Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

103results about How to "Shorten transition time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Biological crust sand fixing technology

InactiveCN1843075AReasonable structureShorten transition timeHorticulture methodsSurface corrosionAgronomy

The invention relates to a method for restoring ground surface by using the natural breeding of culture got from microbiological crust in desert soil. The invention simulates the natural rule of microbiological crust in soil to make the forming time of high cover rate of crust in desert soil be shortened, which can not only treat sand running in desert fast but also make the development between creatures and environment and creatures in treating area be harmonic in the long run. The invention is of great importance in increasing crust cover rate in desert area, increasing stability of sand surface and reducing surface corrosion.

Owner:XINJIANG INST OF ECOLOGY & GEOGRAPHY CHINESE ACAD OF SCI +1

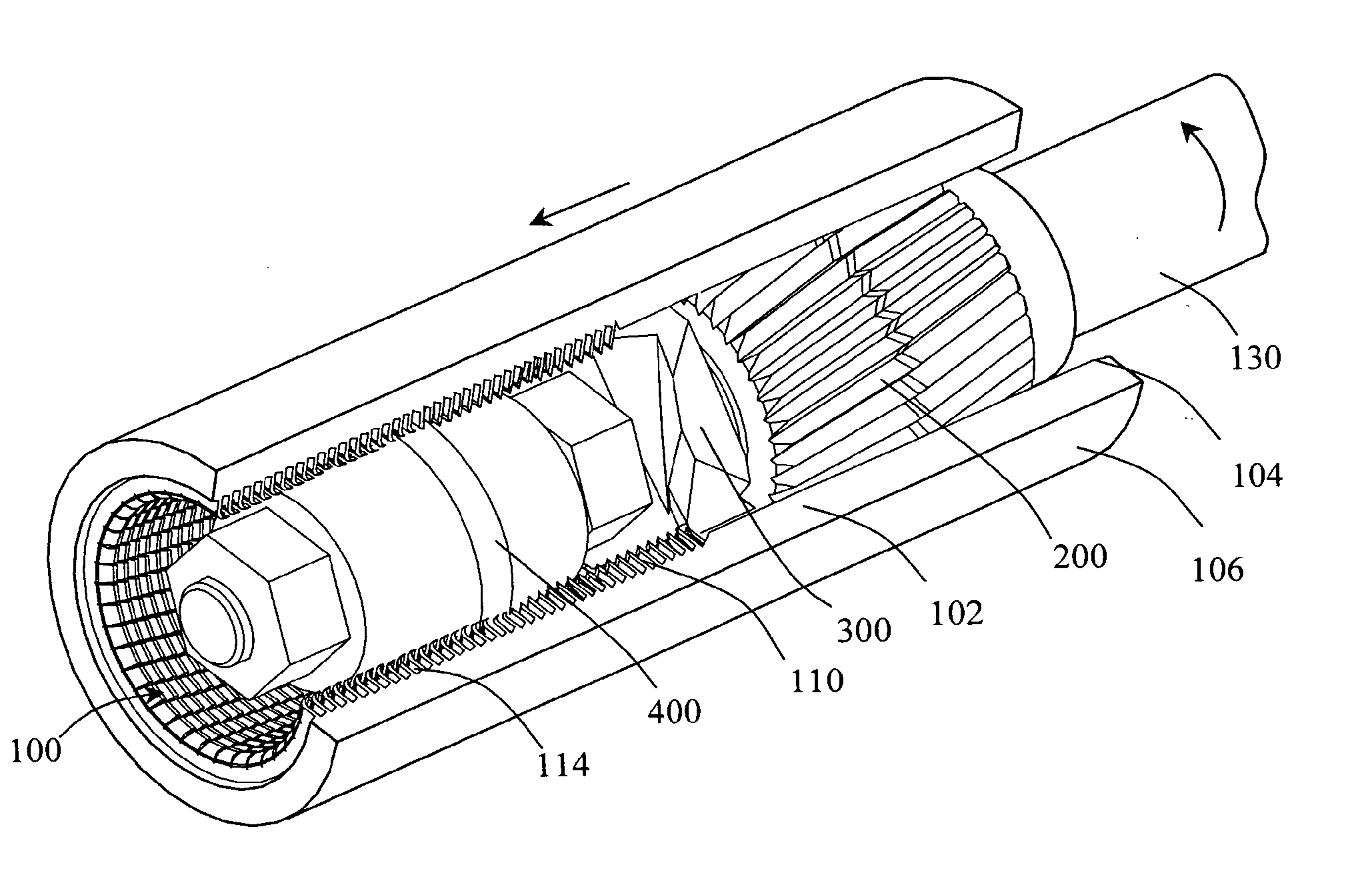

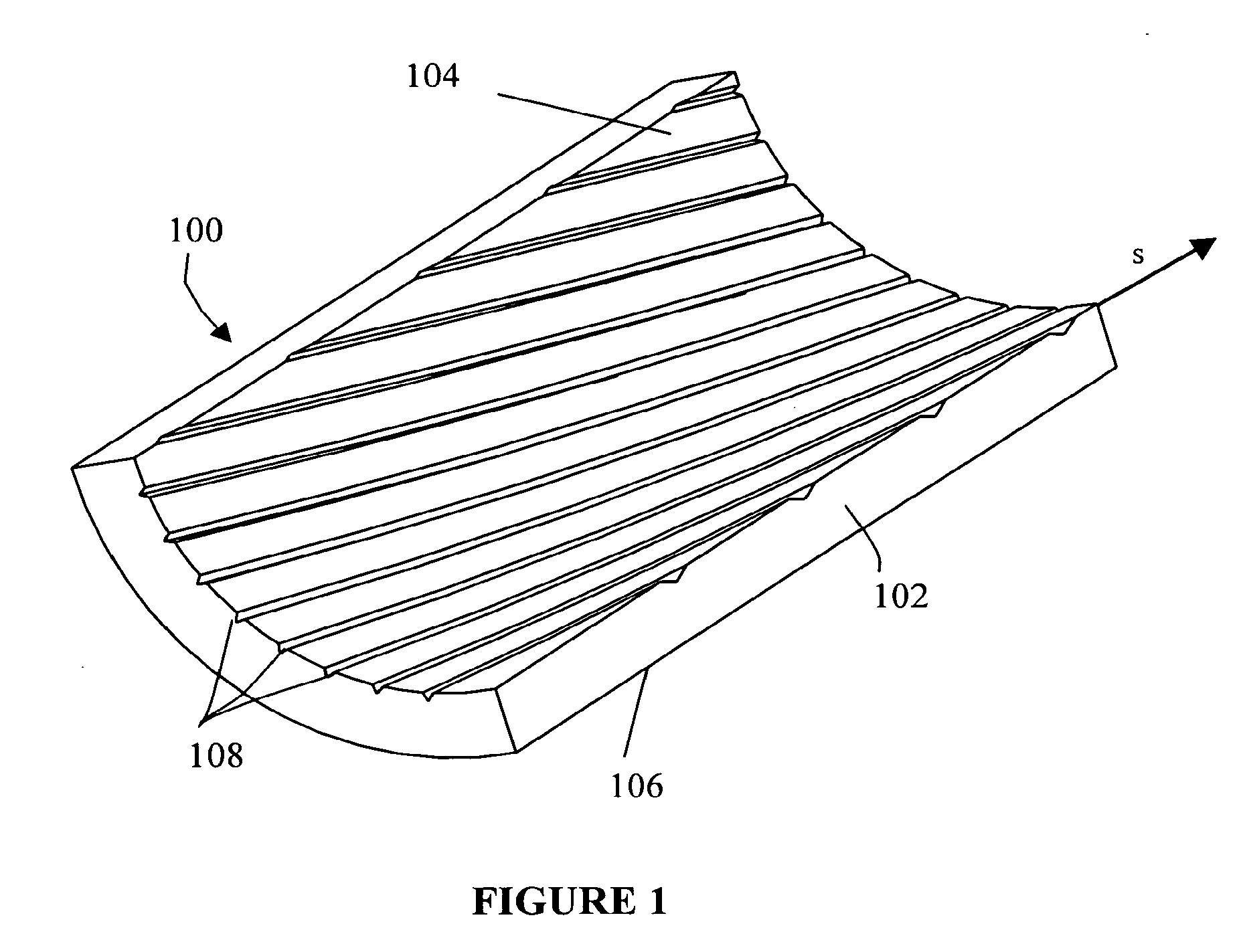

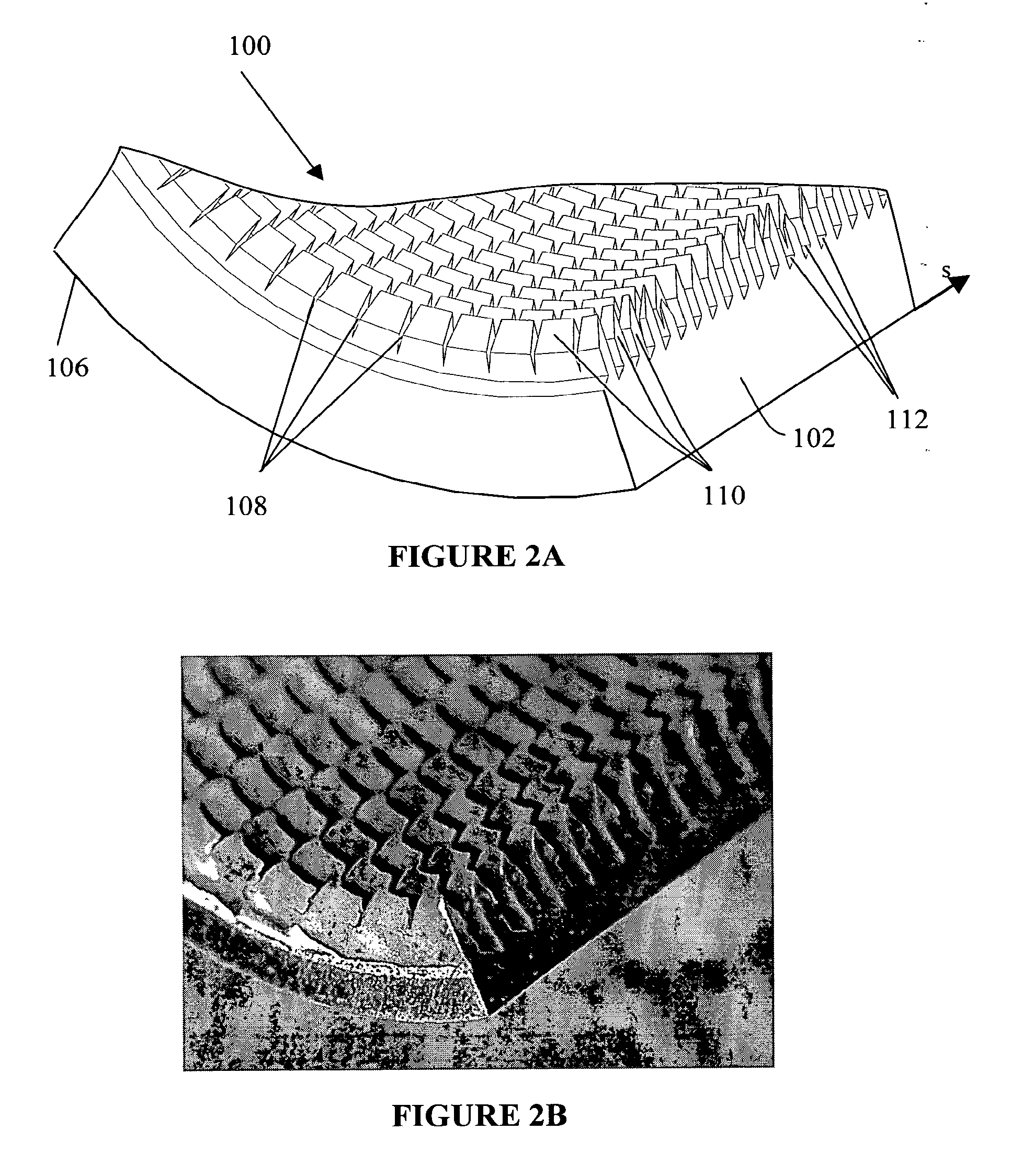

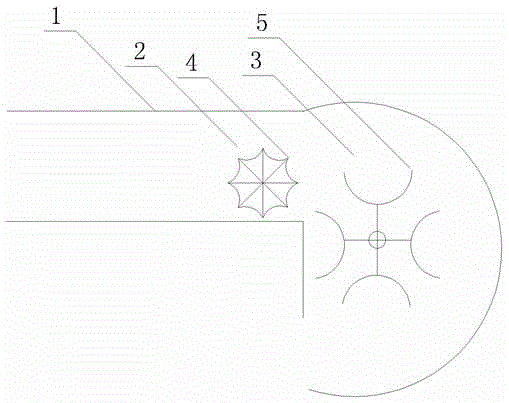

Method for Making Enhanced Heat Transfer Surfaces

ActiveUS20070234871A1Improve heat transfer performanceShorten transition timeHeat transfer modificationMetal working apparatusBiomedical engineeringEnhanced heat transfer

The invention relates to enhanced heat transfer surfaces and methods and tools for making enhanced heat transfer surface. Certain embodiments include a boiling surface that include a plurality of primary grooves, protrusions and secondary grooves to form boiling cavities. The boiling surface may be formed by using a tool for cutting the inner surface of a tube. The tool has a tool axis and at least one tip with a cutting edge and a lifting edge. Methods for making a boiling surface are also disclosed, including cutting through the inner surface of a tube to form primary grooves, then cutting and lifting the inner surface to form protrusions and secondary grooves.

Owner:WIELAND WERKE AG

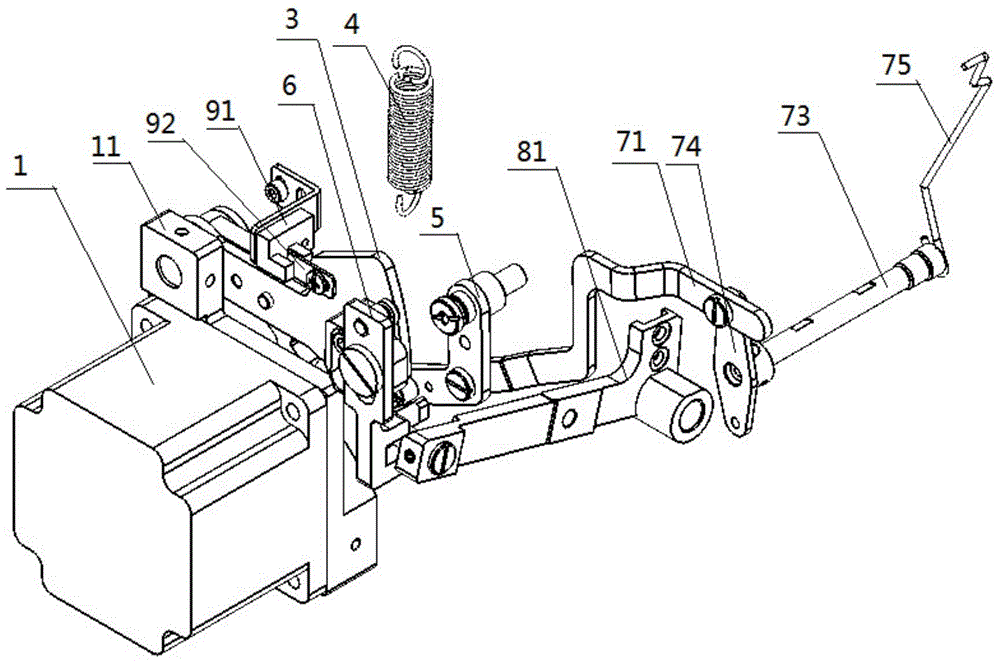

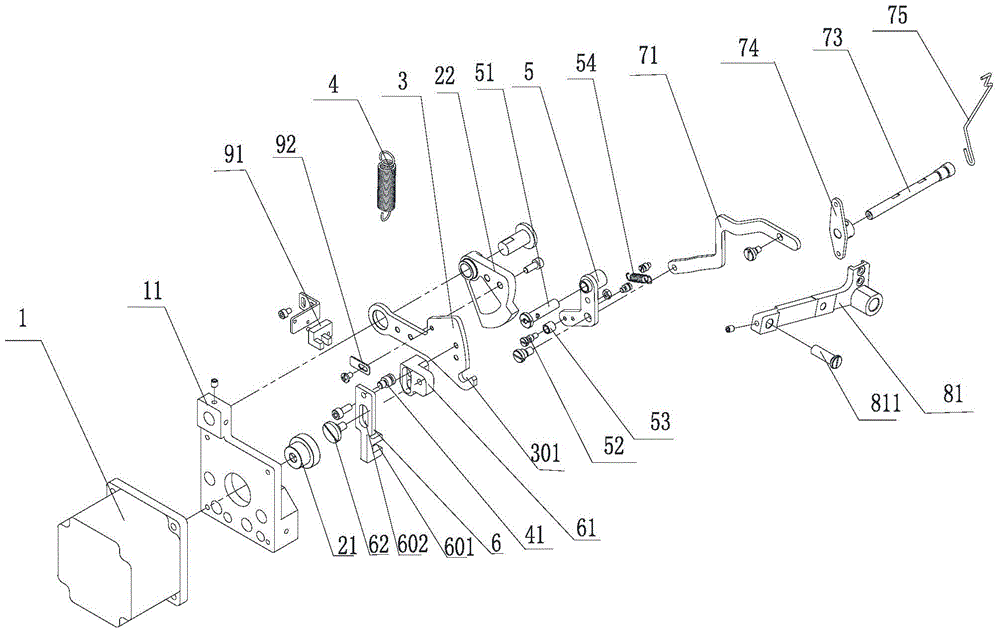

Driving mechanism for thread sewing and presser foot lifting thread-scissoring and buttonholing machine

ActiveCN104099726AHigh degree of automationShorten transition timeNeedle severing devicesSewing-machine control devicesDrive motorEngineering

The invention provides a driving mechanism for thread sewing and presser foot lifting thread-scissoring and a buttonholing machine. The driving mechanism for the thread sewing and the presser foot lifting thread-scissoring comprises a driving motor, a first starting plate, a first transmission piece, a second reset spring, a second transmission piece and a first reset spring, wherein the first starting plate is in transmission connection with the driving motor; the first transmission piece drives a thread sewing component to move; the second reset spring is used for resetting the first transmission piece; the first transmission piece is connected with a thread-loosening connecting rod in a thread sewing component; one end of the first transmission piece is connected with the first starting plate; the other end of the first transmission piece is hinged and fixed; the second transmission piece drives a presser foot lifting thread-scissoring component to move; the first reset spring is used for resetting the second transmission piece; the second transmission piece is connected with a main transmission rod in the presser foot lifting thread-scissoring component; an elongated hole extending along the vertical direction is formed in the second transmission piece; a shaft bolt fixedly connected with the first starting plate penetrates in the elongated hole. According to the driving mechanism and the buttonholing machine, the degree of automation is high; the connection time between every two adjacent actions is shortened; the working efficiency is improved; the labor intensity of workers is decreased greatly.

Owner:BULLMER ELECTROMECHANICAL TECH

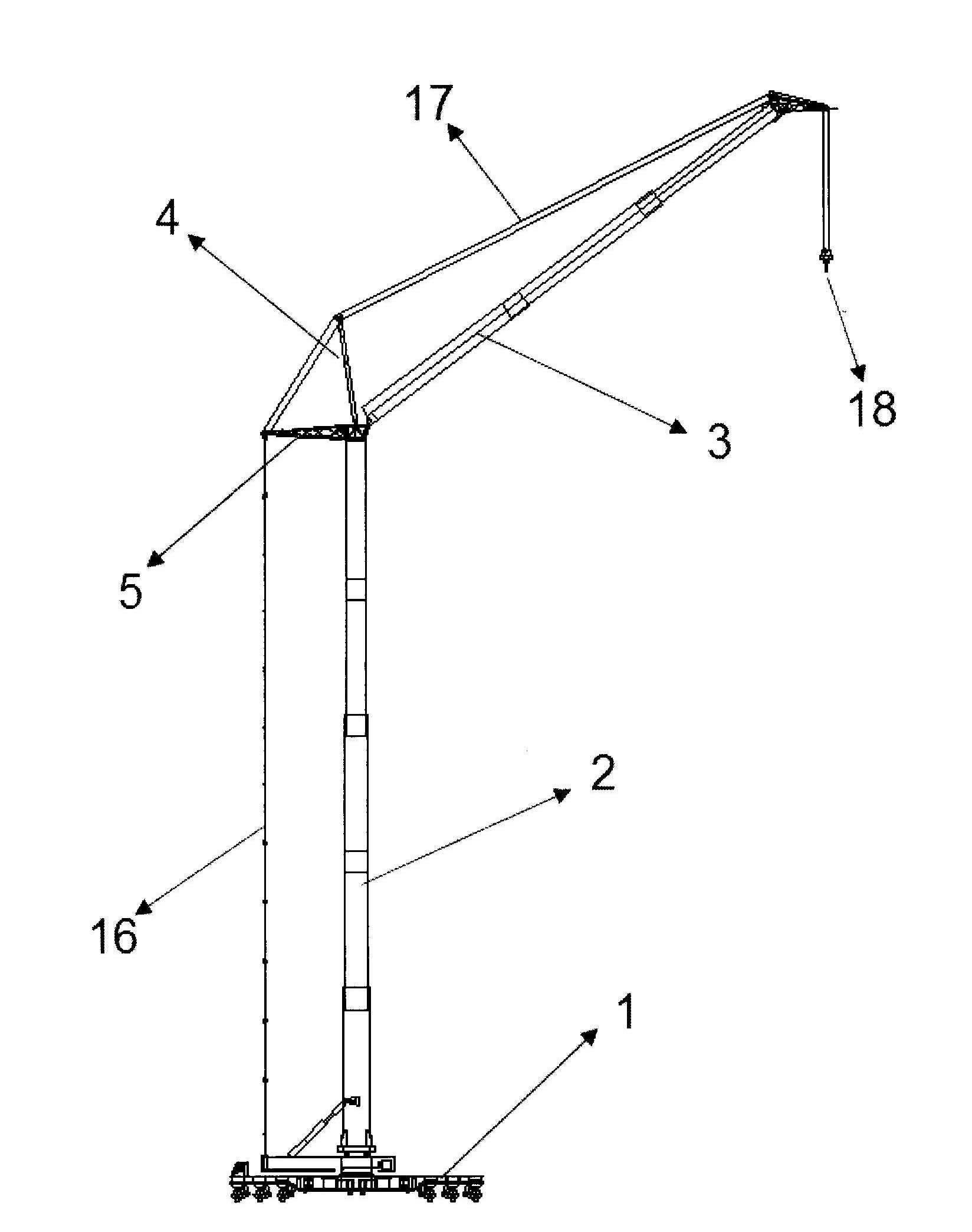

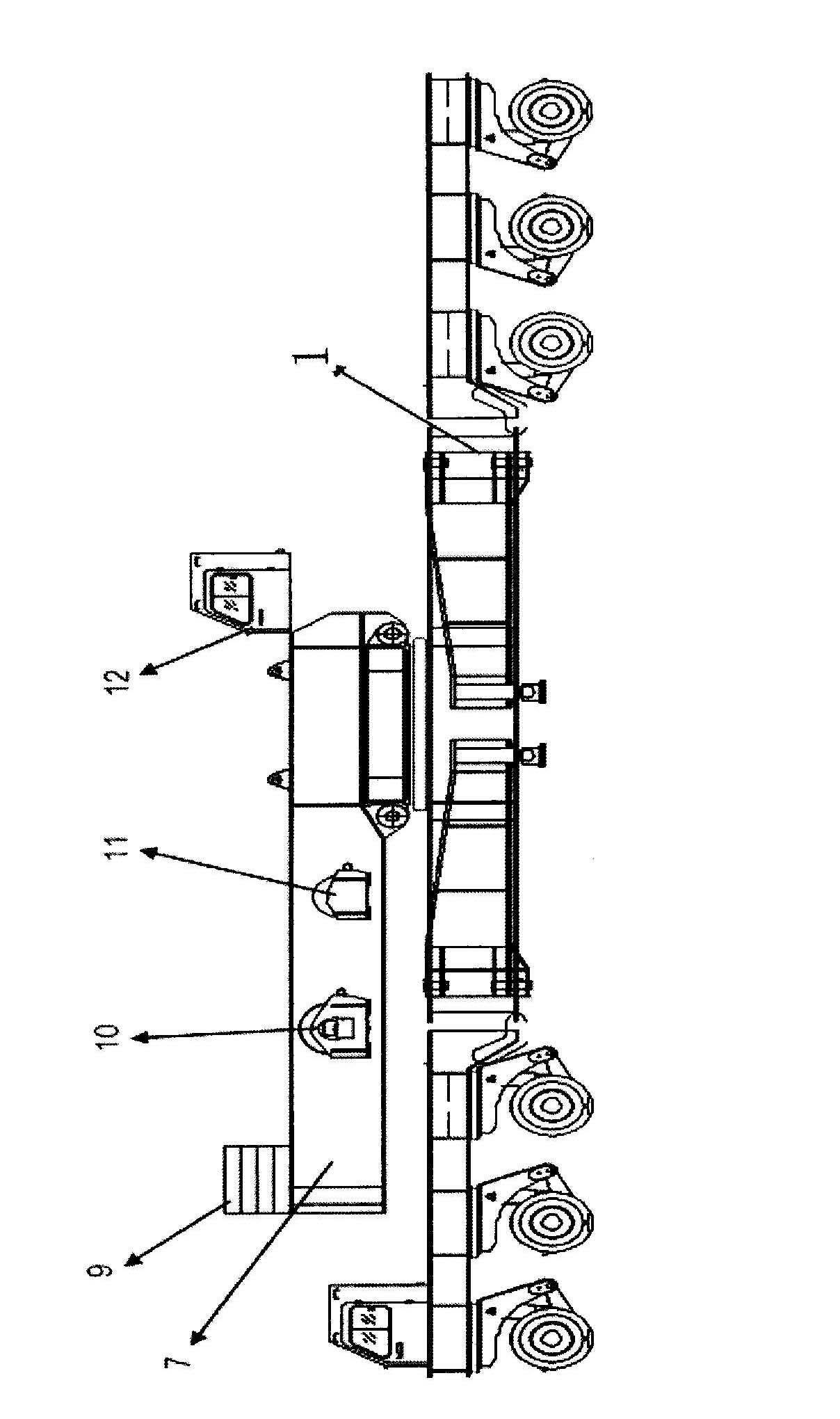

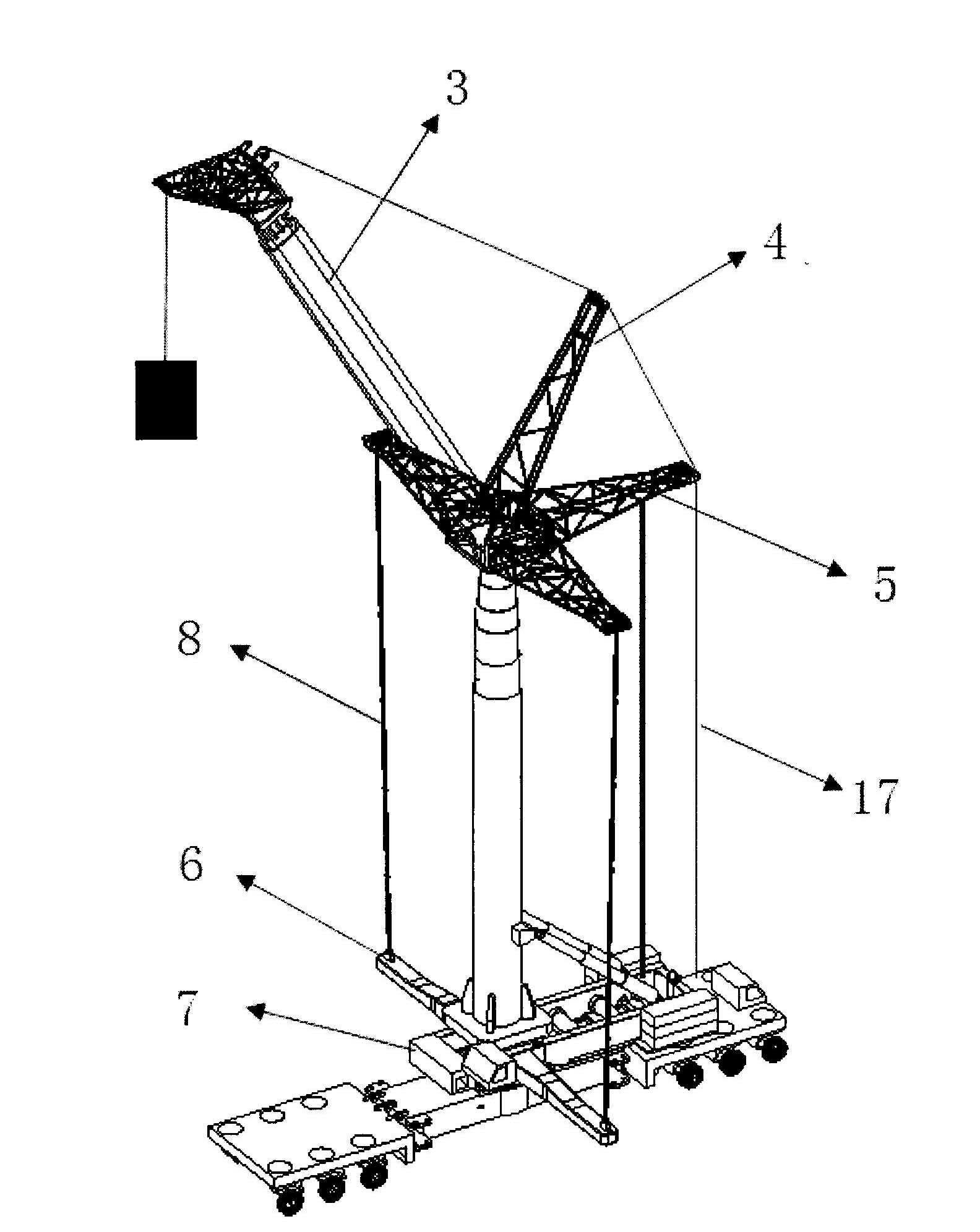

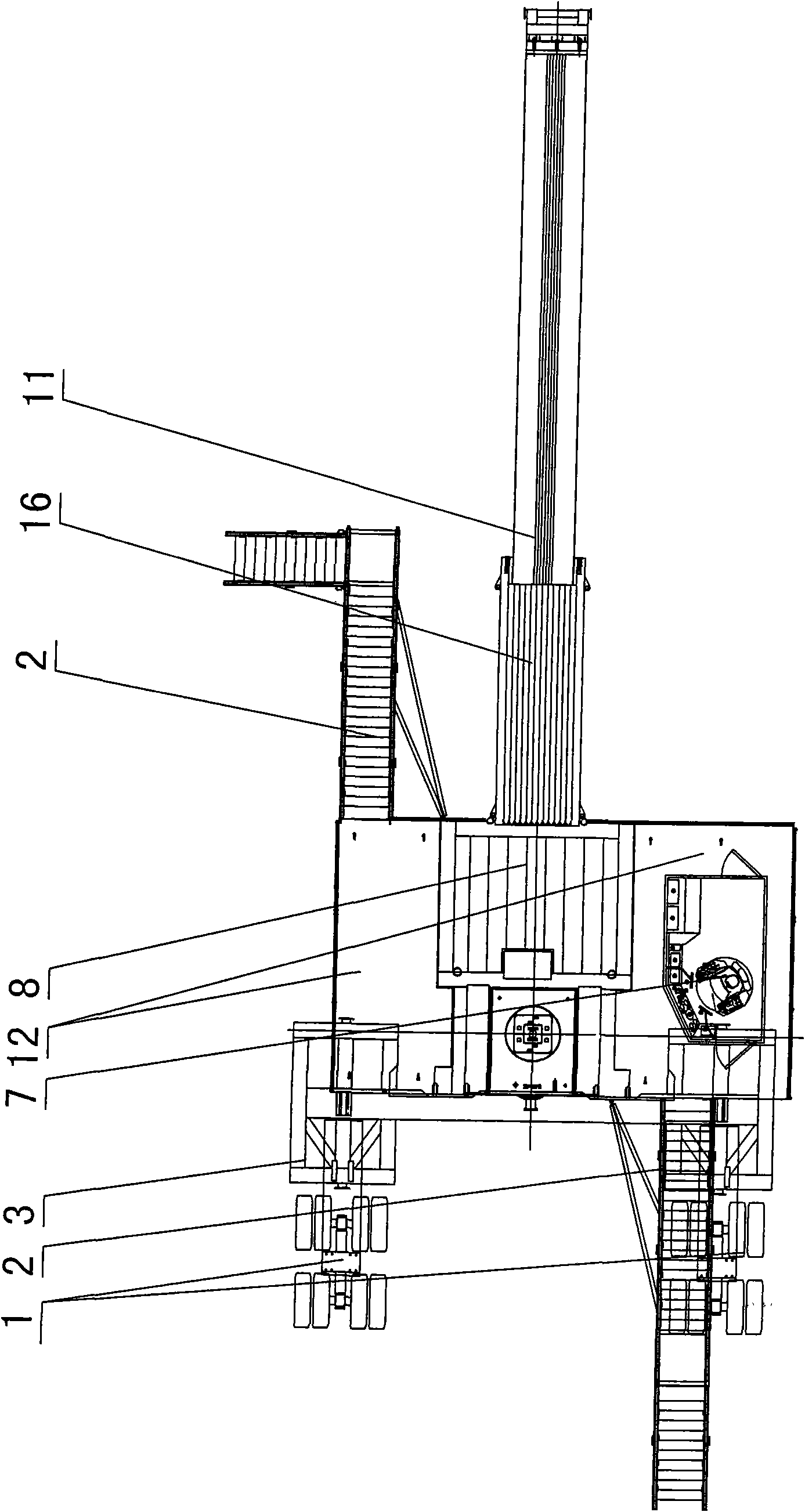

Crane

The invention relates to a crane which comprises a travelling chassis, a rotary platform, a tower body, a suspension arm, a lateral support and a variable-amplitude support arm, wherein the rotary platform is arranged on the travelling chassis and can rotate for 360 DEG; the tower body is positioned on the rotary platform; the suspension arm, the lateral support and the variable-amplitude are arranged at the upper end of the tower body; at least one of the tower body and the suspension arm consists of box-type expansion joints; the lower end of the tower body is articulated to the rotary platform, and the lateral support, the variable-amplitude and the suspension arm are connected to the upper end of the tower body through hinge shafts; the lateral support consists of three lateral supports which are respectively arranged at the left side, the right side and the rear side of the top of the tower body; the suspension arm is positioned at the front side of the tower body; the variable-amplitude support arm is positioned at the top of the tower body; the longitudinal centre lines of the rear lateral support positioned at the top of the tower body, the variable-amplitude support arm and the suspension arm are coplanar and intersected with the longitudinal centre line of the tower body; and the middle part and the root of the first expansion joint at the lower end of the tower bodyare respectively provided with at least one hydraulic cylinder used for realizing the flat or vertical placement of the tower body in an articulating way, and the other end of the hydraulic cylinder is articulated to the rotary platform.

Owner:ZHENGZHOU NEW DAFANG HEAVY IND & TECH

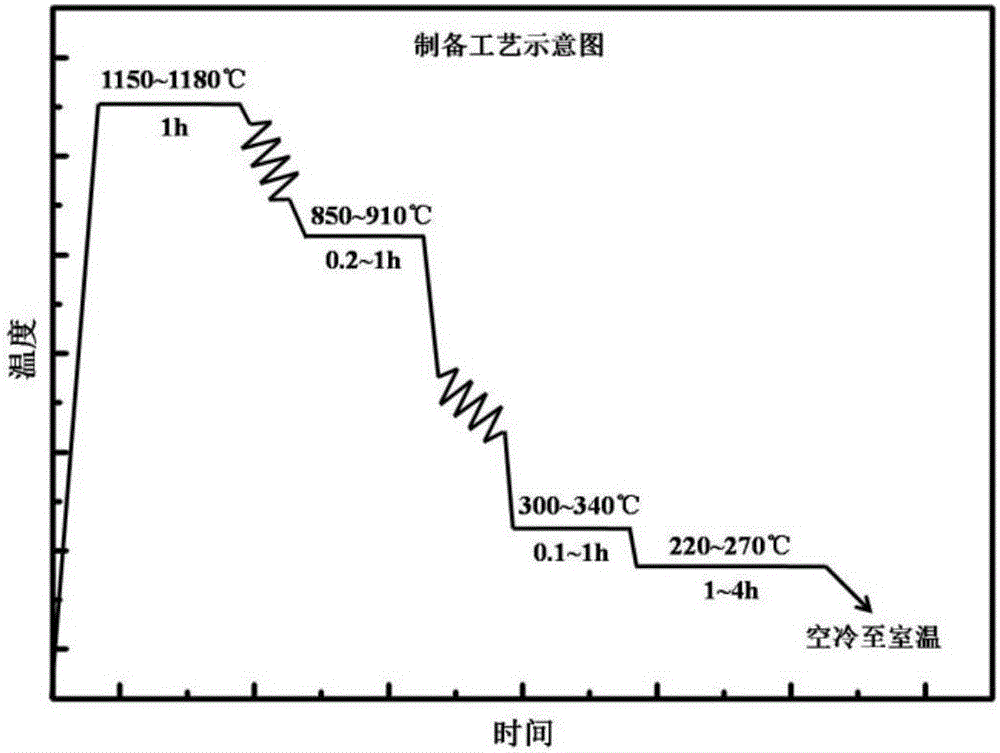

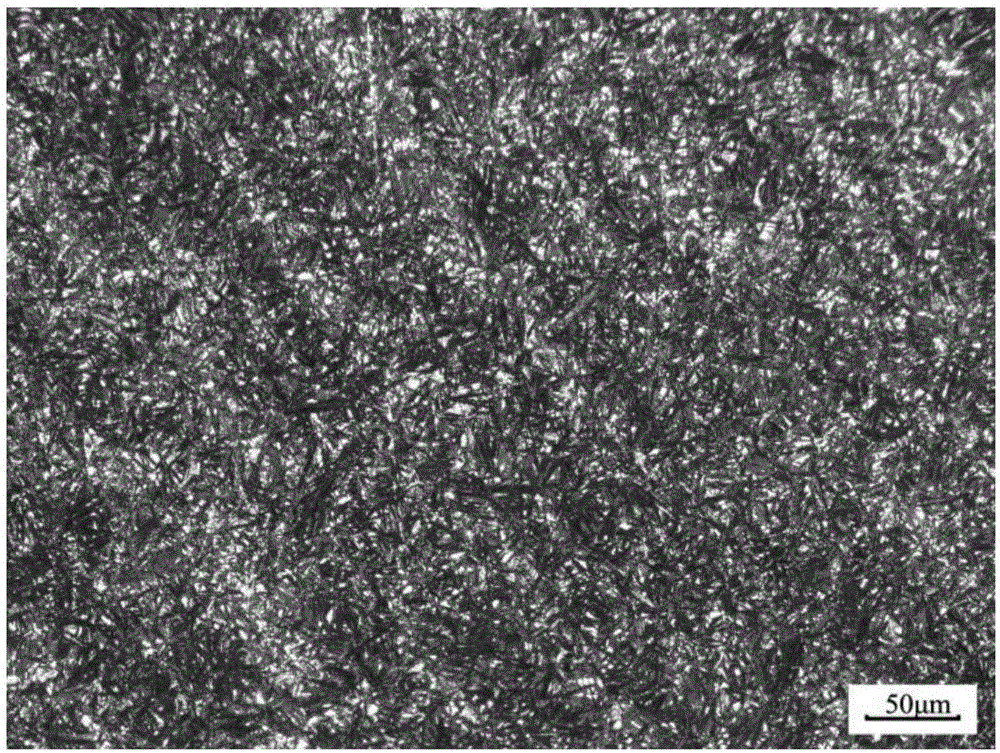

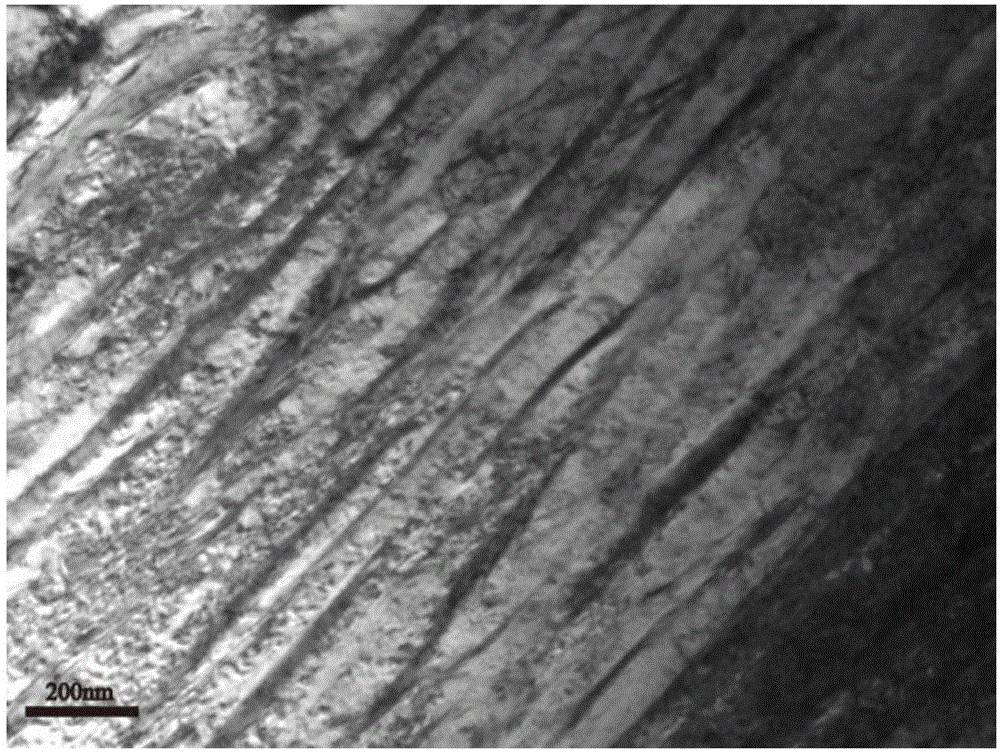

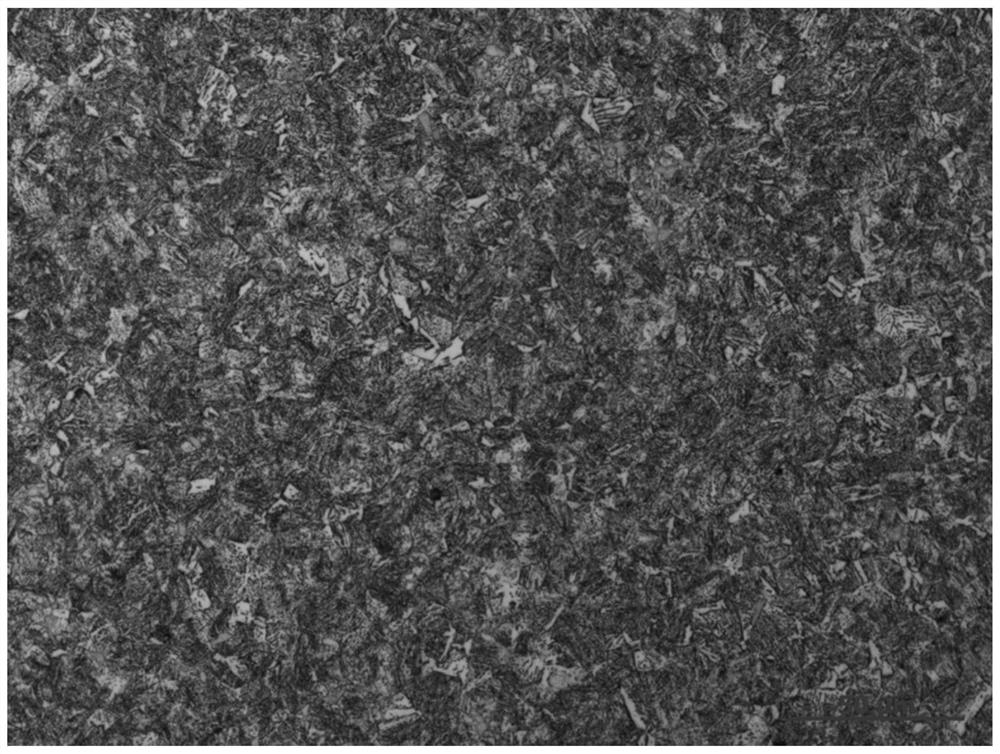

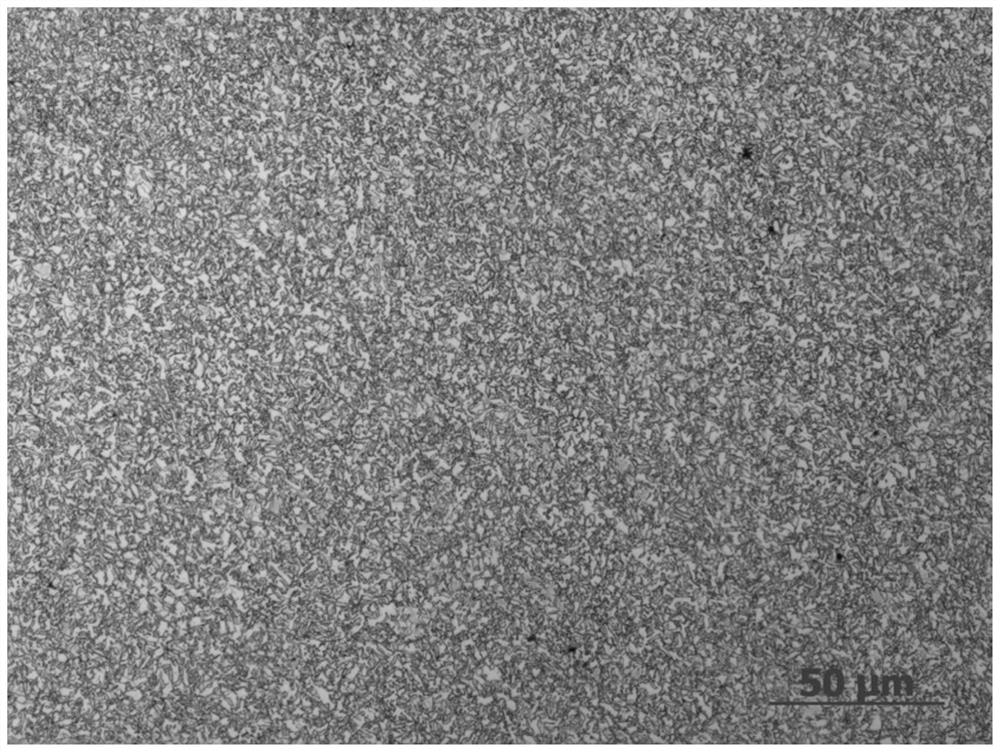

Preparation method of high-tenacity medium-and-high-carbon superfine bainite steel

The invention provides a preparation method of high-tenacity medium-and-high-carbon superfine bainite steel. The high-tenacity medium-and-high-carbon superfine bainite steel comprises, by mass, 0.48%-0.78% of C, 1.5%-2.5% of Si, 0.6%-1.2% of Mn, 0.8%-1.4% of Cr and the balance Fe and inevitable impurities. The preparation method of the high-tenacity medium-and-high-carbon superfine bainite steel comprises the following steps that vacuum melting is conducted on the above ingredients, so that an alloy steel casting blank is obtained, after the casting blank is forged, heat preservation is directly conducted on the casting blank at the temperature of 850-910 DEG C for 0.2-1.0 hour, and then the casting blank is taken out; the taken-out casting blank is cooled to the temperature of 450-600 DEG C at the cooling rate of 10-20 DEG C / s, then rolling deformation is conducted, and the deformation is 15%-33%; then, two-step isothermal treatment is conducted on the deformed steel material, and finally the high-strength high-tenacity superfine bainite steel is obtained. According to the obtained bainite steel, it is guaranteed that the superhigh strength and the good plasticity are achieved, and meanwhile compared with the impact toughness of the superfine bainite steel prepared through an existing method, the impact toughness of the obtained bainite steel is improved by 2-5 times. The preparation method of the high-tenacity medium-and-high-carbon superfine bainite steel has the advantages of being low in production cost and short in production period.

Owner:HEBEI UNIV OF TECH

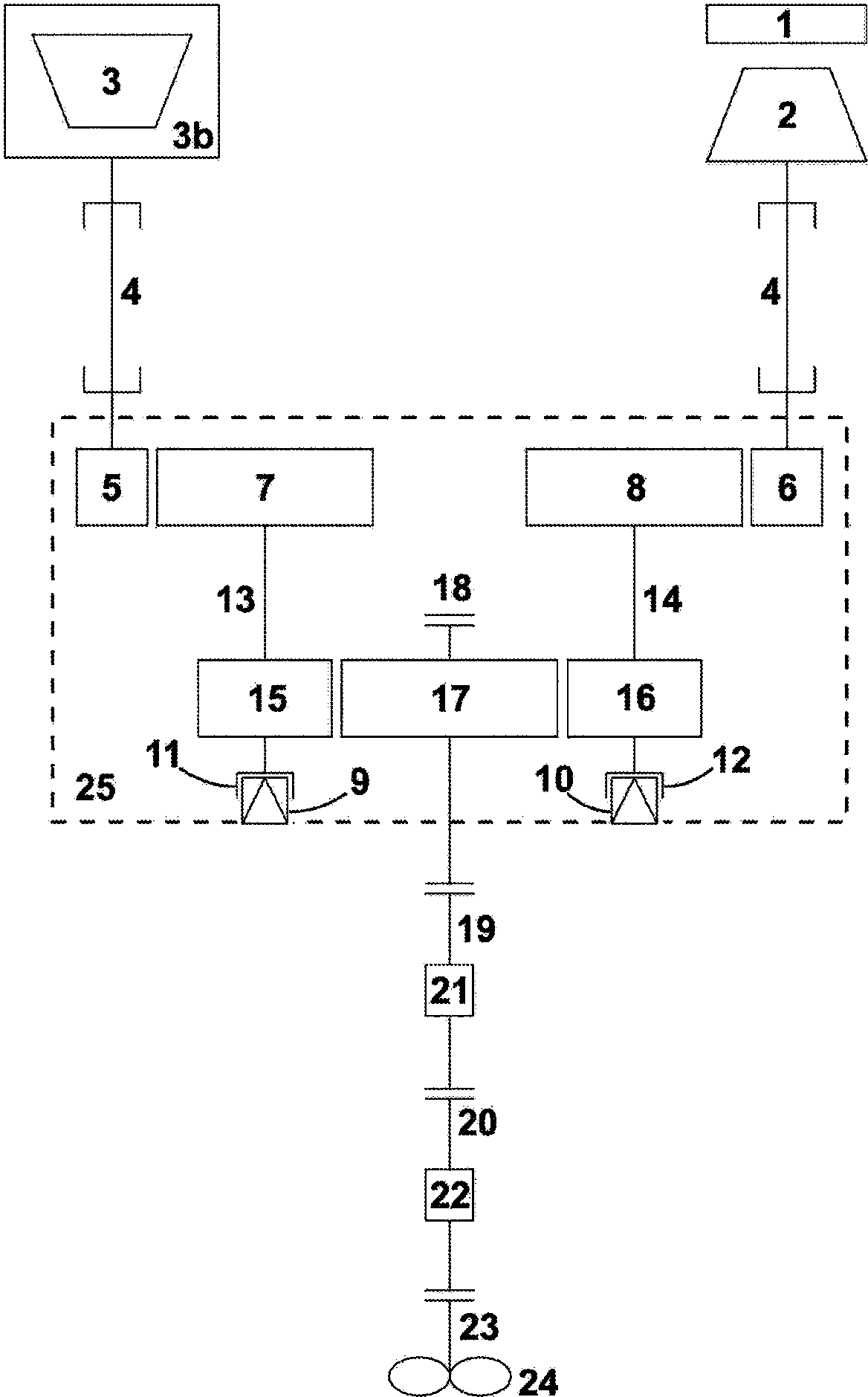

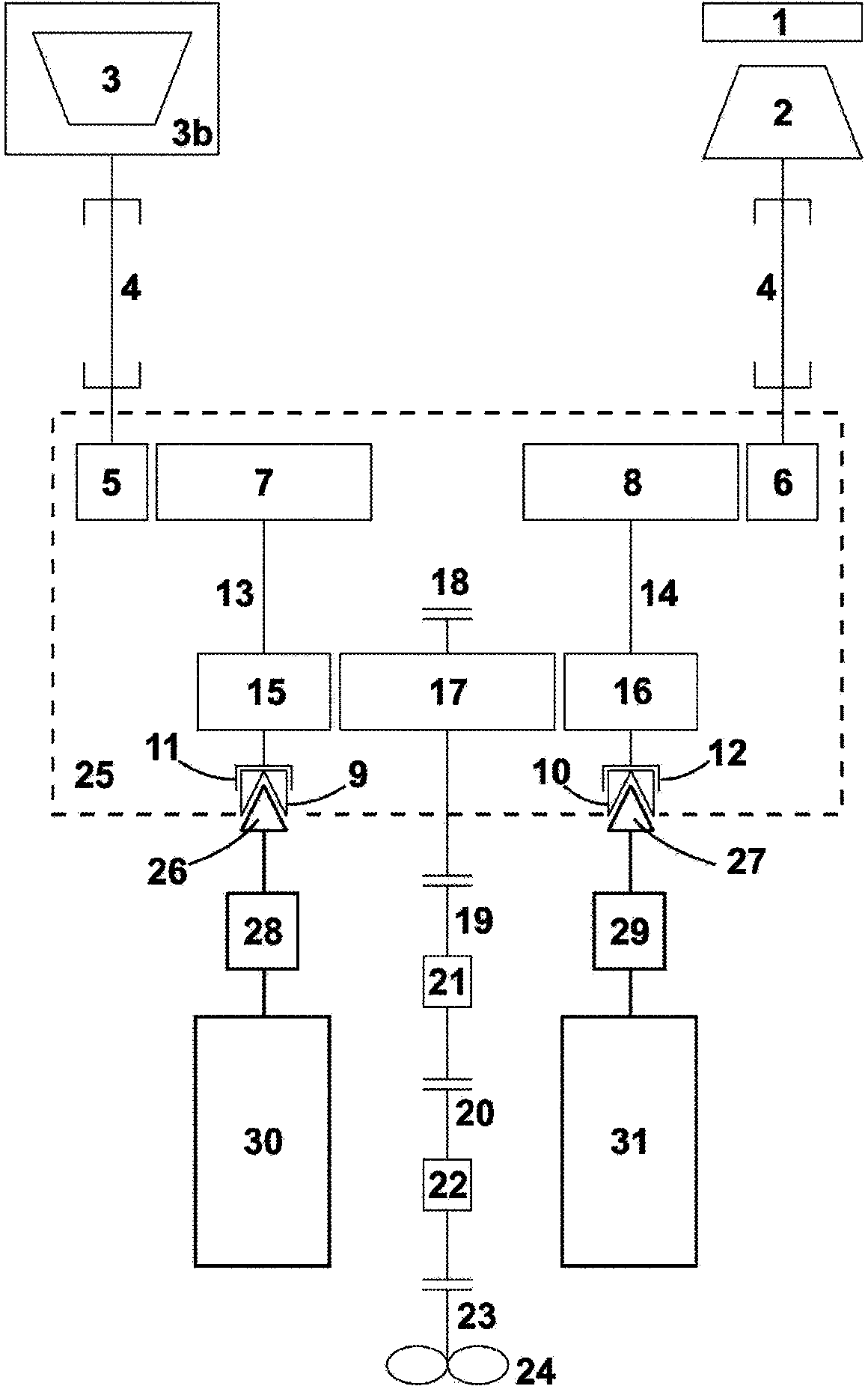

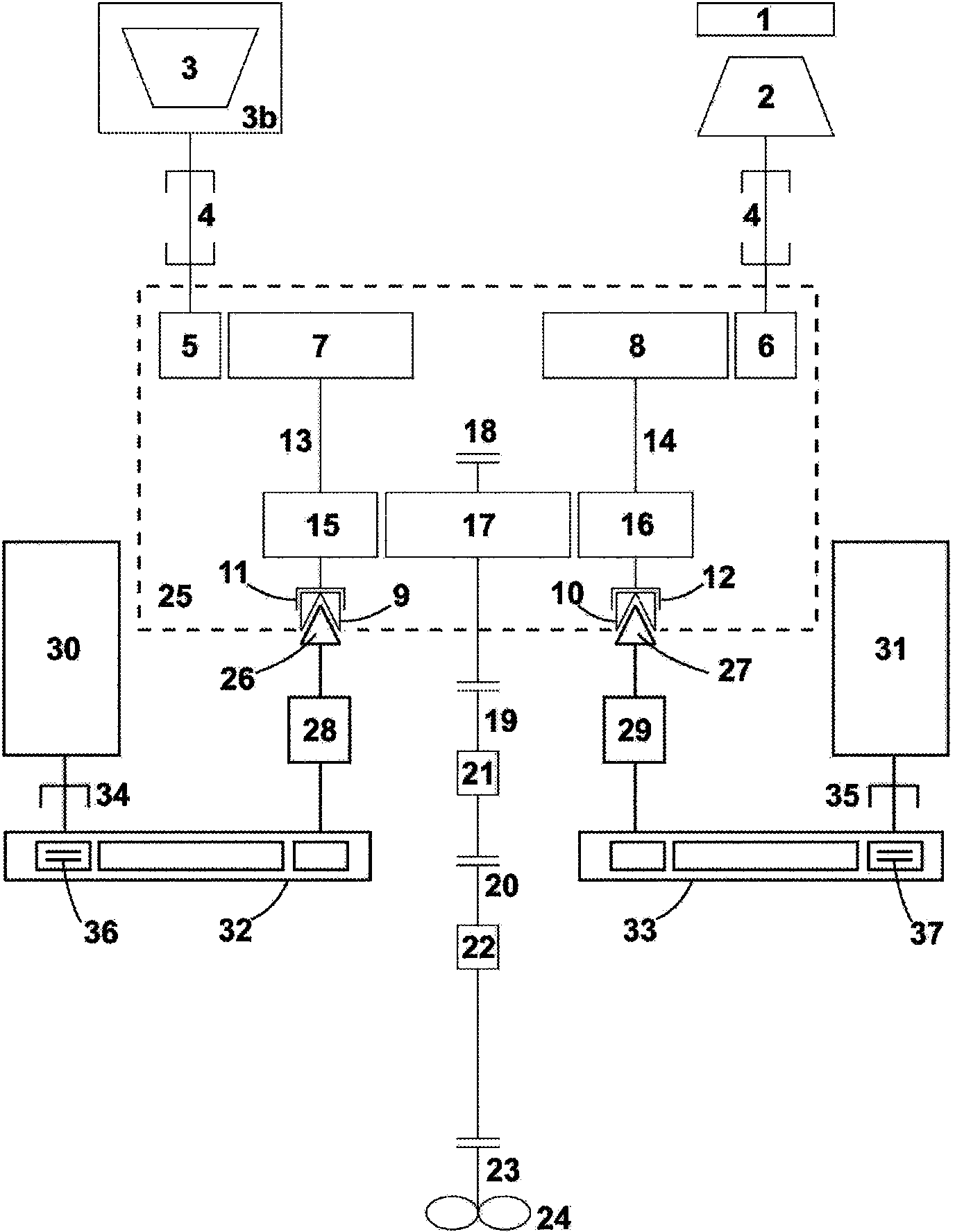

Method of converting steam turbine - powered lng carriers

ActiveCN104334449AImprove operational flexibilitySave fuelPropulsion based emission reductionPower plants using steam turbinesGas turbinesElectric power

The present invention relates to a method of converting steam turbine-powered LNG carriers, in which diesel electric propulsion comprising several dual-fuel electric power diesel, gas turbine generators or others, and several electric propulsion engines, is added, the mechanical power of which is injected in the existing gearbox or in the shaft line, keeping the existing steam turbine propulsion plant fully operative. The main advantage of the present invention is that it allows providing steam turbine-powered LNG carriers with a more economical and energy efficient shipboard power generation and propulsion plant without needing to eliminate the existing propulsion plant, therefore minimizing the conversion time, with the subsequent financial saving.

Owner:EMPRESA NAVIERA ELCANO

Controlled rolling and controlled cooling method for reducing martensite in microstructure of high-alloy steel hot-rolled wire rod

InactiveCN112239803AEasy to changeShorten transition timeFurnace typesHeat treatment furnacesWire rodTemperature control

The invention belongs to the technical field of steel rolling, and particularly relates to a controlled rolling and controlled cooling method for reducing martensite in a microstructure of a high-alloy steel hot-rolled wire rod. After being heated, a steel billet is subjected to rough, medium and pre-finish rolling deformation; the water flow of a water tank is adjusted, so that the temperature ofthe steel billet reaching a finish rolling mill is controlled to be 750-800 DEG C, and low-temperature controlled rolling is achieved; the flow of the water tank is adjusted after rolling, so that the spinning temperature is controlled to be 780-820 DEG C; a Stelmor fan is started so that the temperature of a wire rod is quickly reduced, and then the wire rod immediately enters an insulation cover to continue the organizational transformation; the speed of a Stelmor roller way is set to be 3-5 m / min, so that the transformation time of a bainite structure is prolonged, and the effect that onlya very small number of martensite structures are contained in the microstructure of the high-alloy steel hot-rolled wire rod is ensured; and therefore, the strength is reduced, the plasticity is improved, and it is ensured that the high-alloy steel hot-rolled wire rod has good drawing performance. By means of the controlled rolling and controlled cooling method for reducing martensite in the microstructure of the high-alloy steel hot-rolled wire rod, the martensite content in the microstructure of the obtained high-alloy steel hot-rolled wire rod is less that 2%, and the drawing performance is extremely good.

Owner:ZENITH STEEL GROUP CORP +1

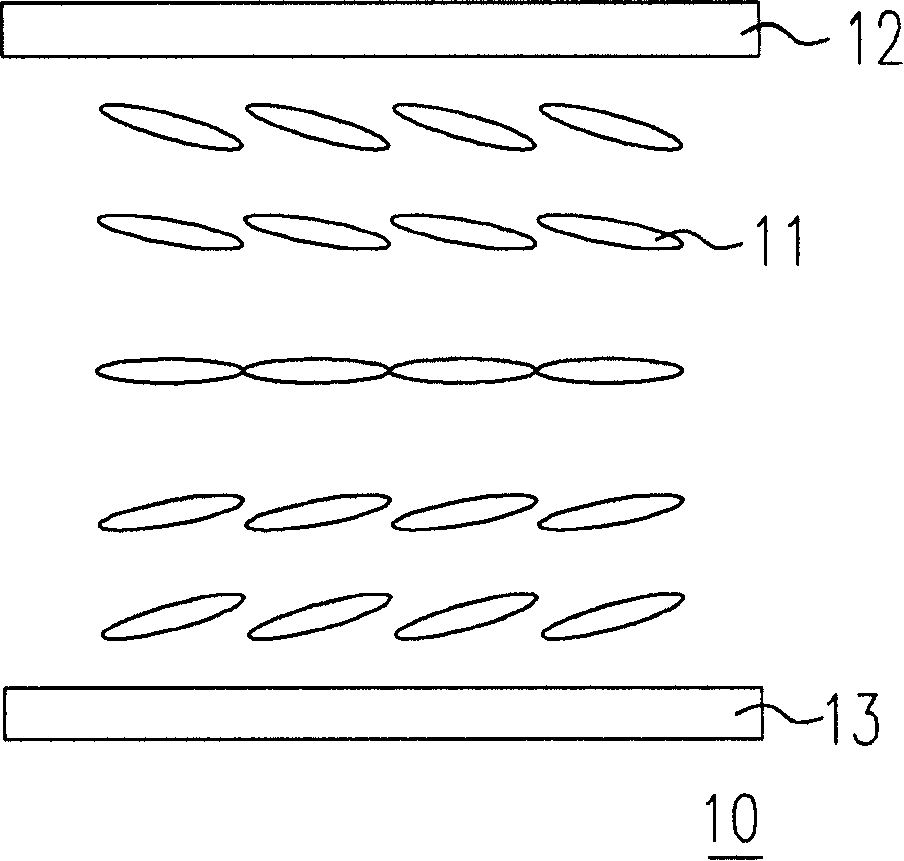

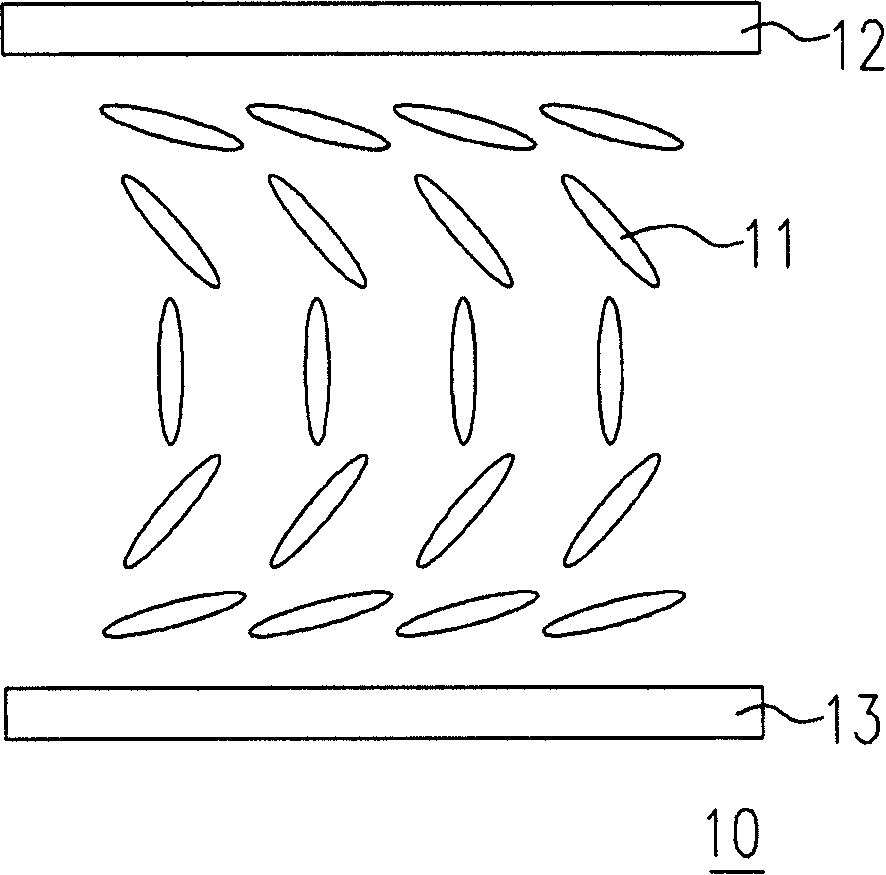

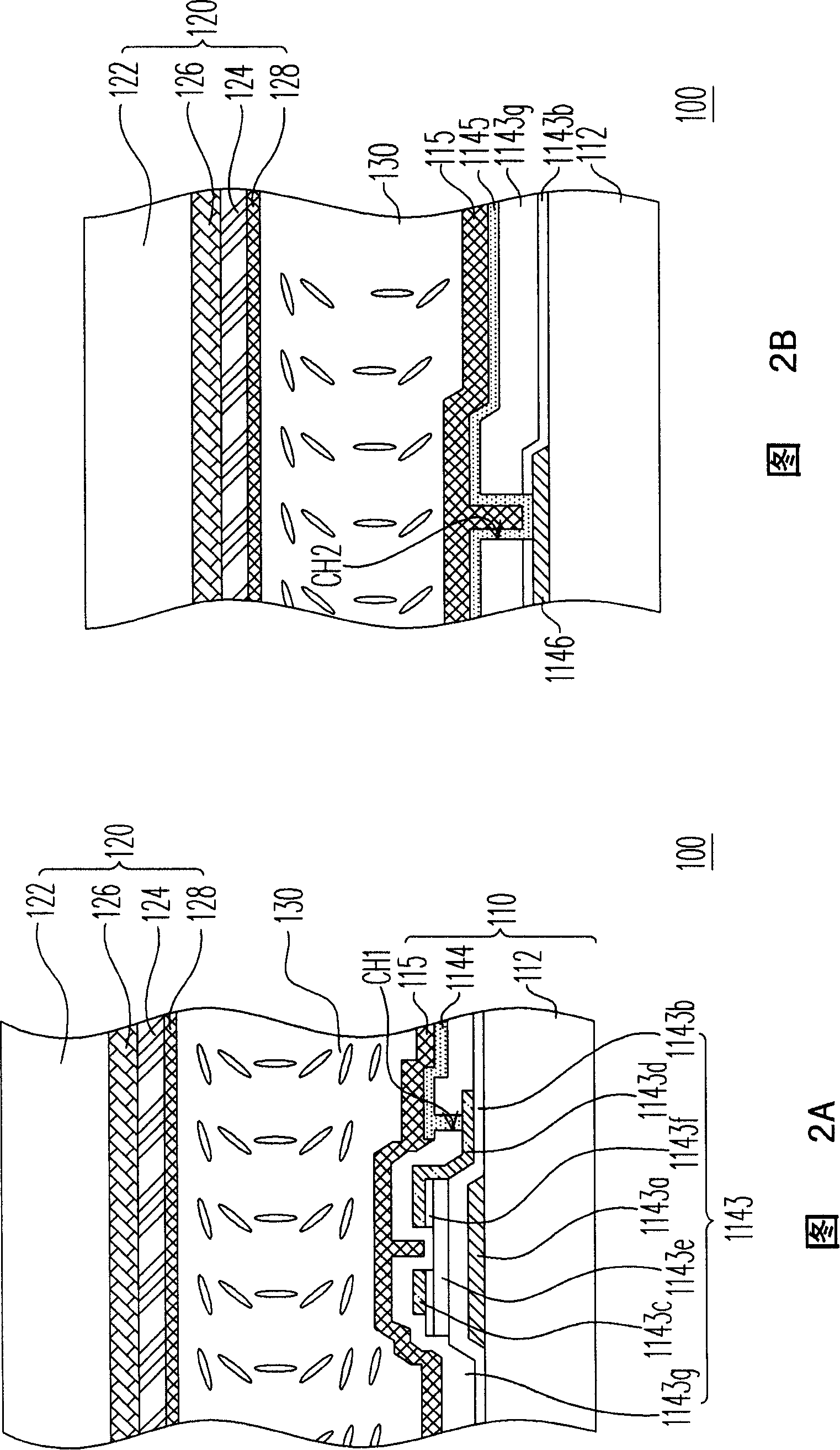

Pixel structure and liquid crystal display panel using same

InactiveCN101169530AIncrease opening ratioQuick conversionStatic indicating devicesNon-linear opticsAuxiliary electrodeLiquid-crystal display

The invention relates to a pixel structure which comprises a base plate, a scanning wiring, a data wiring, a common wiring, an active element, a pixel electrode, a protective layer and a rotating state auxiliary electrode. The scanning wiring and the data wiring are crossly arranged on the base plate, and a pixel area is defined on the base plate. The common wiring is arranged on the base plate and is virtually parallel with the scanning wiring. The active element is arranged in the pixel area, and is electrically connected with the scanning wiring and the data wiring. The pixel electrode is arranged in the pixel area and is electrically connected with the active element. The protective layer is arranged between the pixel electrode and the data wiring. The rotating state auxiliary electrode is arranged around the pixel electrode, and the pixel electrode and the rotating state auxiliary electrode share the same film layer. In addition, the rotating state auxiliary electrode permeates a touching window of the protective layer to electrically connect with the common wiring.

Owner:CHUNGHWA PICTURE TUBES LTD

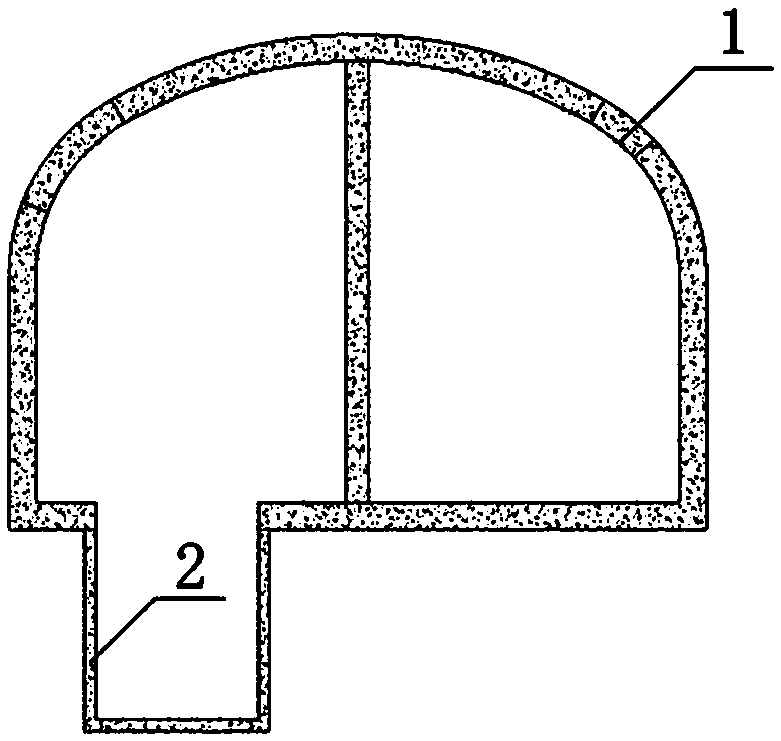

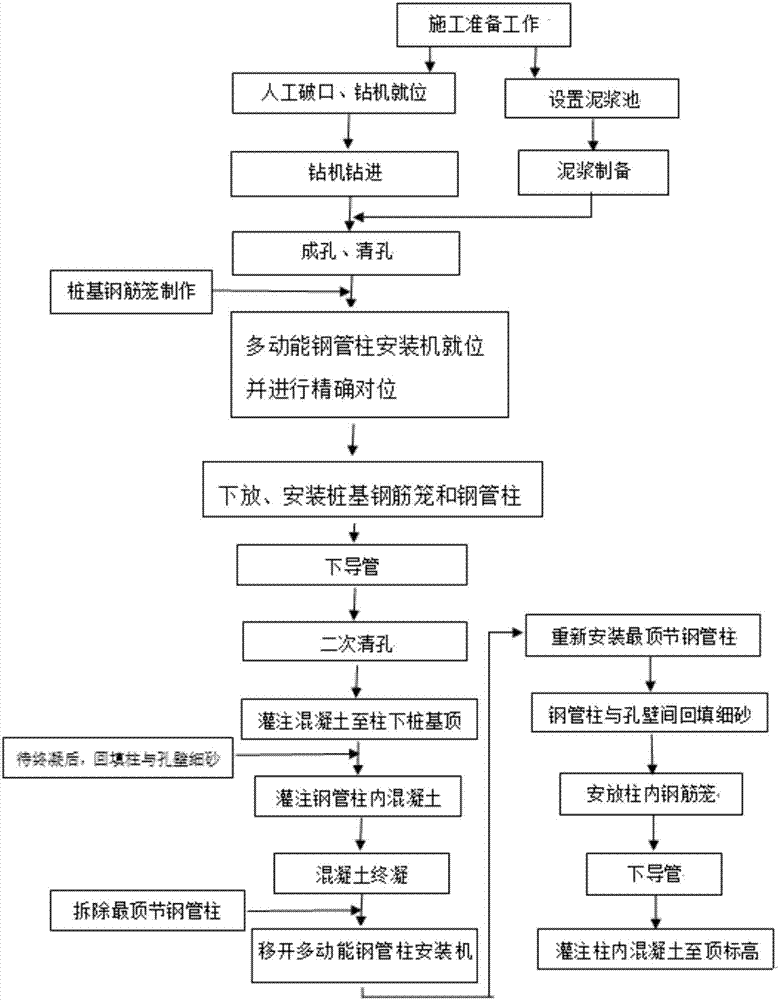

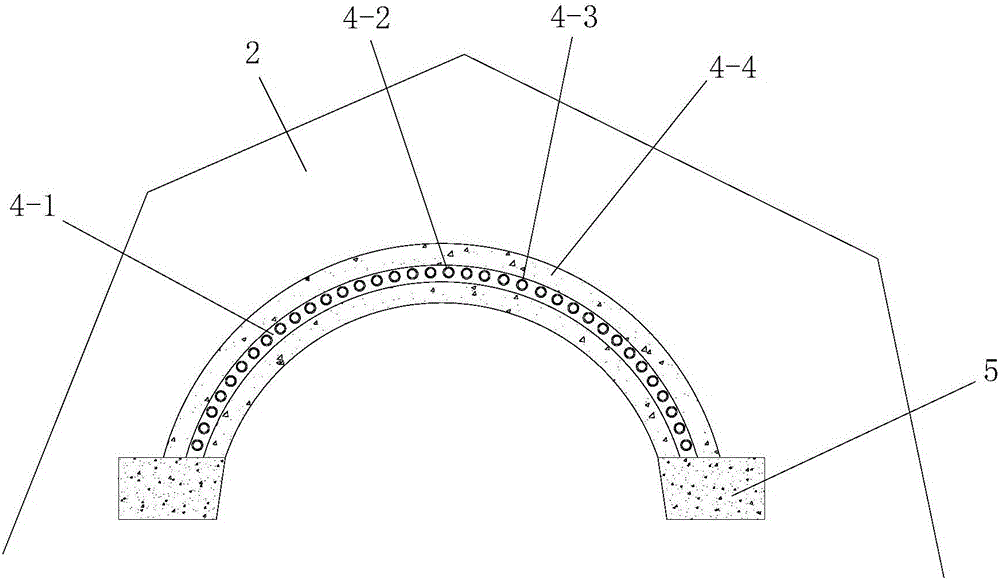

One-time forming construction method for inserting steel pipe column into cast-in-situ bored pile in pilot tunnel

ActiveCN105369800ASolve potential safety hazardsShorten working timeBulkheads/pilesSteel tubeDrill hole

The invention discloses a one-time forming construction method for inserting a steel pipe column into a cast-in-situ bored pile in a pilot tunnel. The method comprises the following steps: 1, carrying out guiding hole construction in a pilot tunnel used for pile operation; 2, carrying out drilling machine positioning and drilling; 3, installing a pile foundation reinforcement cage a steel pipe column and an in-column reinforcement cage in the drilled hole; 4, carrying out accurate positioning and levelling on the steel pipe column by utilizing a hydraulic steel pipe column inserting machine; 5, pouring pile foundation concrete and steel pipe column concrete; 6, backfilling rubbles between the steel pipe column and columns; 7, continuing to pour steel pipe column concrete; 8, backfilling coarse sand, moving away the hydraulic steel pipe column insertion machine, pumping out mud and changing a tool pipe into a first section of steel pipe column; and 9, arranging the in-column reinforcement cage of the first section of steel pipe column, pouring steel pipe column concrete, and carrying out concrete curing, thus finishing pile construction. The construction method disclosed by the invention combines two procedures, including drilling pouring pile construction at the lower part and steel pipe column installation at the upper part, and can achieve one-time forming.

Owner:中建八局轨道交通建设有限公司

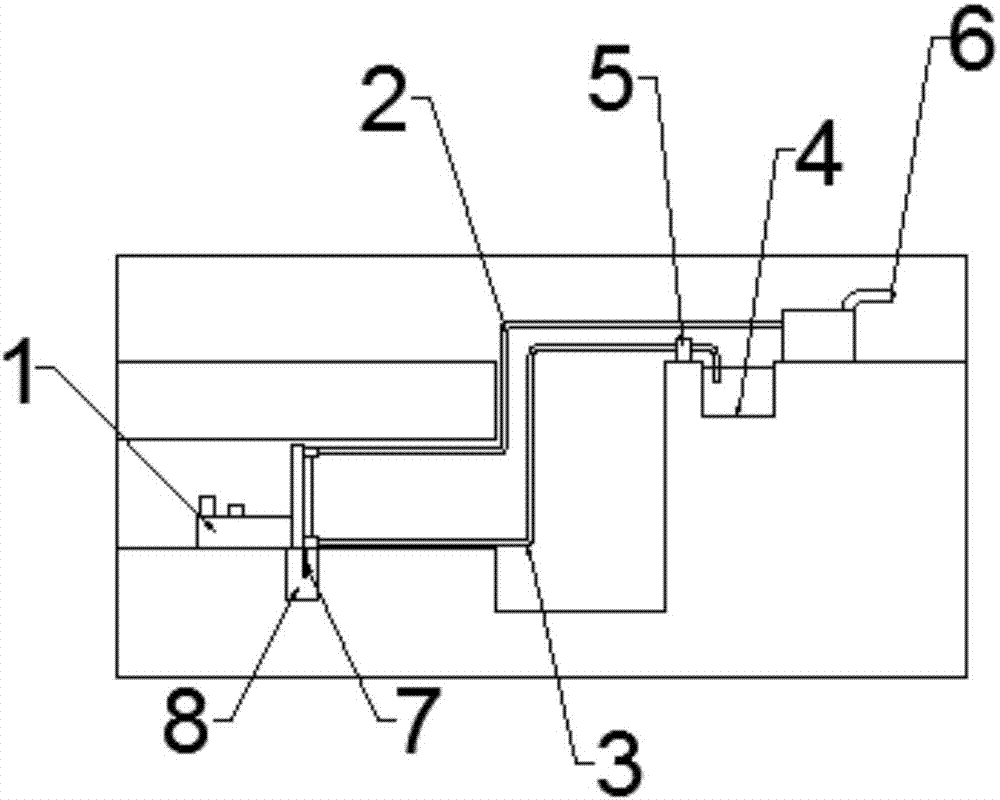

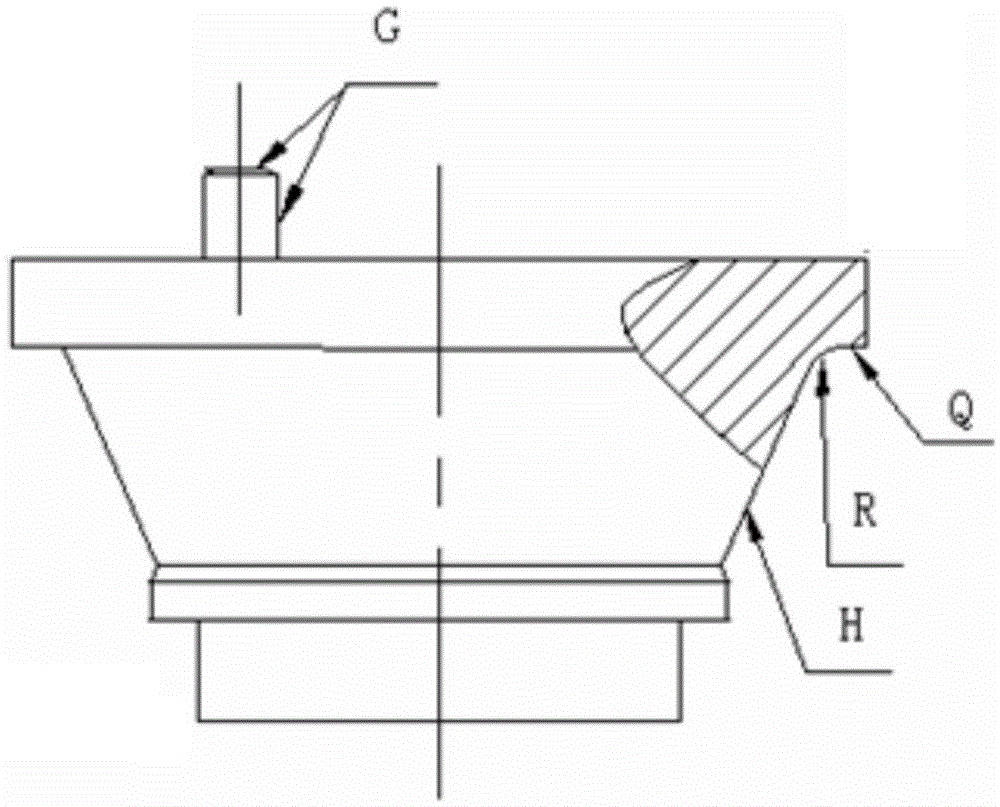

Drilling cleaning circulation equipment and installation method of steel pipe column in pilot tunnel

The invention provides drilling cleaning circulation equipment, and relates to the technical field of underground excavation construction of subway tunnels. The equipment comprises a drilling machine, a mud separation device, a mud tank and pipelines. The pipelines comprise the first pipeline and the second pipeline, and the drilling machine is connected with a gravel pump; drilling slag, generated in drilling of the drilling machine, in a hole is pumped out through the gravel pump and then discharged to the mud separation device through the first pipeline, the mud separation device separates the drilling slag from mud, and the separated mud flows back into the mud tank; a variable-frequency mud return pump is arranged in the mud tank and used for conveying the mud in the mud tank back into the hole through the second pipeline. The drilling cleaning circulation equipment is used for pumping drilling slag and mud in a drilled hole out of the pile hole and then separating the drilling slag from the mud and can convey the separated mud back into the pile hole, and thus a mud and drilling slag mixture in the pile hole can be discharged in time to accelerate drilling of a drill.

Owner:BEIJING MUNICIPAL CONSTR +1

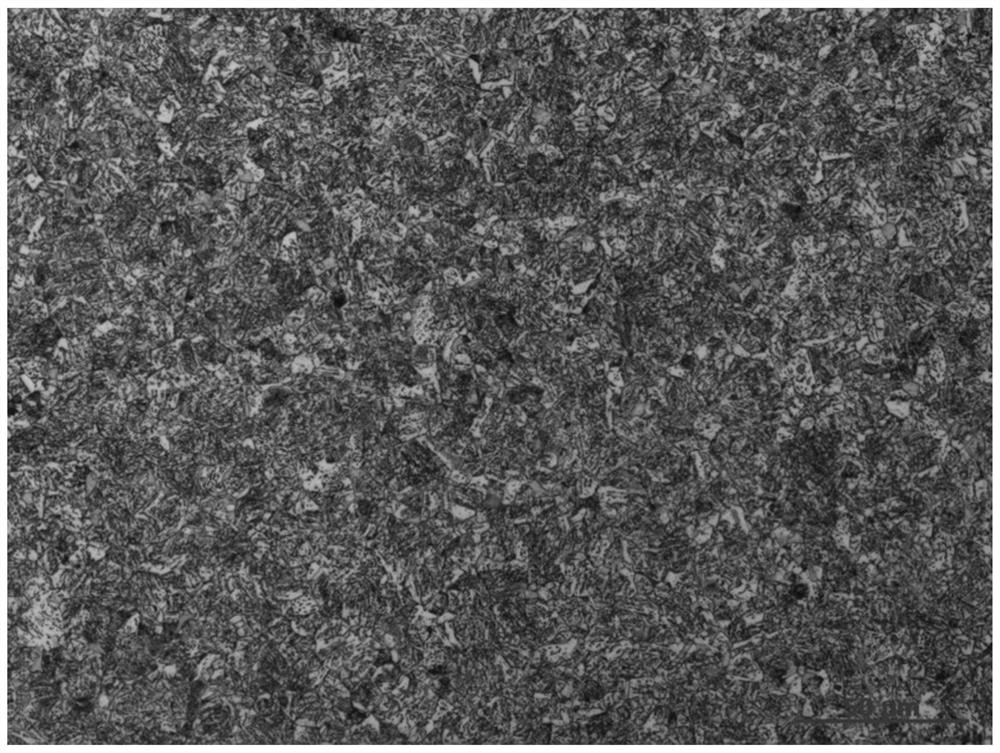

High-performance low-carbon Mo-containing bainite steel and preparation method thereof

The invention relates to high-performance low-carbon Mo-containing bainite steel and a preparation method thereof. According to the technical scheme, the preparation method comprises the following steps of adding Mo into smelting components of Fe-C-Mn-Si low-carbon steel, smelting in vacuum, casting into a steel billet, and rolling the steel billet into a plate; heating the rolled plate to 880-900 DEG C at the heating speed of 5-10 DEG C / s, and keeping the temperature for 10-20 minutes; cooling to 410-420 DEG C by water, cooling to 340-350 DEG C by air, and keeping the temperature for 30-40 minutes; cooling to room temperature by water to prepare the high-performance low-carbon Mo-containing bainite steel. The high-performance low-carbon Mo-containing bainite steel comprises the following chemical components: 0.15wt%-0.22wt% of C, 1.48wt%-1.55wt% of Si, 1.95wt%-2.04wt% of Mn, 0.14wt%-0.15wt% of Mo, less than 0.008wt% of P, less than 0.002wt% of S, less than 0.004wt% of N and the balance of Fe and inevitable impurities. The preparation method has the characteristics of low cost, short cycle and simple process; the prepared high-performance low-carbon Mo-containing bainite steel is excellent in comprehensive performance.

Owner:WUHAN UNIV OF SCI & TECH

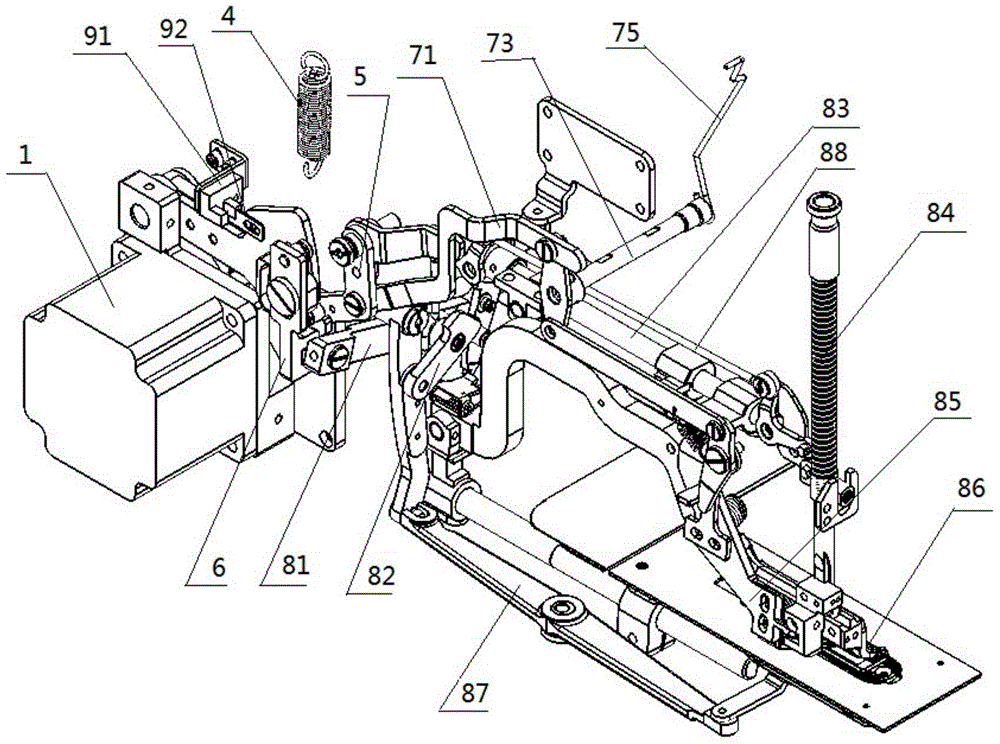

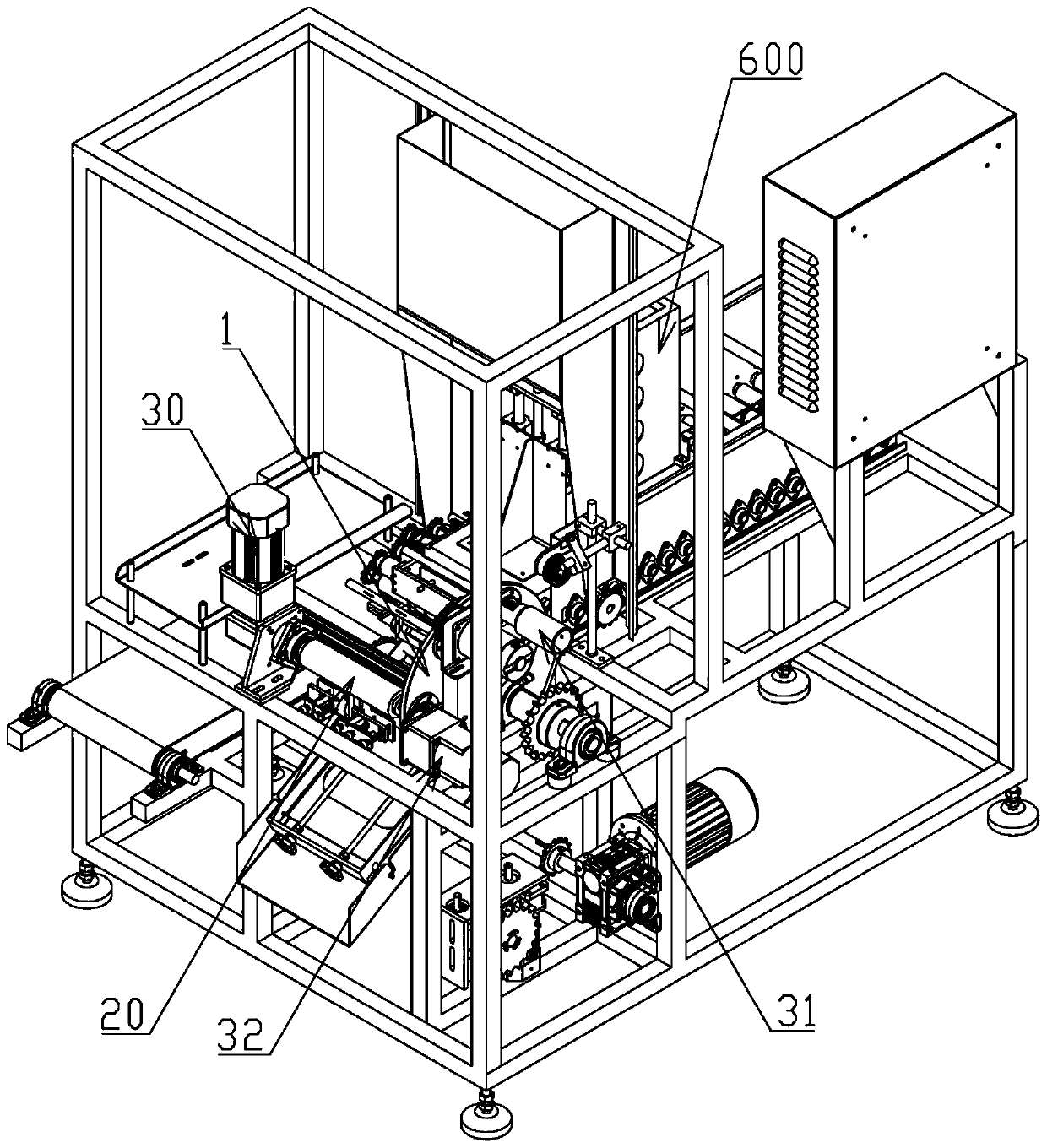

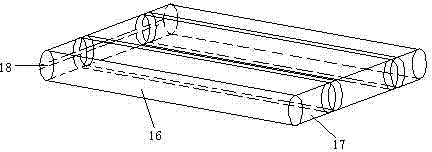

Automatic seaweed roll machine

PendingCN110122800ARealize automatic continuous feedingShorten transition timeFood coatingFood shapingAutomationCoating

The invention discloses an automatic seaweed roll machine, which comprises a feeding device, a winding device, a coating device and a material taking device; the feeding device has a plurality of conveying rollers for conveying the seaweed pieces to a winding station; the winding device has a rotating table that rotates in a vertical direction and winding rollers that are circumferentially distributed on the rotating table, the winding rollers are all rotated, and the rotating table drives the winding rollers to pass through the winding station, a coating station and a material taking stationin sequence, and the winding rollers can contact the seaweed pieces and roll the seaweed pieces into seaweed rolls during the movement to the winding station; the coating device has a coating bar forrolling the outer peripheral surface of the seaweed rolls on the winding rollers of the coating station; and the material taking device has jaws for taking up the seaweed rolls on the winding rollersof the material taking station. The automatic seaweed roll machine has the characteristics of high integration and automation, high production efficiency and good finished product quality.

Owner:KUNSHAN HENGSHAO FOOD MACHINES CO LTD

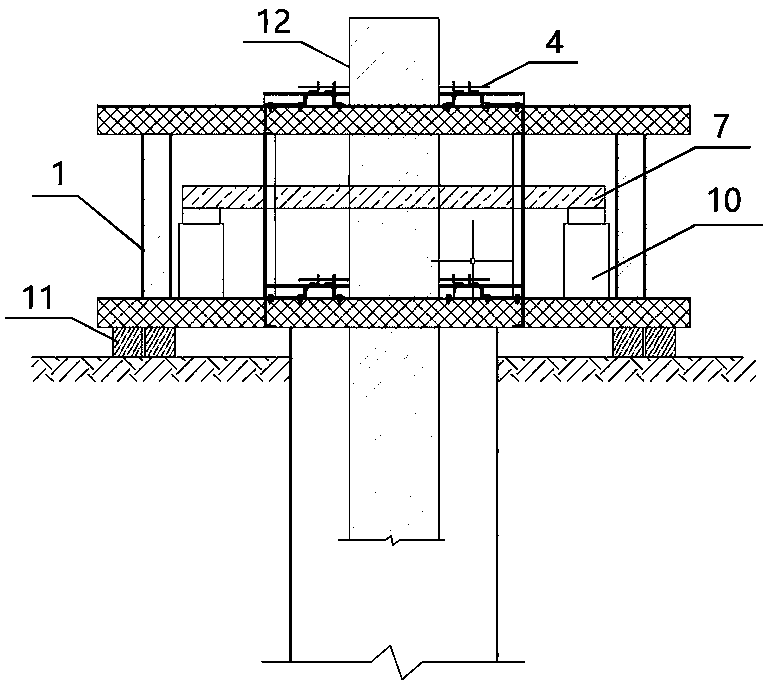

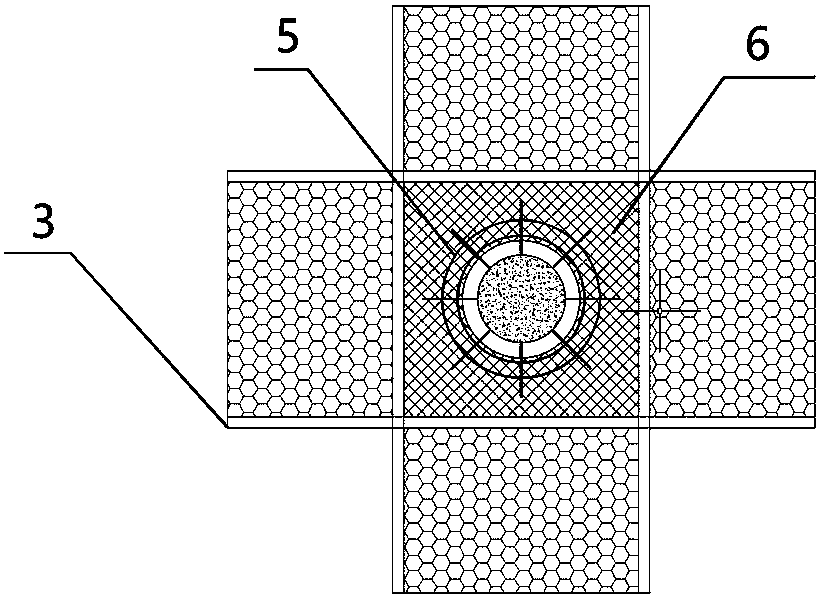

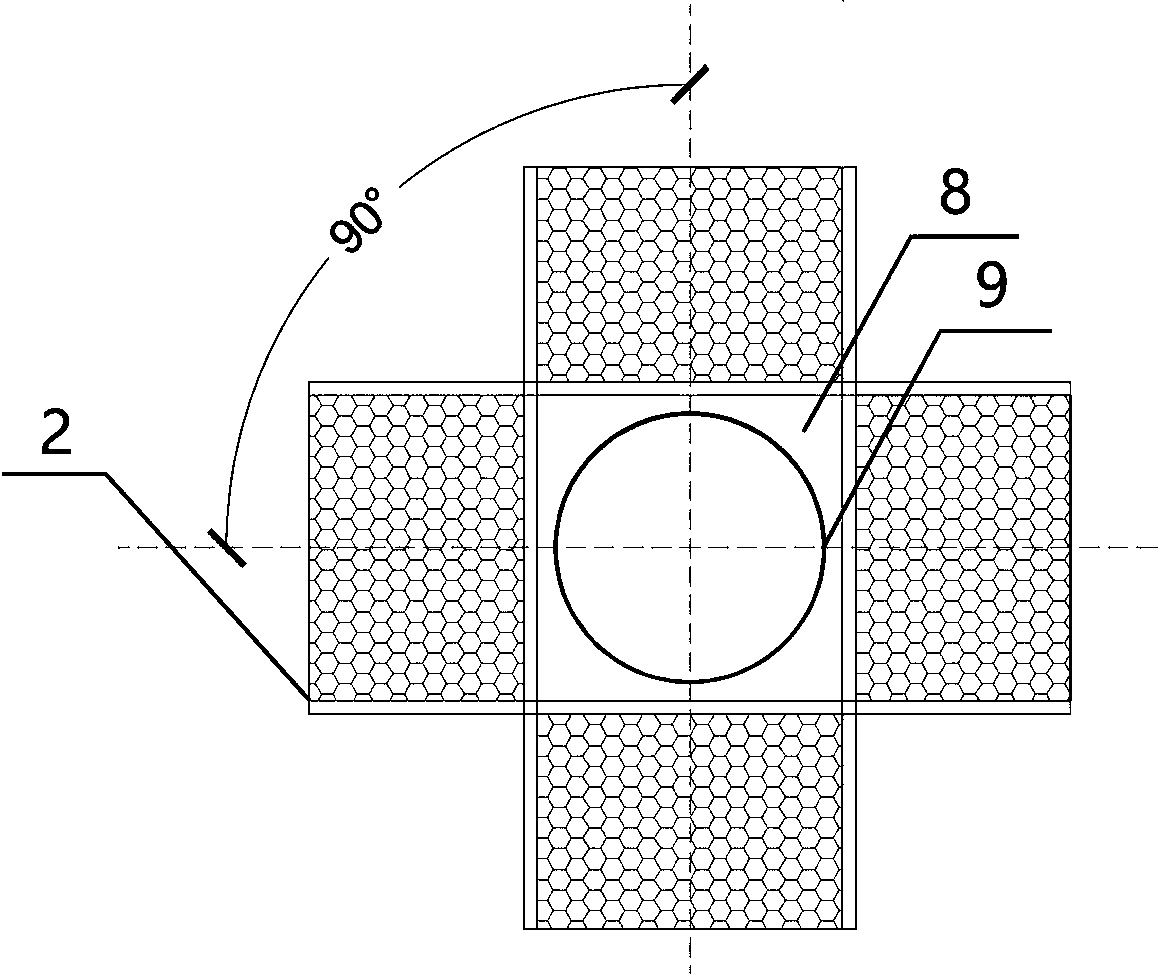

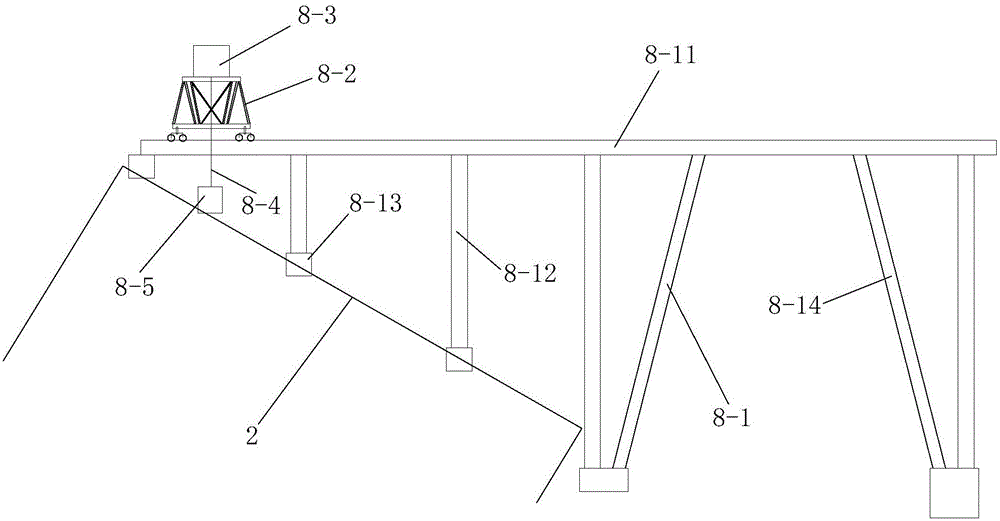

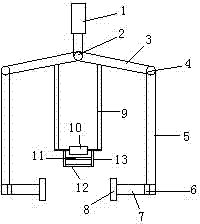

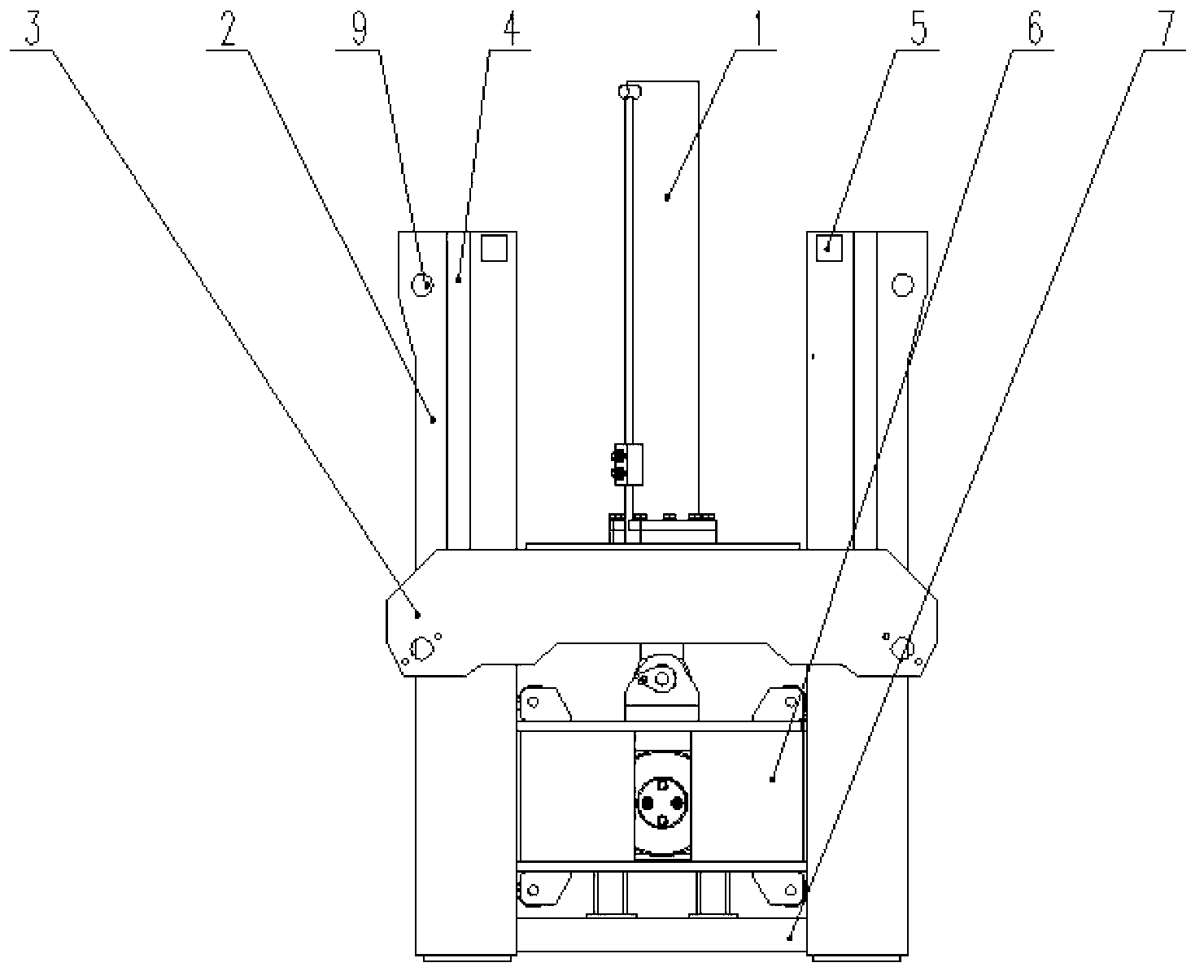

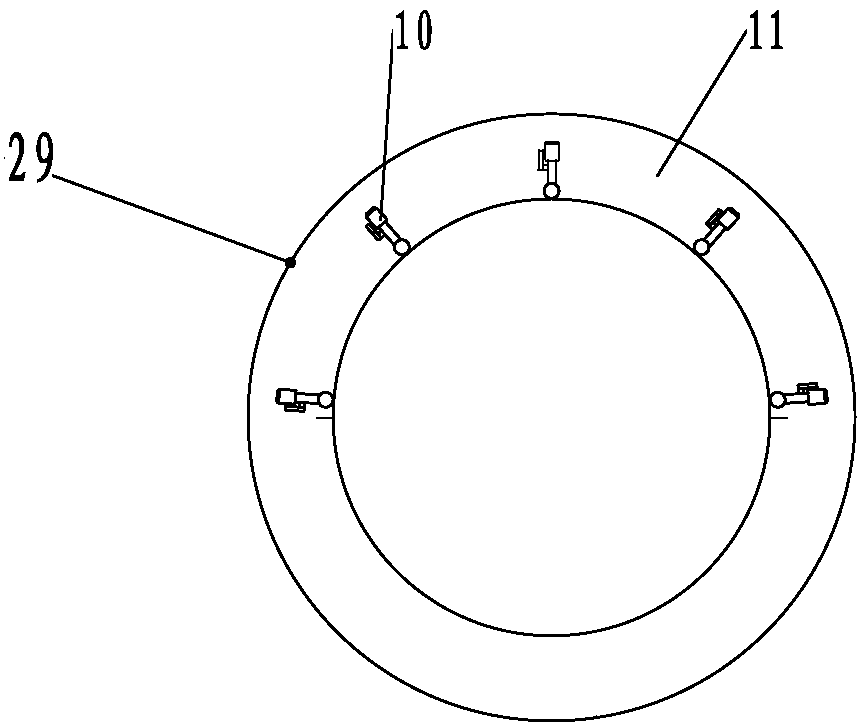

Positioning device for improving insertion of steel pipe column into hollow pile and method for integrally constructing pile column

The invention relates to a positioning device for improving insertion of a steel pipe column into a hollow pile and a method for integrally constructing a pile column, and belongs to the technical field of steel pipe column construction by a cover digging reverse construction method, which mainly solves the problem of positioning the steel pipe column in an ultra-long hollow pile. The positioningdevice is characterized by comprising an integral platform comprising a bottom platform and a top platform, wherein a steel pipe column lifting mechanism is arranged in the integral platform; the bottom platform and the top platform are provided with coaxial steel pipe columns passing-through through holes; and an adjusting mechanism for adjusting a horizontal position of the steel pipe column isarranged on the bottom platform and / or the top platform. The positioning device for improving the insertion of the steel pipe column into the hollow pile and the method for integrally constructing thepile column have the advantages of ensuring that the steel pipe column in the ultra-long hollow pile is not displaced and offset, and are mainly used for integrally constructing the pile column.

Owner:中铁十一局集团第六工程有限公司 +1

Extraction system

InactiveCN107376403AImprove extraction qualityAccurate feeding amountSolid solvent extractionEngineeringMechanical engineering

The present invention relates to the field of extraction, and discloses an extraction system, which comprises a conveying line, a feeding line, an extraction device, a residue discharging device, a washing device and a control device, wherein the control device is respectively connected to the conveying line, the feeding line, the extraction device, the residue discharging device and the washing device. The extraction system of the present invention achieves the automated extraction of the material so as to improve the material extraction efficiency and the material extraction quality, and accurately collect the production data.

Owner:SHANGHAI BANWI INFORMATION TECH

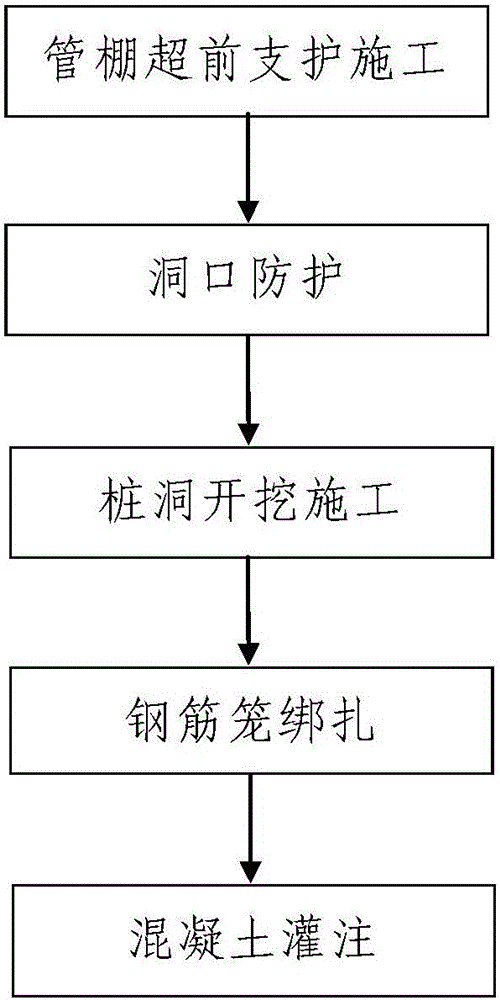

Construction process for superlarge-section and large-dip-angle tunnel type pile foundation

ActiveCN105970992AThe process steps are simpleReasonable designFoundation engineeringReinforced concreteRebar

The invention discloses a construction process for a supperlarge-section and large-dip-angle tunnel type pile foundation. The pile foundation to be constructed is a reinforced concrete pile. A pile hole of the reinforced concrete pile is a superlarge-section large-dip-angle tunnel hole. In construction of the pile foundation to be constructed, the process comprises the steps of firstly, pile hole construction, i.e., 101, advanced pipe shed support construction is conducted at the top of the pile hole, 102, hole mouth protection is conducted and a hole mouth support structure is constructed at a hole mouth of the pile hole, and 103, pile hole excavation construction is conducted, a full section excavation method is adopted for the pile hole excavation with a plurality of construction segments arranged from top to bottom, and a full section support structure is adopted for supporting; and secondly, pile body construction, i.e., the pile body of the reinforced concrete pile is constructed, and the construction process comprises the two steps of reinforcing cage binding and concrete spouting. The construction process for the supperlarge-section and large-dip-angle tunnel type pile foundation is simple in step, reasonable in design, low in investment cost, simple and easy to construct, good in use effect and capable of easily and fast completing the construction process of the tunnel type pile foundation, and the construction process is easy to control.

Owner:CHINA RAILWAY FIRST GRP CO LTD +2

Blade installation seat heat treatment method

ActiveCN106555153AControl carburizing qualityIncrease productivitySolid state diffusion coatingCopper platingEngineering

The invention relates to a blade installation seat heat treatment method. The method is characterized in that coppering treatment is carried out on the whole surface of a blade installation seat workpiece, machining is used for remove a copper layer of an area surface to be carburized, then carburizing processing is carried out, and a carburizing purpose only in a local area can be reached. While quenching heating, a solid gas carburizer is employed for protection, oxidation and decarbonization on the surface of a carburizing layer are avoided, after quenching, a moveable constant-temperature oil groove is used for substituting an original salt bath heat treatment furnace, interprocess connection time is saved, contact of the workpiece and air at high temperature is reduced, decarburization on the surface of the carburizing layer is avoided; the condition that during a quenching transfer process, the temperature of workpiece surface is reduced to lower than Ms point (180 DEG C) can be avoided; the workpiece after isothermal quenching is placed into a tempering tool case equipped with a protection medium, insulation is carried out, the condition that the temperature of workpiece surface is reduced to lower than Ms point (180 DEG C) can be avoided; at the same time, thermal conduction can be accelerated in subsequent tempering, and energy loss is reduced.

Owner:CHINA HANGFA CHANGZHOU LANXIANG MACHINERY CO LTD

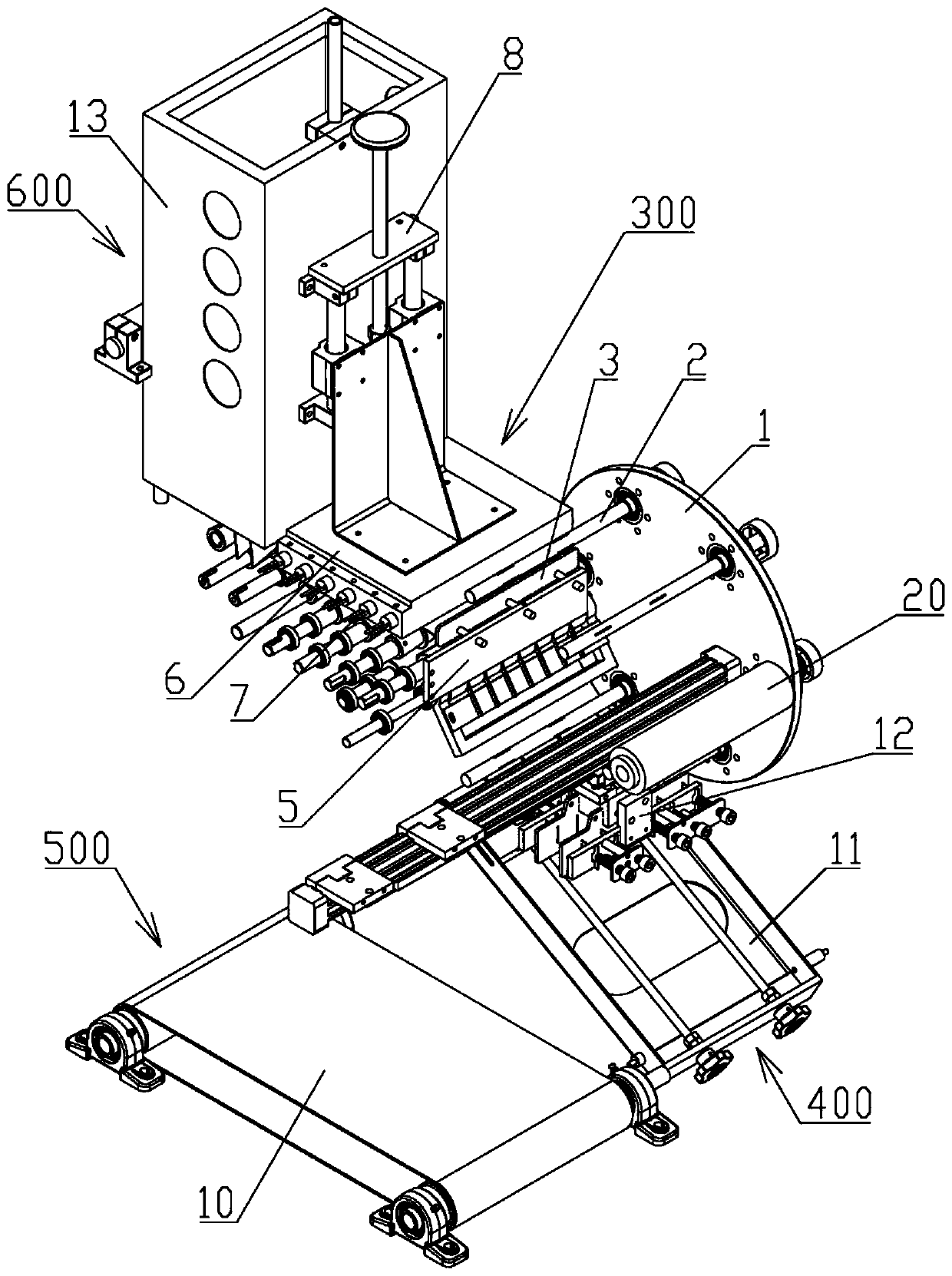

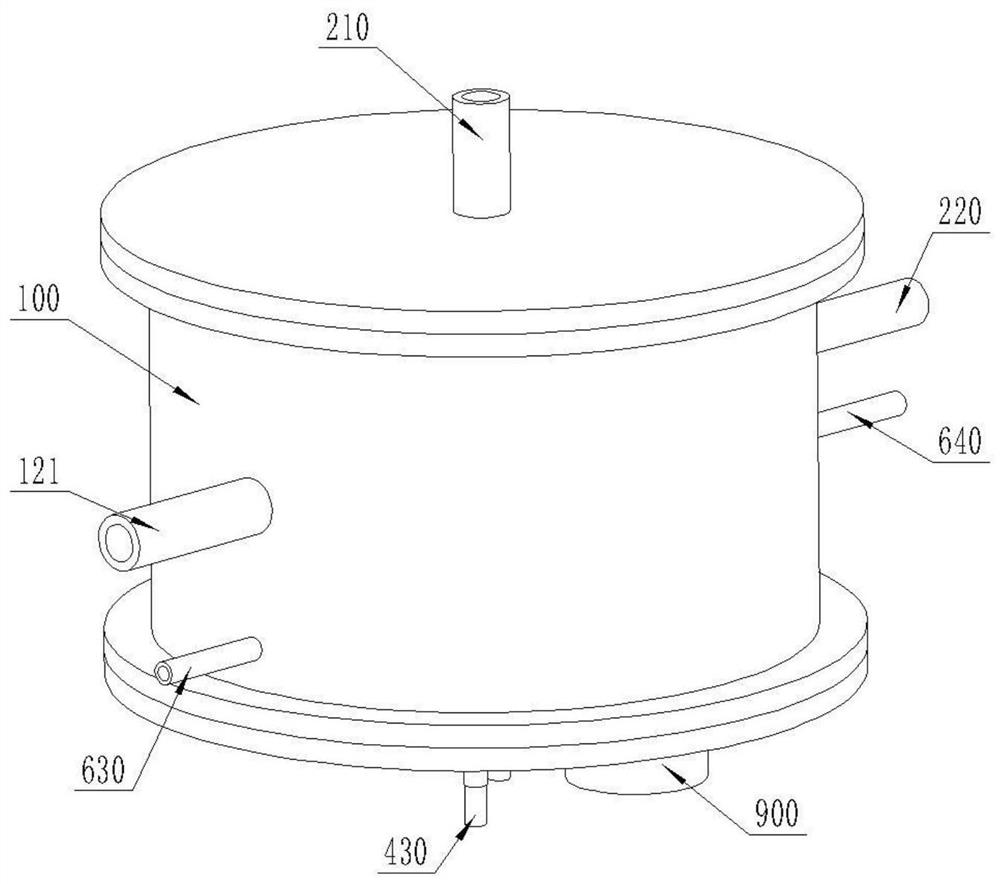

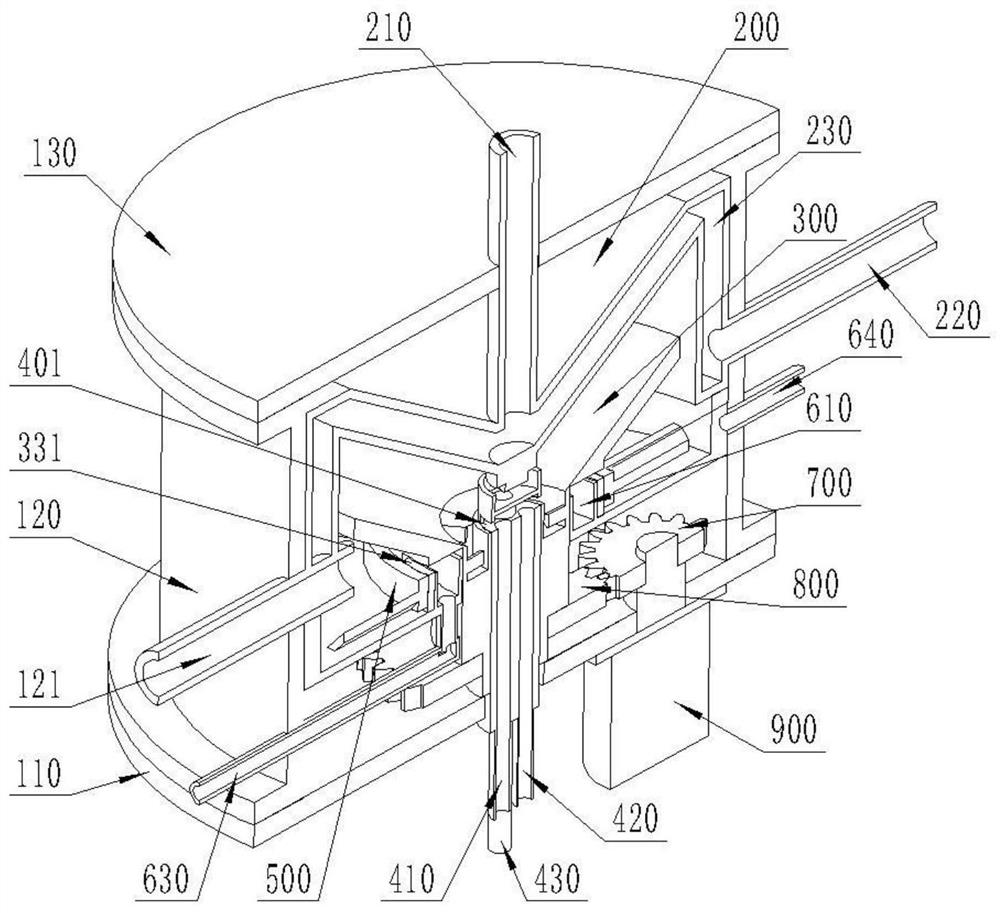

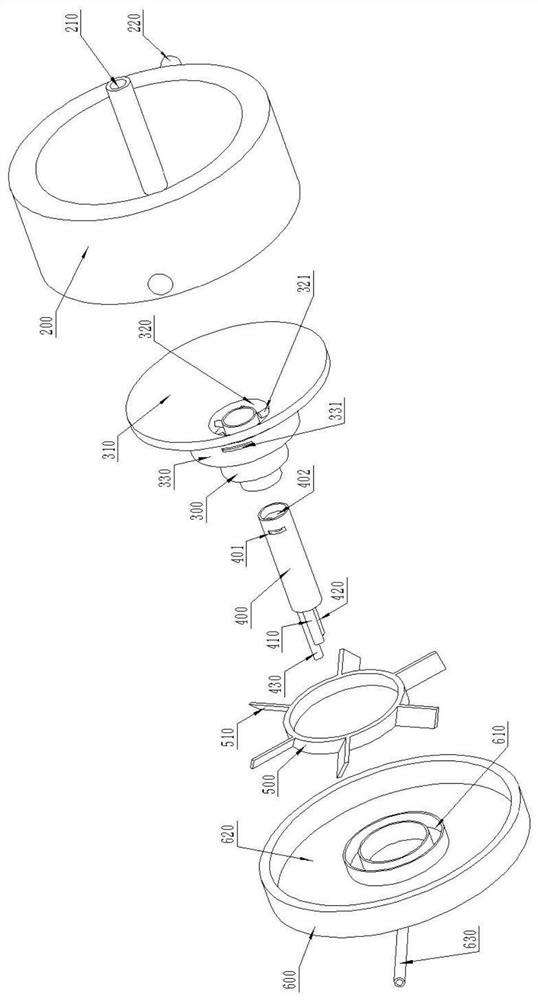

Rotary sucrose-6-ester continuous production equipment and production method

ActiveCN112915565AIncrease productivityShorten transition timeEsterified saccharide compoundsSugar derivativesSucroseGear wheel

The invention relates to the technical field of sucrose-6-ester production, in particular to rotary sucrose-6-ester continuous production equipment and a production method. The production equipment comprises a tank body, a cooling body, a conical heating disc, a spraying pipe, a stirrer, a liquid collecting disc, a small gear, a large gear and a driving motor, and the tank body is formed by connecting a lower tank cover, a main tank and an upper tank cover. The upper tank cover can be detached during installation or detachment to facilitate installation and maintenance, the driving motor is fixedly installed on the lower end face of the lower tank cover, the small gear is fixedly installed on the driving motor, a vacuum pipe is fixedly installed on the circumference of the main tank, a cooling body is fixedly installed in the main tank, and the whole cooling body is of a shell structure. The molecular distillation equipment is modified, so that all reaction processes for preparing the sucrose-6-ester can be completed in the molecular distillation equipment at one time, the reaction processes and upstream and downstream connection time are shortened, and the production efficiency of the sucrose-6-ester is greatly improved.

Owner:ANHUI JINGHE IND

Method for separation, purification, culture and passage of gill epithelial cells of hybridized prussian carp

InactiveCN103122333AReduce incubation timeShorten transition timeVertebrate cellsArtificial cell constructsIon exchangeToxicity

The invention discloses a method for separation, purification, culture and passage of gill epithelial cells of hybridized prussian carp. The method comprises the following steps of: sampling the gill epithelial cells, preparing a culture fluid, culturing tissue masses, purifying the gill epithelial cells, and subculturing the gill epithelial cells. According to the invention, the culture processes of separating, culturing and purifying the gill epithelial cells of the hybridized prussian carp, and components of the culture fluid are improved. According to a primary culture of the gill epithelial cells of the hybridized prussian carp, the normal connection time of culturing among cells can be shortened to 48 hours, thus the culture time is greatly shortened, and a established gill epithelial cell model of the hybridized prussian carp can be used for related researches of cytotoxicity of exogenous substances, ion exchange laws and the like, and provides convenience for the researches.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

Two-in-one automatic packaging production line

ActiveCN103496468AImprove accuracyShorten transition timeWrapper twisting/gatheringPackaging machinesProduction lineAdhesive belt

Provided is a two-in-one automatic packaging production line. The two-in-one automatic packaging production line comprises a carton forming machine, an automatic strapping machine and a code scanning sorter; a box filling machine is arranged between the automatic strapping machine and the carton forming machine; conveyer belts are arranged between the carton forming machine, the automatic strapping machine and the code scanning sorter respectively, wherein the conveyer belts are the same in running speed; the carton forming machine controls the vertical distance adjustment and direction changes of a connecting rod through a lifting rod. Sucking discs at the lower ends of vertical rods are used for sucking a carton and pulling open the carton to be of a three-dimensional shape, the bottom of the carton is sealed through an adhesive tape coil, the carton is filled with objects through a wide-top clamp plate so that the number of the objects is not mistaken, the carton is automatically strapped in a hot melting mode, count and statistics are conducted through code scanning, and therefore the result is reliable.

Owner:JIANGSU XINNING MODERN LOGISTICS

Part surface high-frequency quenching technology

InactiveCN109280747AFast heatingShorten transition timeIncreasing energy efficiencyQuenching agentsHardnessInductor

The invention belongs to the technical field of part processing, and particularly relates to a part surface high-frequency quenching technology. The part surface high-frequency quenching technology comprises the following steps that the first step, a workpiece is cleaned, specifically, impurities and dust on the surface of the workpiece are removed by cleaning fluid, then drying is conducted, andthe drying time ranges from 40min to 50min; the second step, rapid heating is conducted, specifically, the cleaned workpiece is clamped by a clamp and then is put into an inductor which is formed by hollow copper pipes in a winding mode, the clamp can be rotated, the alternating current with the frequency ranging from 1000Hz to 16000Hz is provided, the induced currents with the same frequency areformed on the surface of the workpiece, and therefore the surface or the local portion of the part can be rapidly heated; the third step, cooling soaking is conducted, specifically, the temperature ofthe surface or the local portion of the part is detected by a temperature sensor, and after the temperature ranges from 1000 DEG C to 1100 DEG C, cooling soaking is conducted on the part through liquid spraying holes of the inductor; and the fourth step, quenching is accomplished, the hardness of the surface or the local portion of the part is detected, specifically, the hardness of the surface or the local portion of the part is detected by a hardness detector, and after the requirement for the needed hardness is met, the quenching working procedure is accomplished.

Owner:南充隆固机械工业有限公司

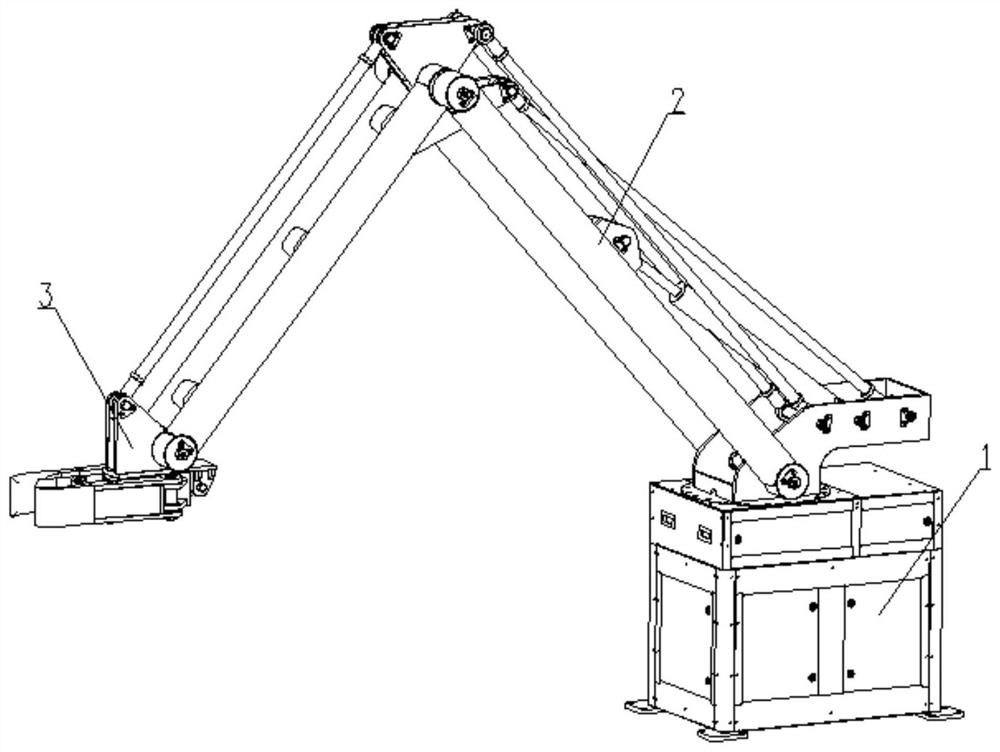

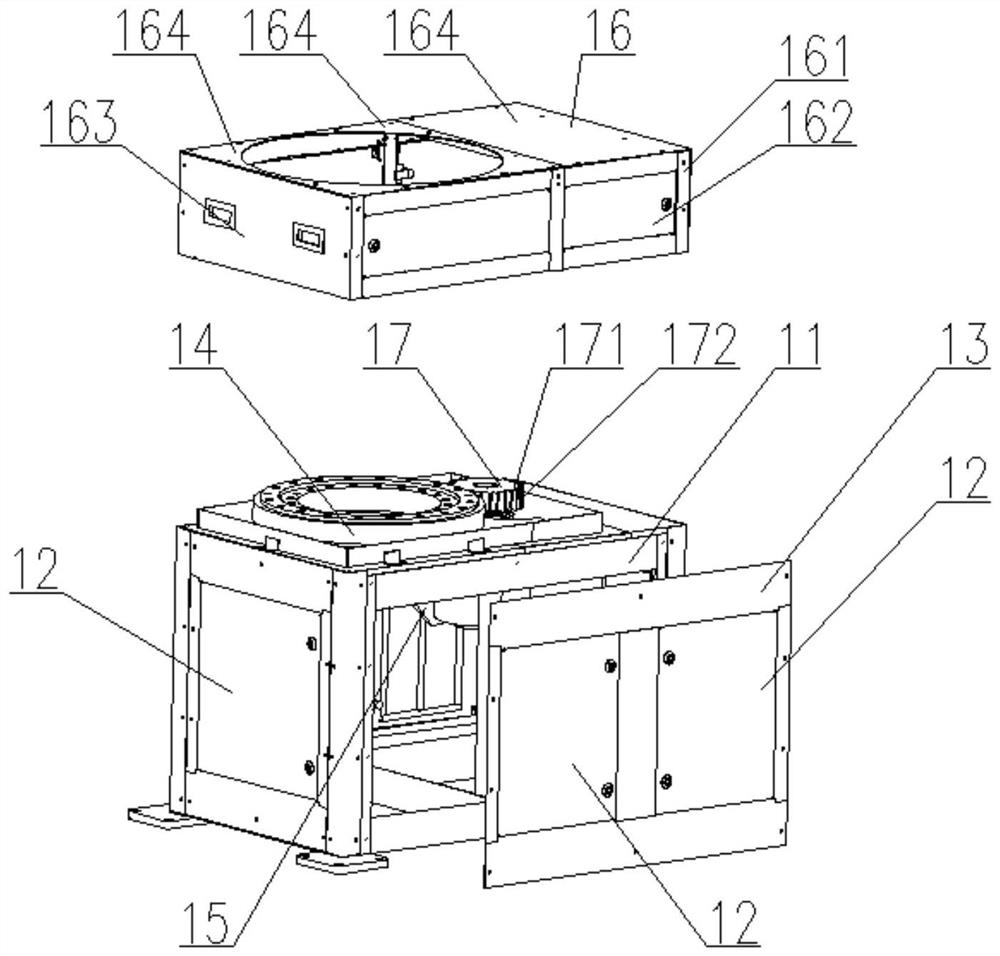

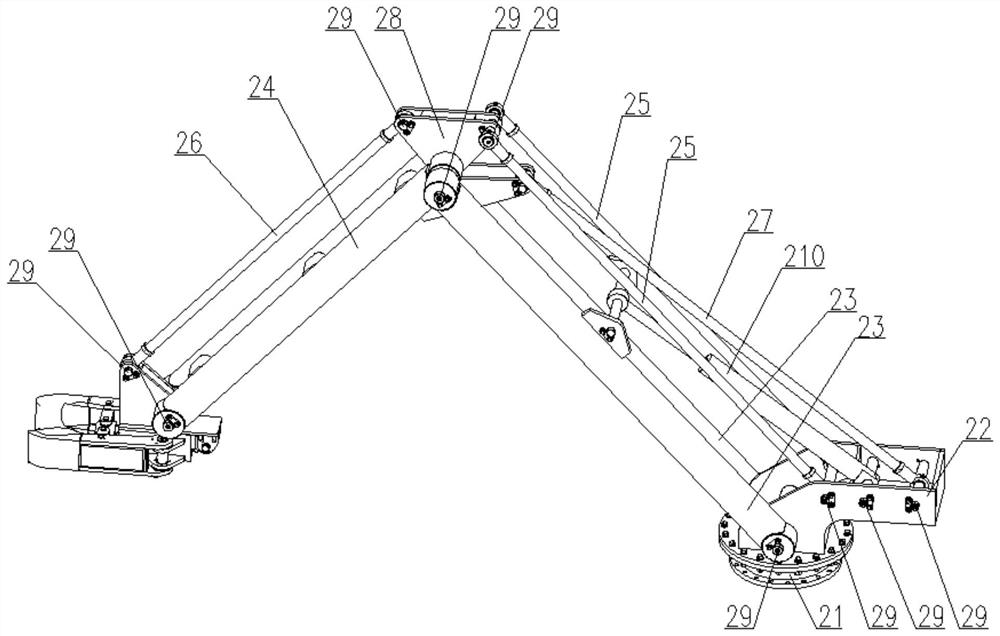

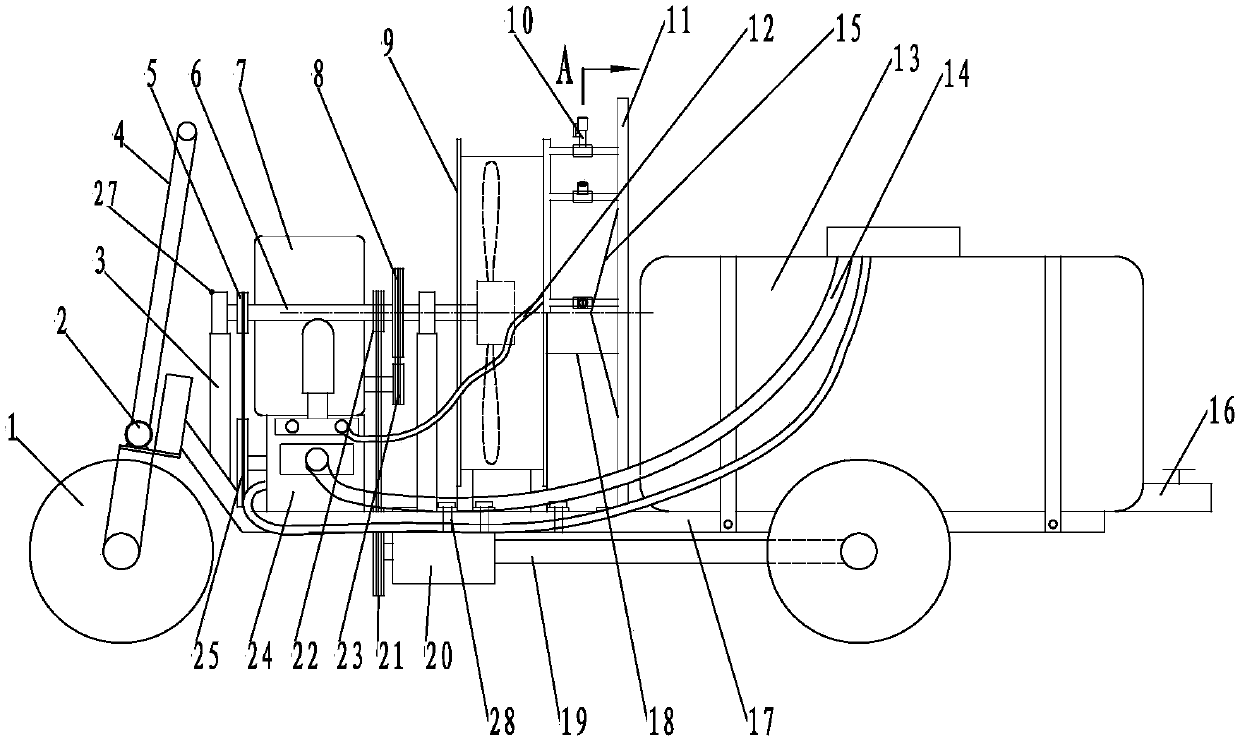

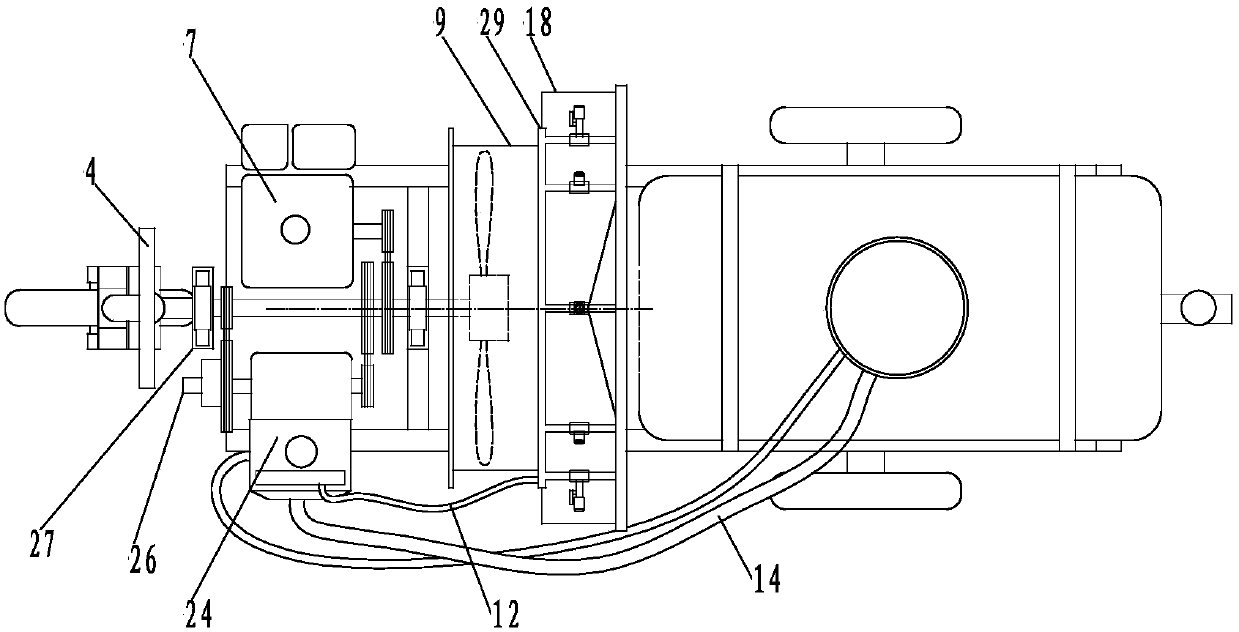

Manipulator for drill floor surface

The invention belongs to the technical field of petroleum drilling equipment, and relates to a drill floor surface manipulator, a main body structure comprises a driving base, a mechanical arm and a pipe holding wrench, and the driving base is fixedly mounted on a drill floor surface through a bottom fixing lug and plays a role in supporting and fixing the whole system; the mechanical arm is fixed together with a rotating device on the driving base through a rotary base at the bottom; the tail end of the mechanical arm is hinged with the pipe holding tongs; by introducing a parallelogram structure and a lever structure, the structure of the mechanical arm part is optimized on the premise of ensuring the strength, the occupied area of the whole mechanical arm is greatly reduced, and the occupied space of a drill floor surface is saved; the mechanical arm is compact in structure, does not occupy aisles between three-joint boxes and the space of the three-joint boxes, can be used in an integrated mode without large transformation of the drill floor surface, is convenient to assemble and disassemble and low in transformation cost, has the advantages of being low in maintenance difficulty and maintenance cost due to the simplified structure, and is convenient to use and maintain.

Owner:QINGDAO TAIZHONG ENERGY TECH

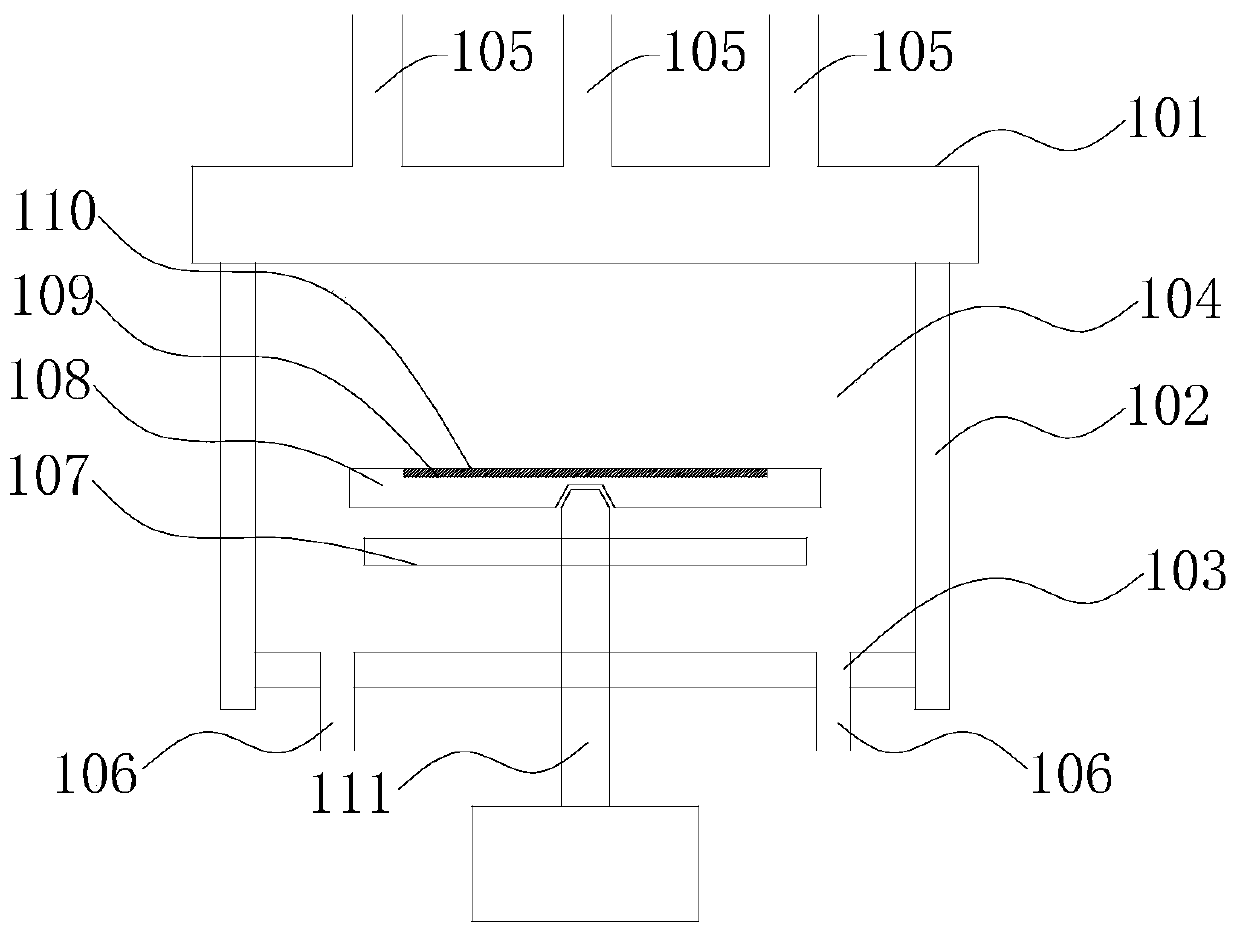

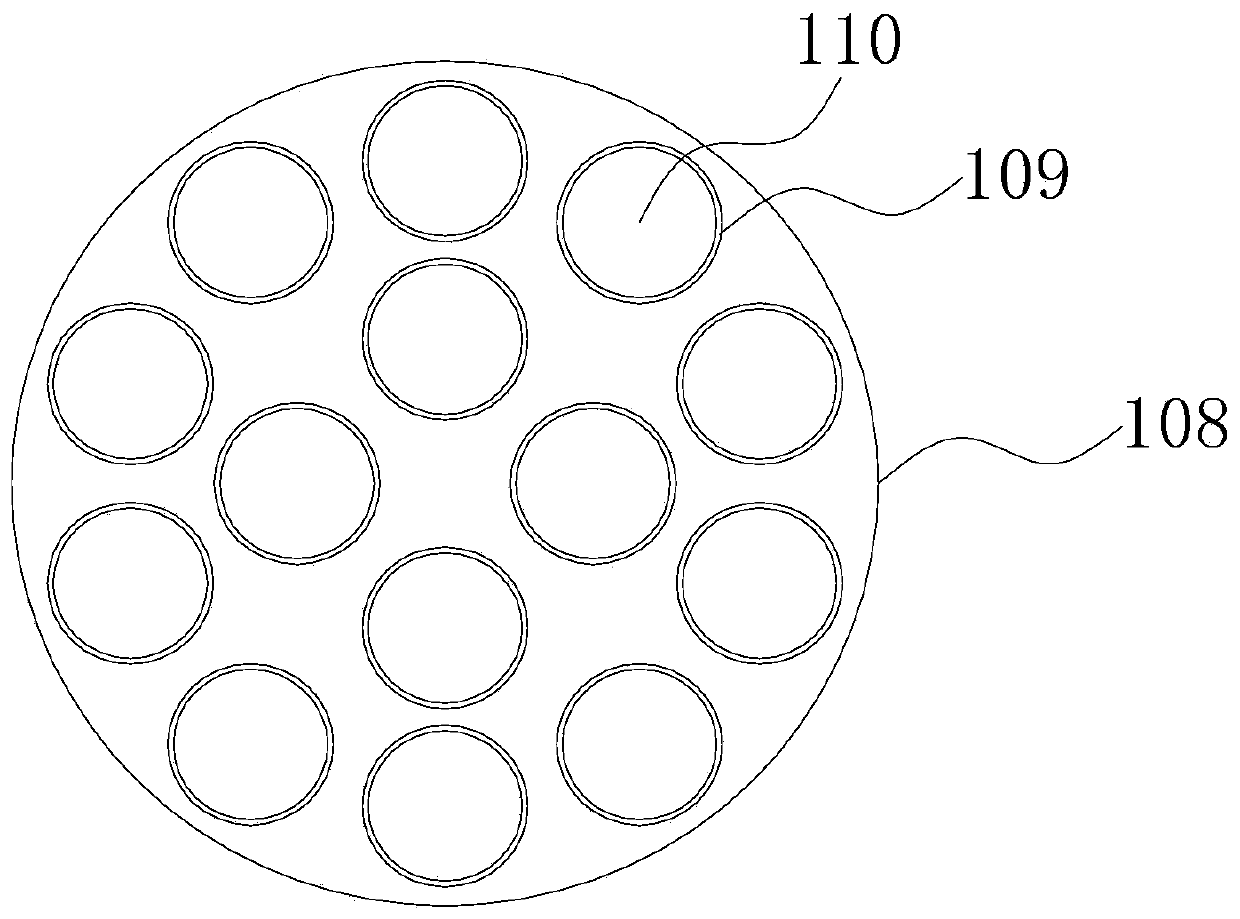

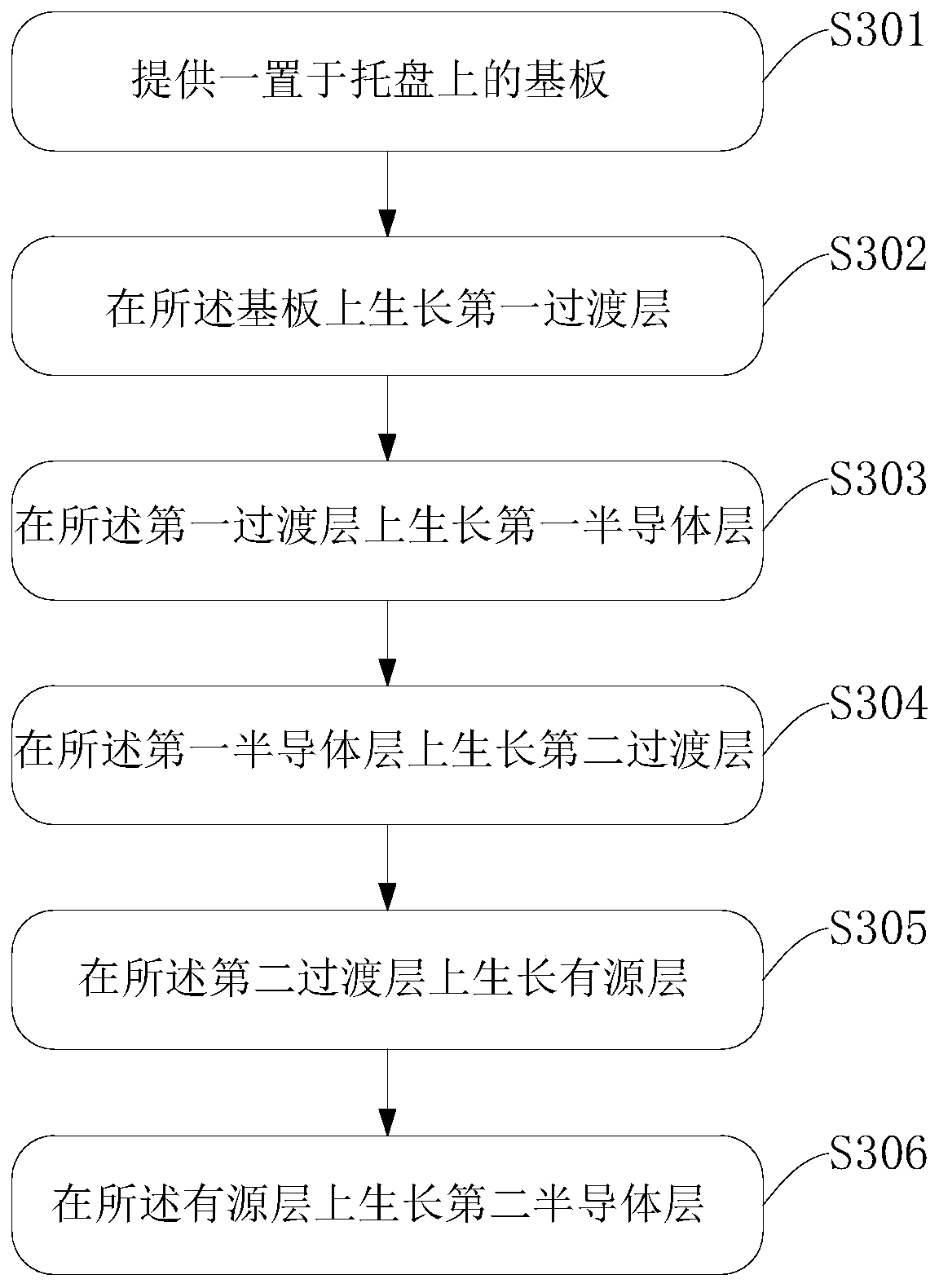

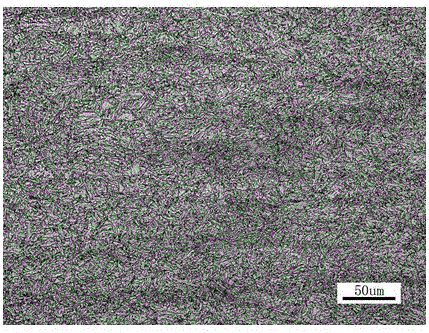

Preparation method of epitaxial structure for medical sterilization and disinfection

InactiveCN110854245AReduced risk of splinteringShorten transition timeSemiconductor/solid-state device manufacturingLight therapyIndiumActive layer

The invention provides a preparation method of an epitaxial structure for medical sterilization and disinfection. The method comprises steps of providing a substrate arranged on a tray; growing a first transition layer on the substrate; growing a first semiconductor layer on the first transition layer; growing a second transition layer on the first semiconductor layer; growing an active layer on the second transition layer; growing a second semiconductor layer on the active layer. The second transition layer comprises front barrier layers and front well layers which are alternately stacked, the aluminum content in the front barrier layers is gradually increased along with the thickness, the indium content in the front well layer is gradually reduced along with the thickness, and the tray rotation speed in the growth process of the first semiconductor layer is the same as the tray rotation speed in the growth process of the second transition layer. The method is advantaged in that the conversion time from the first semiconductor layer to the second transition layer can be reduced, and the cracking risk in the conversion process of different steps is reduced.

Owner:李丹丹

A niobium-molybdenum composite microalloyed high-strength bainite steel and its preparation method

The invention relates to a niobium-molybdenum composite micro-alloyed high-strength bainite steel and a preparation method thereof. The technical solution is: rolling the slab with a hot rolling mill, the starting temperature of the rough rolling is 1150-1200°C, the starting temperature of the finishing rolling is 950-1000°C, and the finishing rolling temperature is 900-950°C; and then Cool at a speed of 30~50°C / s to 420~450°C, then air cool to 330~380°C, keep warm at 330~380°C for 30~45min, and then water cool to room temperature. The chemical composition and content of the billet are: C is 0.19~0.224wt%, Si is 1.43~1.50wt%, Mn is 1.94~2.05wt%, Nb is 0.025~0.027wt%, Mo is 0.142~0.15wt% %, P<0.008wt%, S<0.002wt%, N<0.004wt%, the rest is Fe and unavoidable impurities. The invention has the characteristics of low cost, simple process and production cycle, and the strength and shape of the prepared product are well matched, and the comprehensive performance is excellent.

Owner:WUHAN UNIV OF SCI & TECH

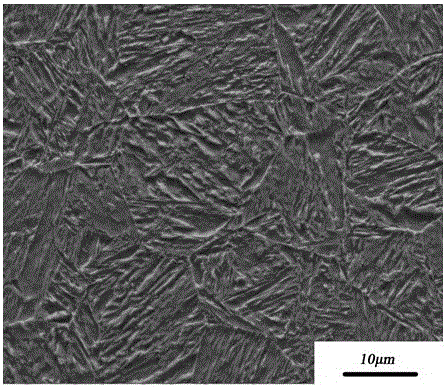

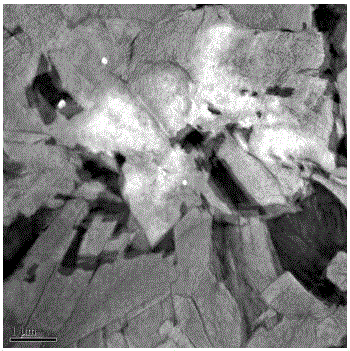

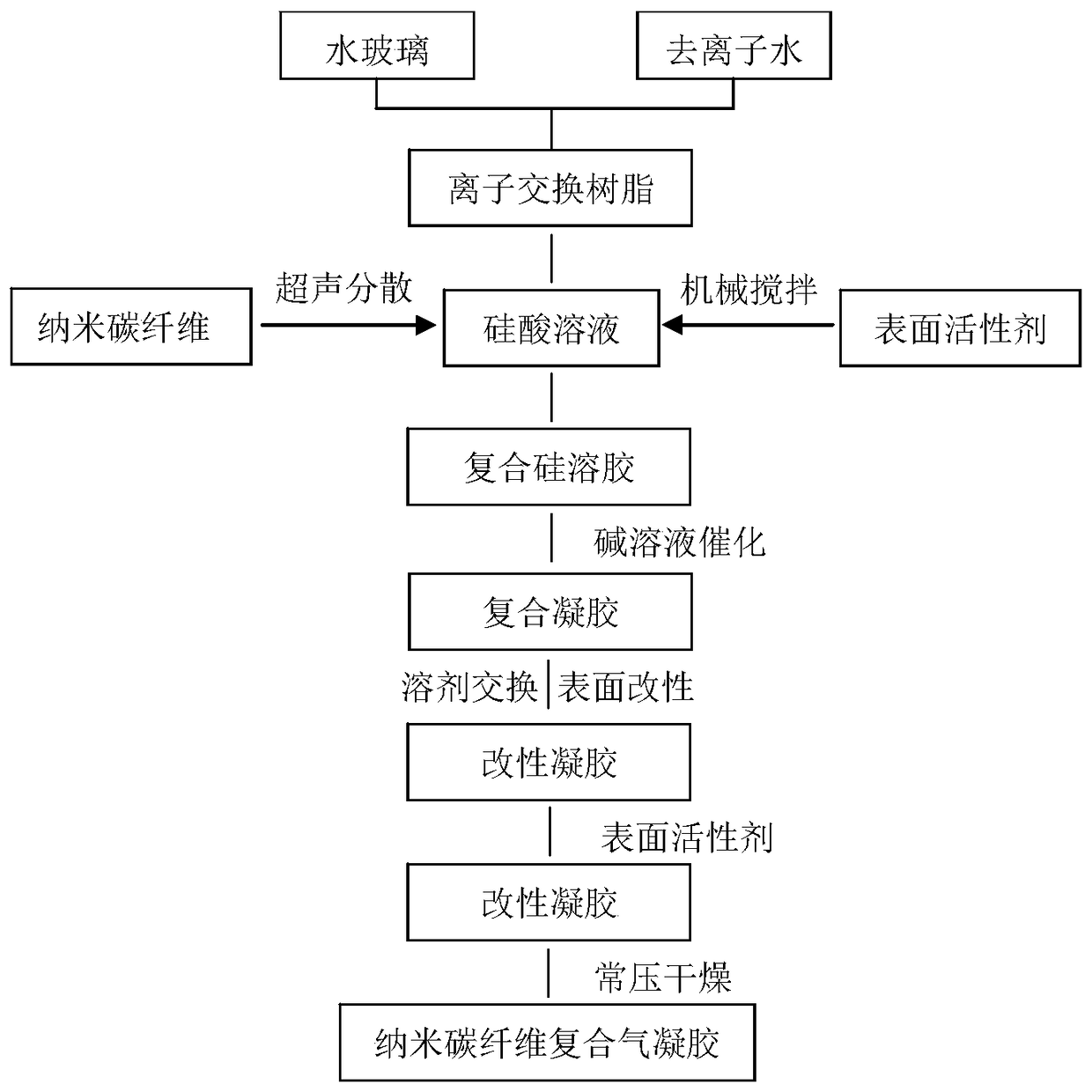

A preparation process of nano-carbon fiber composite silica airgel

InactiveCN105418052BImprove dispersion efficiencyShorten dispersion timeSilicic acidThermal insulation

Owner:DALIAN UNIV OF TECH +1

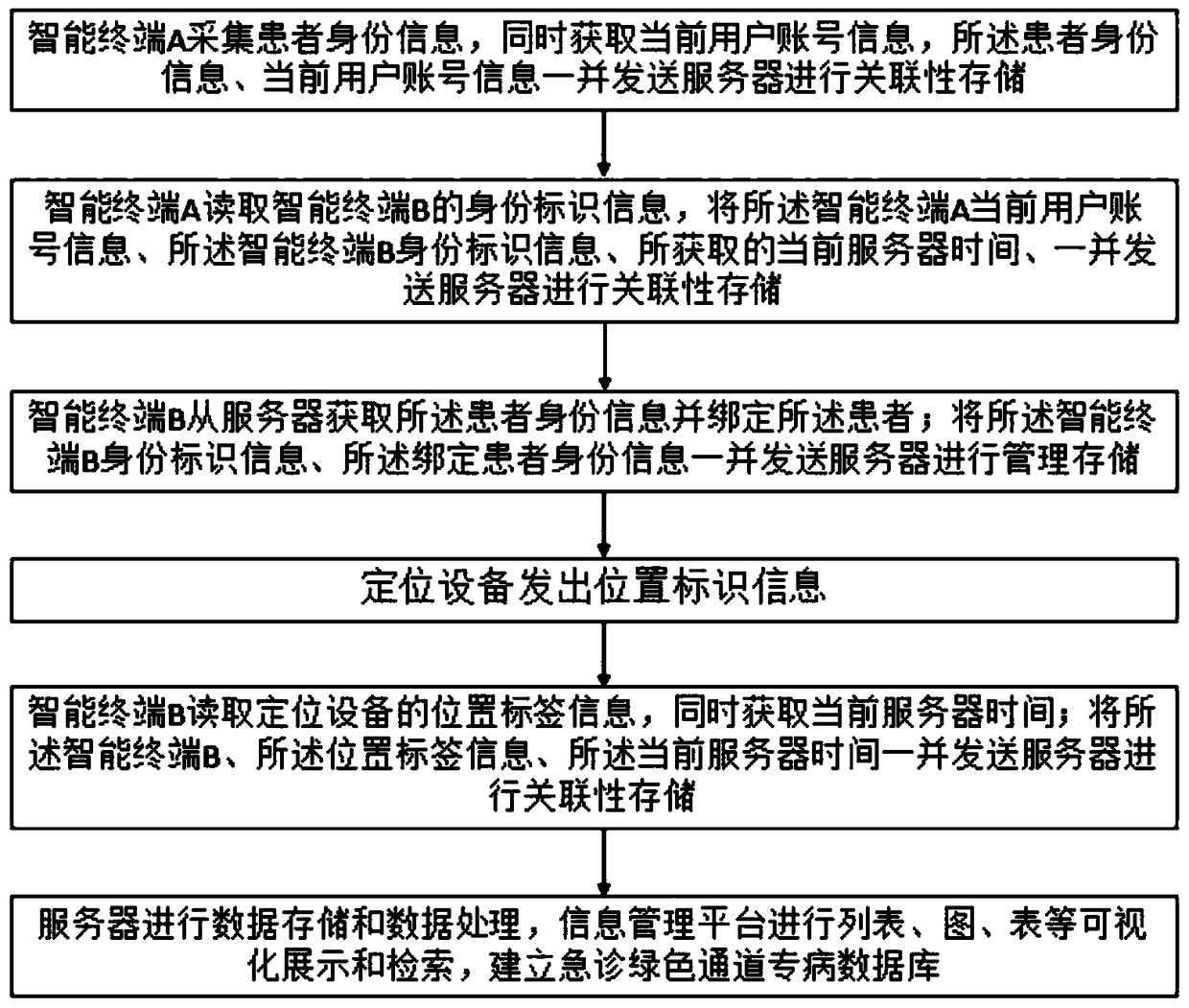

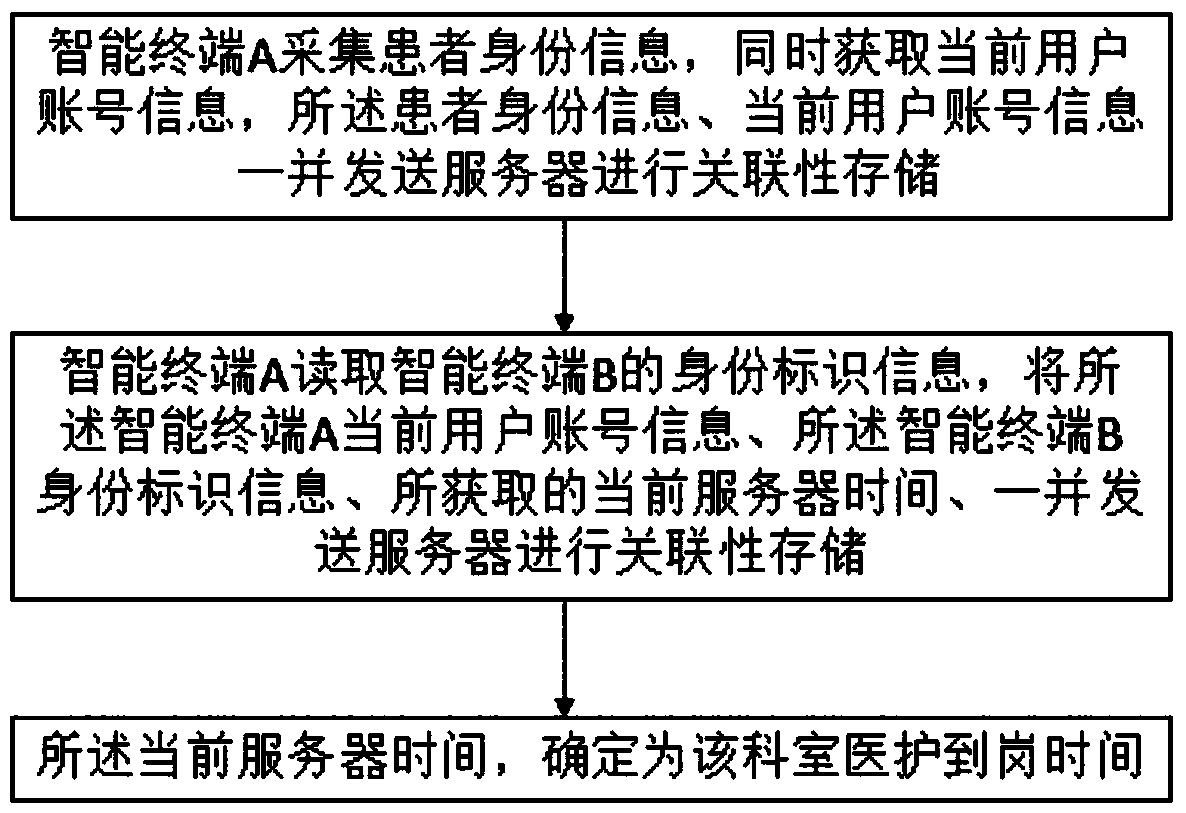

Emergency treatment green channel information management method and device

ActiveCN109003664ARealize refined managementPromote collaborationHealthcare resources and facilitiesEmergency treatmentArrival time

The invention belongs to the technical field of information management, in particular to an emergency treatment green channel information management method and device. An intelligent terminal A, an intelligent terminal B, positioning equipment, an information management platform and a server are utilized to manage the emergency treatment green channel first aid flow. The steps comprise that the intelligent terminal A collects the patient identity information and the user account information, reads the identity identification information of the intelligent terminal B, obtains the server time and sends the information to the server for associated storage; the intelligent terminal B obtains the patient identity information and binds the patient and reads the location tag information and the current server time and sends the information to the server for associated storage; and visual display retrieval is performed through the information management platform and an emergency treatment green channel special disease database is established . Fine management of the emergency treatment green channel rescue flow can be realized, the emergency treatment green channel patient whole process rescue time and medical personnel arrival time, etc. can be intelligently collected, the connecting time of each link can be shortened and the emergency treatment rescue efficiency can be improved.

Owner:健和九州(北京)科技有限公司

Bottle dividing mechanism of liquid filling machine

The invention discloses a bottle dividing mechanism of a liquid filling machine. The bottle dividing mechanism comprises a conveyer belt, a star wheel and a spinner bottle component, wherein the star wheel is arranged at the joint of the conveyer belt and the spinner bottle component; the corresponding ratio of the rotation speed of the star wheel to that of the spinner bottle component is determined according to the gear number of the star wheel and the pushing hand number of the spinner bottle component; the running speed of the conveyer belt is the same as that of the star wheel. According to the technical scheme of the bottle dividing mechanism, the liquid filling machine runs smoothly among bottle feeding, bottle dividing and filling steps, and thus the demanded transition time is saved.

Owner:CHENGDU JIAMEIJIA SCI & TECH

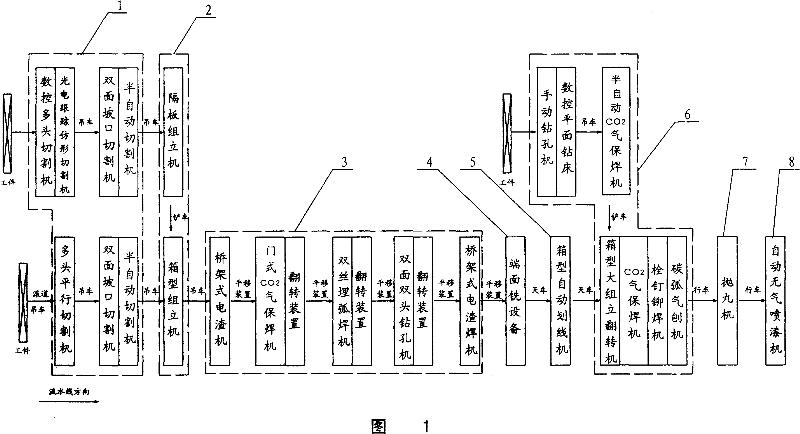

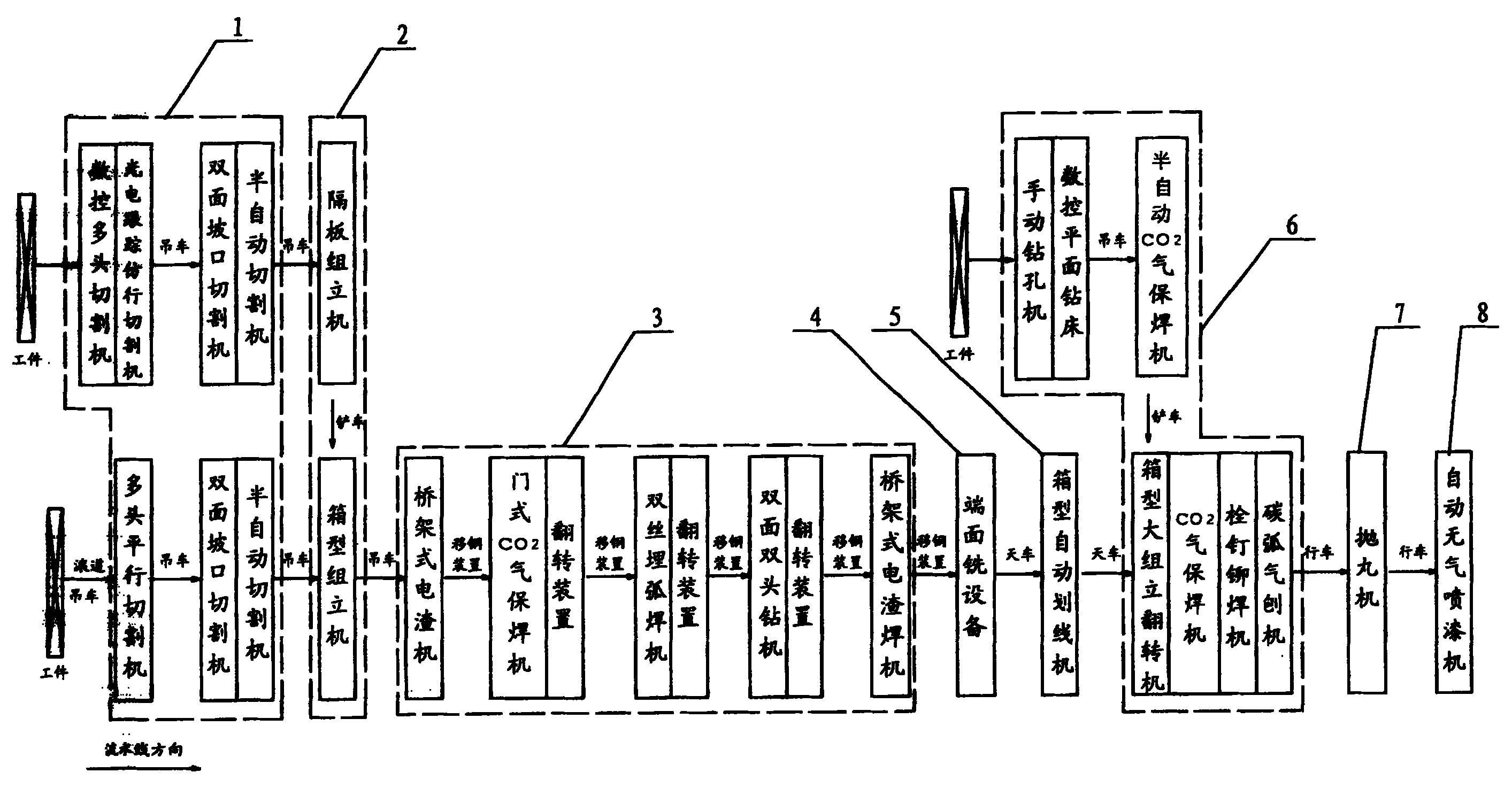

Lateral layout production flow line of box type steel structure element

InactiveCN100337786CShorten the lengthLess investmentOther manufacturing equipments/toolsMetal working apparatusProduction lineIndustrial engineering

A transversely arranged production stream line for manufacturing the case-type steel members features that the cutting unit, assembling unit, welding unit, end face milling unit, marking out unit, great assembling-welding unit and rust-removing and coating unit are sequentially arranged in the direction of stream line, their working directions are perpendicular to the direction of stream line, and the longer direction of workpiece is perpendicular to the direction of stream line. Its advantages are short length of stream line, high productivity and low cost.

Owner:ZHEJIANG JINGGONG STEEL BUILDING GRP +2

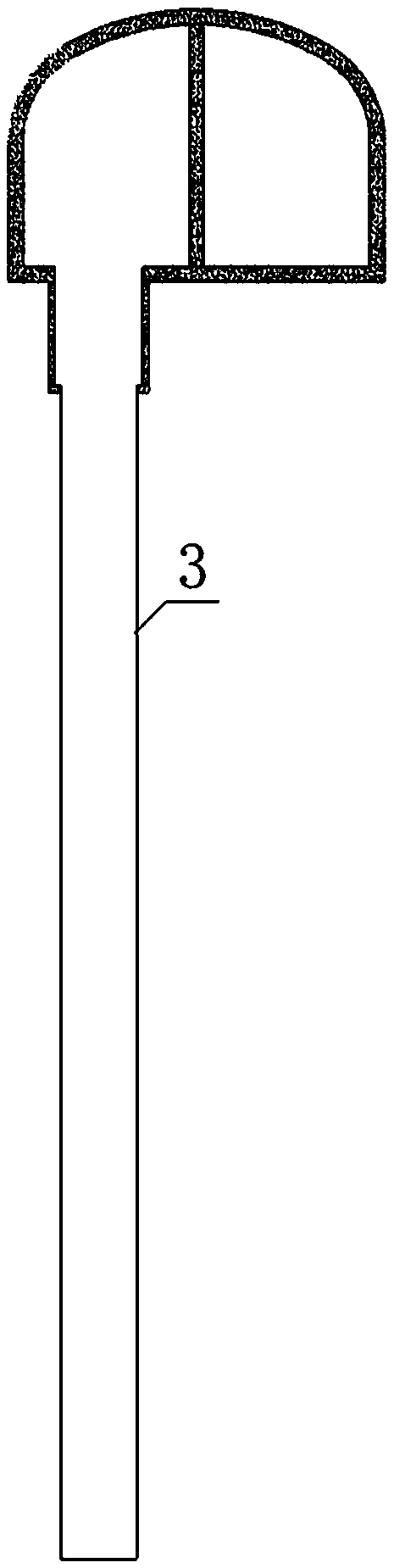

Static pressure pile machine

InactiveCN102839668AReduce extra spaceReduce the overall heightBulkheads/pilesEconomic benefitsEngineering

The invention discloses a static pressure pile machine which comprises a machine body (8), a pressure pile oil cylinder (1) and a pressure pile platform beam (3). Four uprights (2) vertical to the machine body (8) are arranged on the machine body (8); both ends of the pressure pile platform beam (3) are respectively sleeved on the four uprights (2) in a sliding mode; and the pressure pile platform beam (3) is connected with the upper ends of the uprights (2) by detachable positioning shafts (9). According to the invention, by the up-and-down sliding of the pressure pile platform beam, the space and the height which are occupied by the machine in the transporting process are reduced, the aim of not disassembling the pressure pile oil cylinder, the beam and a pressure pile box is fulfilled, the complete machine transportation is implemented, the transition time is shortened, the labor intensity is reduced and the economic benefits are promoted.

Owner:SUNWARD INTELLIGENT EQUIP CO LTD

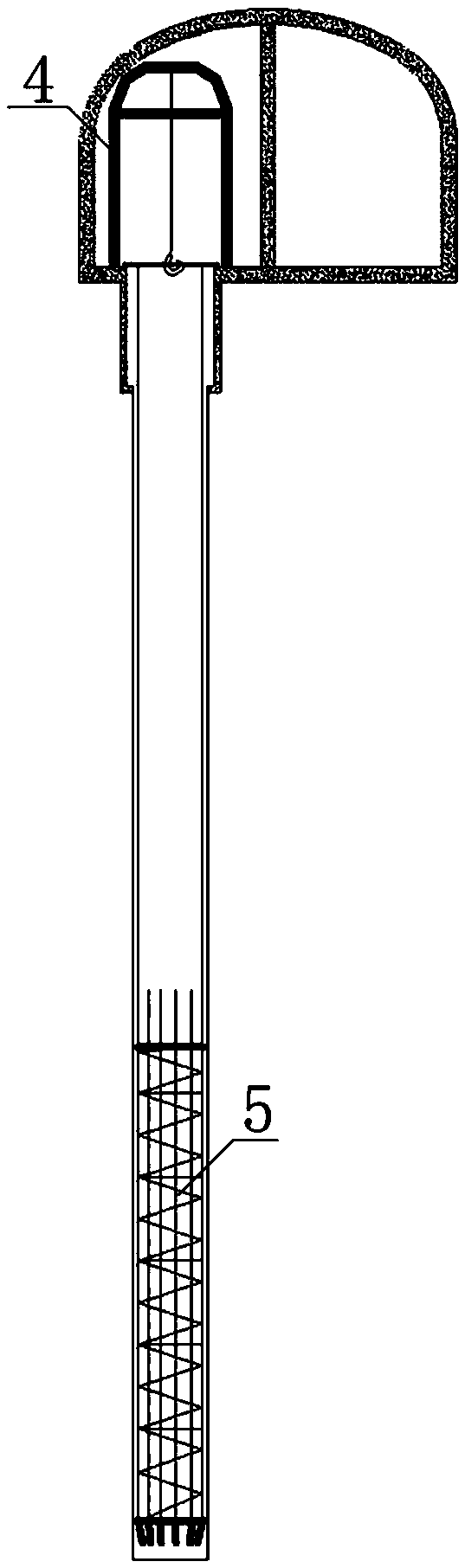

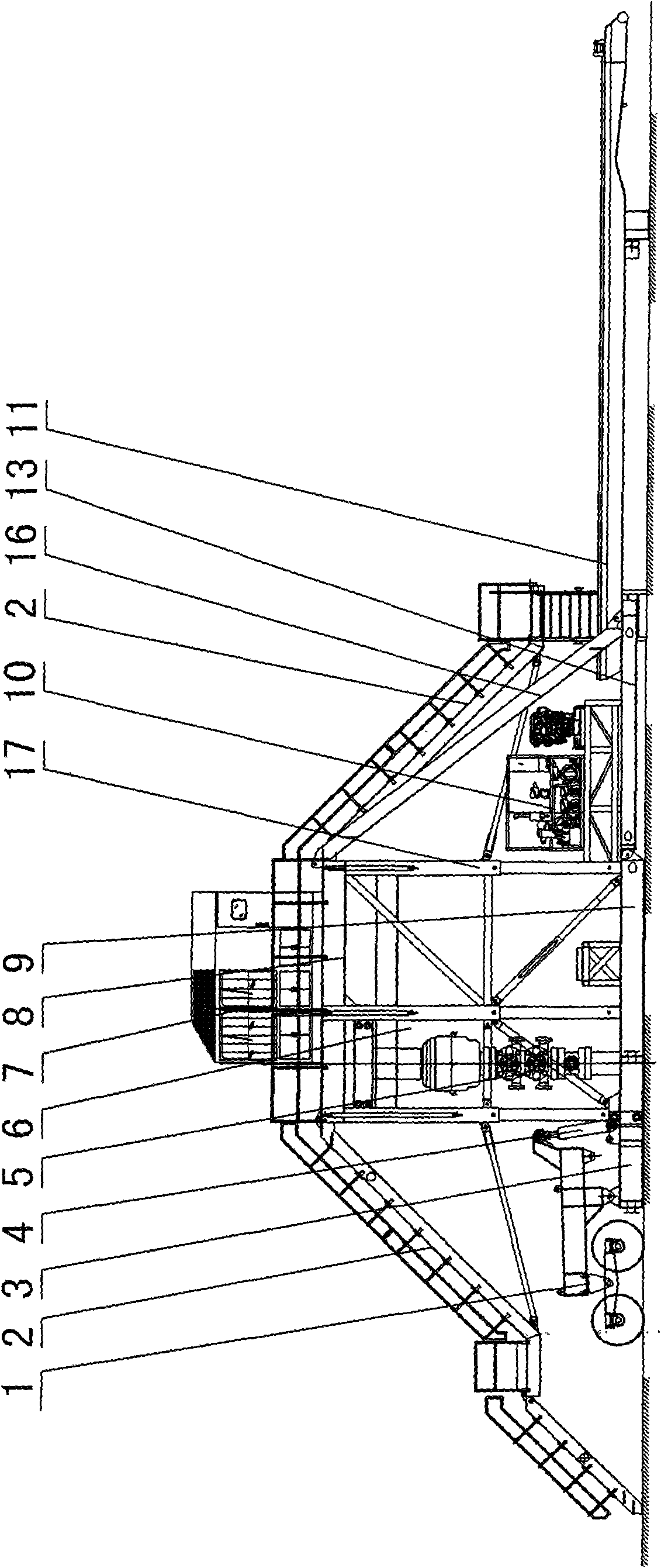

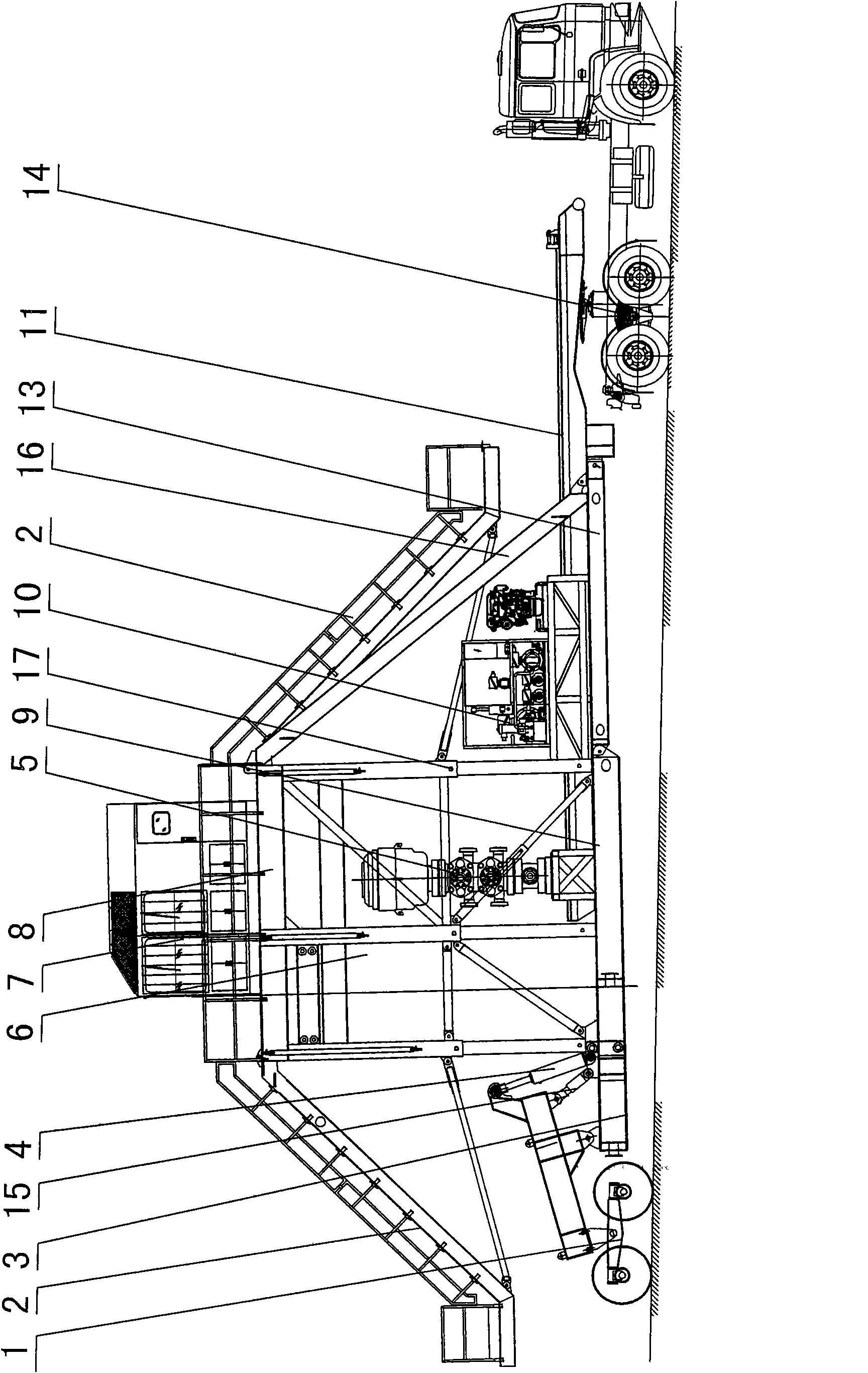

Novel trailing drilling platform

ActiveCN101649723ARealize relocation and transportationShorten transition timeDerricks/mastsDrilling machines and methodsVehicle frameSlide plate

The invention relates to a novel trailing drilling platform which belongs to the field of oil field drilling-repairing machine corollary equipment and comprises a top assembly, a bottom assembly and a drilling platform main body formed by upright posts sleeved together with circular or rectangular tubes. The novel trailing drilling platform is characterized in that a connecting device is arrangedat one end of the bottom assembly and connected with the top assembly through a sliding plate and forms a triangular rigid frame structure with the upright posts; the connecting device is in sliding connection with a catwalk which can be partly retracted to the drilling platform and connected and fixed with the connecting device and the bottom assembly of the drilling platform through lug plates and pin rolls on the catwalk into a whole to form a frame girder, and a towing pin connected with a towing vehicle is arranged at the other end of the catwalk; the bottom assembly on the other side ofthe drilling platform is provided with a wind support saddle, a pair of raising oil cylinders is arranged on the crossed part of the bottom assembly and the upright posts and connected with the end part of a one-line double-bridge wheel carrier. When the novel trailing drilling platform is moved, an upper drilling room of the drilling platform, a rotating disk, a blowout preventer hoisting device, a hydraulic station, a blowout preventer and the like do not need to be dismounted. The removal time is reduced to 2-3 hours from the prior 4-50 hours, the operating efficiency is improved and the operating cost is reduced.

Owner:中石化四机石油机械有限公司 +1

Orchard sprayer with adjustable spray range

InactiveCN109744216AShorten transition timeMaximize scatterInsect catchers and killersSprayerDrive shaft

The invention provides an orchard sprayer with the adjustable spray range. The orchard sprayer comprises a rack, an engine, a fan, a gearbox and a high-pressure pump; traveling wheels are arranged below the rack, and a spraying device is arranged on the rack and is constituted by a plurality of spraying heads which are fixed to an annular frame and radially distributed; a choke plate is arranged behind the spraying device, and the fan is arranged in front of the spraying device; the high-pressure pump and the gearbox are connected, and a clutch is arranged between the high-pressure pump and atransmission shaft for locking; the gearbox drives the traveling wheels; a water tank is arranged behind the chock plate and internally provided with a liquid conveying pipe to be connected to the high-pressure pump; and the high-pressure pump is connected with the spraying heads through outputting pipes. According to the orchard sprayer, the operation efficiency is high, a pesticide sprinkling machine can sprinkle a pesticide for crops with different heights, the heights of spraying droplets can be subjected to stepless adjusting, starting and using are carried out simultaneously, thus the connecting time is shortened, the field operation efficiency can be advantageously improved greatly, and the labor intensity is reduced.

Owner:张新锋

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com