320MPa low-temperature resistant hot-rolled H-shaped steel and preparation method thereof

A technology of low temperature resistant, H-beam steel, used in low temperature resistant low alloy structural steel and metallurgy field, to achieve the effect of improving low temperature resistance, reducing carbon increase in converter and ensuring low carbon requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

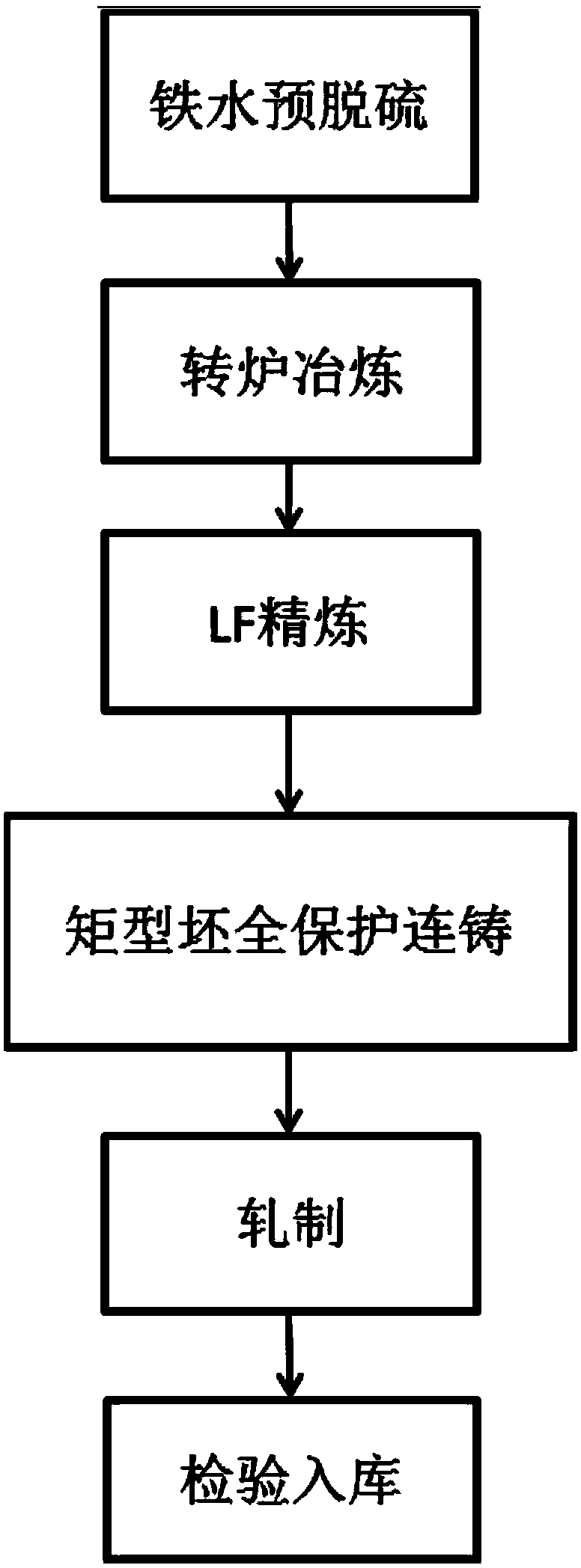

[0035] Such as figure 1 As shown, the process route of a 320MPa grade low-temperature resistant hot-rolled H-beam is:

[0036] Hot metal pre-desulfurization→converter smelting→LF refining→rectangular billet full protection continuous casting→1-7 rolling mill layout type production line rolling→inspection and storage.

[0037] Specifically:

[0038] 1) The molten iron arrives at the desulfurization station, and the sulfur content in the molten iron is guaranteed to be ≤0.010wt% after desulfurization;

[0039] 2) Converter smelting: the ladle is made of red net magnesia-carbon bricks, and the baking temperature is ≥800°C; ferrosilicon, manganese metal, and ferro-niobium are used for alloying, and the alloy composition is controlled according to the middle limit; ferro-aluminum manganese is used for deoxidation, and the addition amount is 2.5 ~4.0kg / t steel; add 1.0kg of slag modifier during the tapping process, start to add alloy evenly when the molten steel reaches 1 / 4, and f...

Embodiment 2

[0049] The specifications of the production process, key points of control and rolled material are the same as in Example 1. See Table 3 for the weight percentage of the chemical composition of the obtained steel, and see Table 4 for the record table of the mechanical properties of the rolled product.

[0050] Table 3: Chemical composition weight percent of steel

[0051] Example

C

Si

mn

P

S

Nb

Ti

2

0.11

0.35

1.30

0.015

0.010

0.035

0.025

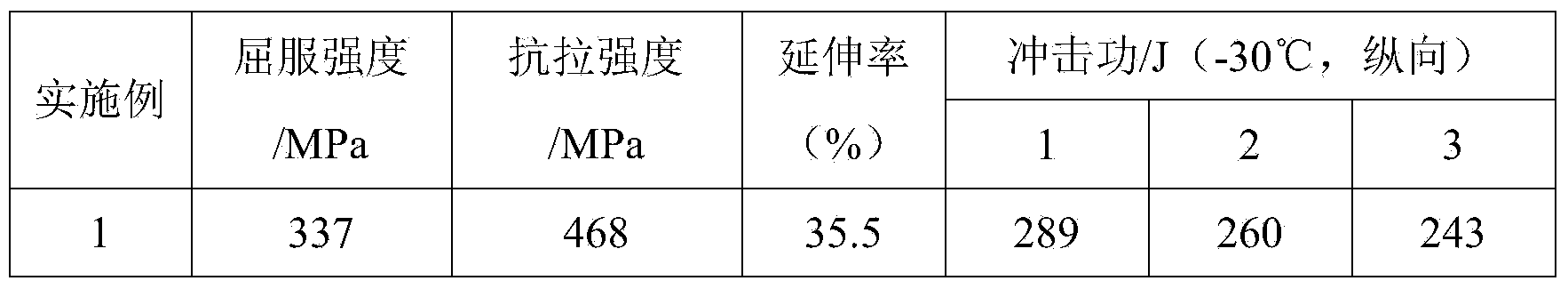

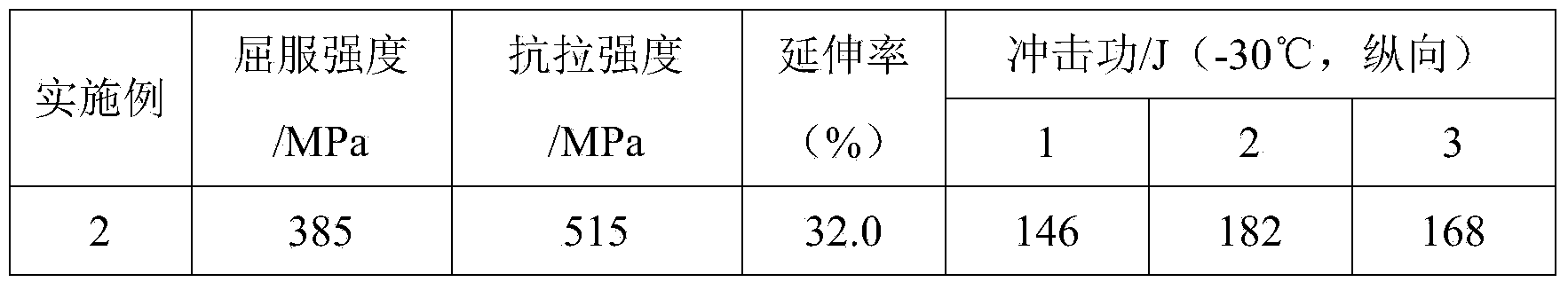

[0052] Table 4: Record table of mechanical properties of rolled products

[0053]

Embodiment 3

[0055] The specifications of the production process, key points of control and rolled material are the same as in Example 1. See Table 5 for the weight percentage of the chemical composition of the obtained steel, and see Table 6 for the record table of the mechanical properties of the rolled material.

[0056] Table 5: Chemical composition weight percent of steel

[0057] Example

C

Si

mn

P

S

Nb

Ti

3

0.10

0.25

1.25

0.016

0.008

0.023

0.020

[0058] Table 6: Record table of mechanical properties of rolled products

[0059]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com