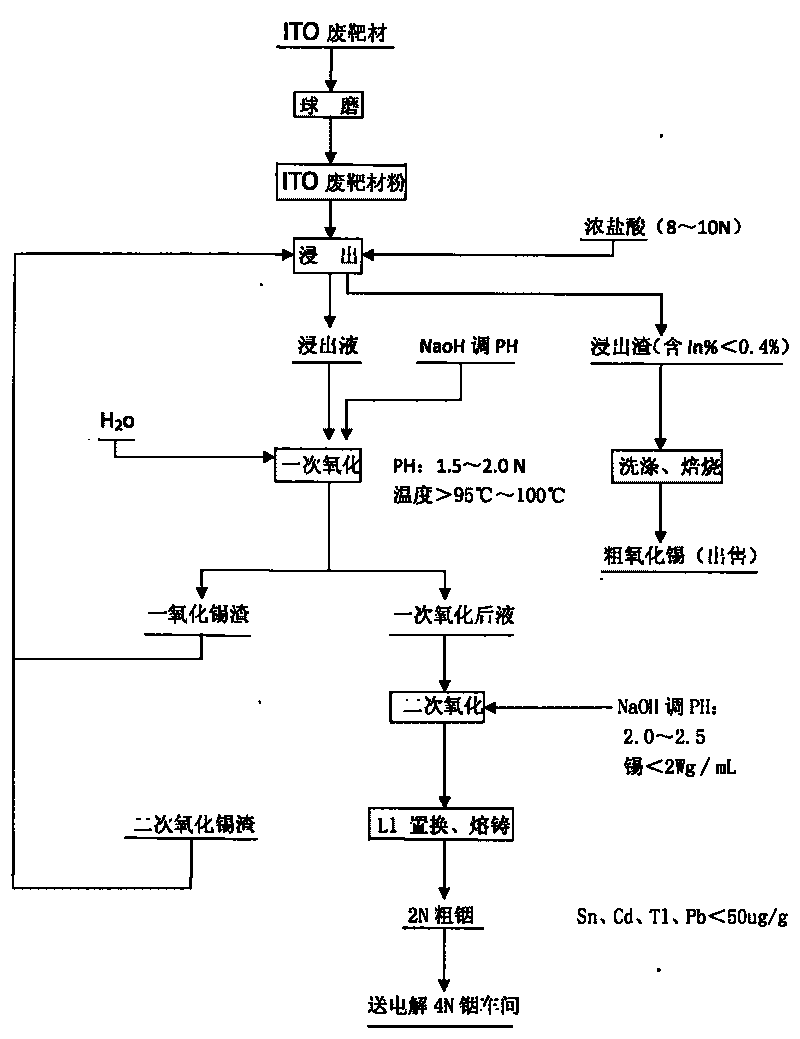

Method for recovering indium and tin from ITO waste targets by utilizing oxidation method

InactiveCN101701292AStable recoveryPhotography auxillary processesProcess efficiency improvementVulcanizationIndium

The invention utilizes the characteristics that tin has two states of bivalence and tetravalence in the solution, and the difference of the pH values is great when the tetravalent tin and trivalent indium ions precipitate in the solution, so the tetravalent tin and trivalent indium ions can be controlled under a certain pH value; oxidant is utilized to oxidize tin ions into tetravalence to generate hydrolysis precipitation, while indium still remains in the water solution, thus achieving the complete separation of indium from tin. At the moment, the tin contained in the indium solution is lowered to 2ppm, aluminium cutter replacement can be directly carried out after vulcanization to ensure that the content of tin, cadmium, thallium and lead is less than 100 PPM, and the content of indium is greater than 99%; while the oxidized tin dregs return and leach, and finally coarse tin oxide can be obtained for sale after washing and roasting the leached dregs, and the grade of indium content is lower than 0.2%.

Owner:南京中锗科技有限责任公司

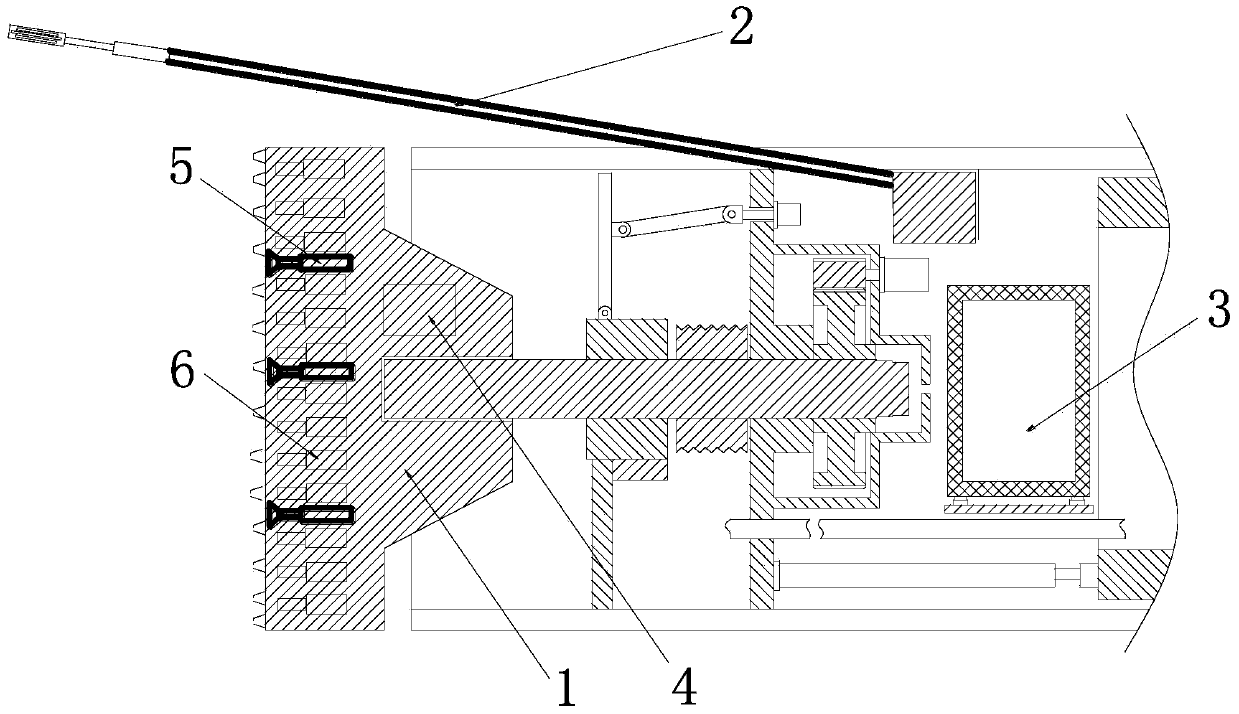

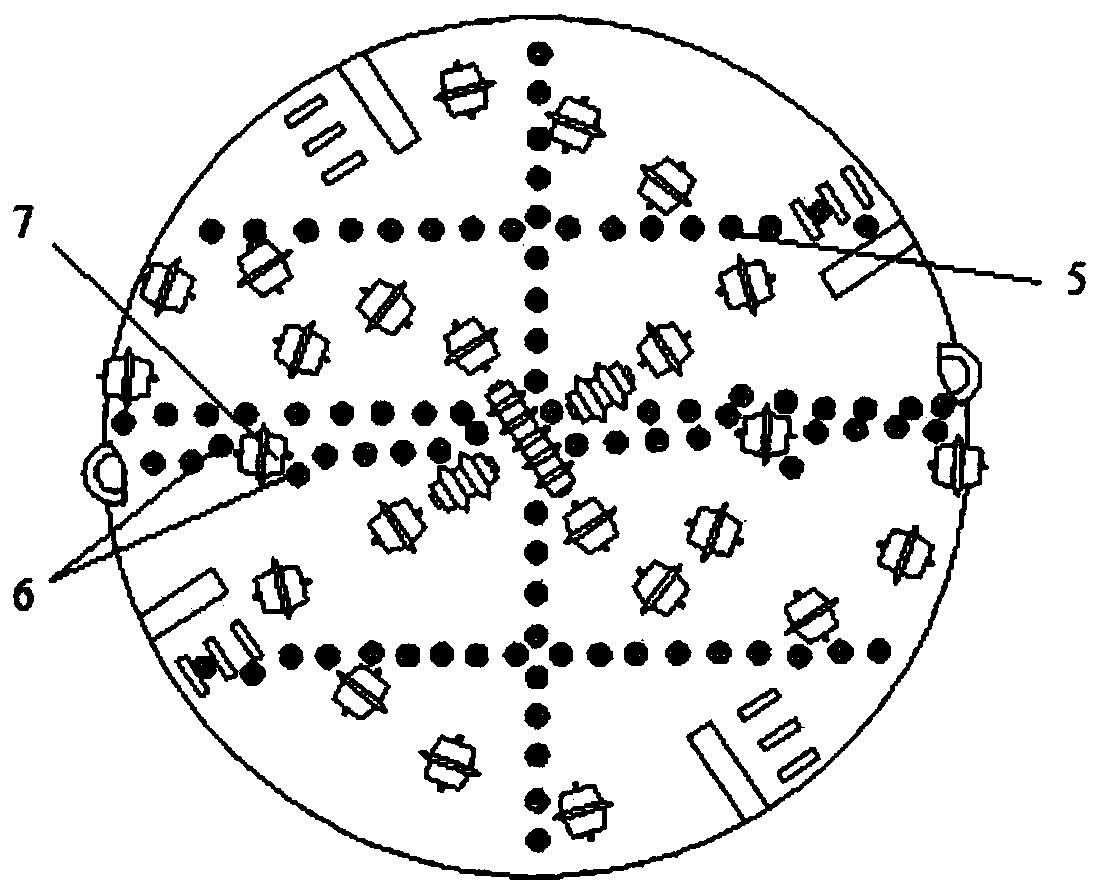

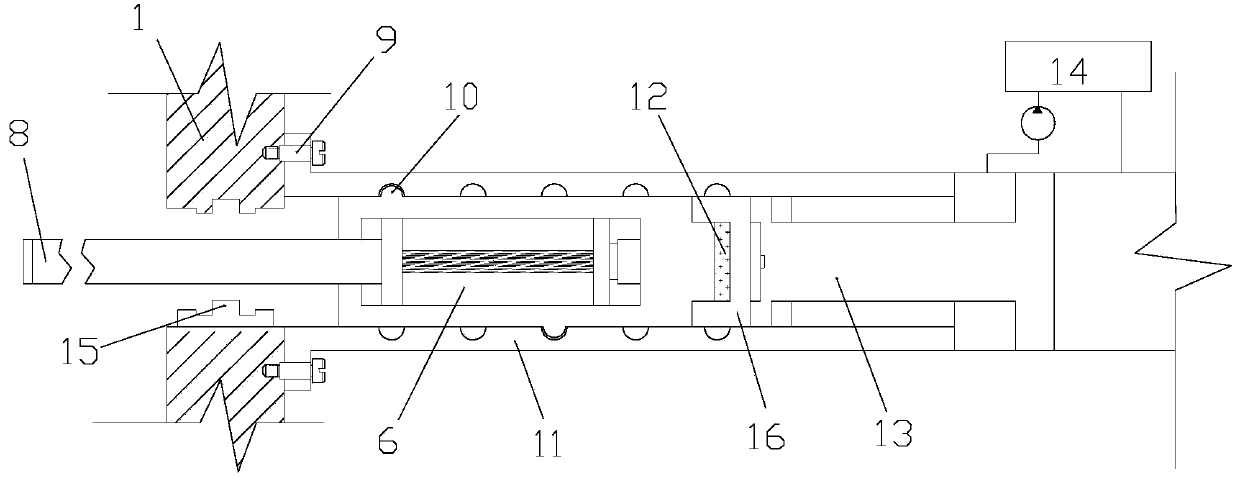

Carrying device of three advance geology forecasting instruments on TBM (Tunnel Boring Machine)

ActiveCN103698806AAdvancement of Geological Forecasting AbilitySimple structureSeismic signal receiversRadarEngineering

The invention discloses a carrying device of three advance geology forecasting instruments on a TBM (Tunnel Boring Machine). The carrying device comprises a transmission supporting and shock absorption device, a telescopic transmission system and an instrument cabin protection device, wherein the transmission supporting and shock absorption device is convenient for carrying power supplying / measuring electrodes, and installing seismic wave vibration exciters and a seismic wave sensor on a TBM cutter disk; the telescopic transmission system is convenient for carrying an oblique single-hole geology radar transmitting and receiving antenna above a TBM rear support; the instrument cabin protection device plays a protection role when the TBM is in boring operation and is convenient for carrying an instrument cabin controlling the whole detection work at the inner part of the TBM rear support. According to the carrying device disclosed by the invention, the integration of detection instruments and the TBM is realized, the detection space and the detection time of a full-face excavation tunnel are fully utilized, the detection instruments are automatically and quickly distributed on a working surface of the TBM, an advance detection hole is drilled, the three advance geology forecasting instruments are successfully carried, the detection efficiency of advance geology forecasting and the automation and rapidity level are increased, and the advance geology forecasting capacity of the TBM is obviously enhanced.

Owner:山东百廿慧通工程科技有限公司

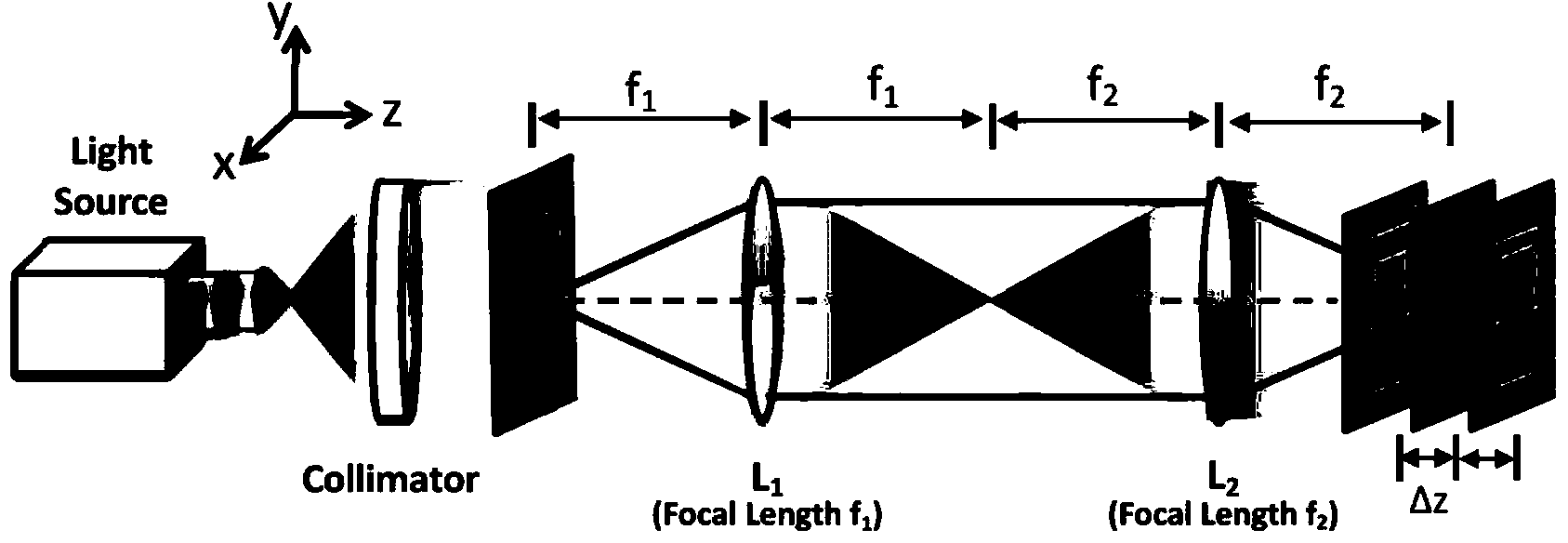

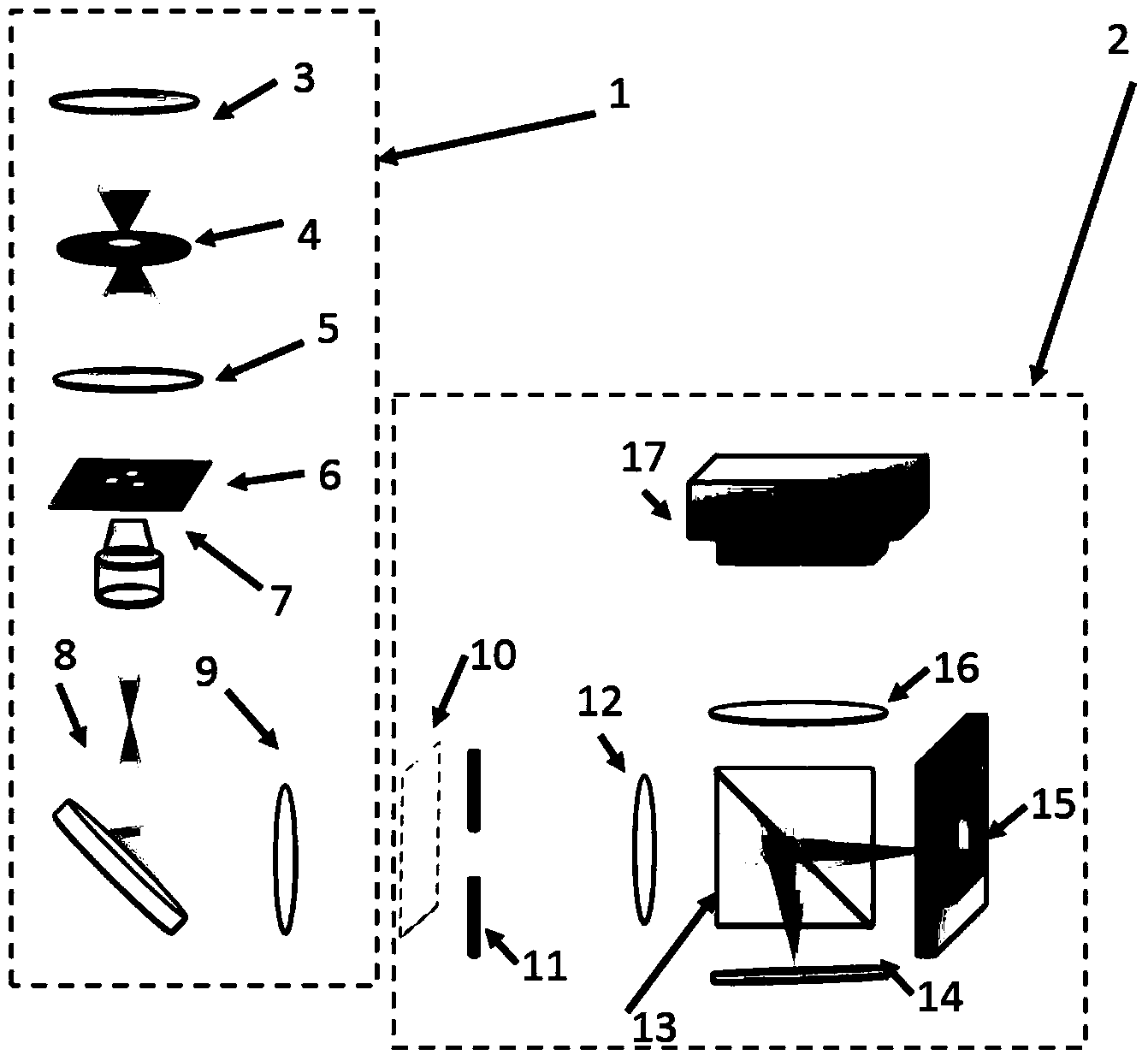

Single-frame light intensity transmission quantitative phase microscope system and method

InactiveCN104344793AImprove spatial resolutionAvoid Speckle NoiseMicroscopesUsing optical meansSingle frameHigh resolution

The invention discloses a single-frame light intensity transmission quantitative phase microscope system and method. The light splitting is realized by utilizing a Michelson structure, digital defocus can be carried out by adopting a space light modulator, the mechanical movement caused by adopting a defocus strength image in a traditional method can be avoided, the acquired series of light intensity is distributed, and the quantitative acquisition of the phase information can be realized by solving the light intensity transmission equation. By adopting the system and the method, the mechanical movement caused by acquiring the defocus strength image in the traditional method can be avoided, the acquisition speed and accuracy of the system can be greatly improved, the application range of the light intensity transmission equation method can be effectively enlarged from a static slowly-varied object to a high-speed dynamic object, and the high-speed and high-resolution three-dimensional quantitative phase microscope imaging can be realized.

Owner:NANJING UNIV OF SCI & TECH

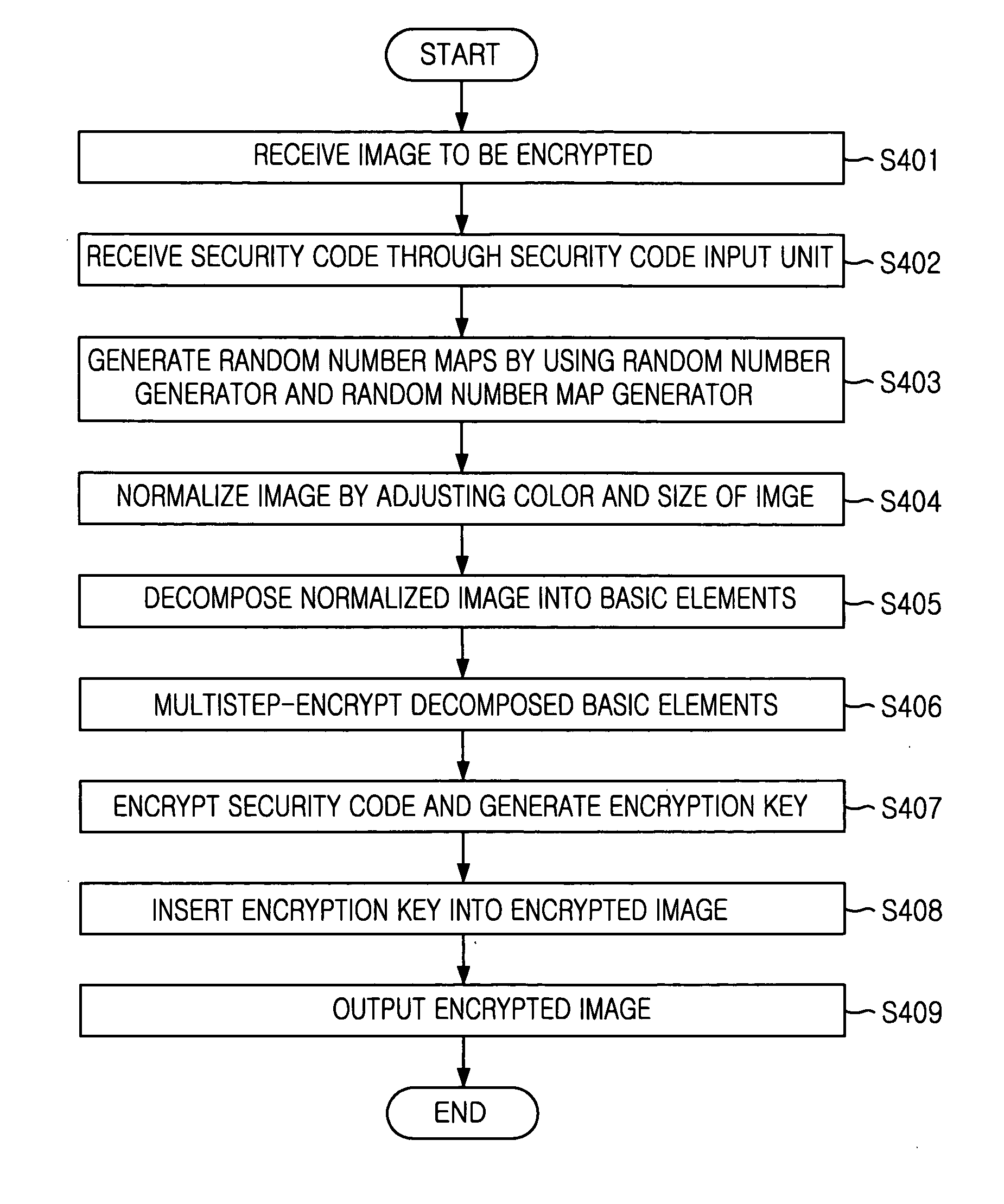

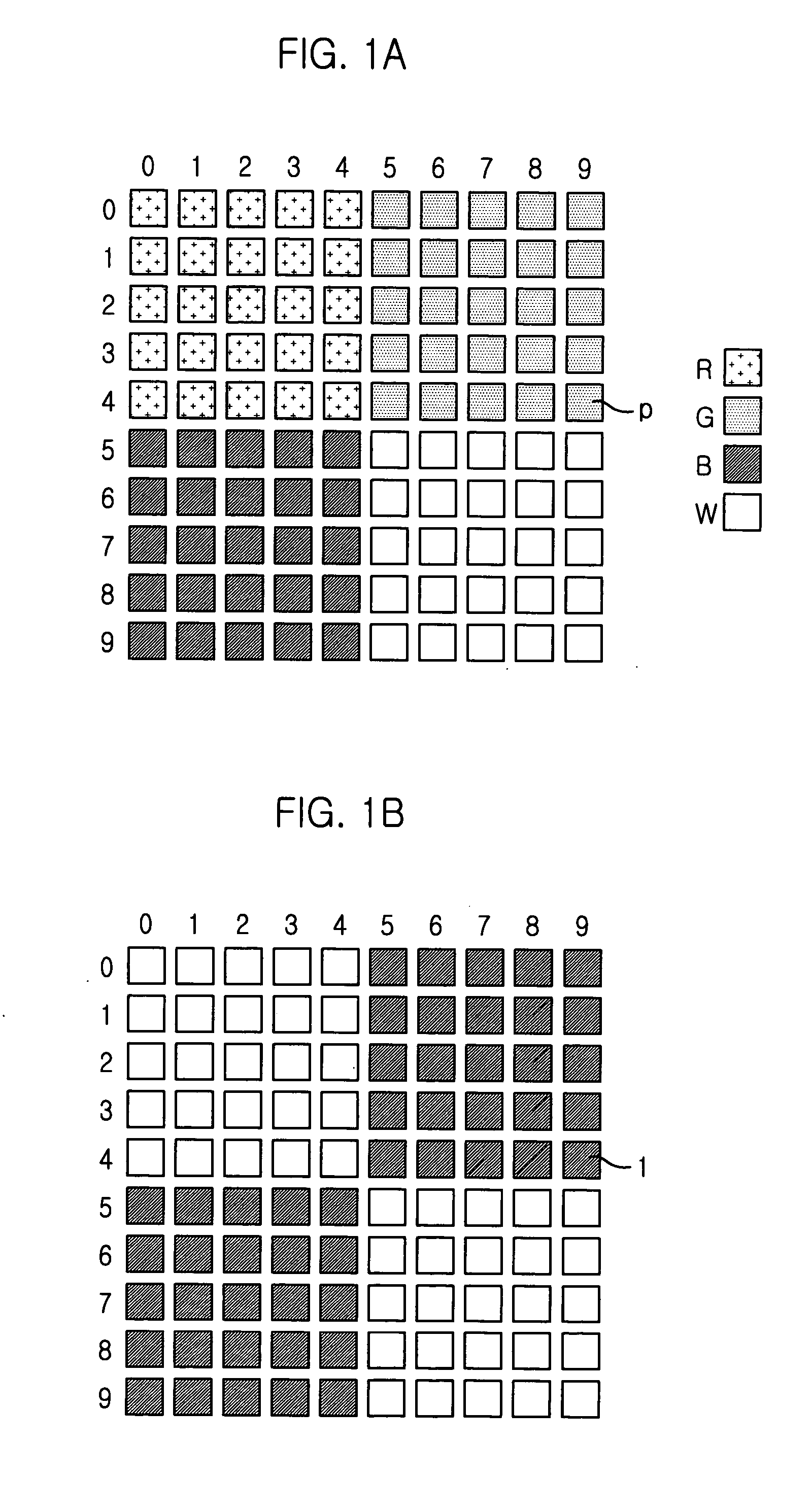

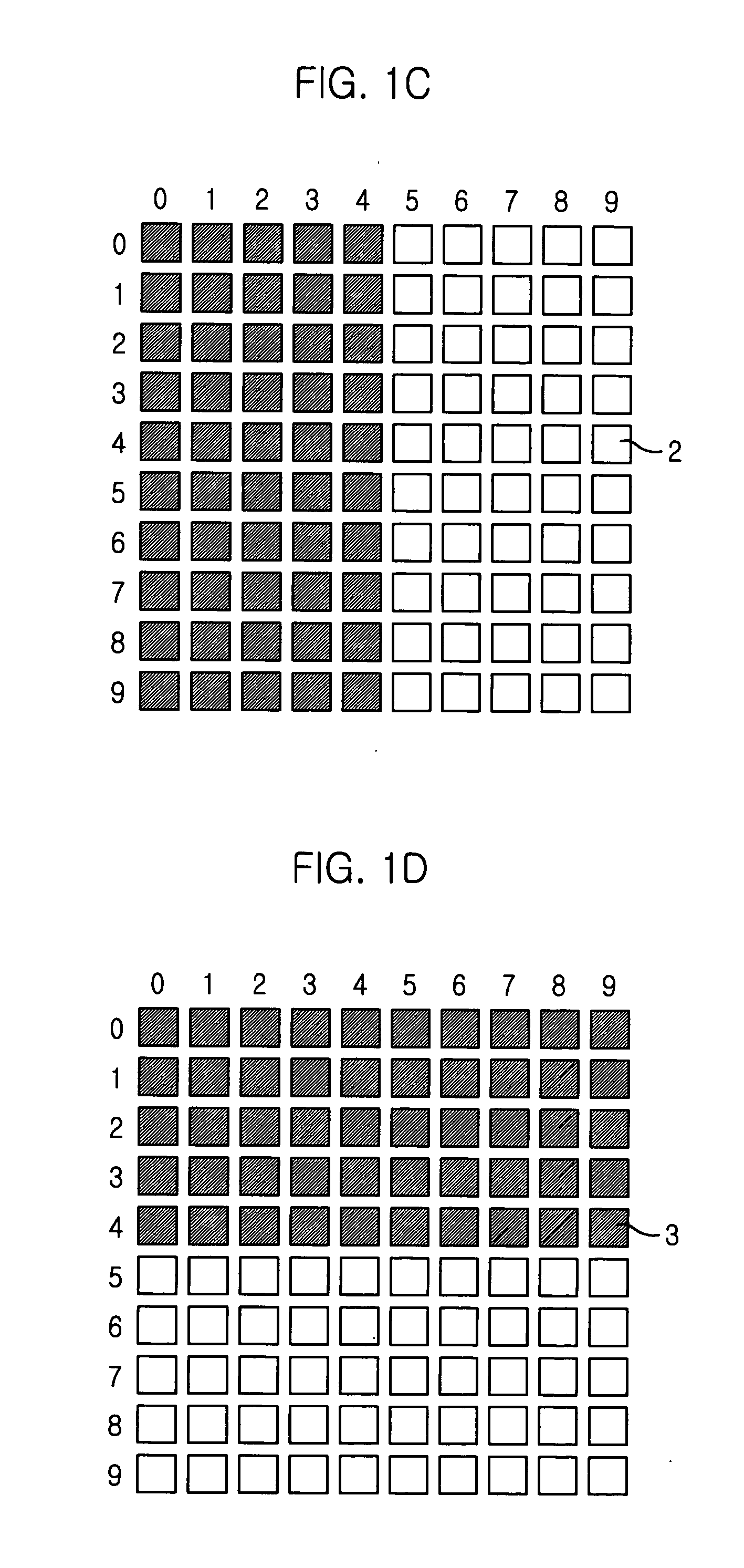

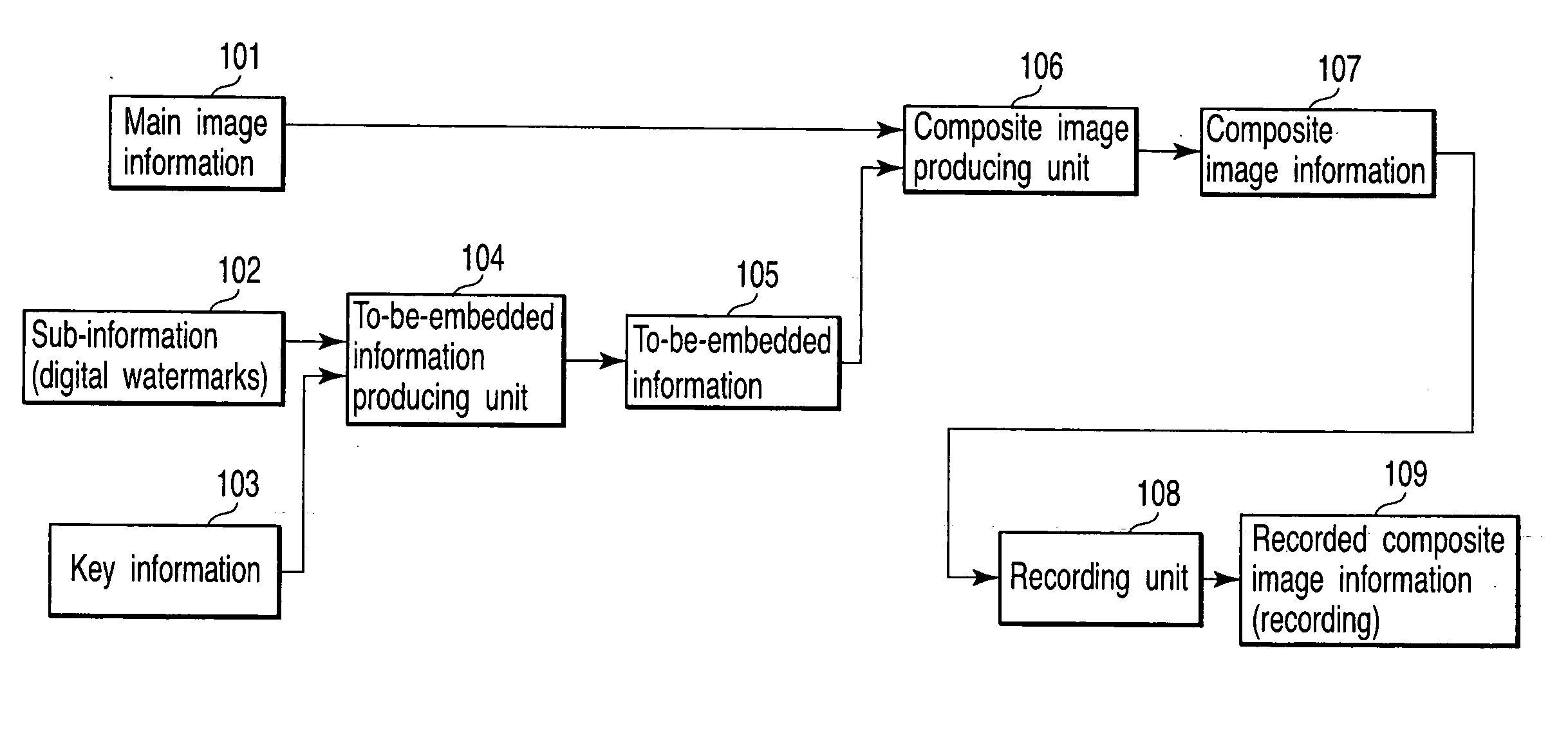

Apparatus and method for encrypting/decrypting information on basic element by element basis and encryption/decryption system using the same

InactiveUS20040096058A1Guaranteed stabilityStable recoverySecret communicationImage data processing detailsComputer hardwareTheoretical computer science

An apparatus and method for encrypting / decrypting information, and the encrypting / decrypting system using the same, and a computer readable recording medium storing programs for realizing the above are disclosed. A method for encrypting information on a basic element-by-basic element basis, includes the steps of: a) receiving information to be encrypted; b) generating random number maps; c) decomposing the information into a plurality of basic elements which are classified into multiple channels; d) encrypting the basic elements and generating encrypted information; and e) outputting the encrypted information.

Owner:ALPHALOGIX

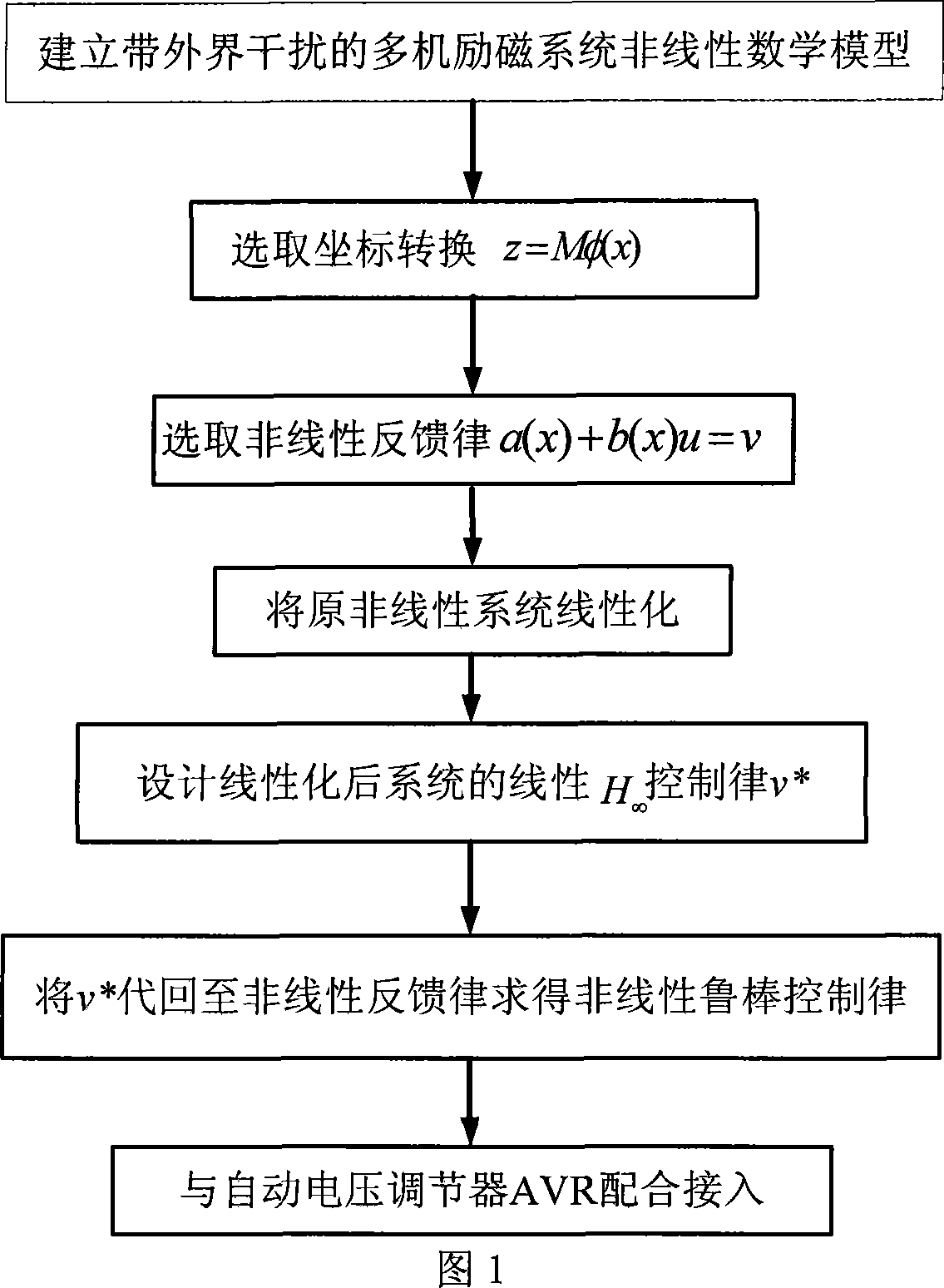

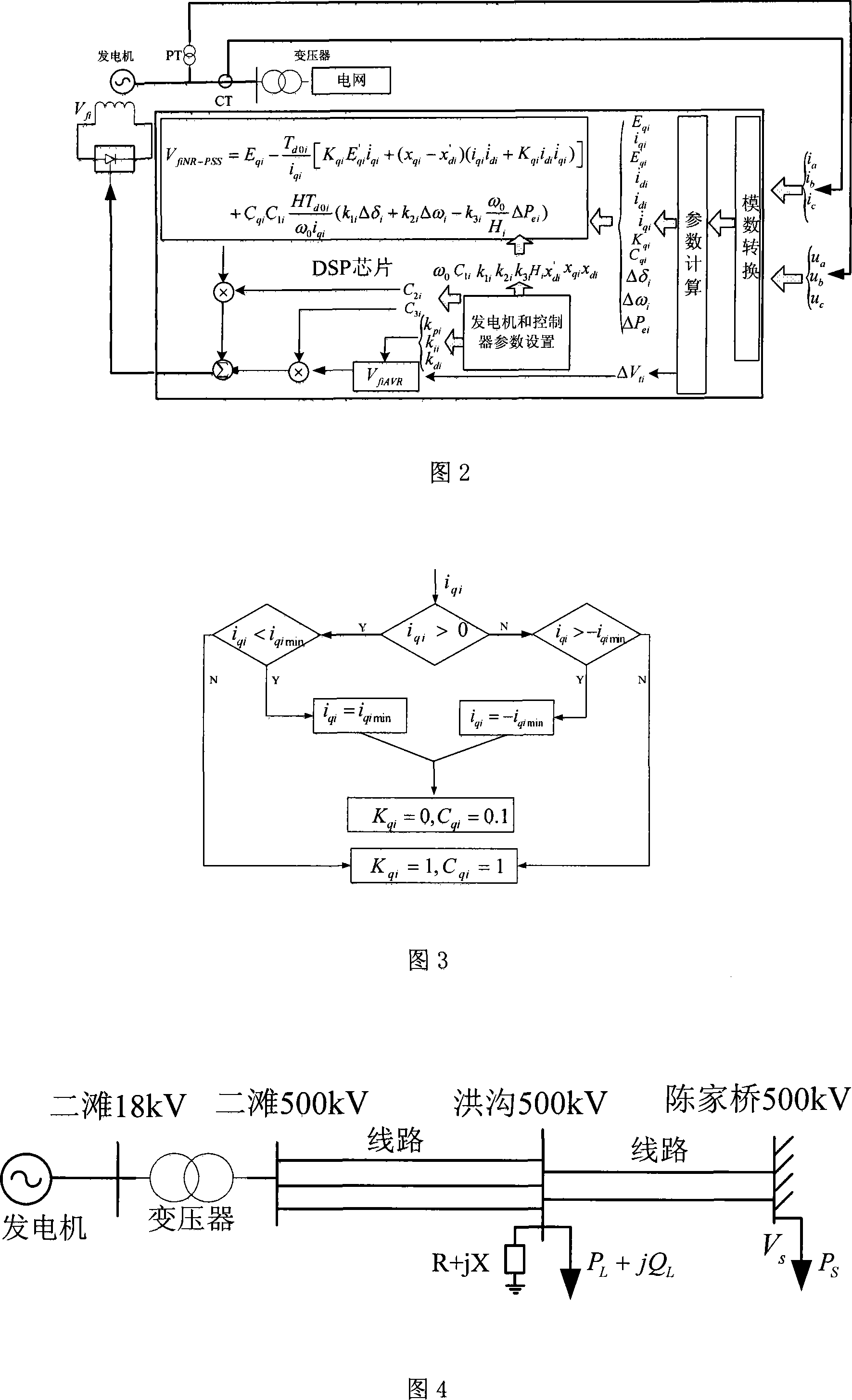

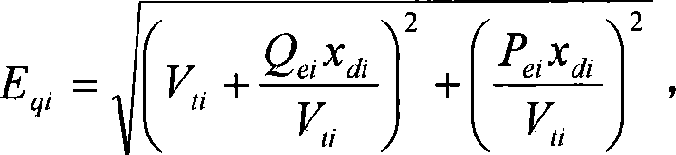

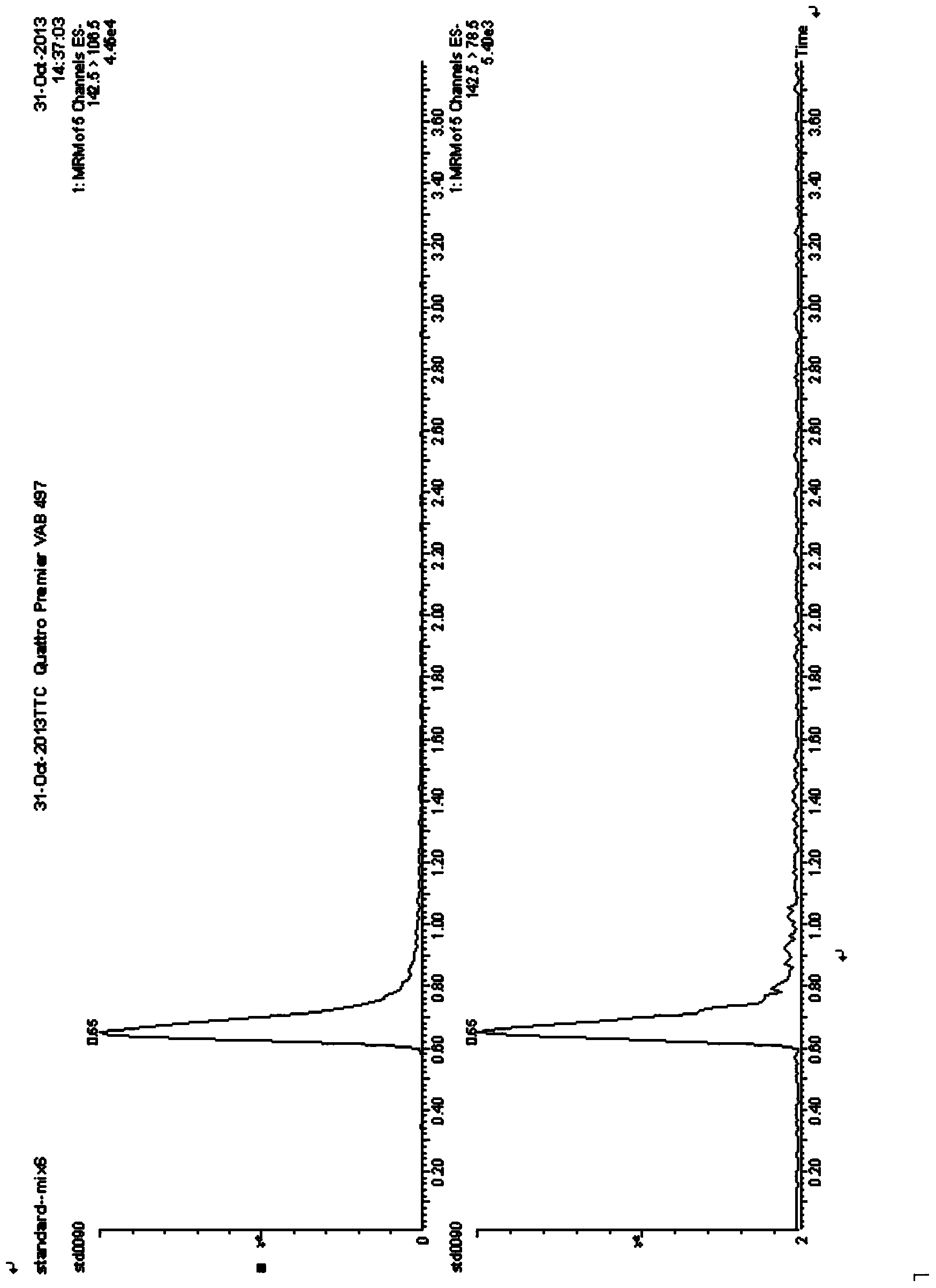

Excitation control method based on non linear robust power system stabilizer

ActiveCN101127445AImprove stabilityImprove power transfer limitPower oscillations reduction/preventionGenerator control by field variationPower system stabiliserPower system stability control

The utility model discloses an excitation control method based on nonlinear robust power system stabilizer, which belongs to the technical field of power system stability control. The utility model is characterized in that a nonlinear robust power system stabilizer is put forth on the basis of multi-machine excitation system nonlinear mathematical model and by combining differential geometry control theory and nonlinear HíÌ method. The output signals of the nonlinear robust power system stabilizer are superimposed with the output signals of an original automatic voltage regulator to generate excited control signals, which are used to control the excitation system of the generating set, thus preventing the influence of external uncertainties, solving the problems of dynamic nonlinearity and high coupling in power system, overcoming the defects of neglecting the nonlinearity inherent in the system in prior art, improving the dynamic stability and expanding the installed capacity of the generating set to the maximum extent.

Owner:TSINGHUA UNIV

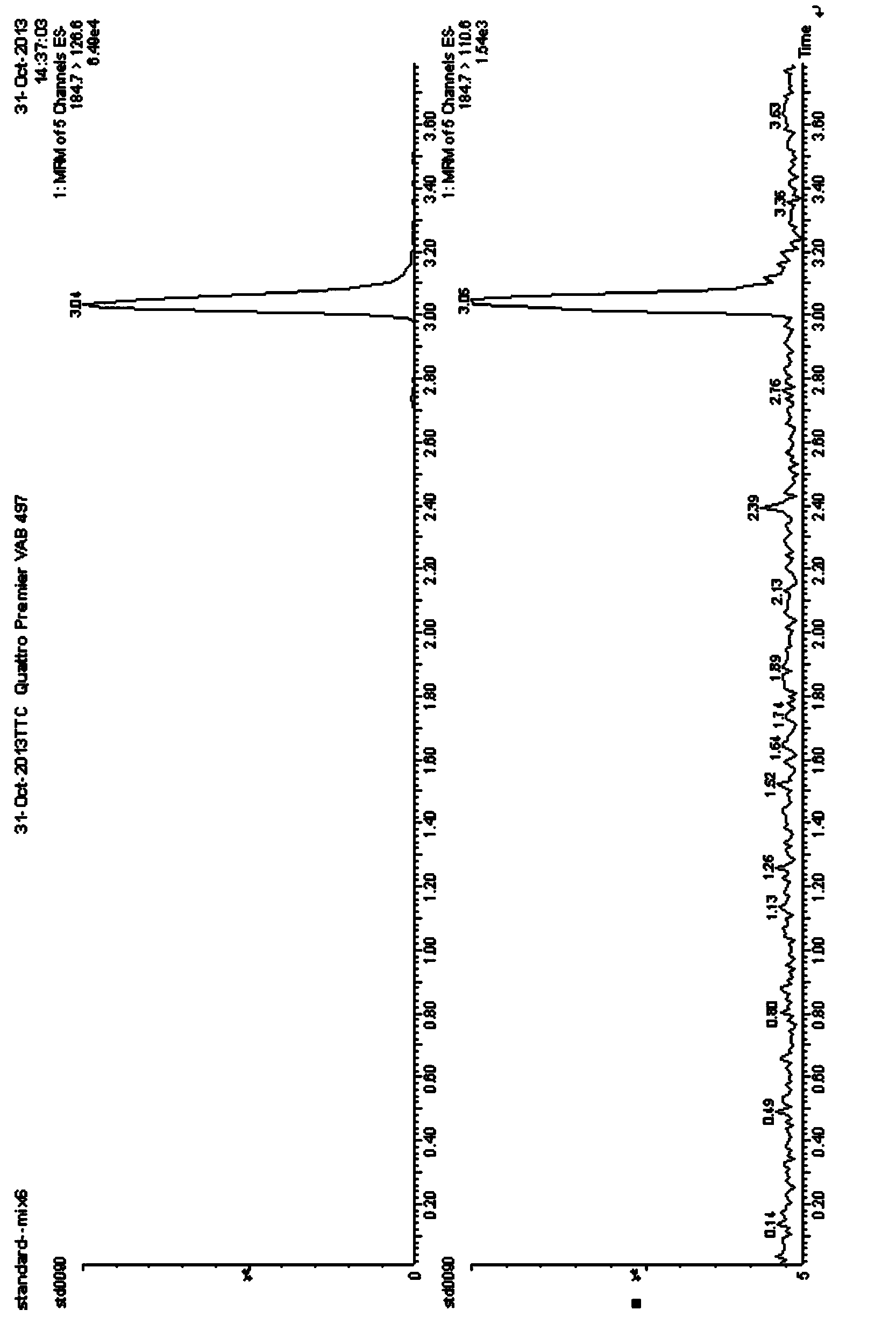

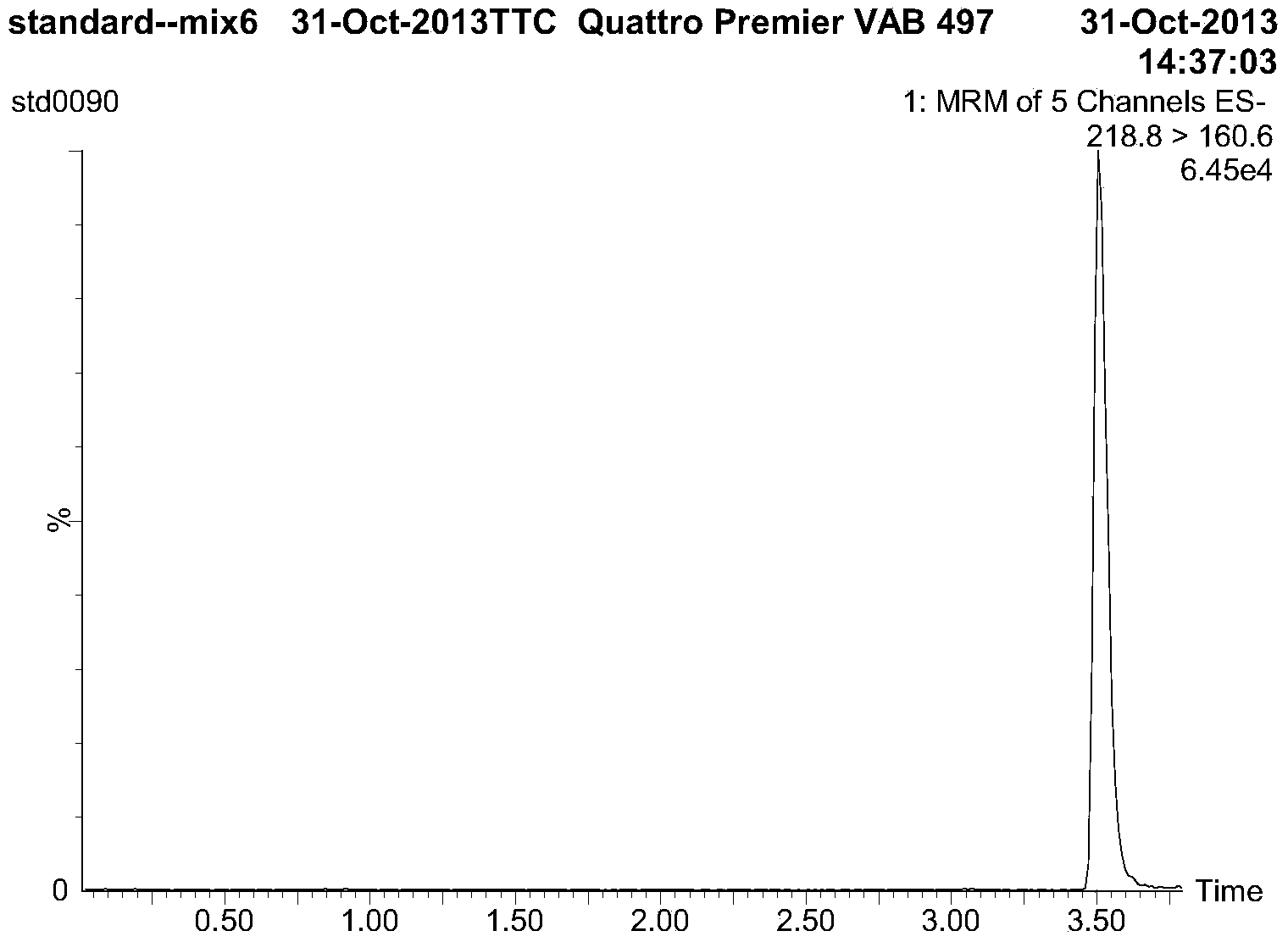

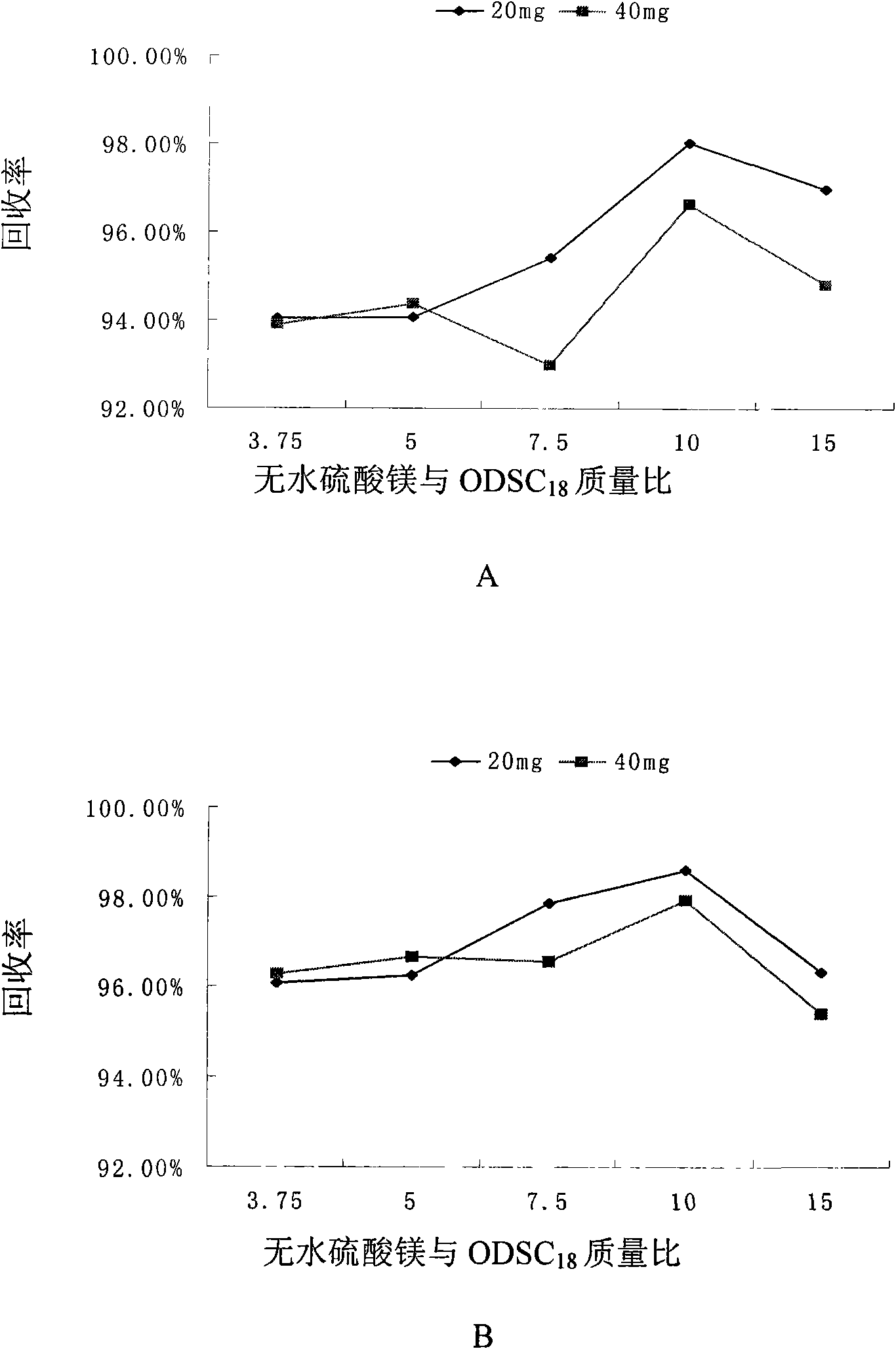

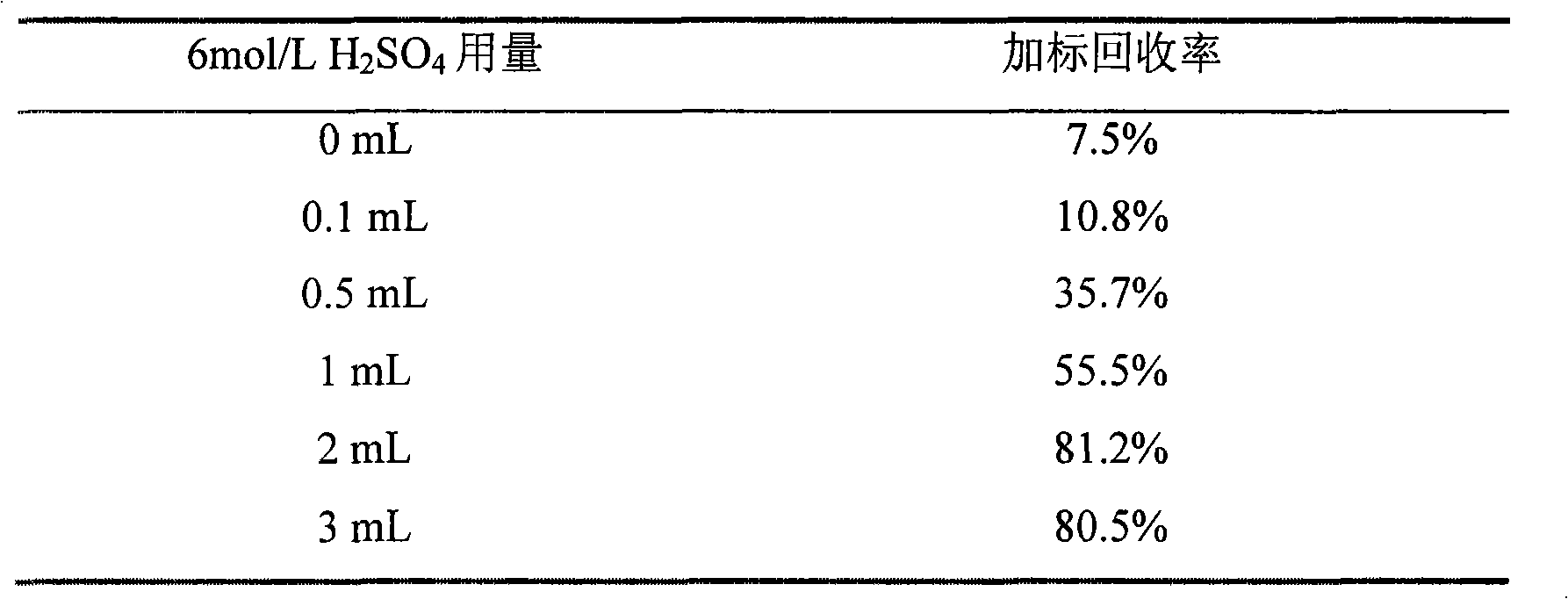

Detection method for plant growth regulator residues in fruits

InactiveCN103969363AStable recoveryAchieving Simultaneous DetectionComponent separationSodium acetateGrowth plant

The invention relates to a detection method for plant growth regulator residues in fruits. The detection method comprises the following steps: the QuEChERS method is adopted to extract and purify the plant growth regulator residues in fruits, so as to enable the adding standard recovery rate of the target compound to reach 71%-98%; the RSD ( relative standard deviation) is not higher than 6%; the sensitivity and selectivity are favorable and the recovery rate is stable; the liquid chromatograph tandem mass spectrogram detection method is adopted to simultaneously detect forchlorfenuron, ethephon, 4-sodium chlophenoxycetate and 2,4- sodium acetate-dichlorobenzene oxygen; the detection limits range from 0.5 microgram / kg to 100 microgram / kg respectively; the sensitivity requirement of national limited standard is met. The detection method has favorable sensitivity and selectivity and can serve as a method for detecting the plant growth regulator residues in fruits.

Owner:WENZHOU INST OF TECH TESTING & CALIBRATION

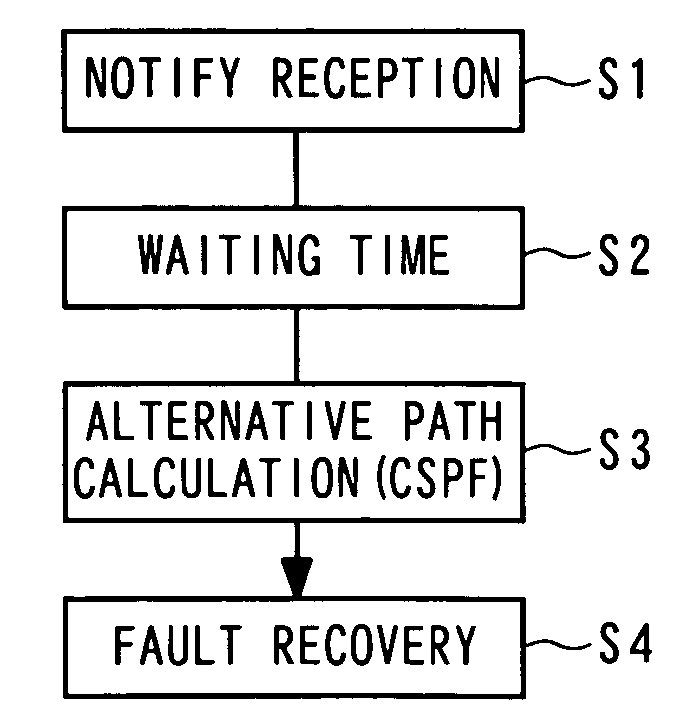

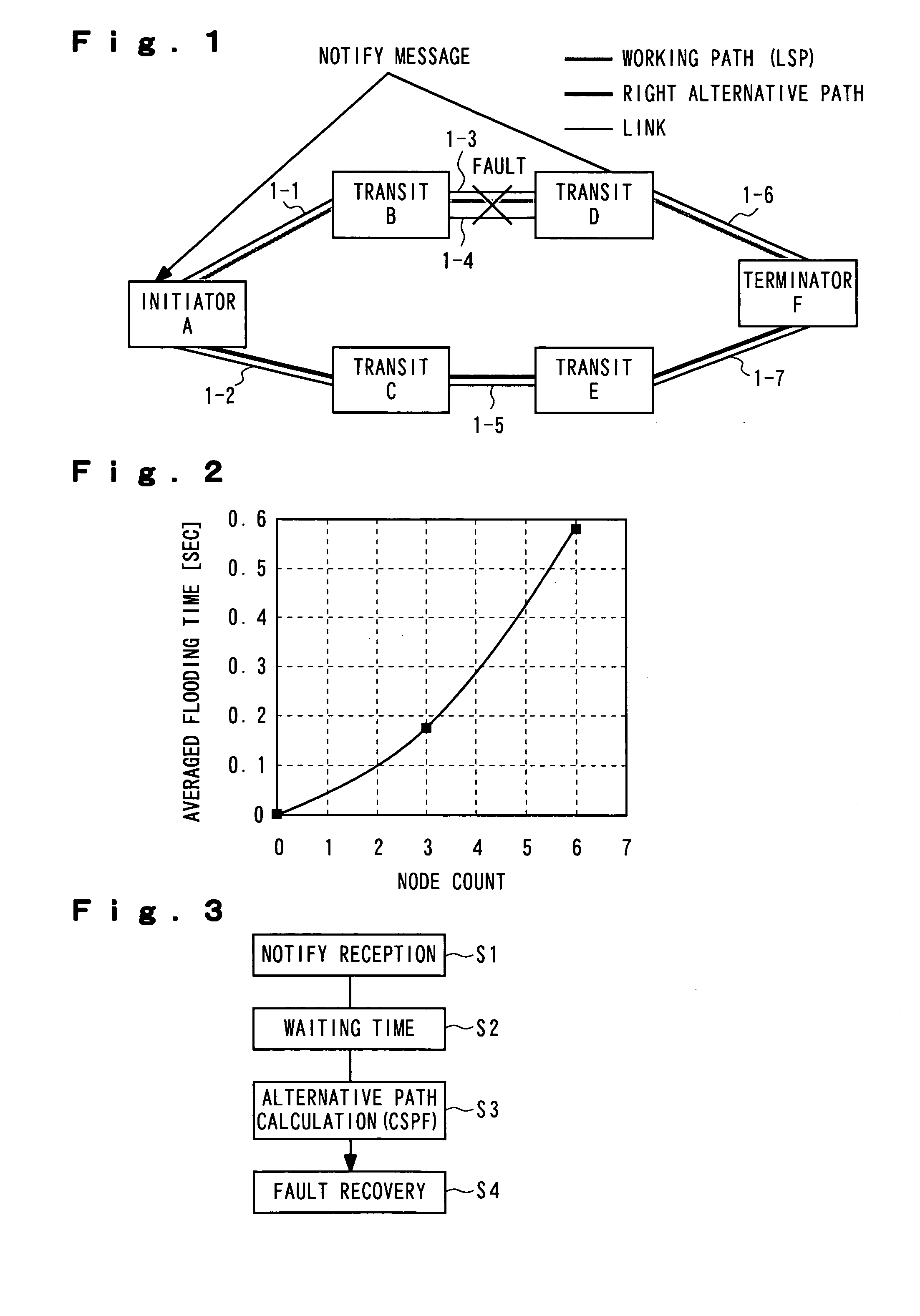

Fault recovery method and program therefor

InactiveUS20050259570A1Stable recoveryRule out the possibilityError preventionTransmission systemsRecovery methodWaiting time

When there occurs a fault in any path of the MPLS or GMPLS network, a node which has detected the fault sends a notify message which is fault event information. A node which performs fault recovery receives the notify message (S1) and counting of the waiting time is triggered by this reception (S2). During this waiting time, LSA of OSPF is collected. When the waiting time is terminated, the node which performs fault recovery calculates alternative path based on the notify message and the LSA of OSPF (S3) and carries out fault recovery by restoration (S4).

Owner:NEC CORP +1

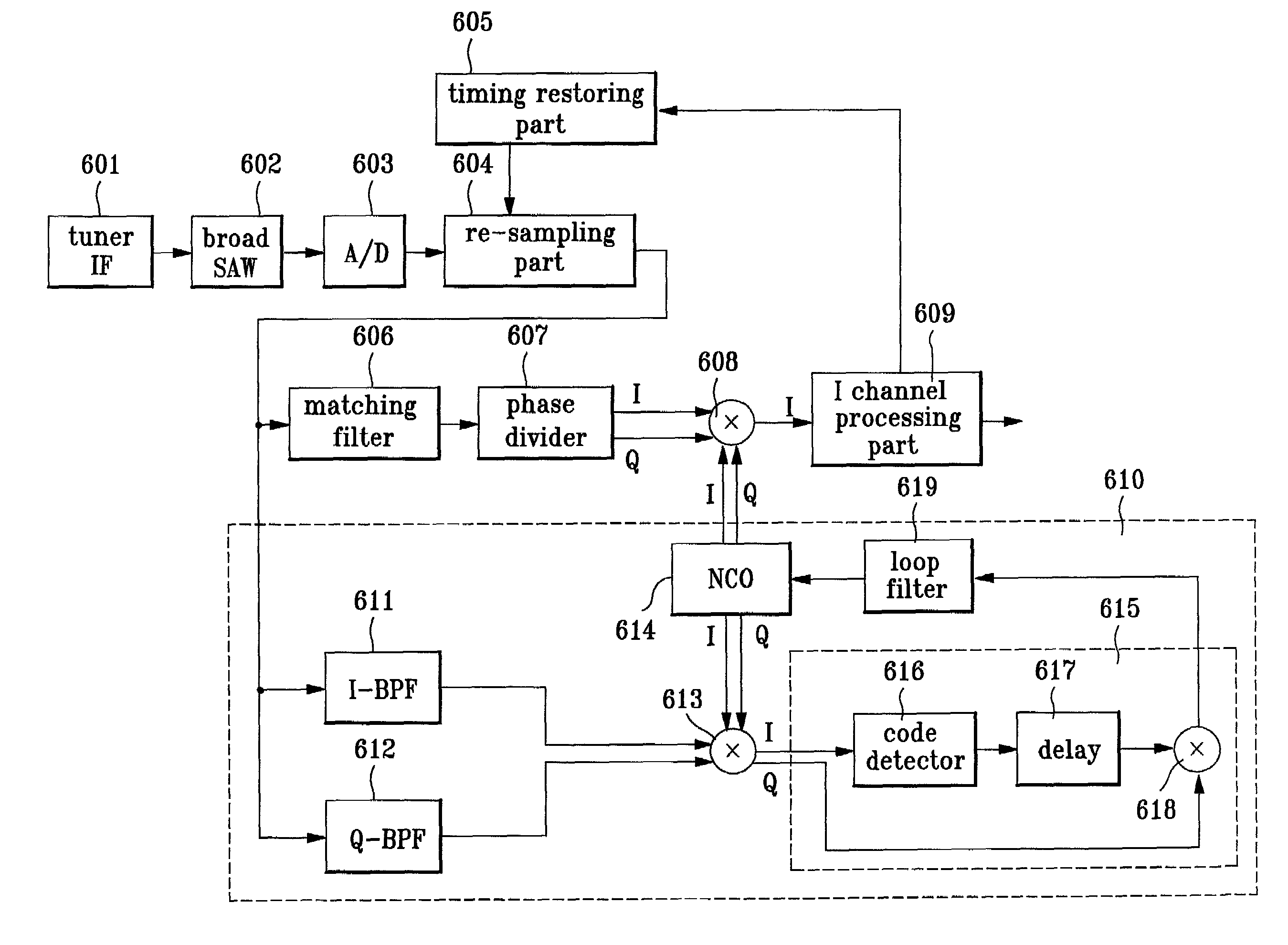

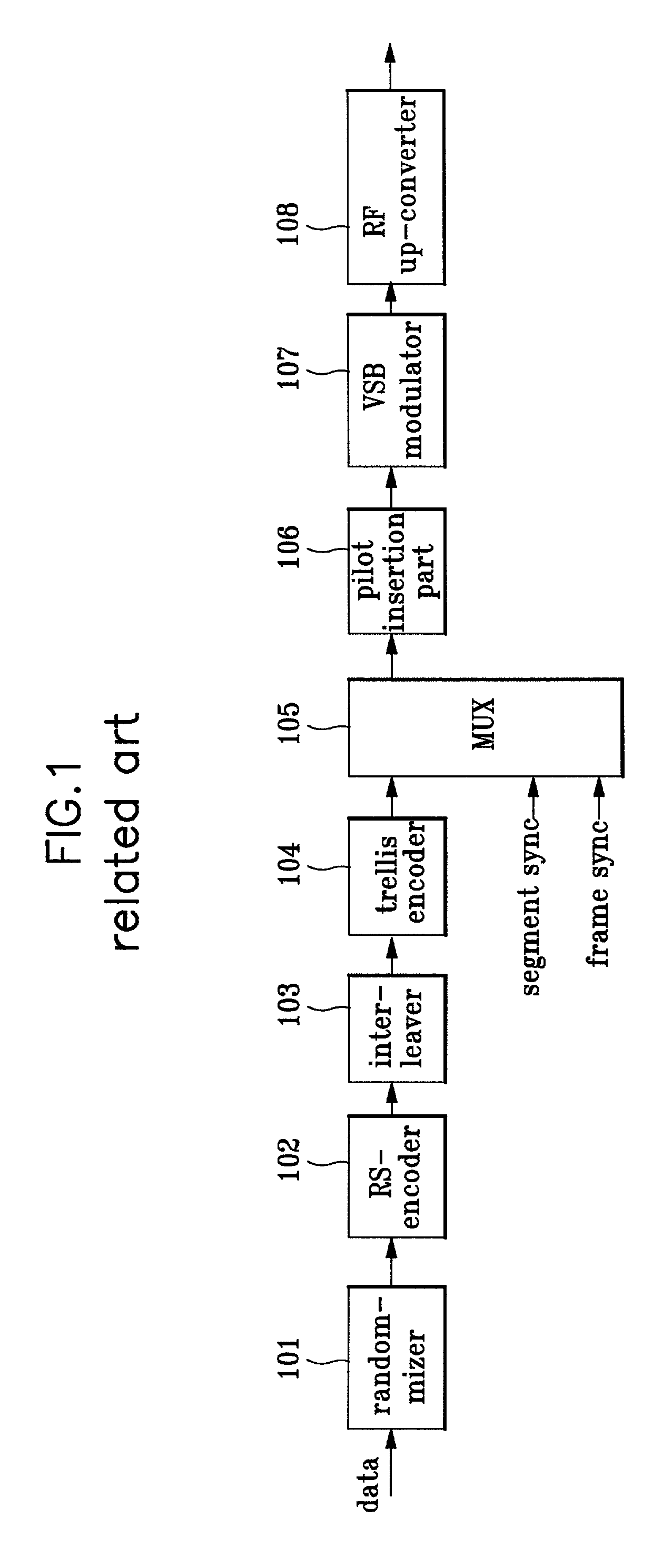

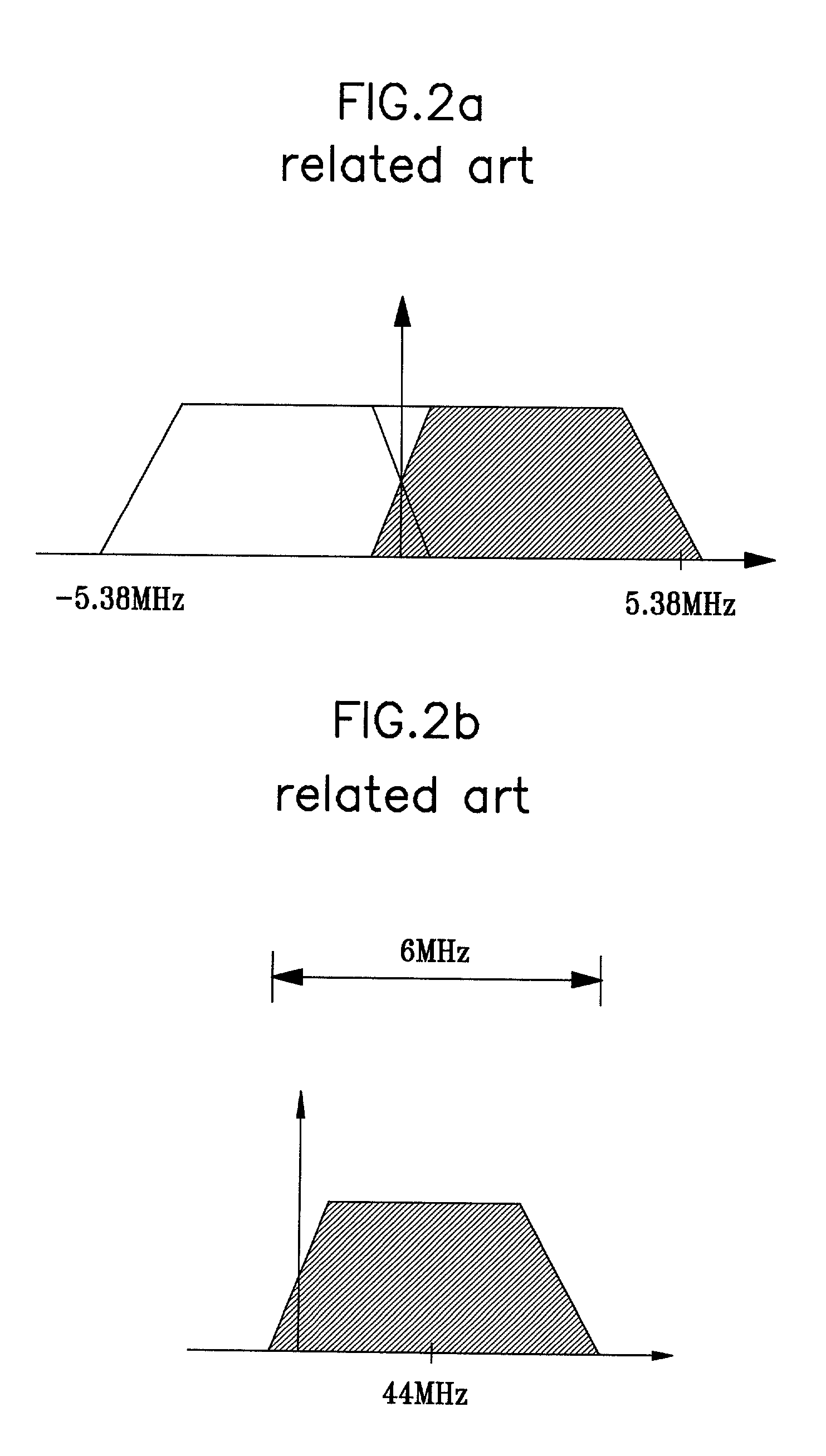

Vestigial sideband receiver and method for restoring carrier wave

InactiveUS7061996B2Stable recoveryImprove performanceTelevision system detailsAmplitude demodulation by homodyne/synchrodyne circuitsIntermediate frequencyEngineering

A vestigial sideband VSB receiver includes a digital processing part for selecting a desired channel frequency via an antenna and converting the desired channel frequency to an intermediate frequency to digitize a predetermined band of the intermediate frequency, a carrier wave restoring part for extracting pilot components from a signal of the digitized pass band to restore carrier waves, and a demodulator for separating components I and Q from the signal of the digitized pass band and multiplying the components with a complex carrier wave, which is restored in the carrier wave restoring part. The carrier waves are restored by extracting the pilot signals from the pass band and detecting the symmetrical errors of the carrier wave frequency, so that the carrier wave may be stably obtained and pursued with relation to the both positive and negative frequency offsets.

Owner:LG ELECTRONICS INC

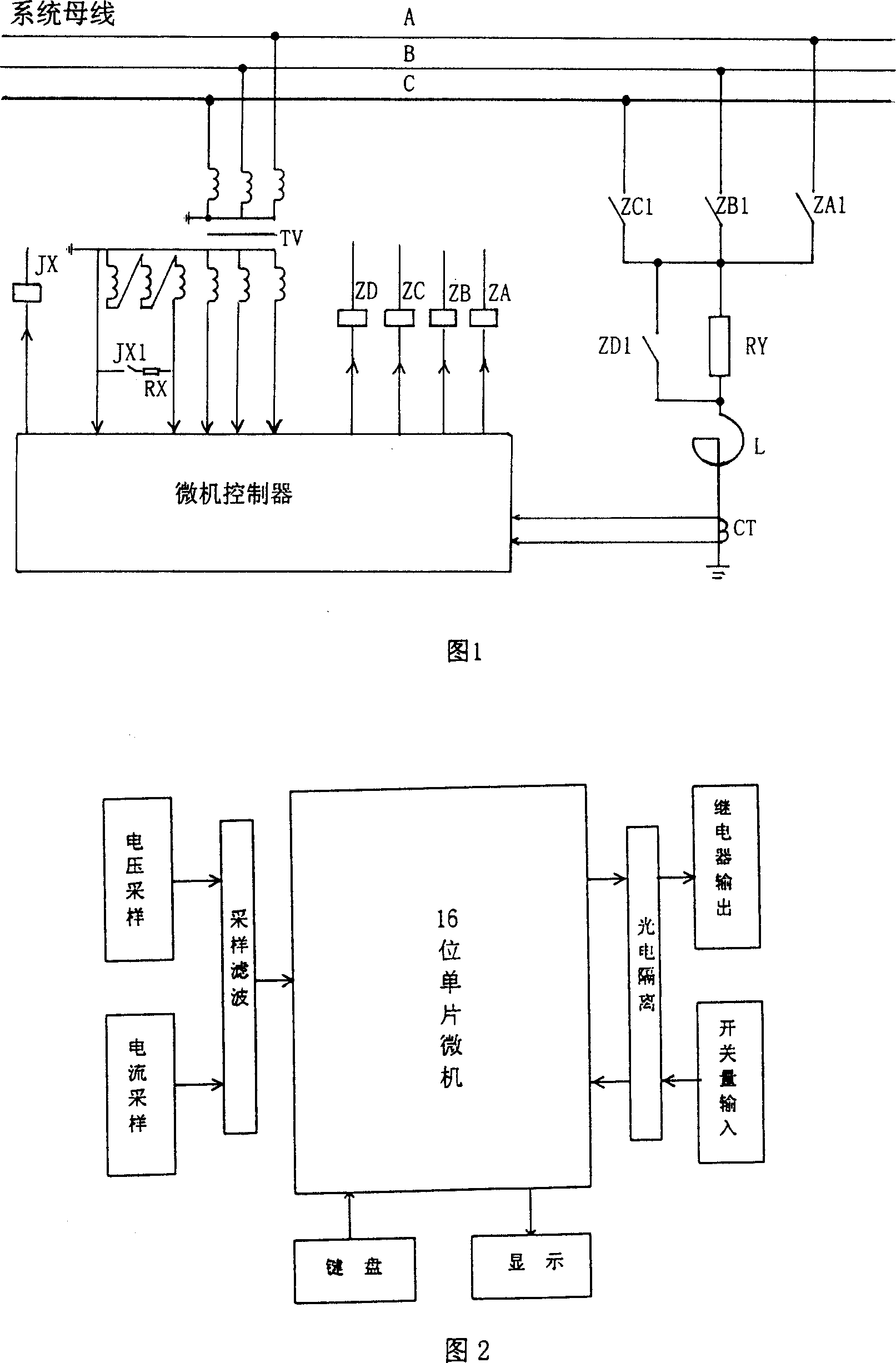

Harmony and arc elimination method of the neutral point non-valid grounding power grid and its integrated protection device

InactiveCN101009429AQuick tuneArc extinguishing quicklyEmergency protective arrangements for limiting excess voltage/currentCapacitanceTransformer

Aiming at problem of poor protecting effect of current harmonic eliminating method and product, the invention discloses a harmonic eliminating and extinguishing arc method and synthesized protecting device of neutral point nonproductive grounding electric network, thereinto the harmonic eliminating method is: When there is syntony, the reactor is merged between the generatrix of the voltage dropping phase and ground to form once harmonic eliminating spur track which can destroy syntony point and suppress syntony overvoltage to harmonic eliminating, and make the capacitance current of the system charge to the reactor to protect the voltage transformer and other electric apploance. Thereinto the extinguishing arc method is: When any phase of the electric network generates single phase arc grounding fault, a reactor is directly merged between the generatrix of the fault phase and ground to form extinguishing arc spur track to suppress the voltage of the fault phase and bypass fault current to realize extinguishing arc. The invention discloses a protecting device which matches with it at the same time, it possesses advantages: the method is novel, simple and reliable, the ratio of property and value is high, and maintenance is convenient.

Owner:孙嘉宁 +1

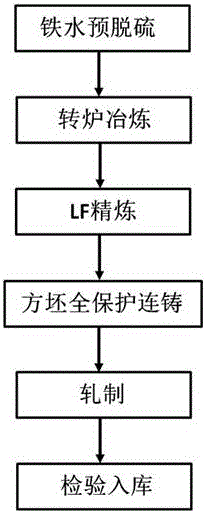

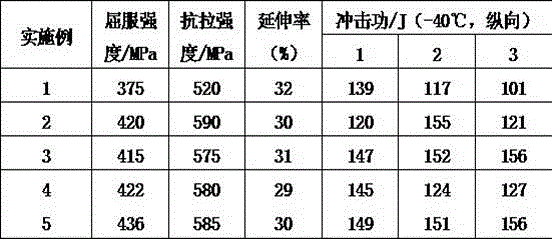

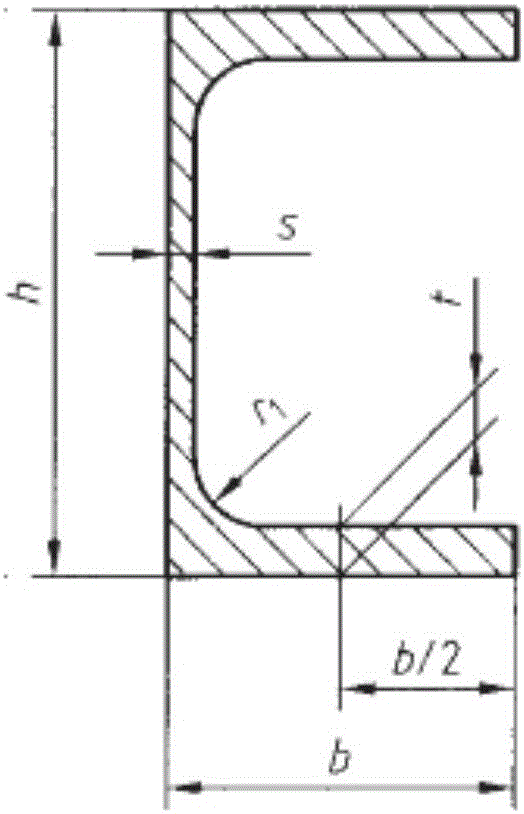

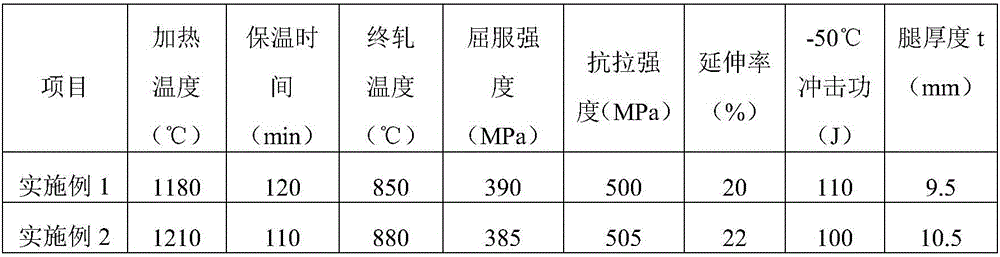

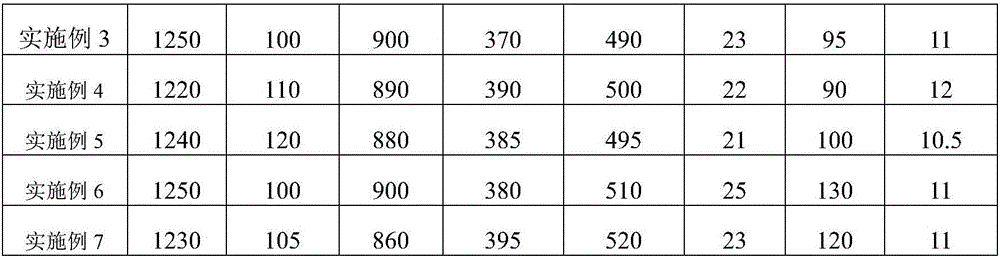

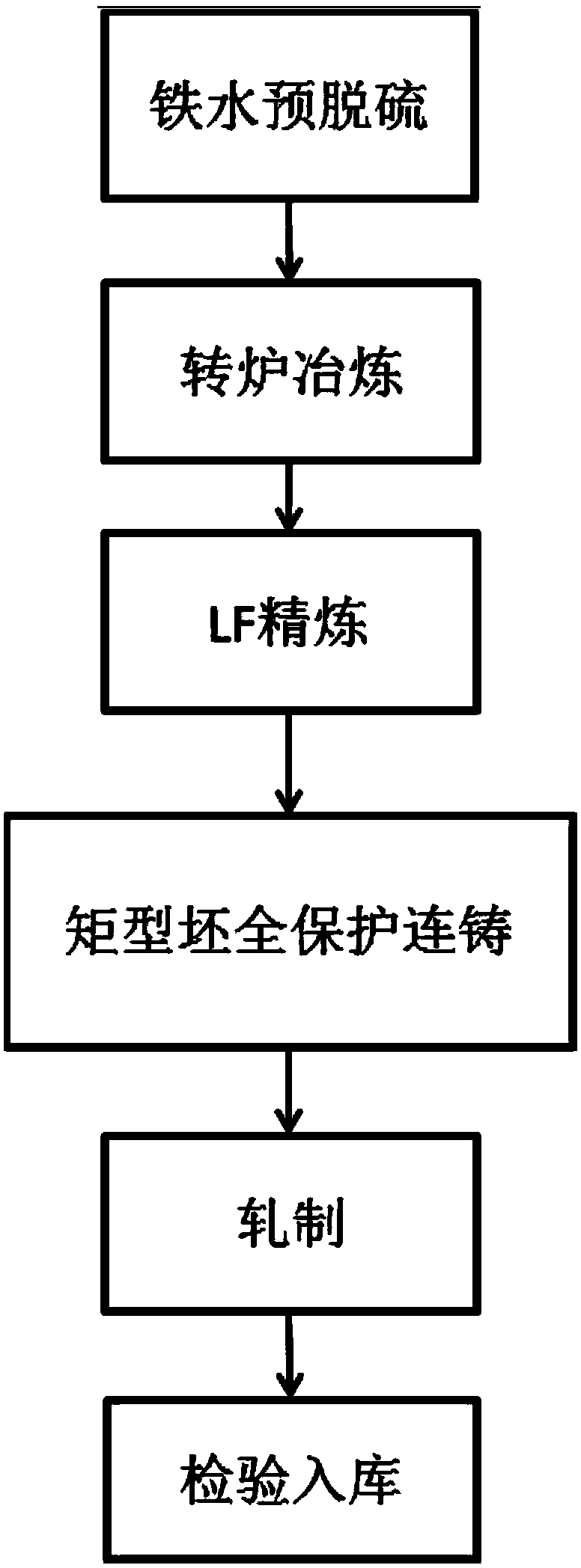

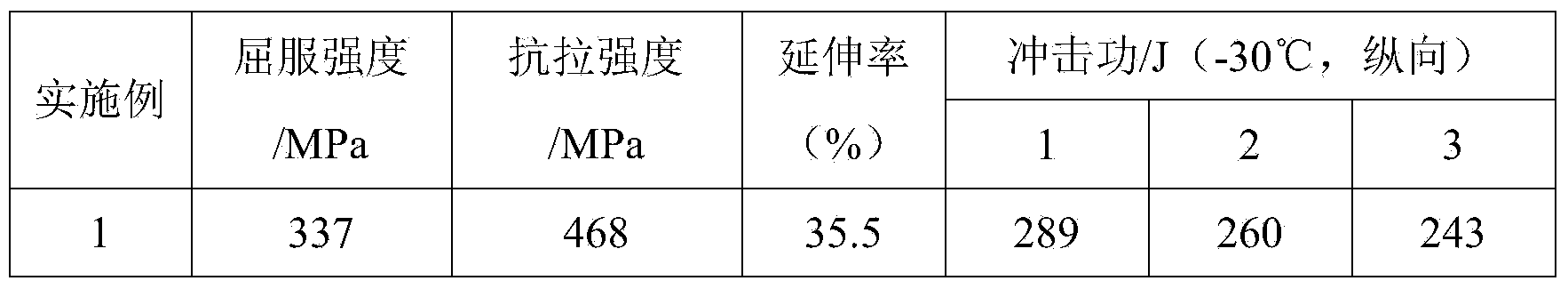

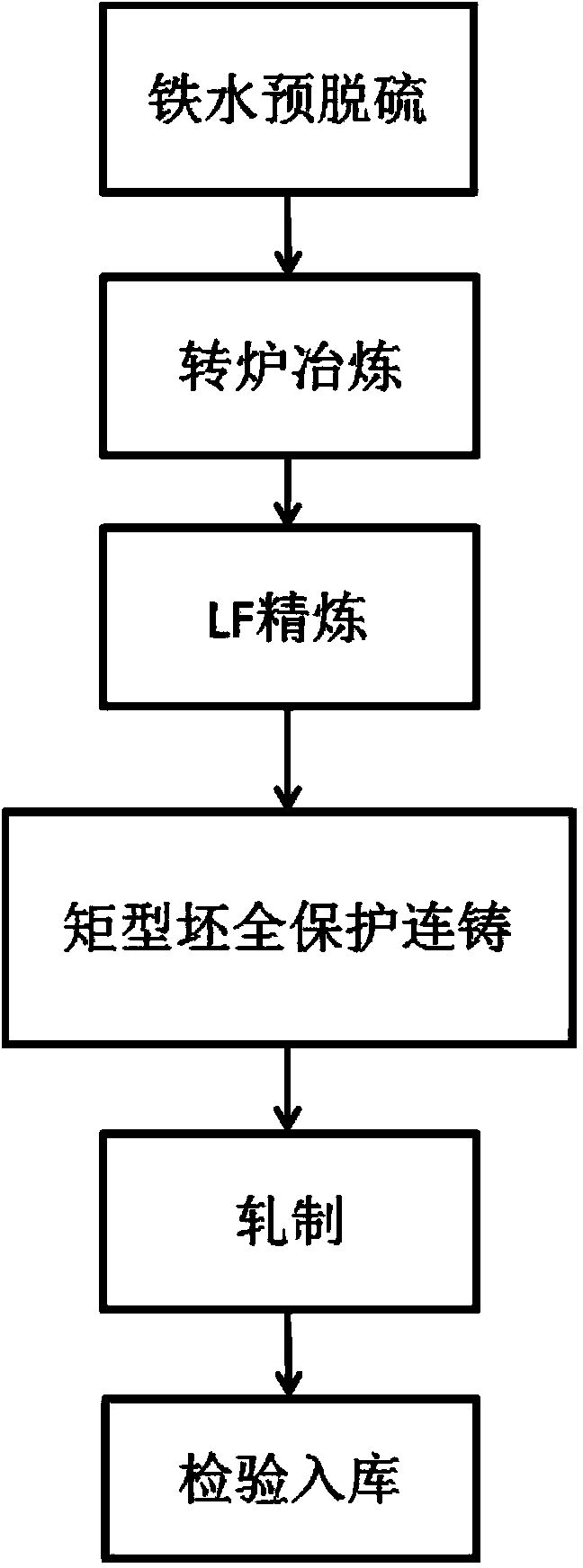

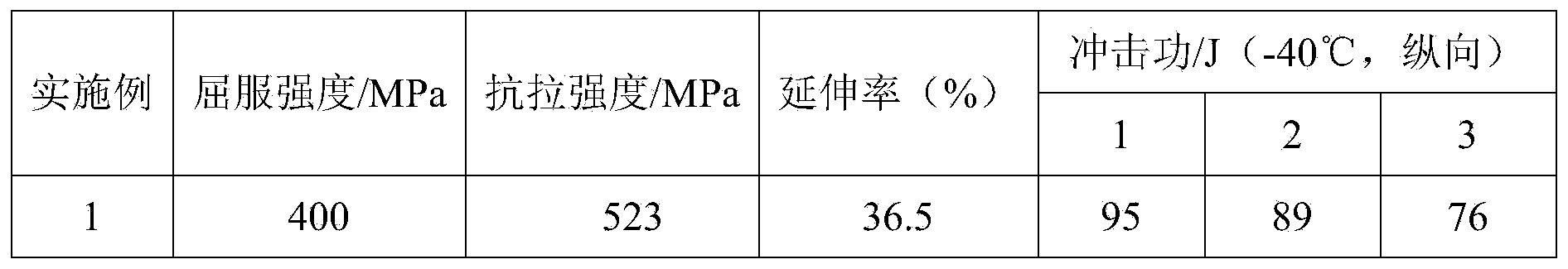

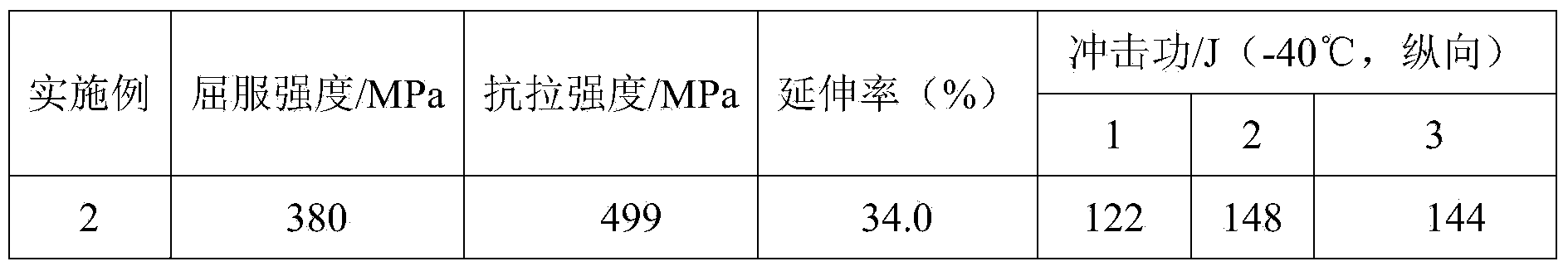

Low-temperature-resistant hot-rolled angle steel and preparation method thereof

The invention discloses low-temperature-resistant hot-rolled angle steel and a production method thereof, and belongs to the technical field of metallurgy. The angle steel consists of the following chemical components in percentage by mass: 0.10-0.15% of C, 0.20-0.50% of Si, 1.3-1.7% of Mn, 0.04-0.06% of V, 0.005-0.015% of Al, less than or equal to 0.01% of N, less than or equal to 0.006% of O, less than or equal to 0.020% of P, less than or equal to 0.010% of S and the balance Fe and inevitable impurities. The production method for the low-temperature-resistant hot-rolled angle steel comprises the following steps: molten iron pre-desulfurization, converter smelting, LF refining, and a continuous-casting and rolling process by a billet continuous casting machine, wherein sulfur content of the molten iron after desulfurization is less than or equal to 0.005wt%. According to the low-temperature-resistant hot-rolled angle steel and the production method thereof, a vanadium micro-alloying process and a steelmaking process are adopted, the control is simple and the alloy recovery rate is stable. The low-temperature-resistant hot-rolled angle steel is good in performance, and has impact energy greater than or equal to 100J at a temperature of (-)40 DEG C.

Owner:宣化钢铁集团有限责任公司

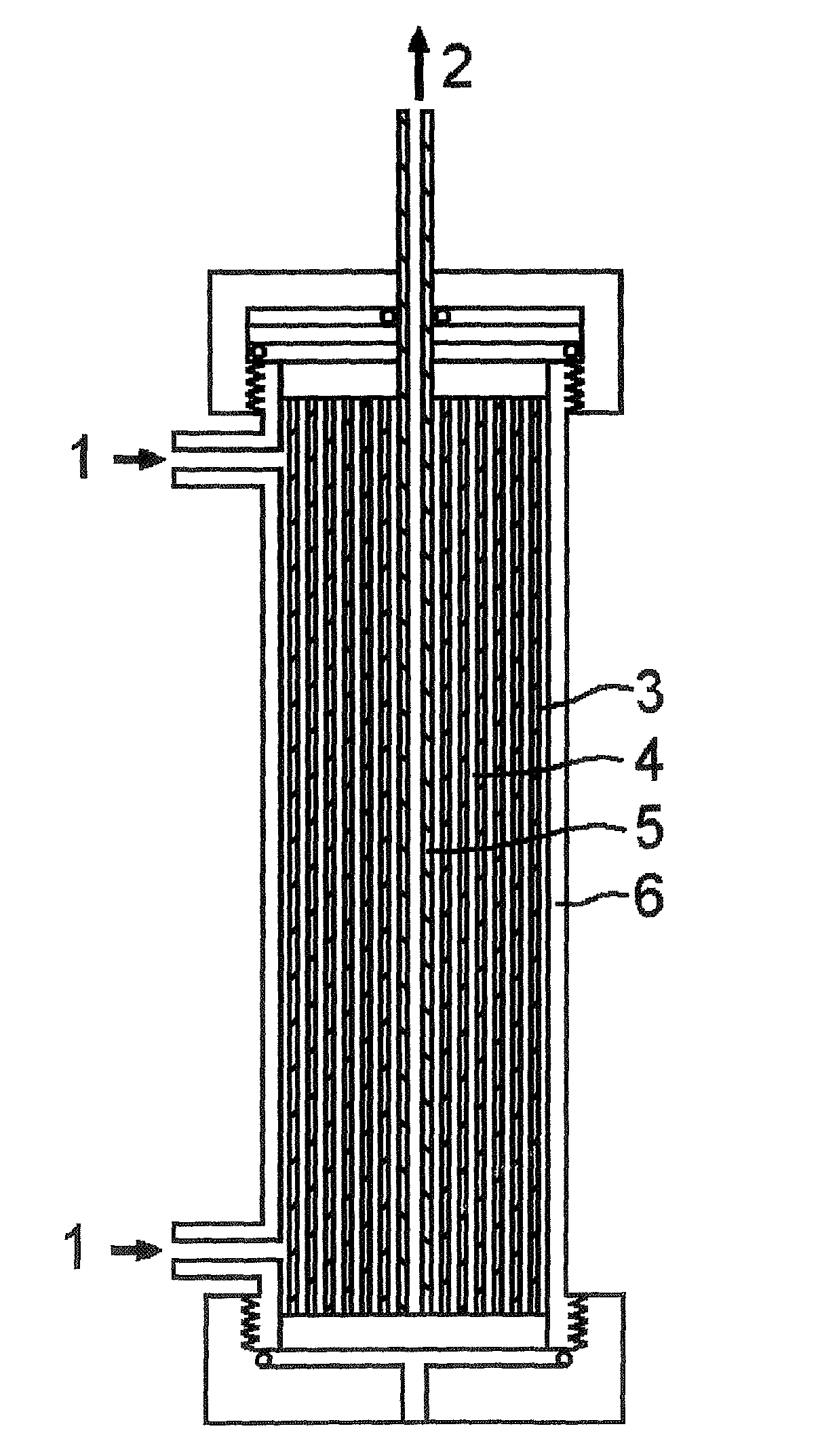

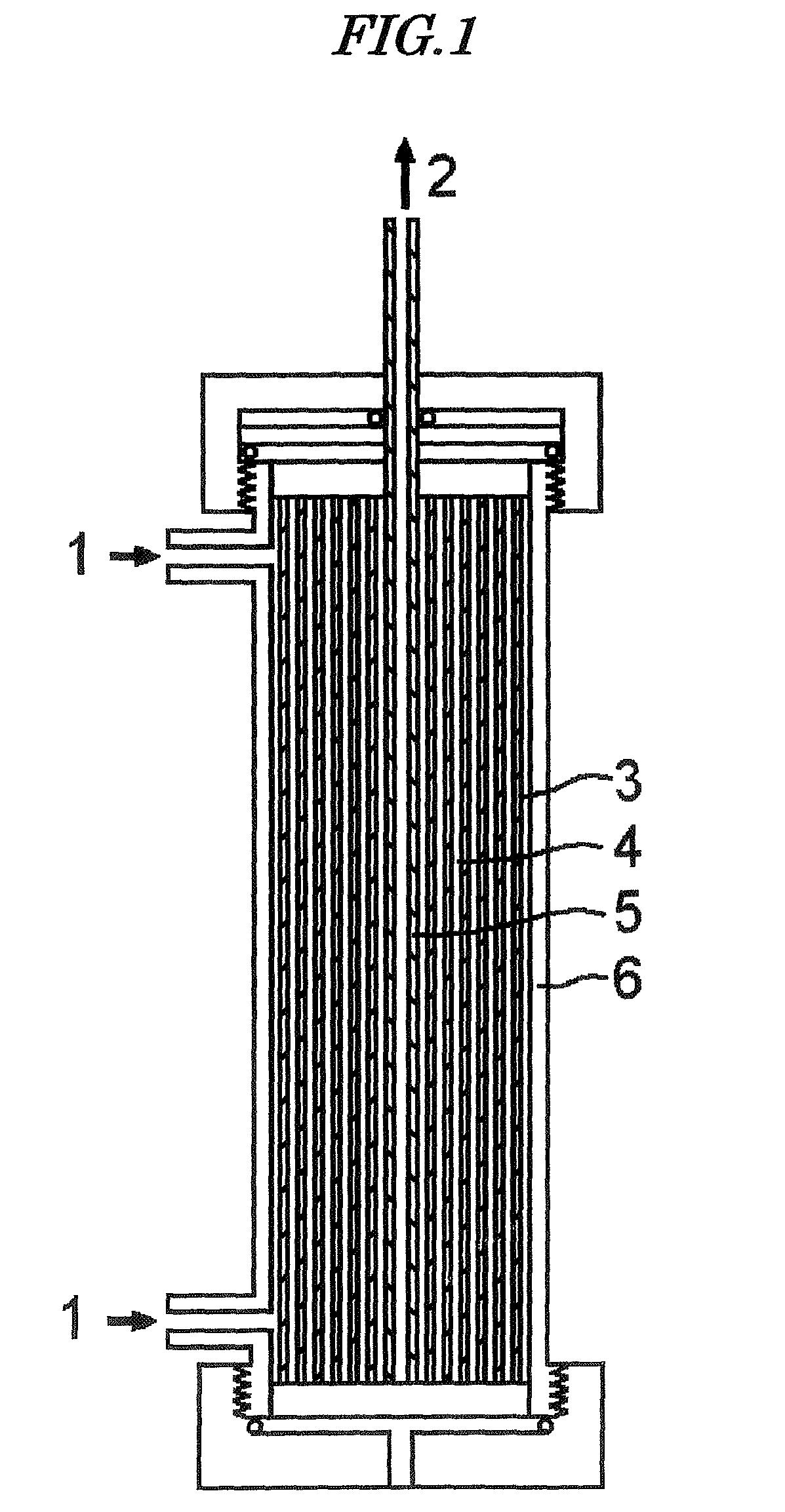

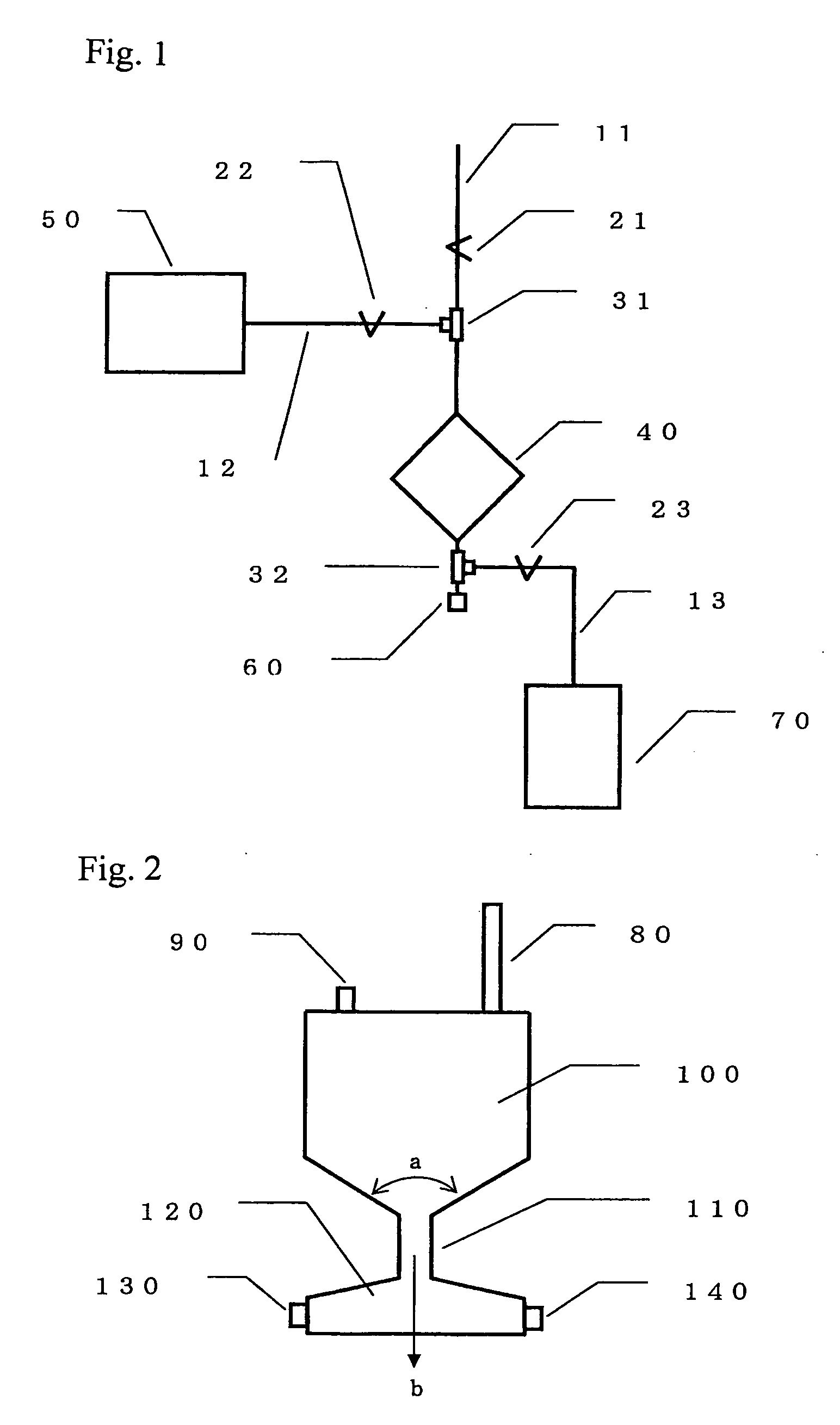

Porous sheet-form material for cell culture, and bioreactor and culturing method utilizing same

InactiveUS8435781B2Stable recoveryNot easy to growBioreactor/fermenter combinationsBiological substance pretreatmentsHigh cellCell adhesion

The present invention provides a bioreactor having a system that can grow cells, tissue, etc. while maintaining or improving their function, and finally recover the cells as they are with good efficiency. The bioreactor has a porous sheet-form material disposed in its main body, the porous sheet-form material being formed from a nonwoven fabric, etc. having high cell affinity in order to retain cells. This porous sheet-form material has a thermosensitive polymer and a cell-adhesive substance incorporated thereinto, and the porous sheet-form material is not only cell-adhesive but also allows cells and tissue to be detached from the porous sheet-form material as they are by, for example, cooling from 37° C. to 25° C. Furthermore, in order to efficiently ensure the bioactivity or the survival of the cells, it is arranged so that circulation of a culture medium in a culturing space of the bioreactor is of a radial flow type.

Owner:NAT UNIV CORP KYUSHU INST OF TECH (JP)

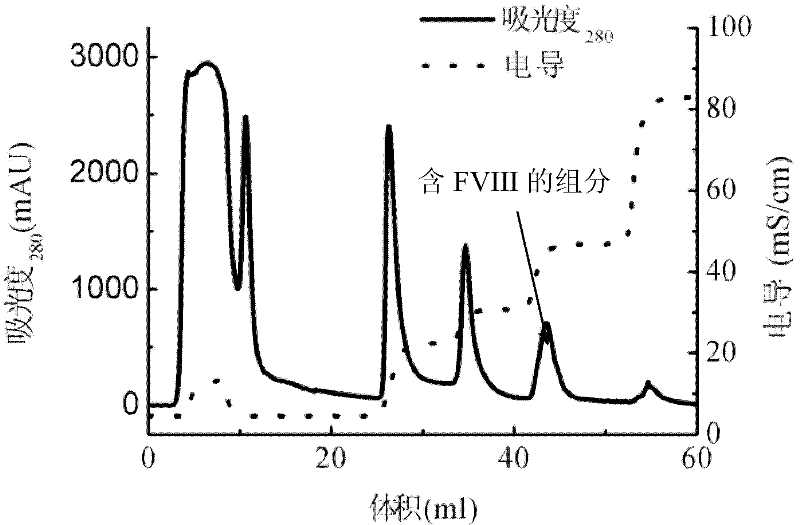

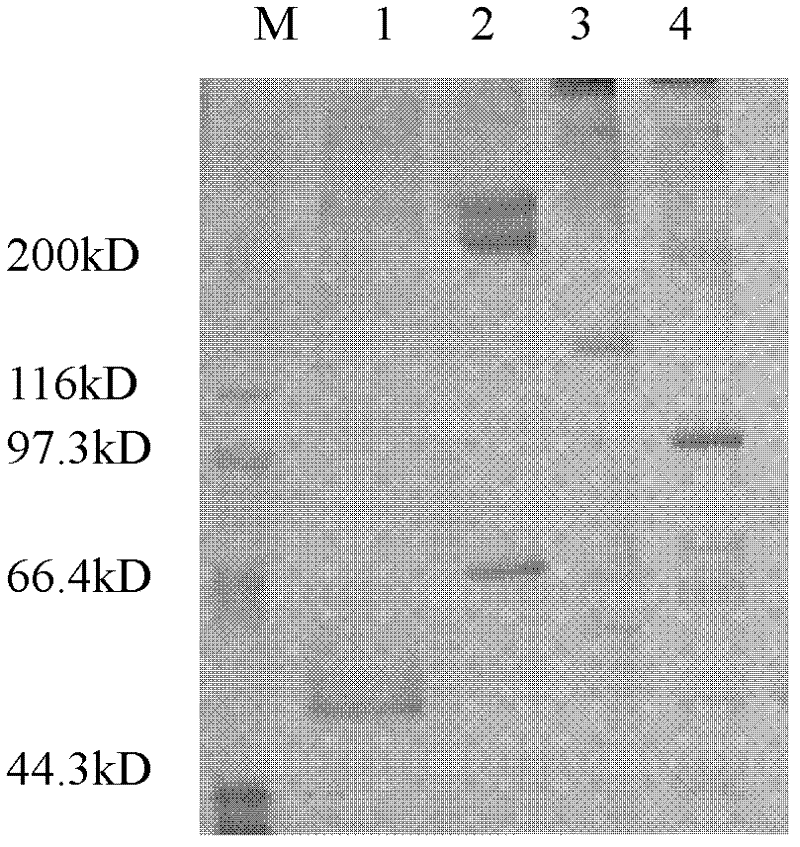

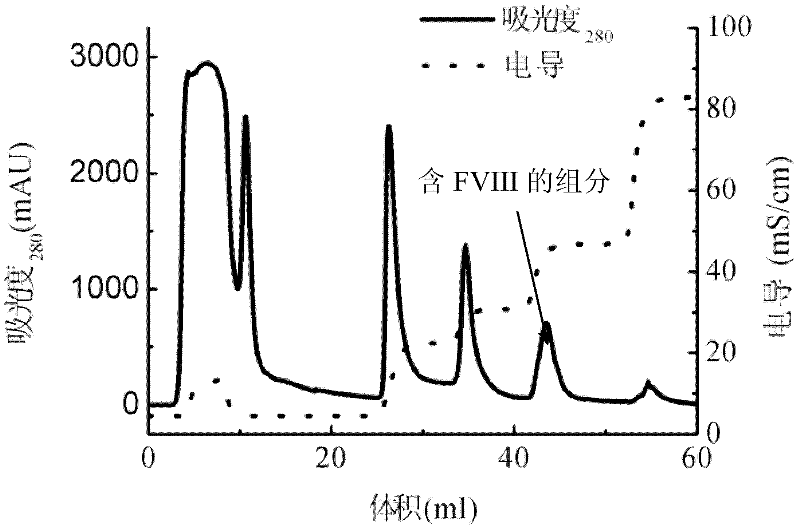

Method for separating and purifying blood coagulation factor VIII

InactiveCN102584983AReduce transfer rateFacilitate dissociationFactor VIIPeptide preparation methodsBlood coagulation factor VIIIWhole blood product

The invention relates to the field of separation and purification of blood products, in particular to a method for separating and purifying blood coagulation factor VIII. According to the method, a chromatographic raw material containing the blood coagulation factor VIII is separated by using super-macroporous ion exchange chromatography. The method also comprises a step of performing coarse separation treatment before separation of the super-macroporous ion exchange chromatography. According to the method, F VIII chromatography recovery rate stably reaches up to about 85 percent, the specific activity reaches up to 154 IU / mg protein, and the process is stable and easy to amplify; while in the prior art, the F VIII chromatography recovery rate is normally stabilized at about 25 percent, and the specific activity is 20-50 IU / mg protein; and thus, compared with the prior art, the method provided by the invention has the advantage of achieving an unexpected technical effect.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

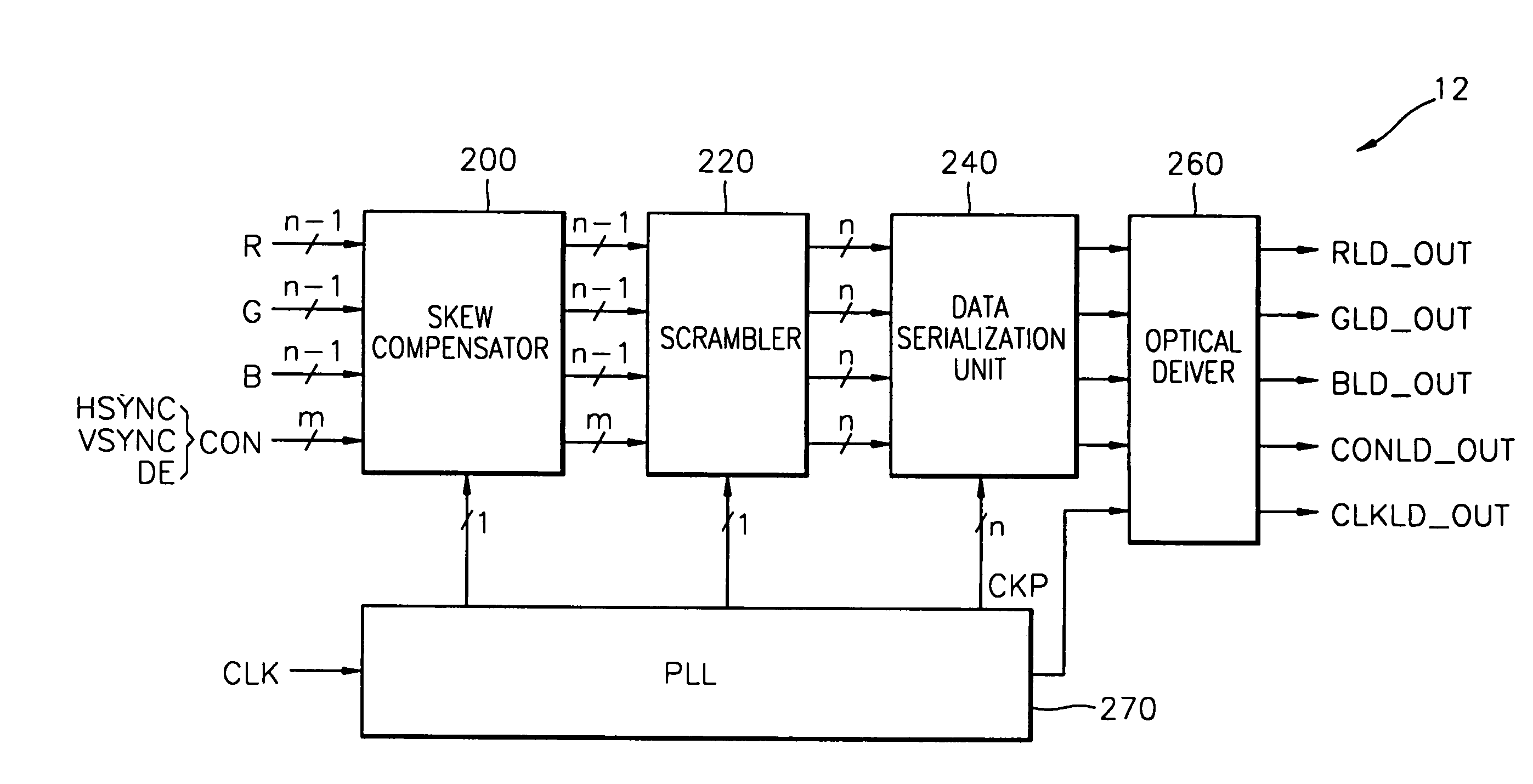

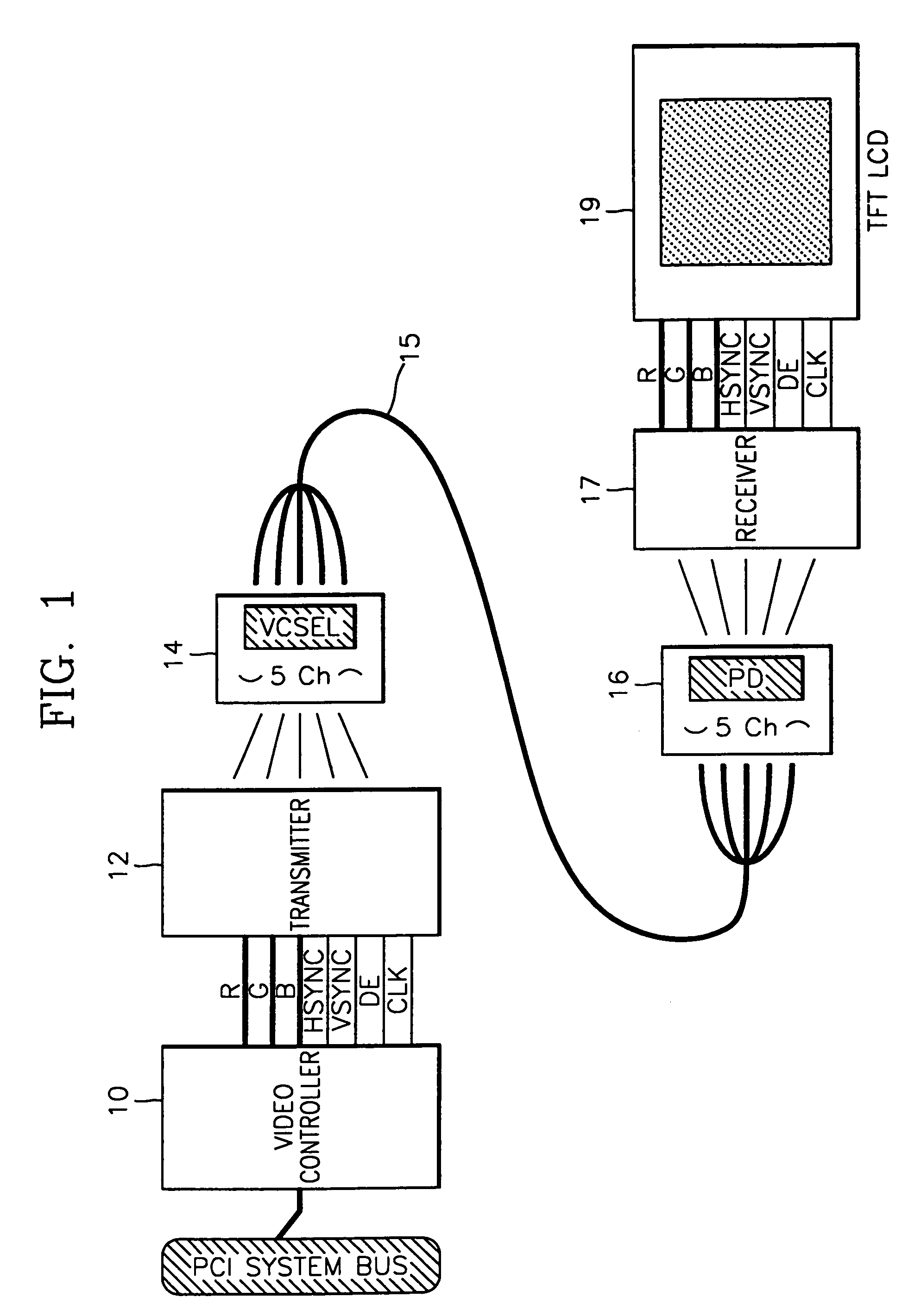

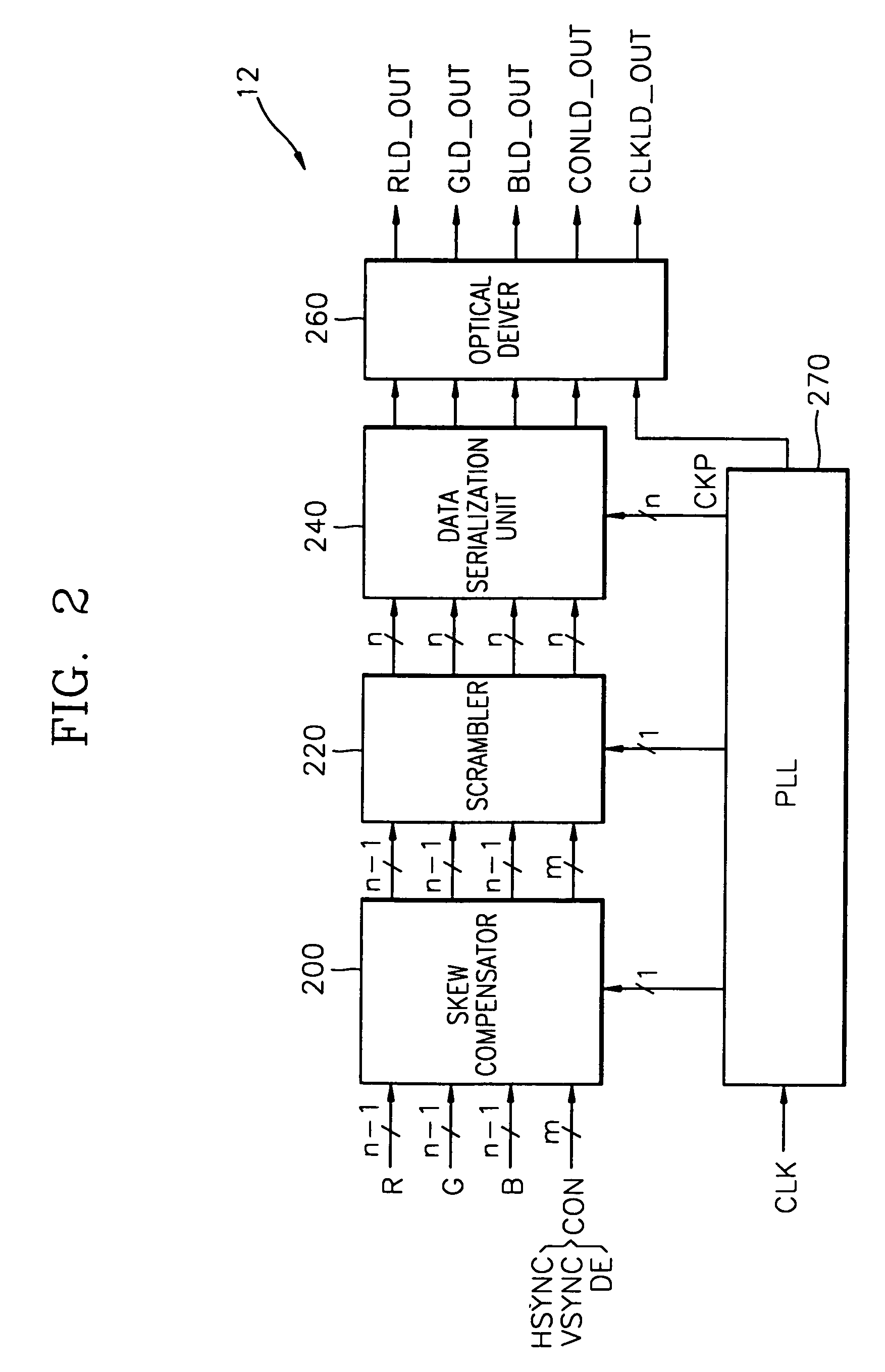

Optical transfer system having a transmitter and a receiver

InactiveUS7209178B1Fast transferElectromagnetic interferenceTelevision system detailsPulse automatic controlPhotodiodeColor signal

An optical transfer system having a transmitter and a receiver converts an externally-applied video signal into an optical signal and restores the optical signal to the original video signal The system includes a video controller, a transmitter, a transmission photo diode, an optical transmission line, a reception photo diode, and a receiver. The video controller separates color signals and a horizontal / vertical synchronous signal from the video signal, and transmits the color signals and the horizontal / vertical synchronous signal in response to externally-applied predetermined data enable and clock signals. The transmitter skew-compensates and compresses signals received from the video controller and converts the compressed signals into a driving current. The transmission photo diode converts the driving current into an optical signal and outputs the optical signal. The optical transmission line is comprised of a predetermined number of channels, and transmits the optical signal. The reception photo diode converts the optical signal received from the optical transmission line into a current signal and outputs the current signal. The receiver converts the current signal into a voltage signal, decompresses the voltage signal, compensates for the skew of the voltage signal, and restores the original signal. Accordingly, data for an LCD monitor is optically transmitted, so that rapid data transmission can be achieved and so that electromagnetic interference (EMI) noise can be removed.

Owner:SAMSUNG ELECTRONICS CO LTD

Low-temperature-resistant hot-rolled channel steel for marine engineering and manufacturing method thereof

InactiveCN106191670AImprove low temperature toughnessImprove tissue uniformityCold areaChemical composition

The invention belongs to the technical field of metallurgy and particularly relates to low-temperature-resistant hot-rolled channel steel for marine engineering and a manufacturing method thereof. The low-temperature-resistant hot-rolled channel steel for marine engineering comprises the following chemical components in percentage by weight: 0.06%-0.10% of C; 0-0.4% of Si; 0.9%-1.6% of Mn; 0.02%-0.08% of V; 0-0.02% of P; 0-0.01% of S; 0-0.015% of N; 0.02%-0.05% of Al; 0-0.004% of O; and the balance Fe and inevitable impurities. The channel steel for marine engineering, provided by the invention, has favorable mechanical properties, the yield strength of the channel steel is greater than or equal to 355 MPa, the tensile strength of the channel steel is greater than or equal to 470 MPs, and especially, the longitudinal impact energy of the channel steel is greater than or equal to 34 J at minus 50 DEG C. Therefore, the channel steel is applicable to extremely cold areas.

Owner:SHANDONG IRON & STEEL CO LTD

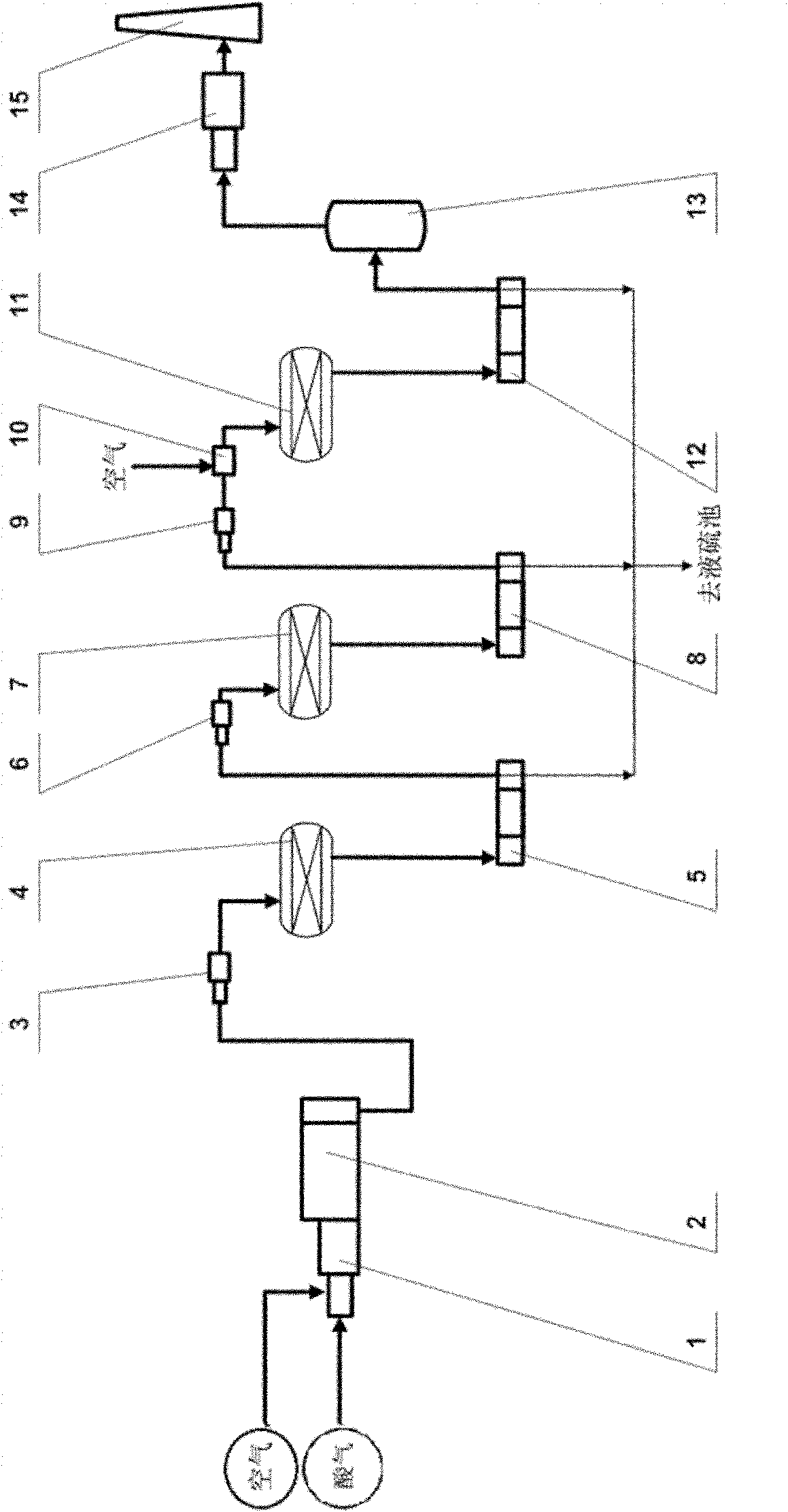

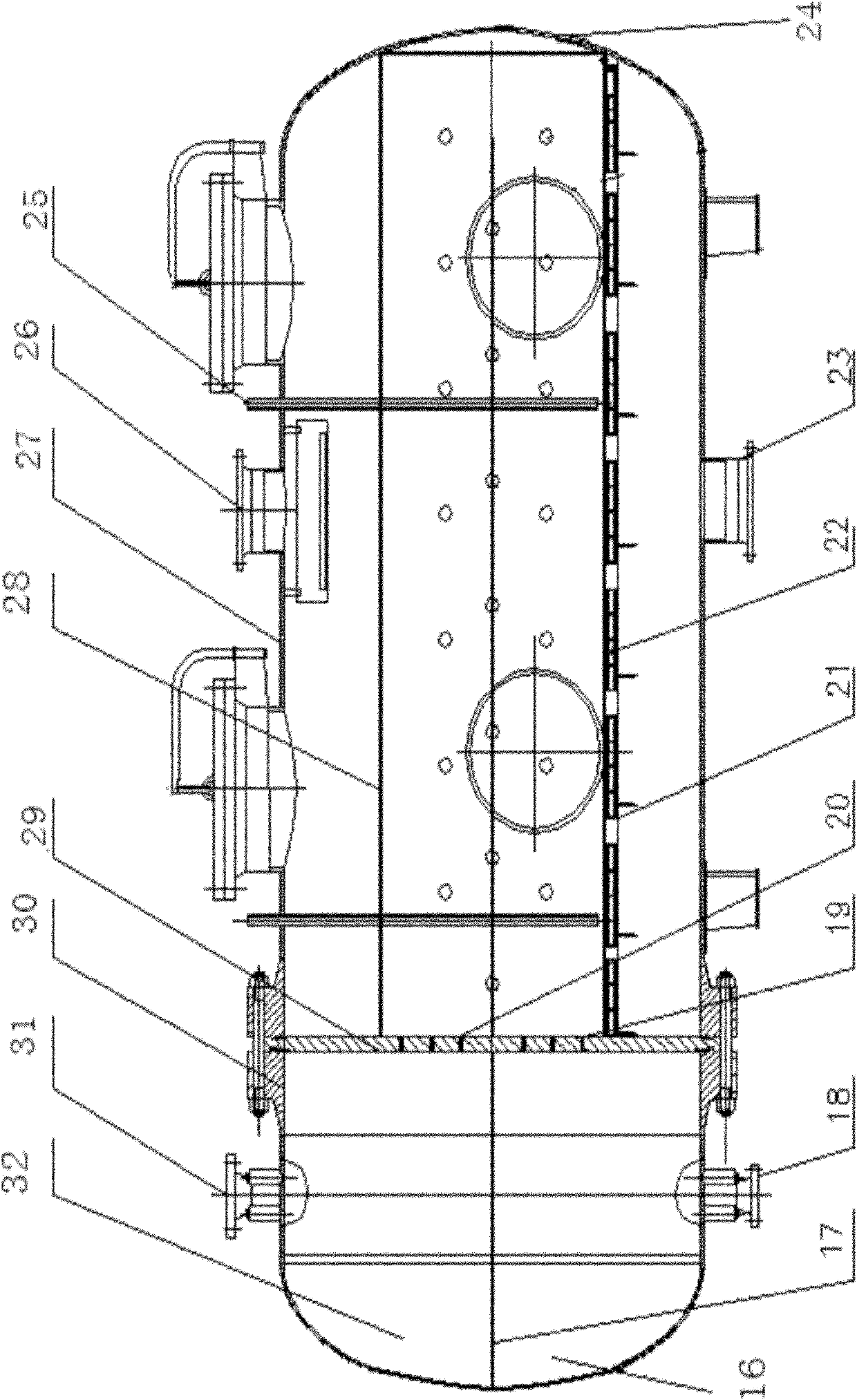

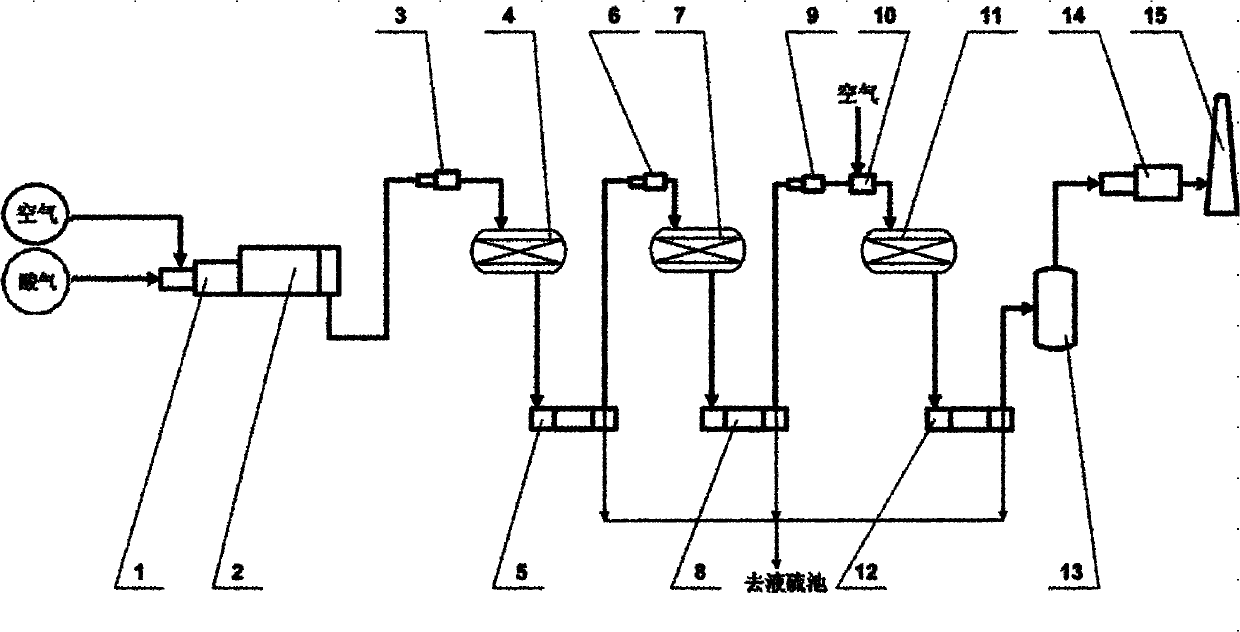

Inner cooling type direct oxidation recycling method and recycling device of sulfur

ActiveCN102556977ASolve the problem of temperature riseOptimizing the Reaction TemperatureEnergy inputSulfur preparation/purificationComing outCombustion

The invention relates to an inner cooling type direct oxidation recycling method and a recycling device of oxidation sulfur. Acid gas and air conduct burning and the Klaus reaction in a main burning furnace, the air flow coming out directly enters a waste heat boiler, most sulfur steam is condensed and enters a first-level Klaus reactor after being heated, H2S and SO2 in procedure gas generate sulfur, the procedure gas enters a first-level condenser to enable most sulfur steam to be condensed to into liquid sulfur to be separated, the procedure gas is heated and enters a second-level Klaus reactor, the liquid sulfur is condensed and separated through the condenser, Klaus tail gas and air are mixed in a static mixer to be heated and then enter an inner cooling type direct oxidation reactor, hydrogen sulfide in the tail gas is oxidized into the sulfur under the effect of a catalyst, heat produced by direct oxidation of the hydrogen sulfide is carried away by the inner cooling structure, and the procedure gas enters a liquid sulfur catcher and a tail gas combustion furnace and is discharged through a chimney after the liquid sulfur is separated from the procedure gas. By means of the method, sulfur recycling rate can be stabilized to be more than 85%.

Owner:PETROCHINA CO LTD

320MPa low-temperature resistant hot-rolled H-shaped steel and preparation method thereof

InactiveCN103834861AEnsure low carbon requirementsReduce carbon increase in converterMechanical propertyImpurity

The invention discloses a 320MPa low-temperature resistant hot-rolled H-shaped steel and a preparation method thereof, the 320MPa low-temperature resistant hot-rolled H-shaped steel comprises the following chemical components by weight percent: 0.05-0.11% of C, 0.20-0.35% of Si, 1.05-1.30% of Mn, not more than 0.020% of P, not more than 0.015% of S, 0.020-0.035% of Nb, 0.005-0.025% of Ti, and the balanced of Fe and trace impurity. The production of the 320MPa low-temperature resistant hot-rolled H-shaped steel is realized by using niobium-titanium composite microalloying process through low-carbon content under the high hot-rolling temperature condition, the prepared low-temperature resistant steel is good in mechanical property, and the longitudinal impact is greater than 165J at -30 DEG C.

Owner:LAIWU IRON & STEEL GRP

Method for Preparing Cell Concentrate and Cell Composition

InactiveUS20070275459A1Stable recoveryHigh yieldDead animal preservationSedimentation separationCryopreservationCell separation

It is an object of the present invention to provide: a method for preparing a cell concentrate which efficiently separates nucleated cells from unnecessary cells contained in a cell-containing solution by simple operations, thereby reducing the volume of a solution used for cryopreservation that contains the nucleated cells, when the cell-containing solution that contains the nucleated cells and the unnecessary cells has been filtrated with a filter device and when a recovery solution is then introduced into the filter device to recover the nucleated cells captured by a filter material; and a cell composition. The present invention provides a method for preparing a cell concentrate, which comprises: introducing a cell-containing solution that contains nucleated cells and unnecessary cells into a filter device comprising a filter material for substantially capturing the nucleated cells and for substantially giving passage to the unnecessary cells, so as to capture the nucleated cells by the above-described filter material and to discharge the unnecessary cells from the above device; and introducing a recovery solution into the above-described filter device, so as to recover the nucleated cells captured by the above-described filter material, wherein the above-described method is characterized in that the cell-containing solution that contains nucleated cells and unnecessary cells are separated into a layer that is rich in nucleated cells and a layer that is rich in unnecessary cells, the layer rich in unnecessary cells is first introduced into the above-described filter device, and the layer rich in nucleated cells is then introduced therein, so as to discharge the unnecessary cells remaining in the above-described filter device while capturing the nucleated cells by the above-described filter material, and a recovery solution is then introduced into the above-described filter device, so as to recover the nucleated cells captured by the above-described filter material.

Owner:ASAHI KASEI MEDICAL CO LTD

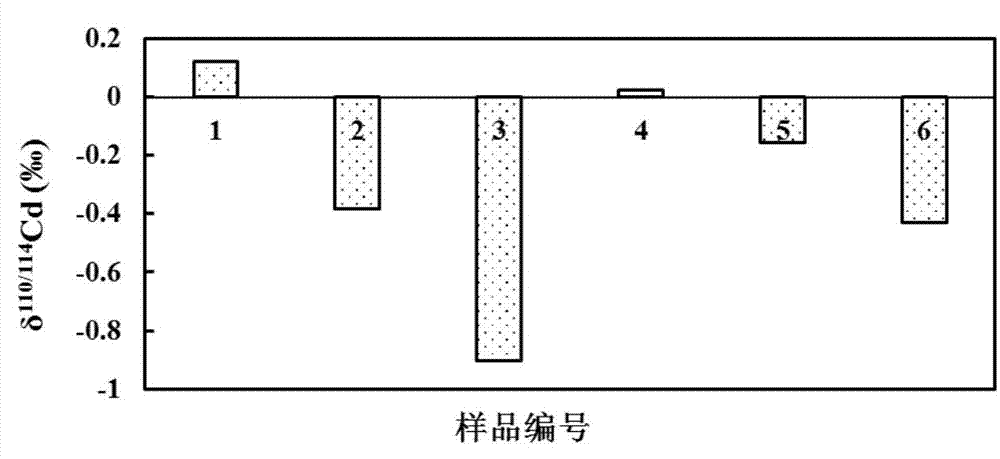

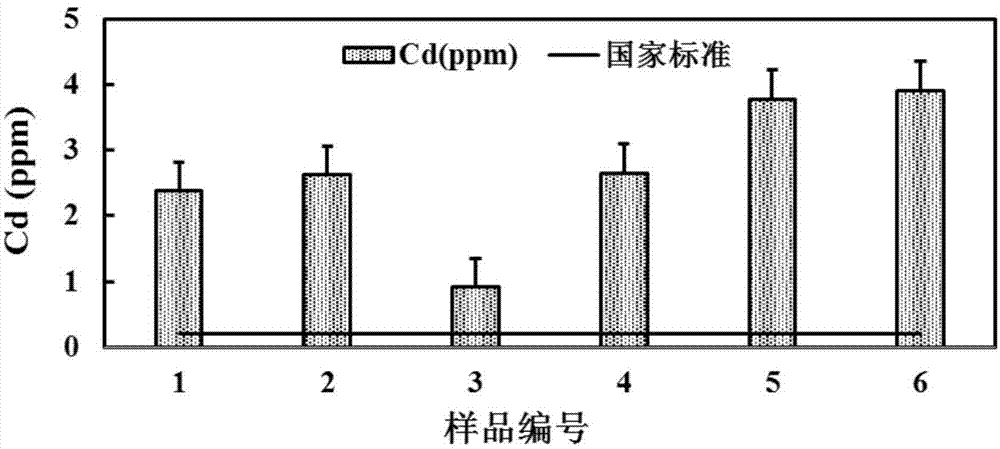

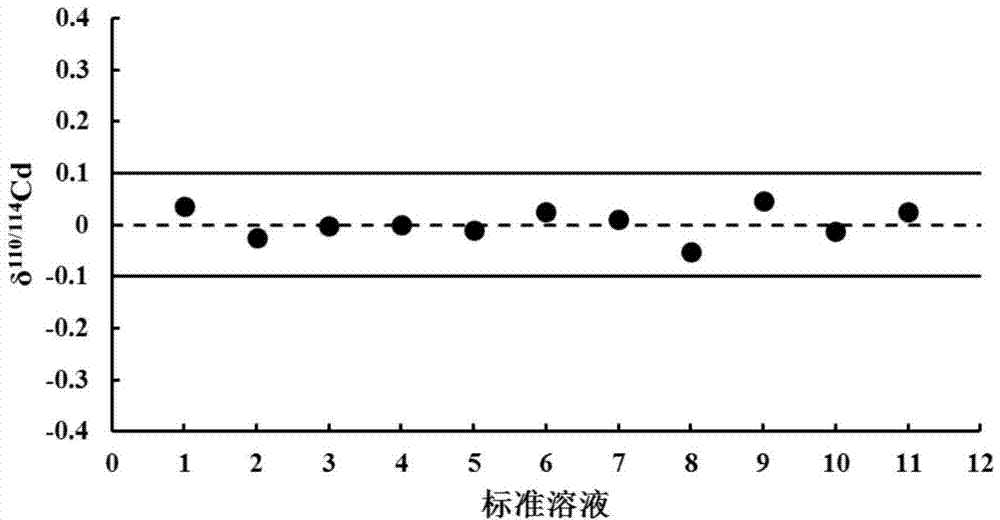

Method for measuring cadmium isotope ratio in rice by using multi-receiving inductance coupling plasma mass spectrum

ActiveCN104713939AData specificationHigh recovery rateMaterial analysis by electric/magnetic meansInductively coupled plasmaIsotope

The invention provides a method for measuring a cadmium isotope ratio in rice by using a multi-receiving inductance coupling plasma mass spectrum. The method comprises the following steps: 1, performing microwave digestion on a rice sample to measure the content of total cadmium; 2, performing microwave digestion on the rice sample to measure the content of total cadmium in a separated and purified rice sample, thereby obtaining a separation and purification rate; 3, performing microwave digestion on a to-be-measured rice sample, and performing separation and purification to obtain to-be-measured liquid; and 4, measuring the cadmium isotope ratio in the to-be-measured liquid by using the multi-receiving inductance coupling plasma mass spectrum, wherein the separation and purification process specifically comprises the following steps: a, converting a nitric acid medium of a digestion solution into a hydrochloric acid medium; b, leaching the digestion solution of the hydrochloric acid medium for five times by using hydrochloric acid, and then leaching for two times by using Milli-Q water to obtain a leachate; c, eluting and collecting the leachate; and d, converting an eluting solution into a nitric acid medium from a hydrochloric acid medium. By adopting the method provided by the invention, the technical problem of separating and purifying cadmium from a rice sample low in cadmium content is solved, and a cadmium pollution source can be quickly and accurately restored, so that the method has a good application value.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

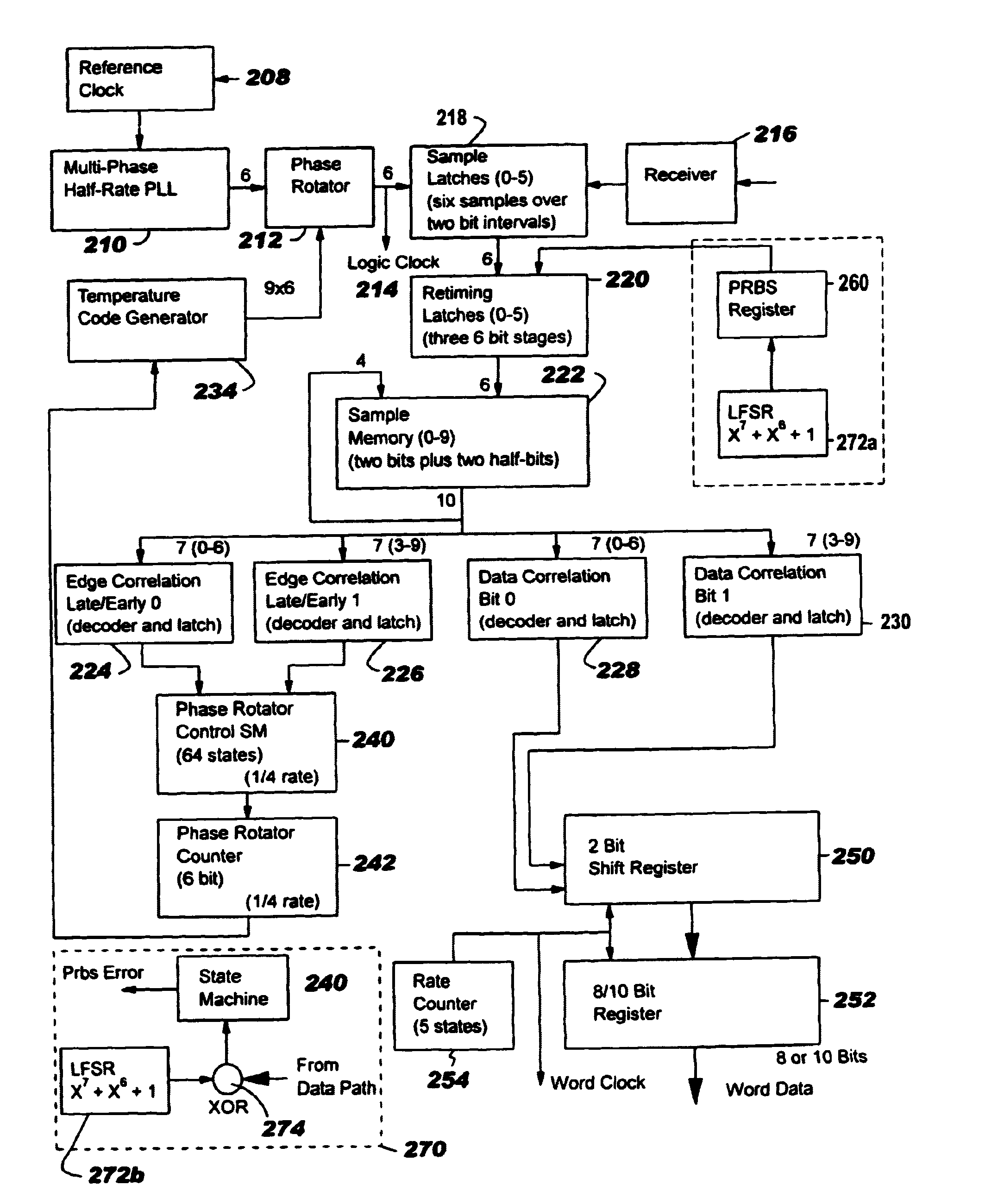

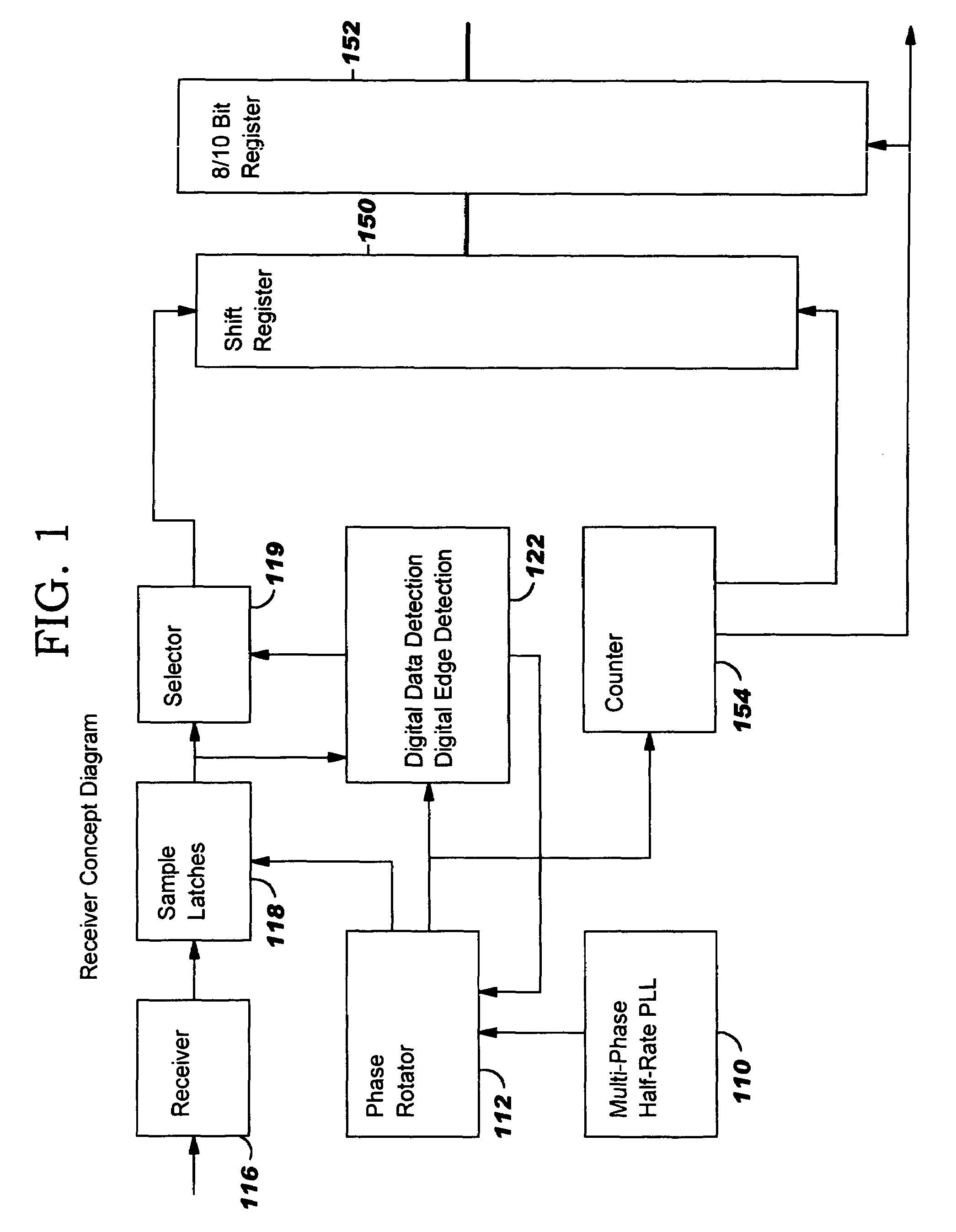

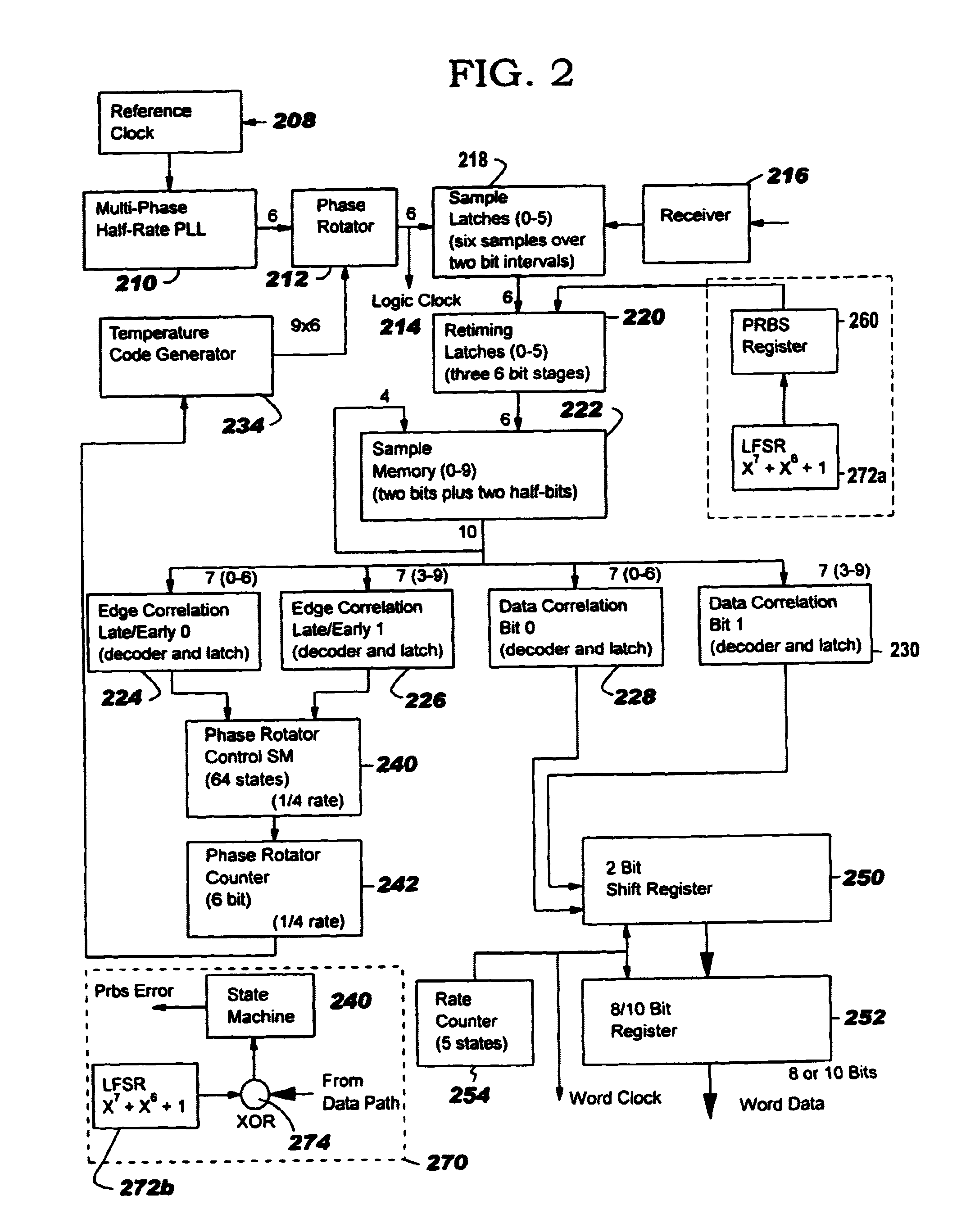

Apparatus and method for oversampling with evenly spaced samples

ActiveUS6999544B2Reduce random errorPower optimizationPulse automatic controlModulated-carrier systemsData streamOversampling

The architecture and the method of operation of a receiver core are described. The core performs clock and data recovery on an incoming serial data stream transmitted across a wired media, such as a chip-to-chip or card-to-card interconnect. The bit error rate and accuracy of the recovery are optimized without centering of oversampling. Further, random errors due to edge mis-tracking are minimized. The receiver utilizes a phase rotator to detect the edge position of the bits of the data stream, select the optimum data sample and generate early and late signals if the detected edge is not in the expected position. A phase locked loop provides a frequency source for the phase rotator. At least three evenly spaced samples are detected for each bit. A sample processing algorithm, preferably an adaptive behavior algorithm, is used for centering the bit edge between two of the samples.

Owner:TWITTER INC

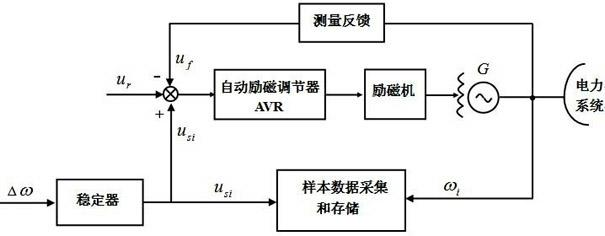

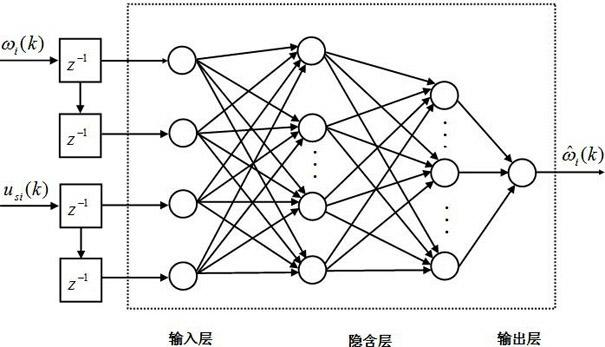

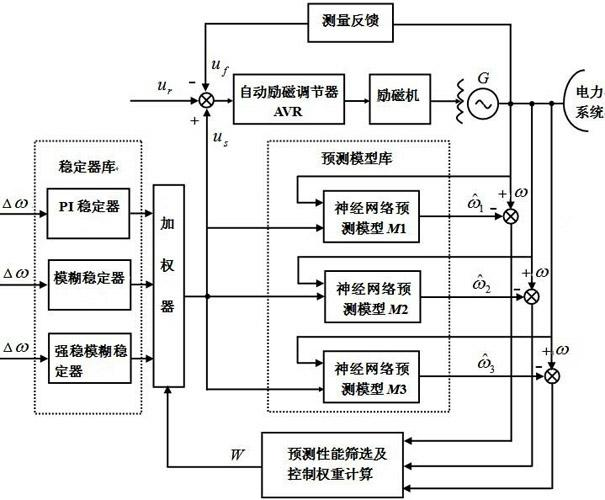

Mixed smart control method of power system multi-stabilizer

InactiveCN102664580AImprove stabilityStable recoveryElectronic commutation motor controlVector control systemsTransient stateControl signal

The invention discloses a mixed smart control method of a power system multi-stabilizer. The method comprises the following steps of: establishing neural network prediction models respectively for different stabilizers; predicting the control effects of the stabilizers on line through the neural network prediction models; screening according to the matching degree of the prediction value and the actual rotation speed; carrying out weighted processing on two controllers with better prediction effects so as to obtain mixed control signals; and controlling the operation state of a power generator by taking the mixed control signals as auxiliary input signals of an automatic excitation regulator. The mixed smart control method of the power system multi-stabilizer provided by the invention has the beneficial effects that the control strategy is flexible, and the performances and characteristics of the stabilizers are fully utilized, thus the system achieves the better operation effect; the defect that an adopted single linear lead-lag power system stabilizer is difficult to be adaptive to large-disturbance post-nonlinear characteristic is overcome, ideal damping control is provided, and the transient state transition time and vibration times are reduced; and the mixed smart control method of the power system multi-stabilizer has favorable comprehensive dynamic property and higher robust property, and the stability of the system under each type of disturbance is improved obviously.

Owner:CHONGQING JIAOTONG UNIVERSITY

350MPa-level low temperature resistant H-shaped steel and preparation method thereof

InactiveCN104294149AEnsure low carbon requirementsReduce carbon increase in converterProcess efficiency improvementChemical compositionSulfur

The invention belongs to the technical field of steel, and particularly relates to 350MPa-level low temperature resistant H-shaped steel and a preparation method thereof. The 350MPa-level low temperature resistant H-shaped steel comprises the following chemical components in percentage by weight: 0.05-0.09% of carbon, 0.20-0.35% of silicon, 1.35-1.50% of manganese, 0.020-0.035% of niobium, 0.015-0.025% of vanadium, 0.005-0.025% of titanium, smaller than and equal to 0.020% of phosphorus, smaller than and equal to 0.015% of sulfur, and iron and inevitable impurities for balance. According to the 350MPa-level low temperature resistant H-shaped steel and the preparation method thereof, mainly through the low carbon content, and the application of niobium-titanium complex microalloying technology, the production of the 350MPa-level low temperature resistant H-shaped steel is realized; a prepared product has a yielding strength larger than 380 MPa, is good in low temperature resistant steel mechanical property, and has low-temperature (minus 40 DEG C) resistant longitudinal impact power larger than 76 J.

Owner:SHANDONG IRON & STEEL CO LTD

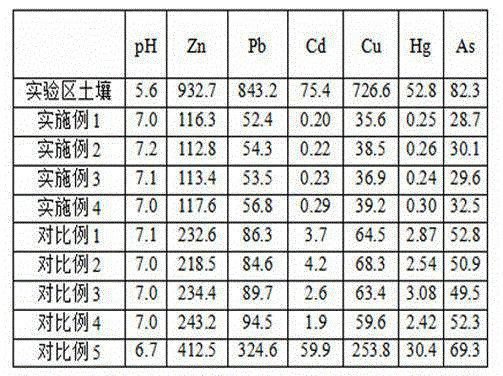

Restoration method for industrial waste land soil heavy metal contamination

ActiveCN105170642AReduce the difficulty of plantingReduce degradationContaminated soil reclamationRestoration methodSoil heavy metals

The invention provides a restoration method for industrial waste land soil heavy metal contamination. Charcoal base fertilizer and a microorganism complex microbial inoculant are applied to heavy metal contaminated soil, and the charcoal base fertilizer, the microorganism complex microbial inoculant and the soil are evenly mixed and then aged; after ageing is over, a willow is planted, and the willow is overall removed after a certain period; after the willow is overall removed, charcoal base fertilizer and a microorganism complex microbial inoculant are applied to the soil where the willow is planted again, and the charcoal base fertilizer, the microorganism complex microbial inoculant and the soil are evenly mixed and aged; after ageing restoration is over, ricinus communis is planted, and the ricinus communis is overall removed after ricinus communis fruits are harvested; and the steps are executed cyclically and repeatedly until the content of heavy metal in the soil reaches the safety standard. The restoration method is good in soil governing effect, fast in effect taking, short in time, capable of beautifying the environment while the heavy metal contaminated soil is governed and high in practicability.

Owner:福建沃土环保集团有限公司

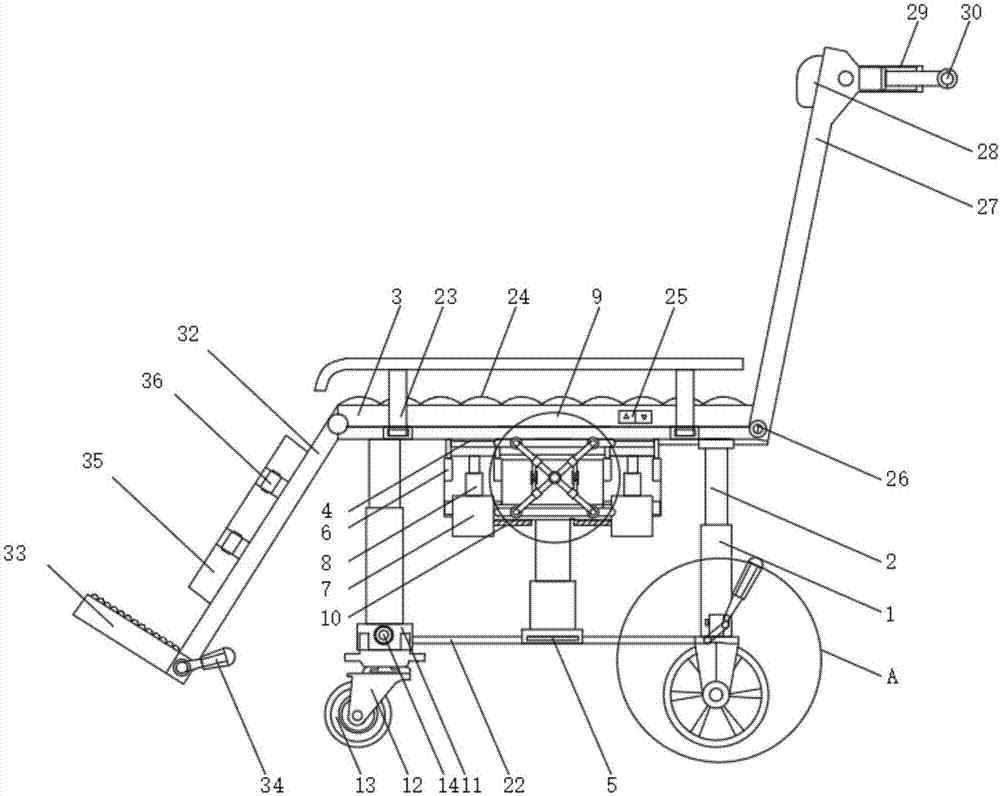

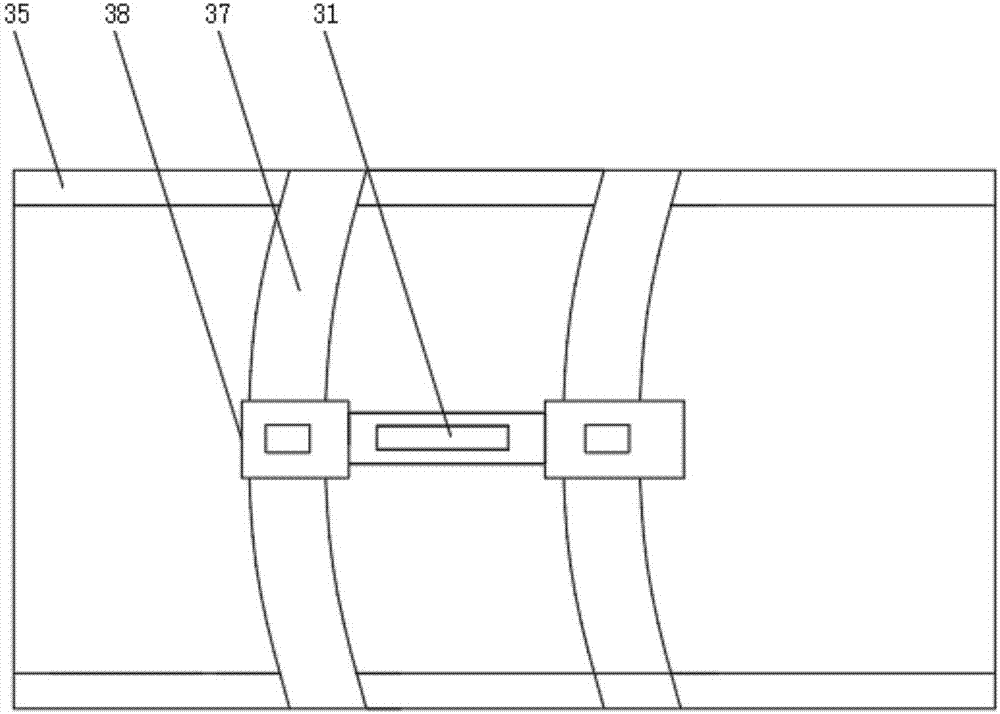

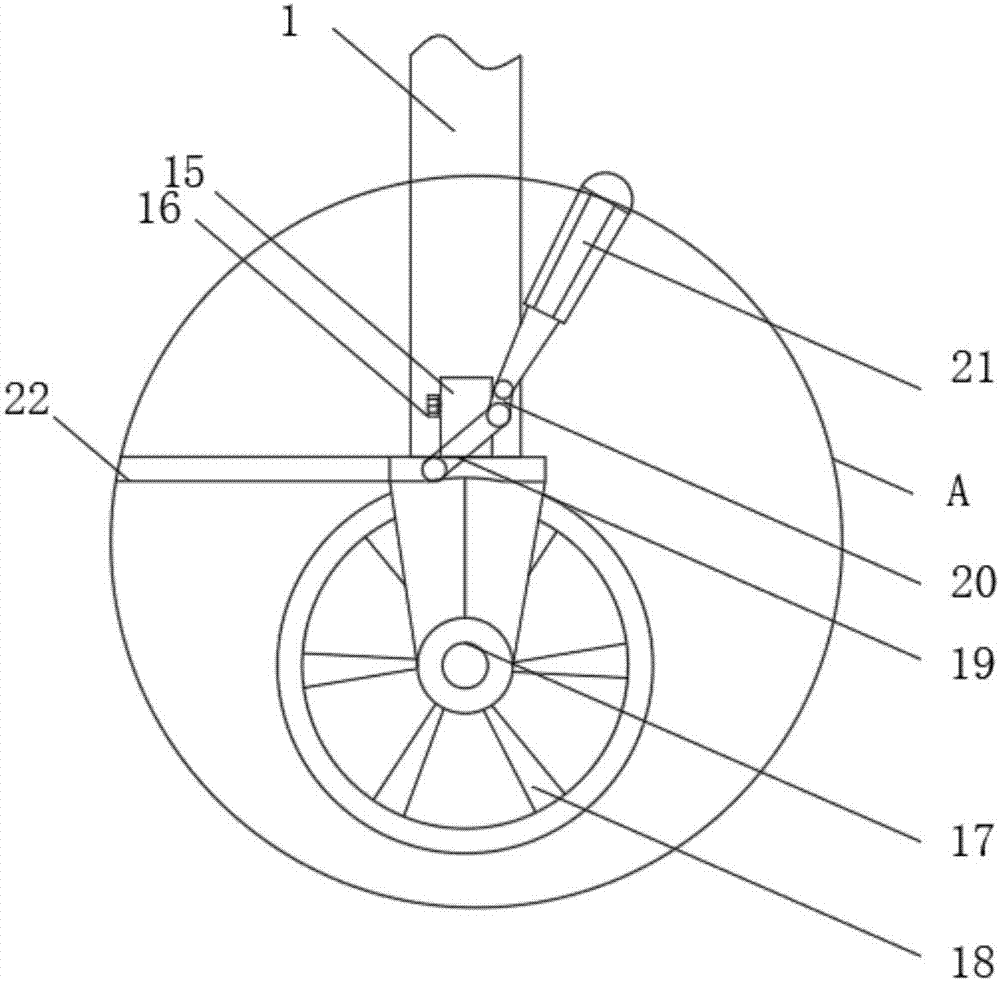

Protective wheelchair for recovery in orthopedics department

PendingCN107981994APrevent slidingSit comfortablyDiagnosticsWheelchairs/patient conveyanceWheelchairOrthopedic department

The invention discloses a protective wheelchair for recovery in an orthopedics department. The protective wheelchair for recovery in the orthopedics department comprises support legs, wherein a retractable leg is mounted on the top of each support leg; the tops of the retractable legs are fixedly connected with a bottom plate; the bottom of the bottom plate is fixedly connected with a buffering support; the bottom of the buffering support is fixedly connected with a hydraulic retractable rod; the bottom of the buffering support is fixedly connected with an explosion-resisting bottom plate; thetop of the explosion-resisting bottom plate is fixedly connected with a buffering device; a seat cushion is arranged on the top of the bottom plate; the outer wall of the bottom plate is fixedly connected with detachable armrests; an adjusting switch is arranged on the outer wall of the bottom plate and is positioned between the detachable armrests; a rotation adjuster is mounted at one end of the bottom plate; and the top of the rotation adjuster is fixedly connected with a backrest. The invention relates to the technical field of recovery in the orthopedics department. By the protective wheelchair for recovery in the orthopedics department, the problem that in a recovery process of a patient, a large amount of nursing time of nursing staff in the orthopedics department is required for protection to the leg of the patient is solved, the patient can comfortably sit on the wheelchair for a long time, and feeling of fatigue is relieved.

Owner:湖南丹尼尔智能科技有限公司

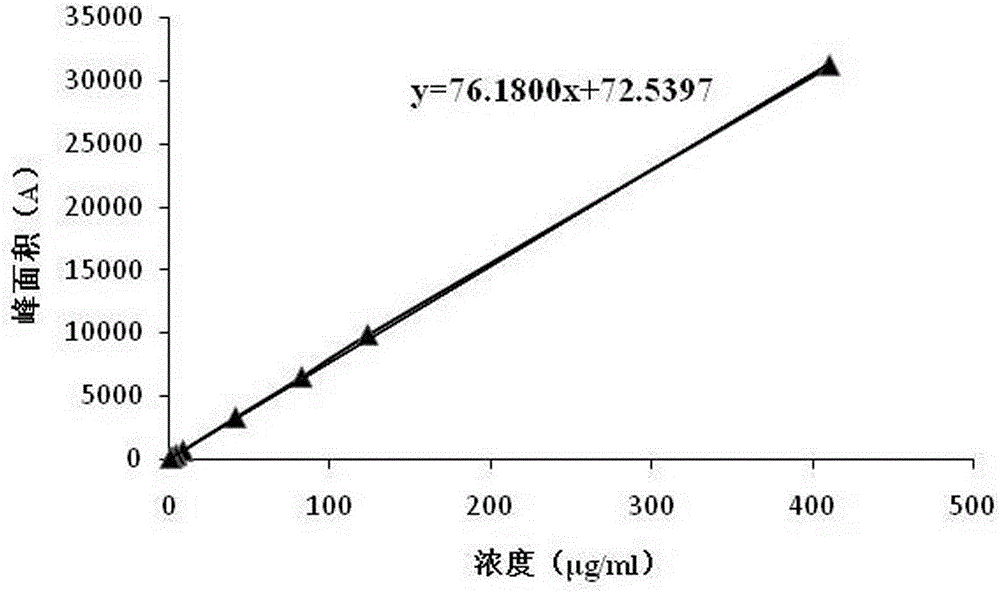

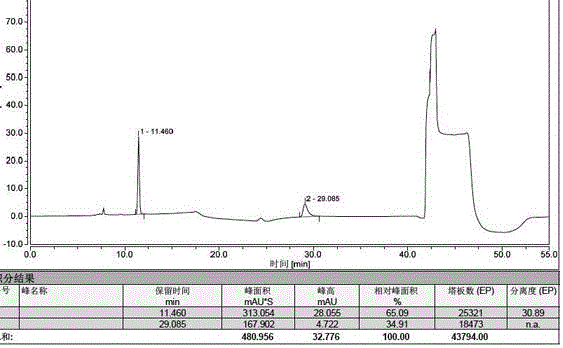

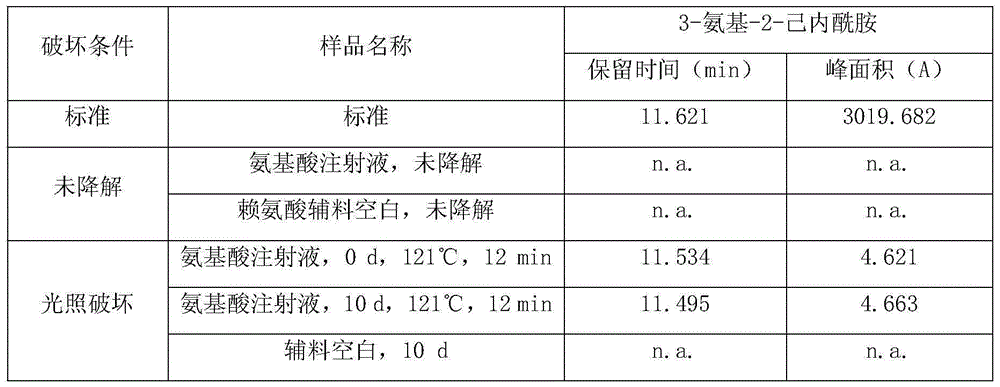

Method for detecting 3-amino-2-azepanone through high performance liquid chromatography

ActiveCN105092741AAccurate determination of contentStrong specificityComponent separationAcetonitrileMonopotassium phosphate

The invention discloses a method for detecting 3-amino-2-azepanone through a high performance liquid chromatography. According to the method, the following chromatographic conditions are adopted: a chromatographic column is an ODS column; a mobile phase A is a 0.01-0.09 mol / L monopotassium phosphate solution; a mobile phase B is a mixed water solution of methanol and acetonitrile in which the volume ratio of methanol, acetonitrile and water is (1-5):(1-5):1; the flow velocity is 0.4-1.2 ml / min; the detection wavelength is 100-300 nm; the column temperature is 20-60 DEG C; the sample size is 5-20 [mu]l. Through adoption of the method, the content of the impurity of 3-amino-2-azepanone degraded by lysine can be accurately measured, and the specificity is good; the quantification limit repeatability is good, the recovery rate is high, and a solution is high in stability; when the column temperature, the detection wavelength and the flow velocity change slightly, the difference between a detected recovery rate of 3-amino-2-azepanone and a result detected at a basic condition is very small, so that the durability of the method is high.

Owner:SICHUAN KELUN PHARMA CO LTD

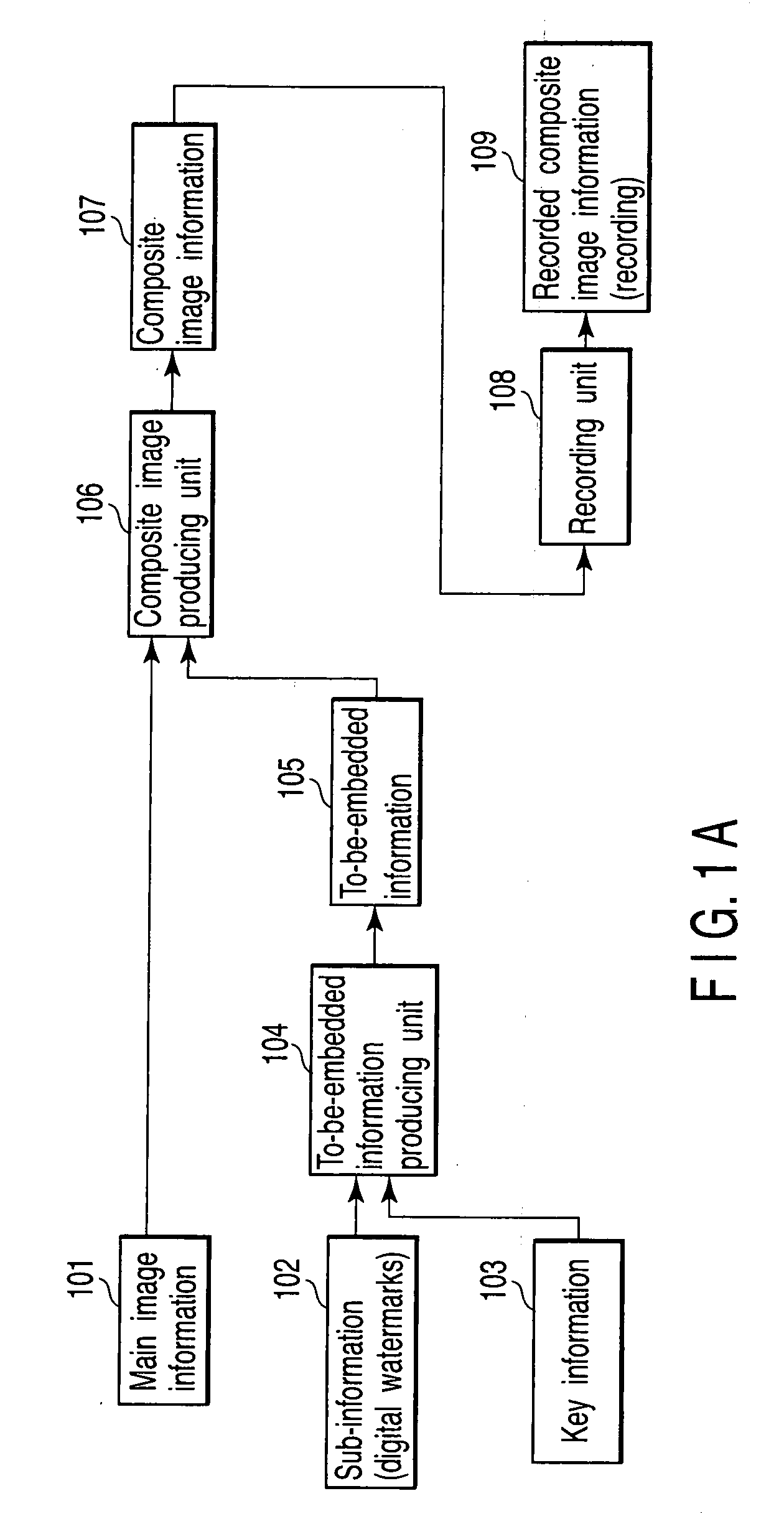

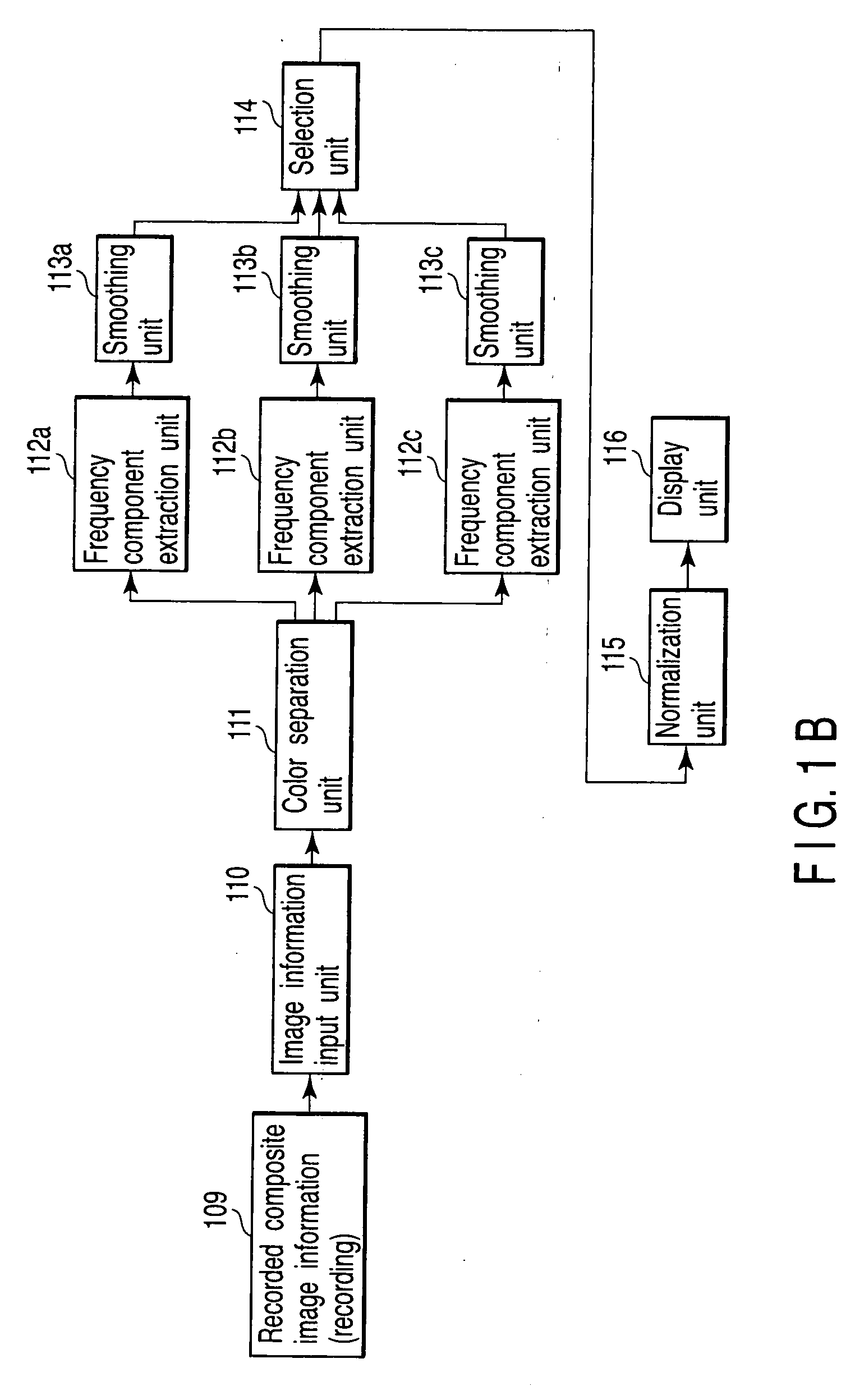

Image processing method and device

ActiveUS20070223780A1Stable recoveryCharacter and pattern recognitionImage data processing detailsComputer graphics (images)Imaging processing

In an image processing device adapted to restore sub-information from composite image information produced by a composite image producing device which embeds invisible sub-information into visible main image information to produce the composite image information, the frequency components of the sub-information extracted for each of its color components are smoothed, and the optimum one is selected from among the results of the smoothing process performed for each color component of the sub-information.

Owner:KK TOSHIBA

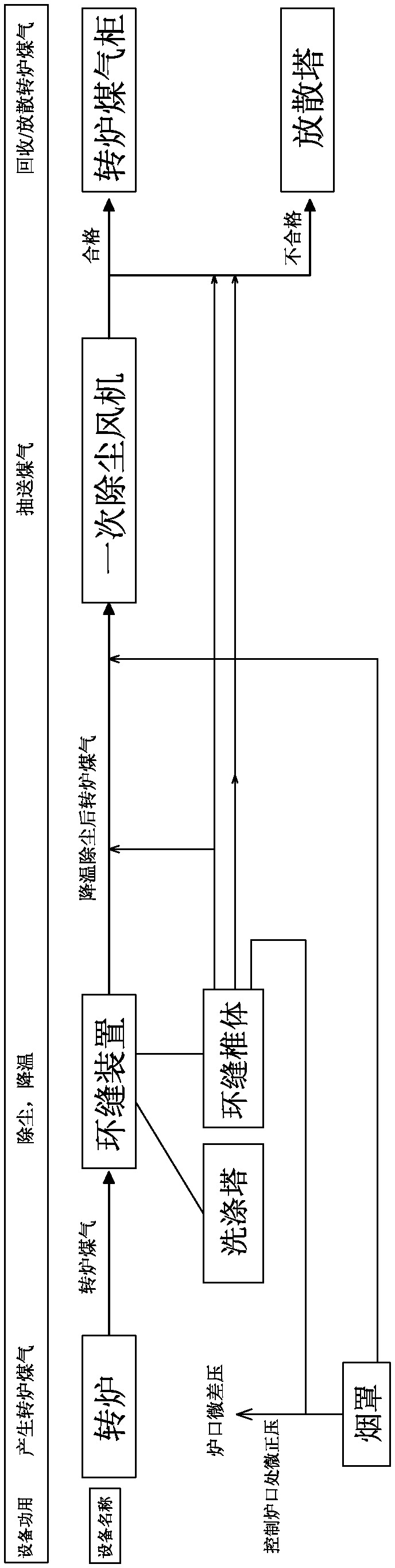

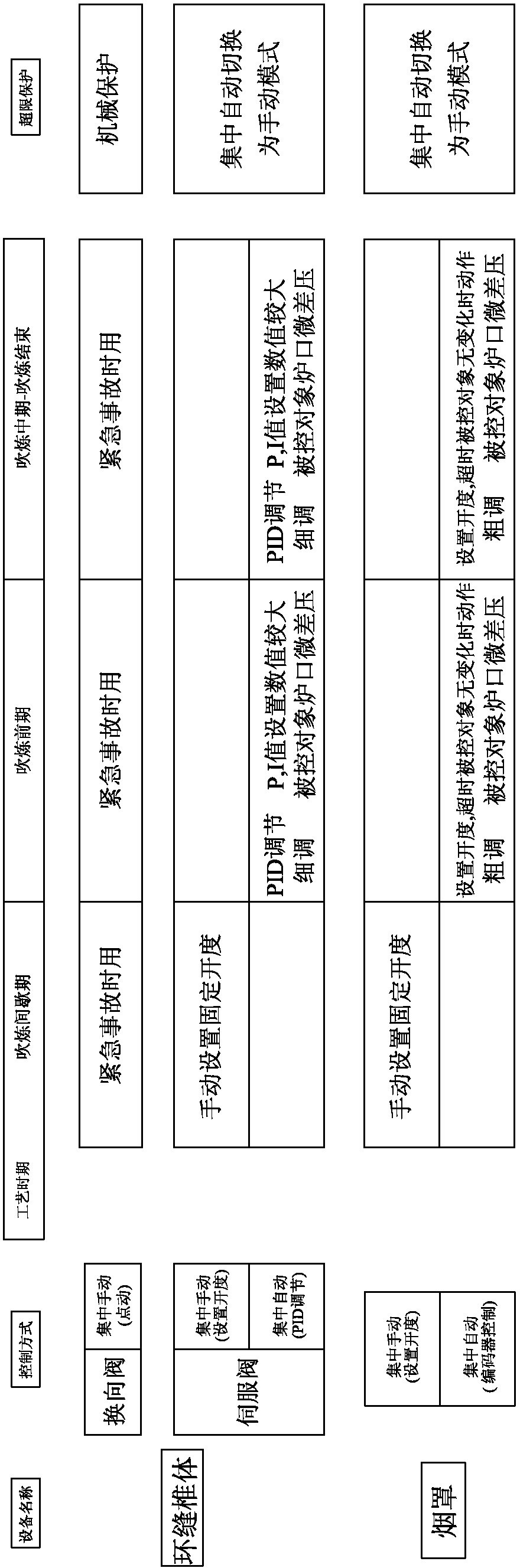

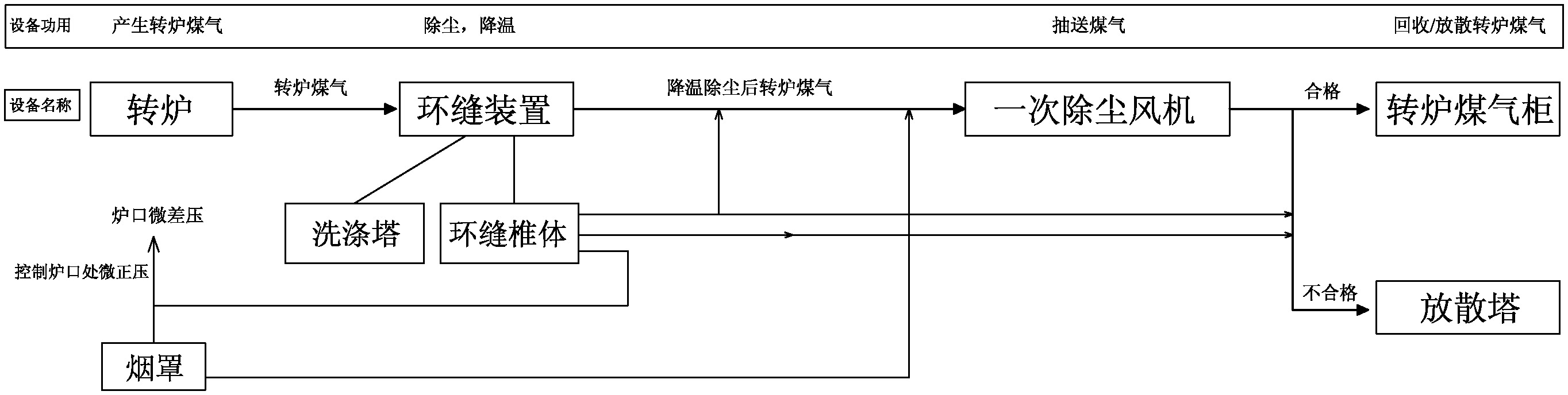

Circular seam control device and process for novel converter one-time dedusting OG (Oxygen Converter Gas Recovery) system

InactiveCN102534100AEasy to recycleEasy to controlManufacturing convertersDifferential pressureProgrammable logic controller

The invention discloses a circular seam control device and process for a novel converter one-time dedusting OG (Oxygen Converter Gas Recovery) system. The circular seam control process comprises the following steps of: accessing a position feedback signal of the circular seam control device to a PLC (Programmable Logic Controller) and accessing a signal output from the PLC to a servo valve; in a blowing intermission, concentratedly manually operating a circular seam cone and a smoke hood and manually setting openness; in the initial blowing stage, enabling a three-way valve to be at a diffusion side, igniting and discharging coal gas of a converter, keeping the position of the smoke hood fixed, and enabling the circular seam control device to be in an concentrated and automatic state of the servo valve; in the intermediate blowing stage, enabling the three-way valve to be at a recovery side, roughly adjusting the height and the micro-differential pressure of the smoke hood, reducing the fluctuation of the micro-differential pressure, and setting the circular seam control device to be in a concentrated and automatic state of the serve valve. The circular seam control device comprises the circular seam cone, a hydraulic station and the PLC. The smoke hood is used for matching control over the circular seam control device; the hydraulic station is used for supplying power; the PLC is used for transmitting the signal to the servo valve and controlling the servo valve to actuate; the servo valve is used for driving and controlling the circular seam cone; and an absolute encoderis additionally arranged on the smoke hood. The circular seal control device and process disclosed by the invention have the advantages of reduced number of installation equipment, increase of energyrecovery, low investment and high system precision.

Owner:WISDRI ENG & RES INC LTD

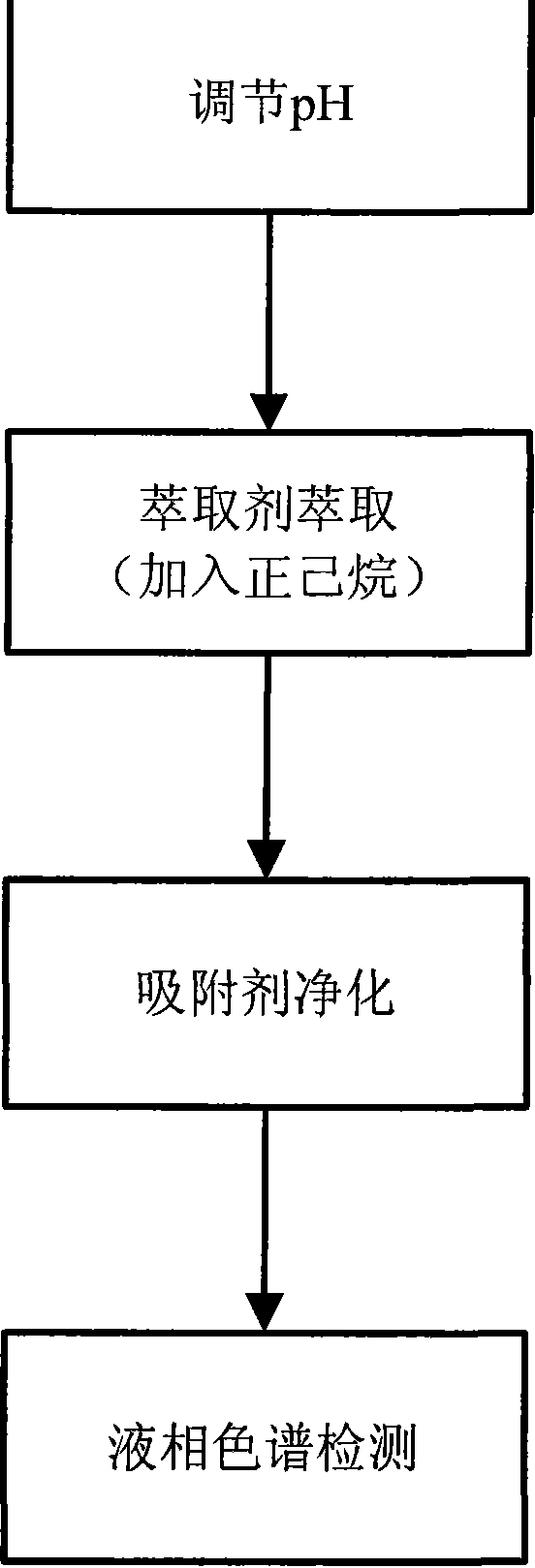

Quantitative detection method of pentachlorophenol in soil

InactiveCN101629937AReduce dosageQuantitatively accurateComponent separationPentachlorophenolSorbent

The invention discloses a quantitative detection method of pentachlorophenol in the soil, which belongs to the field of analysis and detection of compounds. The quantitative detection method comprises the following steps: a) regulating the pH value of a soil sample to be detected, and precipitating the pentachlorophenol in molecular form; b) adding an extraction agent and n-hexane into the sample, and extracting the pentachlorophenol into the extraction agent; c) adding an absorbent into an extract and purifying the extract; and d) detecting the pentachlorophenol in the extract by liquid phase chromatography. The method can be used for quantitative detection of content of the pentachlorophenol in the soil as the standard method and be characterized by rapidness, simplicity, good universality, small toxicity, simple operation, good reproducibility, low detection limit and the like.

Owner:INST OF ENVIRONMENT & SUSTAINABLE DEV IN AGRI CHINESE ACADEMY OF AGRI SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com