A kind of method for preparing lignocellulosic plastic

A technology of wood fiber and plastic, applied in the field of preparation of wood fiber plastic, can solve the problem of needing a large amount of solvents, etc., and achieve the effect of good mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

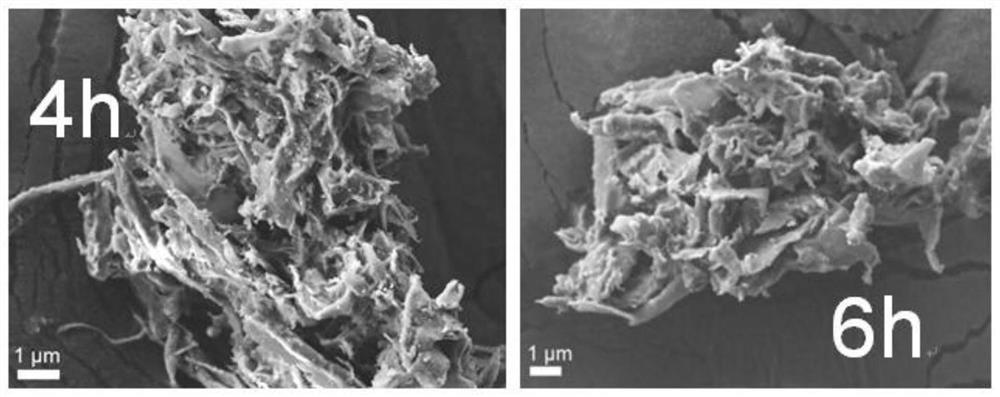

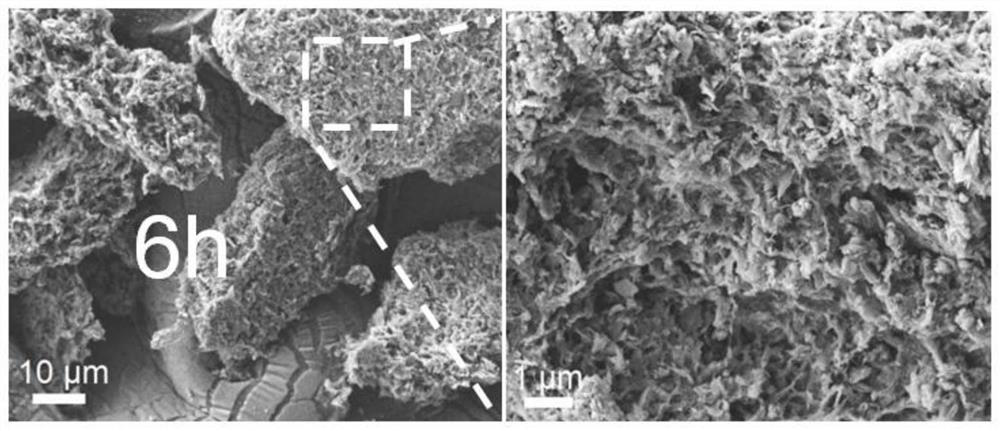

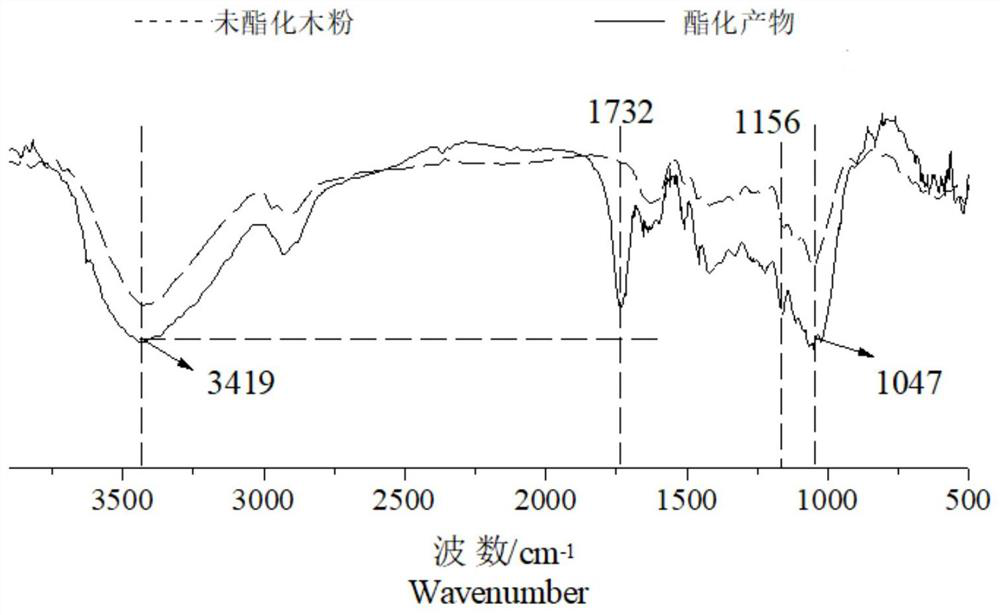

[0036] Take the discarded branches of Hu mulberry, peel them, dry them outdoors, and crush them through a 18-mesh sieve. Add 2g of wood flour, 25g of tetrabutylammonium fluoride solution with a concentration of 0.15 (w / w) into four 500mL zirconia ball milling jars, and 70 zirconia balls with diameters of 10mm, 7mm, and 5mm. The quantity ratio is 1:2:4. Fix these 4 ball milling tanks on the planetary ball mill, set the ball milling time to 4h, rotate at 580r / min, and there is no time interval between forward and reverse rotation; the alternate interval time is 90min, and start the ball milling pretreatment. After the ball milling was finished, 4 g of succinic anhydride and 4 g of pyridine were respectively added into each ball milling tank, and the ball milling was continued for 7 hours. After the reaction, take out and combine the materials of each ball mill tank, add 250mL of ethanol to wash and then filter with suction, then wash with 250mL of deionized water and then filte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com