Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

348 results about "Thermal cutoff" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A thermal cutoff is an electrical safety device that interrupts electric current when heated to a specific temperature. These devices may be for one-time use or may be reset manually or automatically.

Ceramic heater

InactiveUS20020043527A1Improve unevennessSemiconductor/solid-state device manufacturingHot plates heating arrangementsTemperature controlThermocouple

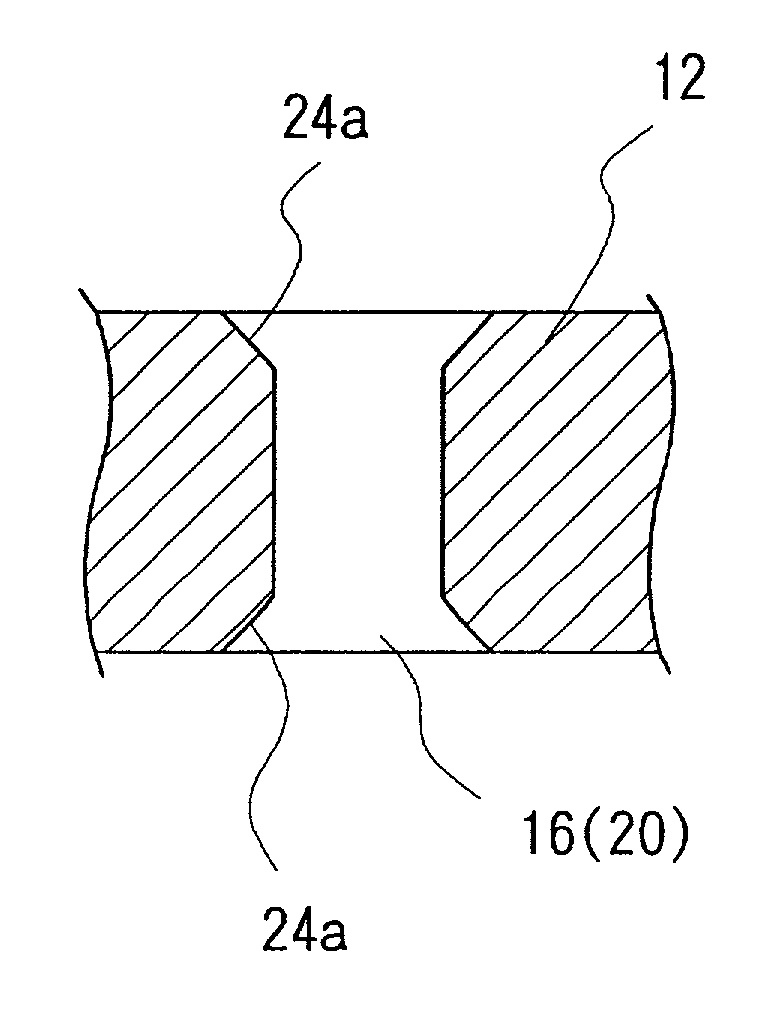

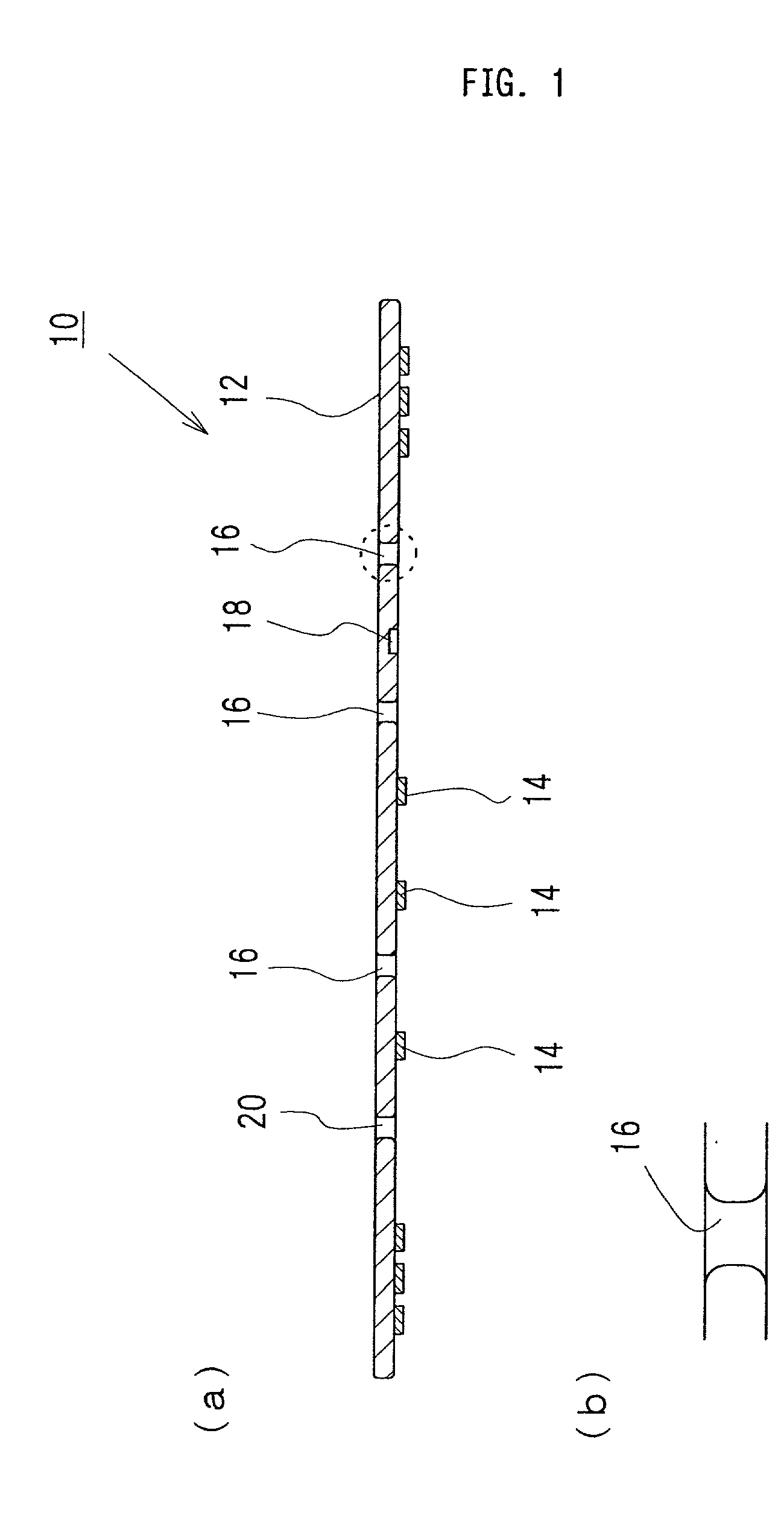

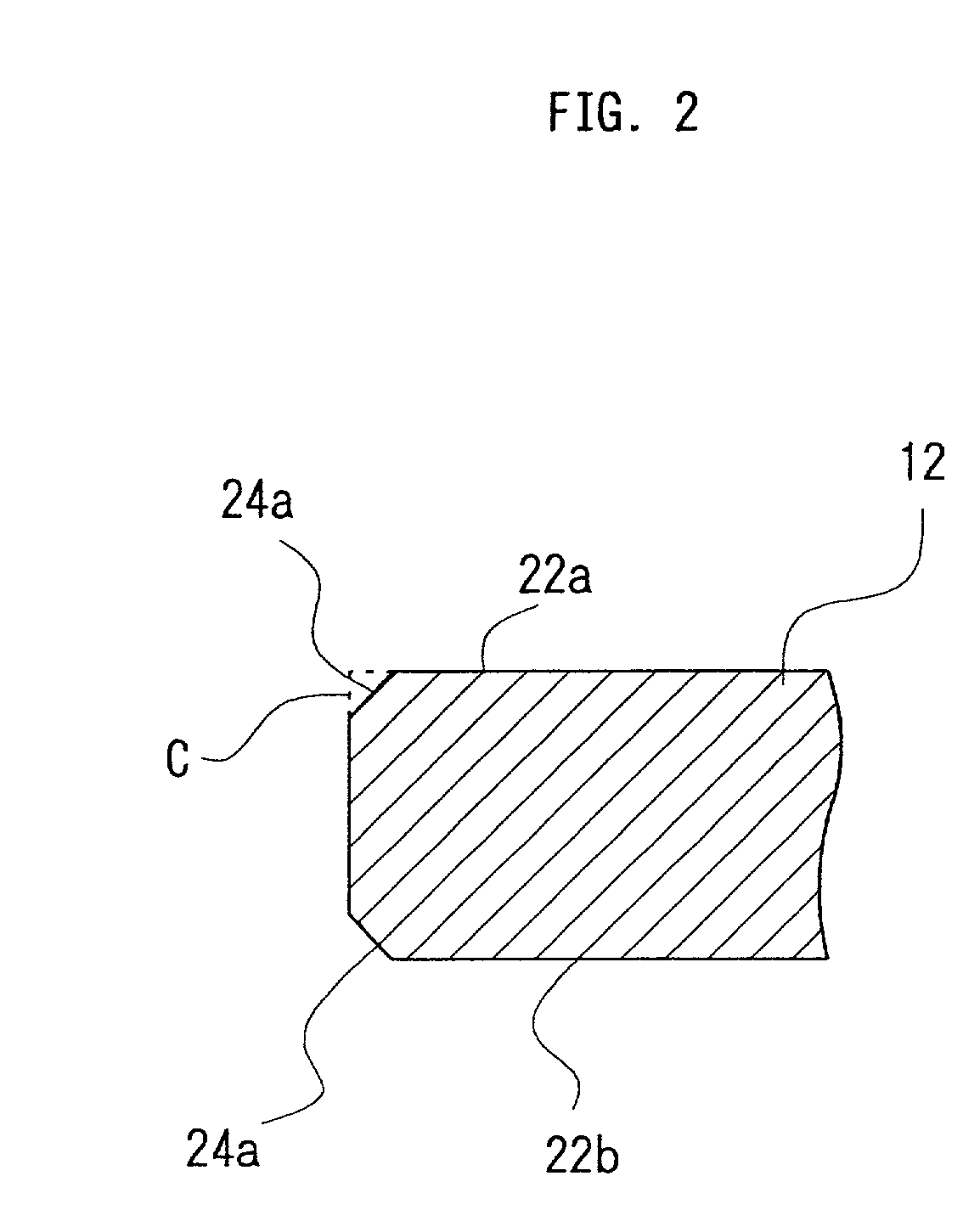

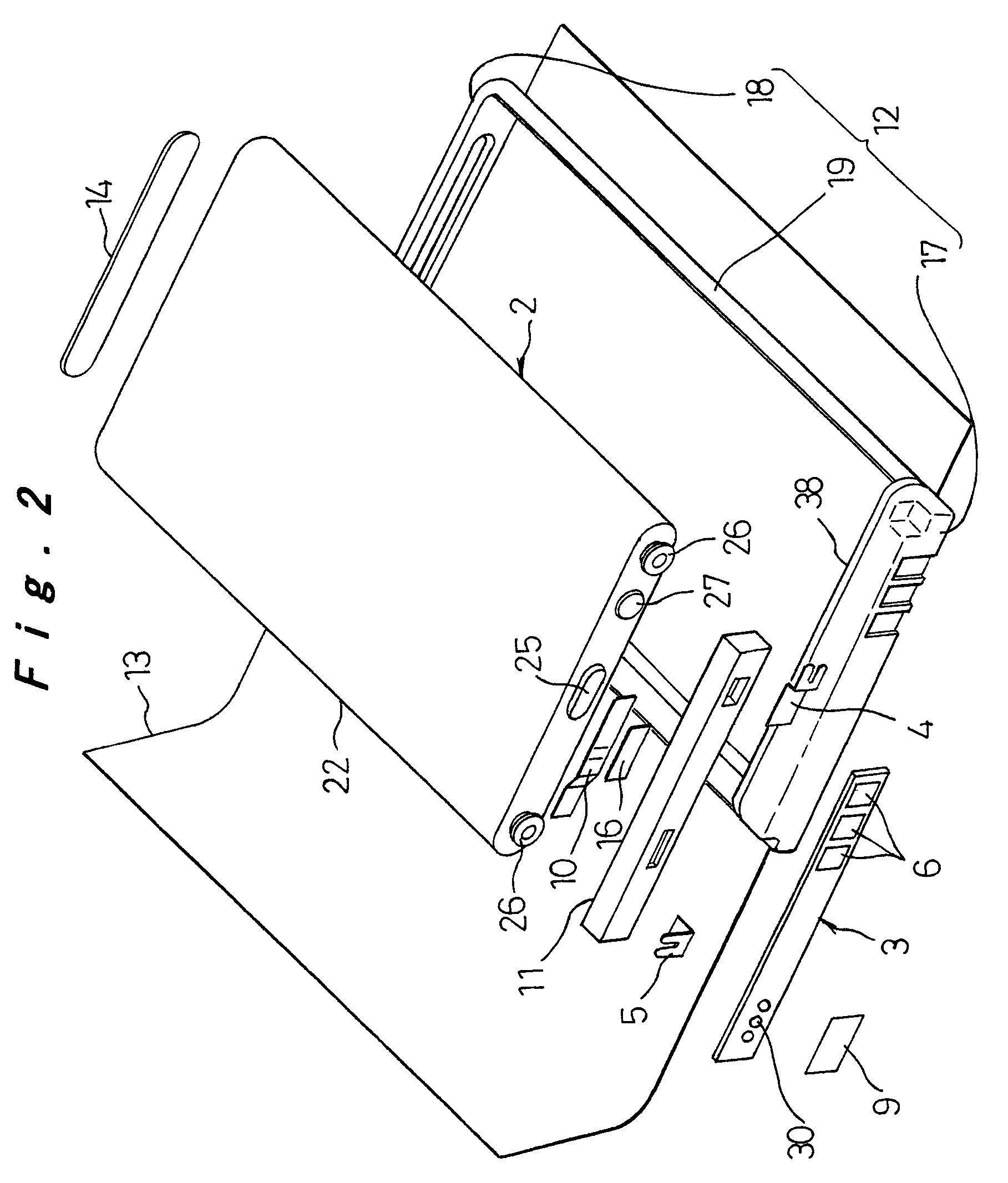

To provide a ceramic heater capable of reducing temperature uniformity at the periphery of through holes such as insertion holes and vacuum suction holes, thereby protecting the wafer against thermal shocks and having improved controllability for temperature control parts such as thermocouples and temperature fuse. Further, a ceramic heater capable of uniform resin curing is provided. A heat generation body 14 is disposed on the surface or inside of the ceramic substrate 12. Further, corners for the insertion holes 16, the recesses 18 and the vacuum suction holes 20 of the ceramic substrate 12 are chamfered.

Owner:IBIDEN CO LTD

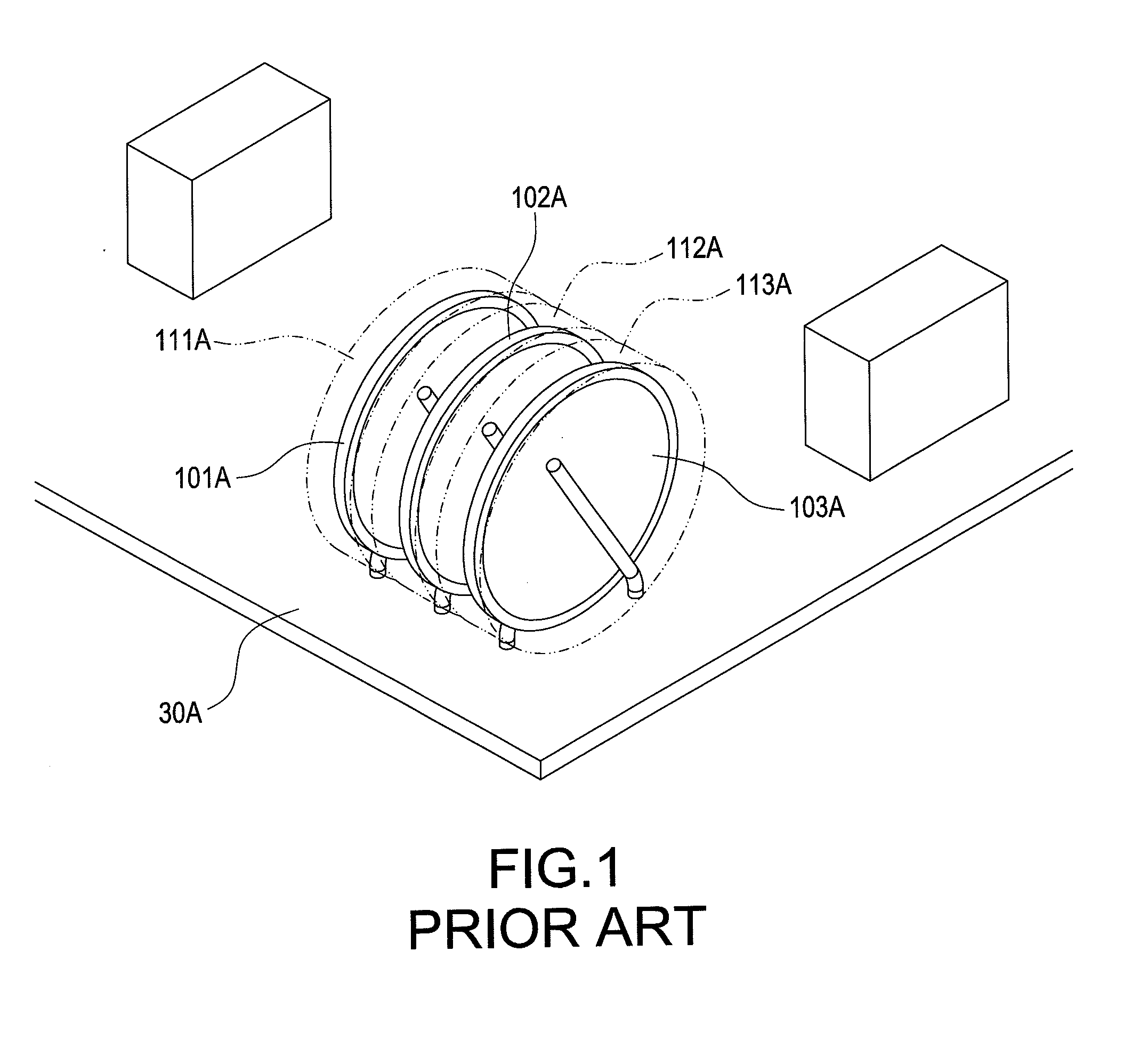

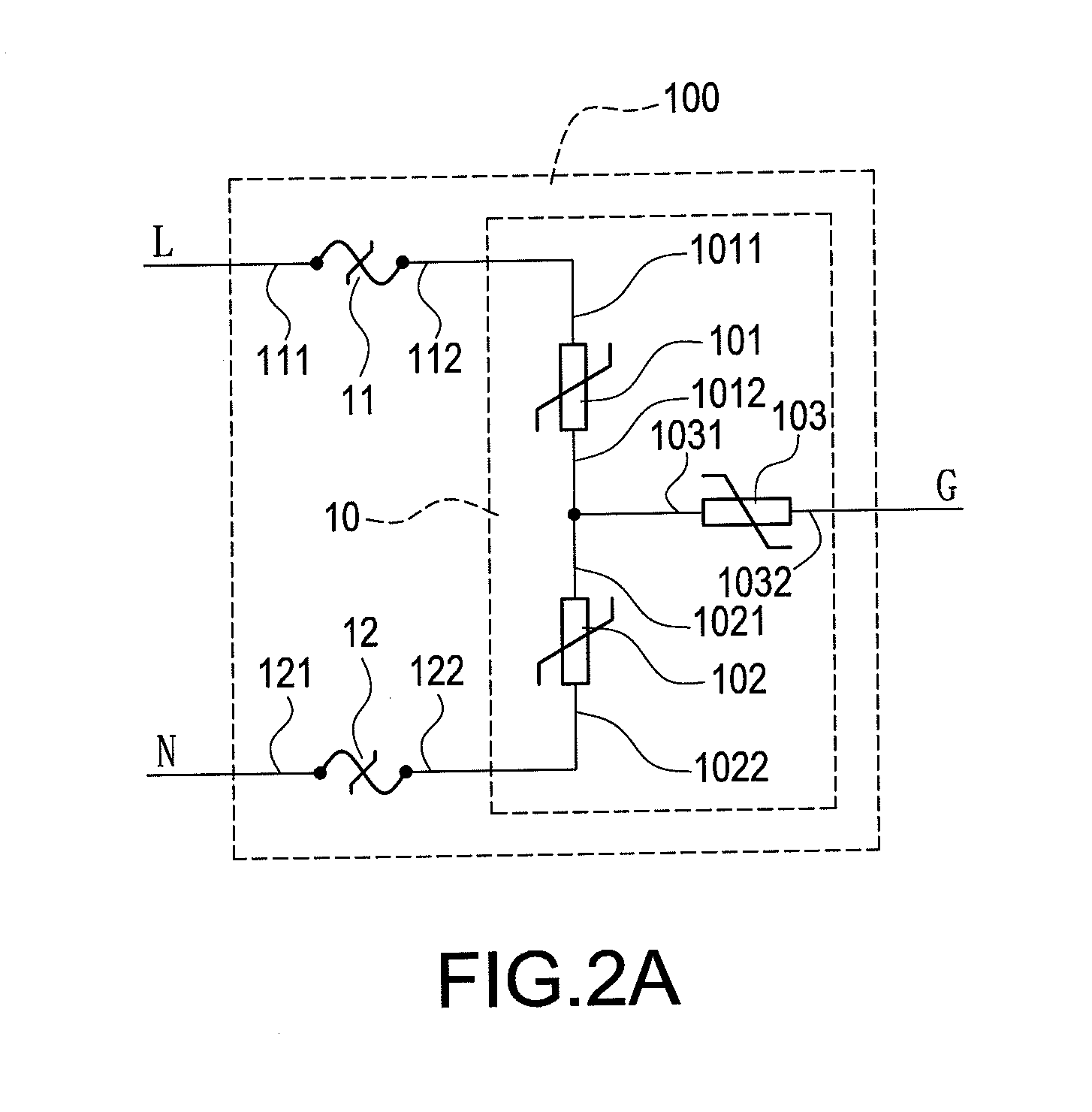

Modular lightning surge protection apparatus

InactiveUS20140092514A1Emergency protective arrangement detailsOvervoltage protection resistorsElectricityElectric power system

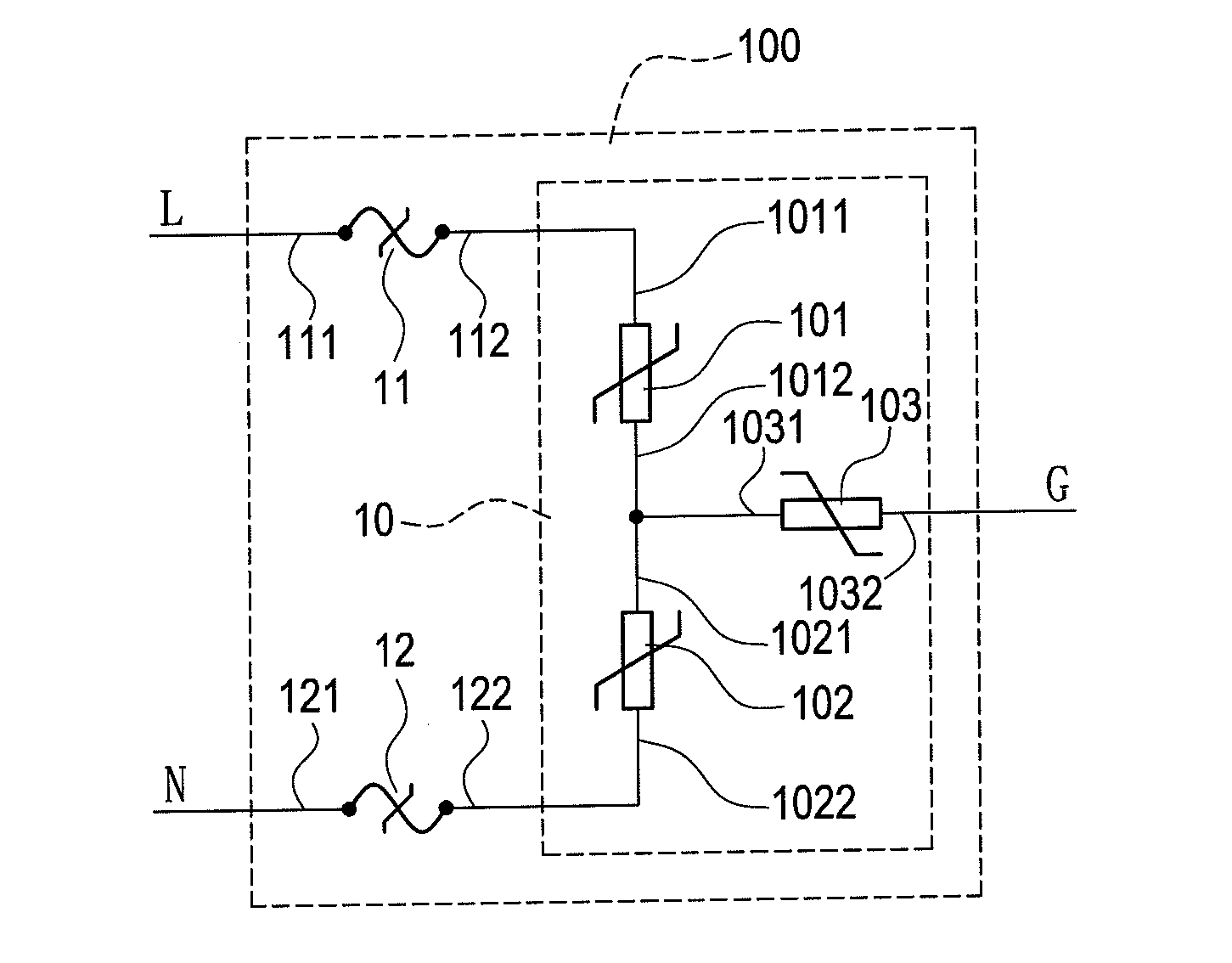

A modular lightning surge protection apparatus is applied to a single-phase three-wire power system with a line, a neutral, and a ground. The modular lightning surge protection apparatus includes a substrate, a surge protection unit, a first temperature fuse, and a second temperature fuse. The surge protection unit has a first surge protection element, a second surge protection element, and a third surge protection element to form a wye connection or a delta connection structure. Furthermore, the surge protection unit, the first temperature fuse, and the second temperature fuse are electrically connected on the substrate to form a small-scale modular circuit integration structure.

Owner:CERAMATE TECH CO LTD

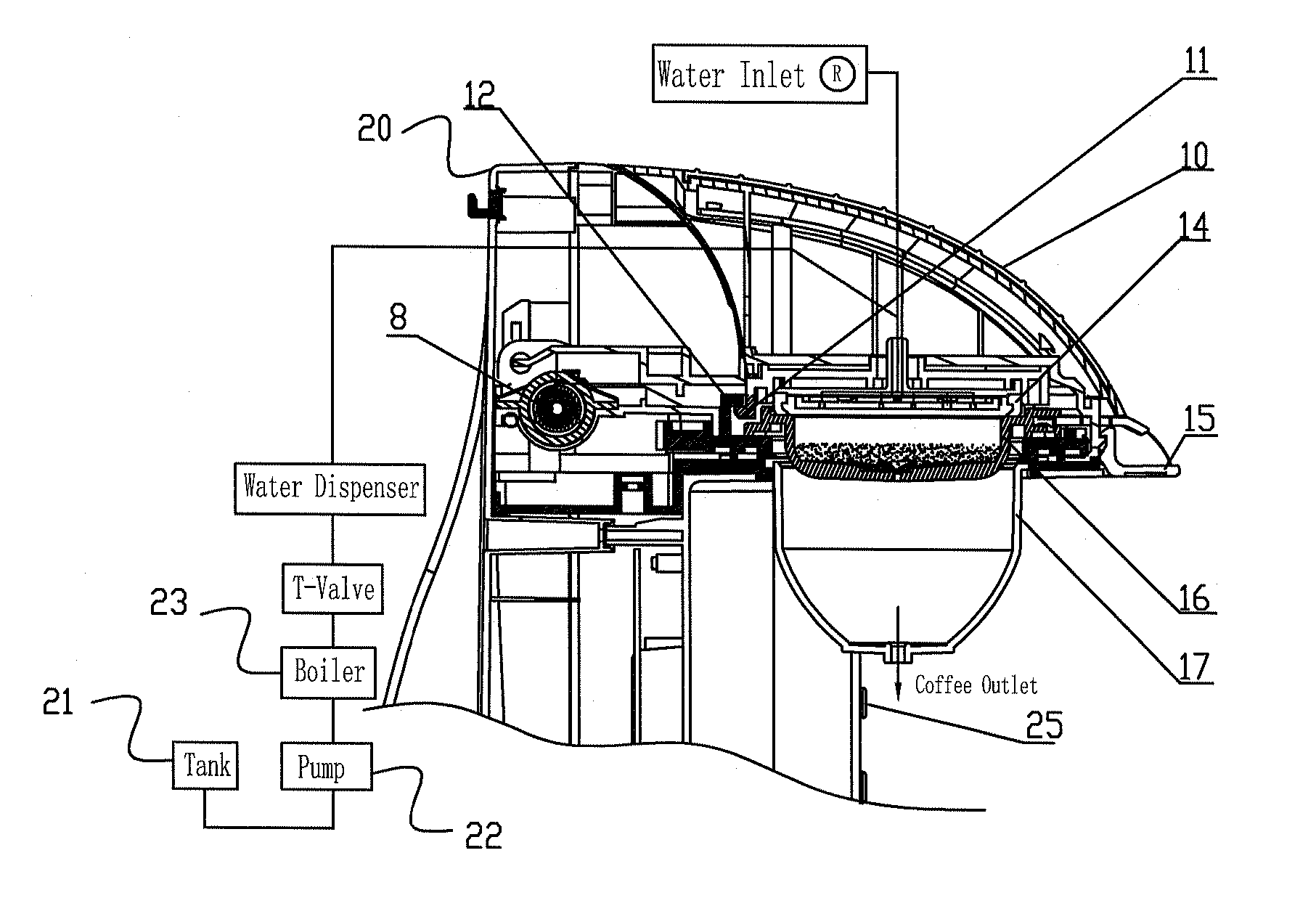

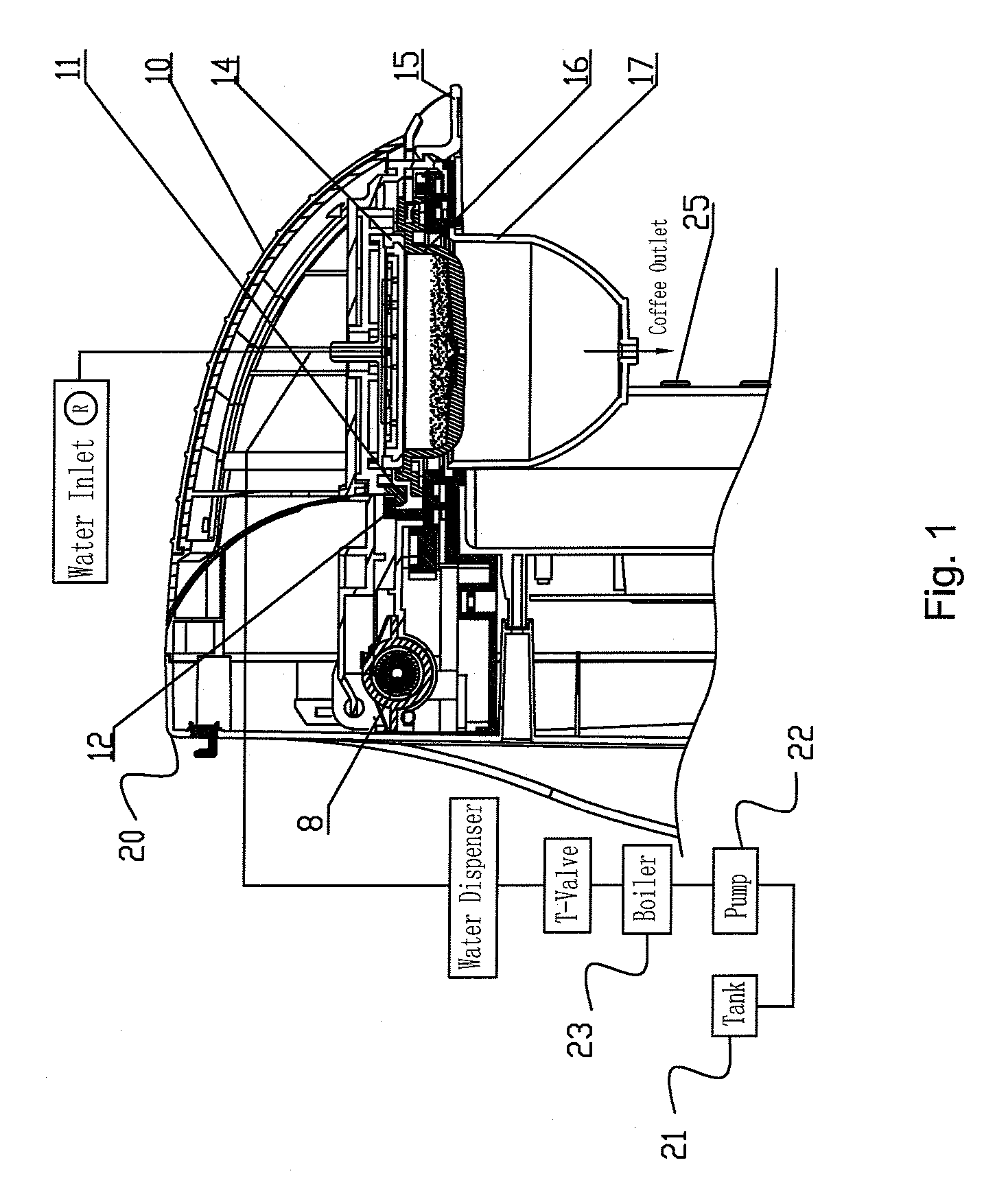

Automatic Coffee Maker And Control Method Thereof

InactiveUS20070044664A1Satisfy safety performance requirementsEasy to failBeverage vesselsWater flowEngineering

The present invention provides an automatic coffee maker, which is compact and safe. In use of the automatic coffee maker, under the control of the control circuit, prior to heating, the pump is started to make certain cold water flow into the boiler, so as to prevent the temperature sensor or temperature fuse from damage by heating. Therefore, the safety performance and the operation performance of the automatic coffee maker of the present invention are greatly improved.

Owner:WANG DONG LEI

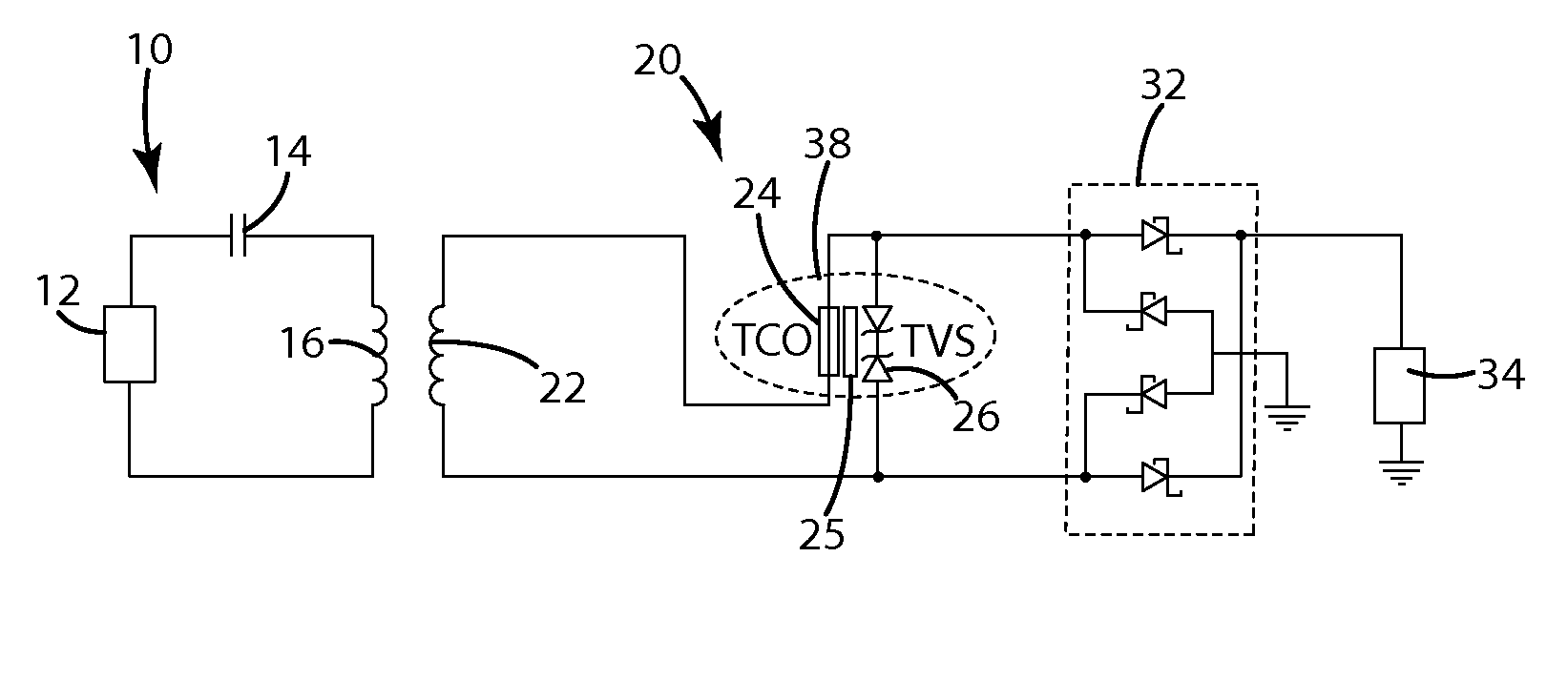

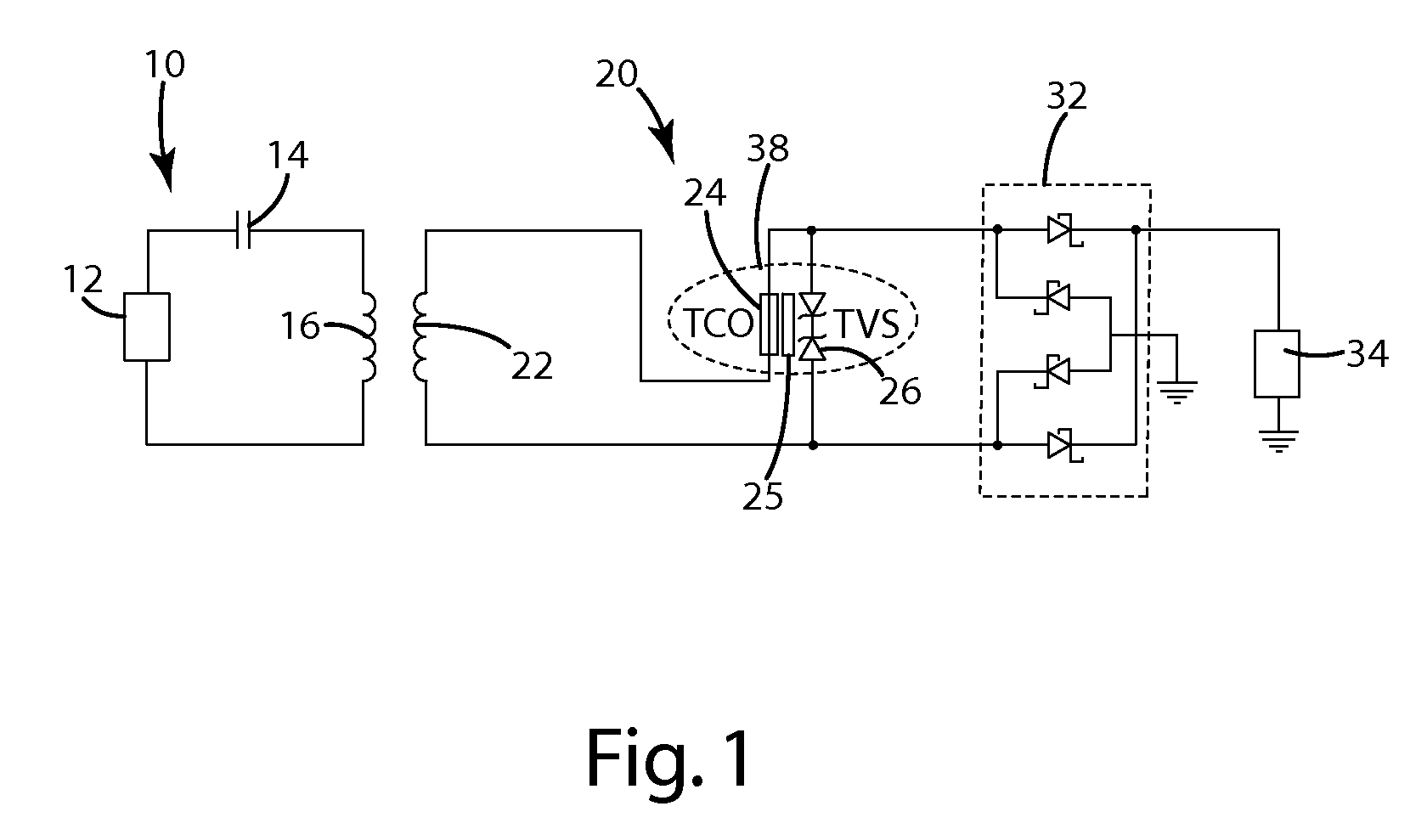

Input protection circuit

ActiveUS8259428B2Sufficient amount of heatAvoid narrow scopeBatteries circuit arrangementsElectric powerOvervoltageVoltage clamp

Owner:PHILIPS IP VENTURES BV

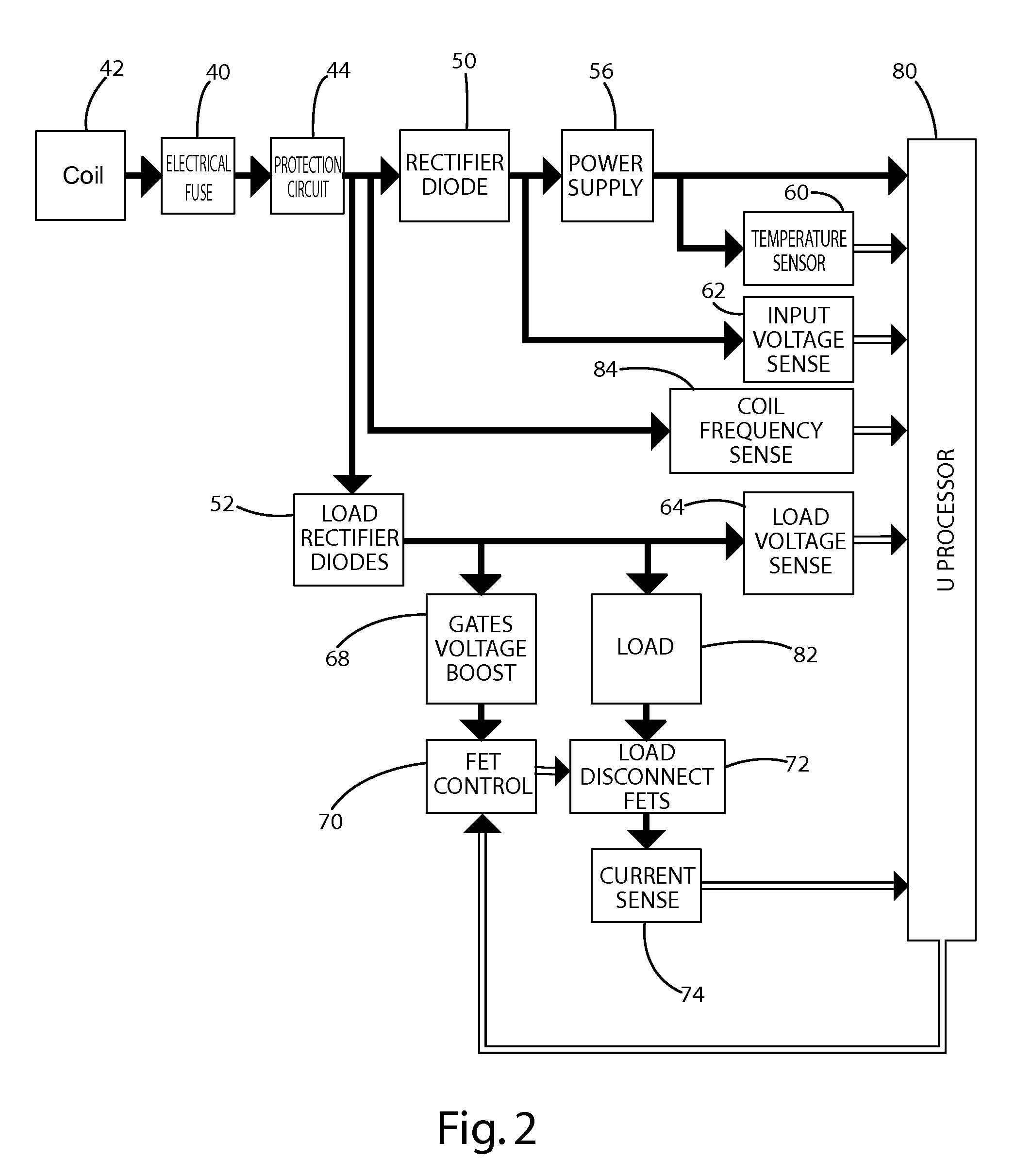

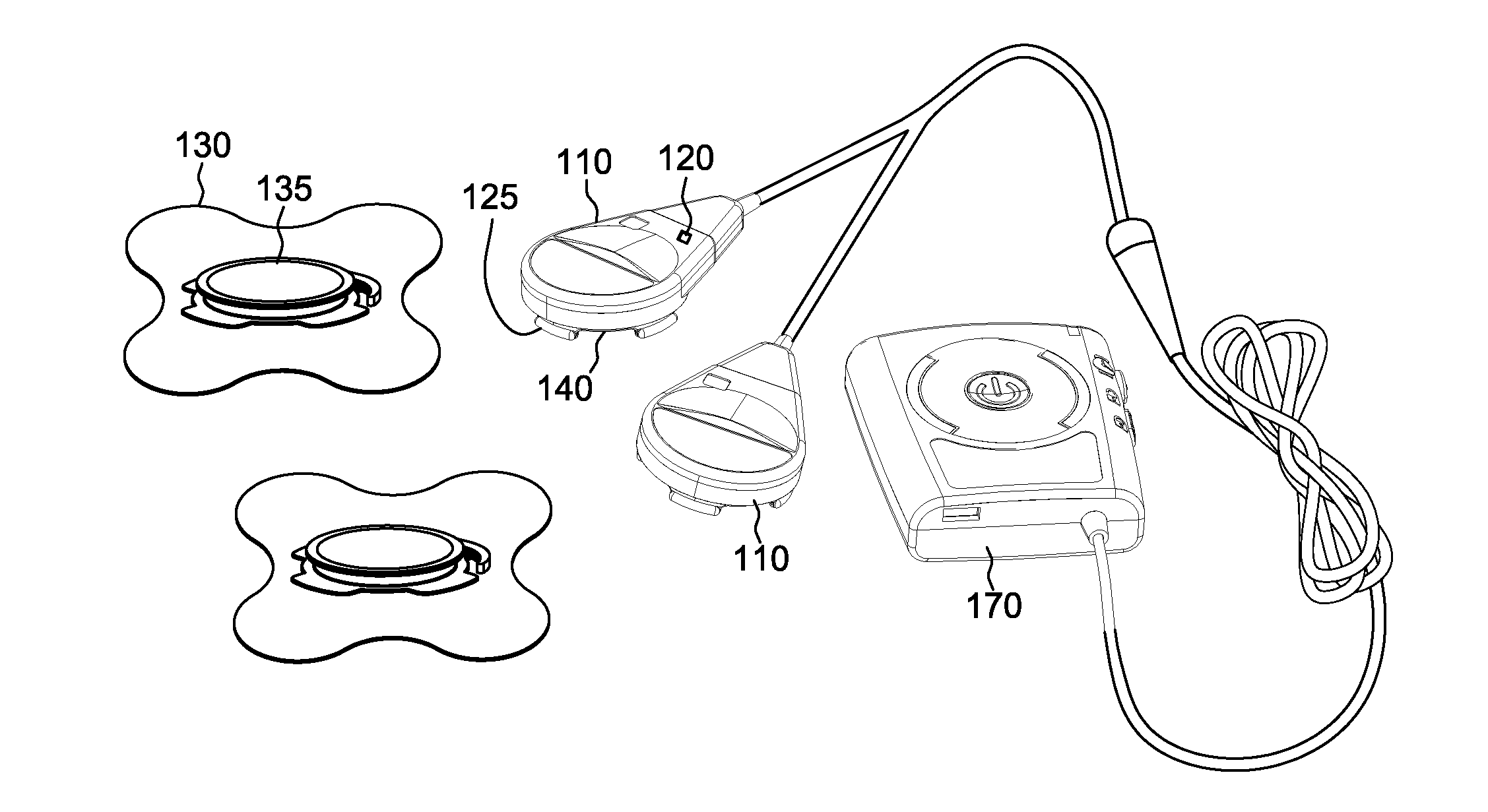

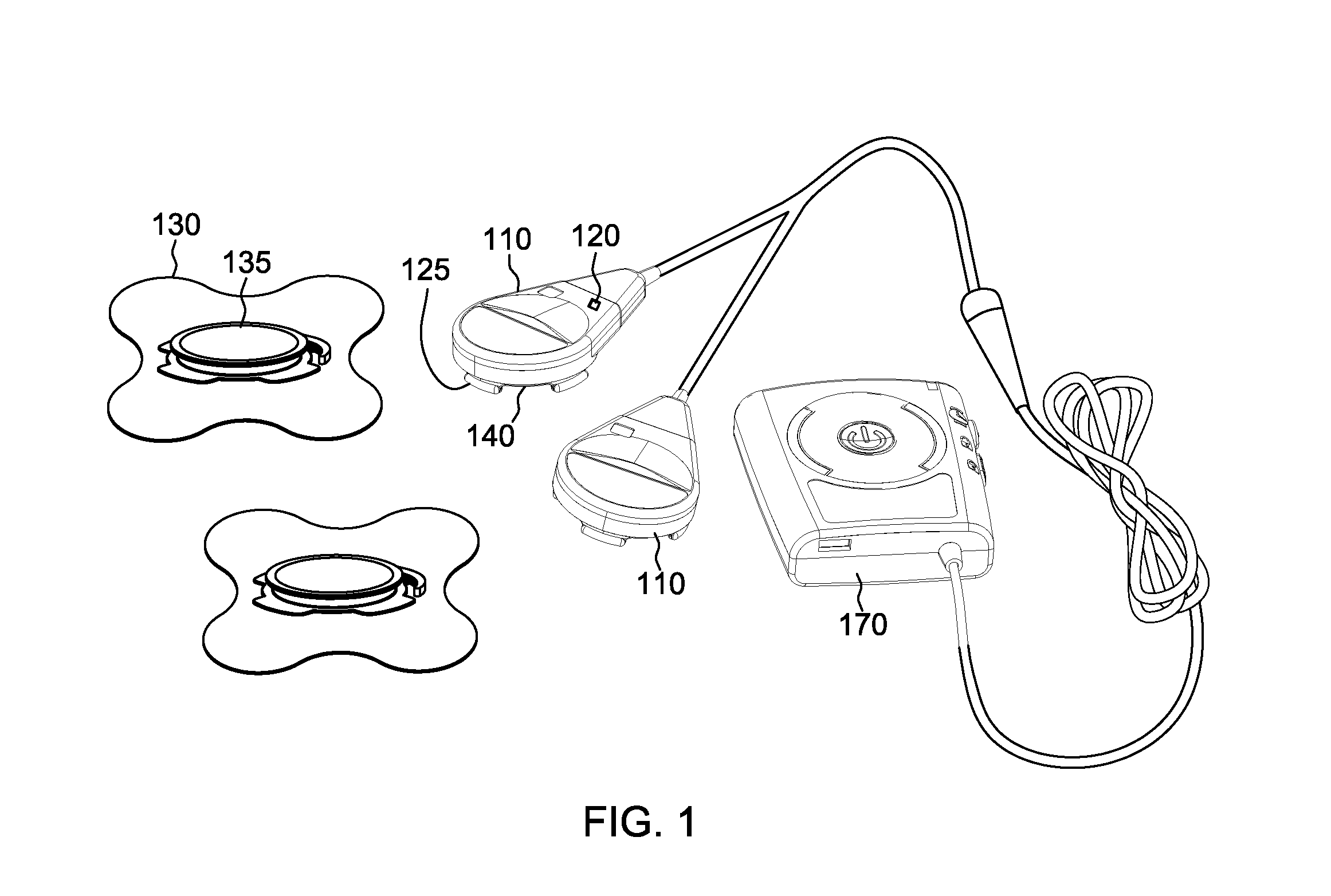

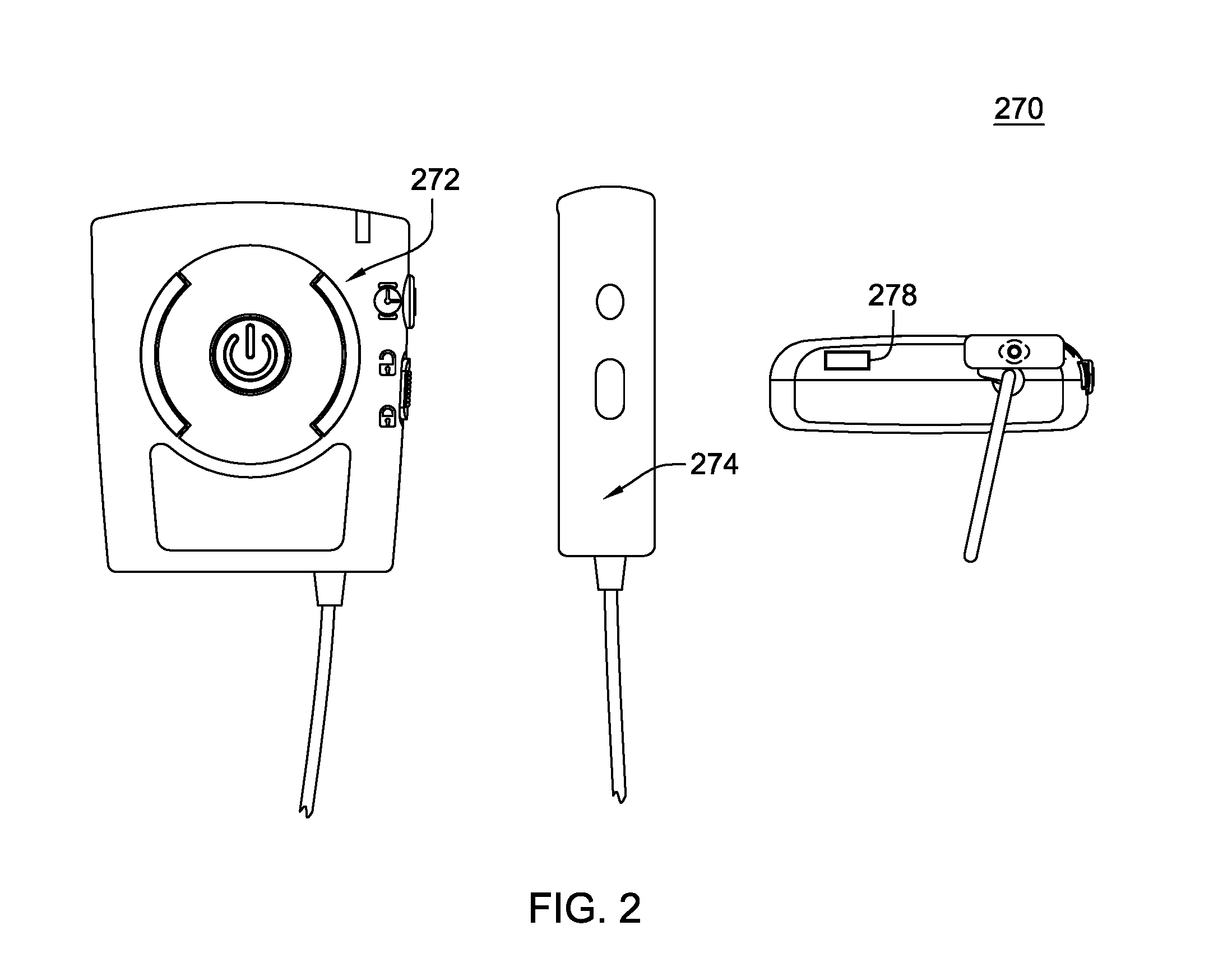

Wearable ultrasound device

A wearable ultrasound device and method of using the device includes a power controller with a power source and at least one integrated circuit that delivers electrical power to an applicator. The applicator is electrically coupled to the power controller and a surface of the applicator transmits ultrasound to a wearer for a given duration. The applicator includes radio frequency (RF) drive electronics, an ultrasound transducer coupled to the drive electronics, a monitoring apparatus that includes a thermal cutoff coupled to the drive electronics, where the monitoring apparatus monitors a temperature of the applicator surface and the thermal cutoff turns off the applicator, if the temperature exceeds a pre-defined threshold, and a coupling bandage coupled to the applicator, where the bandage positions the surface of the applicator proximate to a wearer at a location on the body of a wearer.

Owner:ZETROZ

Protection circuit, battery pack and charging system

ActiveUS20110273137A1Reduce occasionElectric powerCell component detailsElectrical batteryRechargeable cell

A protection circuit having: a connecting terminal for receiving a voltage for charging a rechargeable battery; a switching element interposed between the connecting terminal and the rechargeable battery; a temperature fuse for blocking a conductive path between the connecting terminal and the switching element; a heater for melting the temperature fuse; a voltage detection unit for detecting a voltage relating to the conductive path; a first abnormality detection unit for detecting occurrence of a first abnormality that is pre-set as a recoverable abnormality; a second abnormality detection unit for detecting occurrence of a second abnormality that is pre-set as an abnormality on the basis of which the temperature fuse should be melted; a protection control unit for turning OFF the switching element when the first abnormality is detected by the first abnormality detection unit; and a heater control unit for executing a temperature fuse melting process of applying the voltage of the conductive path to the heater when the second abnormality is detected by the second abnormality detection unit and the voltage detected by the voltage detection unit is not less than a predetermined threshold voltage.

Owner:PANASONIC CORP

Automatic detection equipment

ActiveCN103706578ASave thicknessSave resistor valueSortingElectrical resistance and conductanceAutomatic test equipment

Owner:SUZHOU FANGLIN SCI & TECH

Surge protection device

ActiveUS7242566B2Avoid flowEmergency protective arrangement detailsOvervoltage protection resistorsEngineeringThermal cutoff

A surge suppression circuit with a thermal cutoff includes a first surge suppressor in series with a first thermal cutoff device between a phase conductor and a neutral conductor. A second surge suppressor in series with a second thermal cutoff device is between the phase conductor and a ground conductor. A third surge suppressor is in series with a low temperature thermal cutoff device between the neutral conductor and the ground conductor. The thermal cutoff temperature of the low temperature thermal cutoff device is lower than the thermal cutoff temperature of the first thermal cutoff device.

Owner:LEVITON MFG

Thermal fuse

InactiveUS6838971B2Inspection is accurateEasy to distinguishFuse device manufactureHeating/cooling contact switchesGardner color scaleImaging processing

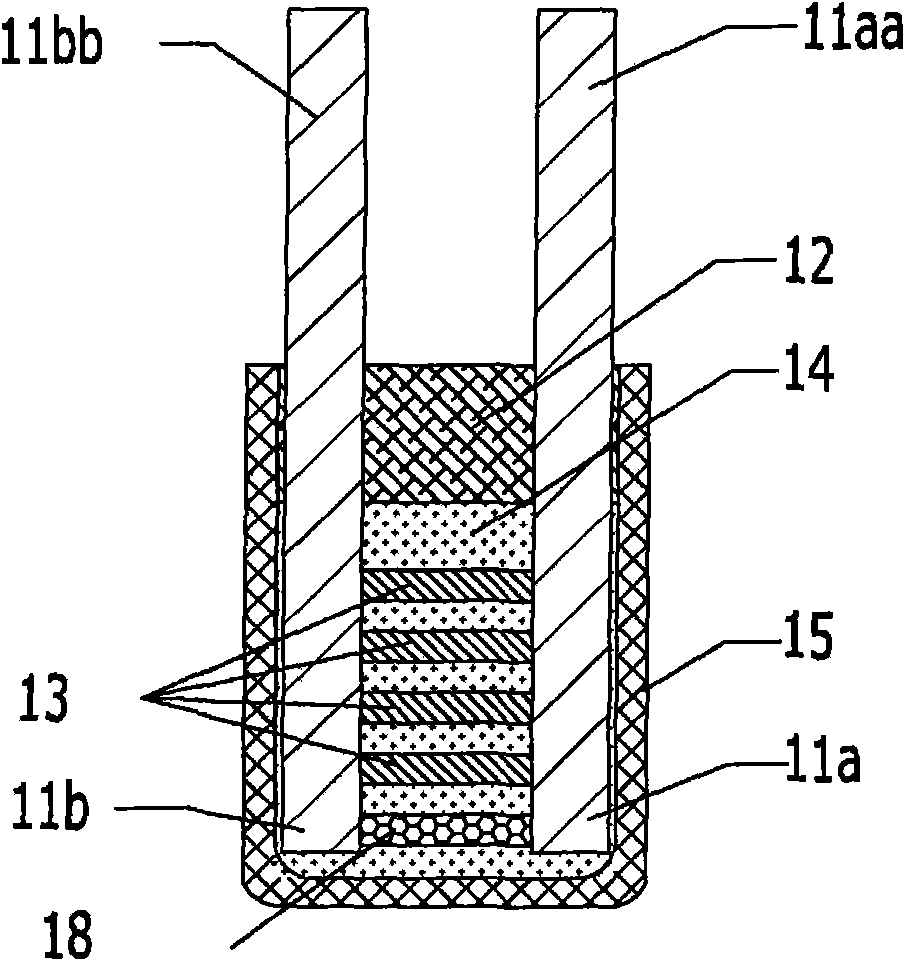

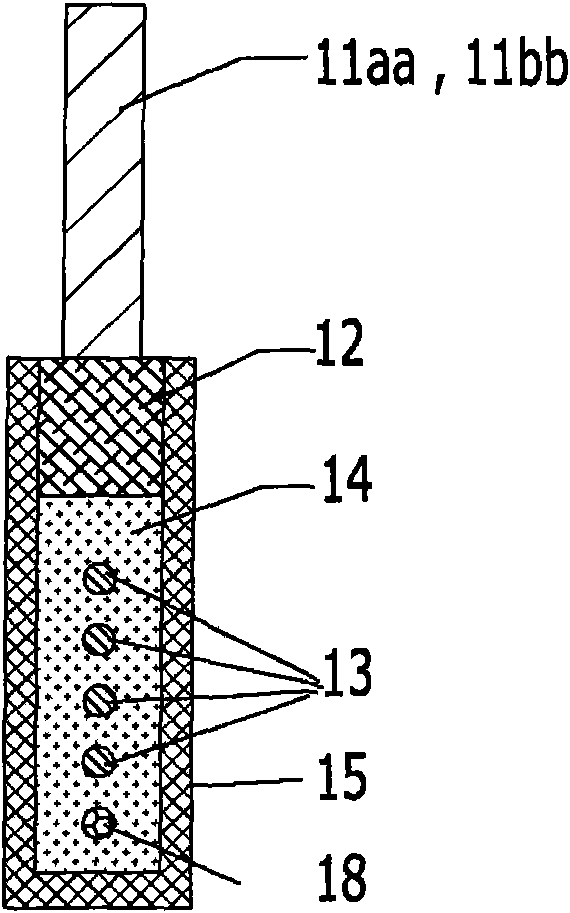

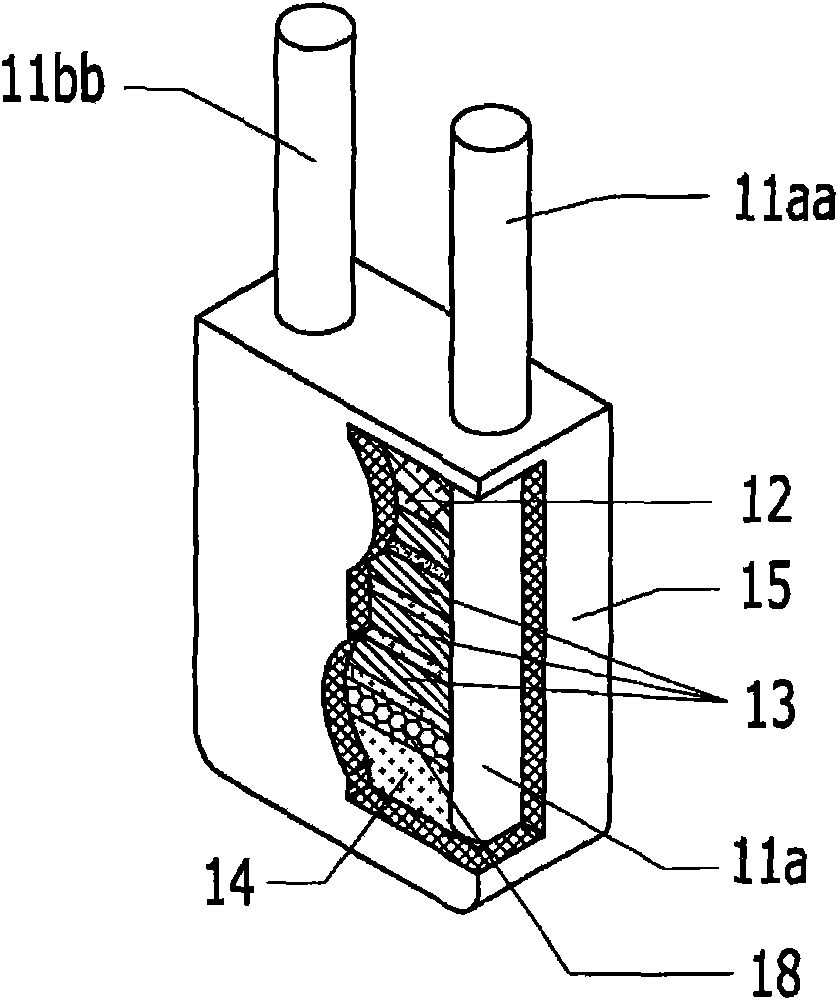

Quantity of flux coated on fusible alloy of a thermal fuse disclosed can be inspected accurately by an image processing method. The thermal fuse comprises:(a) first insulation film 11 coupled with a pair of metal terminals 12; (b) fusible alloy 13 coupled between ends of the metal terminals 12, being placed above first insulation film 11; (c) flux 14 coated on fusible alloy 13; and(d) second insulation film 15 disposed on first insulation film 11 so that an internal space is formed, being placed above fusible alloy 13, wherein at least either of first insulation film 11 or second insulation film 15 is transparent or translucent, and flux 14 has the Gardner color scale from 4 to 16.

Owner:PANASONIC CORP

Method for manufacturing battery pack

InactiveUS7972721B2Work quicklyFacilitate conductionBatteries circuit arrangementsPrimary cell maintainance/servicingElectrical batteryRechargeable cell

Owner:PANASONIC CORP

Temperature Fuse Protection Device

InactiveUS20080117016A1Unstable operationSolution to short lifeFuse device manufactureHeating/cooling contact switchesElectricityHot melt

A temperature fuse protection device uses a hot melt metal to rivet for connecting two terminals in the circuit that are separated for making the two terminals electrically-connected and the circuit complete. There is a spacing in between the two free ends of the two terminals when no external force is being imposed. When an electric overloading or high circuit temperature event occurs, the hot melt metal would be heated to melt and break, which would then make the free ends of the two terminals to be disconnected, and therefore, the circuit will be at “OFF” status.

Owner:YU TSUNG MOU

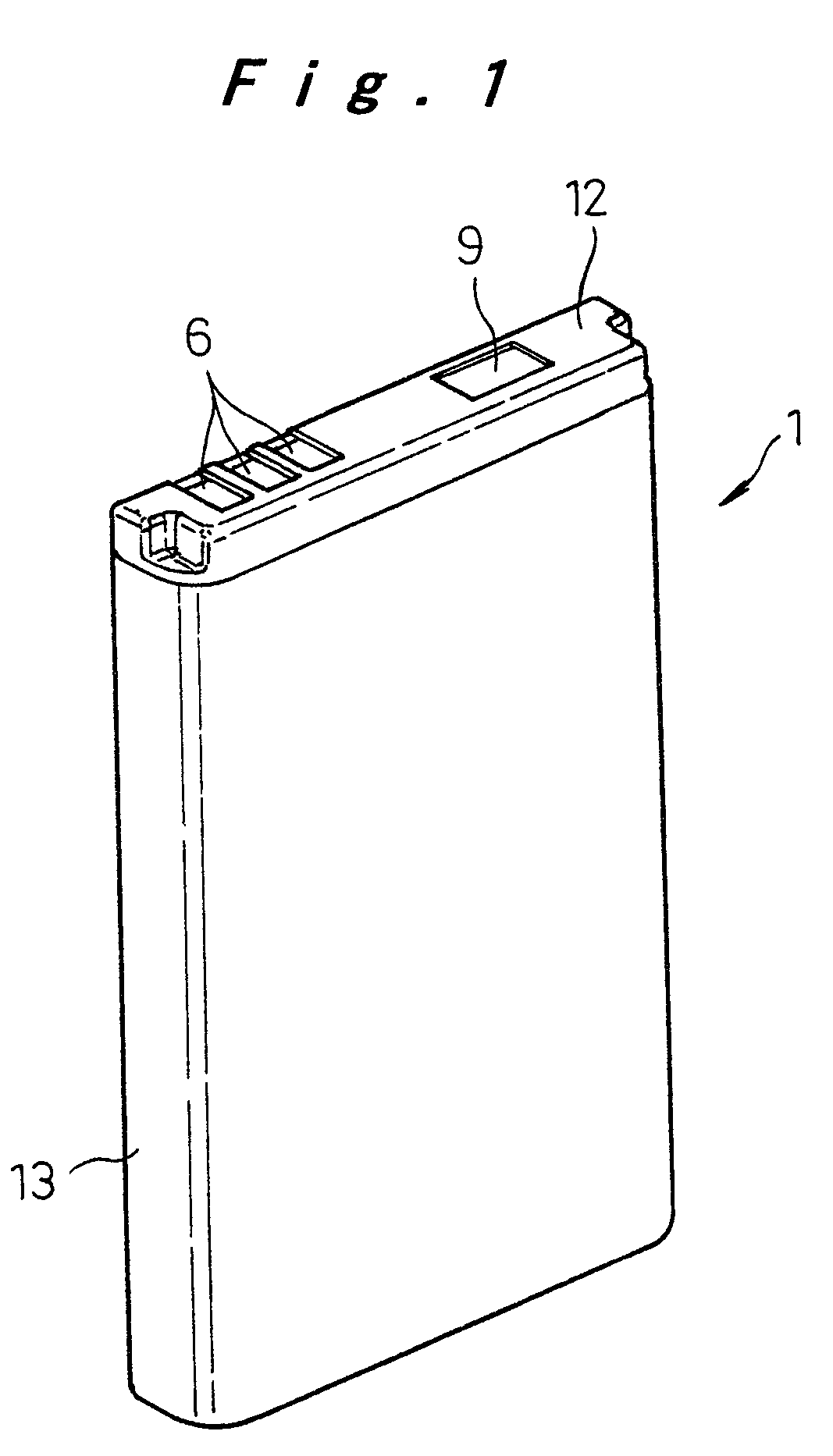

Stacked battery module and battery pack

A stacked battery module or a battery pack is formed by laying a plurality of unit batteries of non-aqueous electrolyte batteries in layers with the surfaces thereof having a large area disposed vis-à-vis and electrically connecting them in series and a temperature fuse is arranged in the central part of the stacked battery module with one of its terminals connected to either the positive electrode terminal or the negative electrode terminal of the stacked battery module while the other terminal connected to a charging terminal for supplying a charging current in a charging operation. One of the terminals of the stacked battery module is connected to a discharging terminal for taking out a discharging current in a discharging operation and the other terminal of the stacked battery module is a common terminal for charging and discharging operations.

Owner:ENVISION AESC ENERGY DEVICES LTD

Alloy type thermal fuse with high ampere capacity

InactiveCN101859665AImprove protectionExcellent protection effect High protection effect High ampacityHeating/cooling contact switchesPower batteryMetal electrodes

The invention relates to an alloy type thermal fuse with high ampere capacity, which can act as a protective action to devices, such as a power accumulator and the like, with the properties of large current. When the devices, such as a power battery and the like, are in an abnormal temperature rise state, the alloy type thermal fuse can be automatically switched off so as to prevent the occurrence of the accidents of explosion or fire and the like of the devices, such as the power accumulator and the like, because of overtemperature. Because the alloy type thermal fuse and the devices with the properties of the large current run in series, the alloy type thermal fuse must bear large current. In order to solve this problem, a plurality of alloy wires with low melting point (containing two alloy wires with low melting point) are welded between two metal electrodes with favorable weldability in parallel, and the periphery of each alloy wire with low melting point is also provided with a fusing assistant material, so that the condition that each alloy wire with low melting point is quickly and completely retracted to the electrodes can be promoted after each alloy wire with low melting point is heated and fused, thereby switching off the large current safely.

Owner:XIAMEN SET ELECTRONICS

Fixing unit and image-forming device using the same

Owner:BROTHER KOGYO KK

Low-melting point alloy wire and temperature fuse adopting the same

ActiveCN101197230APhase transition eliminationEliminate Fuse Temperature UncertaintyEmergency protective devicesAlcoholAlloy

The invention relates to a low molten point alloy wire and a temperature fuse using the alloy wire, wherein the temperature fuse comprises two electrode sheets (1), an insulation bottom film (21) and an insulation upper film (22), a flux (3) and a low motel point allow wire (4). Two electrode sheets (1) are positioned on the insulation bottom film (21). Two ends of the low motel point alloy wire (4) are respectively connected with two electrode sheets (1). The molten flux (3) is coated on the low motel point alloy wire (4) and is coated with the insulation upper film (22). The mass percentages of the low motel point alloy wire (4) include: 50 percent to 56 percent In, 30 percent to 38 percent Sn, 6 percent to 15 percent Bi and a small quantity of Ag, Cu, and Zn. The flux (3) is constituted by rosin, stearine acid, liquid alcohol and small molecule acid. The temperature fuse of the invention can work for longer time on 8A current, thereby improving the blow-out temperature accuracy of the temperature fuse at the same time.

Owner:BYD CO LTD

Temperature fuse element, temperature fuse and battery using the same

InactiveUS20070024407A1Damage suppressionPrimary cell maintainance/servicingHeating/cooling contact switchesAlloyMaterials science

A thermal fuse comprises: a first insulating film to which a pair of metal terminals are attached; a fusible alloy located above the first insulating film and connected between the leading end portions of the pair of metal terminals; and a second insulating film located above the fusible alloy and attached to the first insulating film so as to define a space with the first insulating film. The fusible alloy includes an Sn—Bi—In—Zn alloy containing 0.5 to 15 weight % of Bi, 45 to 55 weight % of In and 0.5 to 5 weight % of Zn with the balance being Sn.

Owner:PANASONIC CORP

Temperature fuse protection device

InactiveUS7639114B2Solution to short lifeUnstable operationFuse device manufactureHeating/cooling contact switchesElectricityEngineering

Owner:YU TSUNG MOU

Inputting overvoltage protection circuit and electric device with the protection circuit

InactiveCN1479424AApparatus with intermediate ac conversionArrangements responsive to excess currentThermal cutoffSemiconductor

To surely cut off a circuit without relying on the performance or reliability of an overvoltage protection element if an input overvoltage is generated in a power supply line. An inrush current prevention circuit 25 is interposed in at least one of AC line L1 and L2, and a detection circuit 24 detects voltages of the AC lines L1 and L2. If a detected voltage exceeds a prescribed value, a switch circuit 26 is turned on to transmit the excess to the inrush current prevention circuit 25 by a phototriac coupler 41 of a transmission circuit 27. In the inrush current prevention circuit 25, a resistor 43 with a temperature fuse and a triac 42 which is a semiconductor switch element are connected in parallel. The triac 42 is normally conductive, and when information that the switch circuit 26 is turned on is transmitted by the transmission circuit 27, it is opened. It makes a current to flow the resistor 43 with temperature fuse, and a power feeding circuit is disconnected when the temperature fuse is blown off.

Owner:TOHOKU RICOH CO LTD

Piezoresistance with alloy type temperature fuse

ActiveCN1925072AEasy to installFast thermal responseVaristor coresOvervoltage protection resistorsElectrical resistance and conductanceSafety wire

This invention relates to alloy temperature safety wire pressure sensitive resistance suitable for zin oxidation pressure sensitive resistance for over voltage protection. This invention comprise pressure sensitive resistance, which locates the resistance and safety wire into one compact chamber with near surface and with leg extending outside chamber with alloy melt agent. This invention locates one resistance and alloy temperature wire into compact chamber with legs extending outside and wire is set into other chamber with alloy assistant agent.

Owner:XIAMEN SET ELECTRONICS

Protection circuit, battery pack and charging system

ActiveUS8890483B2Reduce occasionElectric powerCell component detailsAnomaly detectionElectrical battery

Owner:PANASONIC CORP

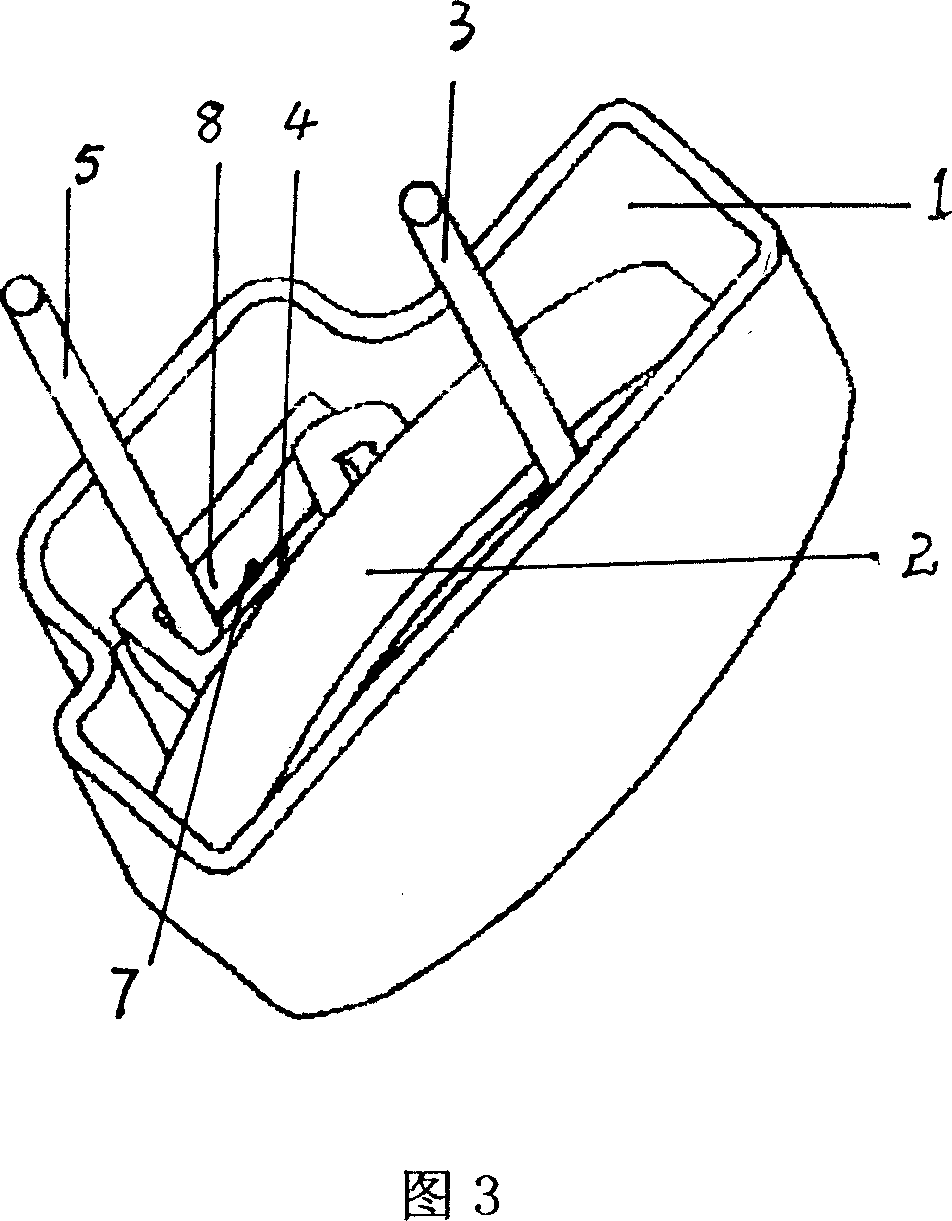

Element for thermal fuse, thermal fuse and battery including the same

InactiveUS20050083166A1Primary cell maintainance/servicingHeating/cooling contact switchesIndiumAlloy

A thermal fuse includes a first insulation film having a pair of metal terminals mounted thereto, a fusible alloy located over the first insulation film and connected between respective ends of the metal terminals, a second insulation film provided over the fusible alloy and bonded to the first insulation film as to provide a space between the first and second insulation films. The fusible alloy includes an Sn—Bi—In alloy containing 20 to 39.5 wt. % of tin, 11.5 to 31 wt. % of bismuth, and 49 to 68.5 wt. % of indium. The fusible alloy does not release lead or cadmium even after being disposed of since it contains no lead and no cadmium.

Owner:PANASONIC CORP

Fusible alloy and thermal fuse

InactiveUS20050007234A1Accurate separationHeating/cooling contact switchesEmergency protective devicesAlloyOperating temperature

The thermal fuse of the present invention contains a fuse element 1 that is formed of a fusible alloy having a composition of 43.5-50 wt % Sn, 0.1-5 wt % In, and balance being Bi and inevitable impurities, or a fusible alloy having a composition of 5-33 wt % In, 4.7-15.5 wt % Zn, and balance being Sn and inevitable impurities; a pair of electric terminals 2, 3 connected to the fuse element; and case 8 for accommodating at least the fuse element 1. The opening end of case 8 has a predetermined shape. By employing the structure above, a thermal fuse having an operating temperature as high as 130-190° C. can be easily obtained.

Owner:PANASONIC CORP

Lead-free low-temperature alloy for making fuse core of thermal fuse and preparation method thereof

The invention relates to a lead-free low-temperature alloy used for making a fuse core of a thermal fuse. Its raw material composition and its weight percentage range are respectively: Bi: 34%-36%; Zn: 3.5%-4.5%; Sn: balance The preparation method has the following steps: put metal tin into a stainless steel crucible, heat it in an electric furnace, after the tin is melted, add metal zinc at 250-280°C, and after melting, then add metal bismuth to melt After cleaning, conventional degassing and slag removal are performed by adding a degassing agent, and cast into a low-temperature alloy rod of the required size. The lead-free low-temperature alloy containing Sn, Bi and Zn involved in the present invention is used for making the fuse core of the thermal fuse, and the melting point is 132±2° C. It has low characteristics and is a lead-free environmental protection material, which itself has good social and economic benefits.

Owner:TIANJIN BAIRUIJIE WELDING MATERIAL

Thermal fuse

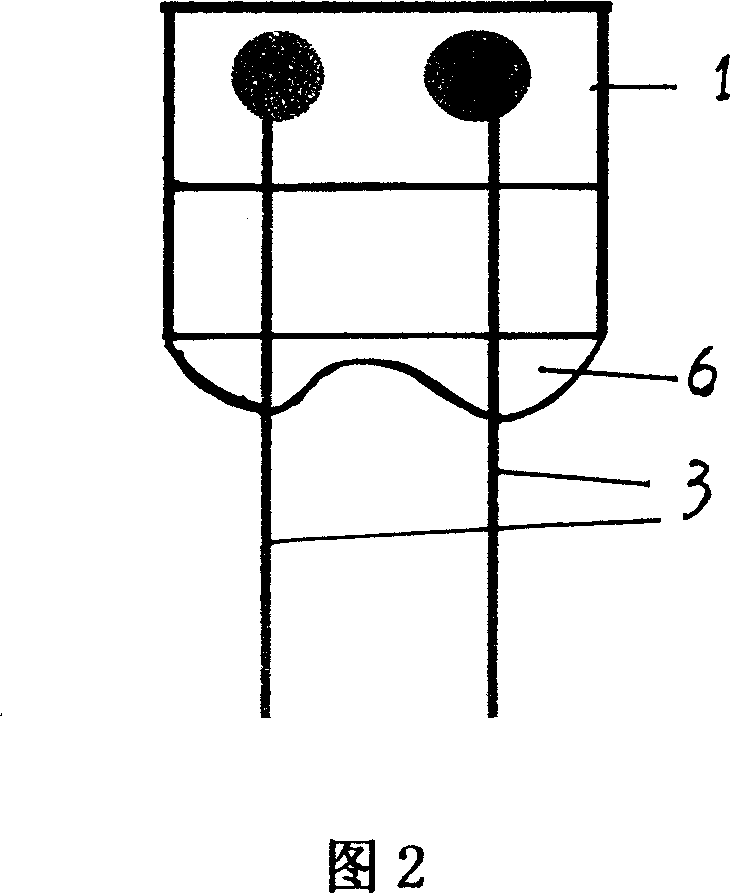

InactiveUS20110181385A1Reliable triggerRisk minimizationHeating/cooling contact switchesEmergency protective devicesEngineeringElectrical and Electronics engineering

The invention relates to a thermal fuse (1) for interrupting a power flow in modules, particularly for use in the automotive field, comprising: - a connecting element having a connecting region, - a fusible element (3) composed of fusible material and attached with one end to the connecting region (2) in order to establish an electrically conductive connection between the fusible element (3) and the connecting element (2), the connecting element (2) comprising an expansion region for accommodating melted fusible material, characterized in that the expansion region has an expansion surface (6) on which part of or all of the melted fusible material spreads as the fusible element melts, the expansion surface (6) having no positive curvature.

Owner:ROBERT BOSCH GMBH

Fusing agent and temperature fuse containing the same

ActiveCN101197224AEliminate corrosionGuaranteed stabilityHeating/cooling contact switchesEmergency protective devicesAlcoholAlloy

The invention relates to a flux and a temperature fuse with the flux, wherein the flux is formed by mixing common rosin, stearic acid, liquid alcohol and minim small molecule acid in the following mixing ratio (weight percent): 50 percent to 70 percent rosin, 5 percent to 20 percent stearic acid, 10 percent to 40 percent liquid alcohol and 0.5 percent to 16 percent small molecule acid. The temperature fuse element comprises an electrode slice (1), an insulation bottom film (21) and insulation upper film (22), the flux (3) and a lower melting point alloy wire (4). Compared with the prior flux, the flux of the invention obviously improves the thermal-link performance and does not decompose during storage, and well maintain the activity of the flux. The thermal-link performance of the temperature fuse element used by lithium ion cell produced by the invention is obviously improved, thus forming better protection for lithium cell.

Owner:BYD CO LTD

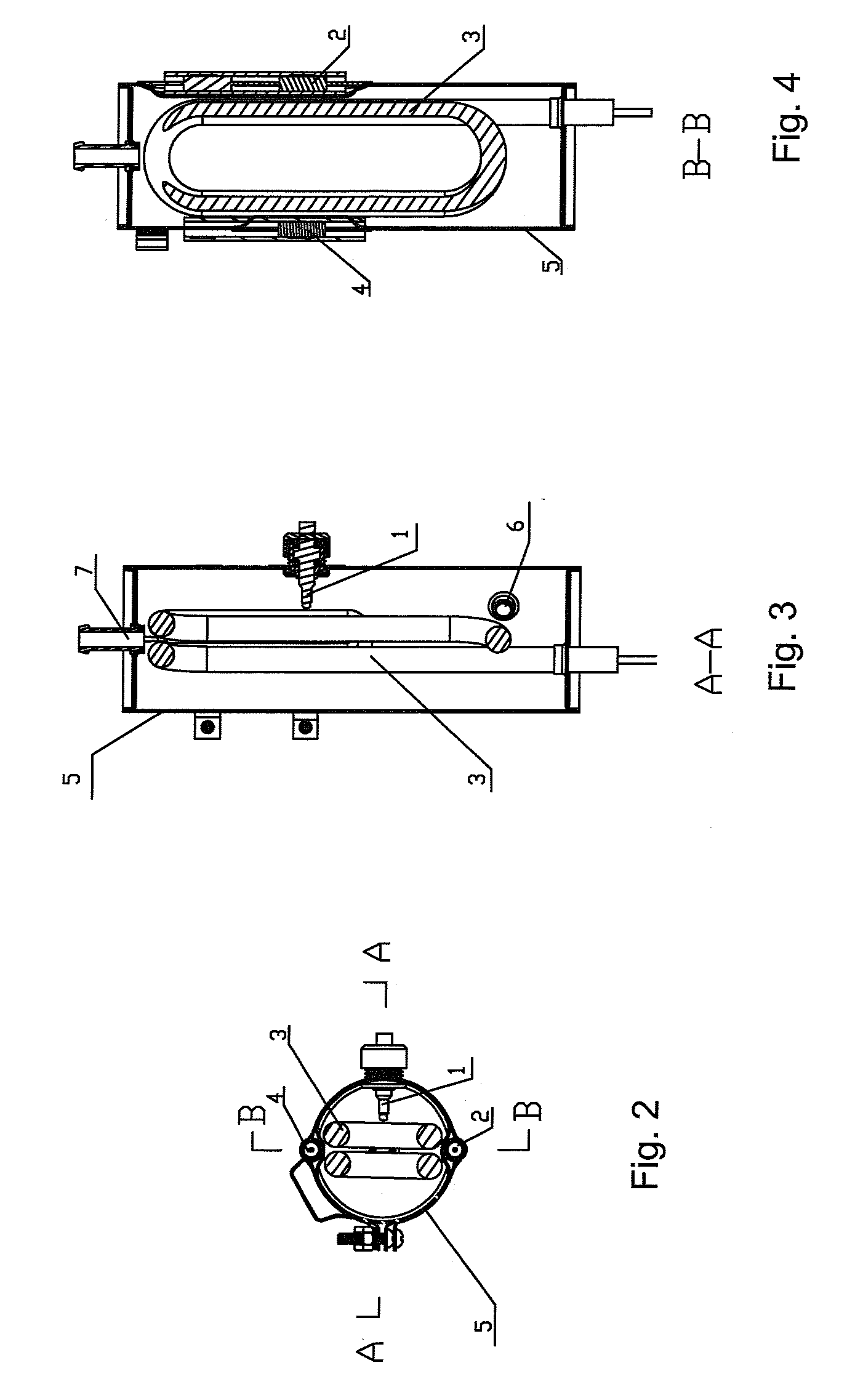

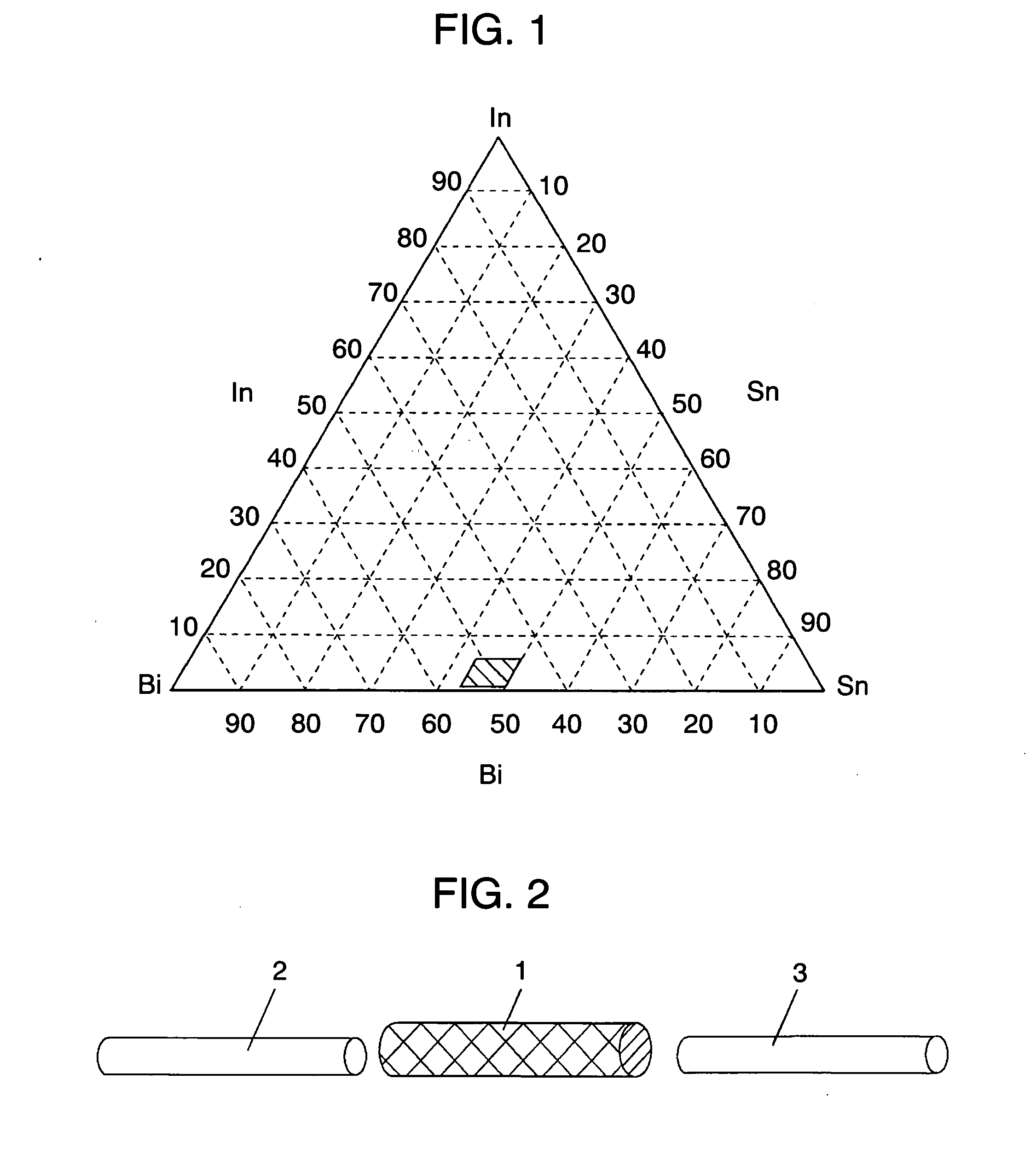

Coupling structure of steam generator in washing device

ActiveUS20090151400A1Avoid fire riskAvoid overall overheatingSteam generation heating methodsTextile treatment machine partsCouplingEngineering

A steam generator for a laundry machine is disclosed, in which the power supplied to a heater is cut off before a water level of water used to generate steam is lower than an end of the heater, thereby avoiding a risk of fire. The steam generator includes a case coupled with the main body of the laundry machine. A heater is provided inside the case. A temperature fuse is provided inside the case when a coupling portion couples the case with the main body of the temperature fuse is configured to be higher than the heater based on a horizontal line.

Owner:LG ELECTRONICS INC

High temperature thermal cutoff device

InactiveCN101685733AFuse device manufactureEmergency casingsSimple Organic CompoundsThermal perception

The present disclosure provides high temperature thermal cutoff devices having a high-temperature thermal pellet with a transition temperature of greater than or equal to about 240 DEG C and comprising at least one organic compound. The pellet is disposed in a housing, which is sealed with a high-temperature seal that provides substantial sealing up to at least the transition temperature. The high-temperature TCO also has a current interruption assembly, which establishes electrical continuity in a first operating condition corresponding to an operating temperature of less than said transitiontemperature and discontinues electrical continuity when the operating temperature exceeds the transition temperature. Methods of making such high-temperature thermal cut off devices are also provided.

Owner:THERM O DISC

Fail-safe insufflators

ActiveUS20140180198A1Avoid overall overheatingSurgical needlesMedical devicesTemperature controlControl system

A fail-safe insufflation device having a thermal cutoff for interrupting power to an electrical heater to prevent overheating of insufflation gas wherein the thermal cutoff operates independent of a temperature control system to provide electrical shutdown of an electrical heater in response to a hostile temperature condition of the insufflation gas or a hostile temperature condition proximate the electrical heater.

Owner:LEXION MEDICAL LLC

Ceramic heater

InactiveUS20030136776A1Improve unevennessSemiconductor/solid-state device manufacturingHot plates heating arrangementsTemperature controlThermocouple

Owner:IBIDEN CO LTD

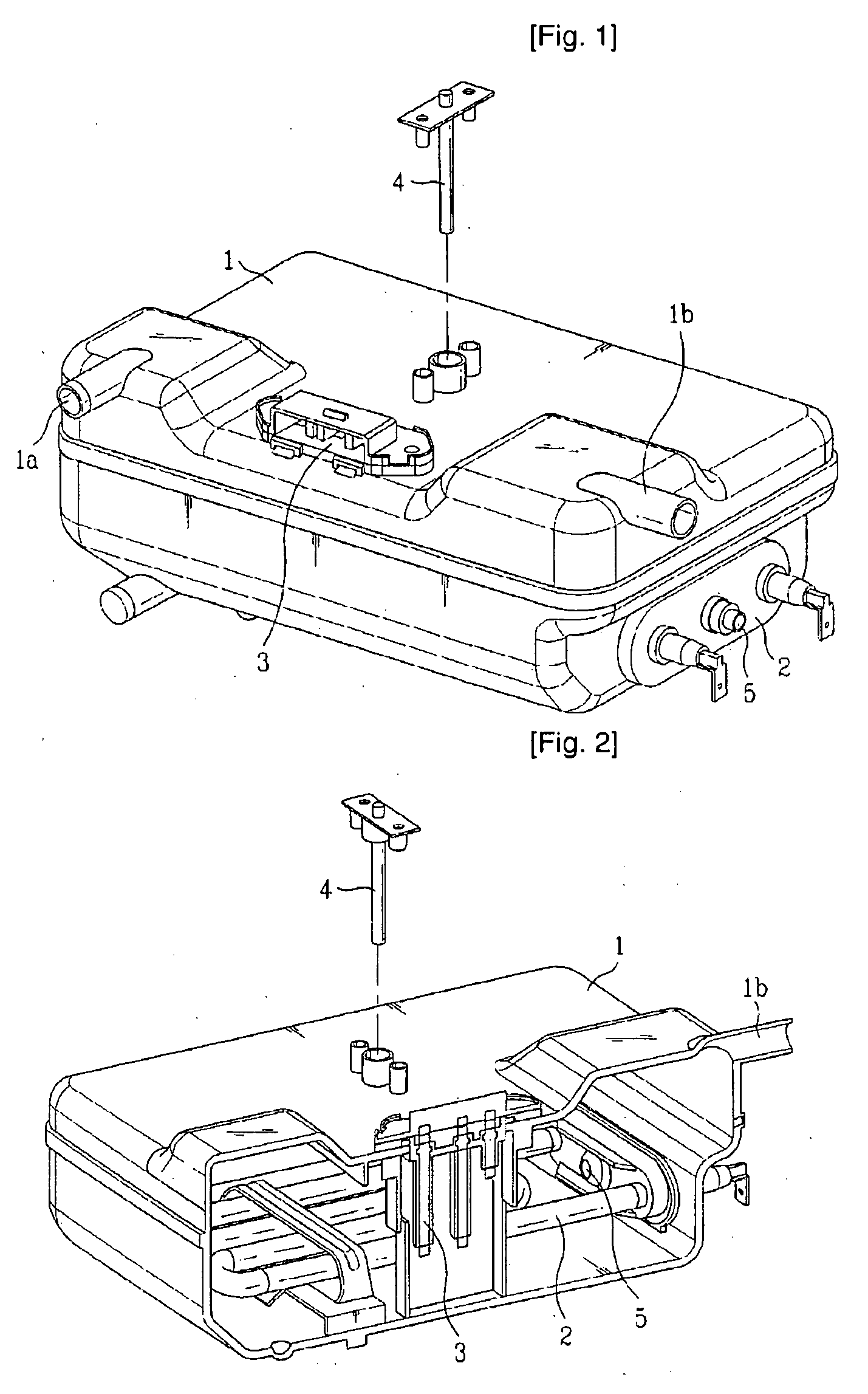

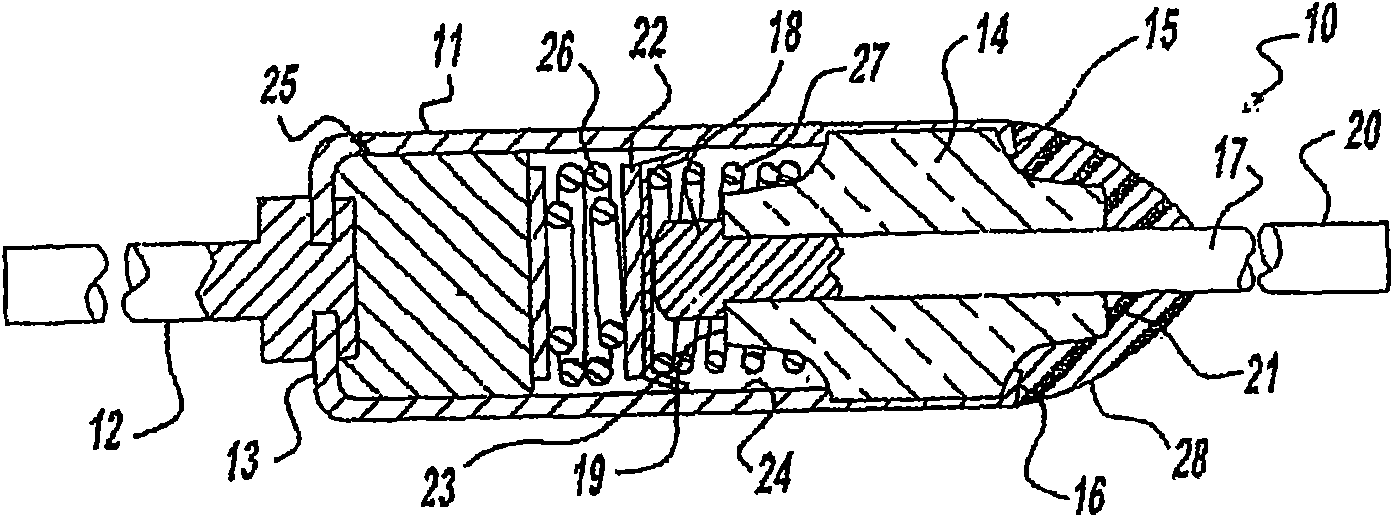

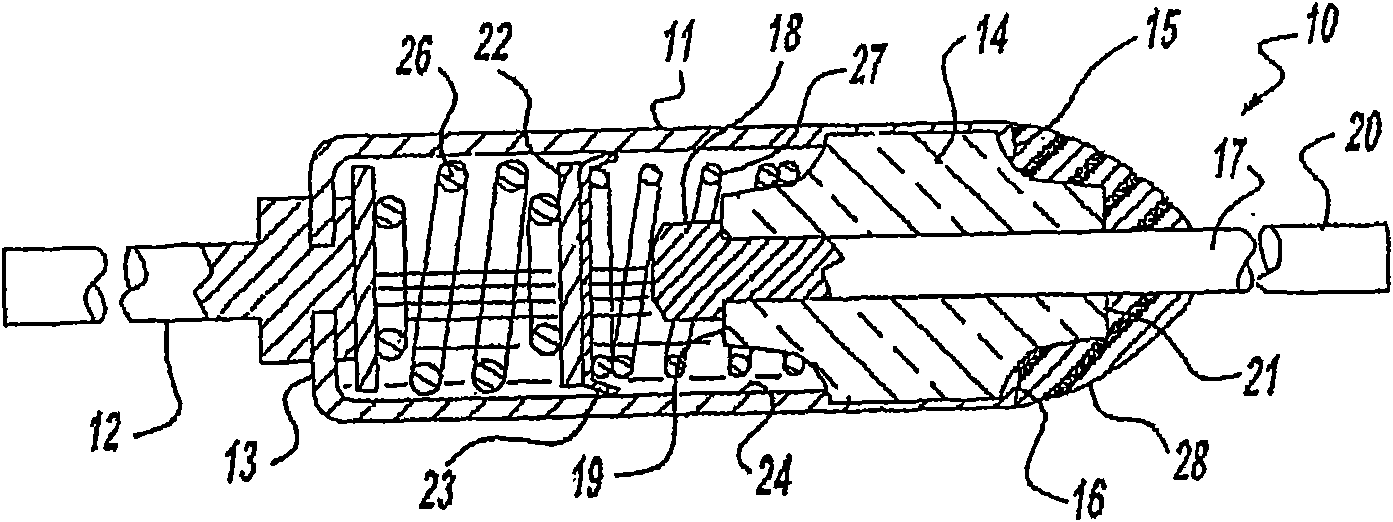

Metal oxide varistor with built-in alloy-type thermal fuse

ActiveUS8780521B2Simple and compact structureRapid responseEmergency protective arrangement detailsThermally actuated switchesEngineeringAlloy

An electronic protection component incorporates both a varistor and an alloy-type thermal fuse. In one embodiment, a melting promoting agent or flux contacts and surrounds both the varistor and the fuse in common in a shared cavity of a case. In another embodiment, the fuse and the flux are disposed in an inner case, which is disposed in contact with the varistor in an outer case. Thus, the varistor and the thermal fuse are incorporated so that the speed of heat transfer is fast, the response time is fast, and the installation for use is convenient.

Owner:XIAMEN SET ELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com