Vacuum valve

A vacuum valve and vacuum technology, applied in the direction of sliding valve, valve details, valve device, etc., can solve the problem of expensive vacuum valve processing, and achieve the effect of saving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

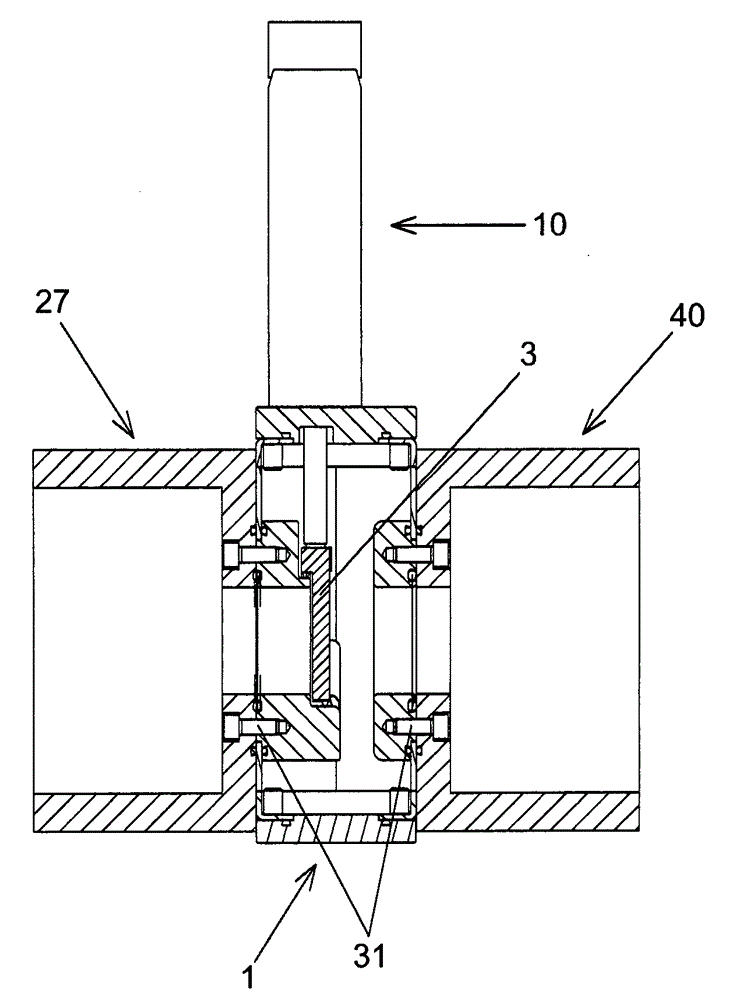

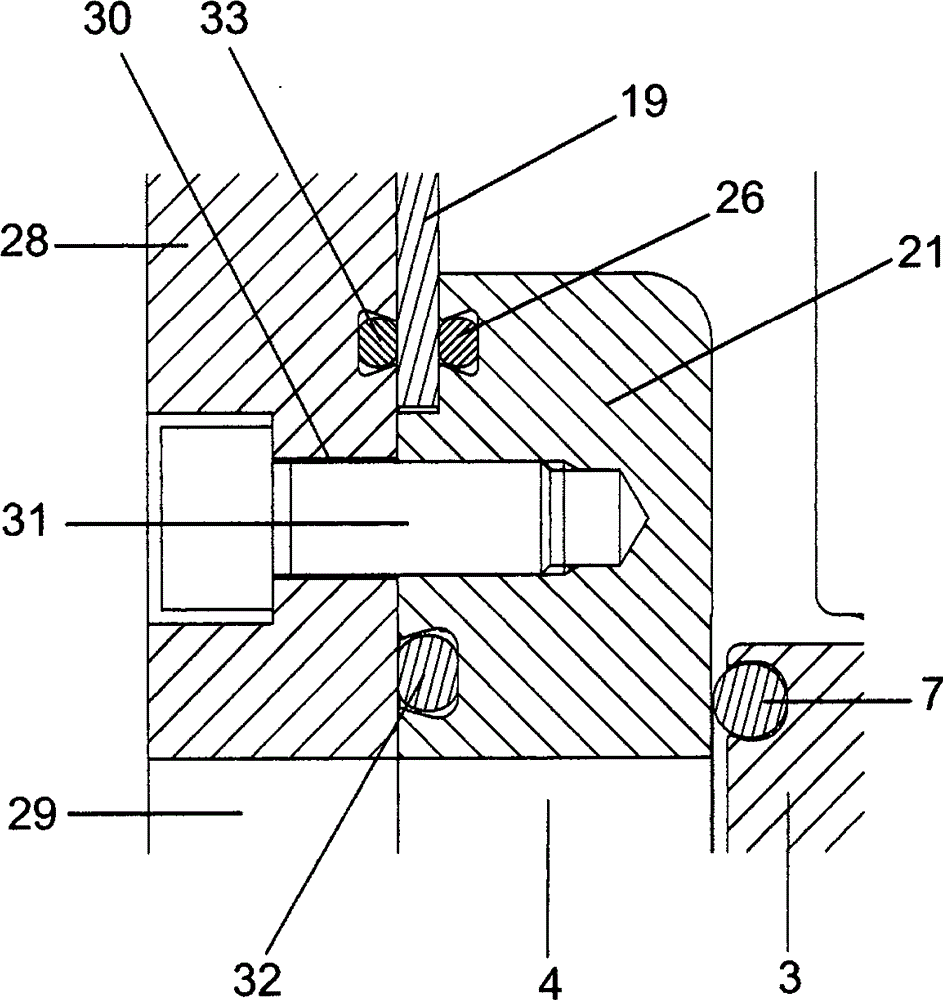

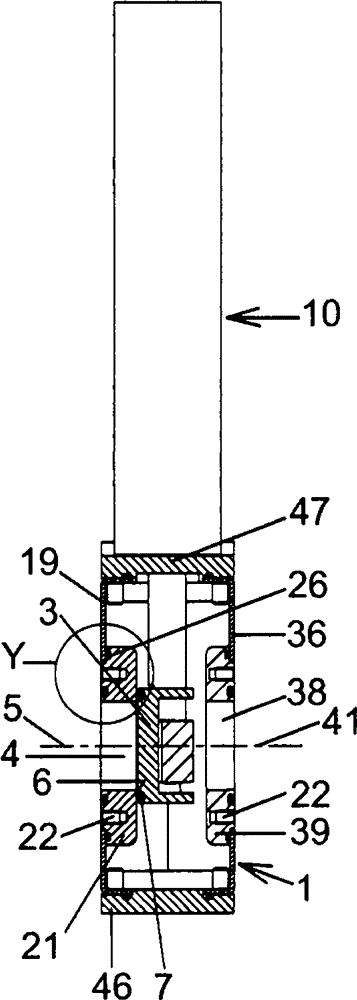

[0033] exist Figures 1 to 14 A first embodiment of a vacuum valve according to the invention is shown in .

[0034] The vacuum valve has a valve housing 1 with an inner chamber 2 in which, in the exemplary embodiment, a plate-shaped closing body 3 is arranged.

[0035] In the closed state of the vacuum valve shown in the drawing, the valve opening 4 of the valve housing, which has an axis 5 , is closed by the closing body 3 . To this end, the closing body 3 presses against the valve seat 6 surrounding the valve opening 4 . In the exemplary embodiment described, an elastic seal 7 is arranged on the closing body 6 , which bears against the sealing surface of the valve seat 6 . In a modified embodiment, the seal can also be arranged on the valve seat 6 and the sealing surface on the closing body 3 .

[0036] In the closed state of the vacuum valve, the closing body 3 assumes the closed position shown in the drawing.

[0037] In the open state of the vacuum valve, the valve o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com