Medlar harvesting machine

A harvester and wolfberry technology, which is applied in the directions of harvesters, harvesters, agricultural machinery and implements, can solve problems such as brokenness and poor flexibility, and achieve the effect of avoiding damage, preventing broken branches and achieving good picking effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

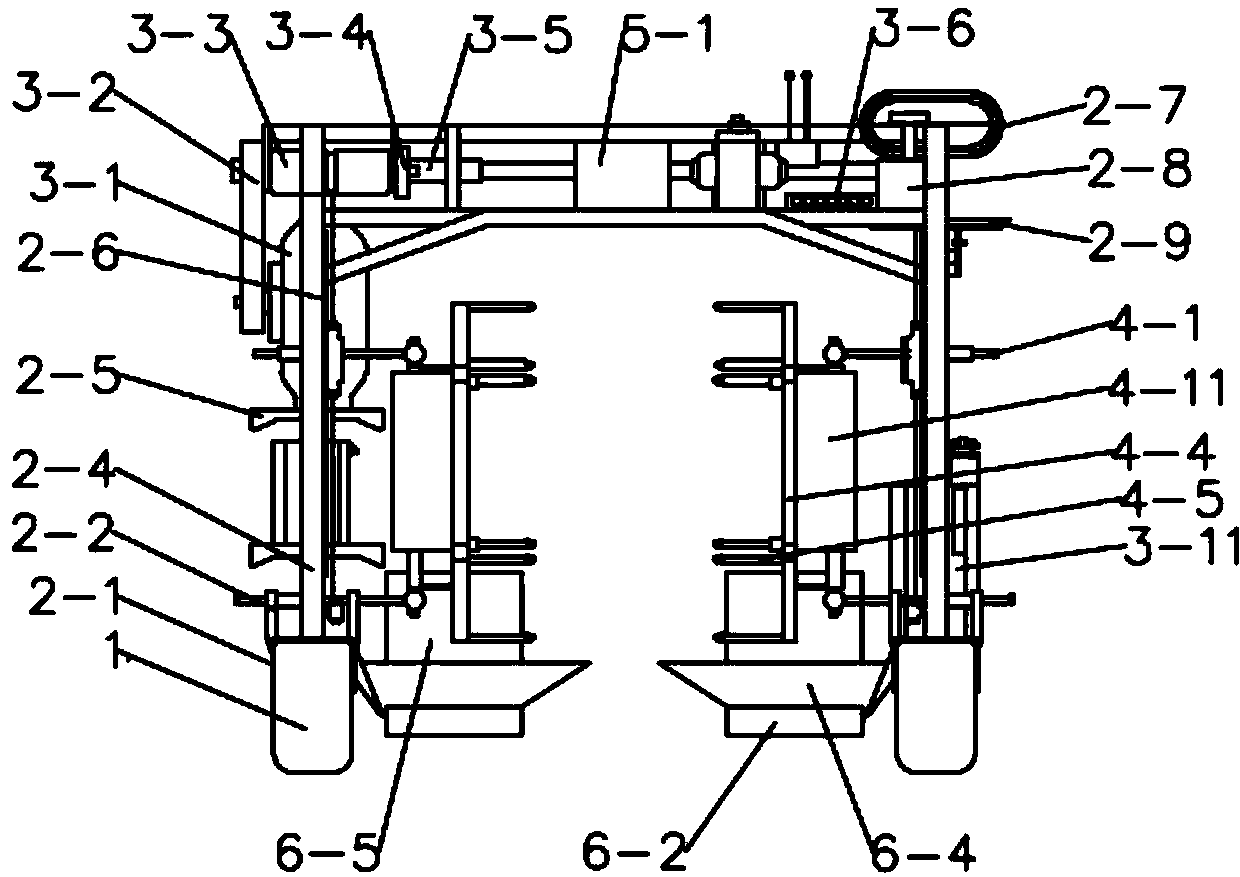

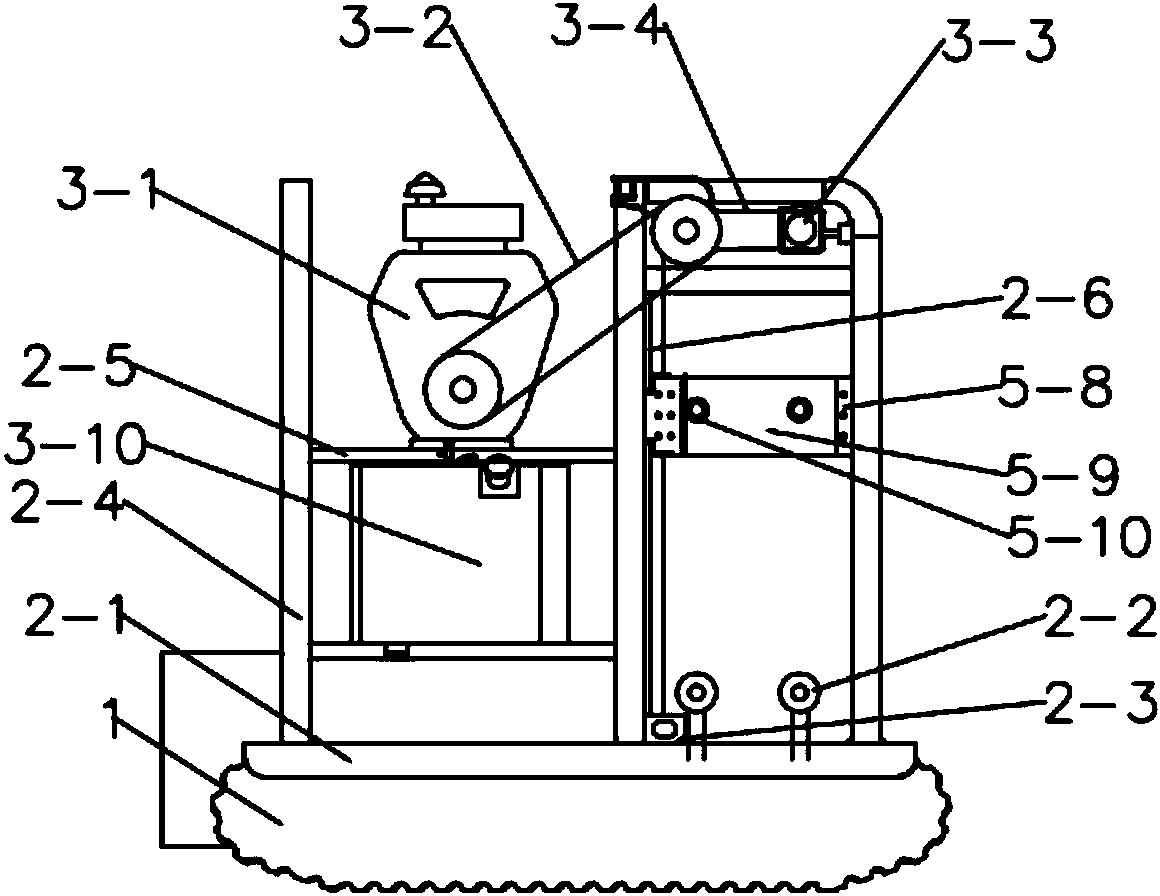

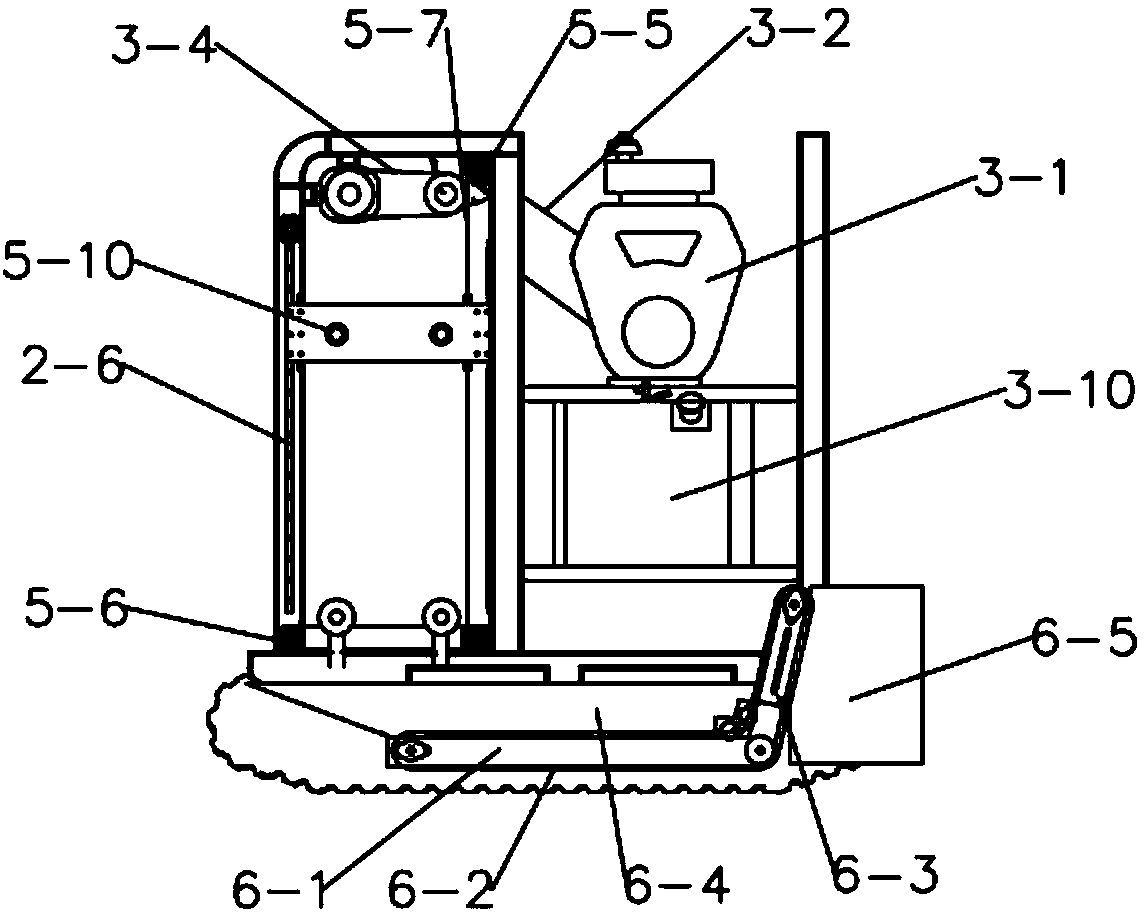

[0029] The basic structure of the wolfberry harvester of the present embodiment is as follows: Figure 1 to Figure 5 As shown, it includes a door-shaped frame 2-4 with four front and rear frame columns placed on the walking mechanism 1 on both sides, and the upper part of one side of the walking mechanism is provided with a handrail 2-7, a steering mechanism 2-8, and a seat 2-9. . The frame column inboard of gantry frame 2-4 has vertical slide rail 2-6 respectively, and vertical slide rail 2-6 is equipped with the lift slide plate 5-8 that lifting driving device drives and the vibrating assembly that is attached to lift slide plate.

[0030] The bottom of the vibrating assembly is mainly composed of collecting funnels 6-4 located on both sides below the gate frame 2-4, a collecting box 6-5 located at one end of the traveling mechanism, and a conveyor belt 6-2 connecting the collecting funnels 6-4 and the collecting box. Composition, the falling goji berries collected by the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com