Method for manufacturing high carbon steel wheel

A manufacturing method and high-carbon steel technology, which is applied in the manufacture of tools, furnaces, heat treatment equipment, etc., can solve the problems of adverse effects on safety performance, reduced crack growth resistance inside the wheel, and decreased impact toughness, etc., to achieve prolonged and effective dehydrogenation The effects of time, increasing difficulty, and increasing impact energy at room temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The technical process and technical parameters of the high carbon steel wheel manufacturing method are:

[0039] Heating the C-Mn high-carbon steel wheel billet with the composition shown in Table 1 to 1270°C to 1290°C according to the conventional process;

[0040] High-carbon steel wheel workpieces are made by conventional high-temperature forging and rolling;

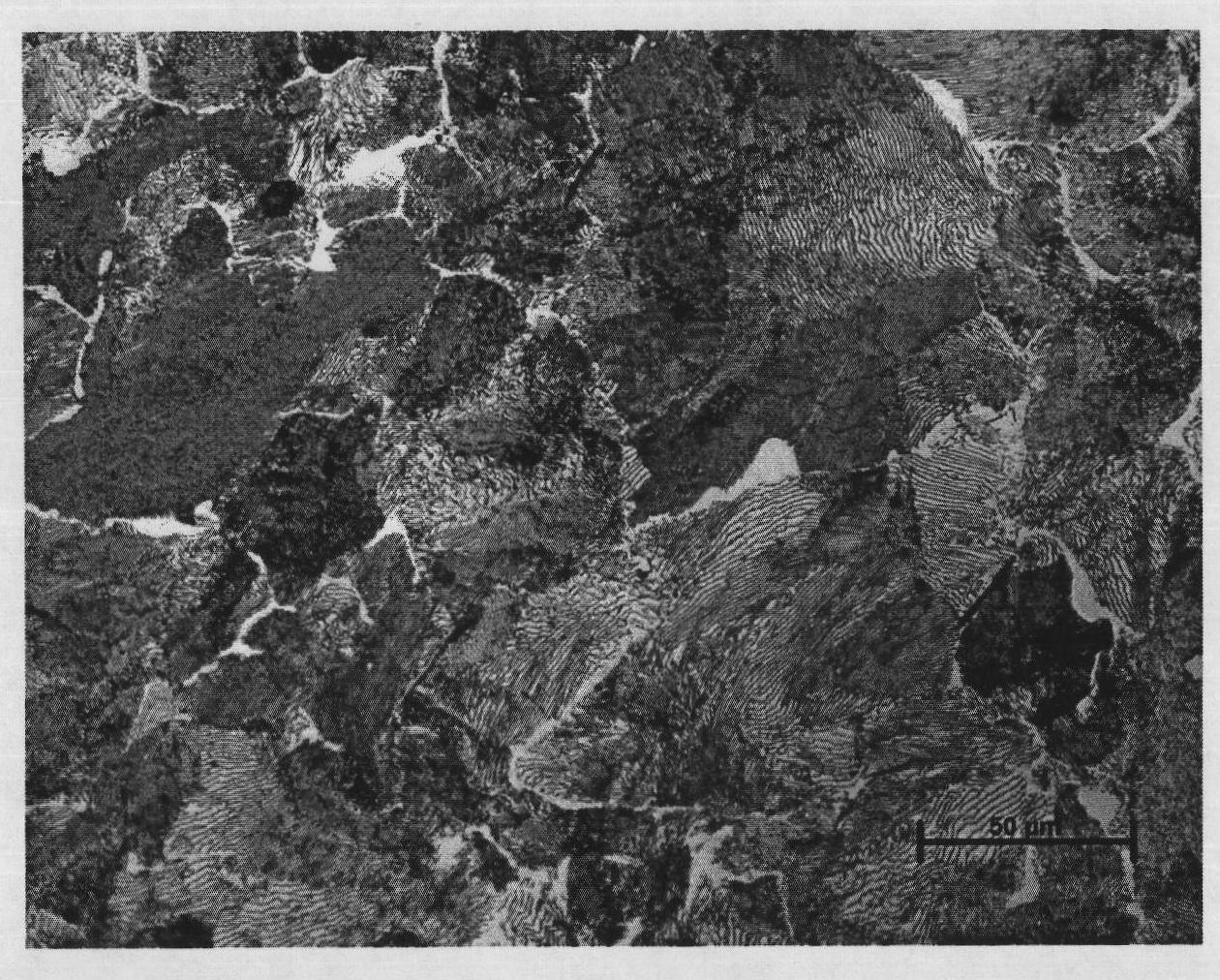

[0041] Air-cool the workpiece to a certain temperature range below point A1, and the infrared thermometer detects that the surface temperature of the wheel rim is 632°C, indicating that the wheel body has completed pearlite transformation;

[0042] Put the high-carbon steel wheel workpiece into the isothermal furnace and heat it to 730°C-750°C for 30 minutes to make the wheel rim undergo partial austenite transformation;

[0043] Cool the high-carbon steel wheel workpiece furnace to 600℃~630℃, so that the pearlite transformation of the wheel rim occurs at a higher temperature, and the temperature change of th...

Embodiment 2

[0052] The technical process and technical parameters of the high carbon steel wheel manufacturing method are:

[0053] Heating the C-Mn high-carbon steel wheel billet with the composition shown in Table 1 to 1270°C to 1290°C according to the conventional process;

[0054] Then through conventional high-temperature forging and rolling into high-carbon steel wheel workpiece;

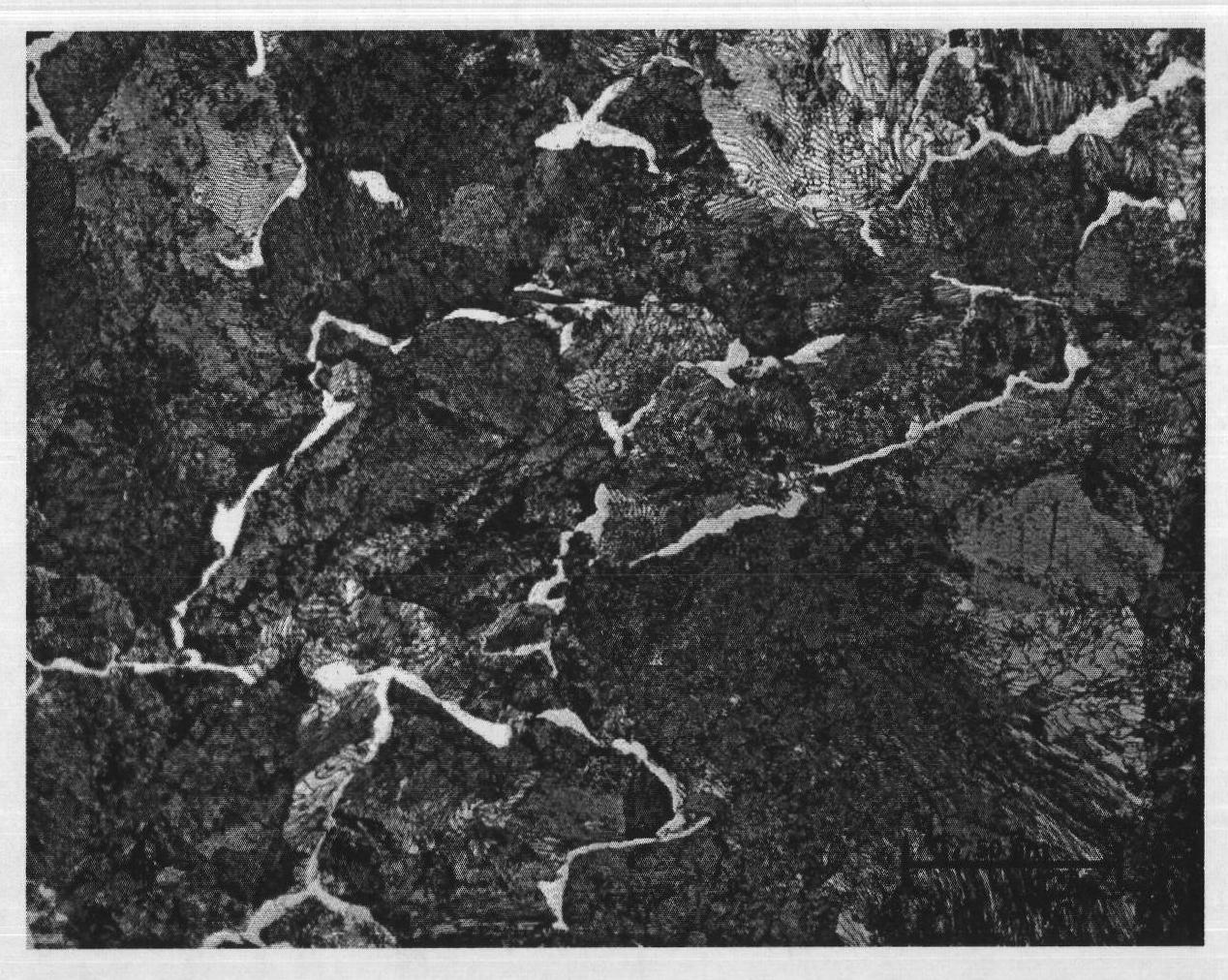

[0055] Air-cool the workpiece to a certain temperature range below point A1, and the infrared thermometer detects that the surface temperature of the wheel rim is 647°C, indicating that the wheel body has completed pearlite transformation;

[0056] Then put the high-carbon steel wheel workpiece into the isothermal furnace and heat it to 730°C-750°C for 40 minutes to make the wheel rim undergo partial austenite transformation;

[0057] Then the high-carbon steel wheel workpiece furnace was cooled to 600 ℃ ~ 630 ℃, so that the pearlite transformation of the rim of the wheel occurred at a higher temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com