Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

38results about How to "Suppress pressure rise" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

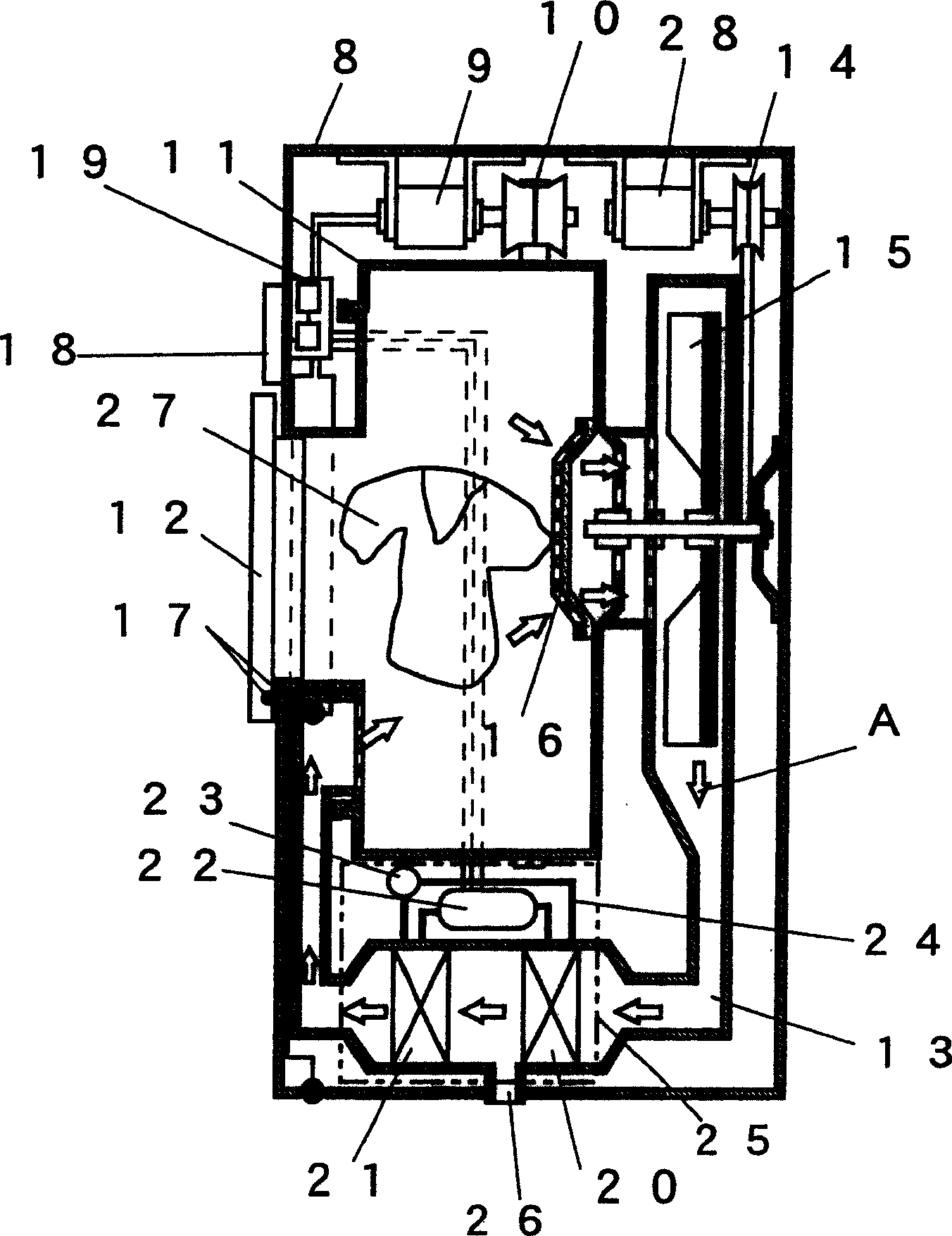

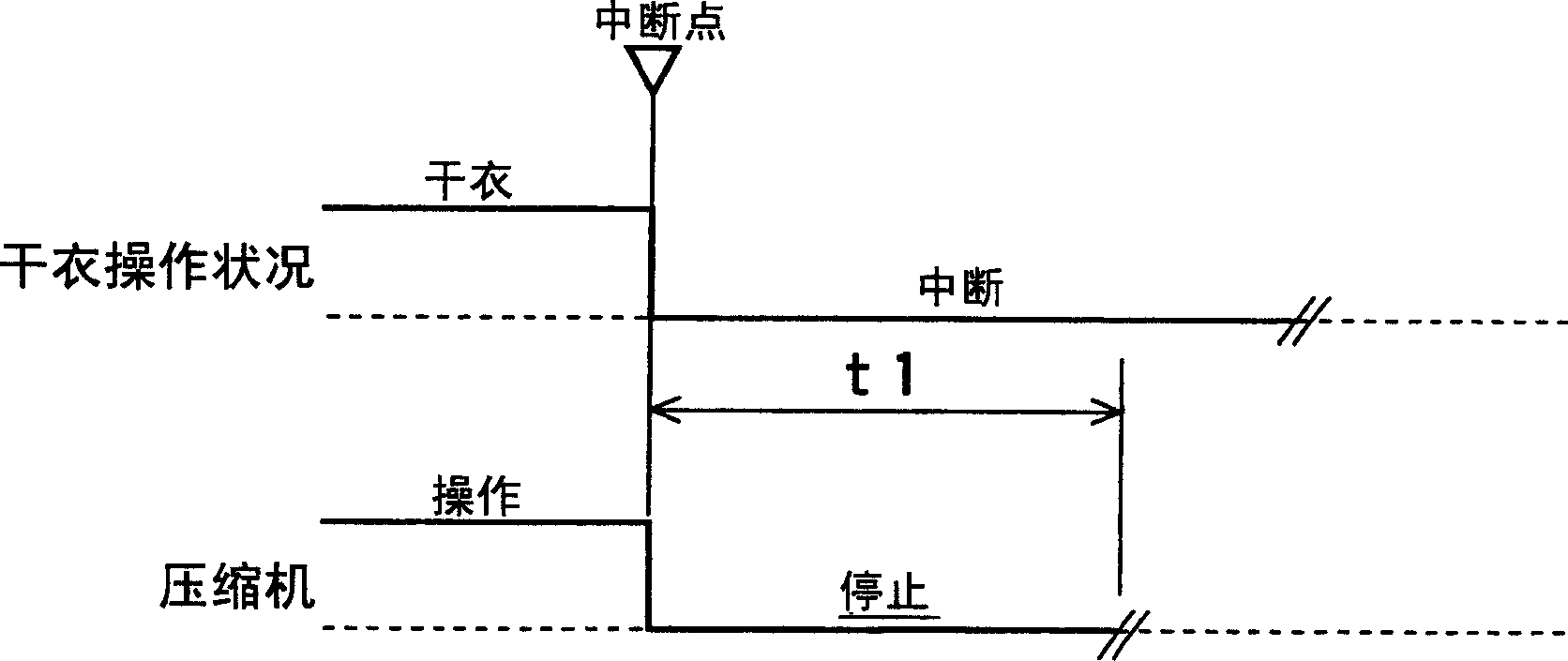

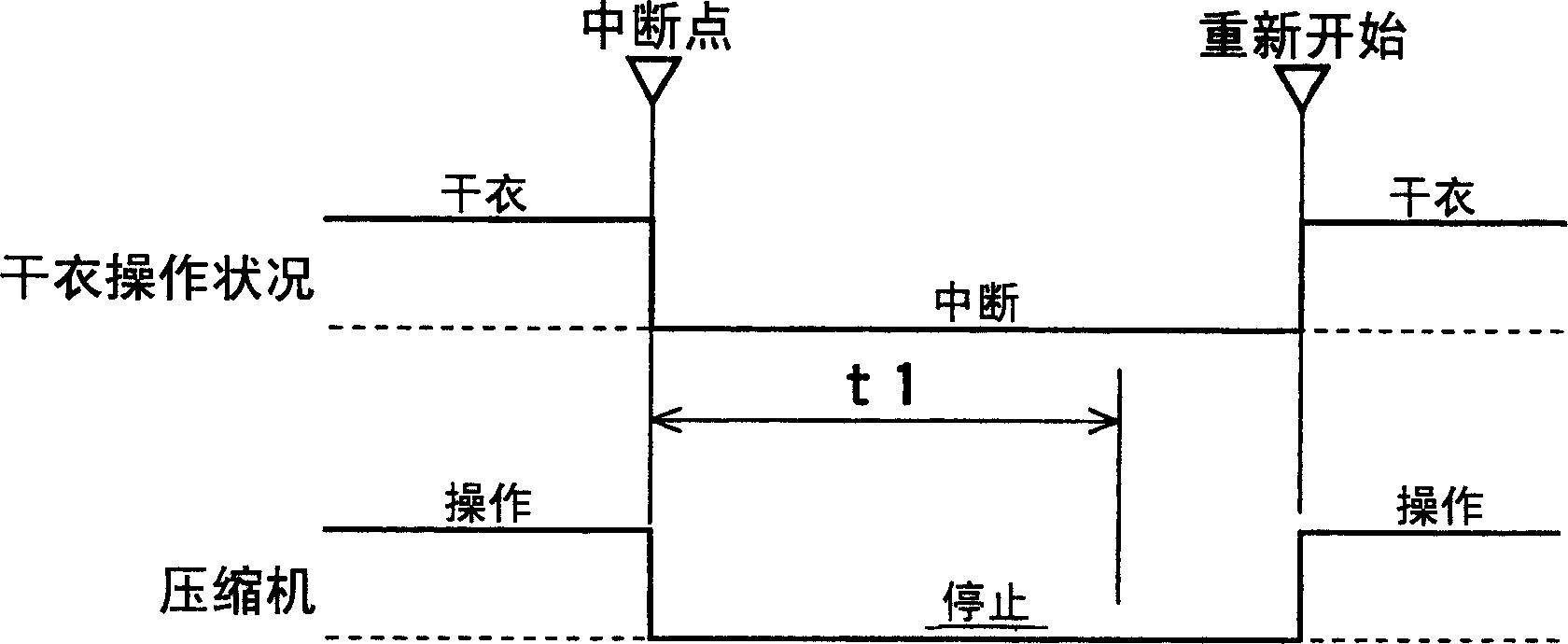

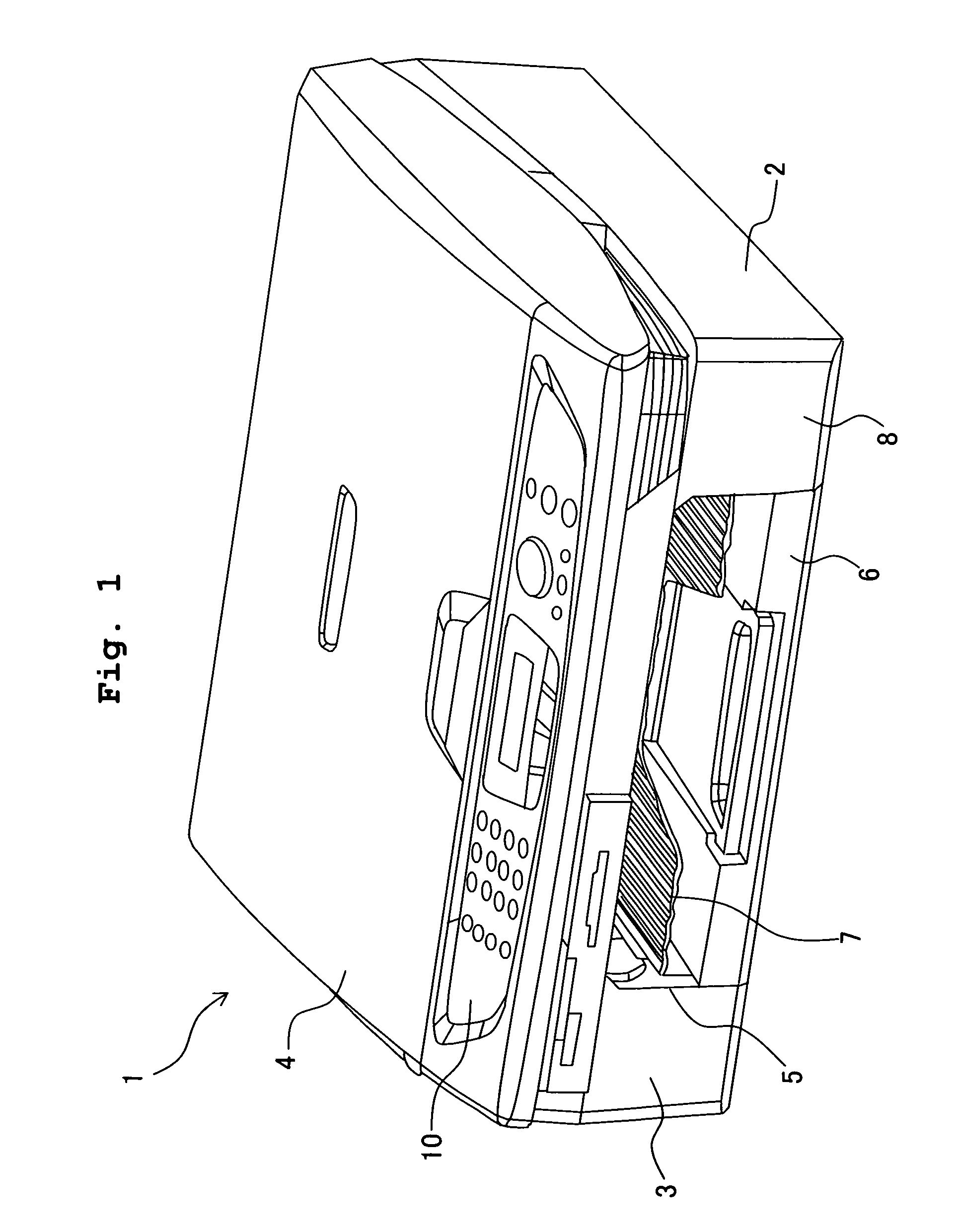

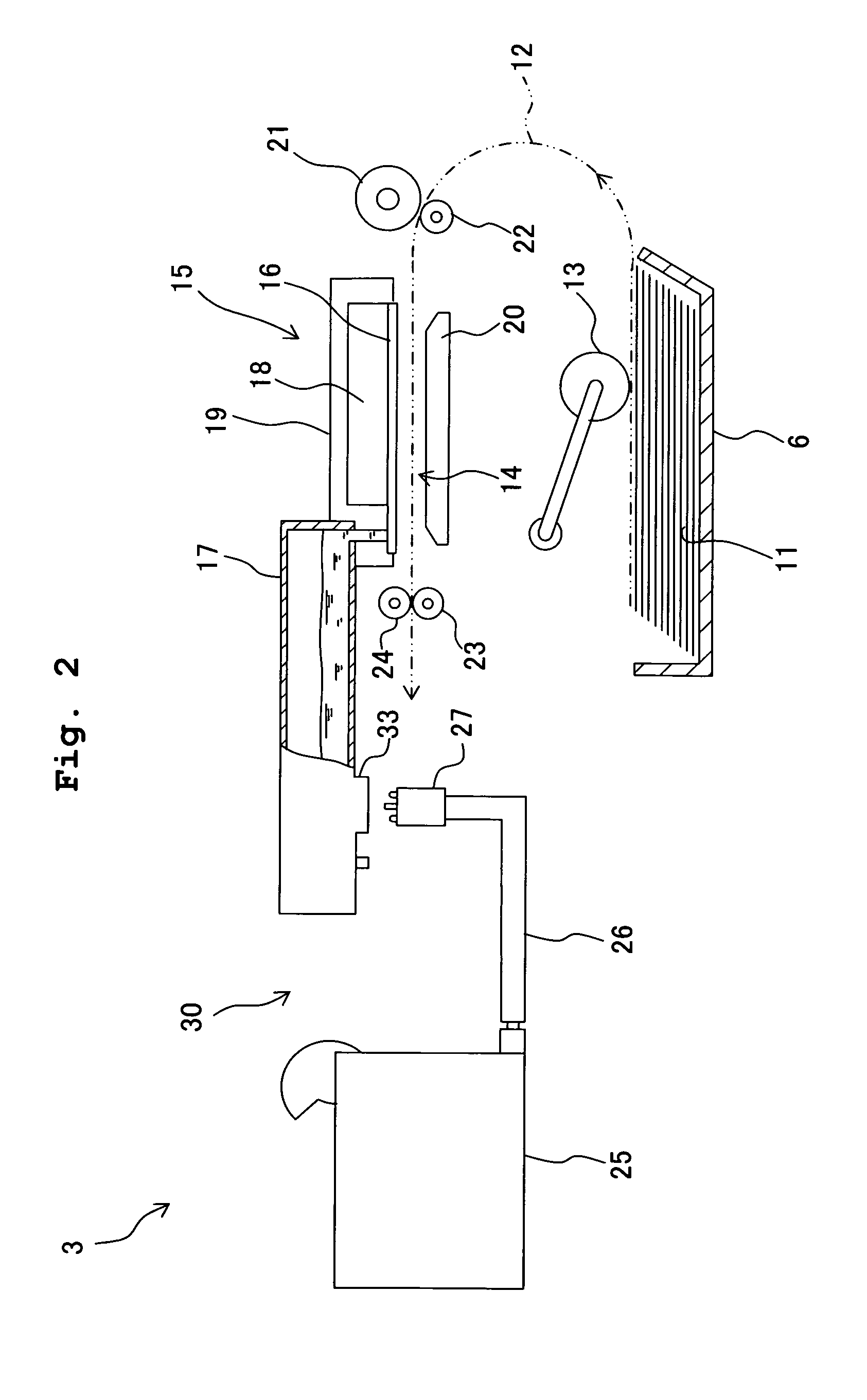

Clothes drier

ActiveCN1626724AReduce the burden onSuppress pressure riseTextiles and paperLaundry driersThermodynamicsEngineering

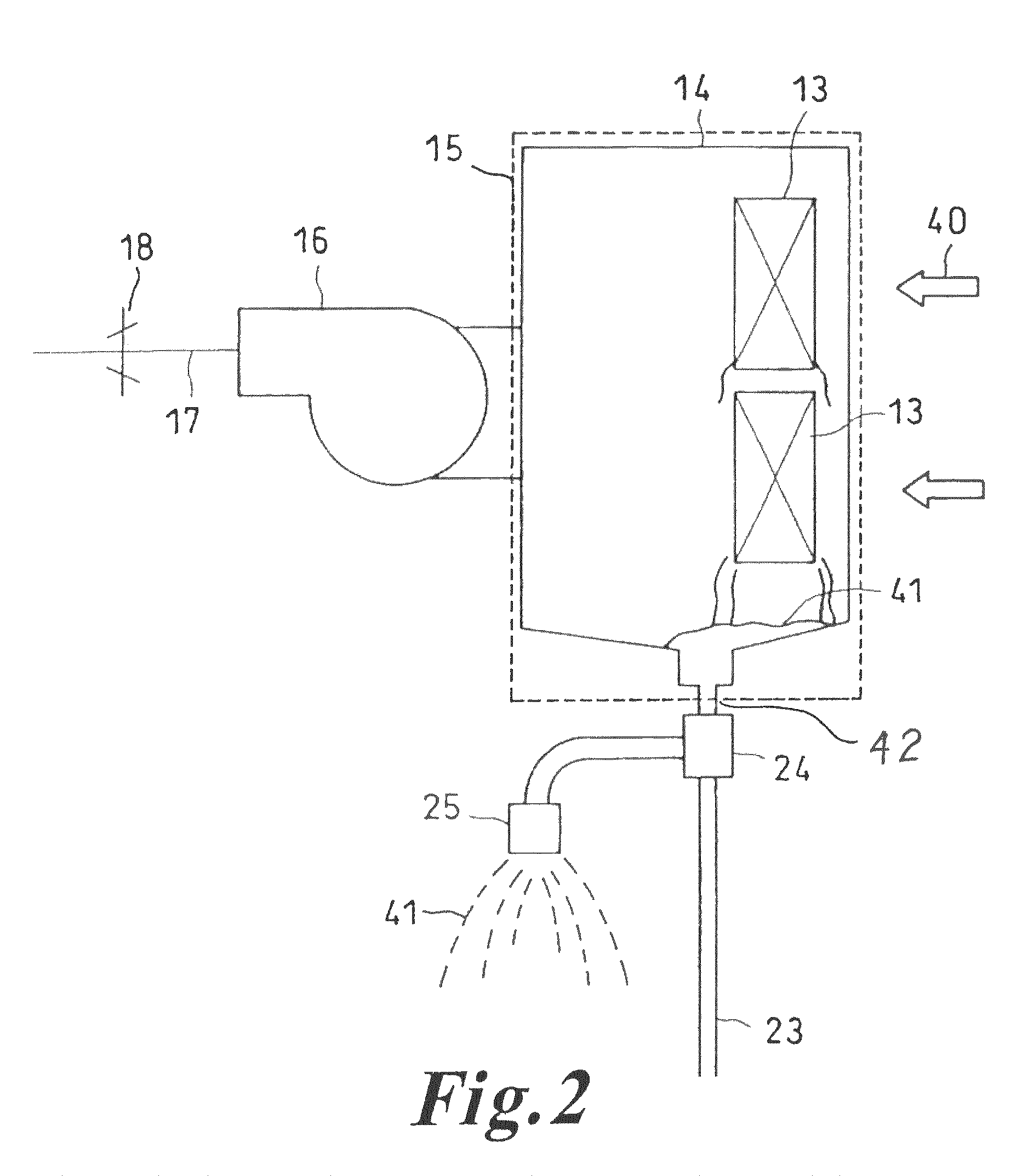

A clothes drying apparatus includes a heat pump mechanism (25), an air path (13) for guiding drying air into a drying drum (11) accommodating therein clothes (27), a blower (15) for supplying drying air to the air path (13), and a controller for controlling a driving of a compressor (22), wherein the controller operates the blower (15) and the compressor (22) during a drying operation; stops the compressor (22) in case the drying operation is suspended; and operates, in case the drying operation is resumed, the compressor (22) after a certain time period has elapsed since the compressor (22) had stopped. In case employing the heat pump mechanism (25) having the compressor (22) as a heat source, it is possible to reduce a load on the compressor (22) and allow temperature of warm air to rapidly return by using the heat pump mechanism (25). <IMAGE>

Owner:PANASONIC CORP

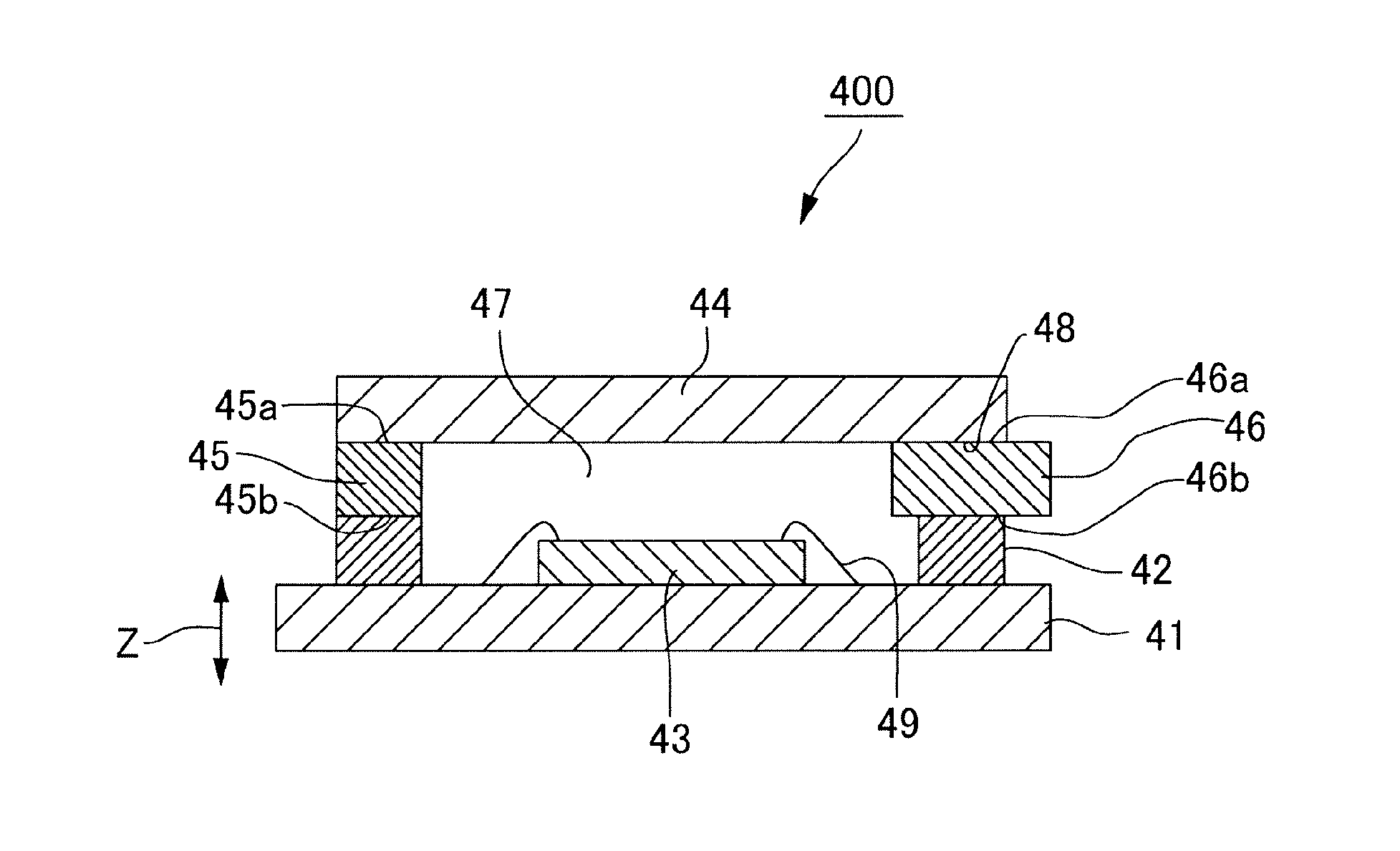

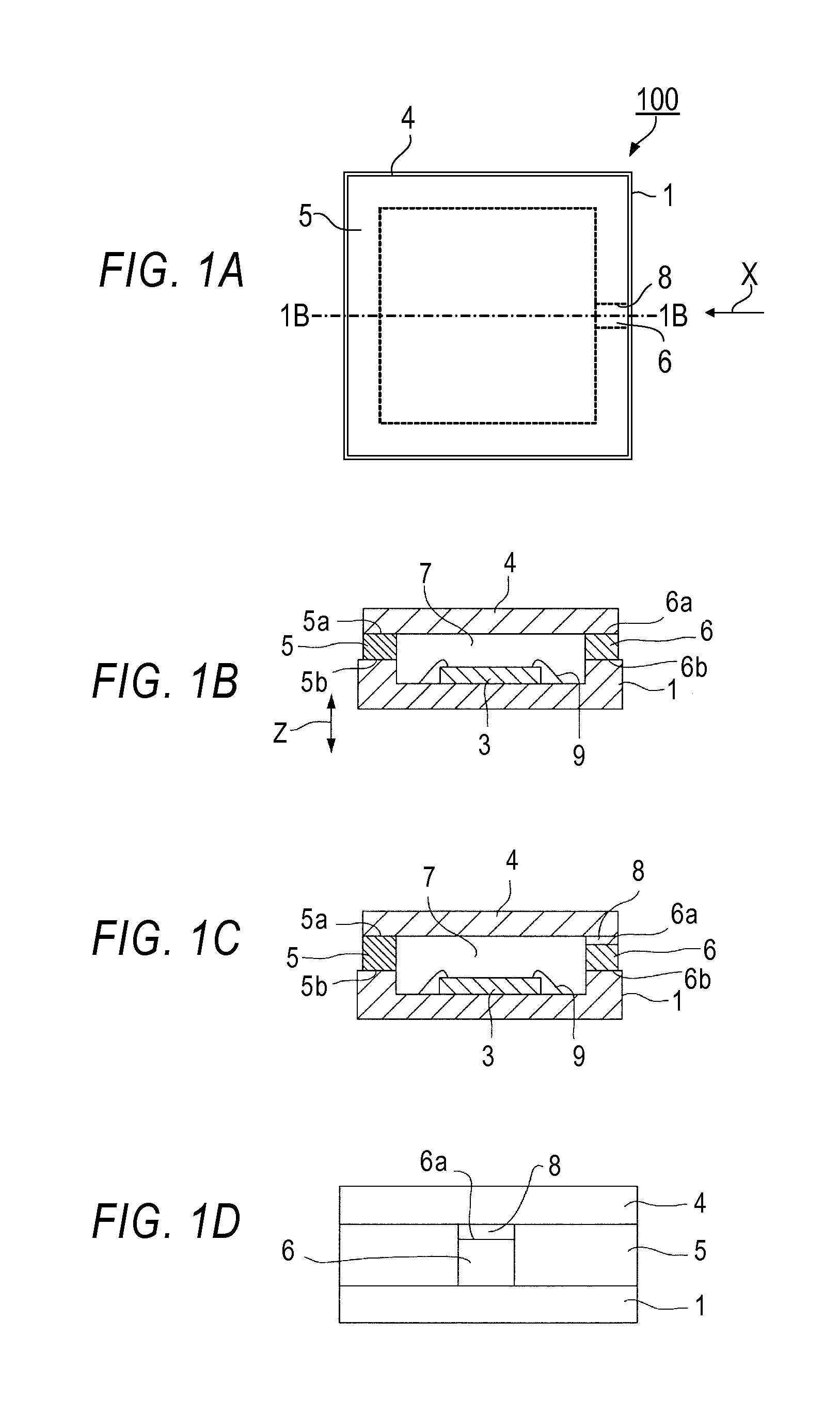

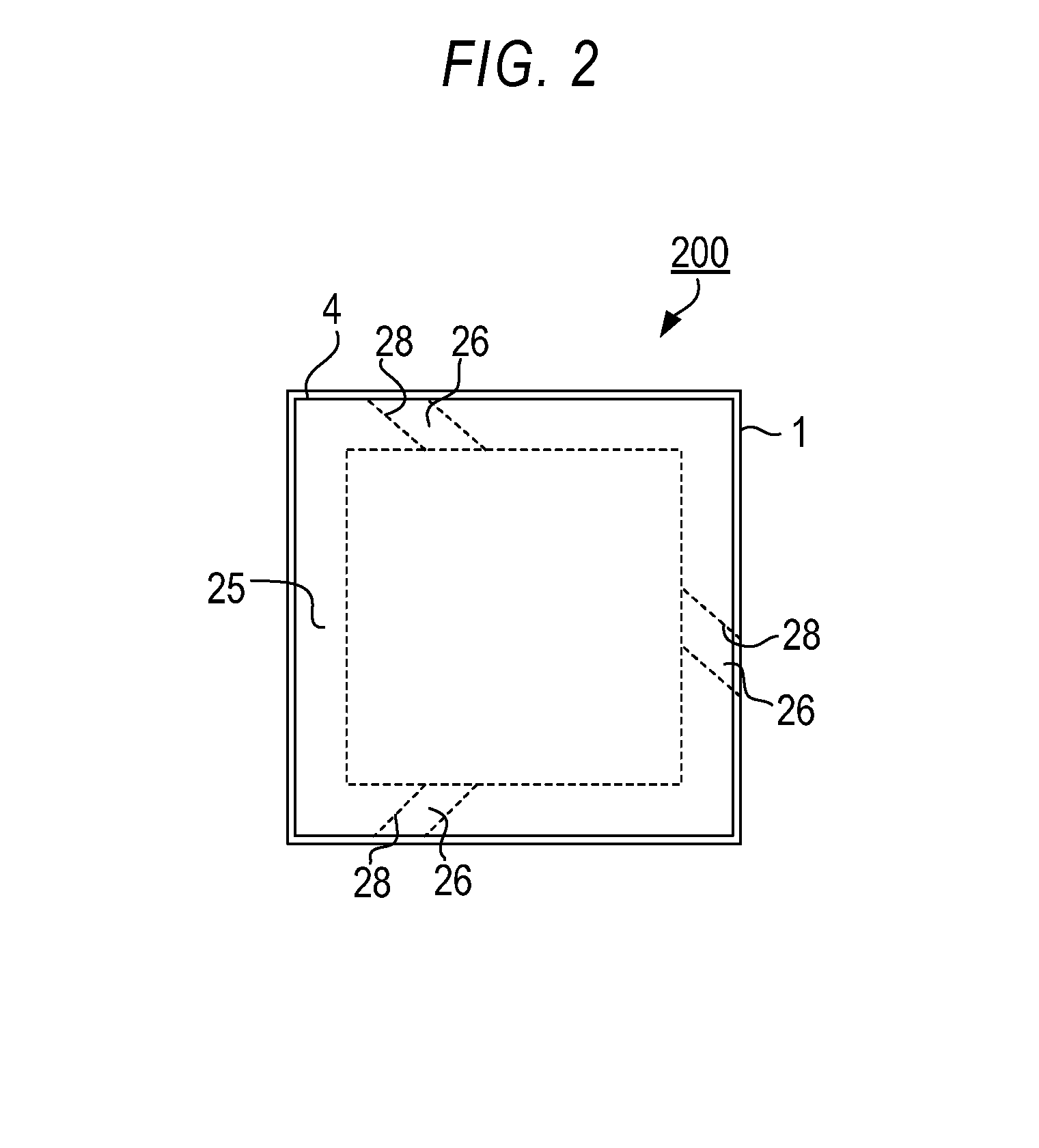

Semiconductor device

ActiveUS20140070411A1Relieve pressureKeep airtightSemiconductor/solid-state device detailsSolid-state devicesForeign matterDevice material

Provided is a semiconductor device in which a semiconductor element mounted on a wiring substrate is placed in a hollow portion, the hollow portion being formed by the wiring substrate, a protective member, and a wall member, with the wiring substrate, the protective member, and the wall member being a bottom surface, a top surface, and side surfaces thereof, respectively. The wall member has a vent hole provided therein, which communicates the hollow portion to / from the outside, and the vent hole includes a pillar member formed of a material having a linear expansion coefficient which is smaller than that of the wall member. Therefore, airtightness of the hollow portion is maintained to prevent entry of foreign matters at ordinary temperature, and vapor pressure in the hollow portion is relieved when heated.

Owner:CANON KK

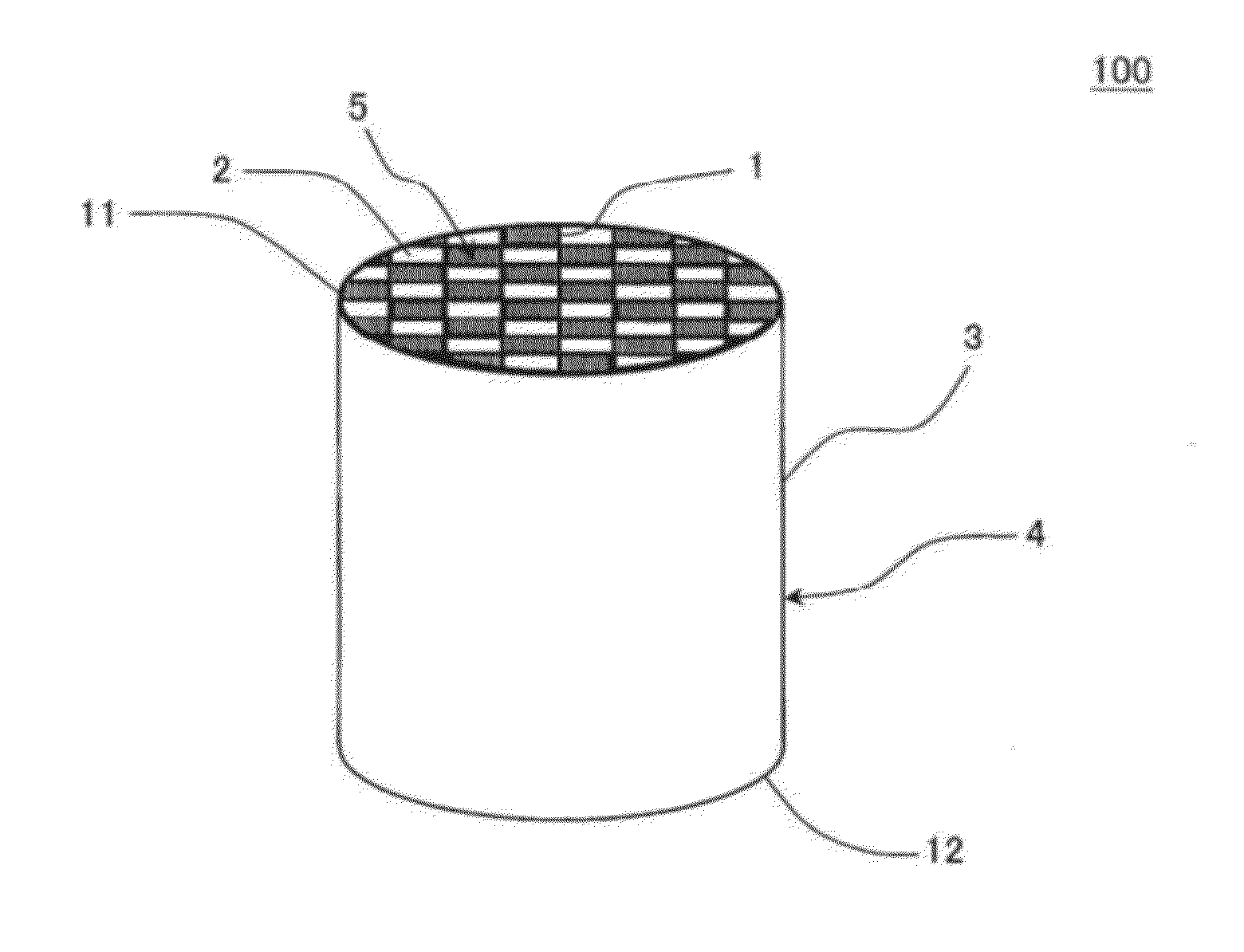

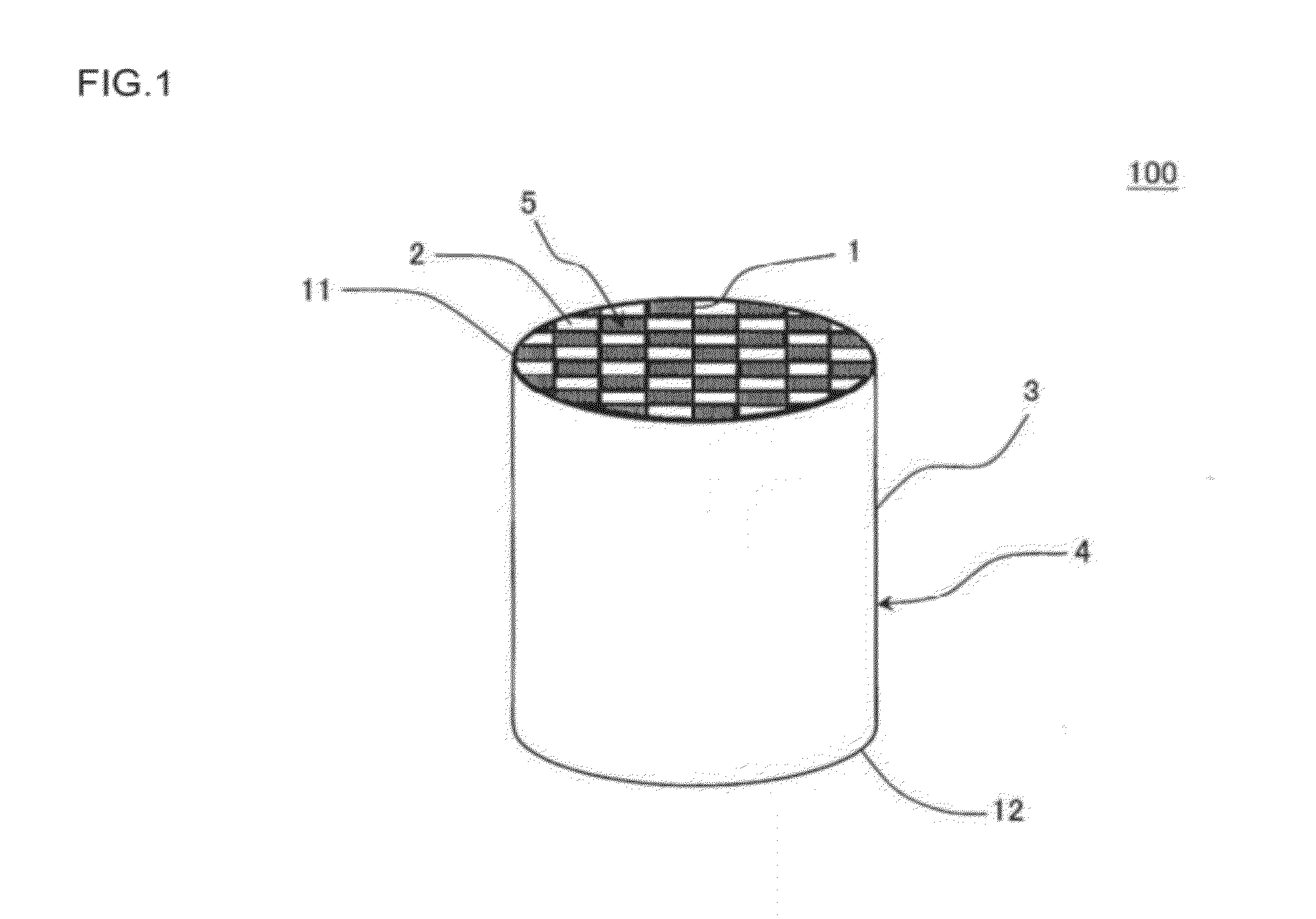

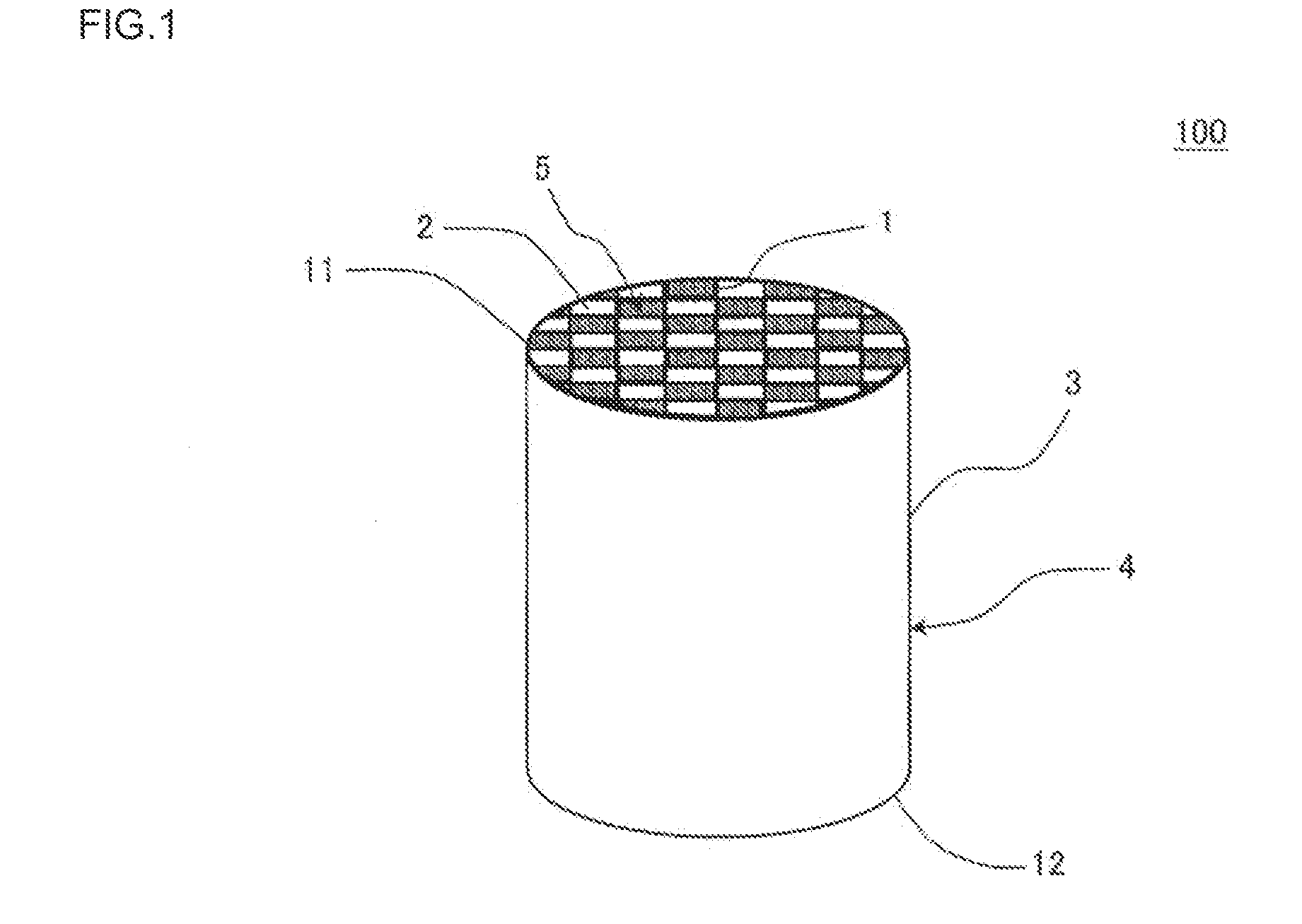

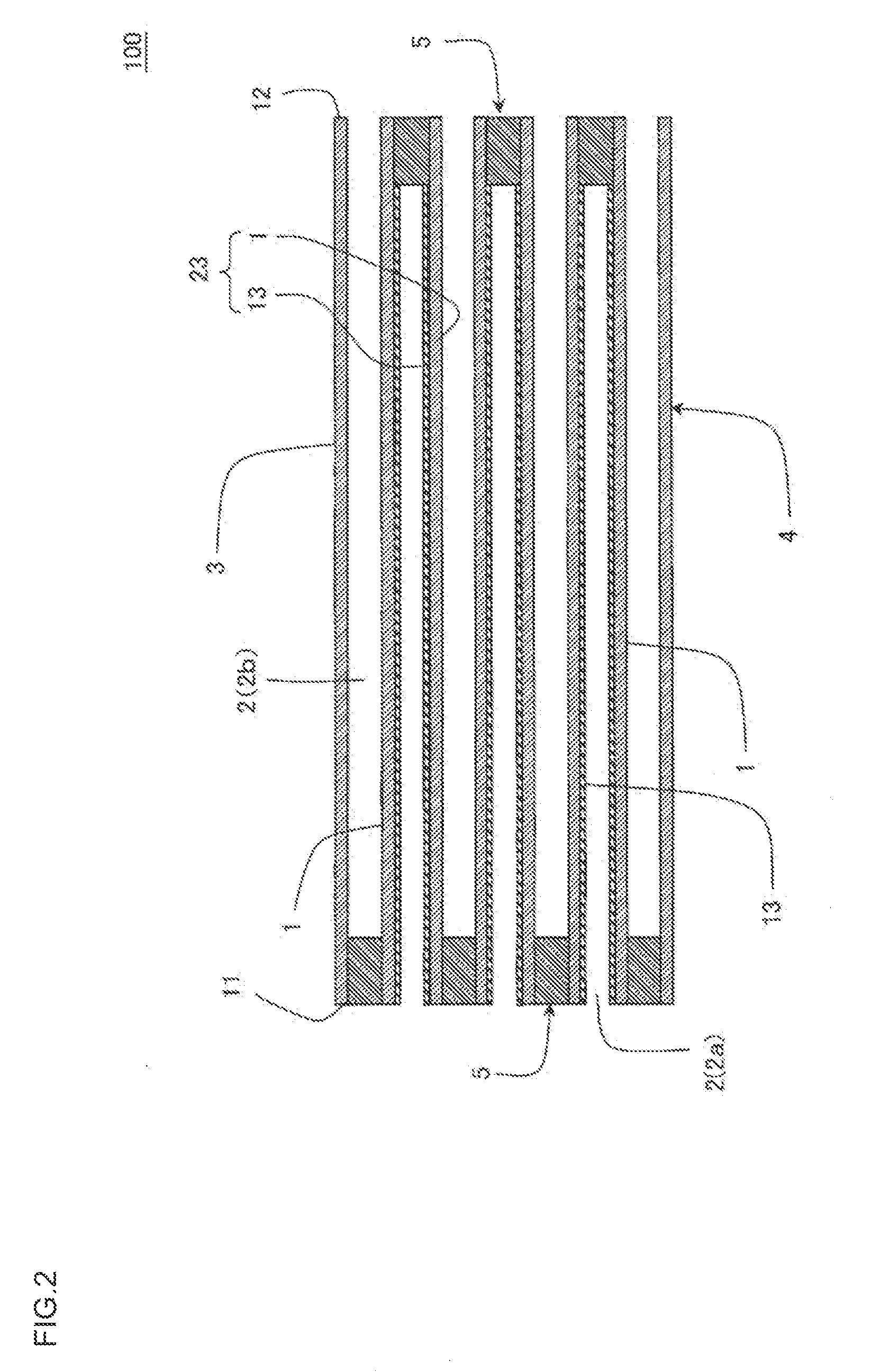

Honeycomb filter and manufacturing method of the same

ActiveUS20120240538A1Suppress increase of initial pressure lossReduce total pressure lossCombination devicesDispersed particle filtrationLongest DiameterHoneycomb

There is provided a honeycomb filter including: a honeycomb base material; plugged portions; and a porous collecting layer disposed on the surface of the partition wall parent material in at least the remaining cells. The collecting layer has a constitution in which a plurality of particles combine or intertwine with one another, and the collecting layer includes flat plate-like particles as the plurality of particles. The plurality of particles are particles in which an average long diameter is 0.2 μm or larger and smaller than 10 μm, an average value of ratios (long diameters / short diameters) of the long diameters to the short diameters of the respective particles is smaller than 3, and an average value of ratios (the long diameters / thicknesses) of the long diameters to thicknesses of the respective particles is 3 or larger. An open area ratio of the surface of the collecting layer is 10% or larger.

Owner:NGK INSULATORS LTD

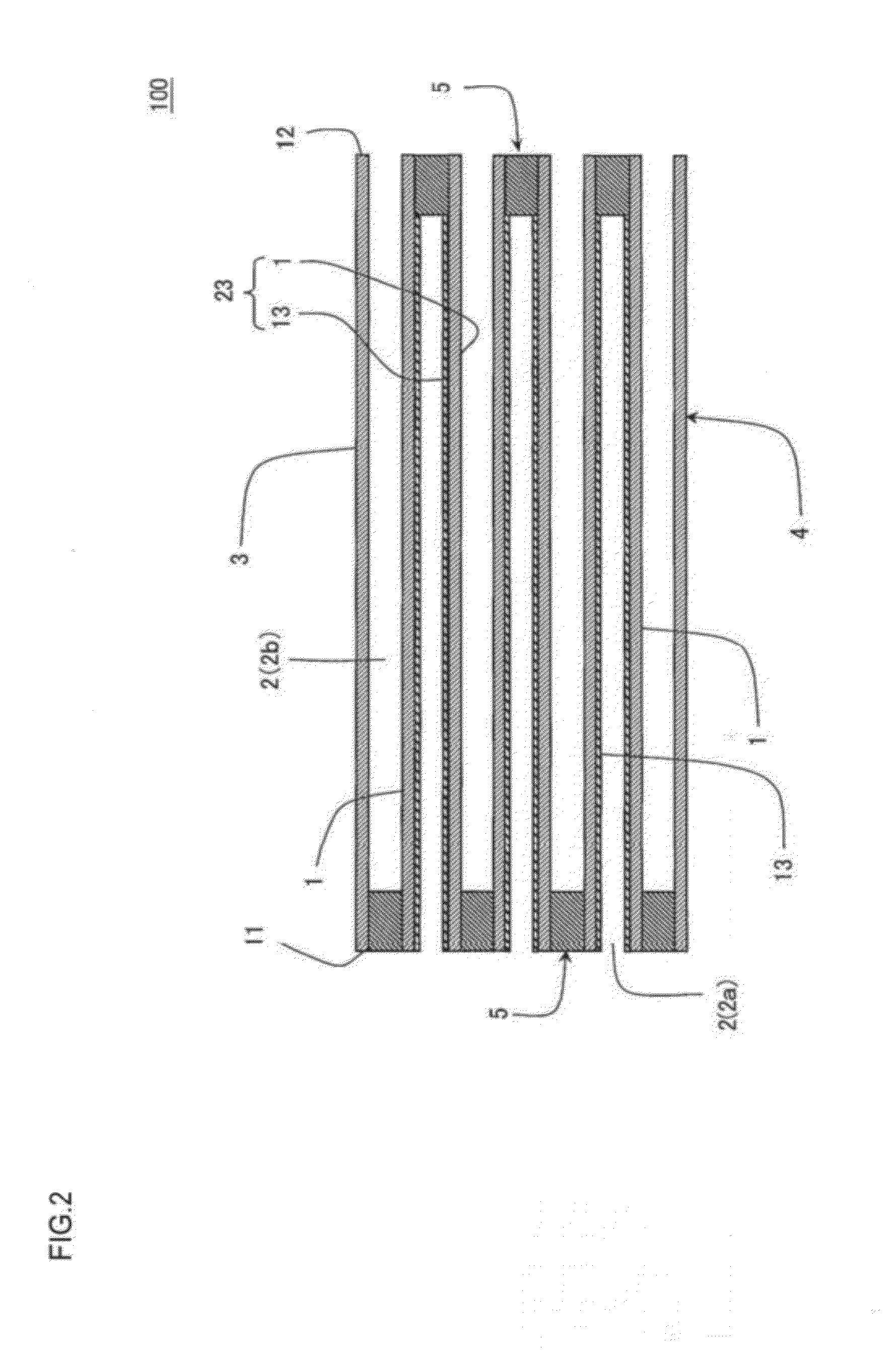

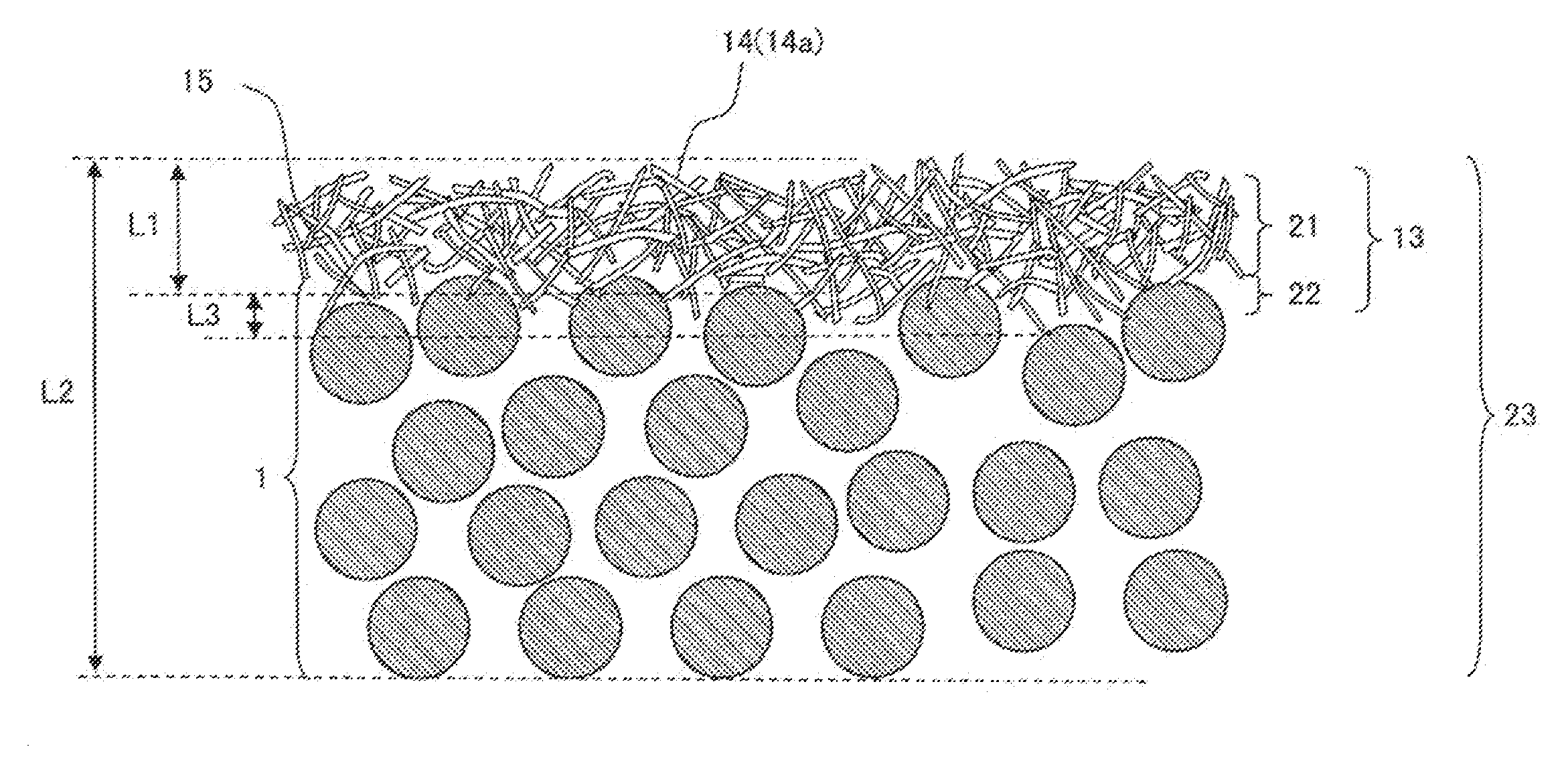

Honeycomb filter and manufacturing method of the same

ActiveUS20120240541A1Suppress increase of initial pressure lossReduce total pressure lossDispersed particle filtrationTransportation and packagingHoneycombFiber diameter

There is provided a honeycomb filter including: a honeycomb base material; plugged portions; and a porous collecting layer disposed on the surface of the partition wall parent material in at least the remaining cells. The collecting layer has a constitution in which a plurality of particles combine or intertwine with one another, and the collecting layer includes fibrous fiber particles as the plurality of particles, and includes the particles having an average fiber diameter of 0.1 to 15 μm and an average aspect ratio of 3 or larger. An open area ratio of the surface of the collecting layer is 20% or larger.

Owner:NGK INSULATORS LTD

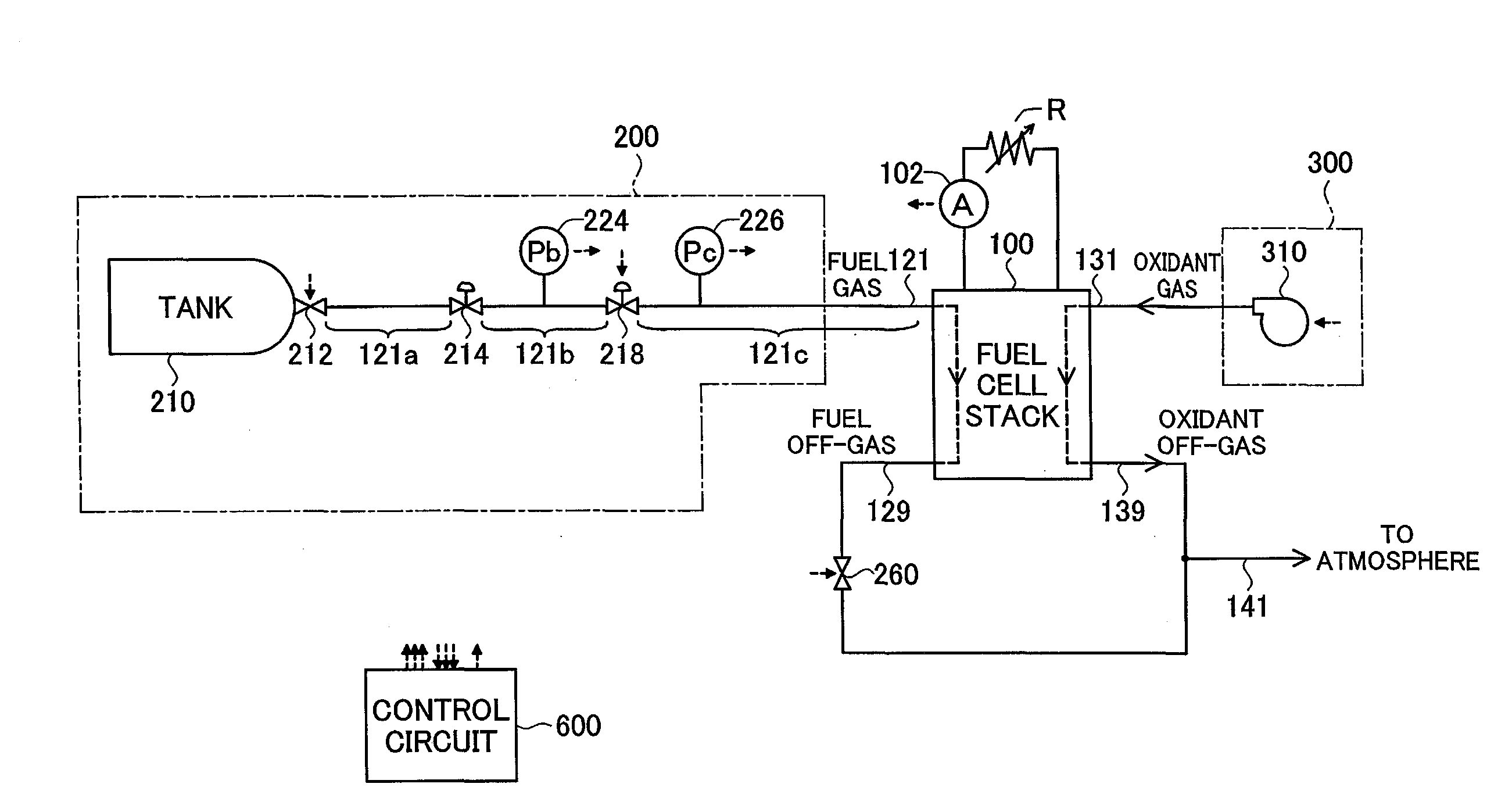

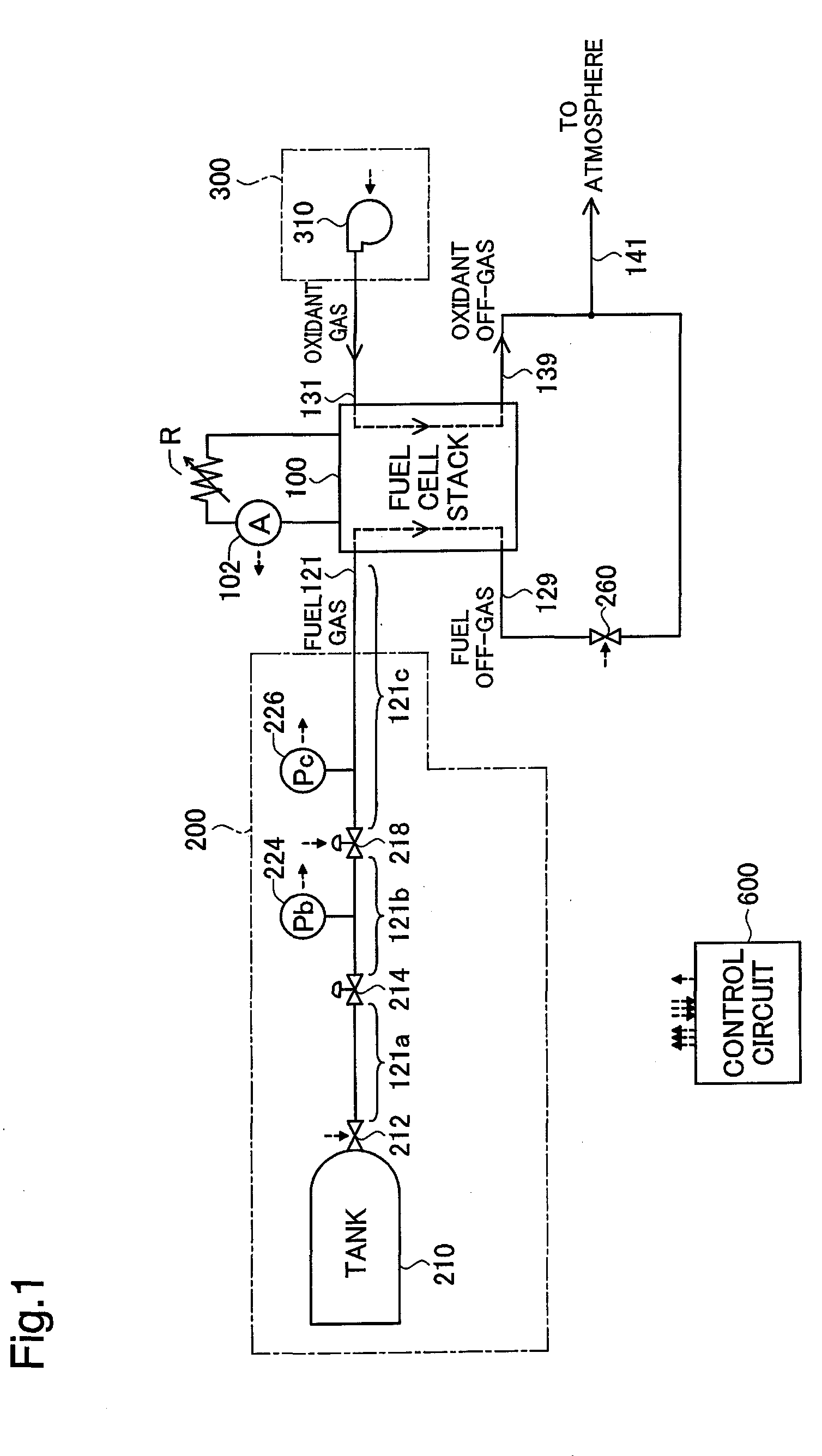

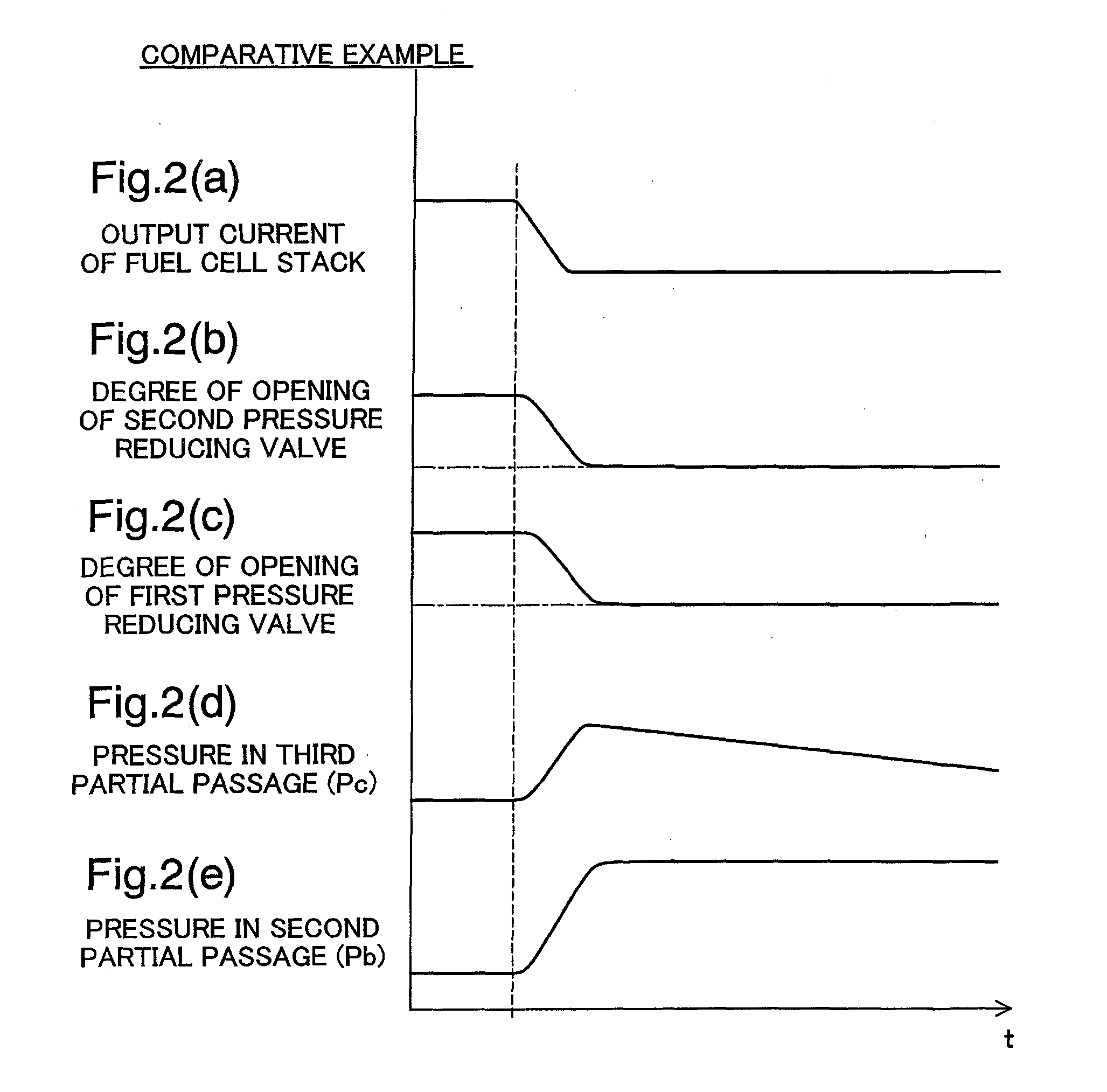

Fuel gas feeding device and control method therefor

InactiveUS20090053567A1Suppress pressure riseReduce the amount of fuelReactant parameters controlTransportation fuel cell technologyFuel cellsProduct gas

To provide a technique to suppress an excessive rise of pressure between two pressure reducing valves if the amount of fuel gas consumed by a fuel cell stack decreases. A fuel gas supply apparatus comprises: a gas passage in which fuel gas to be supplied to a fuel cell stack flows; a first pressure reducing valve provided to the gas passage; a second pressure reducing valve provided to the gas passage and disposed at a downstream side of the first pressure reducing valve; a setting module that sets a value of target pressure at a downstream side of the second pressure reducing valve, to a value depending on a consumed amount of fuel gas consumed by the fuel cell stack; and a modifying module that, if the consumed amount decreases by a prescribed amount or more, modifies the value of target pressure of the second pressure reducing valve to a value greater than a corresponding value that corresponds to the consumed amount subsequent to the decrease.

Owner:TOYOTA JIDOSHA KK

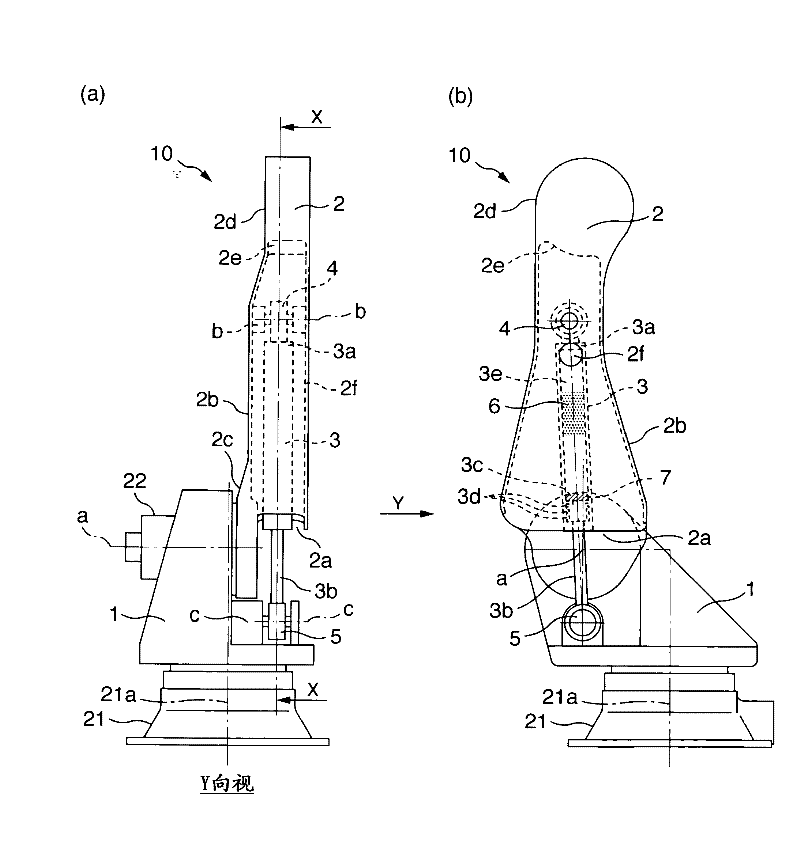

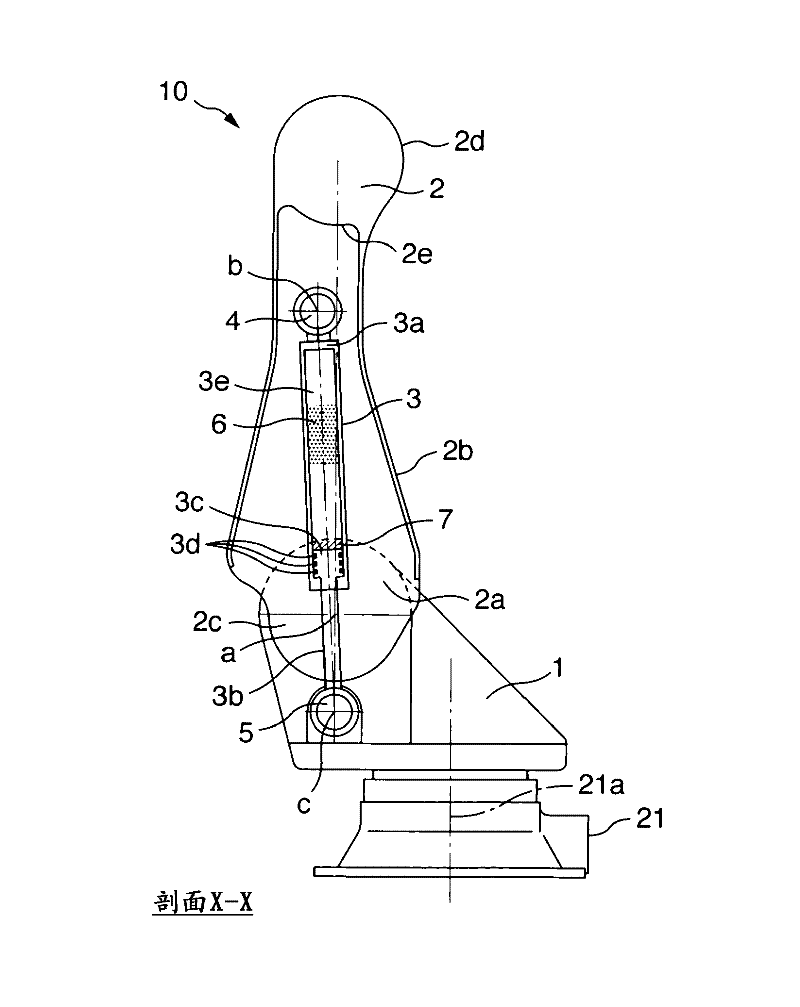

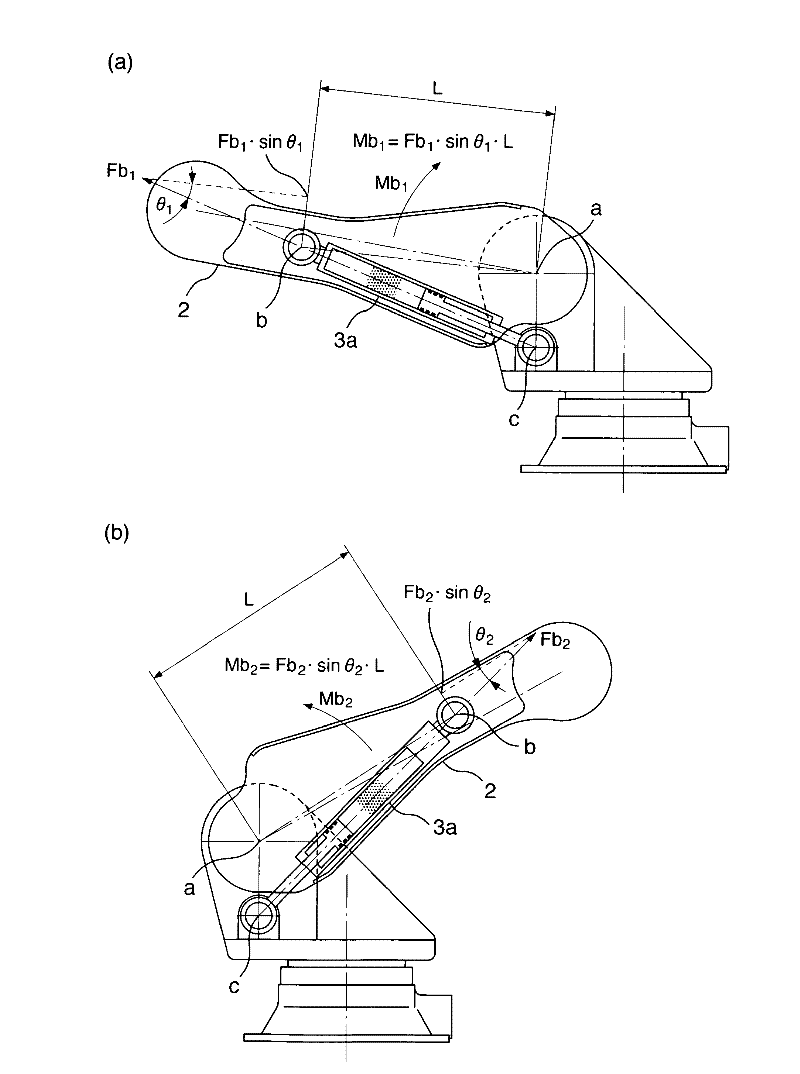

Industrial robot

An industrial robot 10 comprises an arm 2 which includes a proximal portion rotatably supported on a horizontal rotation shaft of a frame 1 in a cantilever state, a cylindrical case portion formed from the proximal portion side to a distal end of the arm to have an opening portion on the proximal portion side, and an arm distal end portion. The industrial robot also comprises a balancer device which includes a rod 3b , and a cylinder 3a in which the rod 3b is reciprocated. An engagement portion at a distal end of the rod, and a rear end 5 of the cylinder are rotatably supported between a pair of first support portions c of the frame, and between a pair of second support portions b inside the cylindrical case portion, respectively, so that the cylindrical case portion and the balancer device do not interfere with each other in an extent of rotation of the arm.

Owner:NACHI-FUJIKOSHI

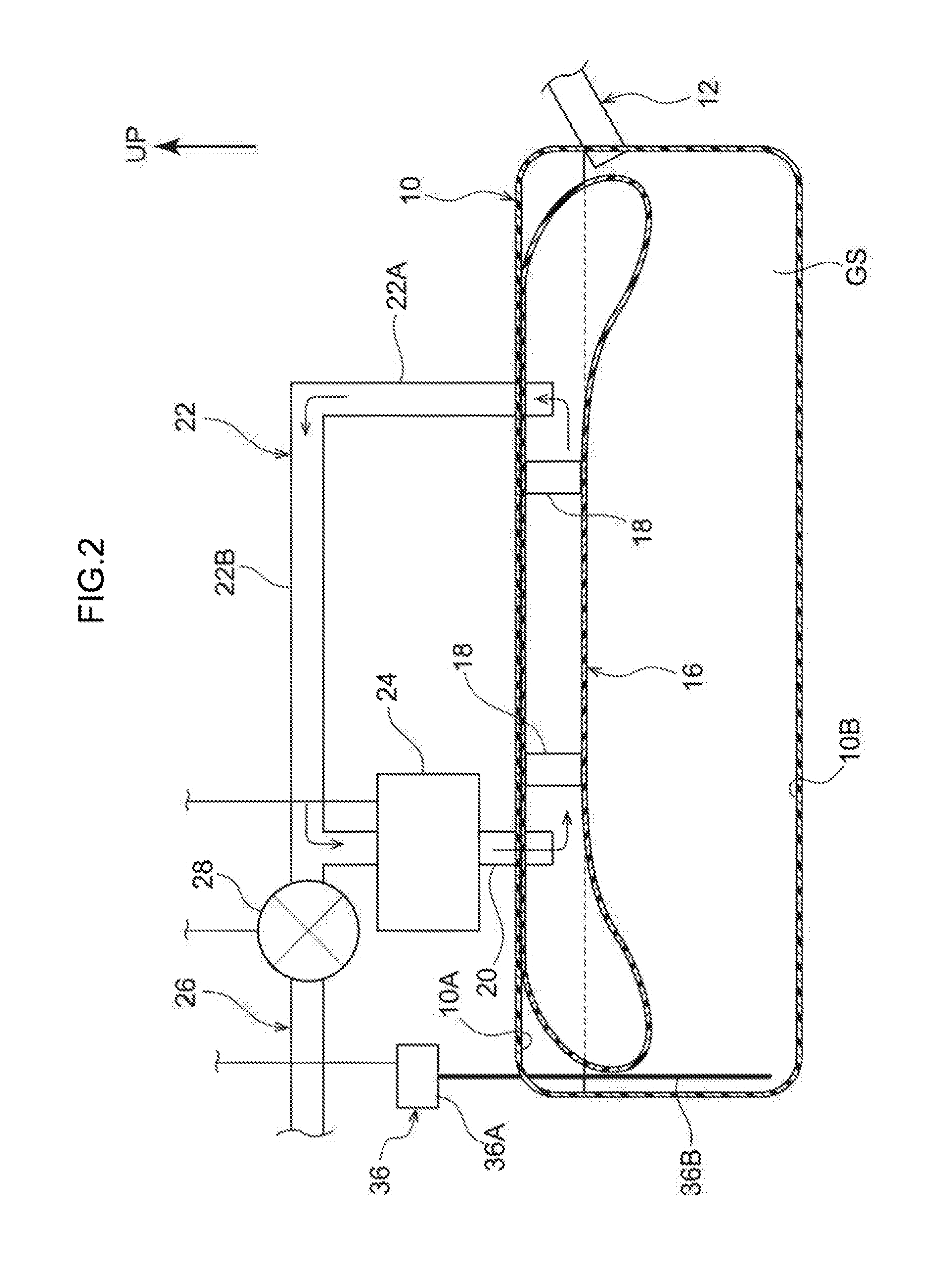

Fuel tank structure

InactiveUS20160361992A1Suppress pressure riseImprove cooling effectUnderstructuresMaterial thermal analysisAutomotive engineeringFuel tank

A fuel tank structure includes: a fuel tank that is installed in an automobile and that accommodates fuel; a bag-shaped member that is fixed to a ceiling portion of an interior of the fuel tank, and whose state of contact with a liquid surface of fuel accommodated in the fuel tank is maintained due to the bag-shaped member inflating or deflating in accordance with a height of the liquid surface; a temperature sensor that senses a temperature of the fuel or evaporated fuel that is within the fuel tank; and a cooling wind introducing section that introduces cooling wind into an interior of the bag-shaped member in a case in which the temperature of the fuel or the evaporated fuel detected by the temperature sensor becomes higher than a predetermined temperature.

Owner:TOYOTA JIDOSHA KK

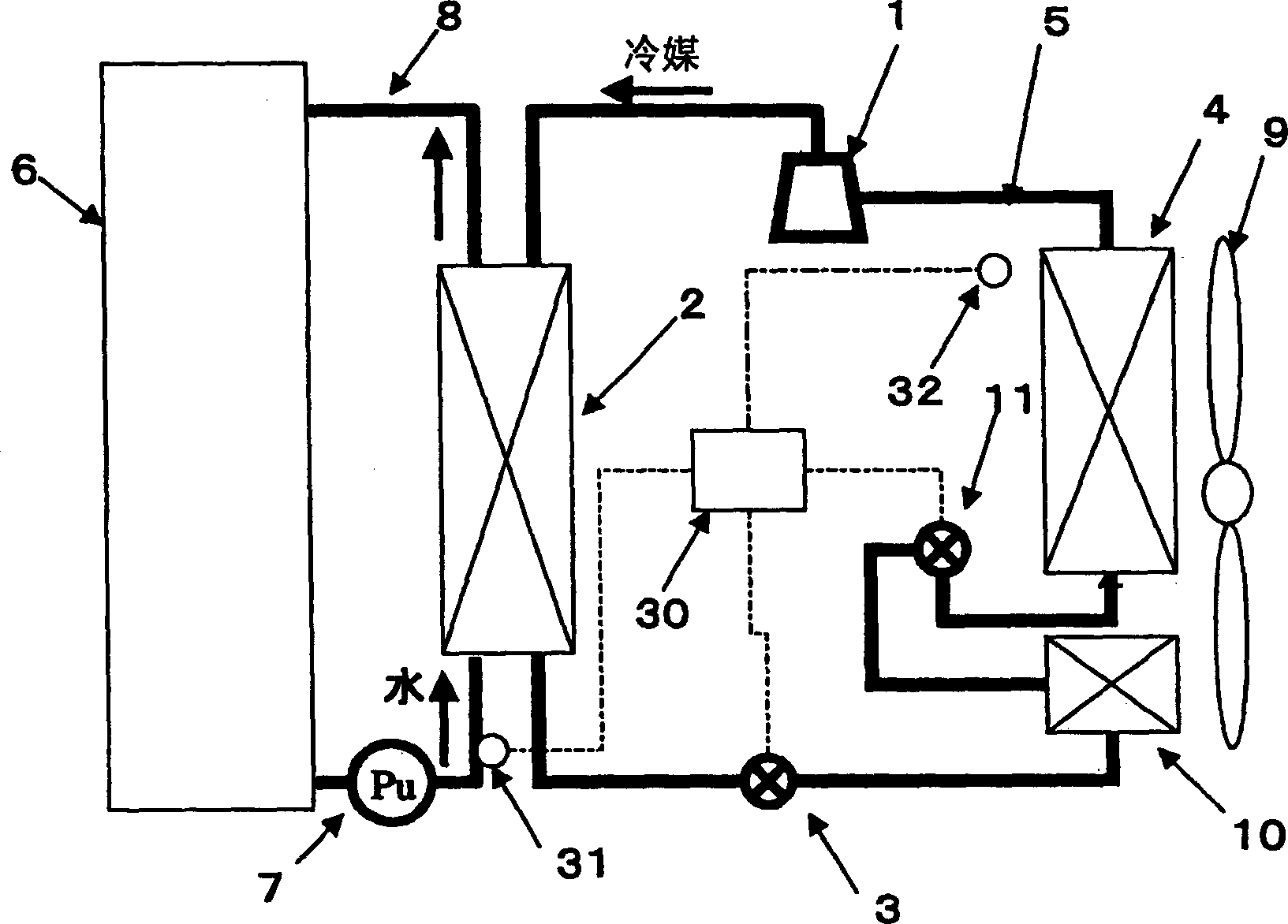

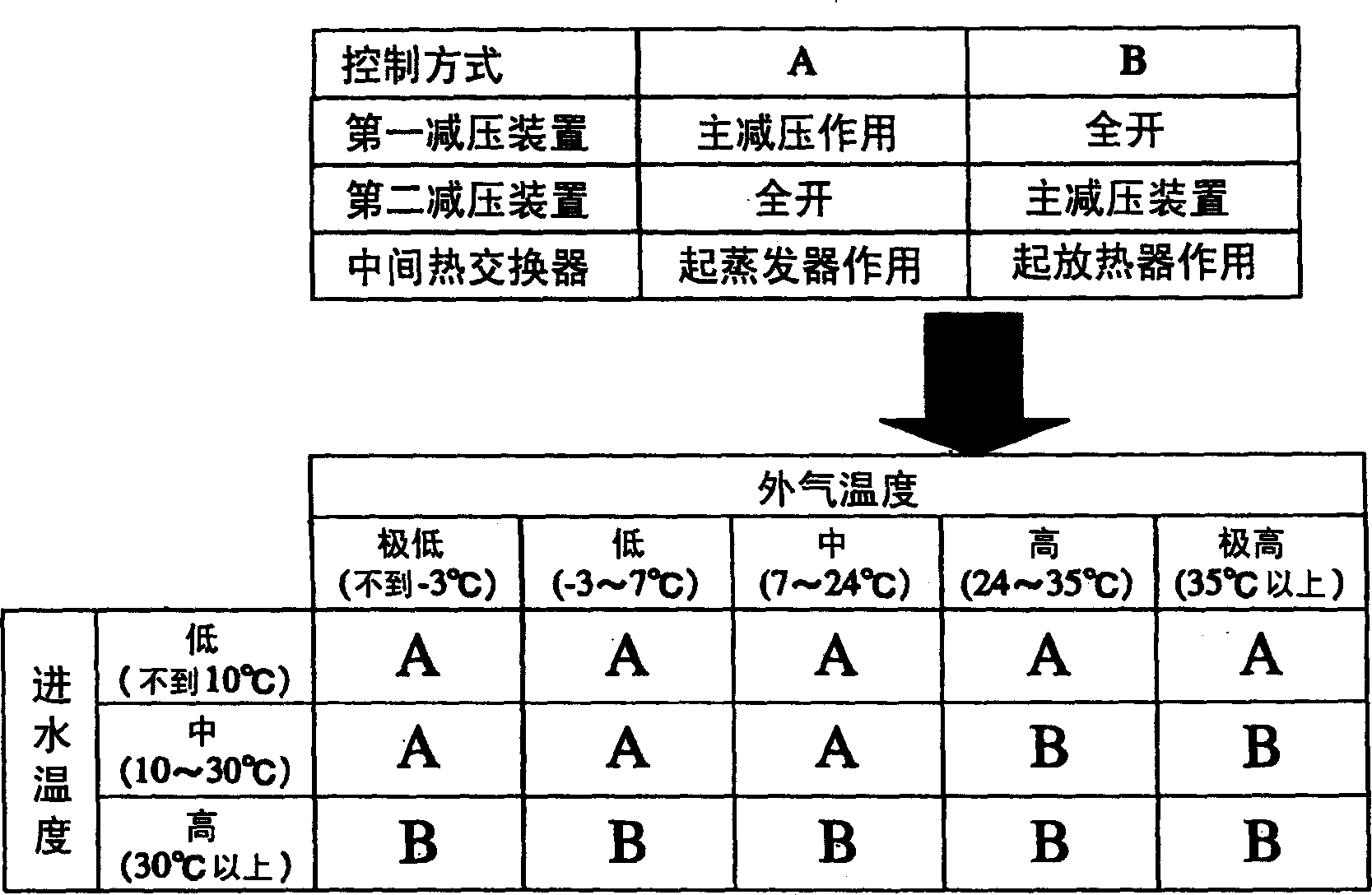

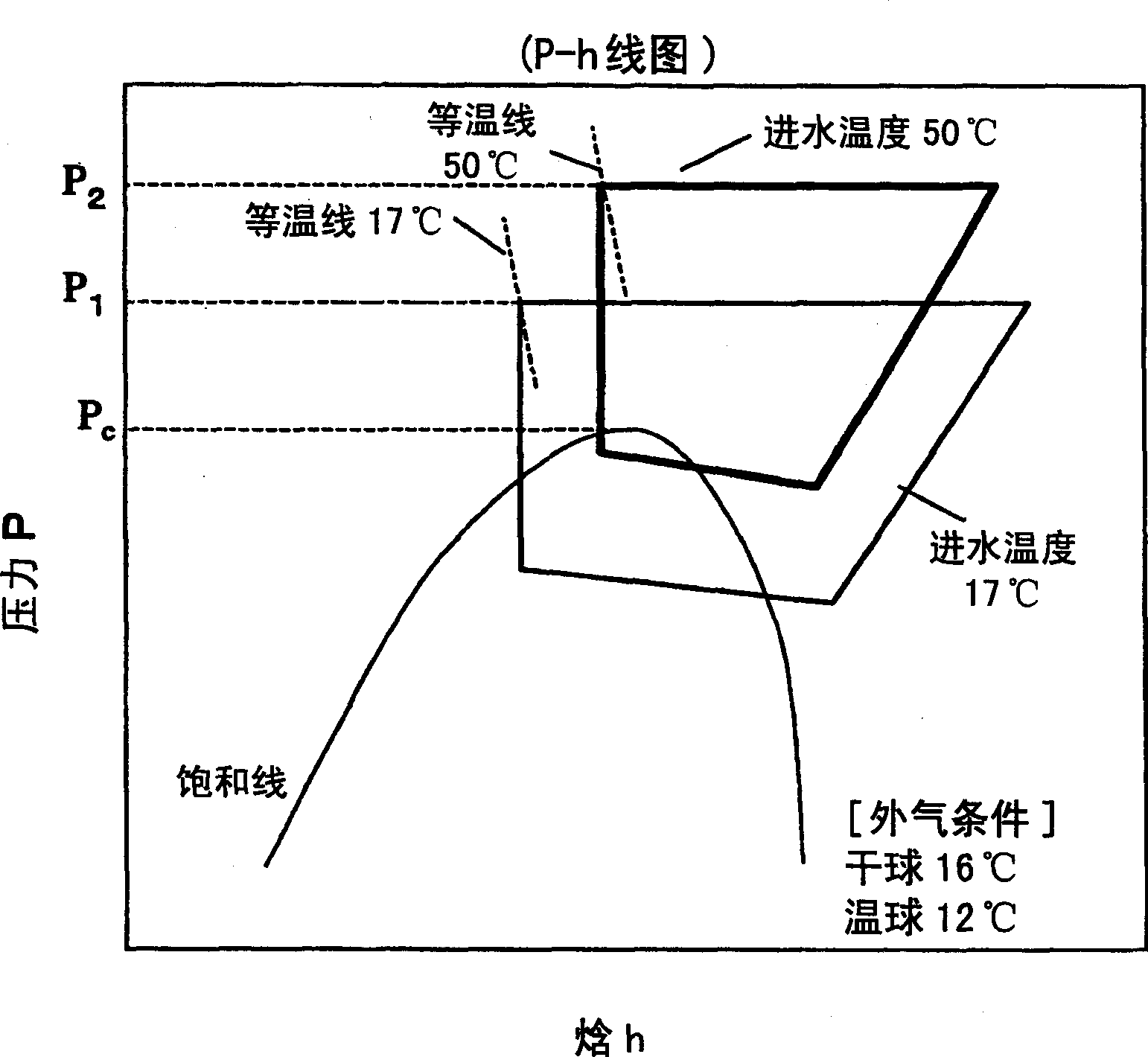

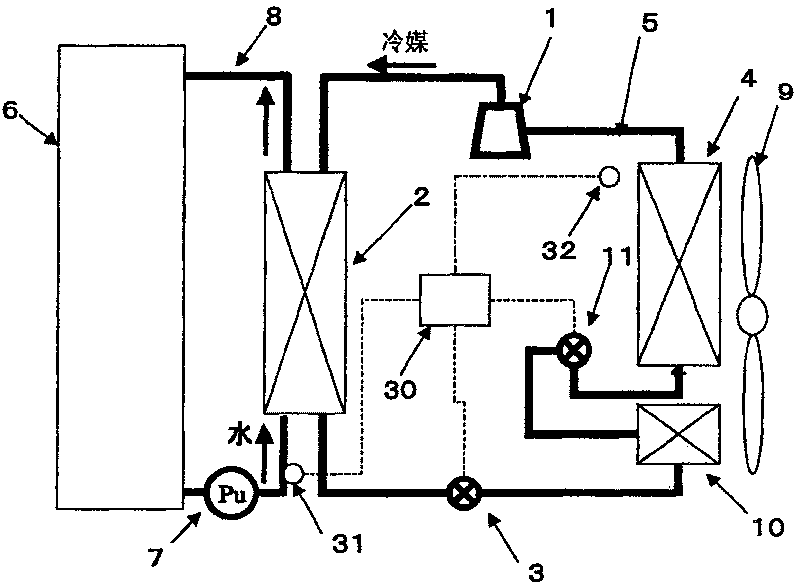

Heat-pump type hot water supply system

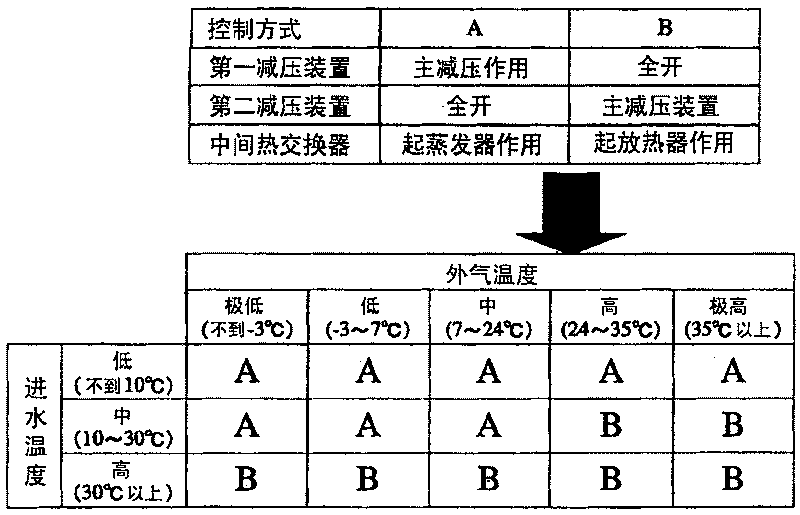

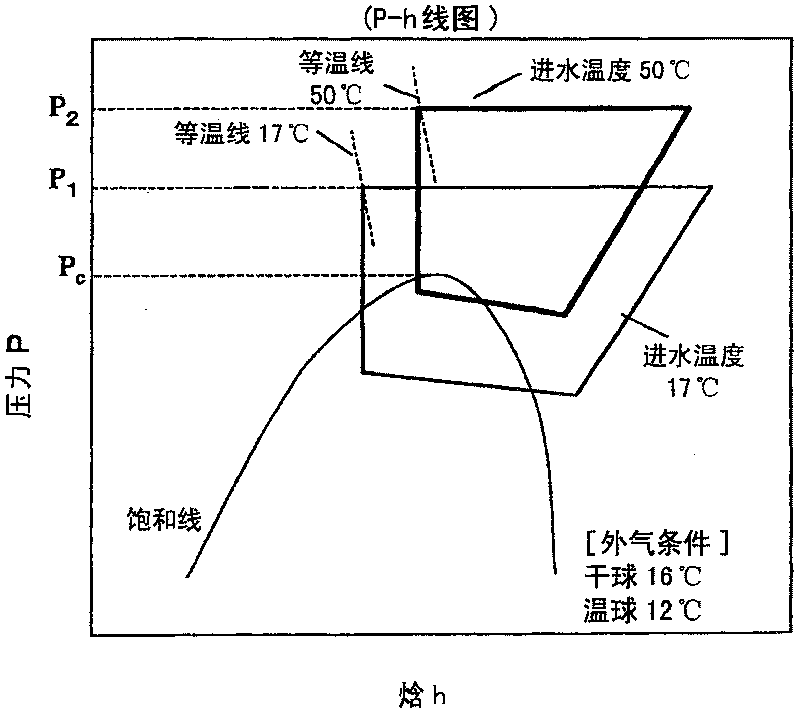

InactiveCN1769811ASuppress pressure risePower coefficient dropFluid heatersMechanical apparatusIntermediate heat exchangerEngineering

Heat-pump type hot water supply system includes a heat pump cycle in which a compressor, a water heat exchanger for performing a heat exchange between water and a refrigerant, a first decompressor, an intermediate heat exchanger for performing a heat exchange between the refrigerant and exterior air, a second decompressor, an evaporator for performing a heat exchange between the refrigerant and the exterior air are connected in order. Heat-pump type hot water supply system further includes a water temperature sensor for detecting a temperature of water entering the water heat exchanger, an exterior air temperature sensor for detecting an exterior air temperature, and a controller for controlling operations of the first and the second decompressor. A valve opening degree of the first and the second decompressor is controlled based on detection values obtained by the water temperature sensor and / or the exterior air temperature sensor.

Owner:PANASONIC CORP

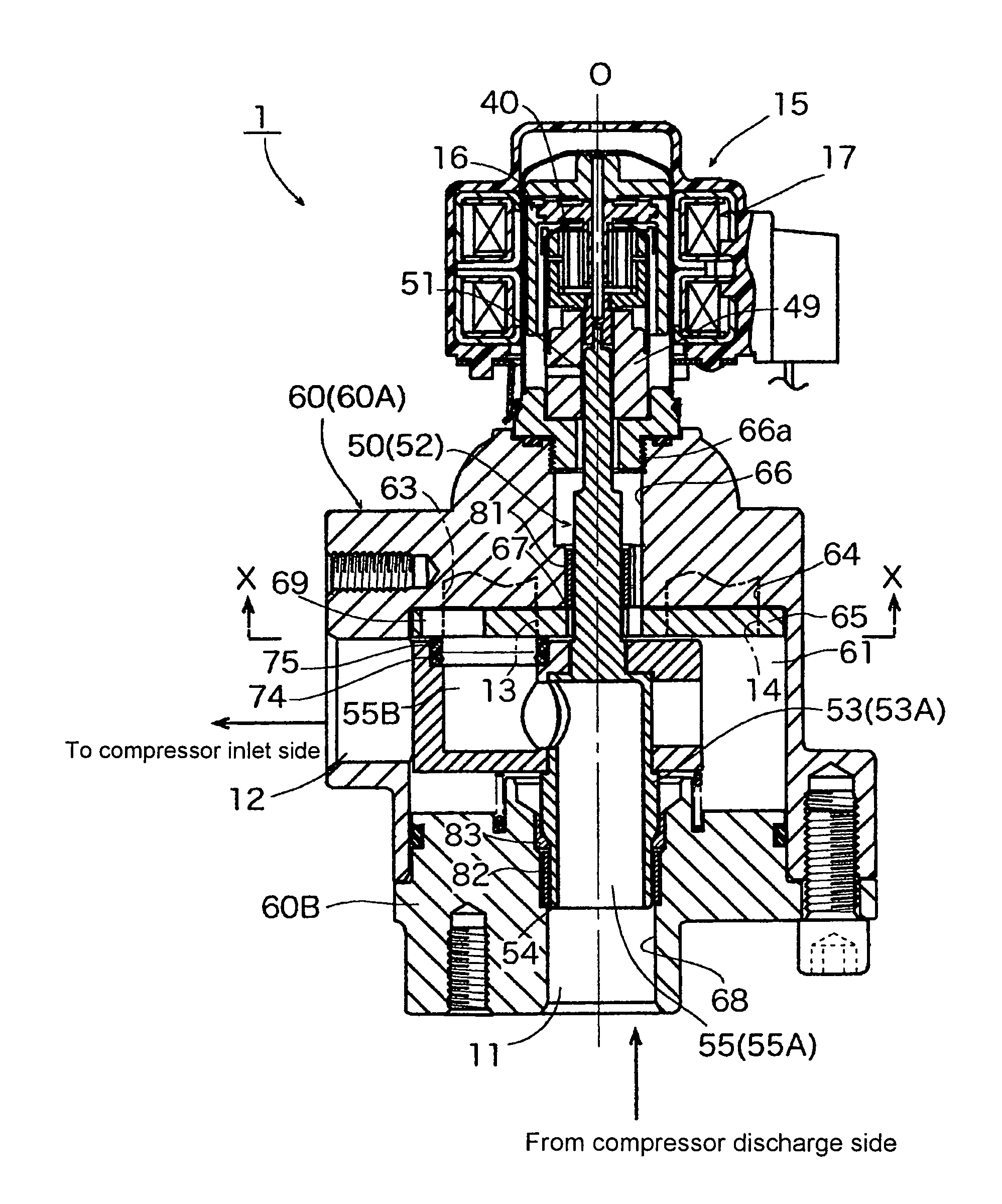

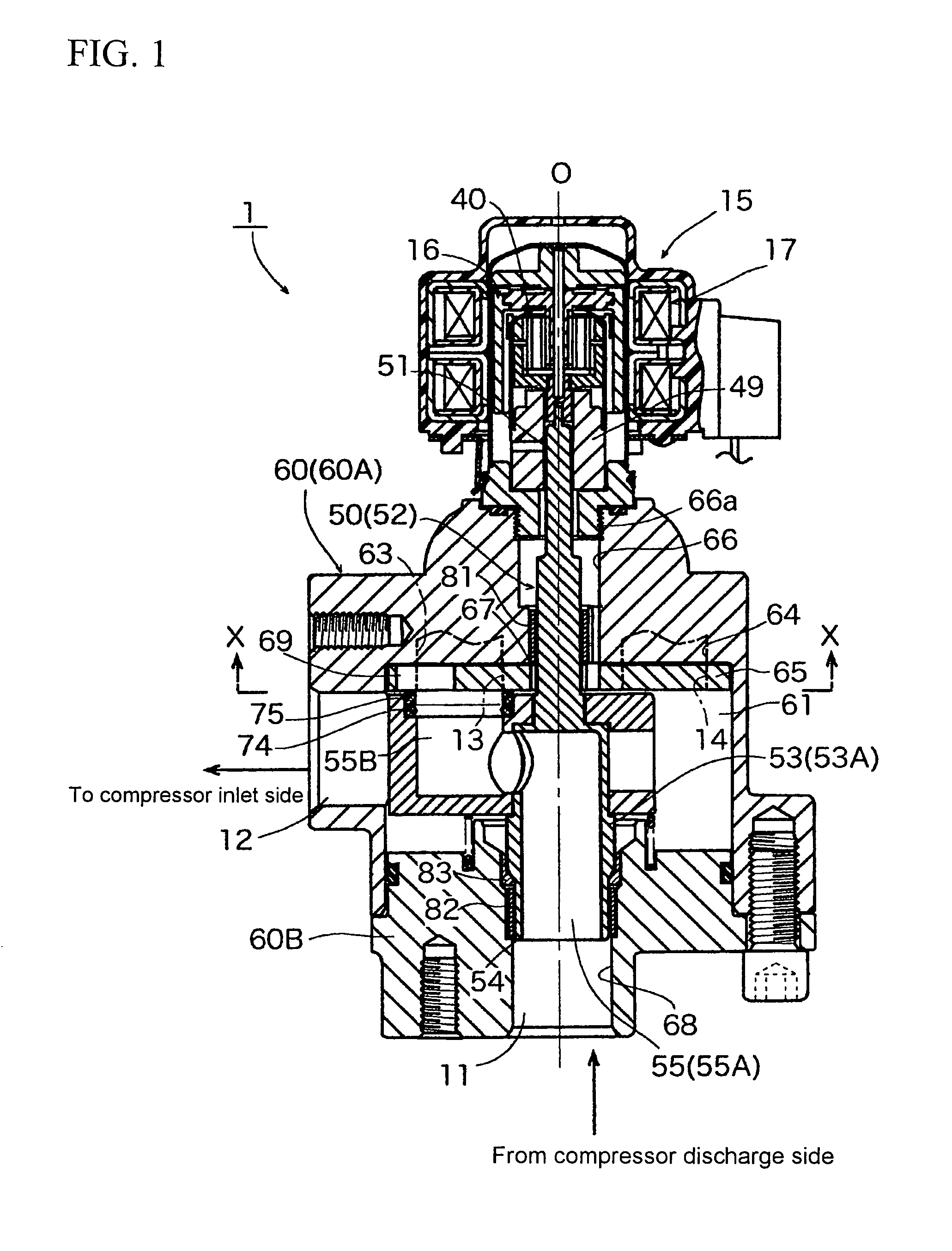

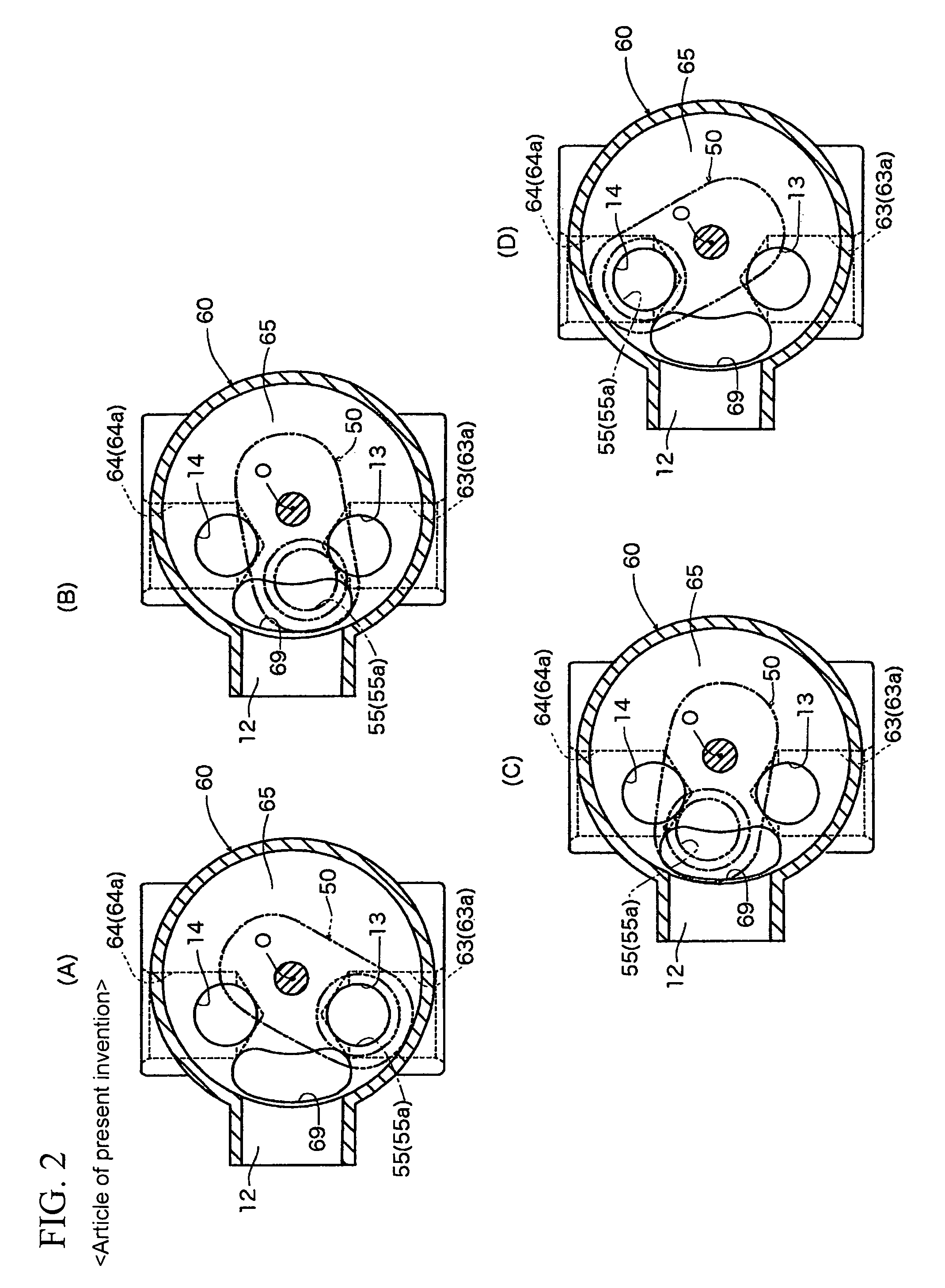

Multi-way selector valve

ActiveUS8327883B2Suppress pressure riseOperating means/releasing devices for valvesServomotor componentsPath switchingEngineering

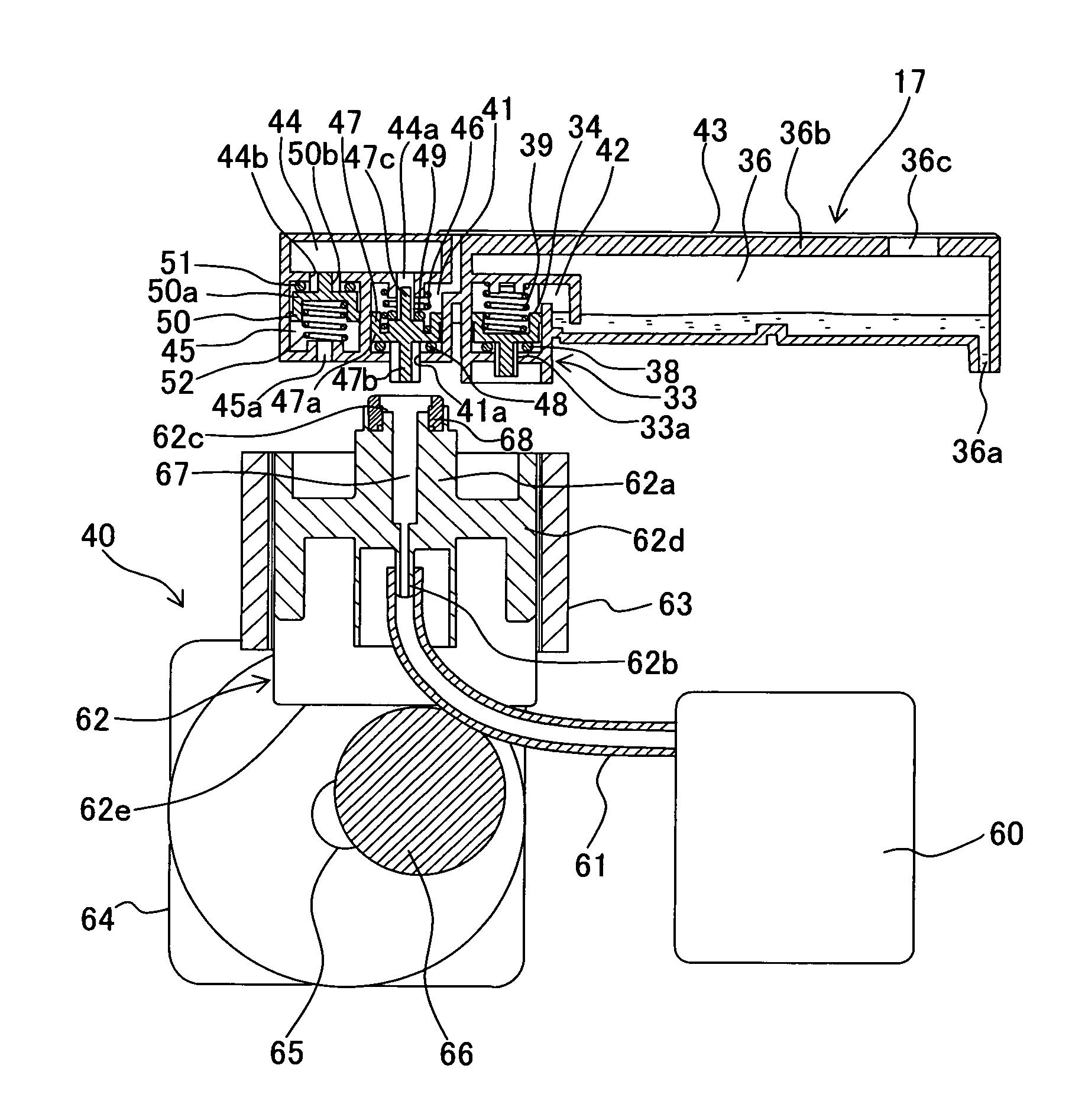

There is provided a multi-way selector valve capable of suppressing any excessive rise in the pressure of a high-pressure refrigerant during a transitional phase of flow path switching and of preventing malfunctioning of a flow path switching operation, while also being capable of preventing situations in which erroneous judgments of anomaly / failure occurrences in the device are made by a fail-safe mechanism to cause the device to stop unduly. A high-pressure passage portion 55 to which a high-pressure fluid is introduced is formed in a valve member 50. A valve seat portion 65 provided with a first inlet / outlet 13 and a second inlet / outlet 14 that are selectively communicated with an outlet-side end portion 55a of the high-pressure passage portion 55, and a valve chest 61 into which a low-pressure fluid is selectively introduced via the first inlet / outlet 13 and the second inlet / outlet 14 are provided in a valve body 60. During the transitional phase of flow path switching, the outlet-side end portion 55a of the high-pressure passage portion 55 of the valve member 50 is made to slide while being pressed against a portion between the first inlet / outlet 13 and the second inlet / outlet 14 in the valve seat portion 65. There is formed between the first inlet / outlet 13 and the second inlet / outlet 14 of the valve seat portion 65 an escape passage portion 69 comprising a groove, notch, through-hole or the like for allowing the high-pressure refrigerant of the high-pressure passage portion 55 to escape to the side of the valve chest 61 during the transitional phase of flow path switching.

Owner:FUJIKOKI CORP

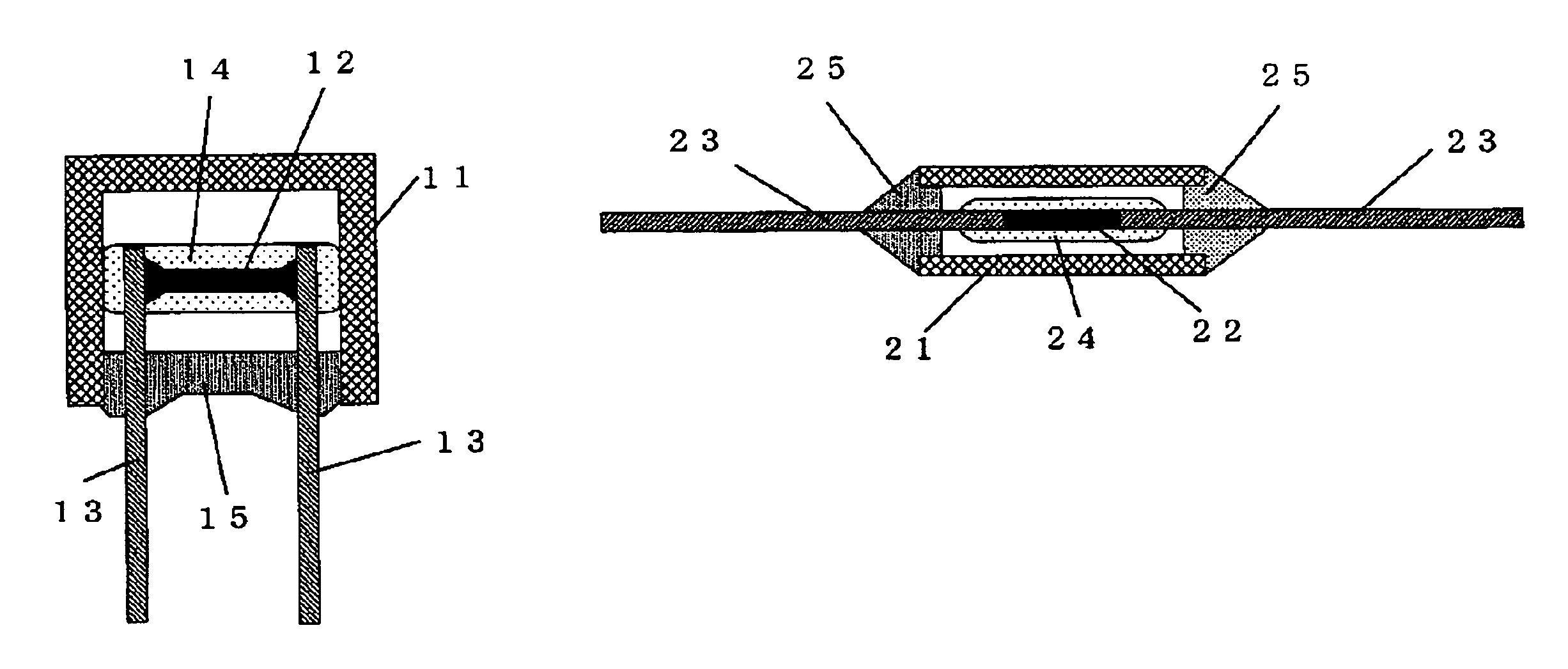

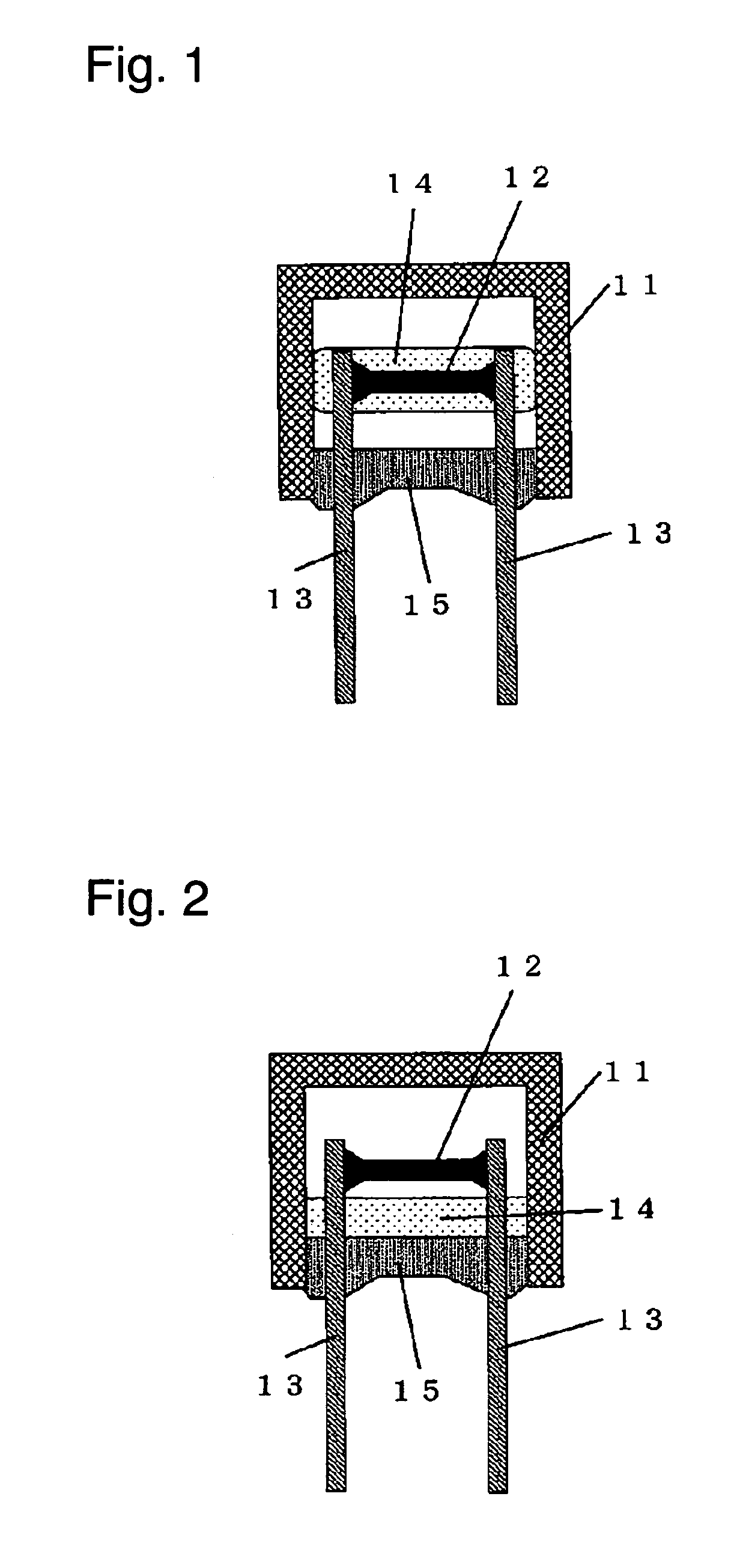

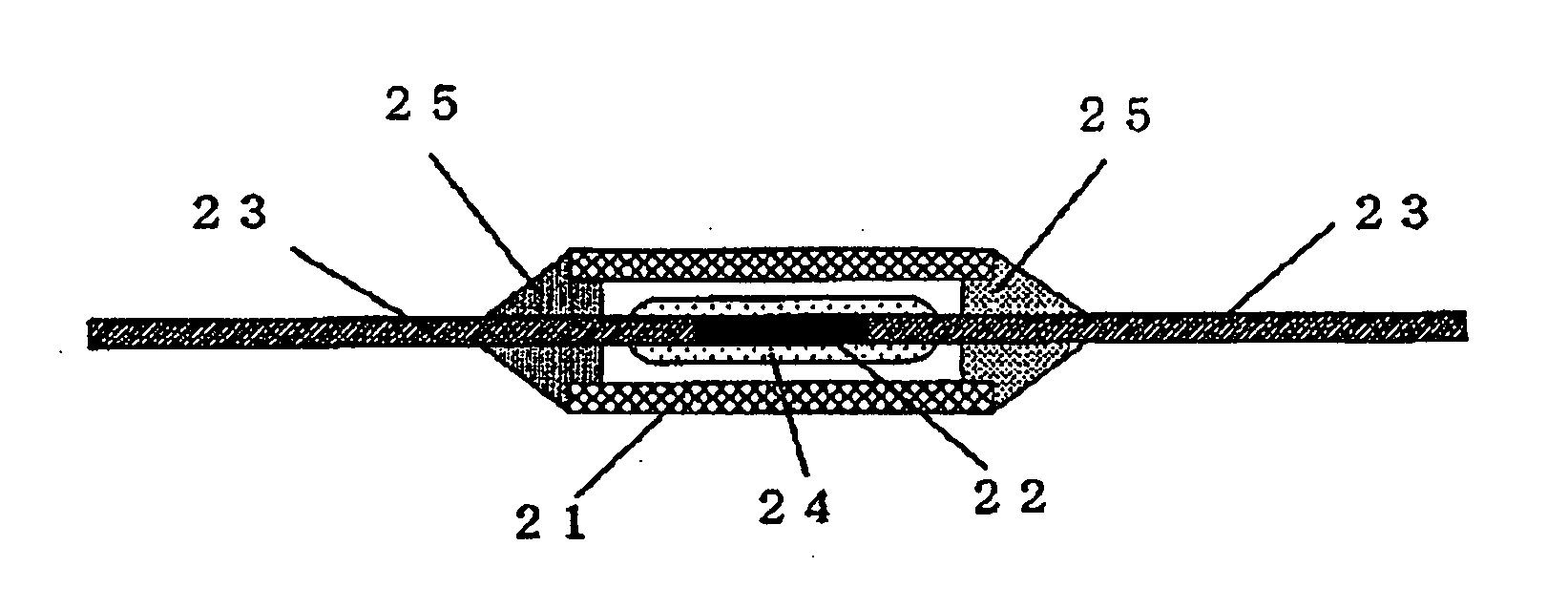

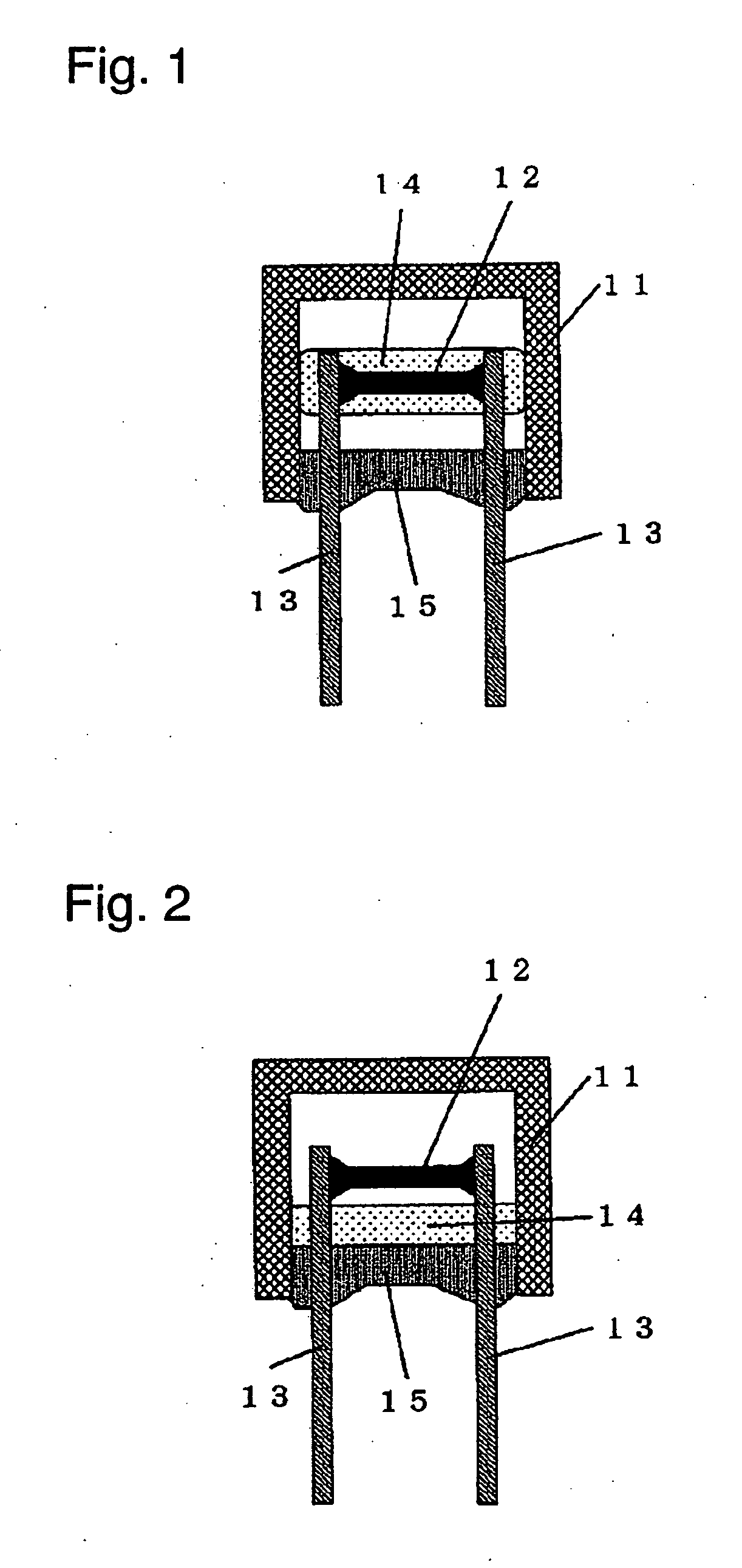

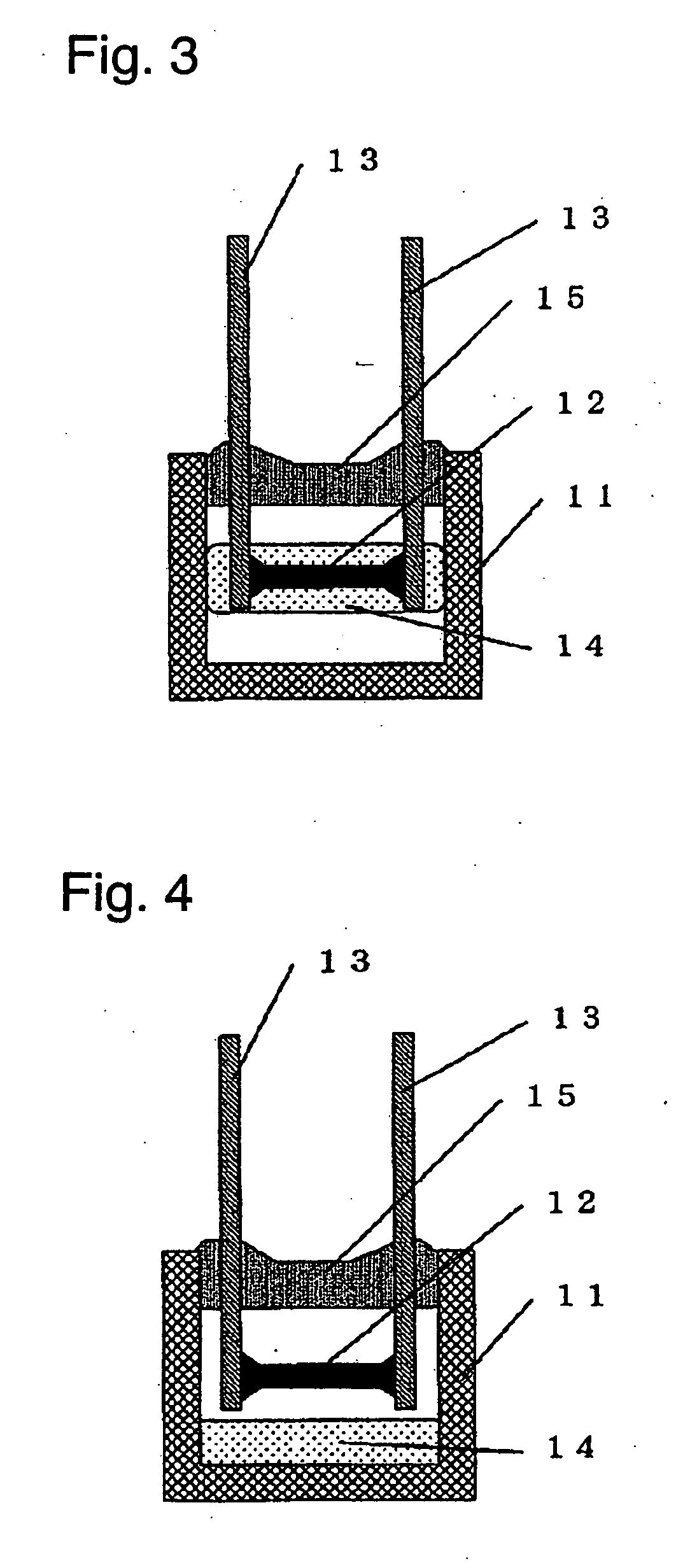

Temperature fuse, and battery using the same

InactiveUS7473487B2Suppress pressure riseReduce the amount requiredPrimary cell maintainance/servicingCell temperature controlAlloySealant

A thermal fuse includes an insulating case having a bottom and having an opening provided therein, a fusible alloy provided in the insulating case, a lead conductor having one end connected to the fusible alloy and other end led out from the insulating case through the opening of the insulating case, a flux provided on the fusible alloy, and a sealer for sealing the opening of the insulating case. The volume of a space between the fusible alloy in the insulating case and the sealer is larger than the volume of the flux. Sealing of the fuse is prevented from deteriorating, and the insulating film is prevented from damage even when the thermal fuse is used for breaking a large current at a high voltage.

Owner:PANASONIC CORP

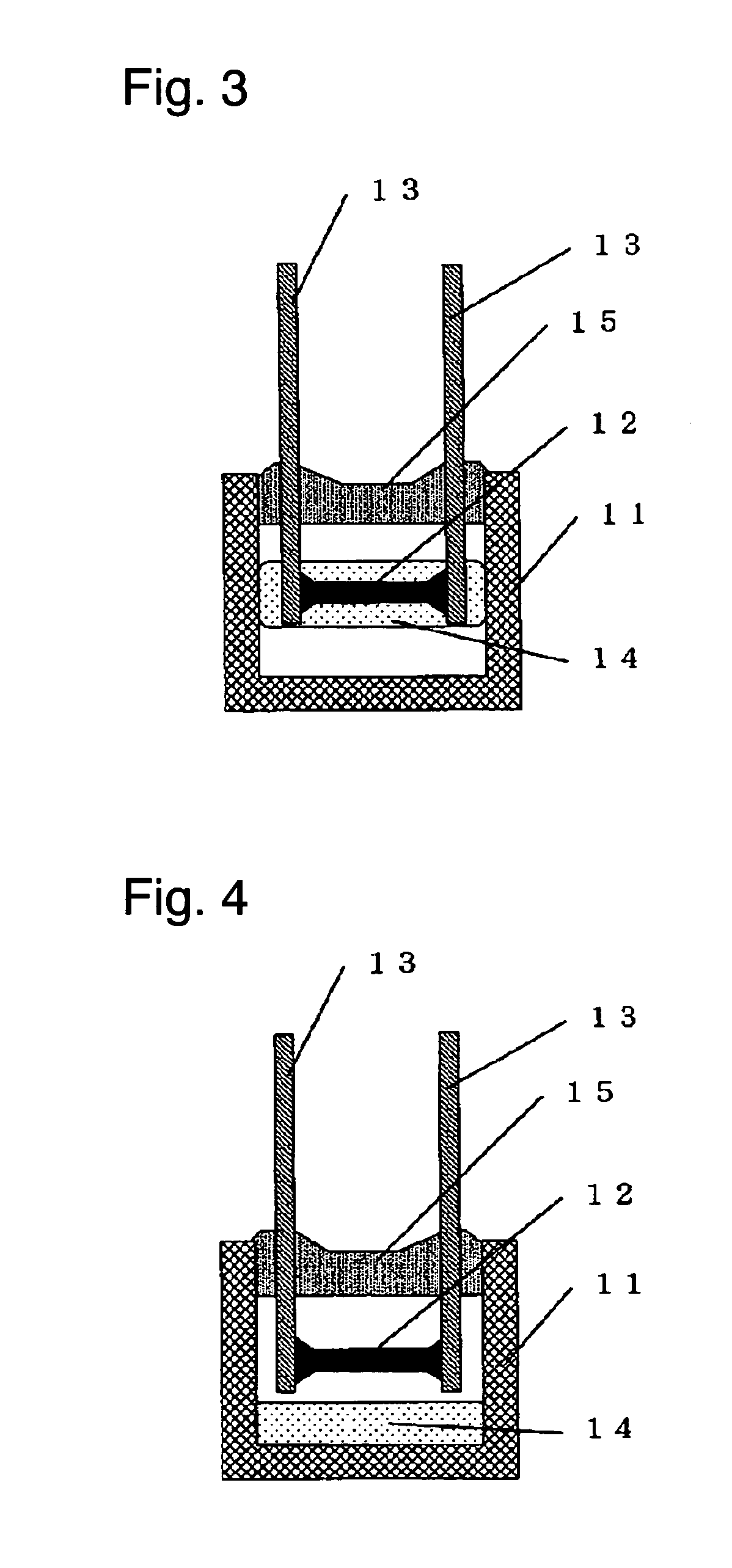

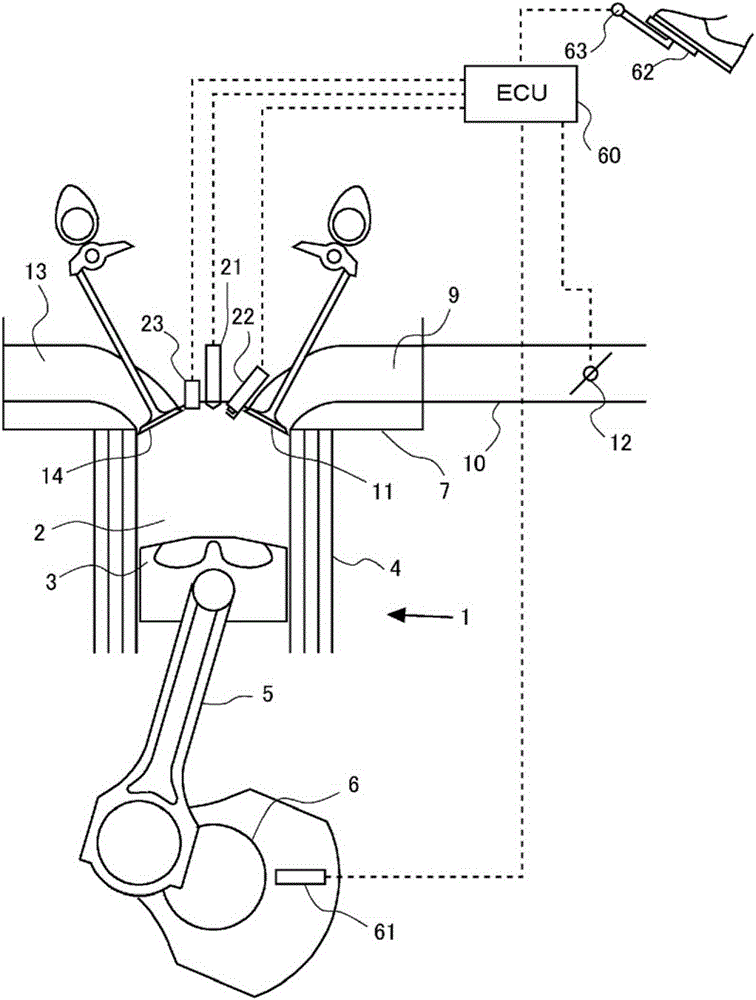

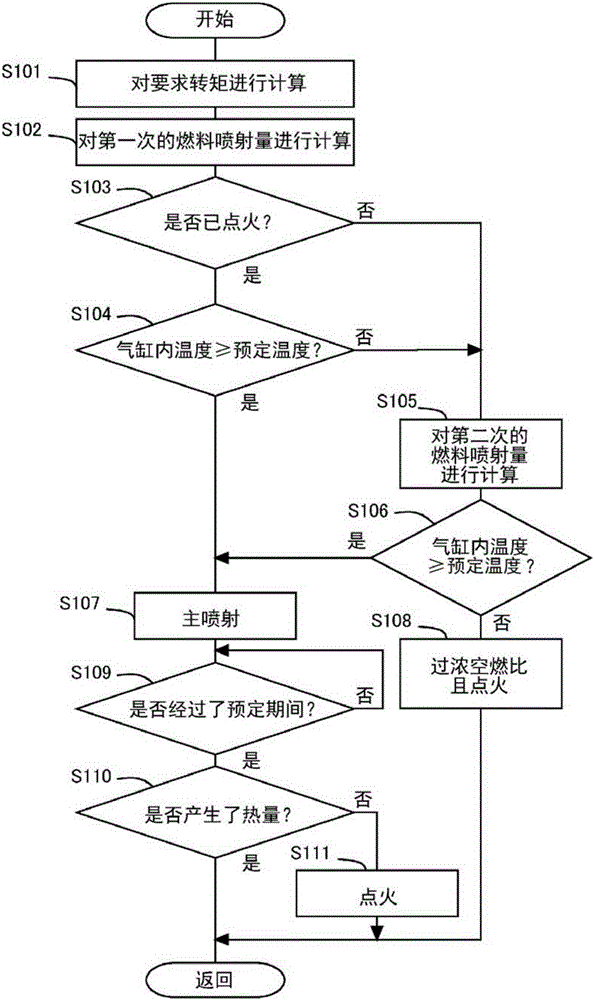

Control system for internal combustion engine

ActiveCN105247204ASuppress pressure riseElectrical controlInternal combustion piston enginesControl systemControl unit

The purpose of the present invention is to minimize misfiring and sudden increases in pressure. This control system is for an internal combustion engine that, in at least one part of the operating range thereof, carries out diffusive combustion of fuel from a main injection using compression ignition and carries out stratified charge combustion of fuel injected prior to the main injection at a spark plug using spark ignition, and is provided with: a determination unit that determines whether diffusive combustion will occur; and a control unit that carries out combustion of fuel from the main injection at a spark plug using spark ignition when it is determined that diffusive combustion will not occur.

Owner:TOYOTA JIDOSHA KK

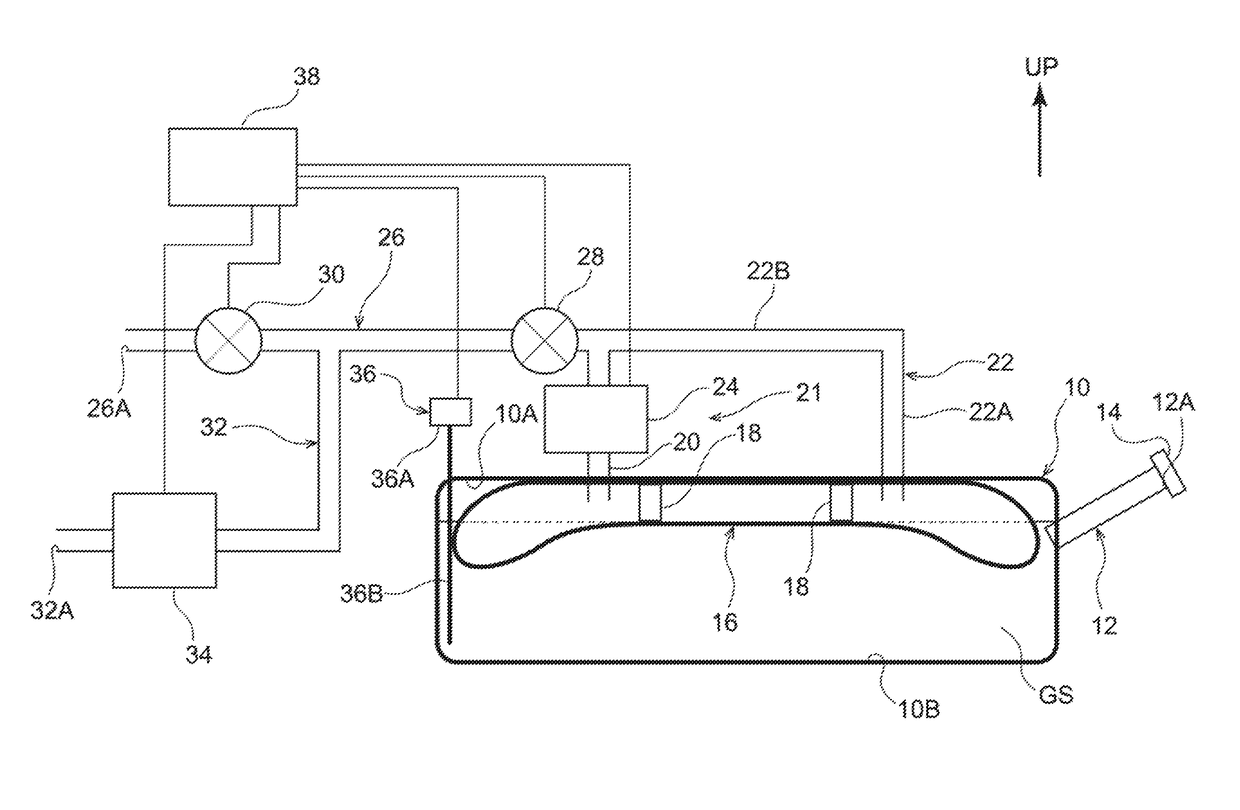

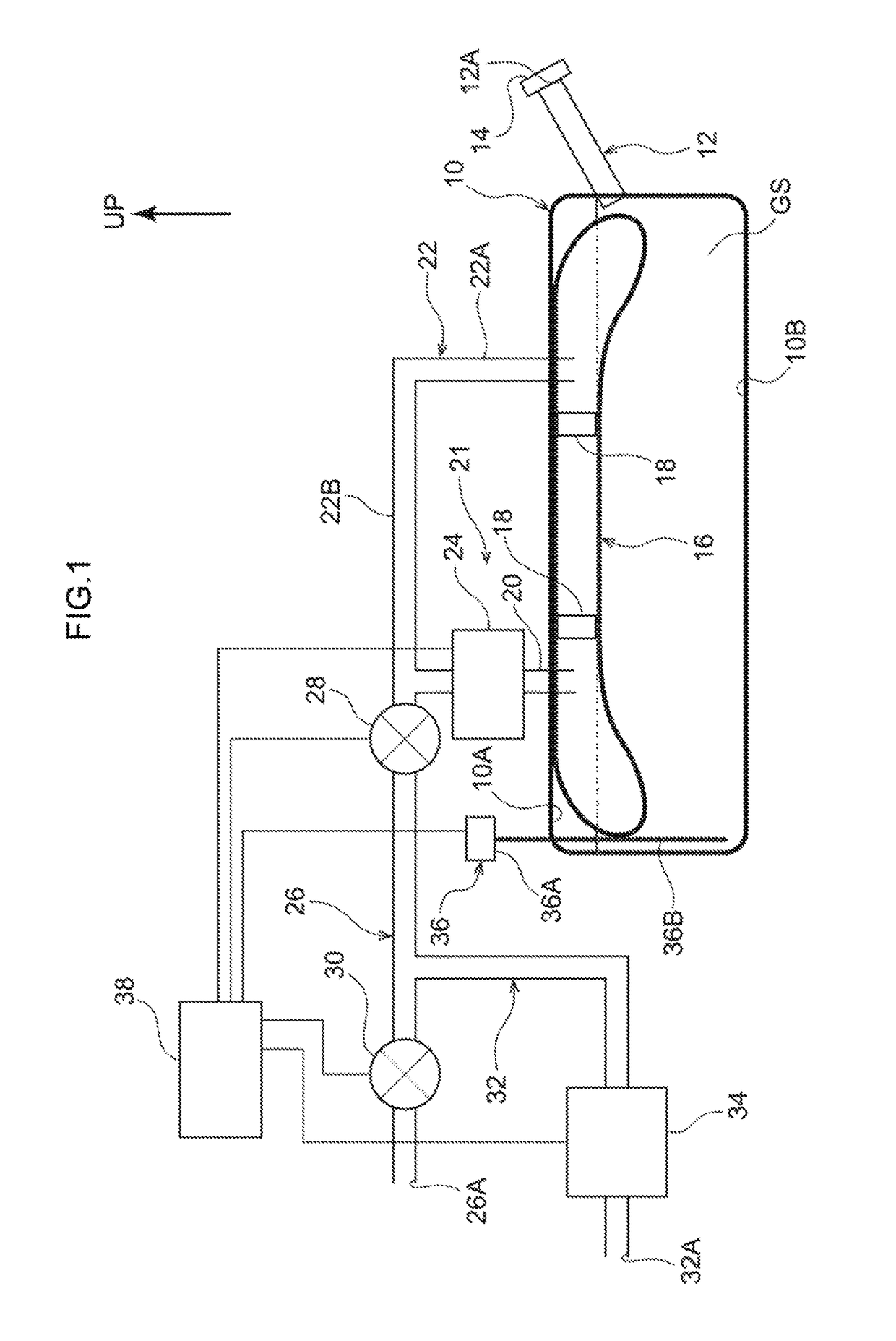

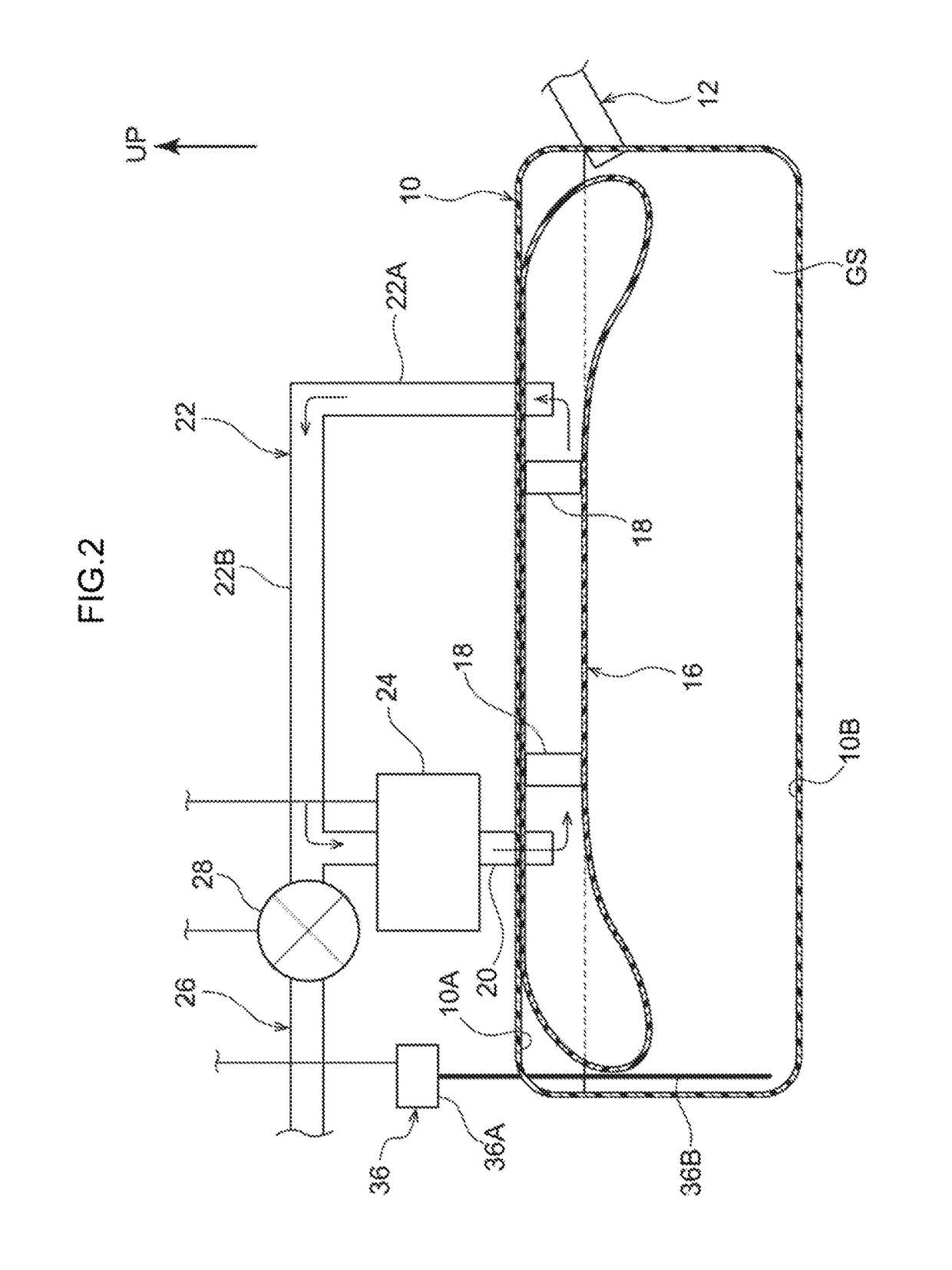

Fuel tank structure

InactiveUS9834089B2Suppress pressure riseImprove cooling effectUnderstructuresMaterial thermal analysisFuel tankAutomotive engineering

A fuel tank structure includes: a fuel tank that is installed in an automobile and that accommodates fuel; a bag-shaped member that is fixed to a ceiling portion of an interior of the fuel tank, and whose state of contact with a liquid surface of fuel accommodated in the fuel tank is maintained due to the bag-shaped member inflating or deflating in accordance with a height of the liquid surface; a temperature sensor that senses a temperature of the fuel or evaporated fuel that is within the fuel tank; and a cooling wind introducing section that introduces cooling wind into an interior of the bag-shaped member in a case in which the temperature of the fuel or the evaporated fuel detected by the temperature sensor becomes higher than a predetermined temperature.

Owner:TOYOTA JIDOSHA KK

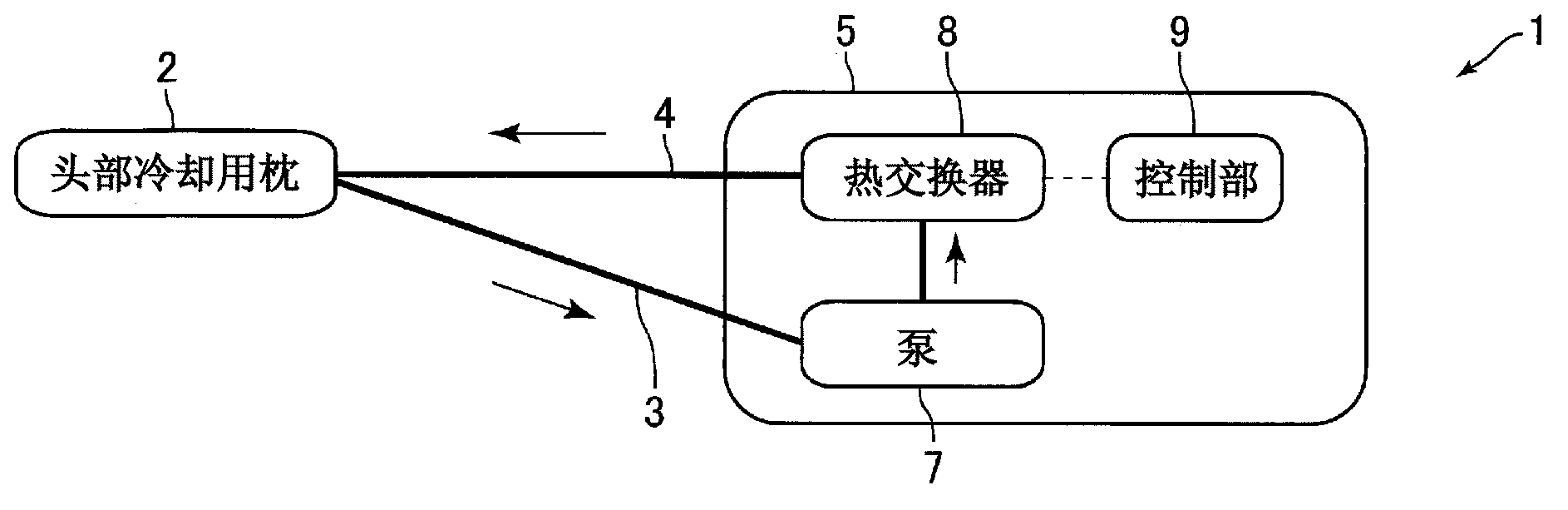

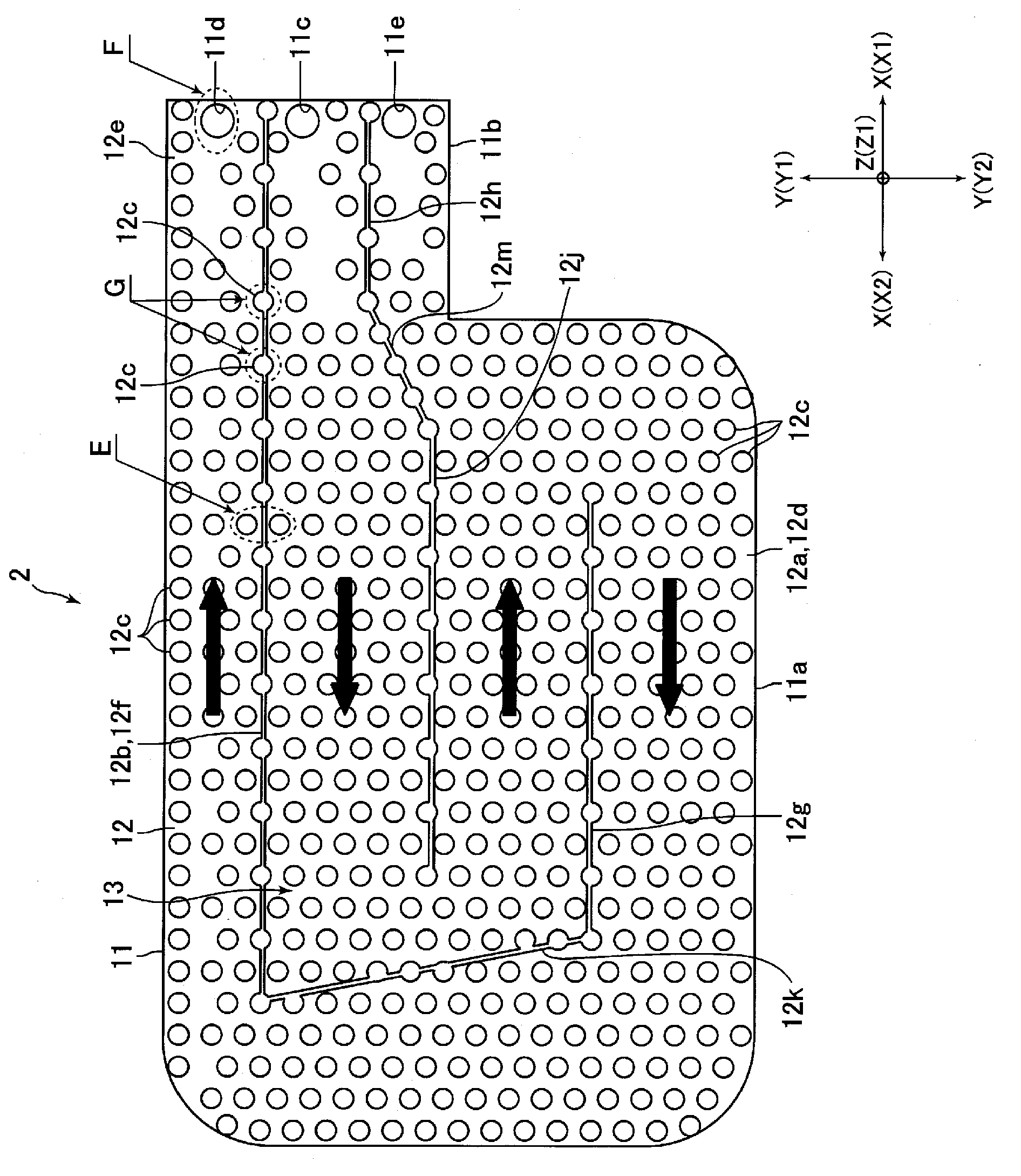

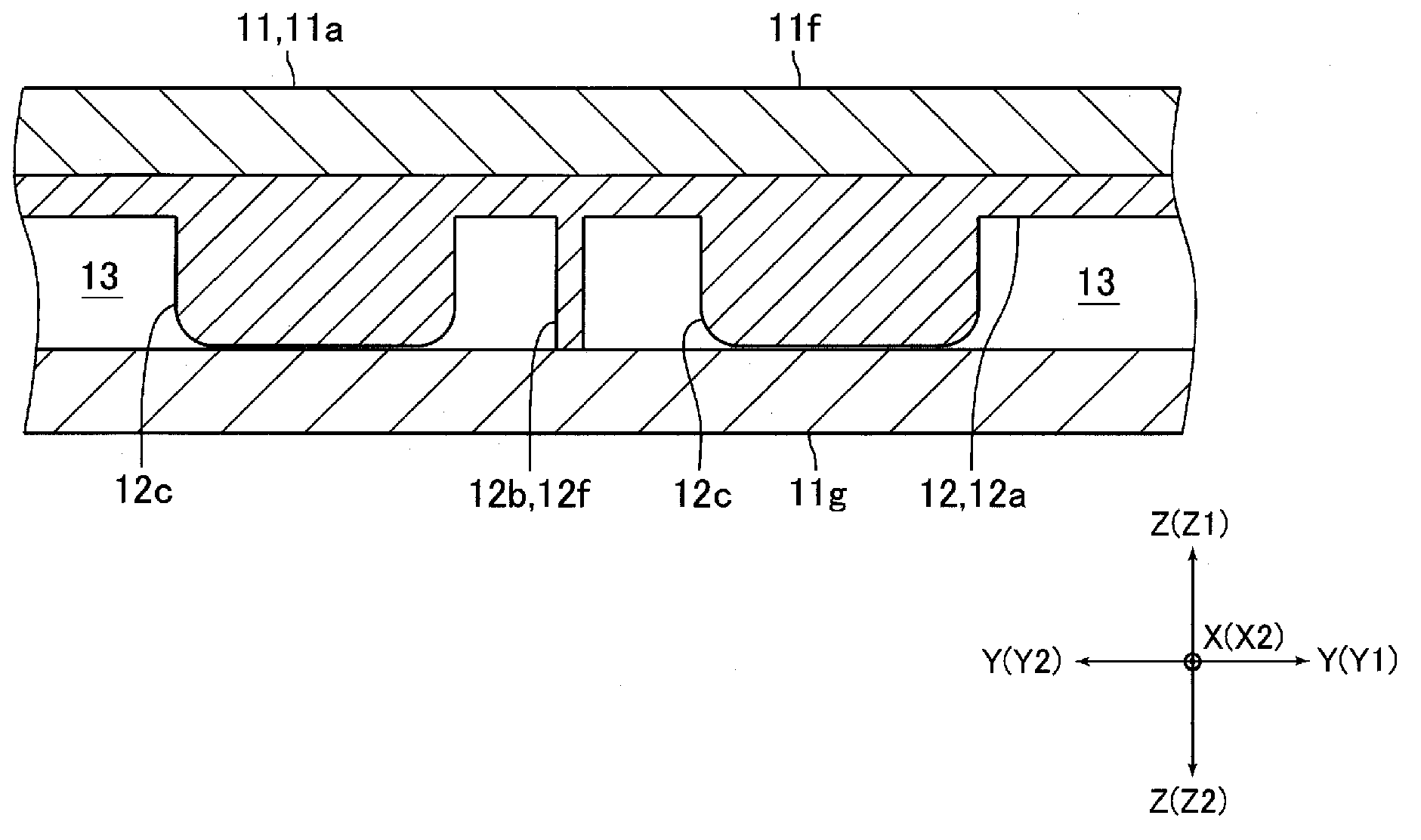

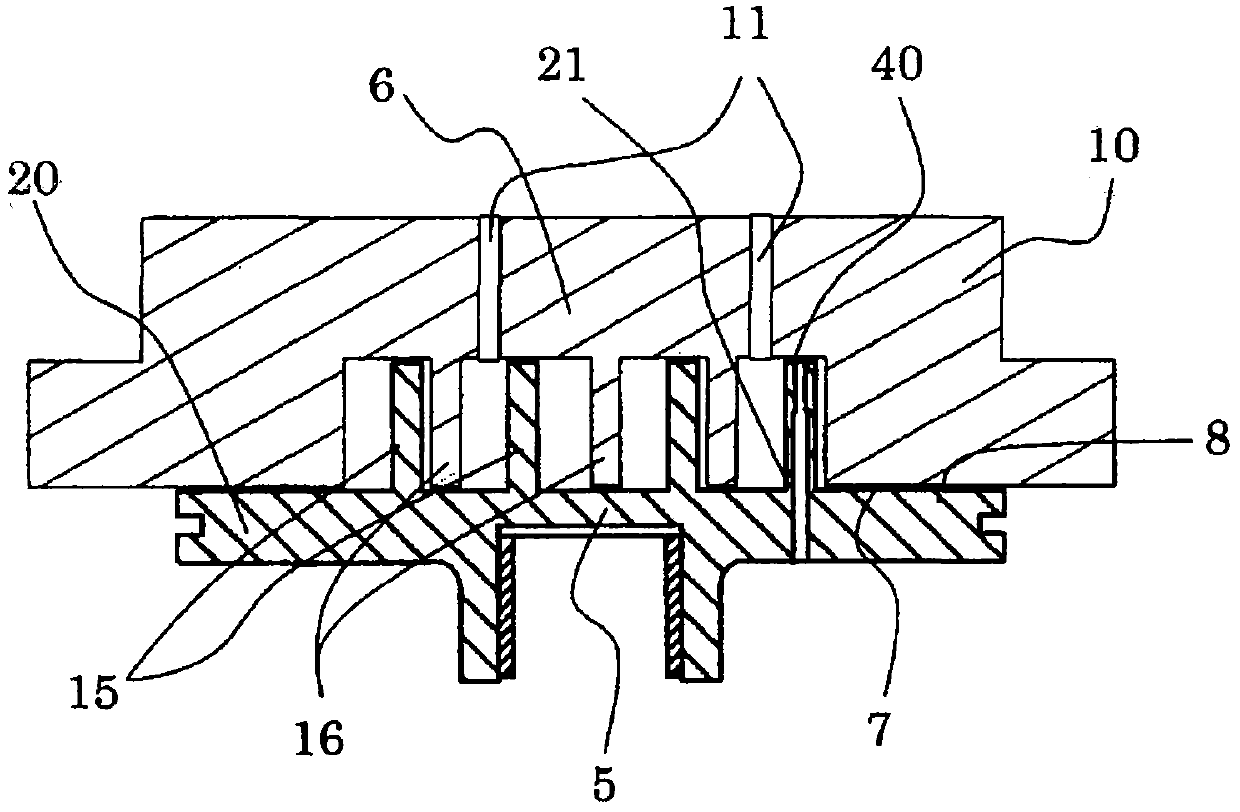

Head-cooling pillow and head-cooling device

InactiveCN102917675AImprove cooling efficiencySuppress pressure risePillowsTherapeutic coolingEngineeringCoolant

A head-cooling pillow provided by the present invention is capable of increasing head-cooling efficiency and controlling pressure increase inside the pillow while also making the pillow more comfortable when a person's head is placed thereon. The head-cooling pillow (2) is provided with a main pillow body (11) that is formed in the shape of a sac through which a coolant is passed, a partitioning part (12b) disposed inside the main pillow body (11) to form a channel (13) through which the coolant passes, and support parts (12c) for supporting the user's head. In the head-cooling pillow (2), the head is cooled by the coolant that passes through the channel (13).

Owner:LIGHT OPTICAL WORKS

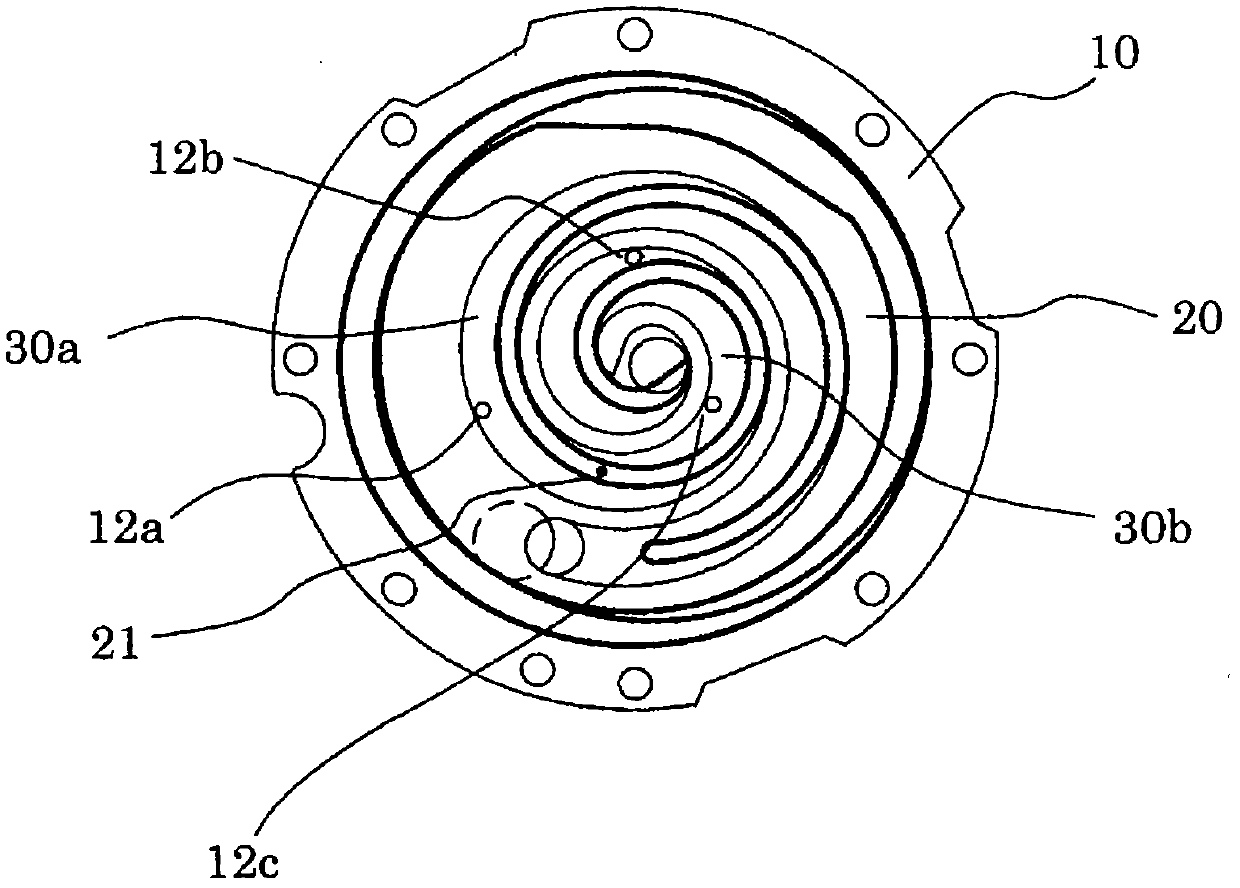

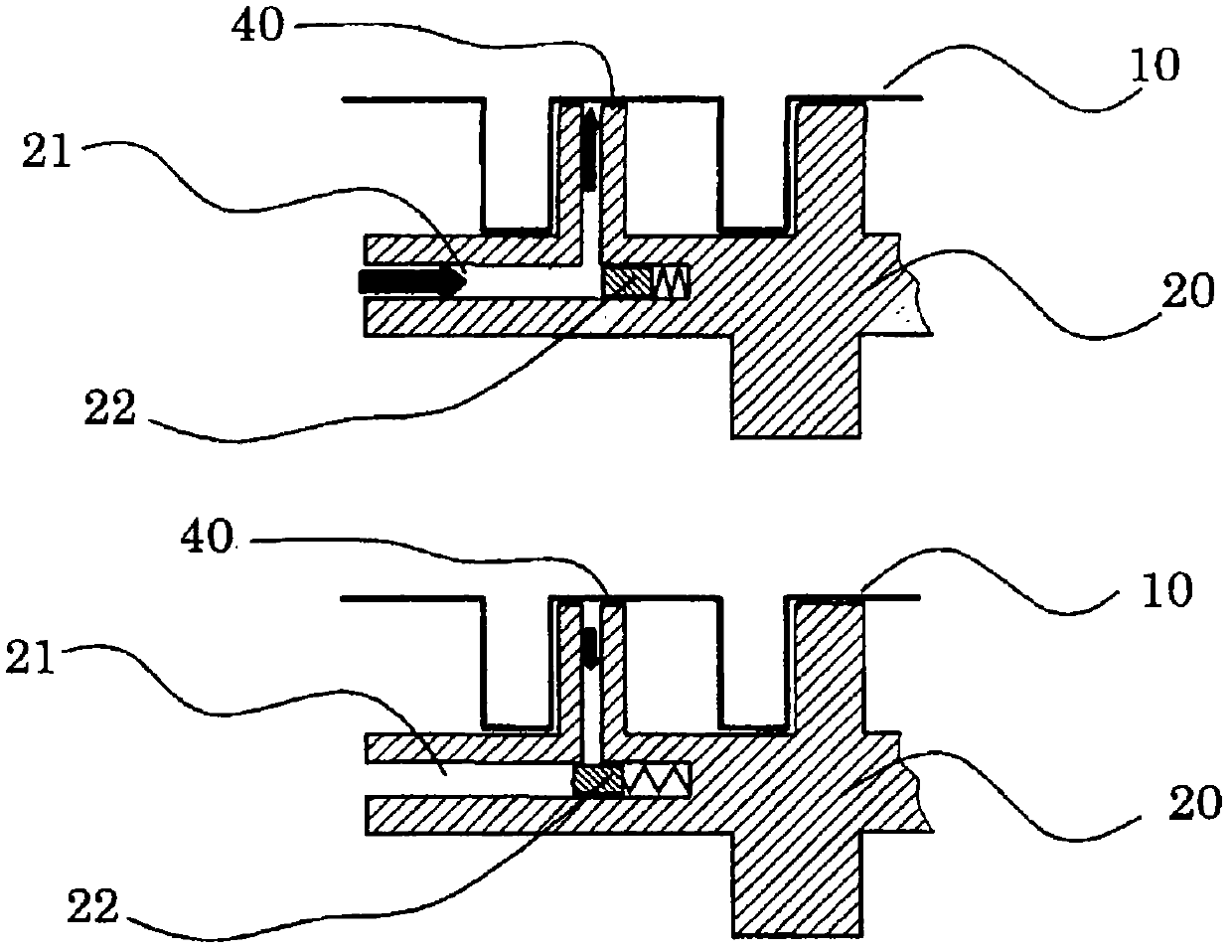

Scroll fluid machine

InactiveCN102207088AImprove efficiencyImprove reliabilityRotary piston pumpsRotary piston liquid enginesPressure riseEngineering

Owner:HITACHI JOHNSON CONTROLS AIR CONDITIONING INC

Temperature fuse and battery using the same

InactiveUS20070212600A1Reduce amountPrevents sealPrimary cell maintainance/servicingSecondary cellsThermal cutoffHigh pressure

A thermal fuse includes an insulating case having a bottom and having an opening provided therein, a fusible alloy provided in the insulating case, a lead conductor having one end connected to the fusible alloy and other end led out from the insulating case through the opening of the insulating case, a flux provided on the fusible alloy, and a sealer for sealing the opening of the insulating case. The volume of a space between the fusible alloy in the insulating case and the sealer is larger than the volume of the flux. Sealing of the fuse is prevented from deteriorating, and the insulating film is prevented from damage even when the thermal fuse is used for breaking a large current at a high voltage.

Owner:PANASONIC CORP

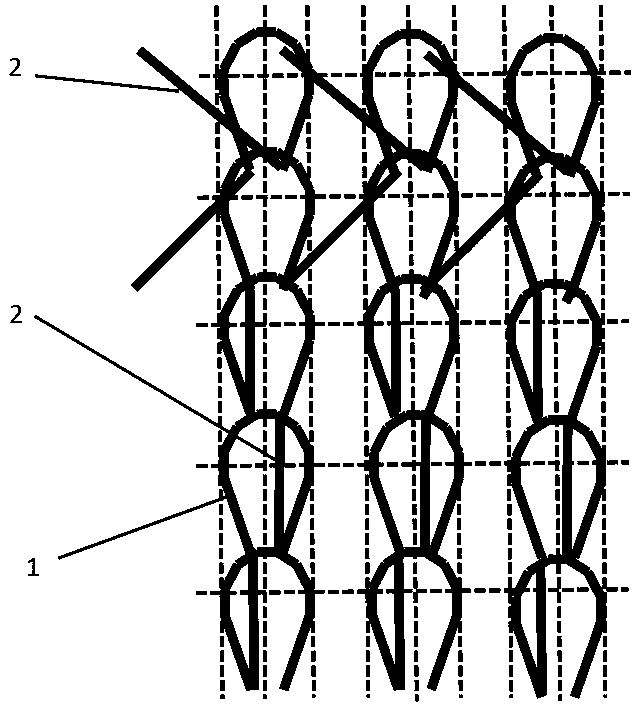

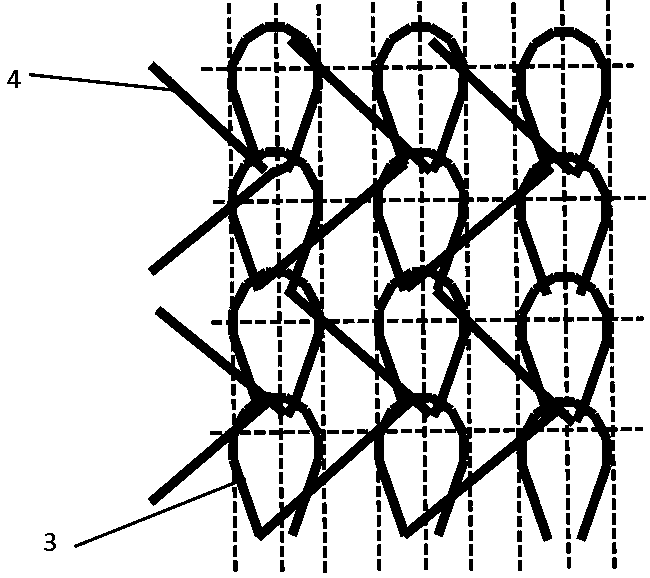

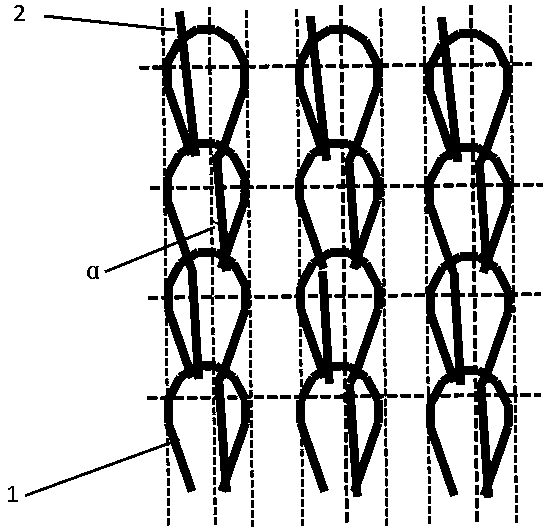

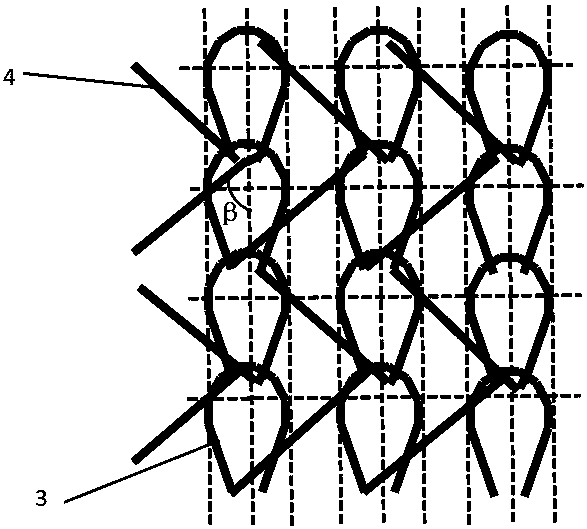

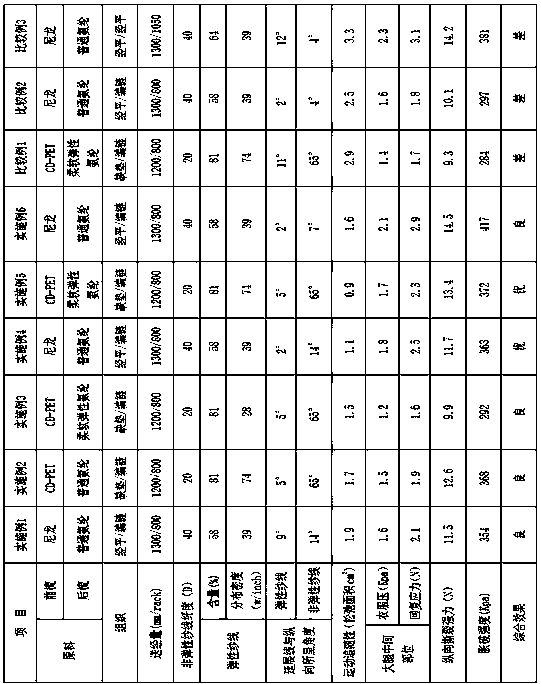

Movement following-up fabric

The invention discloses a movement following-up fabric. The fabric is a warp knitted fabric knitted by back comb elastic yarn and front comb yarn; the texture of the back comb elastic yarn is a changing texture formed by at least one of a chain stitch, a warp flat stitch, a miss-lapping stitch, and a warp satin; the texture of the front comb yarn is a changing texture formed by a warp flat stitch,a miss-lapping stitch, a warp satin or two or more of thereof. In particular, in a high-speed telescopic motion conditions, increase in the pressure due to the elongation stress and decrease in the pressure due to by the delayed recovery can be effectively suppressed, the wearing comfort can be maintained, and the muscle vibration can be prevented.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

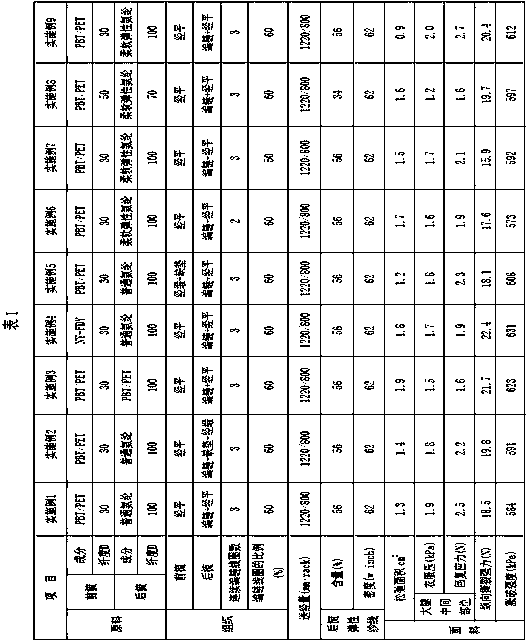

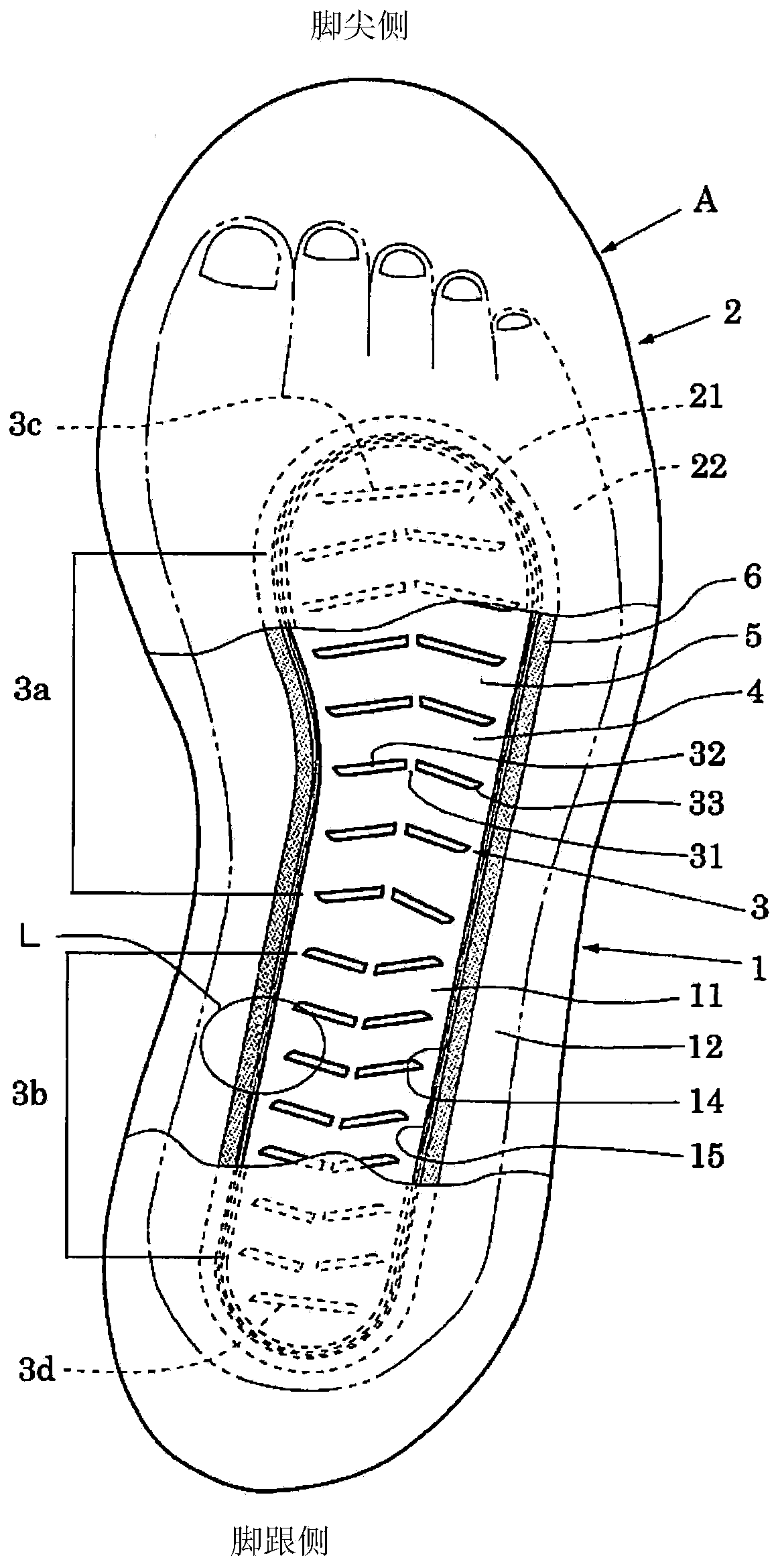

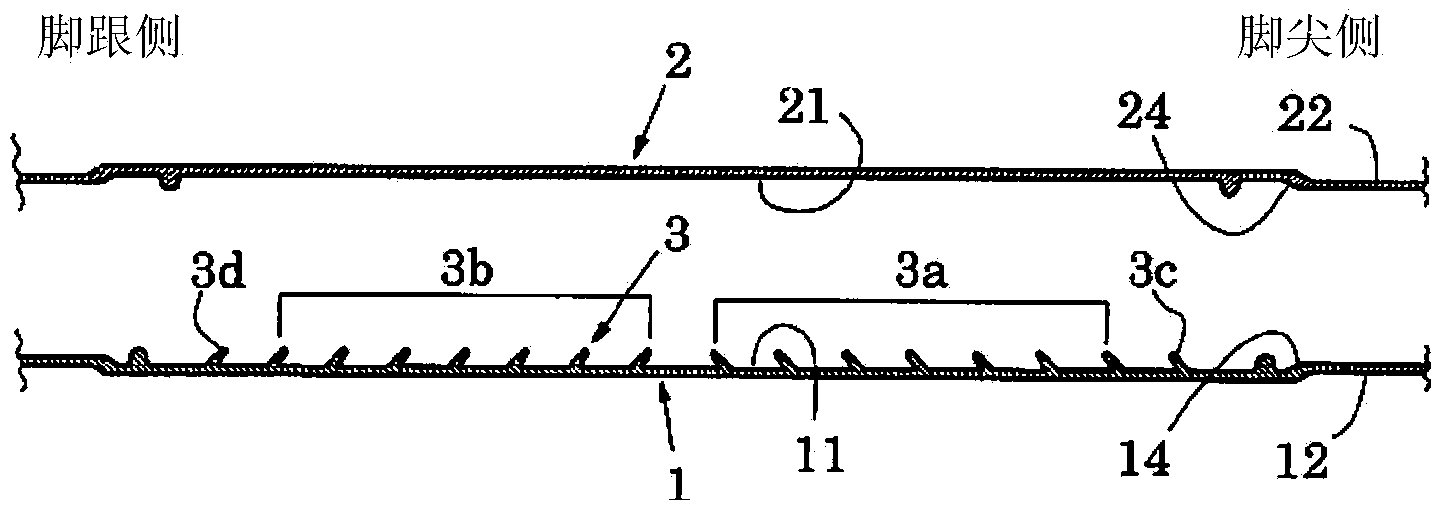

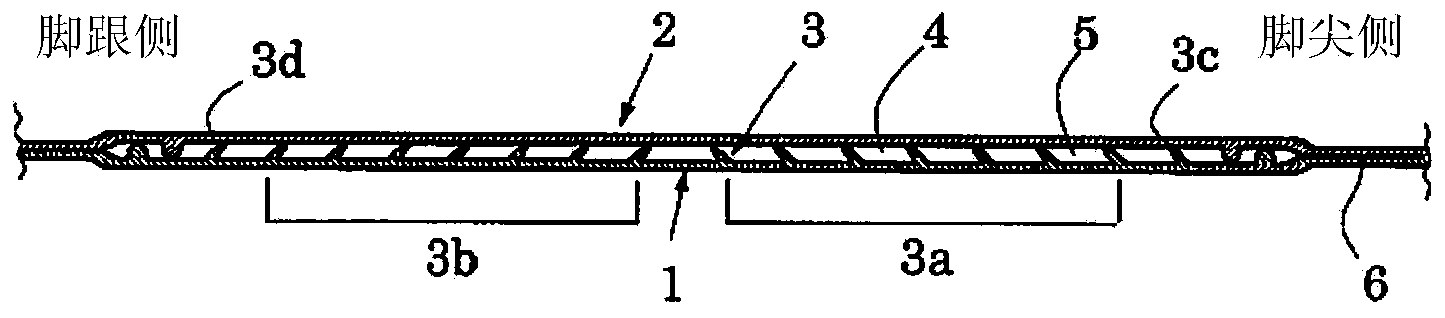

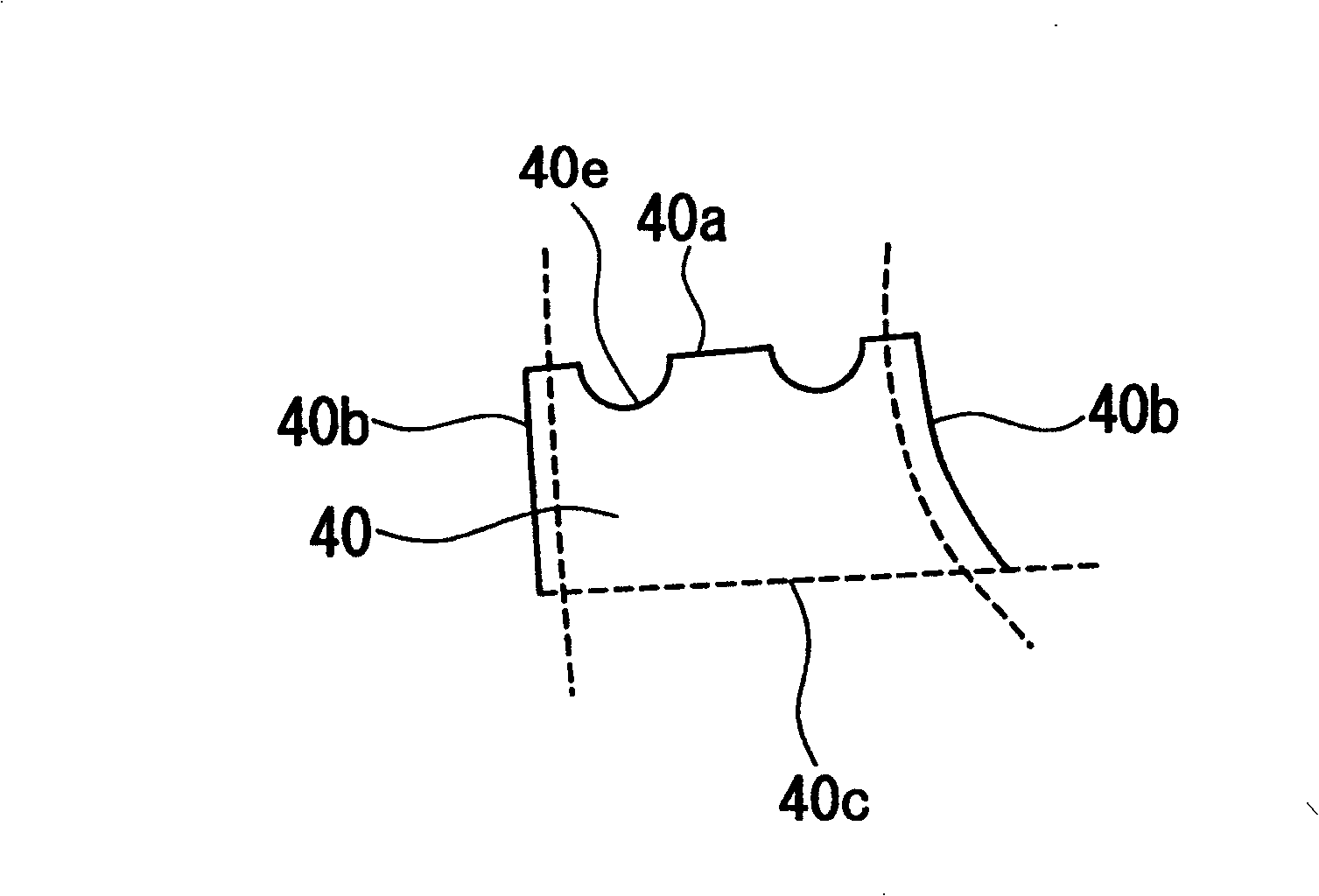

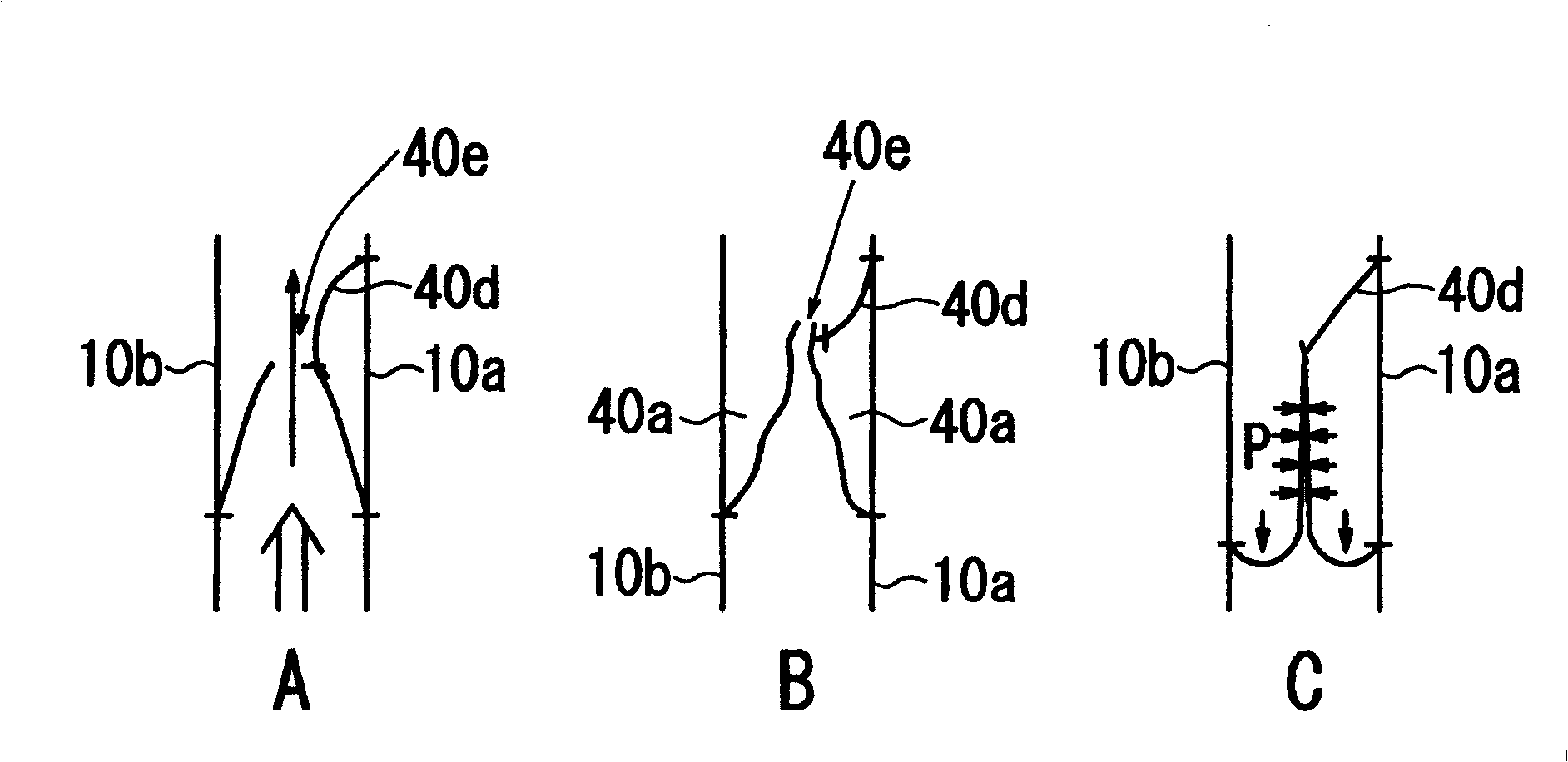

Footwear outsole member

InactiveCN104321118ASuppress pressure riseAvoid enclosingEntertainmentSolesEngineeringMechanical engineering

A shoe midsole is configured from a bottom plate (1), a cover (2), a plurality of blades (3), and a liquid (4). The blades (3) are formed so as to rise on a first region (11) provided in the bottom plate (1). The blades (3) are made from a plurality of flat blade elements (32, 33) mutually separated by slits (31) and tilt toward either the toe side or the heel side. The flat blade elements (32, 33) are disposed so as to spread open toward the toe side or the heel side. A sealed space (5) is formed by mutually joining the bottom plate (1) and the cover (2), and the liquid (4) is sealed in the sealed space.

Owner:HIMIKO

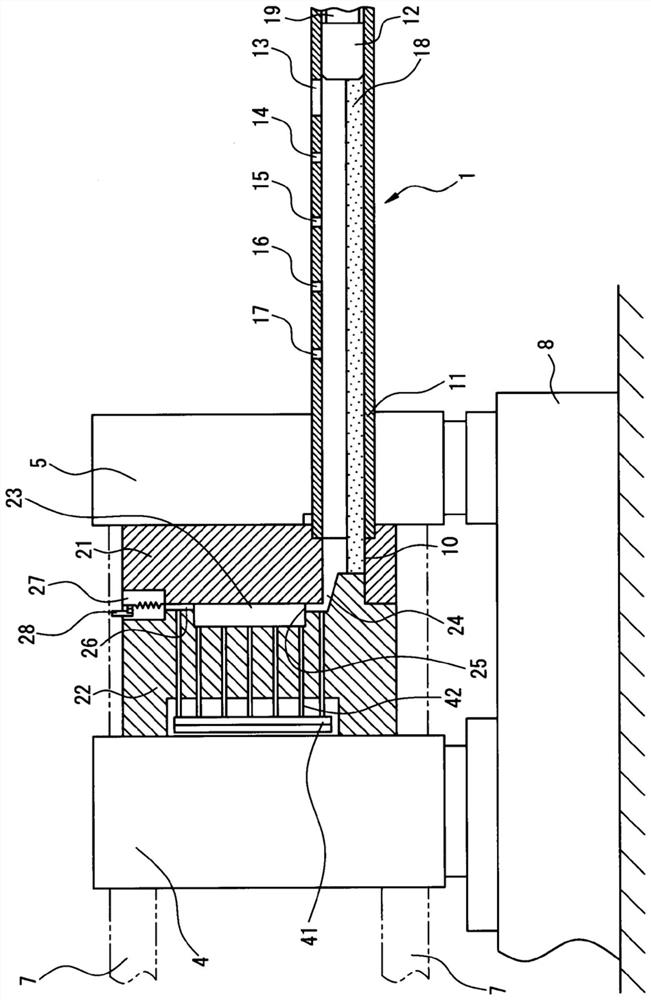

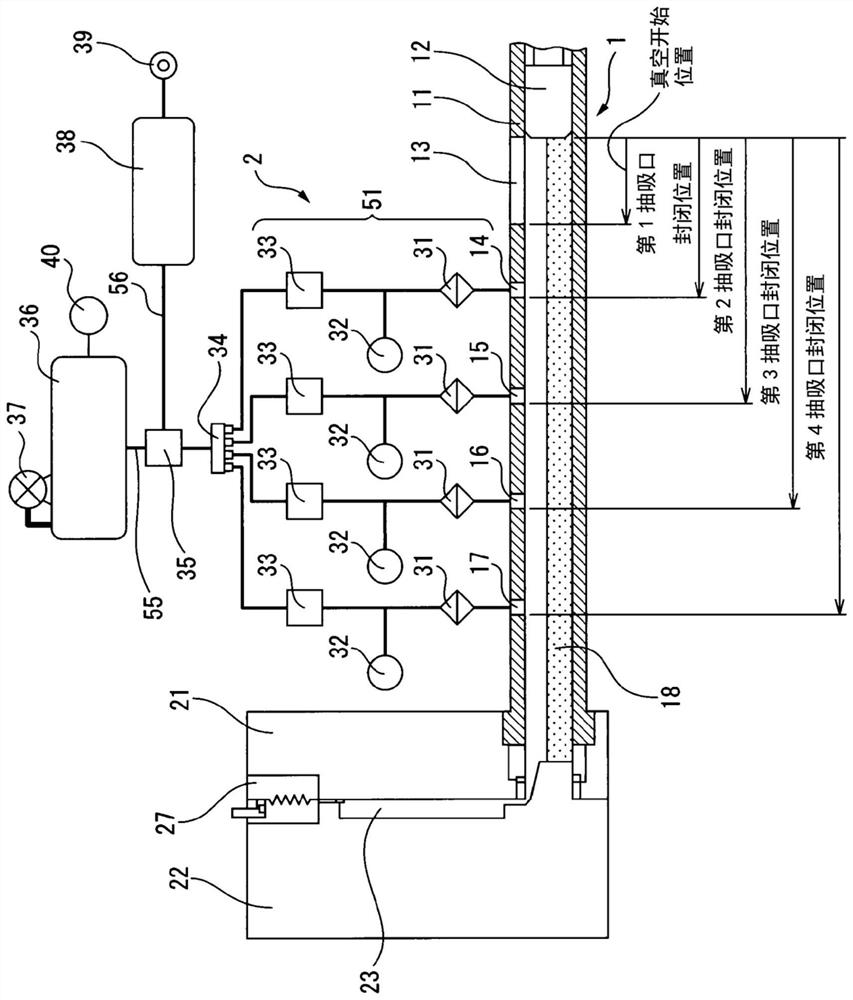

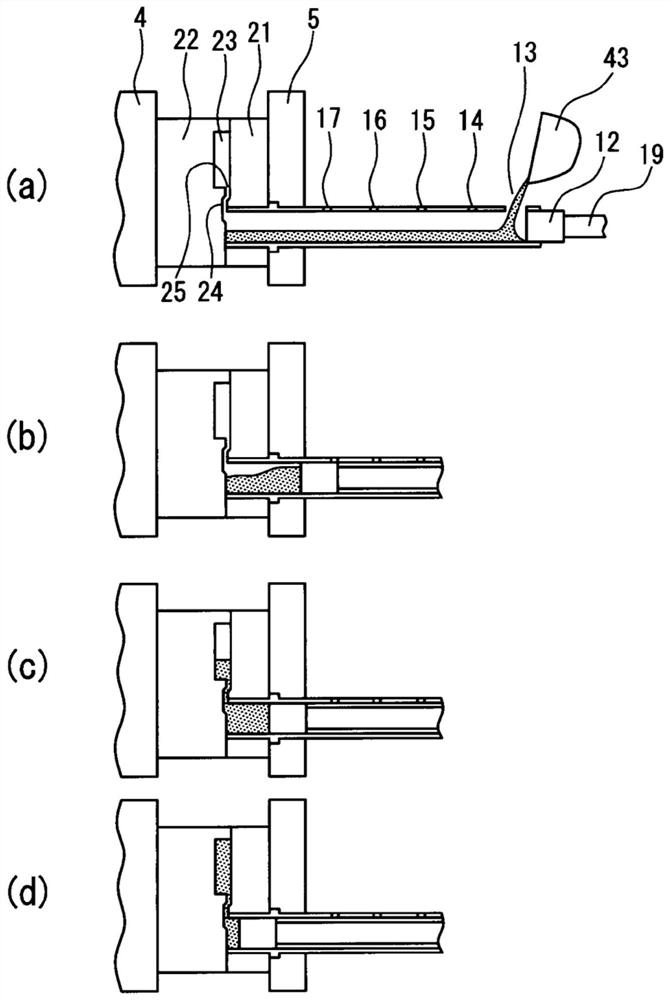

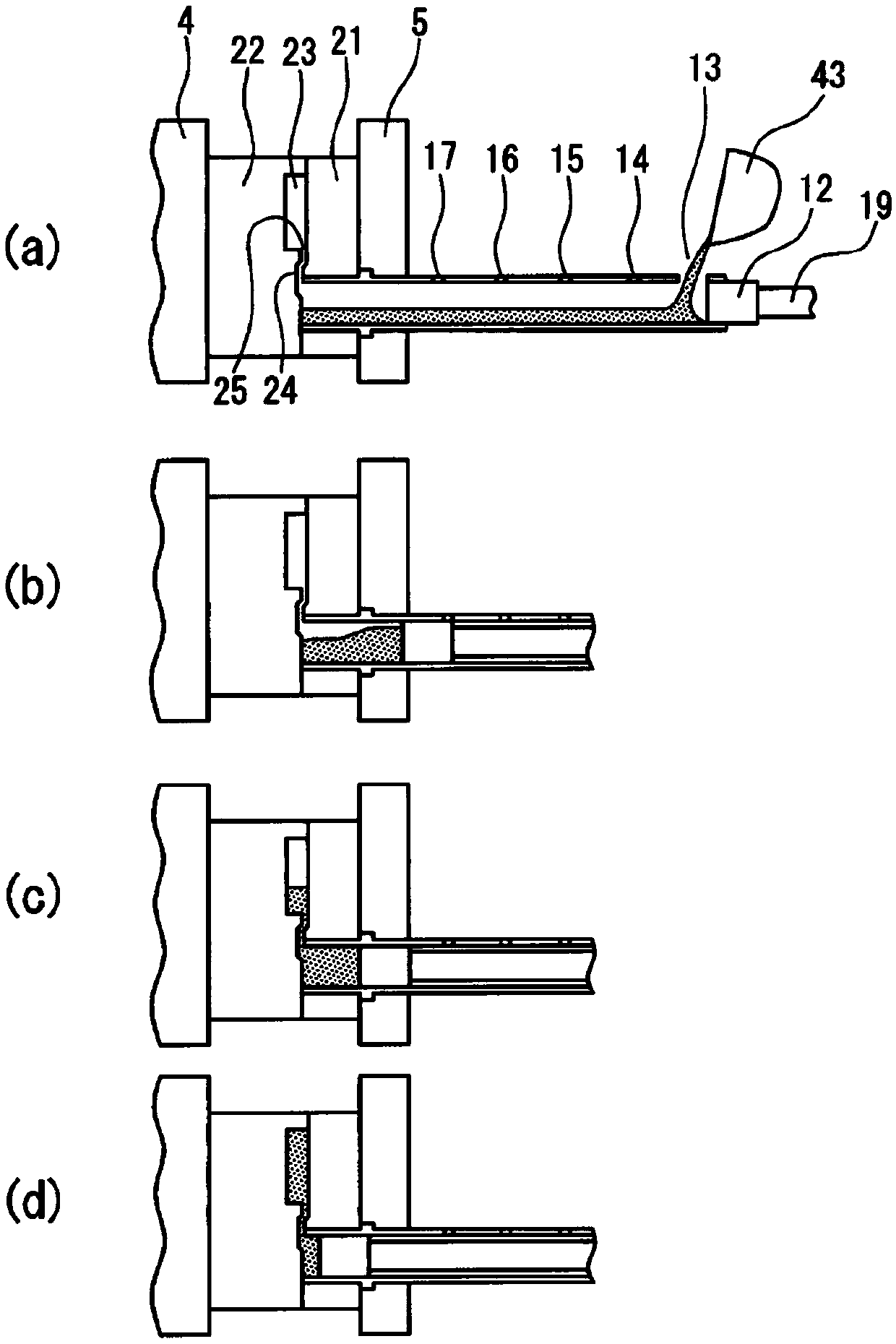

Injection device for casting device and casting method

Owner:UBE MASCH CORP LTD

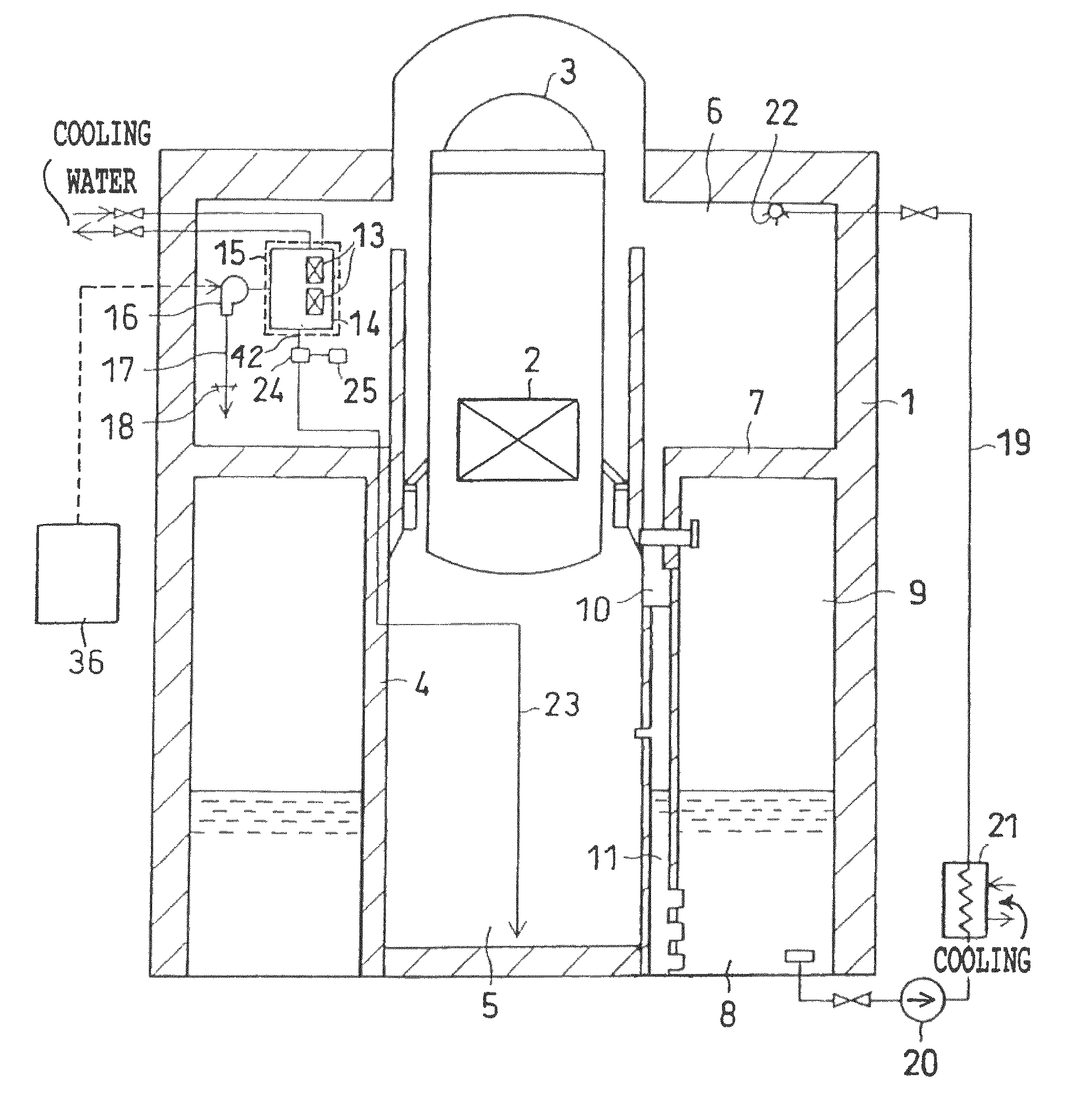

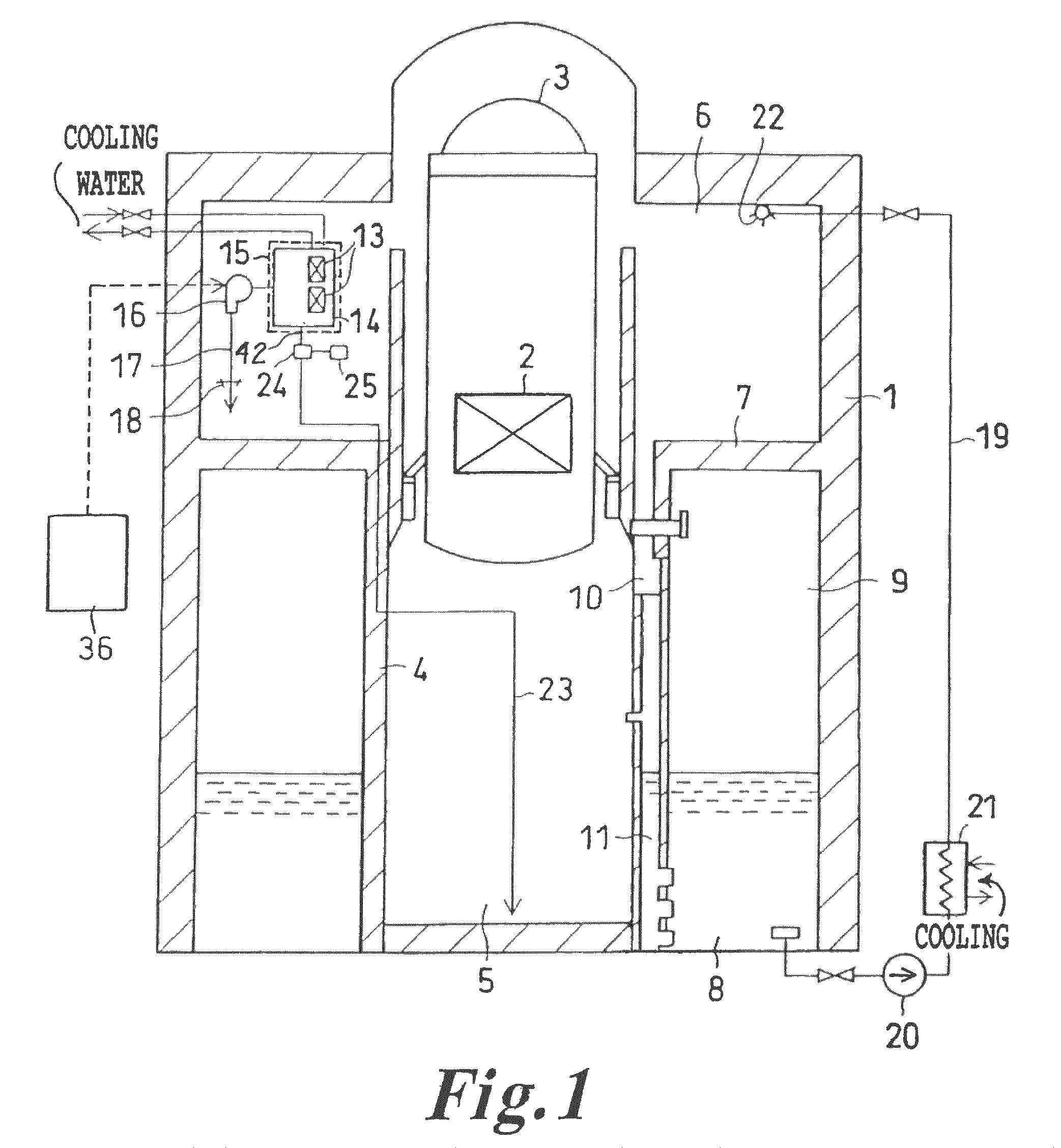

Pressure suppression and decontamination apparatus and method for reactor container

InactiveUS7813465B2Suppress pressure riseSuppress the density increase of radioactive substancesNuclear energy generationNuclear engineering problemsReactor pressure vesselProduct gas

A pressure suppression and decontamination apparatus for a reactor container which is provided with a reactor pressure vessel containing nuclear core fuel and forms a dry well space including, a dry well cooling unit for cooling a gas in the dry well space and for producing a condensate of the gas, a circulation device for leading the gas in the dry well space to the dry well cooling unit, and a sprinkling device for sprinkling the condensate in the dry well space.

Owner:KK TOSHIBA

Fabric having motion following ability

The invention discloses a fabric with motion following property. The fabric is a warp knitted fabric composed of non-elastic yarns and elastic yarns, wherein the acute angle between the extension line of the elastic yarn and the wale direction of the coil is 0-10°, and the extension of the non-elastic yarn The acute angle formed between the wire and the coil wale direction is 5-85°. Especially under the condition of high-speed telescopic movement, the pressure rise caused by elongation stress and the pressure drop caused by delayed recovery can be effectively suppressed, and it can maintain wearing comfort and prevent muscle vibration.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

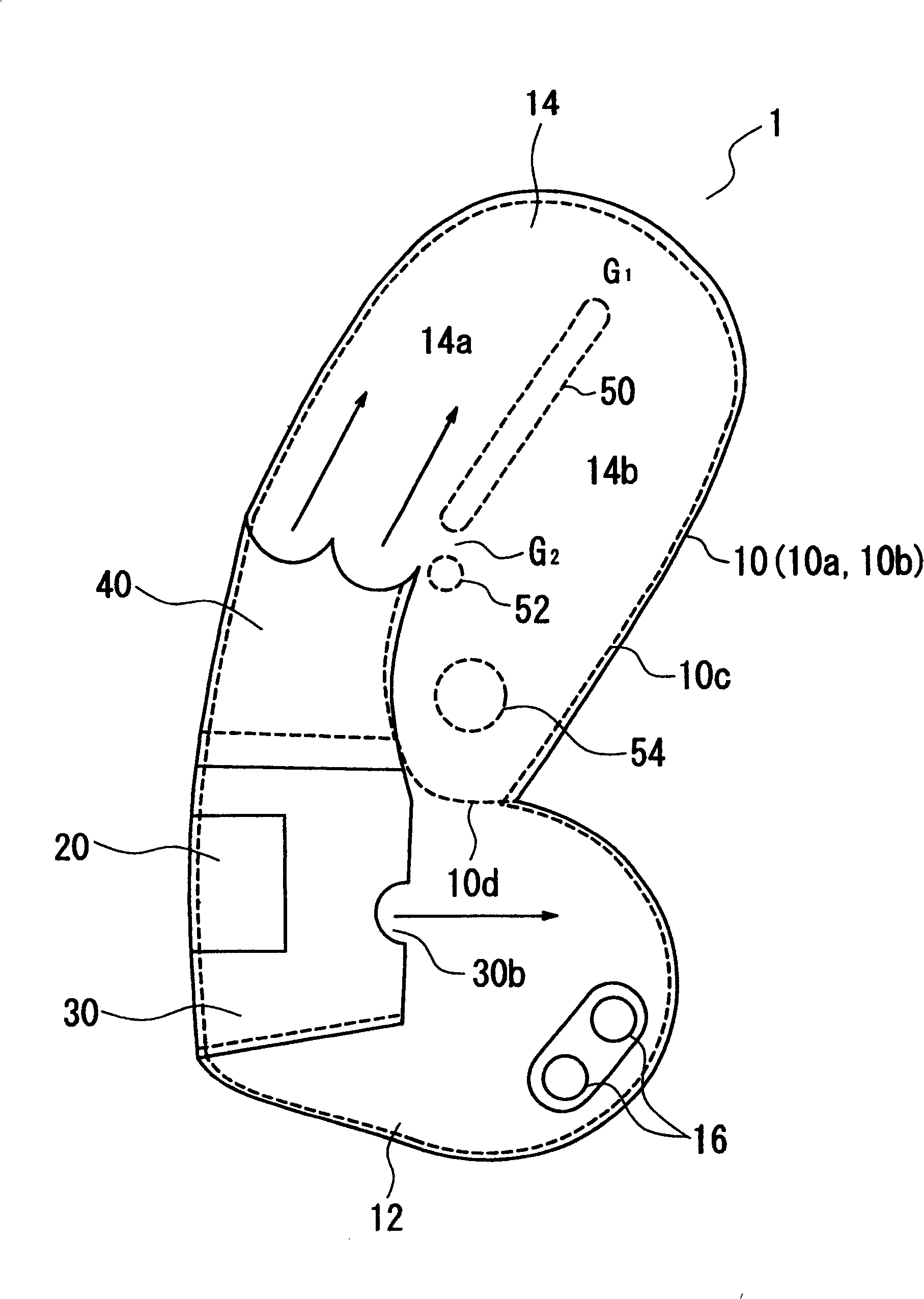

Air bag device

InactiveCN100441447CSuppress pressure riseExact protectionPedestrian/occupant safety arrangementEngineeringAirbag deployment

PROBLEM TO BE SOLVED: To smoothly deploy an airbag in even a narrow space by performing the regulation of thickness of the airbag and a conduction control of expansion gas, and to quickly and surely protect the head part of an occupant by comparatively small amount of gas. SOLUTION: This device is provided with a first air chamber 12 for protecting a breast part, a second air chamber 14 for protecting the head part, and a diffuser 30 interposed between the air chambers 12 and 14 to rectify gas jetted from an inflator 20. In the second air chamber 14, a first tether 50 to form a gas conducting passage 14a for guiding gas blown from a blowoff port of the diffuser 30 to penetrate from a rear side of the head part protecting region of the airbag 1 to a front side is provided. At a lower end of the first tether 50 in the vicinity of the gas blowoff port, a second tether 52 for forming a gap to release a part of gas to a front part of the second air chamber 14 is provided in a space between the first tether 50.

Owner:ASHIMORI INDS

Heat-pump type hot water supply system

InactiveCN1769811BPower coefficient dropImprove power factorFluid heatersMechanical apparatusPressure riseIntermediate heat exchanger

The invention provides a heat pump type water heater capable of suppressing refrigerant pressure rise and reduction in coefficient of performance at an increased water inlet temperature of the heat pump type water heater or an increased outside air. Heat-pump type hot water supply system includes a heat pump cycle in which a compressor, a water heat exchanger for performing a heat exchange betweenwater and a refrigerant, a first decompressor, an intermediate heat exchanger for performing a heat exchange between the refrigerant and exterior air, a second decompressor, an evaporator for performing a heat exchange between the refrigerant and the exterior air are connected in order. Heat-pump type hot water supply system further includes a water temperature sensor for detecting a temperatureof water entering the water heat exchanger, an exterior air temperature sensor for detecting an exterior air temperature, and a controller for controlling operations of the first and the second decompressor. A valve opening degree of the first and the second decompressor is controlled based on detection values obtained by the water temperature sensor and / or the exterior air temperature sensor.

Owner:PANASONIC CORP

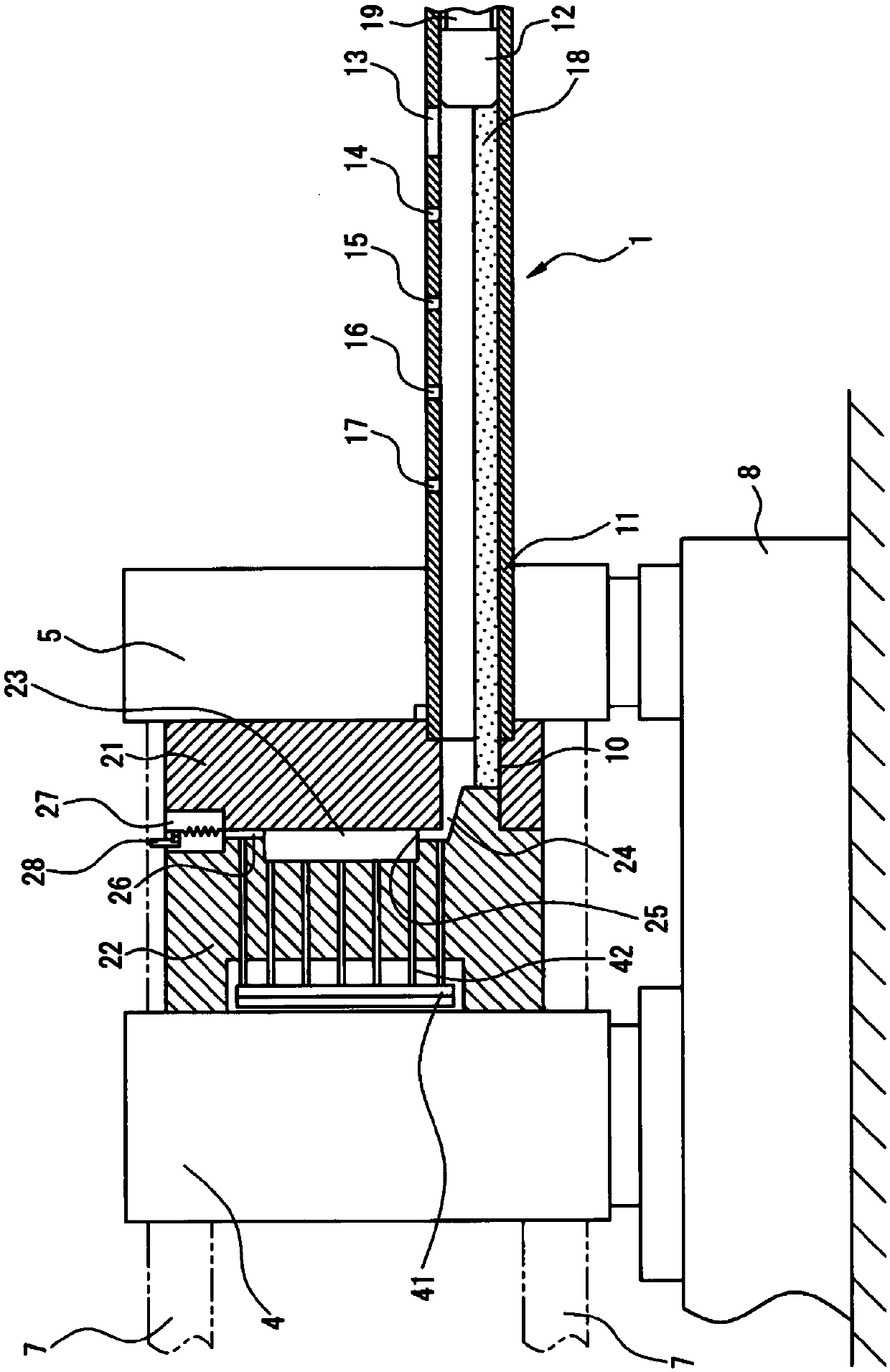

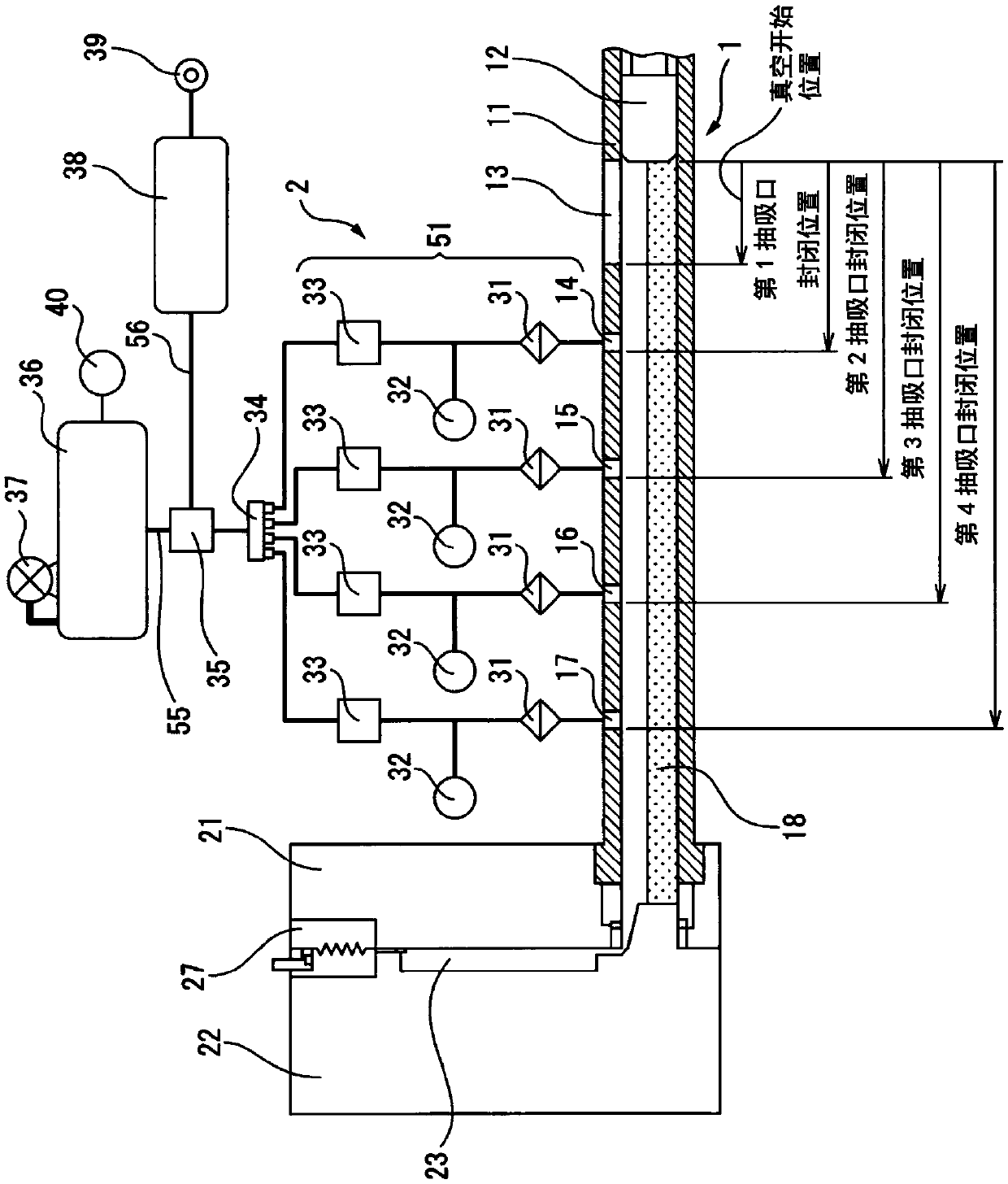

Injection device for casting device and casting method

A casting device is provided with an injection device and a vacuum device and is characterized in that the injection device is formed from a sleeve having suction openings for connecting to a vacuum device and an injection plunger, the vacuum device is formed from a suction opening selection valve capable of selecting to use or not to use vacuum suction, a pressure tank for air blowing to clean asuction pathway, and a vacuum tank for forming a vacuum within the sleeve, and the sleeve is formed from a plurality of suction openings.

Owner:UBE MASCH CORP LTD

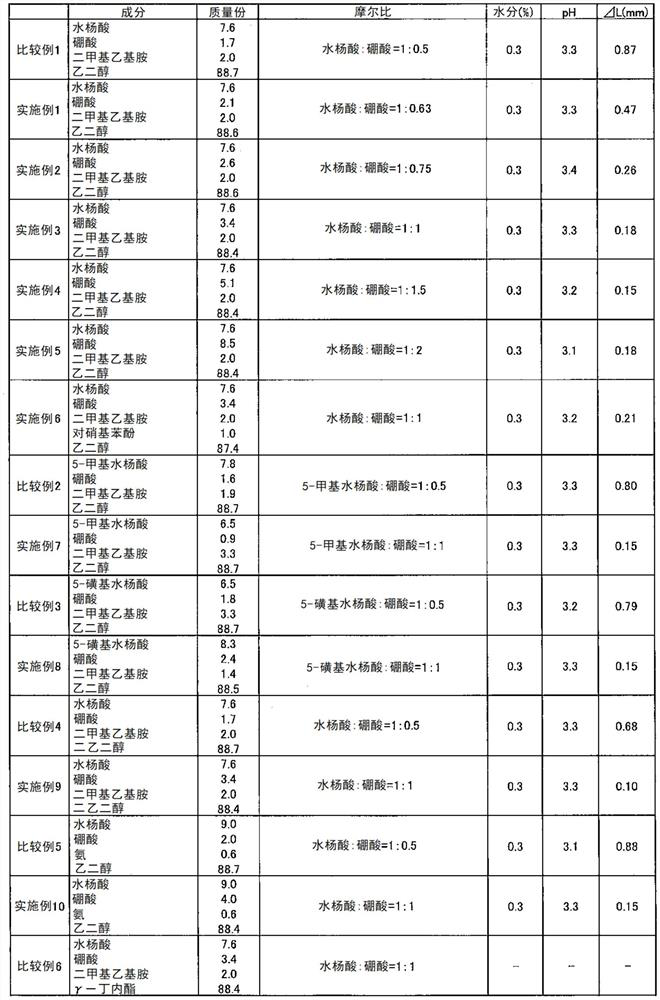

Electrolyte solution for electrolytic capacitor, and electrolytic capacitor

PendingCN114730665ASuppress pressure riseInhibit swellingSolid electrolytic capacitorsLiquid electrolytic capacitorsReflow solderingOrganic solvent

Provided is an electrolytic solution for an electrolytic capacitor, which is capable of suppressing expansion of a housing container even during reflow soldering. The electrolytic solution for an electrolytic capacitor is characterized in that: the electrolytic solution for an electrolytic capacitor comprises a capacitor element having a positive electrode foil having a dielectric oxide film layer on the surface thereof, a negative electrode foil, and a solid electrolyte layer, and an electrolytic solution impregnated into the capacitor element inside a housing container; the electrolytic solution contains an organic carboxylic acid having a hydroxyl group, a boron compound, and a solvent, the content of the boron compound being 0.6 mol or more with respect to 1 mol of the organic carboxylic acid having a hydroxyl group, the solvent containing a protic organic solvent, and the content of the boron compound being 1 mol or more when the electrolytic capacitor is exposed to a high temperature of 250 DEG C or more. A pressure increase in the outer shell container can be suppressed.

Owner:富山药品工业株式会社

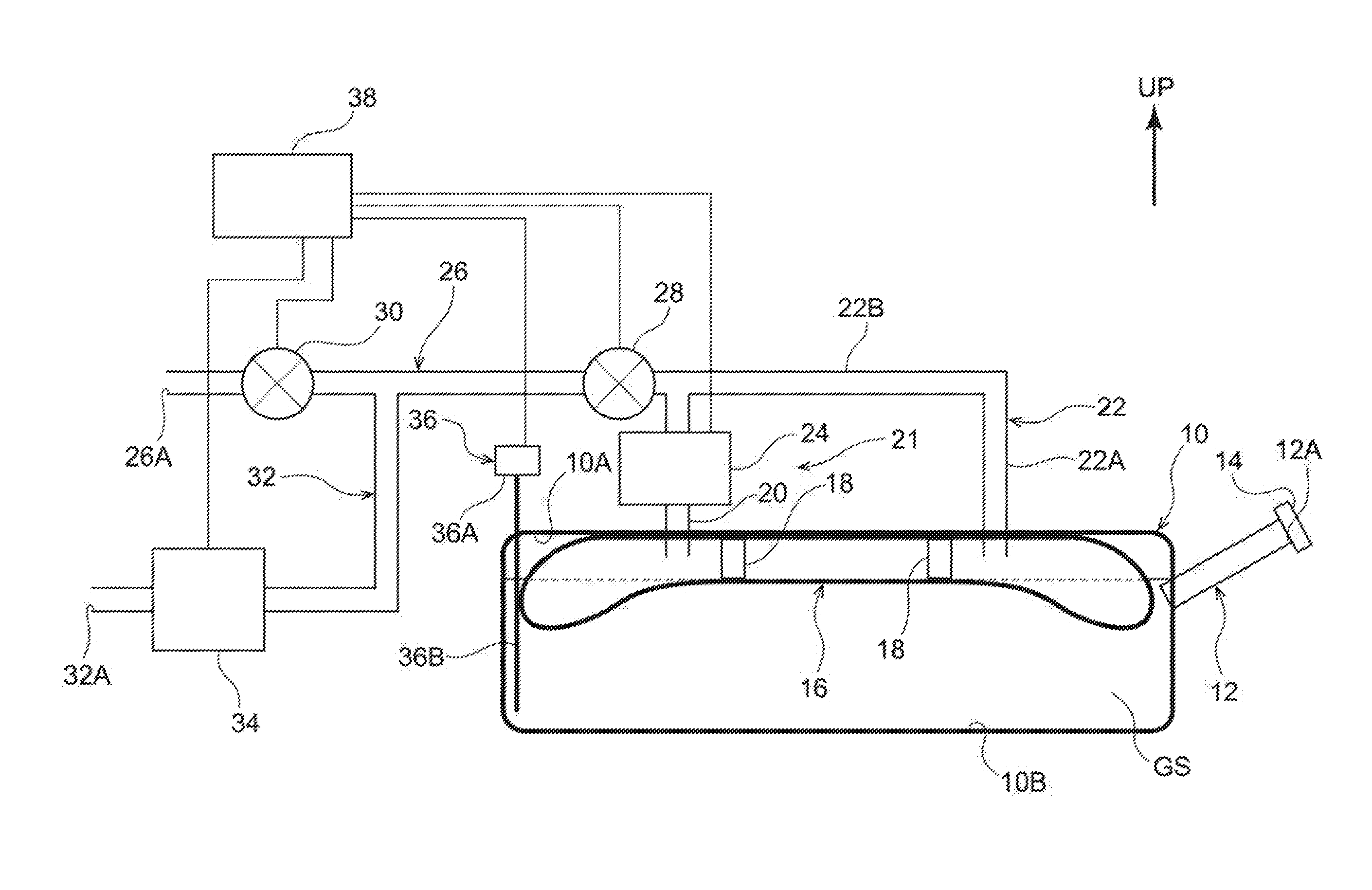

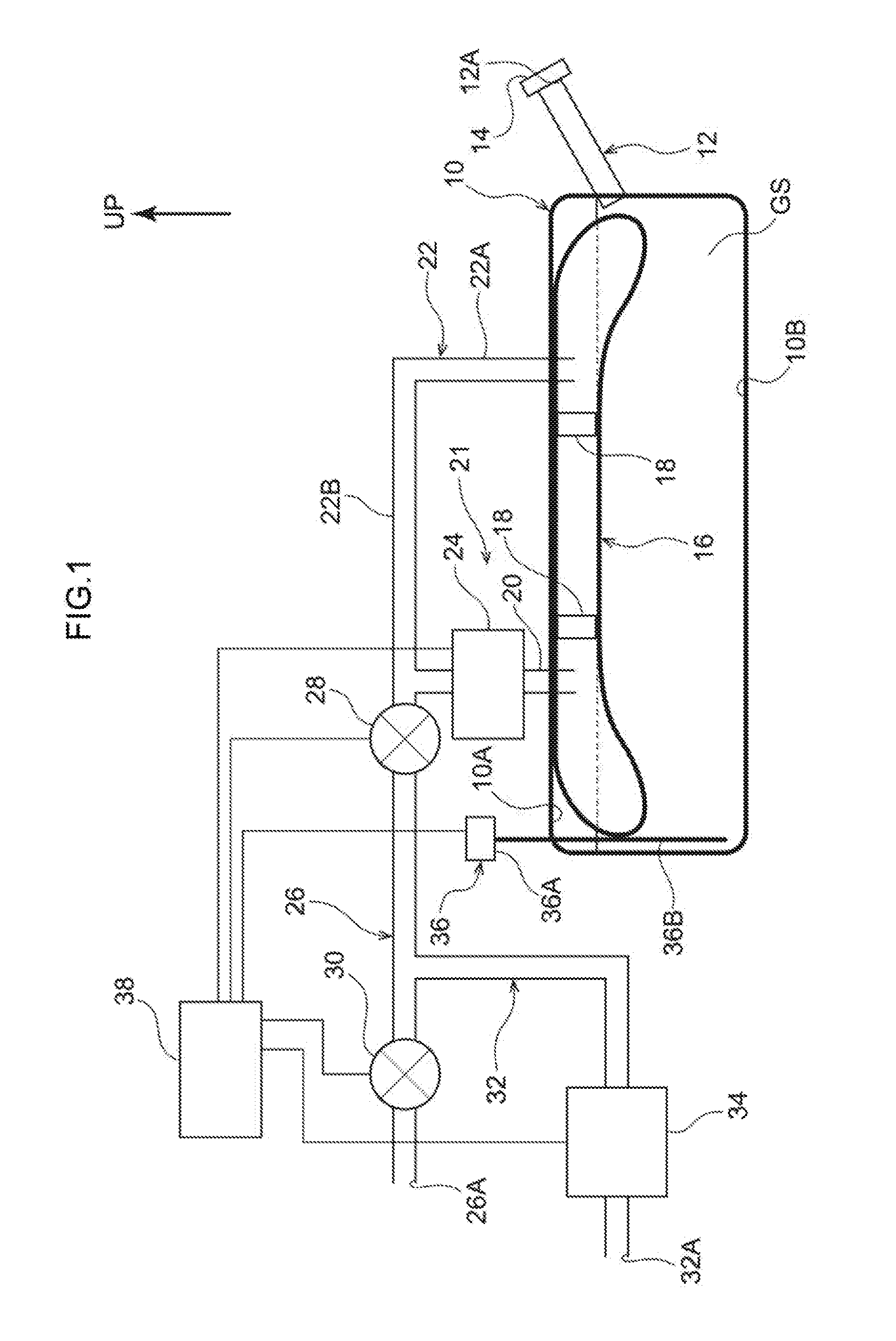

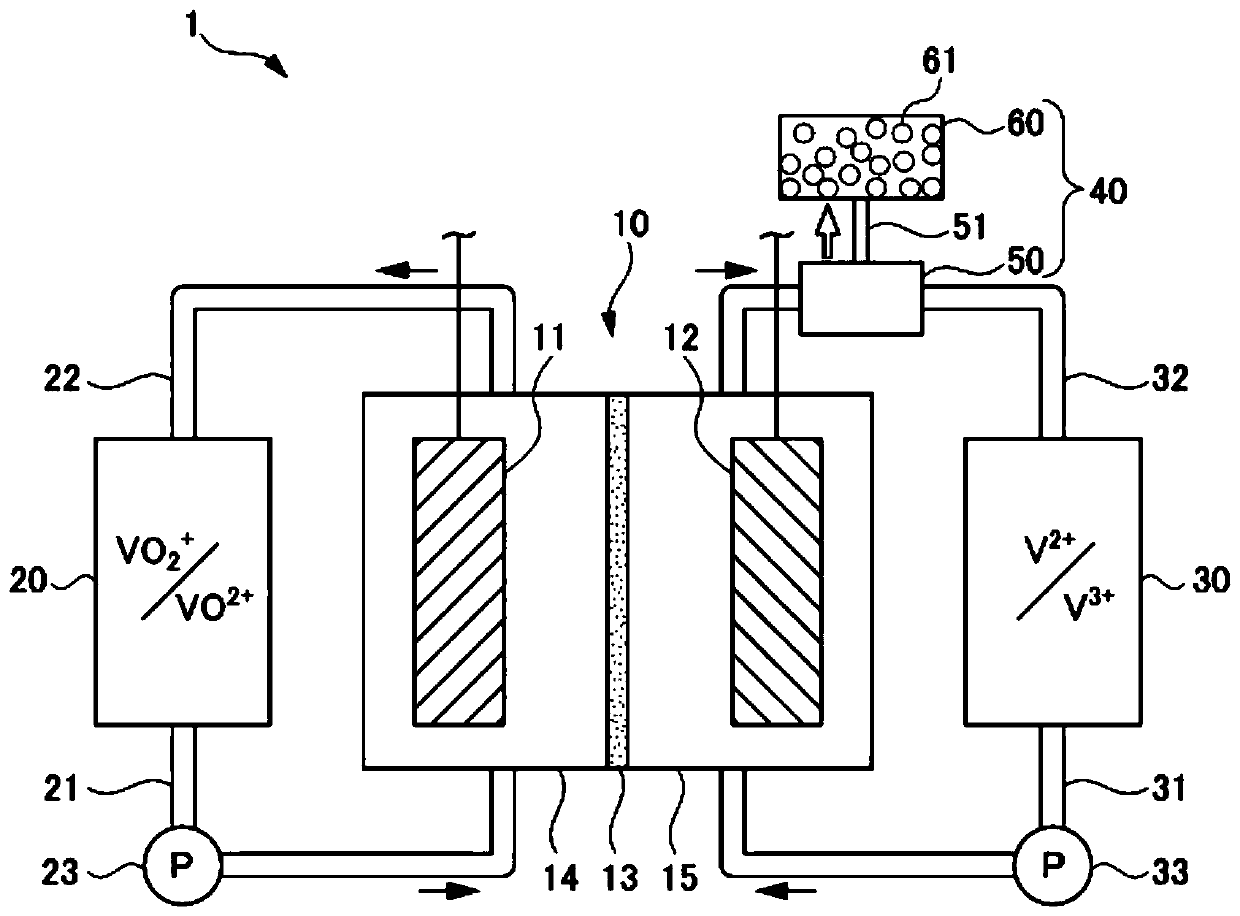

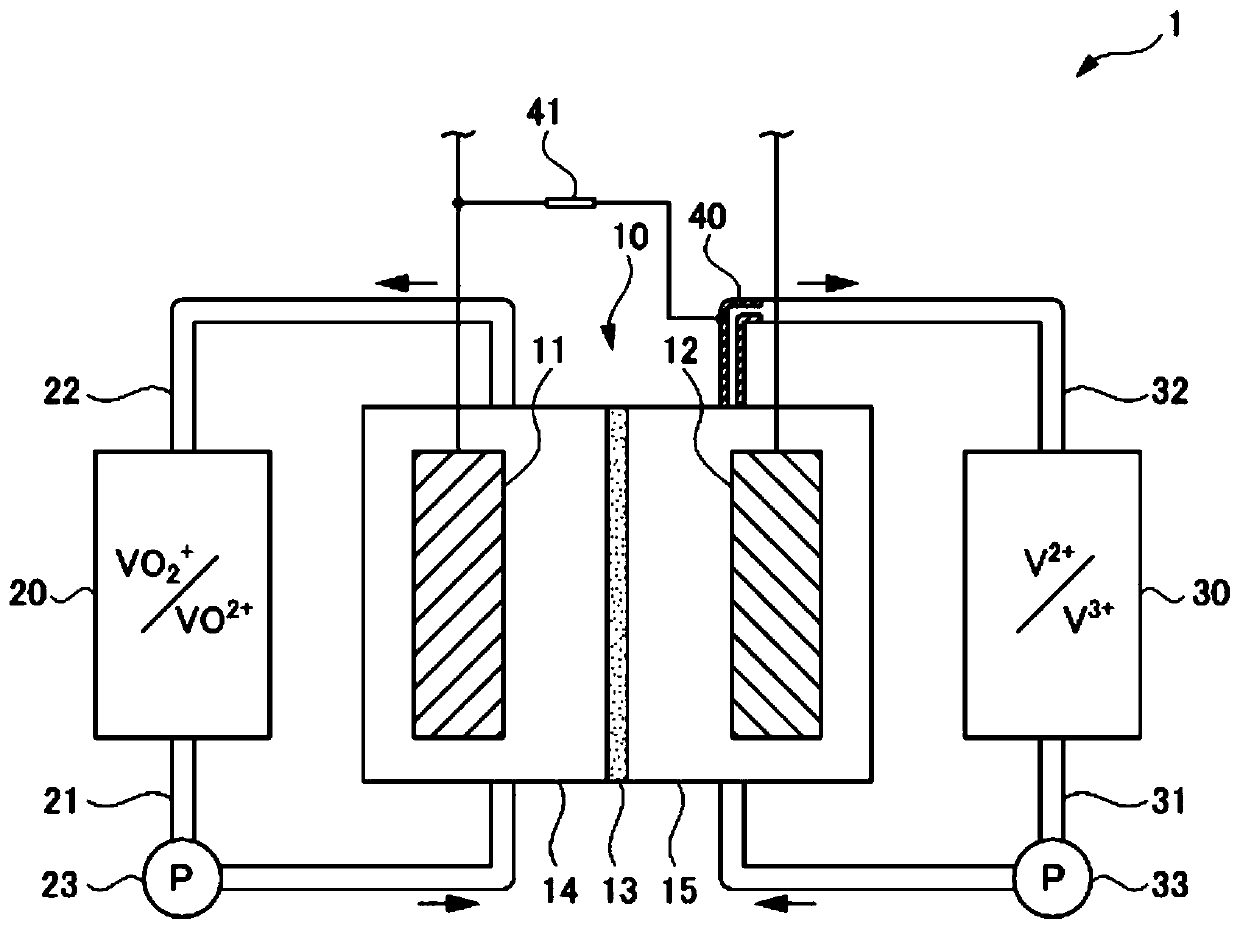

Redox flow battery

InactiveCN111448699AImprove reliabilitySuppress pressure riseElectrolyte moving arrangementsRegenerative fuel cellsElectrolytic agentElectrical battery

Owner:SHOWA DENKO KK

Redox flow battery

InactiveCN111433957AImprove reliabilitySuppress pressure riseCell electrodesFuel cell auxillariesElectrolytic agentPtru catalyst

The present invention provides a redox flow battery capable of preventing pressure increase caused by hydrogen gas generation at a negative electrode within a battery system. This redox flow battery (1) has: a battery cell (10) equipped with a positive electrode (11), a negative electrode (12), and an ion-exchange membrane (13); a positive electrode-side electrolytic solution tank (20) for housingan electrolytic solution containing a positive electrode active material appropriate for the positive electrode (11); a negative electrode-side electrolytic solution tank (30) for housing an electrolytic solution containing a negative electrode active material appropriate for the negative electrode (12); a positive electrode-side piping for connecting the battery cell (10) and the positive electrode-side electrolytic solution tank (20); and a negative electrode-side piping for connecting the battery cell (10) and the negative electrode-side electrolytic solution tank (30), wherein charging and discharging are performed by having a configuration causing the electrolytic solutions to circulate between the battery cell (10 )and the positive and negative electrode-side electrolytic solution tanks (20, 30) via the positive electrode-side piping (21, 22) and the negative electrode-side piping (31, 32). The negative electrode-side piping (31, 32) has a hydrogen oxidation catalyst (40 provided to at least a portion of an inner surface side thereof.

Owner:SHOWA DENKO KK

air conditioner

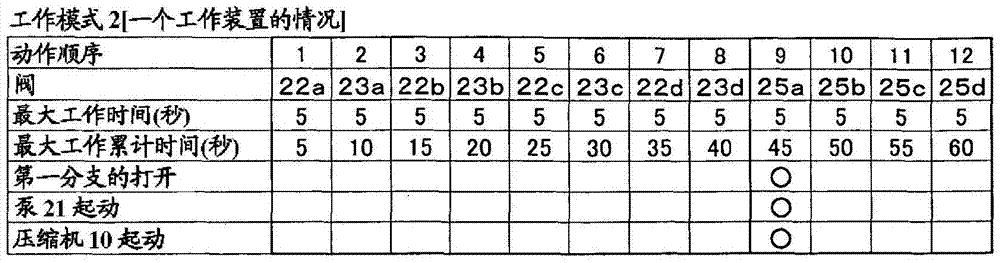

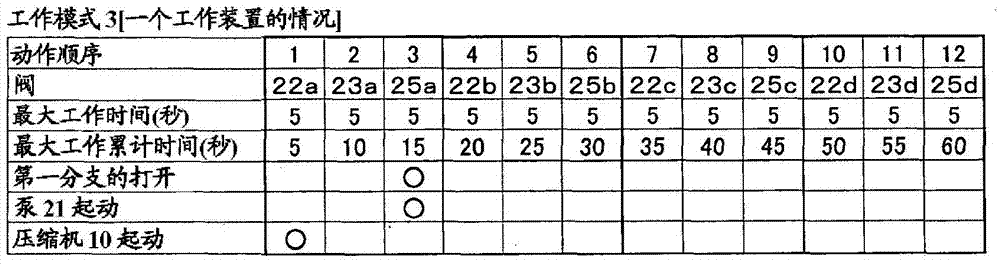

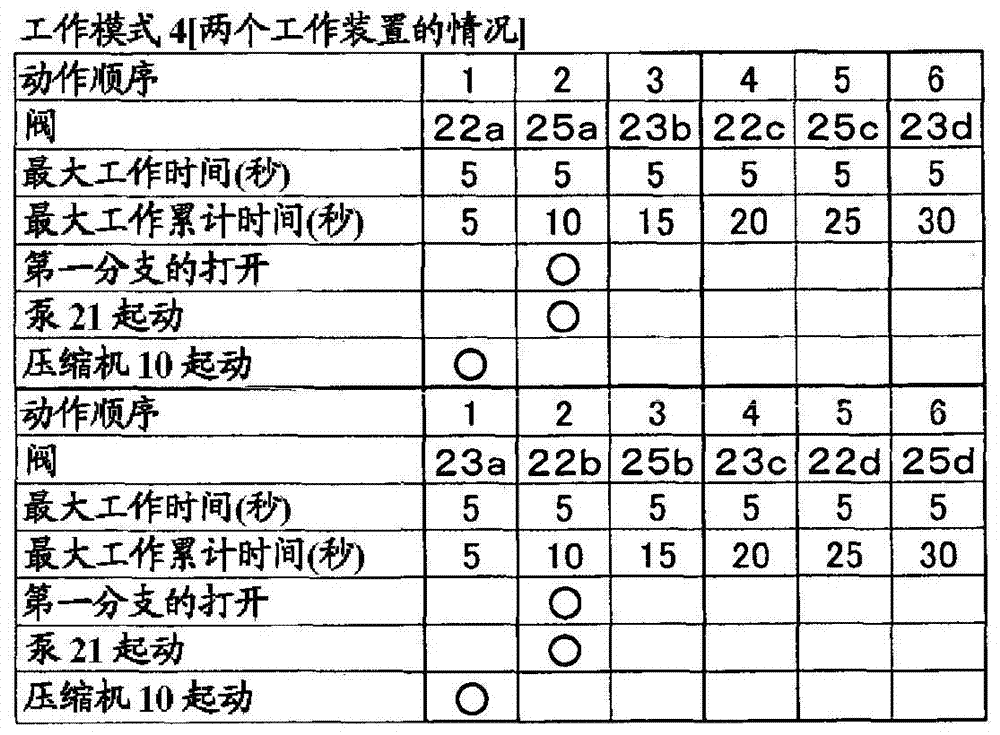

ActiveCN104781614BSuppress pressure riseDrive lessCompressorMechanical apparatusStart timeAir conditioning

An air-conditioning apparatus includes actuation control means including an actuation unit that sequentially opens heat medium flow switching devices or heat medium flow control devices on a one-by-one basis. The actuation control means performs control in such a manner that start time of driving of pumps is later than start of actuation of the heat medium flow switching devices and the heat medium flow control devices.

Owner:MITSUBISHI ELECTRIC CORP

Liquid jetting apparatus

A liquid jetting apparatus includes: a head; an ink storage chamber communicating with the head; a gas distributing chamber in which a gas introducing hole is formed; a buffer chamber in which a communicating hole for communicating with the gas distributing chamber, and an atmosphere opening hole for opening to the atmosphere are formed; a combination valve which is capable of opening and closing the gas introducing hole and the communicating hole; a gas introducing mechanism which introduces the compressed air through the gas introducing hole to the head to jet the ink forcibly, and a positive-pressure control valve which opens the atmosphere opening hole when a pressure in the buffer chamber exceeds a predetermined value. It is possible to operate a positive-pressure purge while suppressing an excessive increase in the pressure inside the liquid storage chamber, without increasing a size and a cost of the apparatus.

Owner:BROTHER KOGYO KK

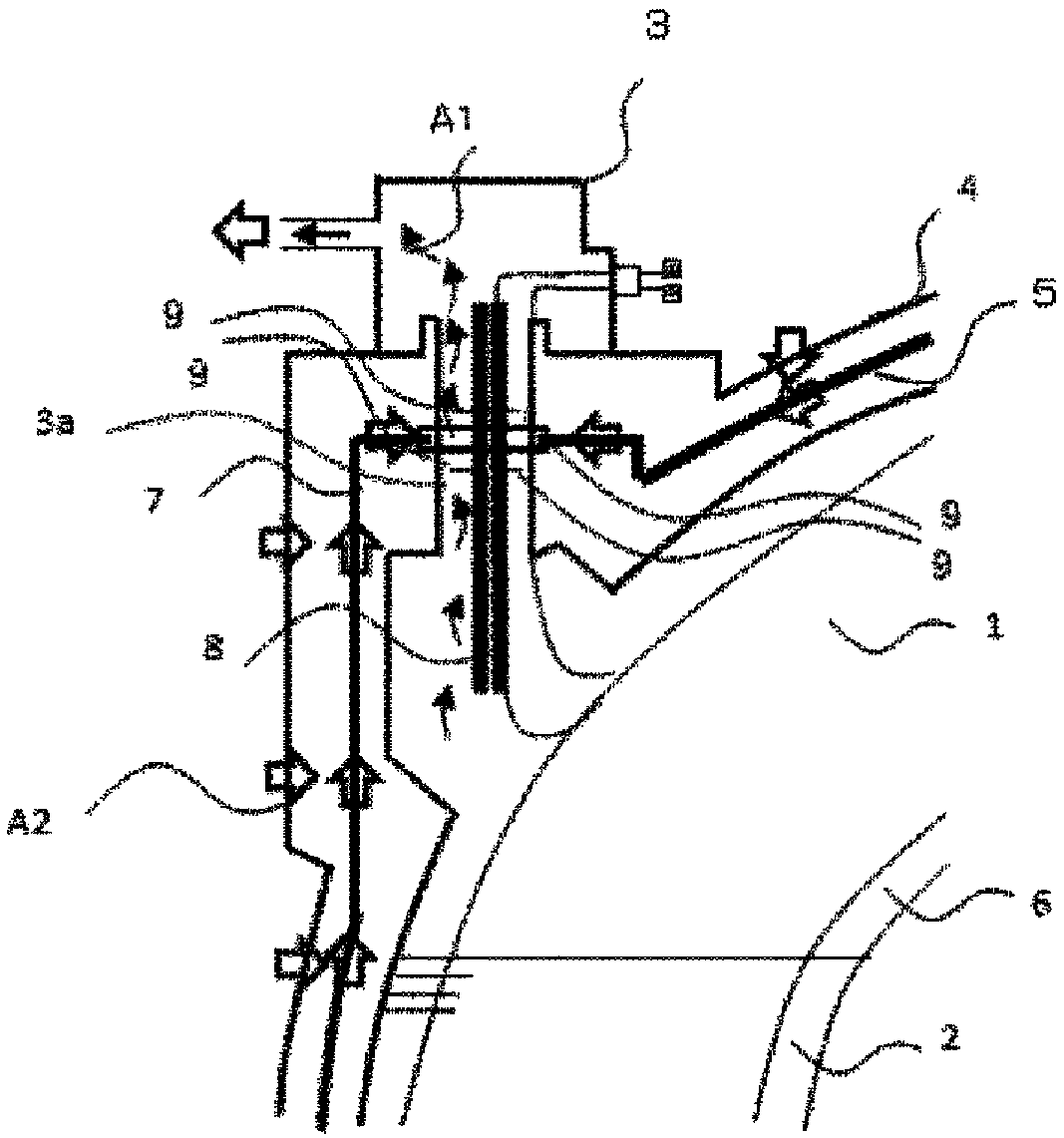

Superconducting magnet device

ActiveCN108028117AEmission reductionSuppress pressure riseMagnetic measurementsSuperconductor detailsInternal pressureGaseous helium

Provided is a superconducting electromagnet device with which it is possible to prevent damage attributable to quenching, while reducing helium consumption. Heat exchanging performance during transport is improved by providing a sheet-like convection-preventing member (9) which is disposed in such a way as to cover a helium gas exhausting tube (3a) for gaseous helium (6), above and / or below a heattransfer member (7) which transfers to the gaseous helium (6) heat that has penetrated in from the outside. In the event that quenching occurs, the convection-preventing member (9) is lifted upward in the exhaust tube, thereby ensuring a channel for the gaseous helium (6) and preventing an excessive increase in the internal pressure.

Owner:MITSUBISHI ELECTRIC CORP

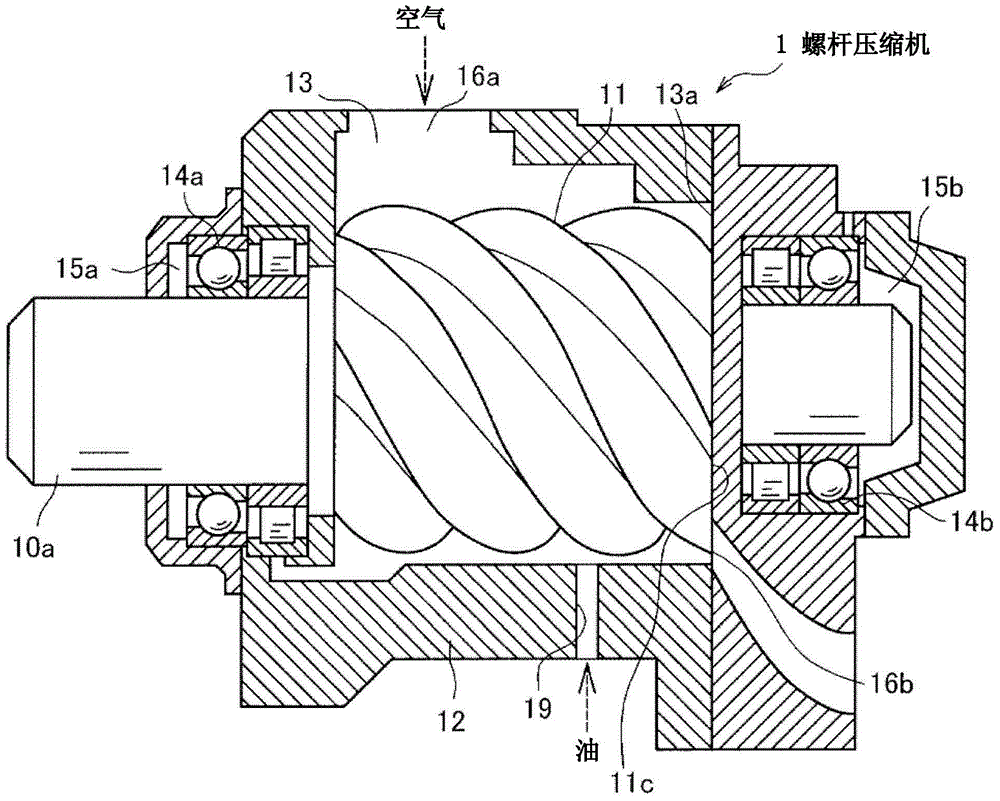

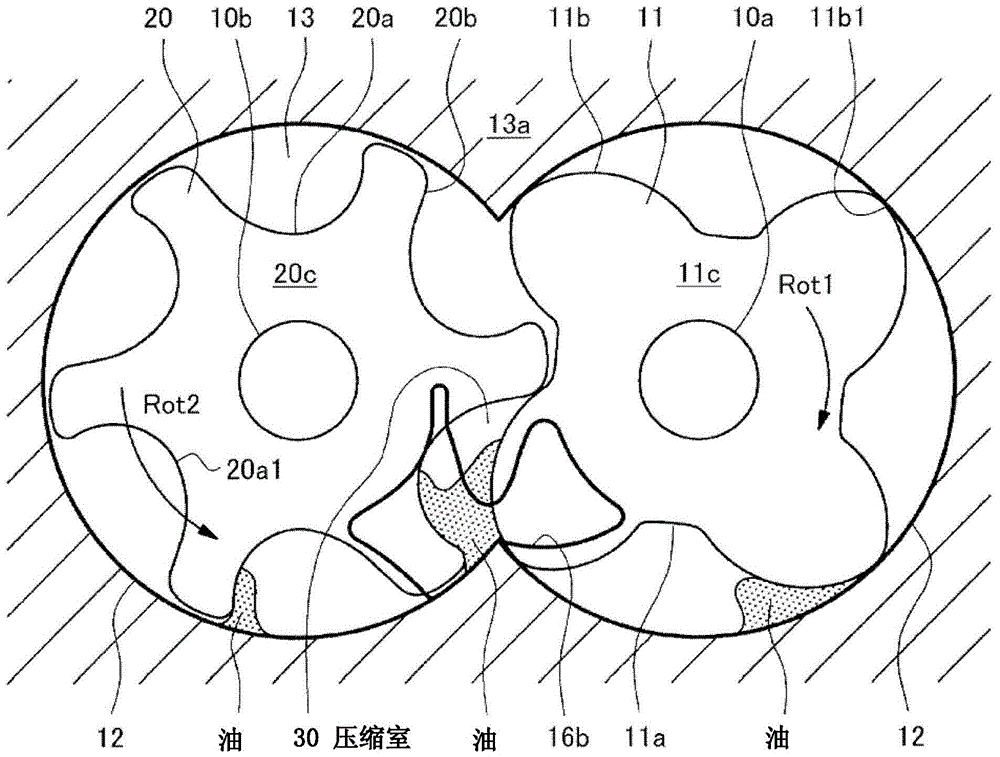

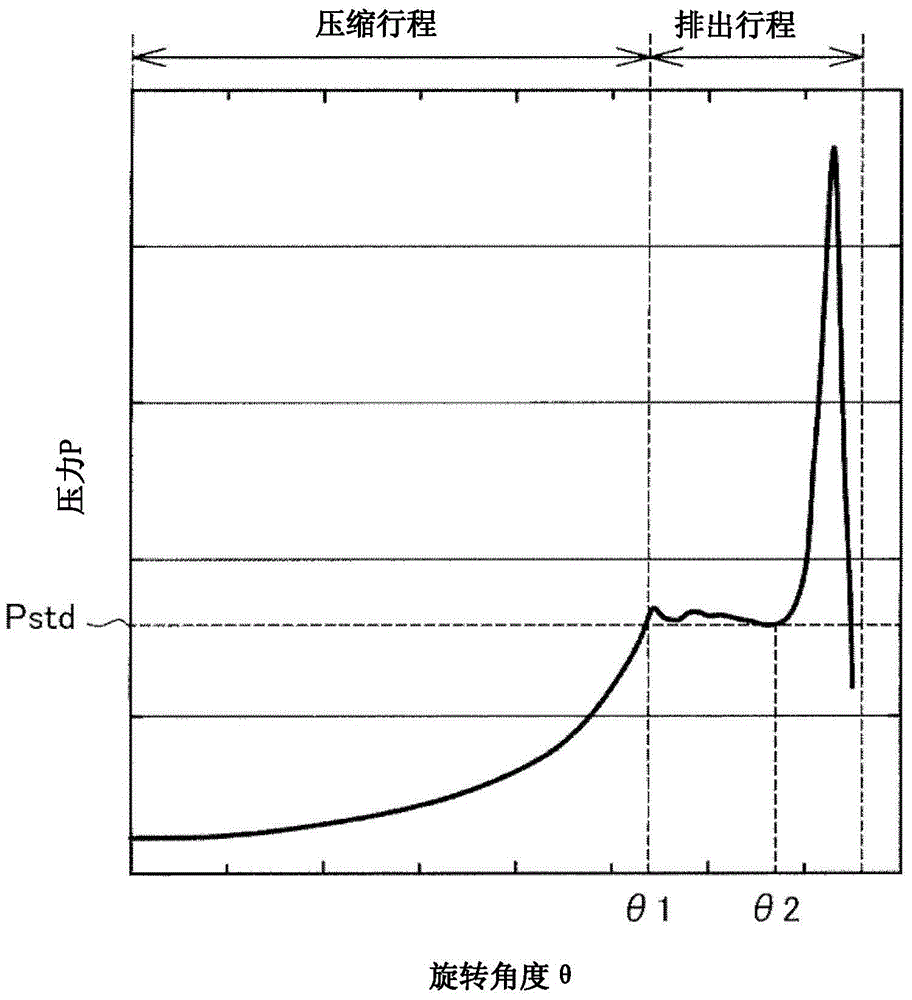

Screw compressors

ActiveCN104595185BInhibition lossSuppress pressure riseRotary piston pumpsRotary piston liquid enginesPressure riseWorking fluid

The invention provides a screw compressor as a subject which can suppress disappearance of a compressed working fluid and pressure rise in discharging. The screw compressor of the invention comprises a first rotor (11) and a second rotor (20) which are engaged with each other and rotate to compress the working fluid. Air is compressed as a compression chamber (30) formed by engagement between the first rotor (11) and the second rotor (20) shrinks. The compression chamber (30) shrinks until the compression chamber (30) disappears. Furthermore, the screw compressor is characterized in that a recessed first oil storing portion (22) forms in an axial end surface (11c) of a tooth portion (11b) of the first rotor (11); the first oil storing portion (22) is communicated with a working chamber (13) or the compression chamber (30) through a first opening portion (22a) forming in a tooth top (11b1) of the tooth portion (11b); the first opening portion (22a) is at a position where the tooth top (11b1) of the tooth portion (11b) is superposed with a tooth bottom (20a1) of a tooth groove (20a) when the compression chamber (30) disappears.

Owner:HITACHI IND EQUIP SYST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com