Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

43results about How to "Prevent oxidative decarburization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

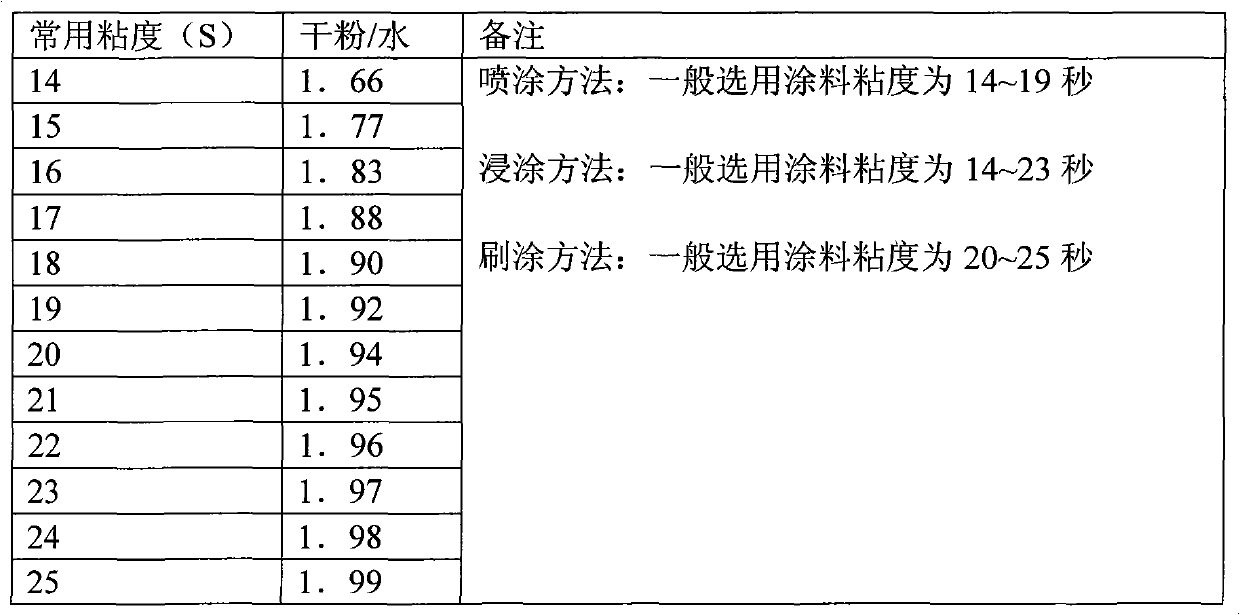

High temperature anti-oxidation dry powder coating

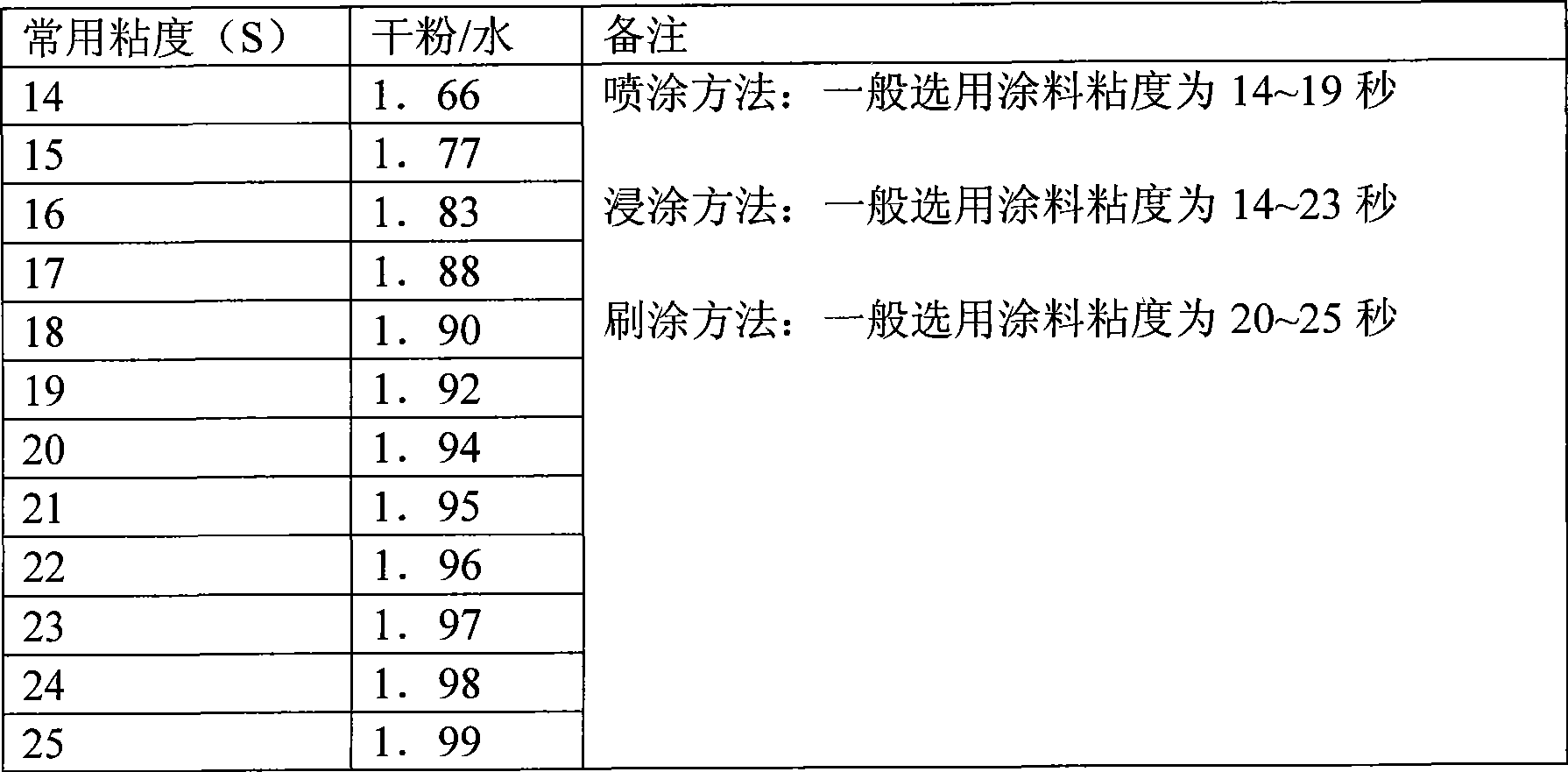

A high temperature anti-oxidation coating is a protective coating used for inhibiting oxidation at high temperature and aims at solving the defects of comprehensive properties of present high temperature protective coatings used for stainless steel and refractory steel. A high temperature anti-oxidation dry powder coating consists of the following raw materials according to weight percentage: 45-50% of frit, 40-45% of clay and 5-10% of talcum powder. The coating has the advantages of good protection effect when being used in high heat treatment of stainless steel and refractory steel, prevention of oxidation and decarbonization at high temperature between 900-1200 DEG C; no increase of hydrogen in the process of inhibiting oxidation, no harmful effect on parts; automatic fall-off in cooling, reduction of subsequent processing procedures; and convenient coating brush application, as well as readily available raw materials.

Owner:SHENYANG AIRCRAFT CORP +1

Heat treatment process for 65Mn spring washer

ActiveCN103194588APrevent oxidative decarburizationGuaranteed performanceFurnace typesHeat treatment furnacesThermal insulationQuenching

The invention relates to a heat treatment process for a 65Mn spring washer. The heat treatment process comprises the following steps: blanking; electric spark perforation of basic bores; linear cutting and forming; correction by a fitter; heat treatment; performance test; and surface treatment; wherein during quenching in the step of heat treatment, firstly, the 65Mn spring washer is subjected to preheating which means the 65Mn spring washer is put into a quenching tool heated in advance, then a quenching furnace is heated, charcoal is added into the quenching furnace, the quenching tool is placed into the quenching furnace with a temperature maintained to be constant, then the quenching tool is taken out, the 65Mn spring washer is put into the quenching tool, quenching is carried out immediately after thermal insulation, and the surface of the 65Mn spring washer is coated with an anti-oxidation decarburization paint before the 65Mn spring washer is placed into the quenching tool. According to the invention, the charcoal is added into the quenching furnace for generation of protective gas, the anti-oxidation decarburization paint is coated on the surface of the spring washer for prevention of oxidation and decarburization, so desired performances of the spring washer are guaranteed.

Owner:HANGZHOU BRANCH ZHEJIANG GEELY AUTOMOBILE RES INST +2

Hot spraying process of metal ceramic coating on surface of valve rod

The invention discloses a hot spraying process of a metal ceramic coating on surface of a valve rod, and relates to the field of manufacture of a valve. The hot spraying process comprises the technical procedures of mechanical pre-processing, surface purifying, surface coarsening, pre-heating treatment, hot spraying, accurately grinding and polishing and the like; a vacuum electric furnace is adopted in the heat treatment; the valve rod is pre-heated to 80-150 DEG C; hypersonic flame hot-spraying is adopted; and a valve rod base body is cooled by a forcible air cooling device when being subjected to hot spraying, and a smooth and compact high-performance metal ceramic coating with wear resistance, corrosion resistance, high binding strength and low porosity is formed on the surface of the valve rod after being polished. The process is high in coating efficiency, free from pollution, high in binding strength of the coating and low in porosity; wear-resisting and corrosion-resisting performances and high-temperature and heat vibration resistance of the surface of the valve rod are greatly improved without changing the precision of the overall size of the valve rod; the usability of the valve rod is greatly improved; the service life of the valve rod can be improved by 2-5 times; and the hot spraying process can be applied to a steam valve of a steam turbine unit, a special valve for a power station and other valves.

Owner:黄红霞

New technology for preparing hard wear resistant coating through shaped charge detonation gun spraying

The invention relates to a new technology for preparing a hard wear resistant coating through shaped charge detonation gun spraying and solves the defects of the conventional shaped charge detonation gun spraying technology that the workpiece to be sprayed is easy to have pits, the coating is uneven and the spraying area is small. The technology comprises the following steps: pressing shaped charge of which the density is 1.3-1.6g / cm<3> and the energy focusing cave cone angle is 40-60 degrees, then filling the WC-Co mixed powder of which the mass is 10-30% of the shaped charge and the density is 2-3g / cm<3> in the top of the energy focusing cave, fixing with a film, then arranging the shaped charge 200-400mm above the workpiece, covering a protective cover filled with inert gas outside the shaped charge and workpiece, and finally detonating the shaped charge to complete the spraying of the workpiece. The coating sprayed by the technology has the advantages of uniform surface, large area, low porosity, hardness, wear resistance and the like. In addition, the technology is simple, does not require large operation equipment and is suitable for industrialized spraying production.

Owner:ZHONGBEI UNIV

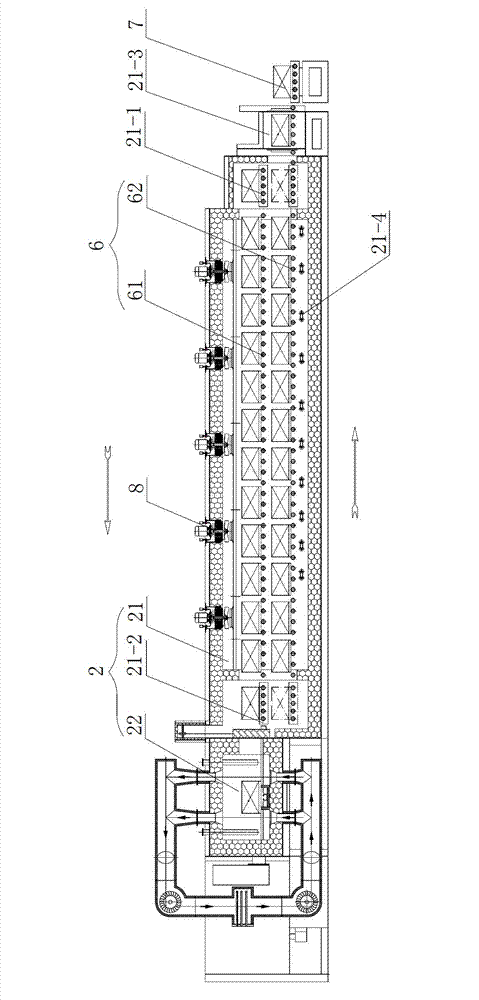

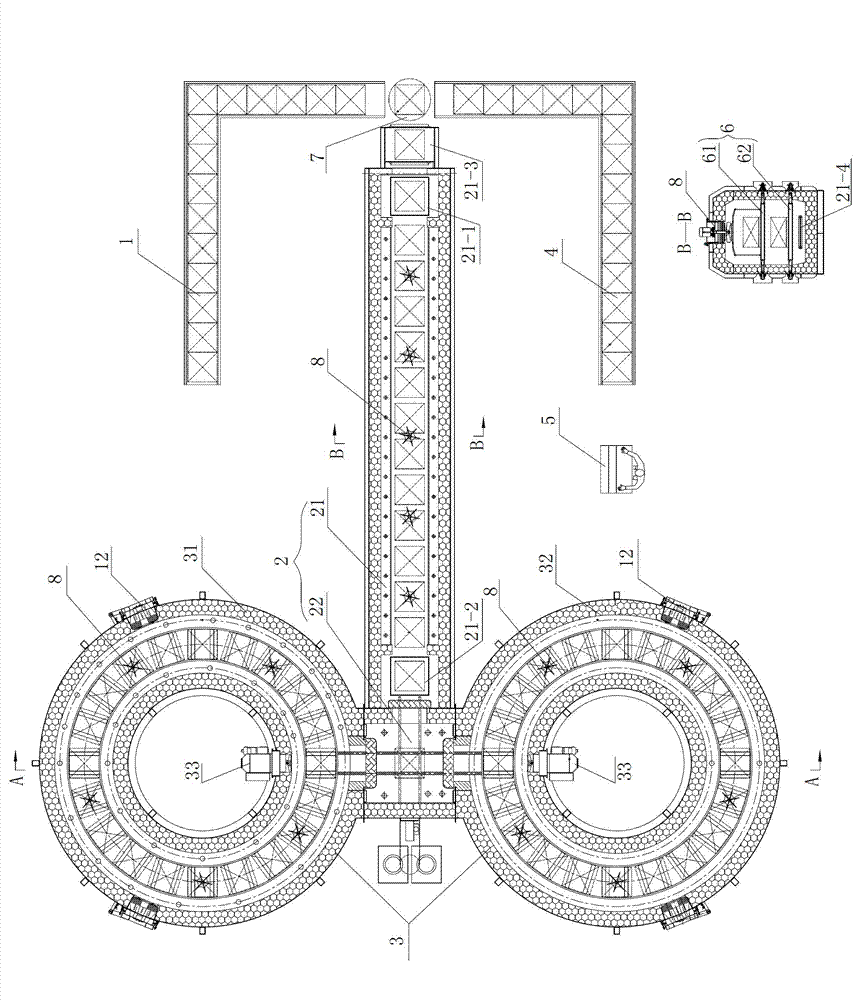

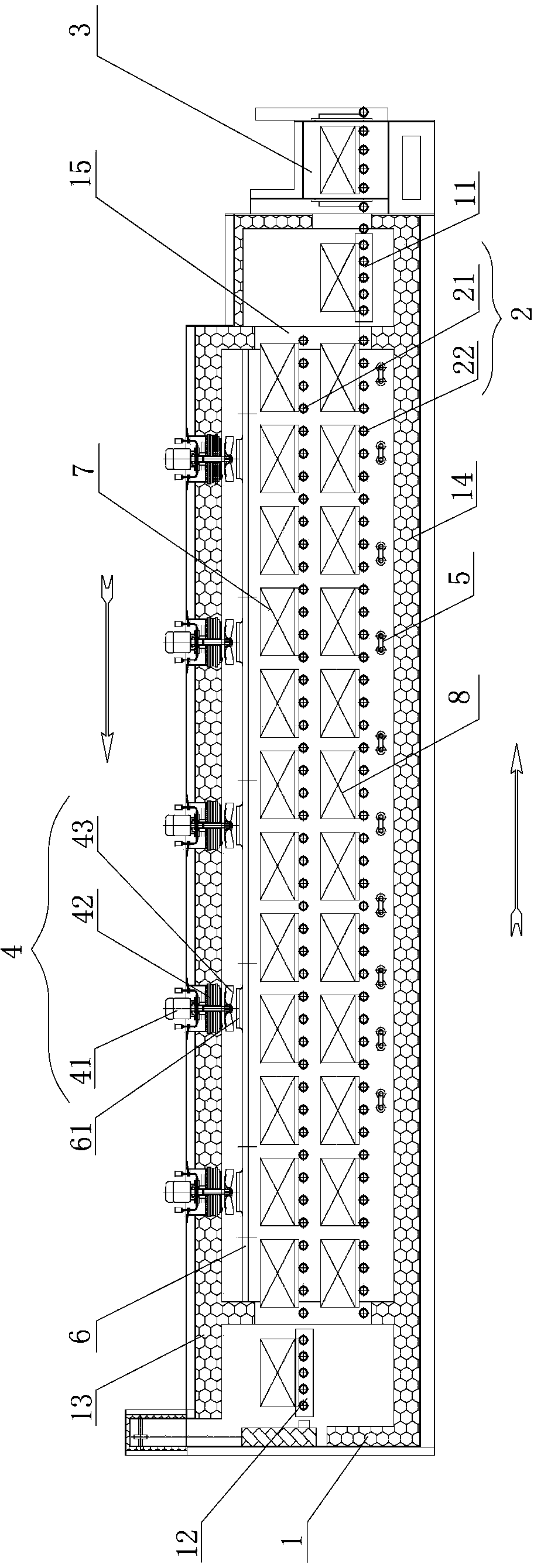

Roller-type spheroidizing annealing production line and isothermal spheroidizing annealing method

ActiveCN103074471AAvoid crackingAvoid defects such as deformationComputer control systemProduction line

The invention relates to a roller-type spheroidizing annealing production line and an isothermal spheroidizing annealing method using the roller-type spheroidizing annealing production line. The roller-type spheroidizing annealing production line sequentially comprises a roller-type feeding table, a cooling device, a heating device, a roller-type discharging table and an upper computer control system, wherein the cooling device comprises a roller-type quick cooling furnace and a forced quick cooling chamber at the tail end of the roller-type quick cooling furnace; a workpiece conveying device is arranged inside the roller-type quick cooling furnace; and the workpiece conveying device has a double-layer structure and comprises an upper cold workpiece feeding device and a lower hot workpiece discharging device. The isothermal spheroidizing annealing method comprises the following steps: feeding, exchanging heat of a cold workpiece and a hot workpiece in the furnace, austenitizing the workpieces, performing isothermal treatment, cooling and outputting the workpieces, discharging and the like. The isothermal spheroidizing annealing method is wide in application, can be applied to spheroidizing annealing treatment of parts or raw materials on a large scale as well as isothermal normalizing treatment of the parts; and the roller-type spheroidizing annealing production line has the advantages of energy conservation, environment friendliness, small floor area, high production efficiency and the like.

Owner:HEPHAES HEAT TREATMENT SYST JIANGSU

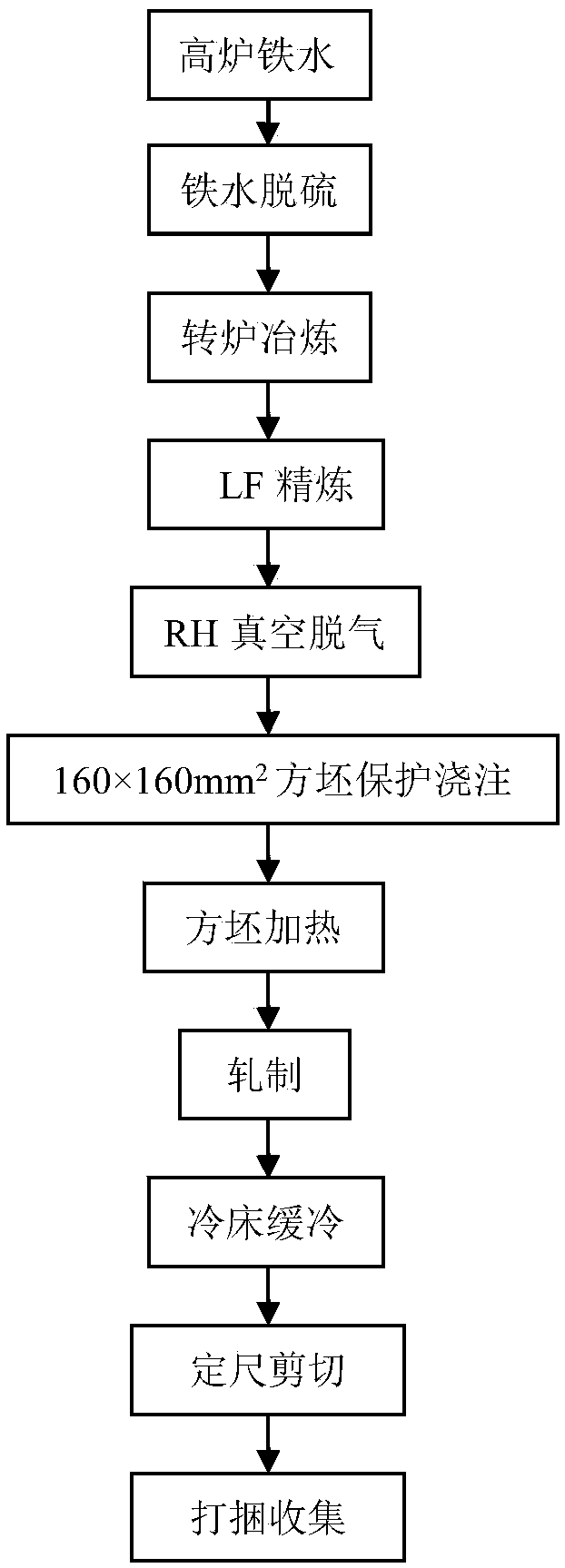

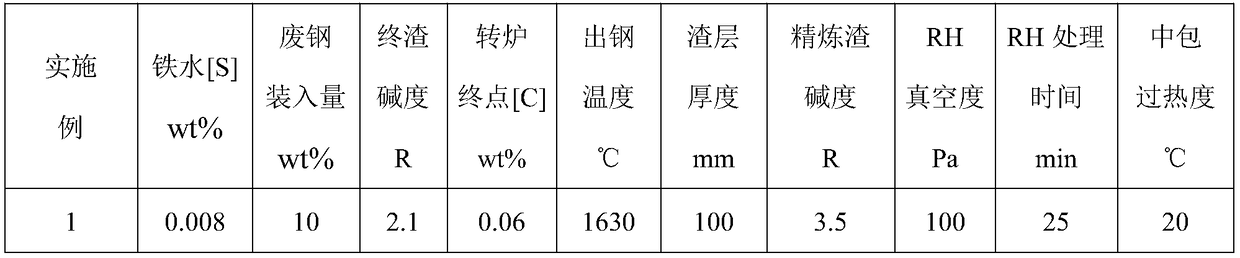

1550MPa-level spring flat steel and production method thereof

ActiveCN109161803AHigh strengthImprove toughnessManufacturing convertersProcess efficiency improvementSpring steelImpurity

The invention discloses 1550MPa-level spring flat steel. The 1550MPa-level spring flat steel comprises the following components in percentage by mass: 0.48 to 0.61 percent of C, 0.4 to 0.9 percent ofSi, 0.60 to 1.20 percent of Mn, less than or equal to 0.025 percent of P, less than or equal to 0.025 percent of S, 0.75 to 1.25 percent of Cr, 0.01 to 0.05 percent of Nb, 0.001 to 0.004 percent of B,0.010 to 0.025 percent of Al, 0.005 to 0.009 percent of N and the balance of Fe and unavoidable impurities. The steel for a spring, which has an excellent use property and an optimal tissue structure, is developed by combining composition and process innovation; furthermore, the preparation method is simple and low in cost, and has an important popularization and application value.

Owner:武汉钢铁有限公司

Heat treatment method for automobile SCM435 steel high-strength fastener

InactiveCN107502708AAvoid crackingReduce processing timeFurnace typesHeat treatment furnacesCarbon potentialQuenching

The invention discloses a heat treatment method for high-strength fasteners made of SCM435 steel for automobiles, comprising steps: (1) In the heating stage, the fasteners are sent into a heating furnace, the heating temperature is controlled at 870°C ± 5°C, and methanol is passed through , the feed rate is 20-40ml / min, feed propane, control the carbon potential to be 0.40%±0.04%, and the heating time is 50-80 minutes; (2) quenching stage, the heated fastener enters the oil tank for quenching, When quenching and cooling, the oil temperature is 60-70°C, and the quenching oil is stirred in circulation; (3) Tempering stage, after quenching, the fastener enters the tempering furnace, and the tempering time is 130-170min; when the hardness requirement is 33-38HRC, tempering The temperature is 500-530°C; when the hardness requirement is 38-42HRC, the tempering temperature is 430-460°C. Passing methanol and controlling the carbon potential at 0.40±0.04% can better balance the carbon concentration inside and on the surface of the workpiece to avoid carburization and ensure that no cracks appear on the surface of the workpiece.

Owner:厦门真冈热处理有限公司

Residual-heat available roll-bar type rapid-cooling furnace

InactiveCN103898280AAvoid crackingAvoid defects such as deformationHeat treatment process controlEngineeringOutput device

The invention relates to heat treatment equipment, and particularly relates to a residual-heat available roll-bar type rapid-cooling furnace. The rapid-cooling furnace comprises a rectangular furnace body and an in-furnace transmission device, wherein the in-furnace transmission device is divided into a cold workpiece input device in the upper layer and a hot workpiece output device in the lower layer, and a roller is respectively arranged at each of the bottom of the cold workpiece input device and the bottom of the hot workpiece output device. According to the rapid-cooling furnace, a cold workpiece to be treated and a treated hot workpiece can be respectively put in the upper layer and the lower layer; energy released when the hot workpiece is cooled can be used for pre-heating the cold workpiece in the upper layer, the preheating temperature can be 300-500 DEG C, and the time of temperature rise can be reduced when the preheated workpiece is subjected to lower high-temperature heating treatment, so that energy can be greatly saved, and defects of cracking, deformation and the like of a cold workpiece caused by thermal stress directly generated in the quick temperature-rise process in a heat furnace can be avoided.

Owner:HEPHAES HEAT TREATMENT SYST JIANGSU

Technology for machining positioning rings

InactiveCN105983818AHigh surface hardnessExtended service lifeSolid state diffusion coatingFurnace typesEngineeringMachining

The invention discloses a technology for machining positioning rings. The technology is characterized by comprising steps of carrying out technological processes of discharging, forging, annealing, machining, tempering, machining, ion nitriding, inspecting and finished product acquiring and the like. The technology for machining the positioning rings has the advantages that the comprehensive performance of the positioning rings can be improved, and the service lives of the positioning rings can be prolonged.

Owner:重庆沁煌实业有限公司

Large-sized deformed bar and manufacturing method thereof

InactiveCN104847054AHigh mechanical strengthAccelerated corrosionBuilding reinforcementsEngineeringRebar

The invention discloses a large-sized deformed bar and a manufacturing method thereof. The large-sized deformed bar comprises polished wall sections and a waveform section, wherein the two polished wall sections are respectively arranged at two ends of the large-sized deformed bar; the waveform section is arranged in the middle of the large-sized deformed bar, and the two ends of the waveform section are respectively connected with the polished wall sections at the two ends; and the waveform section is shaped like a spiral waveform. The manufacturing method of the large-sized deformed bar mainly comprises the following steps: smelting; hot-rolling of a seamless pipe; thermally treating; surface-treating; reducing and drawing; cold-rolling and moulding; and examining and putting into a storeroom. The large-sized deformed bar disclosed by the invention disclosed by the invention is moderate in manufacturing cost, high in mechanical strength, good in corrosion resistance and excellent in anti-seismic property.

Owner:杭州蓝筹企业管理有限公司

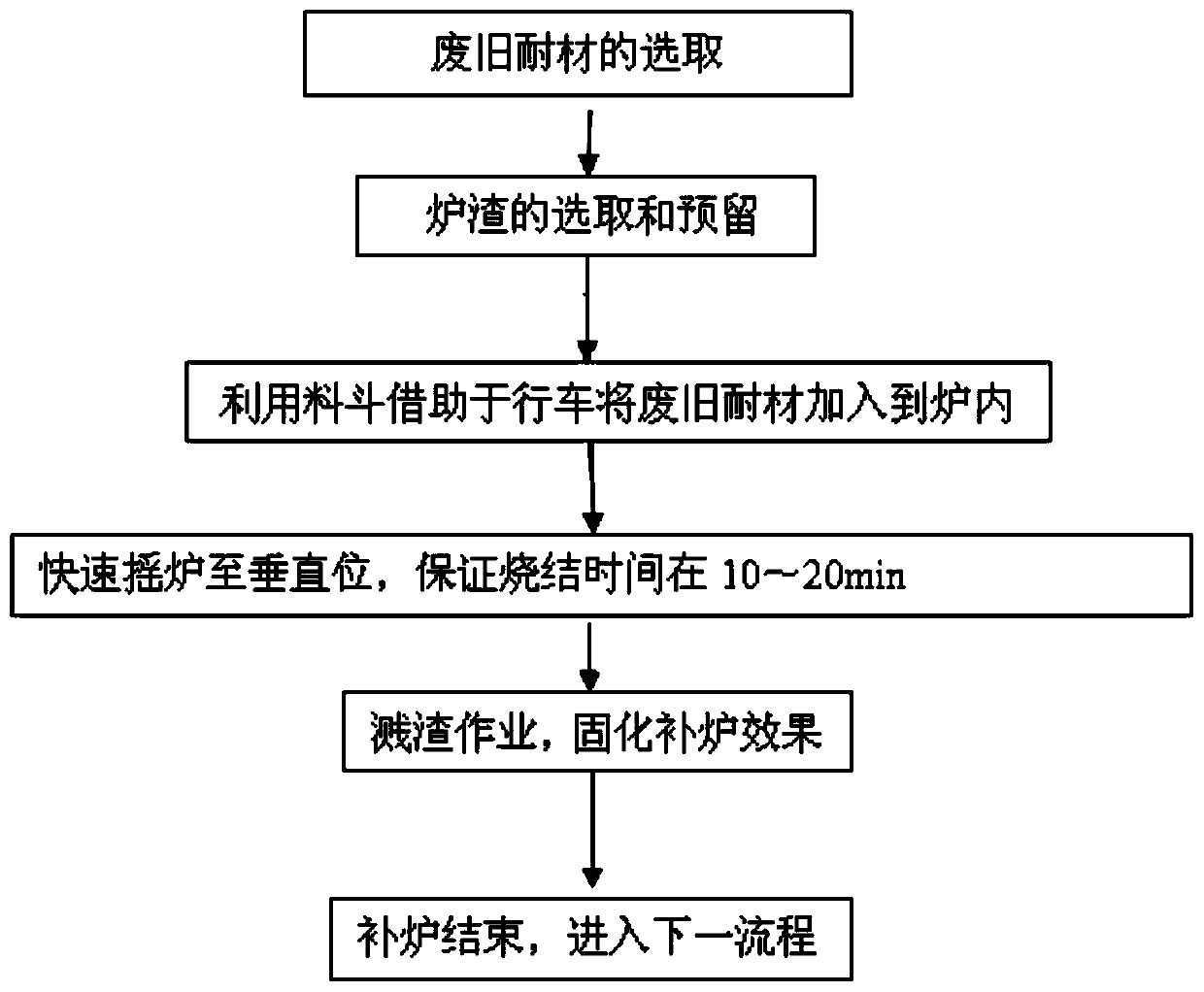

Shaping refractory material converter protection method for converter

InactiveCN110042196AExtended service lifeImprove corrosion resistanceManufacturing convertersBrickErosion rate

The invention discloses a shaping refractory material converter protection method for a converter. The method specifically comprises the following steps of: (1), selecting waste shaping refractory materials; (2), selecting slag and determining the allowance of the slag; and (3), fettling by using the shaping refractory materials. The converter protection method is simple and easy to implement; after the tapping of the converter is finished, how much of the slag to be reserved in the converter is determined according to the size of the slag and the required amount of the shaping refractory materials, the slag is quickly cooled and bonded together after a waste magnesia carbon brick or magnesite is added in, and the slag is integrated with converter lining by utilizing the temperature difference of the slag and the interface of the converter lining and through mutual diffusion among minerals, so that the fettling effect is achieved, the erosion rate of a working layer of the converter lining is slowed down, smoothness of a bottom blowing pipeline is protected, and long-acting visual operation of bottom blowing is achieved

Owner:NANJING IRON & STEEL CO LTD

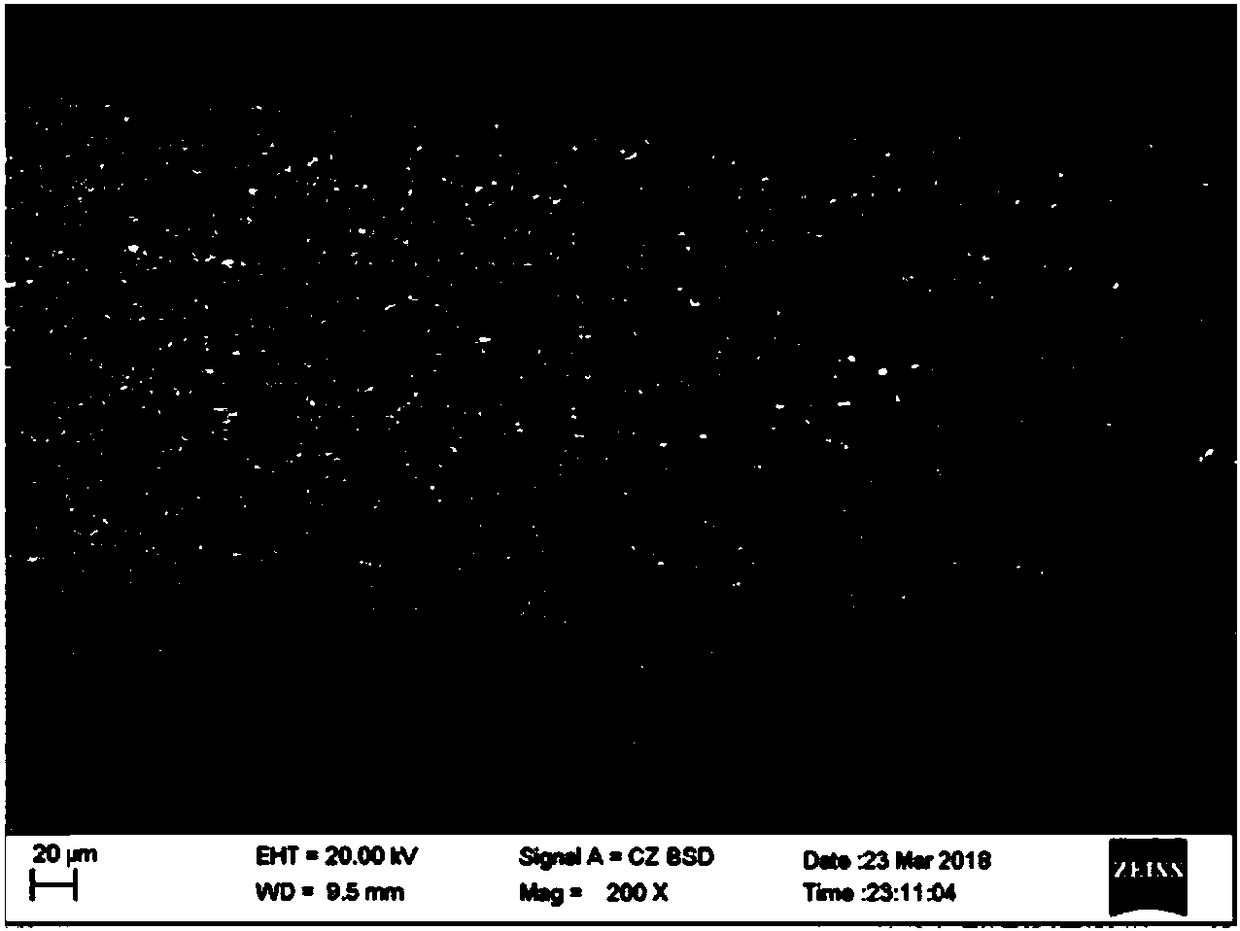

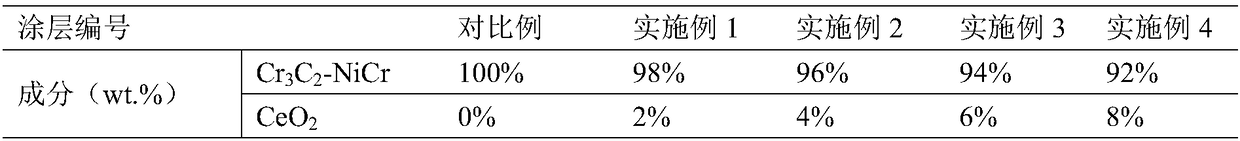

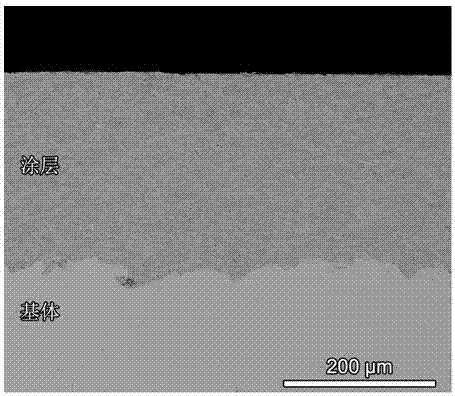

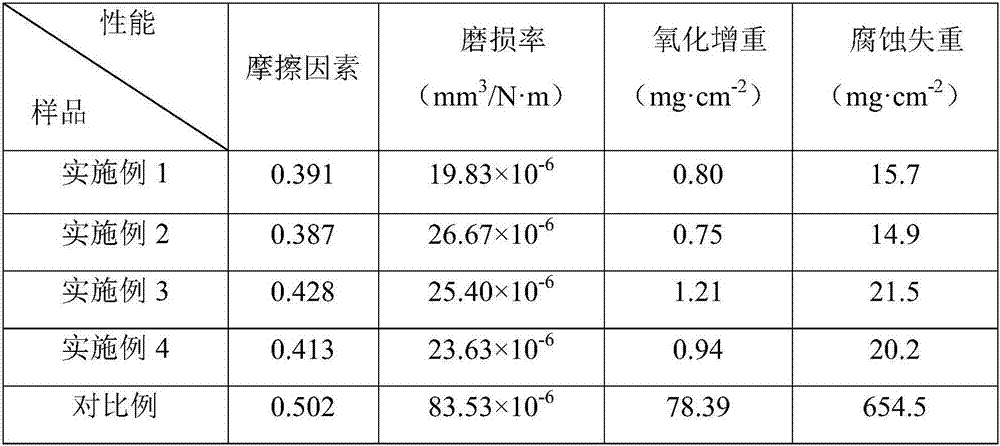

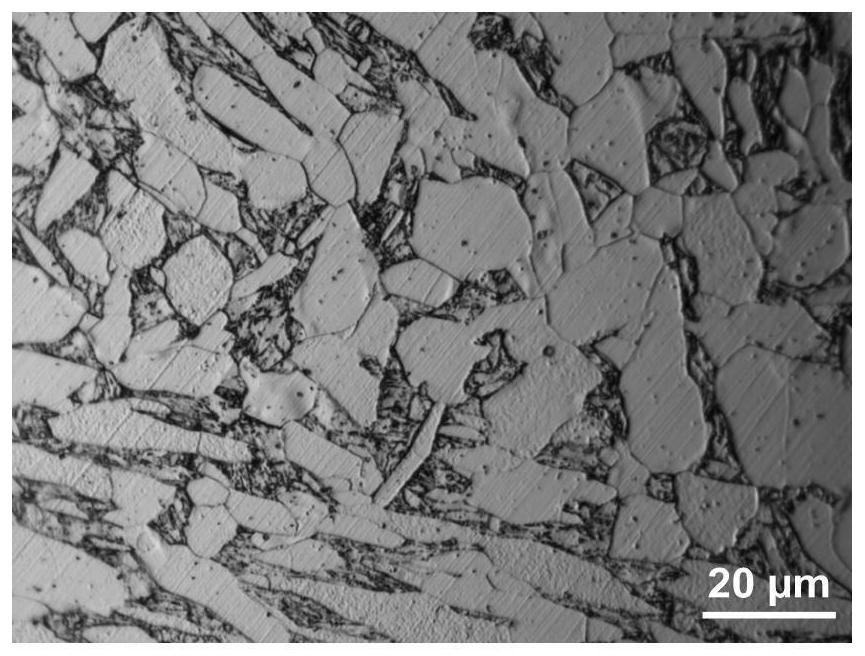

Preparation method of rare earth oxide doped high temperature oxidation resisting and abrasion resisting coating for H13 steel surface protecting

The invention discloses a rare earth oxide doped high temperature oxidation resisting and abrasion resisting coating for H13 steel surface protecting and a preparation method of the coating. Accordingto the method, an active combustion-high velocity air fuel (AC-HVAF) technology is adopted for spraying powder on a base body (H13 steel) to form the composite coating; and the powder comprises Cr3C2-NiCr powder and nanometer CeO2 powder, the doping content of the nanometer CeO2 powder is 2-8 wt%, and the balance is the Cr3C2-NiCr powder. The coating prepared through the method is compact in structure and uniform in distribution, a flattened structure is achieved, and the coating is closely combined with a boundary. Besides, after doping of the nanometer CeO2 powder, the tissue compactness ofthe coating is further improved, the porosity is reduced, the defects of non-molten matter, micro cracks and the like are less, better high temperature oxidation resisting performance and abrasion resisting performance are both achieved, and the high temperature oxidation resisting performance and the abrasion resisting performance of the H13 steel in the using process can be improved easily.

Owner:GUANGDONG ZHENGDE MATERIAL SURFACE TECH

Composite carbon tool steel/plain carbon steel metallurgical lining board with high resistance, high uniformity and long service life

InactiveCN102154537AHigh hardnessImprove uniformityIncreasing energy efficiencyFurnace typesHigh resistanceWear resistant

The invention discloses a composite carbon tool steel / plain carbon steel metallurgical lining board with high resistance, high uniformity and long service life. Aiming at characteristics of an explosive composite wear-resistant material and operating requirements of a metallurgical wear-resistant lining board, the surface induction heating principle and the metal phase transformation theory are used for controlling the depth of heat penetration, the hardness of an appropriate layer interface, and the depth and uniformity of a quench hardening layer so that the hardness of the composite layer is distributed in gradient, and the complete martensite phase change is avoided from occuring in the composite interface layer during quenching so to reduce the structure stress formed on the interface and keep the original combination state of the composite board to the greatest extend. The composite metallurgical lining board with high resistance, high uniformity and long service life has surface hardness of larger than 61HRC (rockwell hardness) and uniformity of hardness of less than 3 HRC (rockwell hardness); A 5mm place of the composite layer in the thickness direction has a hardness value of larger than 50HRC (rockwell hardness); and the three fifth to four fifth place of the composite layer thickness has the hardness value of less than 35HRC (rockwell hardness).

Owner:JIANGSU RUNBANG NEW MATERIAL GRP CO LTD

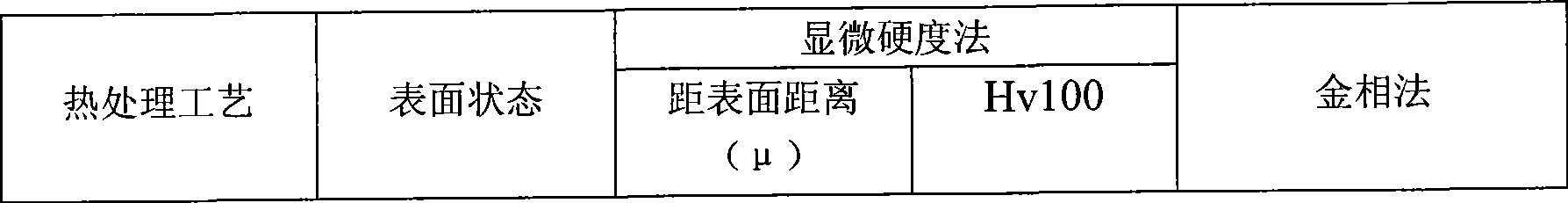

Blade installation seat heat treatment method

ActiveCN106555153AControl carburizing qualityIncrease productivitySolid state diffusion coatingCopper platingEngineering

The invention relates to a blade installation seat heat treatment method. The method is characterized in that coppering treatment is carried out on the whole surface of a blade installation seat workpiece, machining is used for remove a copper layer of an area surface to be carburized, then carburizing processing is carried out, and a carburizing purpose only in a local area can be reached. While quenching heating, a solid gas carburizer is employed for protection, oxidation and decarbonization on the surface of a carburizing layer are avoided, after quenching, a moveable constant-temperature oil groove is used for substituting an original salt bath heat treatment furnace, interprocess connection time is saved, contact of the workpiece and air at high temperature is reduced, decarburization on the surface of the carburizing layer is avoided; the condition that during a quenching transfer process, the temperature of workpiece surface is reduced to lower than Ms point (180 DEG C) can be avoided; the workpiece after isothermal quenching is placed into a tempering tool case equipped with a protection medium, insulation is carried out, the condition that the temperature of workpiece surface is reduced to lower than Ms point (180 DEG C) can be avoided; at the same time, thermal conduction can be accelerated in subsequent tempering, and energy loss is reduced.

Owner:CHINA HANGFA CHANGZHOU LANXIANG MACHINERY CO LTD

Energy-saving environment-friendly steel cord hot-dip coating copper-zinc alloy and thermal treatment production process thereof

The invention provides an energy-saving environment-friendly steel cord hot-dip coating copper-zinc alloy layer and a thermal treatment production process thereof in the process of steel cord production. The process comprises electrolytic degrading, washing, coating an assistant coating agent, drying, coating copper in hot-dip mode and austenitizing, coating zinc in hot-dip mode and isothermal treatment and diffusion annealing. The temperature for the process of coating the copper in hot-dip mode and austenitizing ranges from 1100 DEG C to 1140 DEG C, and the temperature for the process of coating the zinc in hot-dip mode and diffusion annealing ranges from 550 DEG C to 600 DEG C. After diffusion annealing, mass percentage of zinc in the copper-zinc alloy coating layer ranges from 30%-37%. The production process respectively utilizes the two procedures of coating the copper in hot-dip mode and austenitizing and coating the zinc in hot-dip mode and isothermal treatment to replace four procedures of austenitizing, copper coating, isothermal treatment and zinc coating, solves the problems of heavy metal iron sewage discharging, waste gas exhaust during austenitizing heating and lead and powder pollution during isothermal treatment in the existing production process, and has the advantages of being good in environment protection performance, high in production efficiency and low in production cost.

Owner:NANJING INST OF TECH

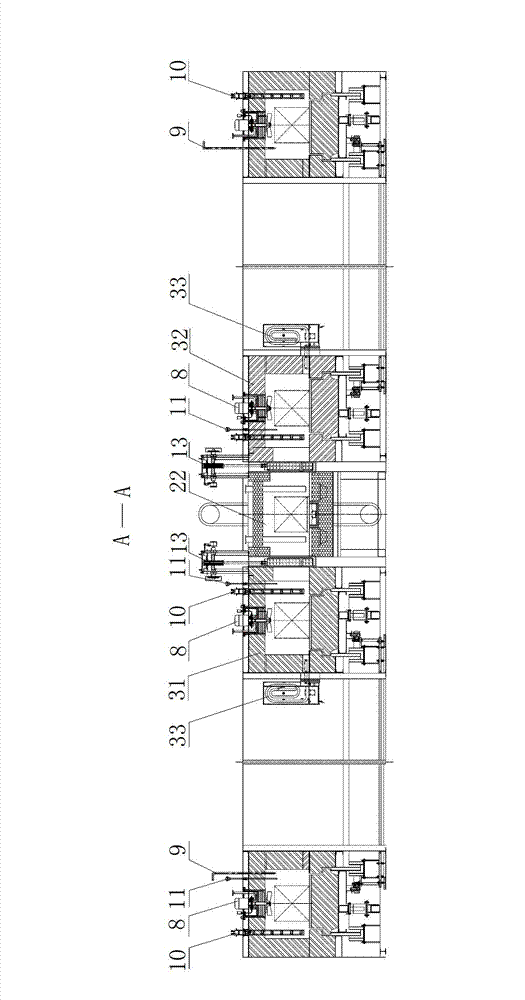

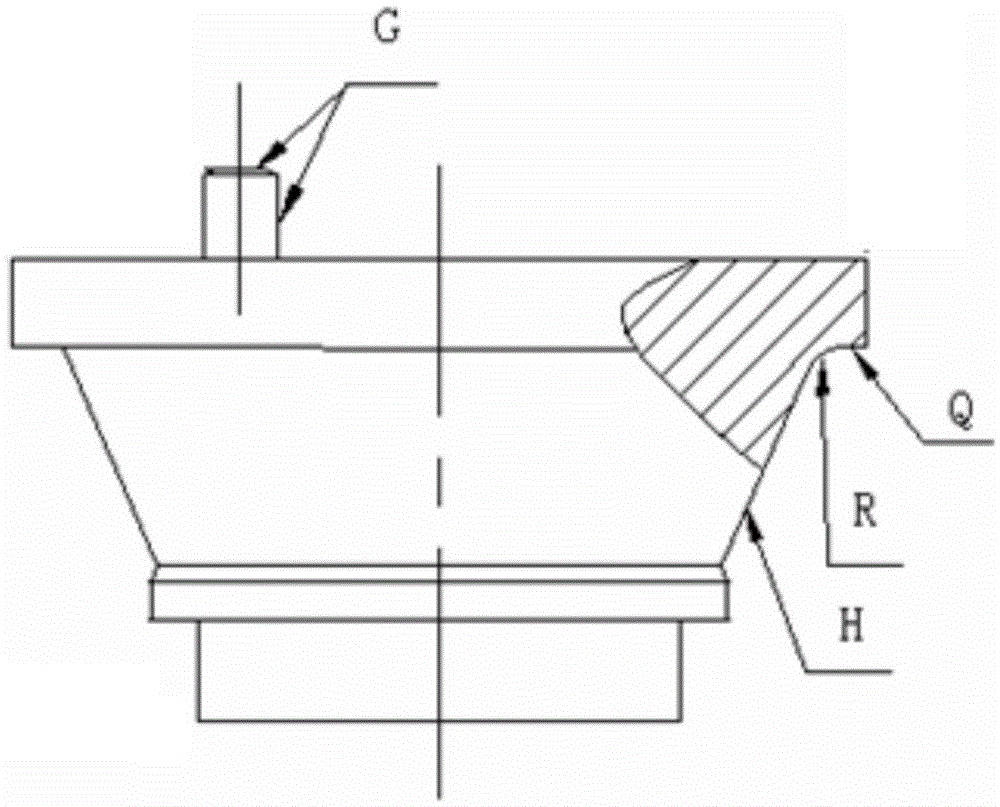

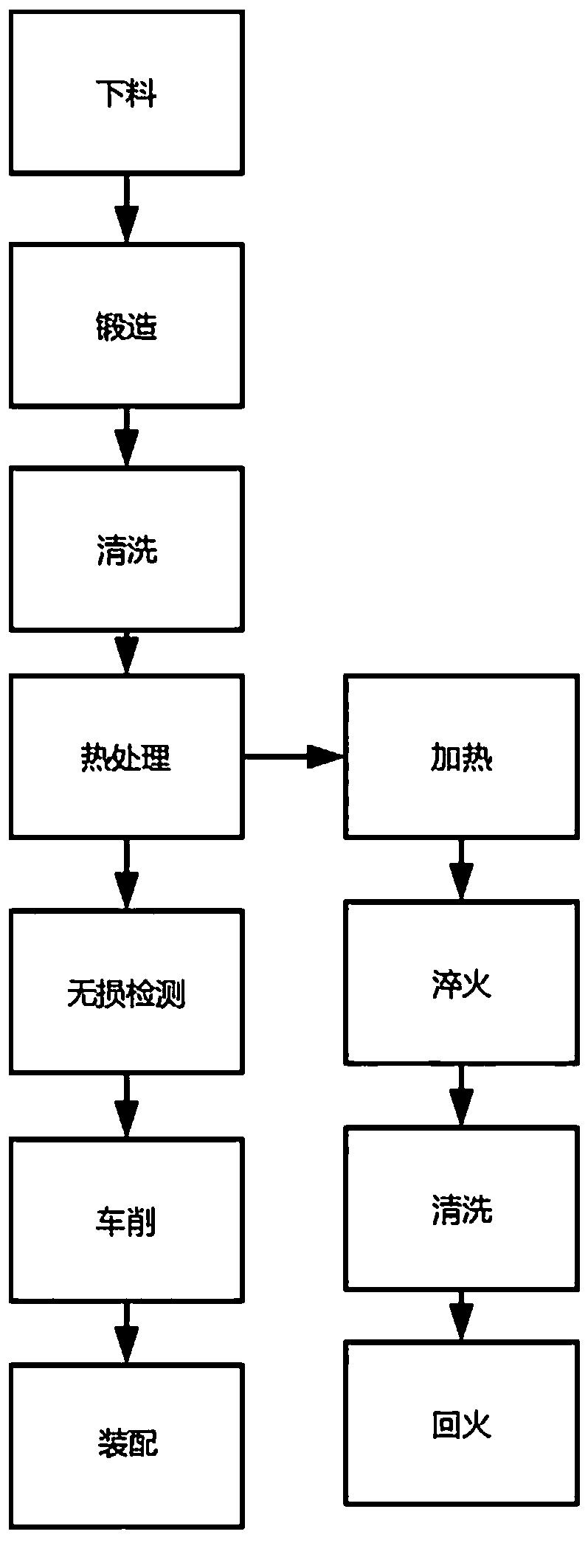

Machining method and device for low-carbon and medium-carbon steel car clutch part

InactiveCN109722505APrevent oxidative decarburizationIncrease productivityFurnace typesHeat treatment furnacesClutchQuenching

The invention discloses a machining method of a low-carbon and medium-carbon steel car clutch part. The method solves the technical problem that for a product center structure state and a product quenching process, cracking happens. The method at least comprises following steps of forging, wherein a workblank is directly forged to the outline of the part, and the section is provided with at leastone ladder, and the wall thickness ranges from 5 to 20 mm; heat treatment, wherein the product is placed on a main furnace mesh belt, the product enters a main furnace to be heated and austenitized, the austenitizing temperature of 820 to 860 DEG C is selected for heating the product, heat preservation is carried out about 40 to 90 minutes, the product is conveyed to a brine tank through the meshbelt, quenching is carried out, after quenching, the product enters a cleaning tank, and the product continuously enters a tempering furnace to be subjected to tempering along with mesh belt transmission; and nondestructive examination, wherein the product subjected to heat treatment is subjected to flaw detection through a nondestructive examination device, cracks on the product crack sensitive size segment can be avoided, the product comprehensive mechanical property is good, and the use condition needs can be completely met.

Owner:ZHEJIANG 81 PRECISION MACHINERY CO LTD +1

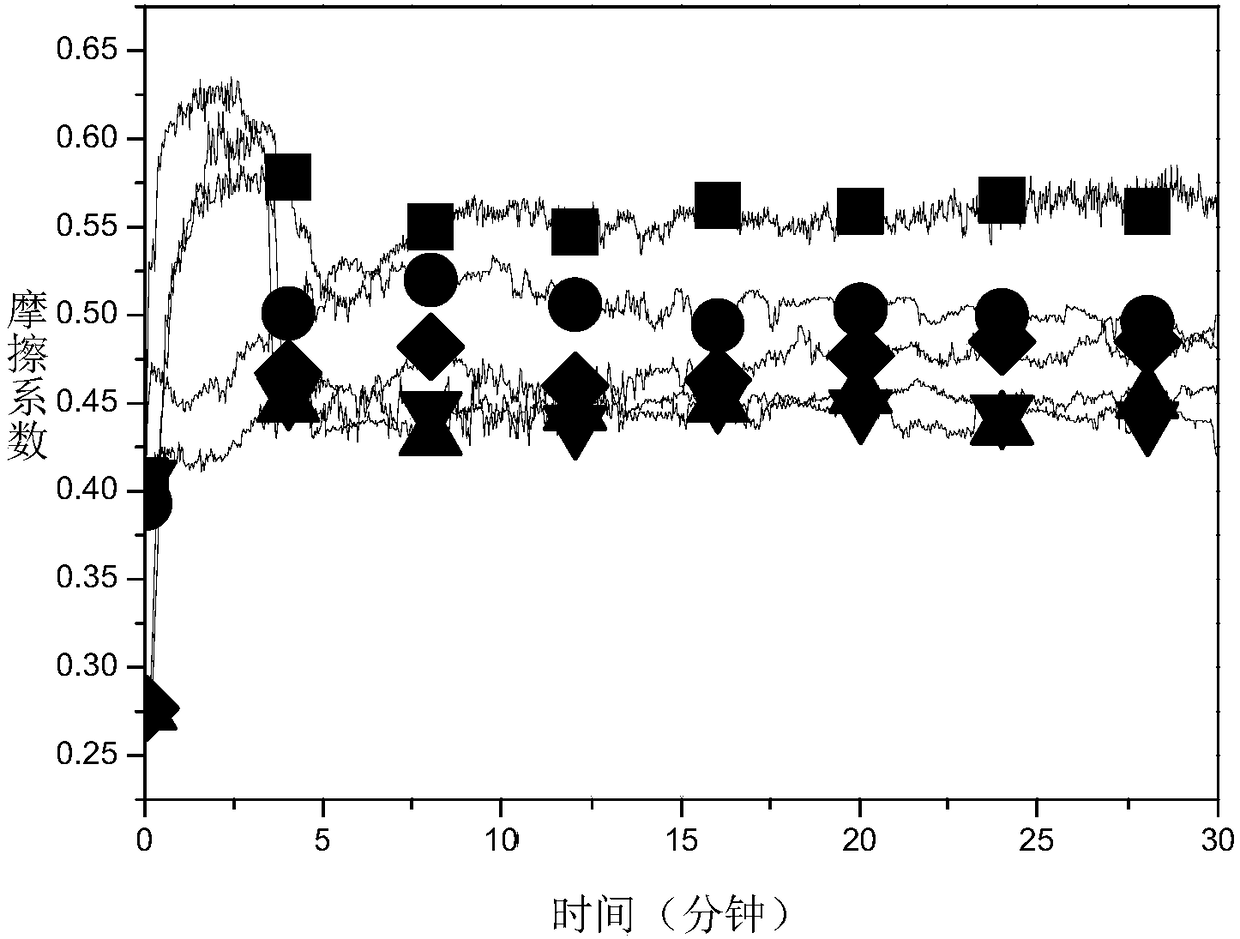

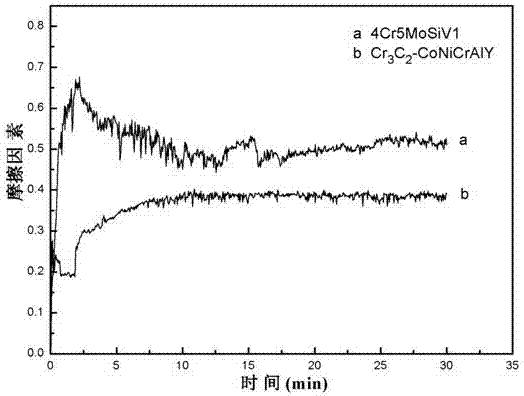

High-performance metal ceramic composite coating for surface strengthening of hot-working die and preparation method thereof

InactiveCN107099766AHigh temperature wear resistanceExcellent high temperature wear resistanceMolten spray coatingThermal fatigueCombustion

The invention discloses a high-performance metal ceramic composite coating for surface strengthening of a hot-working die and a preparation method thereof. The metal ceramic compound coating is prepared by spraying composite powder onto the surface of a pretreated die through adopting active combustion high-speed fuel spraying technology by using Cr3C2-CoNiCrAlY composite powder as a coating material, wherein the composite powder contains the following components in percentage by weight: 70-80% of Cr3C2 and 20-30% of CoNiCrAlY. The metal ceramic coating which is well bonded with a matrix and has high-temperature-resistant and wear-resistant, thermal-fatigue-resistant, corrosion-resistant and high-temperature oxidization-resistant performances can be prepared by using the method, so that the service life of the hot-working die can be greatly prolonged.

Owner:SOUTH CHINA UNIV OF TECH

High temperature anti-oxidation dry powder coating

A high temperature anti-oxidation coating is a protective coating used for inhibiting oxidation at high temperature and aims at solving the defects of comprehensive properties of present high temperature protective coatings used for stainless steel and refractory steel. A high temperature anti-oxidation dry powder coating consists of the following raw materials according to weight percentage: 45-50% of frit, 40-45% of clay and 5-10% of talcum powder. The coating has the advantages of good protection effect when being used in high heat treatment of stainless steel and refractory steel, prevention of oxidation and decarbonization at high temperature between 900-1200 DEG C; no increase of hydrogen in the process of inhibiting oxidation, no harmful effect on parts; automatic fall-off in cooling, reduction of subsequent processing procedures; and convenient coating brush application, as well as readily available raw materials.

Owner:SHENYANG AIRCRAFT CORP +1

Vehicle gear cold extrusion process

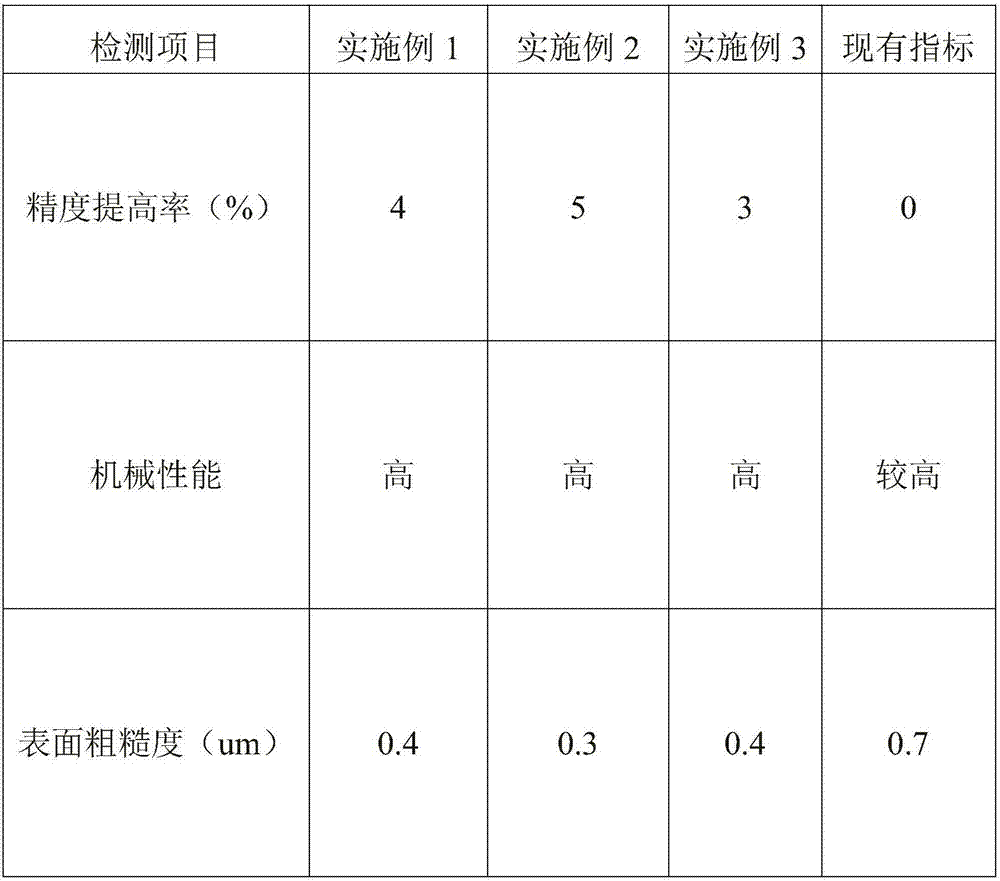

InactiveCN107214287AHigh precisionImprove mechanical propertiesSolid state diffusion coatingFurnace typesPunchingEngineering

The invention discloses a cold extrusion process for automobile gears. The blanking adopts a high-precision band sawing machine and the control of the thickness of the saw blade of the high-precision band sawing machine and the gap between the saw blades can ensure the precision of blanking. The control of the semi-vacuum electric furnace , can prevent oxidation and decarburization of workpieces, and affect the surface quality of cold extrusion processed products. Carburizing treatment after the punching can improve the precision and mechanical properties of automotive gears. The cold extrusion process of automotive gears has high precision and mechanical properties. Advantages, the market prospect is broad.

Owner:ANHUI CAREMIC CONSULTING CO LTD

Method for improving yield deformation resistance of water heater glassed steel inner container welded joint

ActiveCN108620761APrevent oxidative decarburizationLarge bearing capacityWorkpiece edge portionsWelding apparatusWater leakageBurn treatment

The invention relates to a method for improving yield deformation resistance of a water heater glassed steel inner container welded joint. The method mainly solves the technical problems of surface oxidation decarburization, low yield deformation resistance, and cracking and water leakage of an existing water heater glassed steel inner container welded joint. The method for improving the yield deformation resistance of the water heater glassed steel inner container welded joint comprises the steps that 1, a water heater inner container blank is prepared; 2, the surface of the water heater inner container blank is degreased and activated in sequence; 3, the surface of the water heater inner container blank is coated with porcelain enamel through a wet coating method; and 4, the water heaterinner container blank is subjected to enameling burning treatment. The method is capable of improving the yield deformation resistance of the water heater glassed steel inner container welded joint by 5-15%, easy and convenient to operate and control and low in implementation cost.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

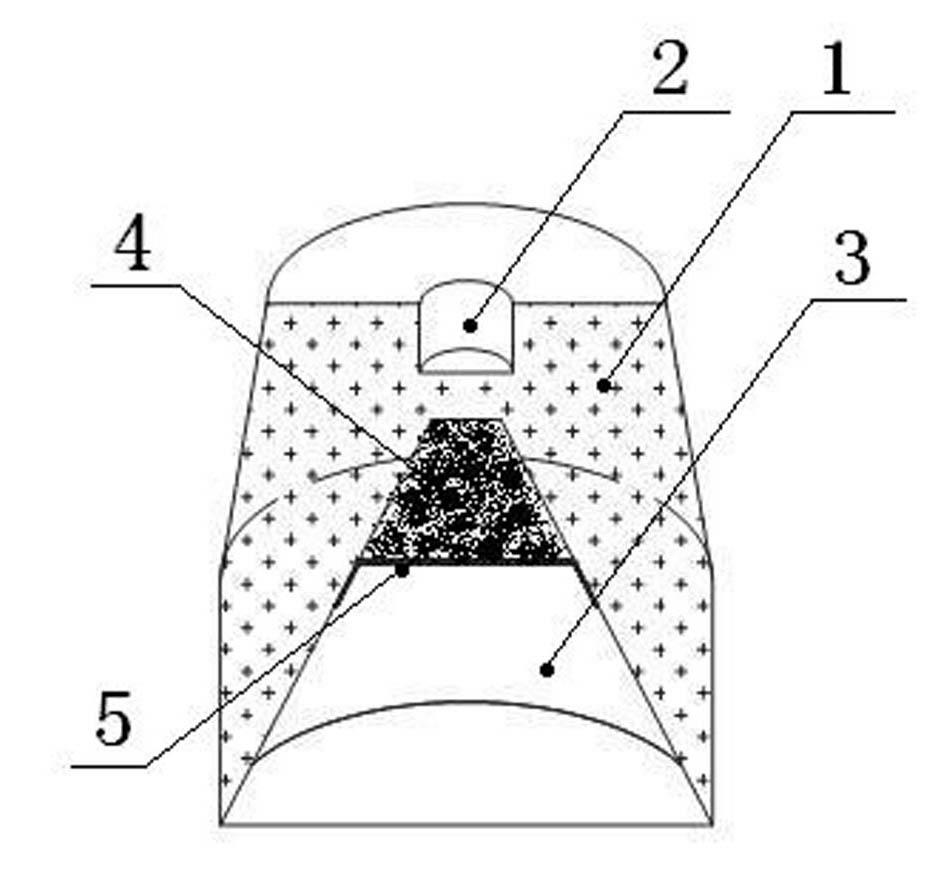

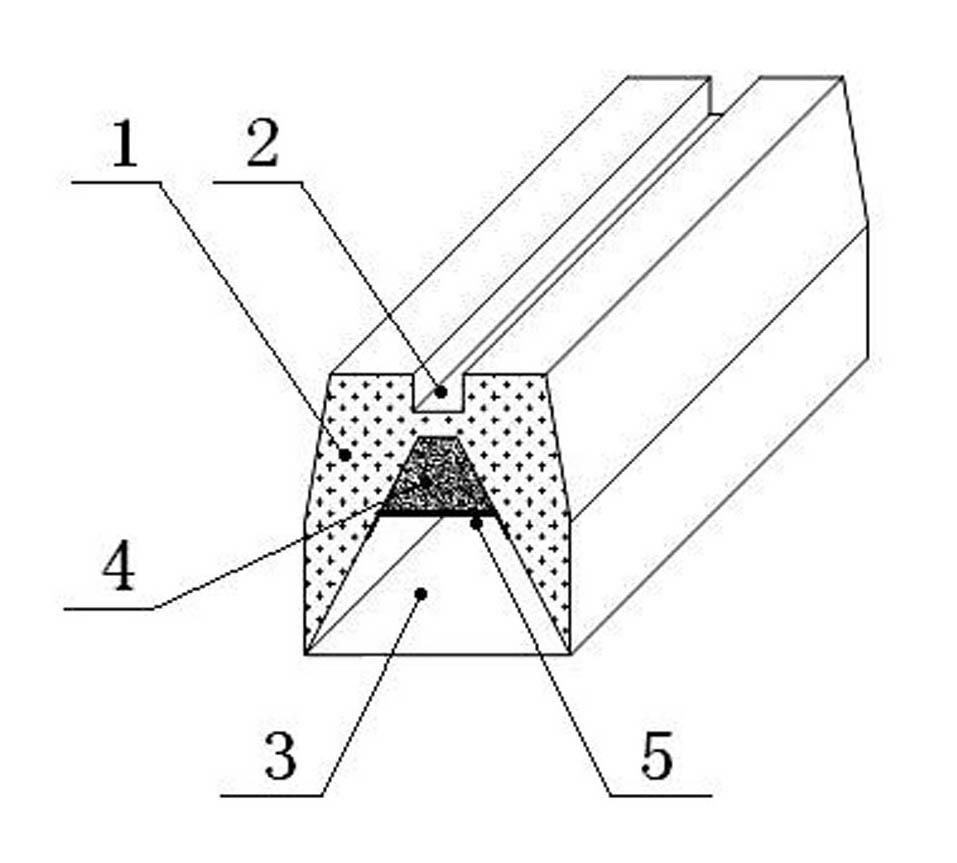

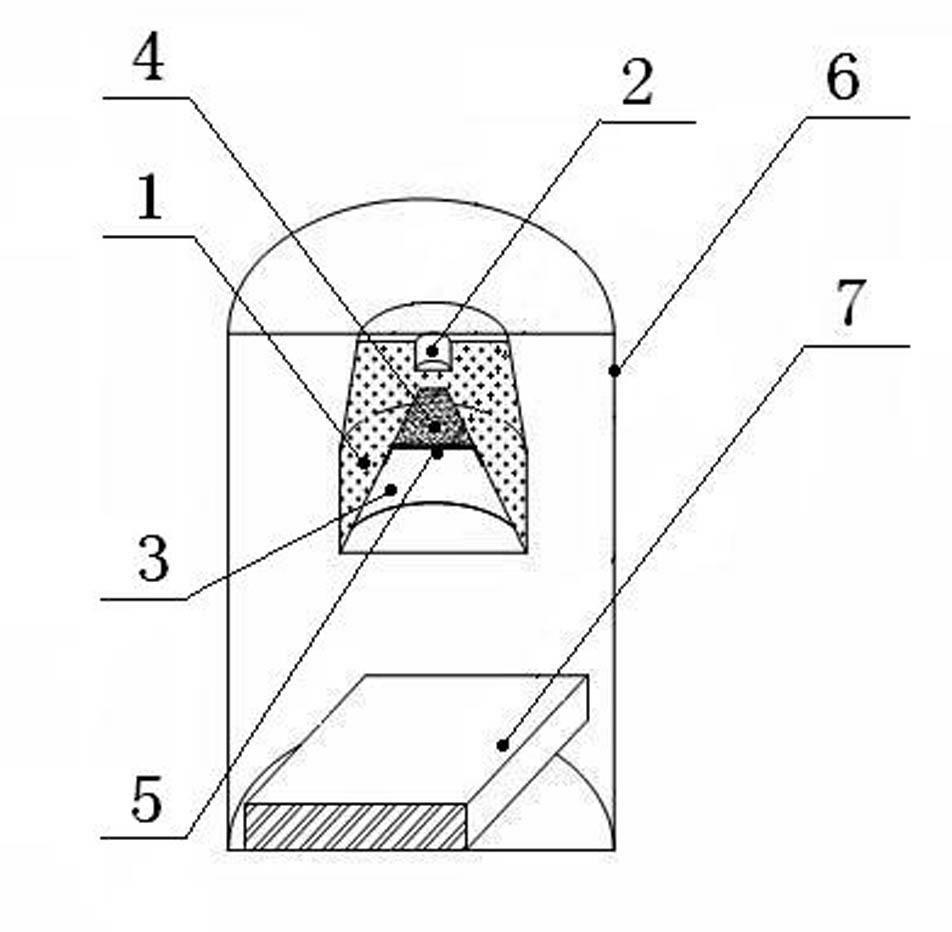

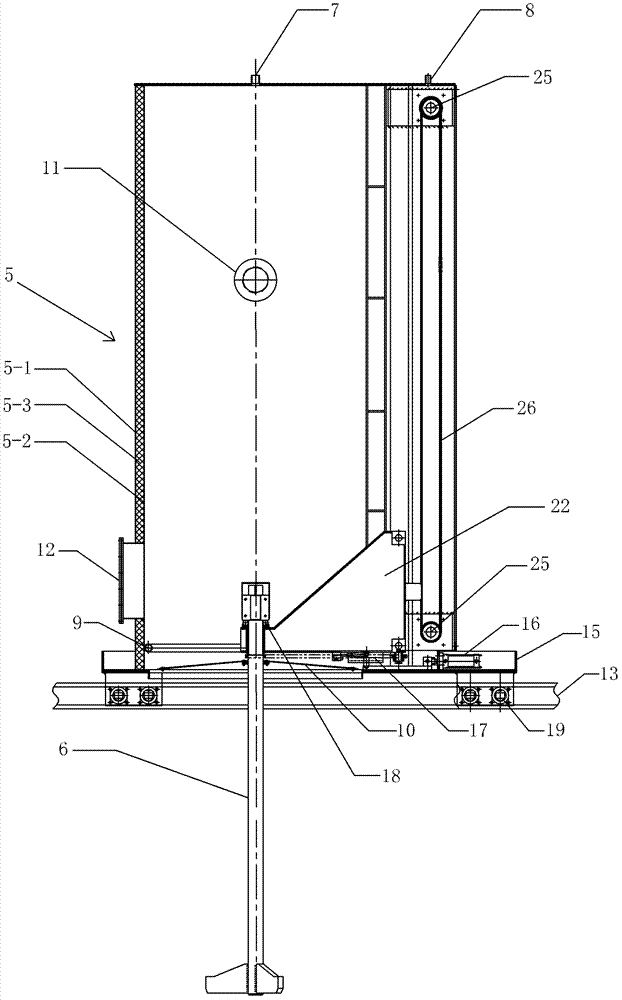

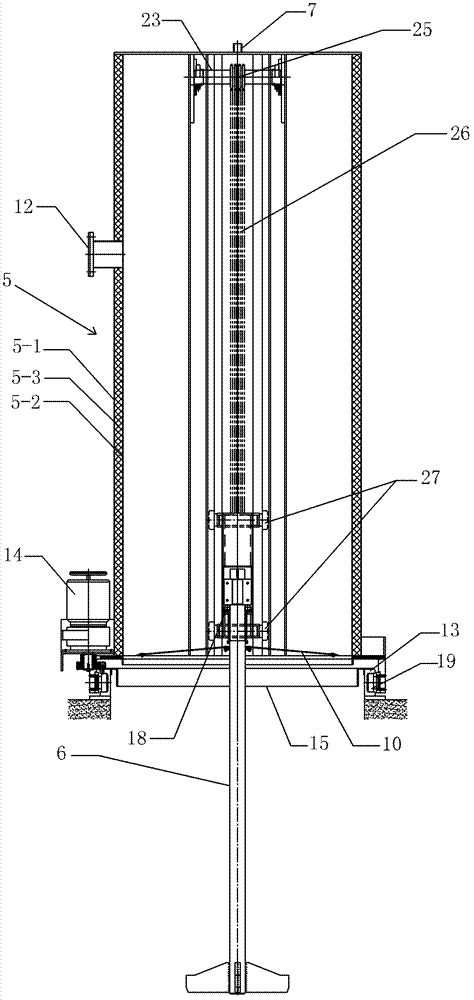

Pit furnace with protective atmosphere device and automatic workpiece transferring device in quenching

ActiveCN102634648APrevent oxidative decarburizationQuality improvementFurnace typesHeat treatment furnacesQuenchingAtmosphere

The invention relates to a pit furnace with a protective atmosphere device and an automatic workpiece transferring device in quenching. The pit furnace comprises a furnace body (1), and is characterized in that a protective atmosphere device, a transfer device (2) and a control device are arranged in the furnace body (1), the protective atmosphere device comprises a protective gas input end (3) and a quenching tank (4), the transferring device (2) consists of a translation mechanism and a vertical movement mechanism, the translation mechanism is connected with a shell (5), and the vertical movement mechanism is connected with a lifting hook (6); a first protective gas inlet (7) and an air exhaust port (8) are arranged at the top of the shell (5), and a second protective gas inlet (9) is arranged at the bottom of the shell (5); the first protective gas inlet (7) and the second protective gas inlet (9) are communicated with a protective gas input end (3); and the control device is connected with the control input end of the translation mechanism, the control input end of the vertical movement mechanism, and the control input end of an air valve. The pit furnace not only can prevent oxidation and decarburization of workpieces through protective atmosphere, but also can conduct automatic quenching, a worker does not need to get close to operate at high temperature, the quality of products is improved, and the labor conditions are also improved.

Owner:GUANGDONG STRONG METAL TECH

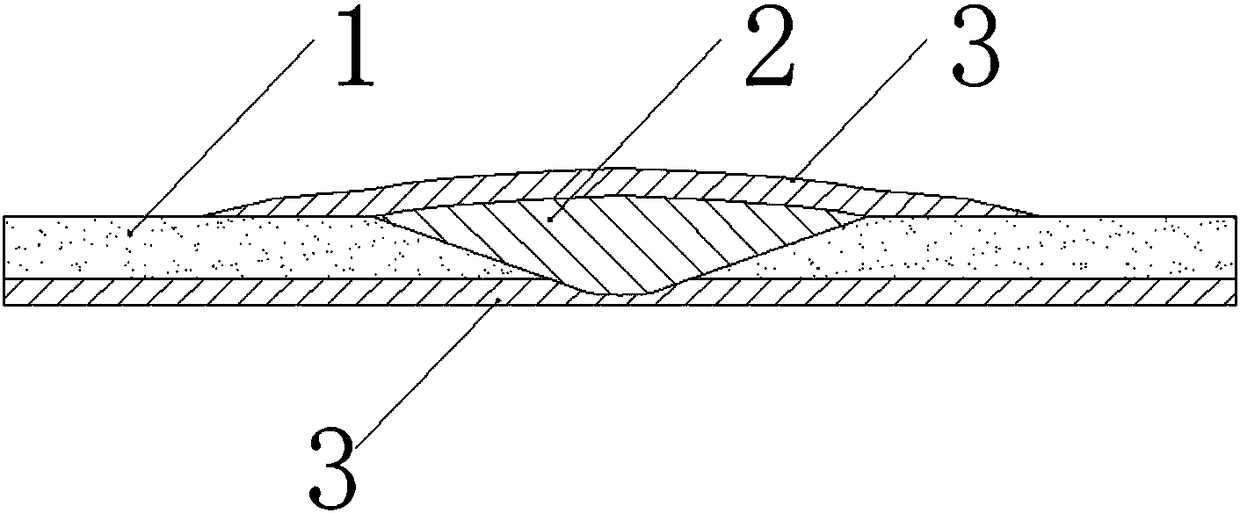

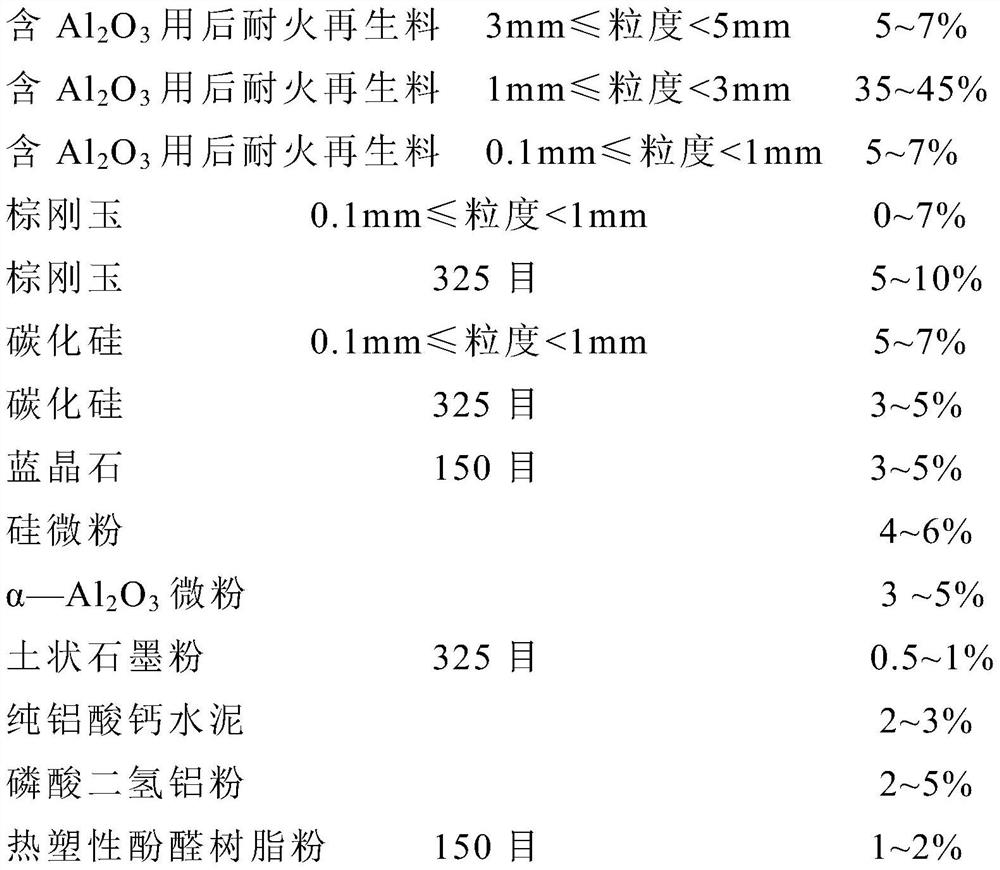

Torpedo ladle lining smearing repair material, preparation method and use method

PendingCN111943693AExcellent performance indexExtended service lifeMelt-holding vesselsCarbon filmTorpedo

The invention discloses a torpedo ladle lining smearing repair material, a preparation method and a use method. The torpedo ladle lining smearing repair material comprises three Al2O3-containing usedrefractory reclaimed materials with different granularities and two brown fused alumina with different granularities, and the surfaces of the three Al2O3-containing used refractory reclaimed materialswith different granularities and the two brown fused alumina with different granularities are coated or partially coated with nano carbon films; wherein the thickness of the nano carbon film is 20-200 nanometers, and the fixed carbon content of the nano carbon film is more than or equal to 90%. The repair material has the characteristics of low raw material cost, wide renewable resource source, excellent thermal shock resistance, high interface bonding strength of a repairing layer, strong slag iron erosion resistance, simplicity and convenience in preparation and application and the like. Bymeans of the repair material, the service life of the torpedo ladle is prolonged, the consumption and maintenance cost of torpedo ladle refractory materials are reduced, the heat preservation and insulation performance of the torpedo ladle refractory material lining is improved, and the temperature drop of molten iron is reduced.

Owner:武汉钢铁有限公司

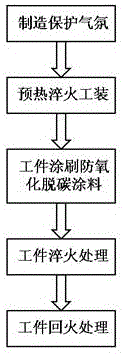

Heat treatment improvement process of wave spring for bearing

InactiveCN106191415APrevent oxidative decarburizationImprove performanceFurnace typesHeat treatment furnacesProcess conditionsQuenching

The invention provides a heat treatment improvement process of a wave spring for a bearing. The heat treatment improvement process comprises the following steps: (a), creating a protective atmosphere; (b) preheating a quenching tooling; (c) coating a workpiece with oxidation-decarbonization resistant paint; (d) subjecting the workpiece to quenching treatment; and (e) subjecting the workpiece to tempering treatment. The heat treatment improvement process disclosed by the invention has the advantages that the process conditions are optimized and a quenching protection method is improved, thereby effectively protecting the workpiece from oxidation and decarbonization during a heating process, and guaranteeing the performance stability of the workpiece.

Owner:SUZHOU CITY HUQIU DISTRICT HUSHUGUAN SPRING FACTORY

Heat treatment process for 65Mn spring washer

ActiveCN103194588BGuaranteed performancePrevent oxidative decarburizationFurnace typesHeat treatment furnacesThermal insulationShielding gas

The invention relates to a heat treatment process for a 65Mn spring washer. The heat treatment process comprises the following steps: blanking; electric spark perforation of basic bores; linear cutting and forming; correction by a fitter; heat treatment; performance test; and surface treatment; wherein during quenching in the step of heat treatment, firstly, the 65Mn spring washer is subjected to preheating which means the 65Mn spring washer is put into a quenching tool heated in advance, then a quenching furnace is heated, charcoal is added into the quenching furnace, the quenching tool is placed into the quenching furnace with a temperature maintained to be constant, then the quenching tool is taken out, the 65Mn spring washer is put into the quenching tool, quenching is carried out immediately after thermal insulation, and the surface of the 65Mn spring washer is coated with an anti-oxidation decarburization paint before the 65Mn spring washer is placed into the quenching tool. According to the invention, the charcoal is added into the quenching furnace for generation of protective gas, the anti-oxidation decarburization paint is coated on the surface of the spring washer for prevention of oxidation and decarburization, so desired performances of the spring washer are guaranteed.

Owner:HANGZHOU BRANCH ZHEJIANG GEELY AUTOMOBILE RES INST +2

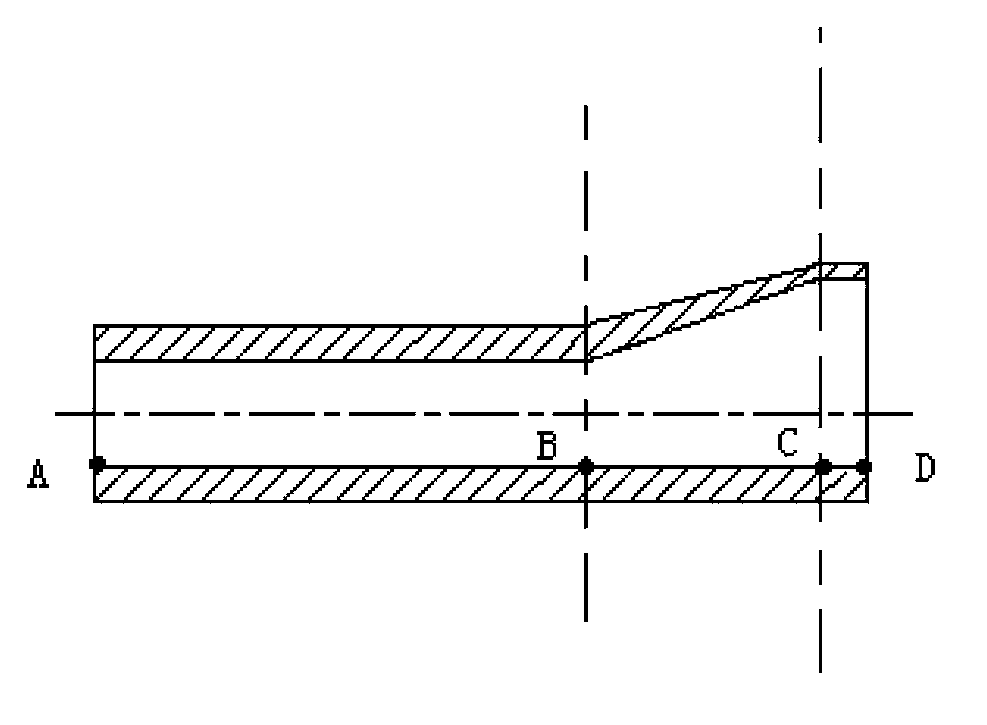

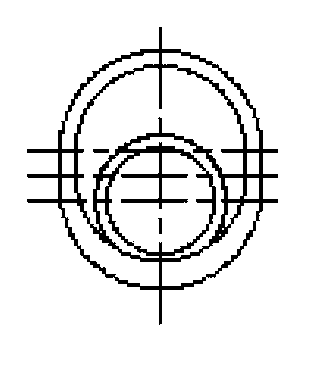

Eccentric check reducer forging method

InactiveCN103801644AAvoid deformationPrevent oxidative decarburizationMetal-working apparatusEngine componentsSlope angleEngineering

The invention belongs to the field of the metal forging technology, and particularly relates to an eccentric check reducer forging method. The method includes the following steps that (Step 1) a slope is turned on the front end of a pipe billet, and the slope angle Alpha is 5 to 13 degrees; (Step 2) glass lubricant is applied in the bore of the pipe billet, and the spraying range includes the shaped part and is extended backward for 15mm to 30mm; (Step 3) the coated pipe billet is heated, and the heating range includes the shaped part and is extended backward for 5mm to 10mm; (Step 4) a die with a guiding mechanism is used for forging on a horizontal forging machine, including: preforging: a semi-conical surface, of which the slope is smaller than 26 degrees, is first forged on the shaped orifice of the pipe billet; final forging: the shaped orifice of the pipe billet is then forged into an eccentric check reducer; (Step 5) the finally forged eccentric check reducer is put into an insulating box and slowly cooled.

Owner:CHINA HANGFA SOUTH IND CO LTD

Decarburization-resistant coating

The invention discloses a decarburization-resistant coating. The decarburization-resistant coating consists of Na2O.SiO2, Al2O3 and Cr2O3. The decarburization-resistant coating adopts relatively cheaper industrial raw materials, is reasonable in formula and great in high temperature resistance, can greatly reduce oxidization decarburization during thermal treatment, can automatically fall off from the surface of a base body after the heating of a workpiece is finished, and thus has great application prospects.

Owner:JINAN HAOZE ENVIRONMENTAL PROTECTION TECH CO LTD

Oxidation and decarbonization preventing coating

The invention discloses an oxidation and decarbonization preventing coating. A first coating consists of Na2O.SiO2, Al2O3 and TiO2; and a second coating is composed of graphite powder and polyinternalolefin. According to the oxidation and decarbonization preventing coating, a double-layer coating is adopted, so that oxidation and decarbonization are greatly reduced during thermal treatment; and after workpieces are heated, the coating can be automatically peeled off from the surface of a basal body; and meanwhile, the coating is low in price, and has a good application prospect.

Owner:JINAN HAOZE ENVIRONMENTAL PROTECTION TECH CO LTD

A kind of preparation method of rare earth oxide doped high temperature oxidation resistant and wear resistant coating for H13 steel surface protection

ActiveCN108531844BImprove bindingWith high temperature wear resistanceMolten spray coatingCrazingWear resistance

The invention discloses a rare earth oxide doped high temperature oxidation resisting and abrasion resisting coating for H13 steel surface protecting and a preparation method of the coating. Accordingto the method, an active combustion-high velocity air fuel (AC-HVAF) technology is adopted for spraying powder on a base body (H13 steel) to form the composite coating; and the powder comprises Cr3C2-NiCr powder and nanometer CeO2 powder, the doping content of the nanometer CeO2 powder is 2-8 wt%, and the balance is the Cr3C2-NiCr powder. The coating prepared through the method is compact in structure and uniform in distribution, a flattened structure is achieved, and the coating is closely combined with a boundary. Besides, after doping of the nanometer CeO2 powder, the tissue compactness ofthe coating is further improved, the porosity is reduced, the defects of non-molten matter, micro cracks and the like are less, better high temperature oxidation resisting performance and abrasion resisting performance are both achieved, and the high temperature oxidation resisting performance and the abrasion resisting performance of the H13 steel in the using process can be improved easily.

Owner:GUANGDONG ZHENGDE MATERIAL SURFACE TECH

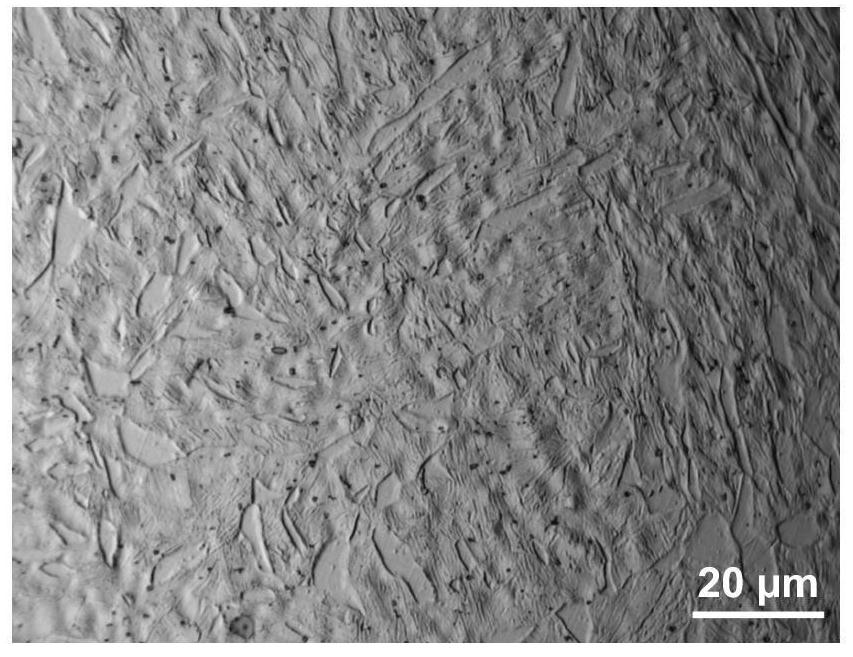

Anti-decarburization heat treatment method for hobbing cutter ring of shield tunneling machine

ActiveCN112143863AMitigation of oxidative decarburization behaviorReduce oxygen contentFurnace typesHeat treatment furnacesHobbingEngineering

The invention belongs to the technical field of cutters of shield tunneling machines, and particularly relates to an anti-decarburization heat treatment method for a hobbing cutter ring of a shield tunneling machine. The anti-decarburization heat treatment method of the hobbing cutter ring of the shield tunneling machine comprises the following steps of: placing the hobbing cutter ring with the surface coated with an oxidation coating, of the the shield tunneling machine in a cavity of heat treatment equipment, and raising the temperature to the final temperature under the normal pressure, performing heat preservation and heat treatment, wherein coal balls are placed in the cavity of the heat treatment equipment; the oxidation coating comprises a first anti-oxidation coating and a second anti-oxidation coating in sequence from inside to outside; the first anti-oxidation coating is prepared from Na2O. 2SiO2, Al2O3, Cr2O3, NaF, TiO2 and V2O5; and the second anti-oxidation coating is prepared from SiC, graphite powder and polyinternalolefin. Test results show that the surface structure of the hobbing cutter ring treated by the anti-decarburization heat treatment method provided by theinvention is a large amount of lath martensite, and the hobbing cutter ring has obvious embossments on the surface and the hardness of 54 HRC.

Owner:广州鑫润丰东热处理有限公司

Pit furnace with protective atmosphere device and automatic workpiece transferring device in quenching

ActiveCN102634648BPrevent oxidative decarburizationQuality improvementFurnace typesHeat treatment furnacesQuenchingAtmosphere

The invention relates to a pit furnace with a protective atmosphere device and an automatic workpiece transferring device in quenching. The pit furnace comprises a furnace body (1), and is characterized in that a protective atmosphere device, a transfer device (2) and a control device are arranged in the furnace body (1), the protective atmosphere device comprises a protective gas input end (3) and a quenching tank (4), the transferring device (2) consists of a translation mechanism and a vertical movement mechanism, the translation mechanism is connected with a shell (5), and the vertical movement mechanism is connected with a lifting hook (6); a first protective gas inlet (7) and an air exhaust port (8) are arranged at the top of the shell (5), and a second protective gas inlet (9) is arranged at the bottom of the shell (5); the first protective gas inlet (7) and the second protective gas inlet (9) are communicated with a protective gas input end (3); and the control device is connected with the control input end of the translation mechanism, the control input end of the vertical movement mechanism, and the control input end of an air valve. The pit furnace not only can prevent oxidation and decarburization of workpieces through protective atmosphere, but also can conduct automatic quenching, a worker does not need to get close to operate at high temperature, the quality of products is improved, and the labor conditions are also improved.

Owner:GUANGDONG STRONG METAL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com