Device and method for preparing fine-grained material by directly extruding continuous variable cross section

A variable cross-section and fine-grained technology, applied in the direction of metal extrusion dies, metal extrusion mandrels, etc., can solve problems such as high process requirements, high requirements, and material deterioration, and achieve uniform grain refinement and mechanical properties Good, the effect of less production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

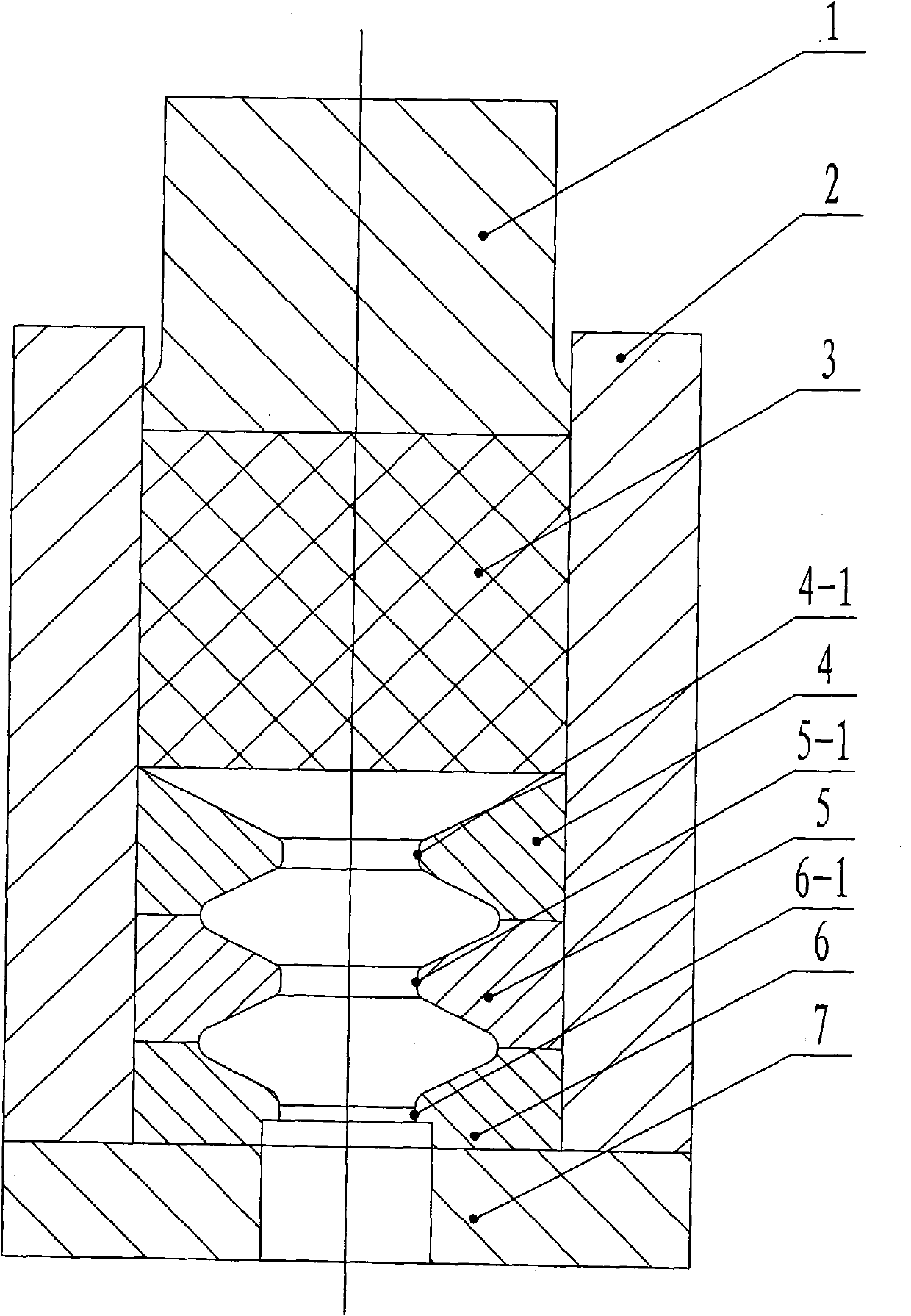

[0011] Specific implementation mode one: combine figure 1 and figure 2 To illustrate this embodiment, the device for producing fine-grained materials by direct extrusion with continuously variable cross-section in this embodiment is composed of a punch 1, a die 2, a primary transition die 4, a secondary transition die 5, and a core die 6. The primary transition mold 4, the secondary transition mold 5 and the core mold 6 are sequentially installed in the guide cavity of the die 2 from top to bottom, and the primary transition mold 4, the secondary transition mold 5 and the core mold 6 are arranged coaxially. The cavity of the first-stage transition die 4, the die cavity of the second-stage transition die 5 and the die cavity of the core mold 6 are combined to form an axially corrugated extrusion mold cavity with a continuously variable section, and the punch 1 is placed in the first-stage transition die 4 Above, and located in the die 2, the punch 1 and the die 2 clearance fi...

specific Embodiment approach 2

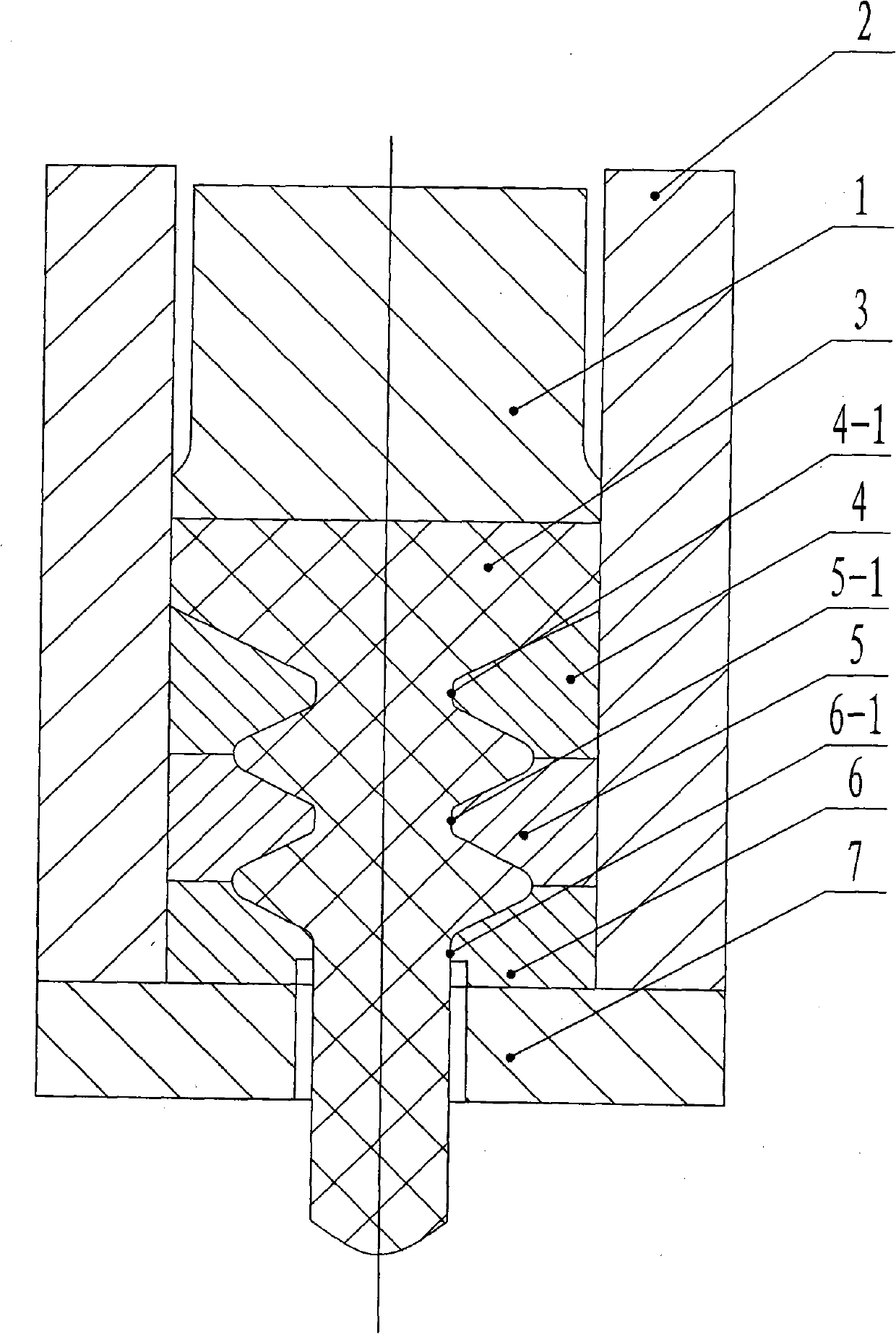

[0013] Specific implementation mode two: combination image 3 and Figure 4 Describe this embodiment, the difference between this embodiment and specific embodiment 1 is that the cavity of the primary transition mold 4, the cavity of the secondary transition mold 5 and the cavity of the core mold 6 are combined to form an axial cross section with continuously variable cross section. The cavity of the corrugated extrusion model gradually converges inward from top to bottom.

[0014] In this embodiment, when the plasticity and fluidity of the metal material are poor, the cavity of the primary transition mold 4, the cavity of the secondary transition mold 5 and the cavity of the core mold 6 are combined to form axial corrugations with continuously variable cross-sections. The cavity of the shaped extrusion model gradually converges from top to bottom, which can not only achieve the purpose of material grain refinement, but also improve the uniformity of metal deformation and flo...

specific Embodiment approach 3

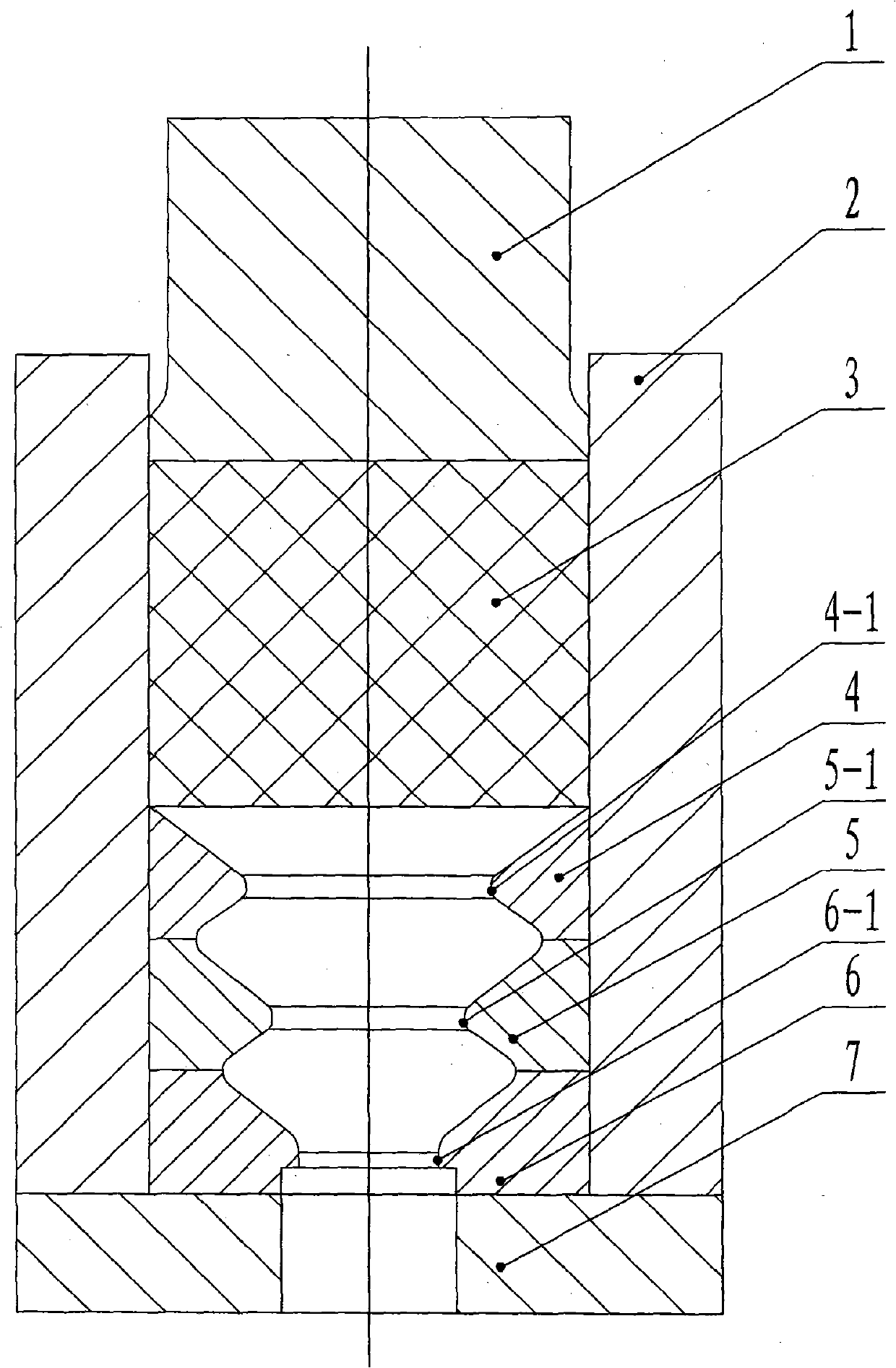

[0015] Specific implementation mode three: combination Figure 1-Figure 4 Describe this embodiment, the steps of the method for preparing the fine-grained material by direct extrusion of the continuous variable section of the above-mentioned preparation device in this embodiment are as follows: 1. Fix the mandrel 6 on the workbench 7; 2. Set the die 2 on the core die 6 and fixed on the workbench 7; three, install the secondary transition die 5 and the primary transition die 4 in the die 2 from bottom to top, and place them on the mandrel 6; The blank 3 is placed in the die 2 and positioned on the primary transition die 4; five, the punch 1 is moved down to the die 2; six, the die mouth 6-1 at the extrusion end of the mandrel 6 is closed with a closure; 7. Apply pressure to the punch 1 to move downward, and the blank 3 is plastically deformed and extruded from the die opening 4-1 of the primary transition die 4 and the die opening 5-1 of the secondary transition die 5; 8. Conti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com