Blade installation seat heat treatment method

A heat treatment method and blade installation technology, which is applied in the field of heat treatment of 18Cr2Ni4WA workpieces, can solve the problems of oxidative decarburization, formation of tempered sorbite in the carburized layer, and the surface hardness of the carburized surface cannot meet the requirements, so as to control carburizing quality and production high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

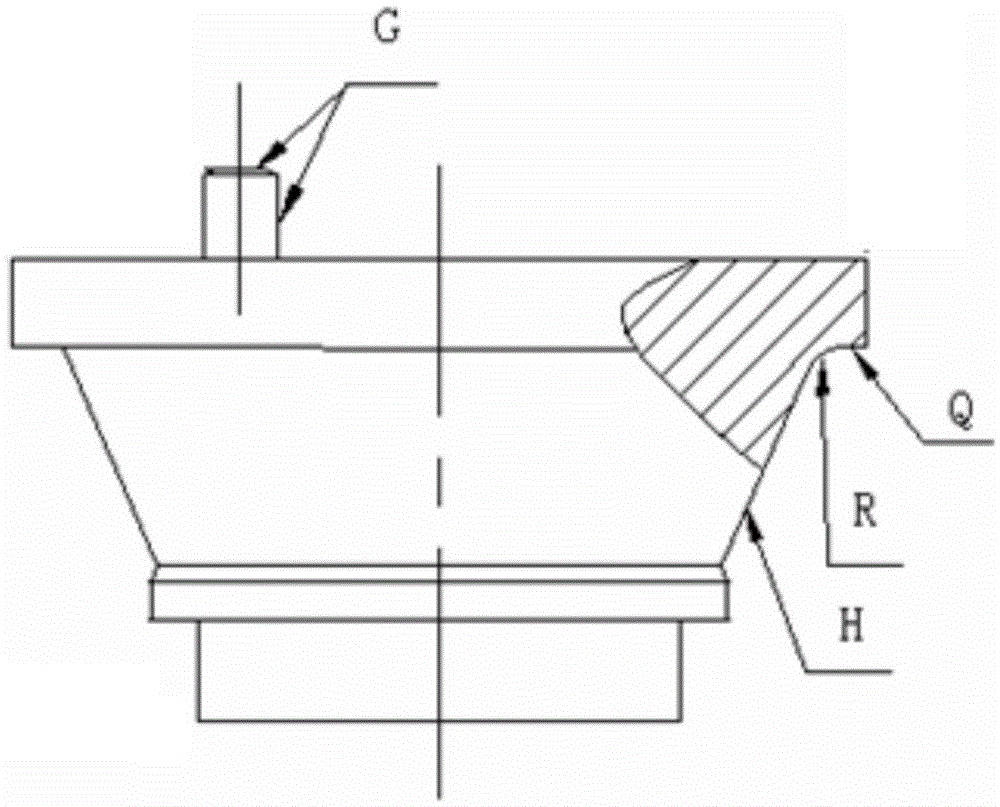

[0021] In the heat treatment method of the blade mounting seat in this embodiment, the blade mounting seat after quenching and tempering treatment is mechanically processed to remove the surface scale; the surface of the blade mounting seat workpiece is copper-plated to ensure that the surface of the workpiece is completely covered with a copper-plated protective film; The mounting seat is machined to remove the copper-plated protective film attached to the surface of the Q, R, H, and G areas, which is convenient for subsequent carburizing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com