Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

61results about How to "Realize automatic continuous feeding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

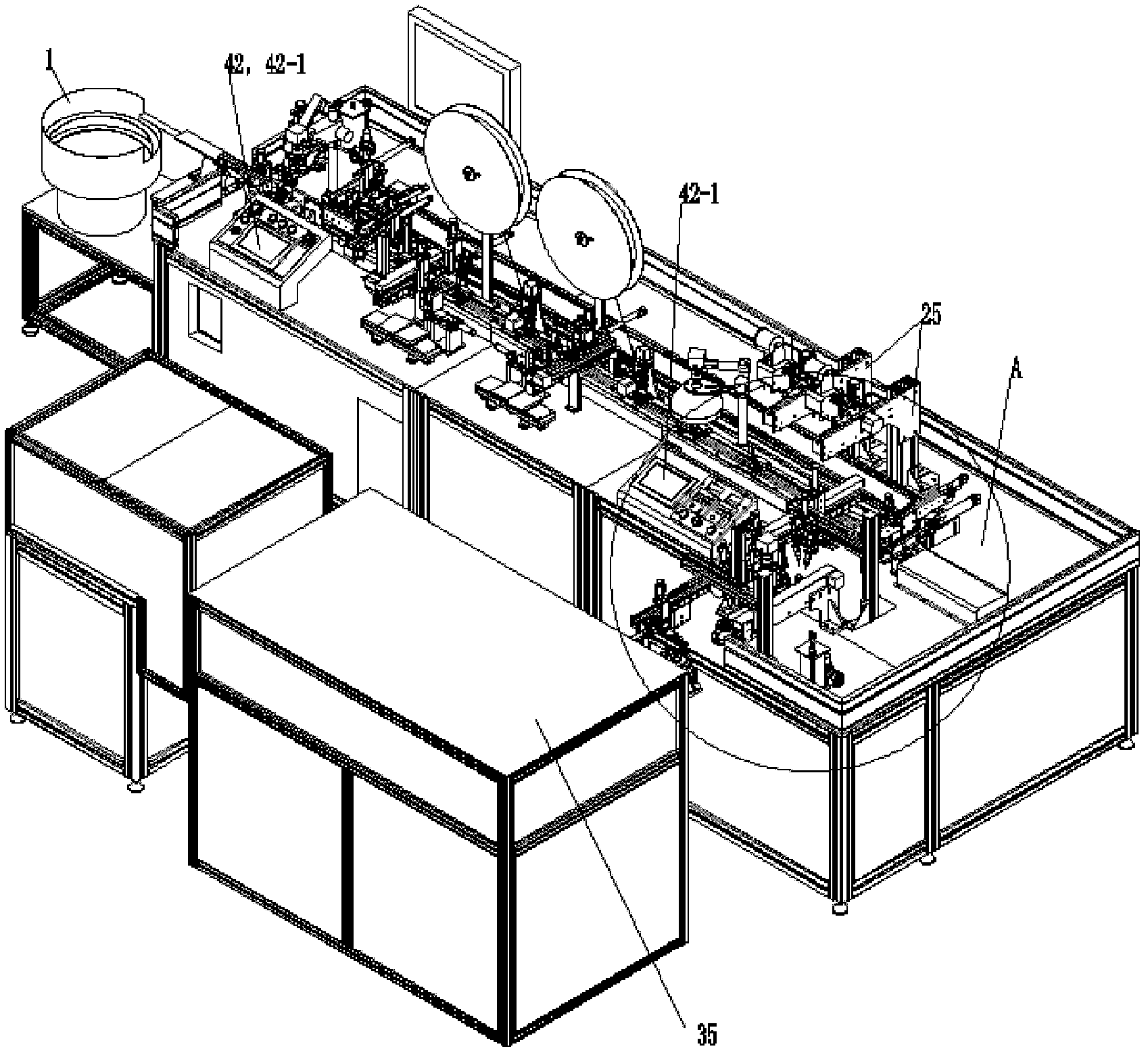

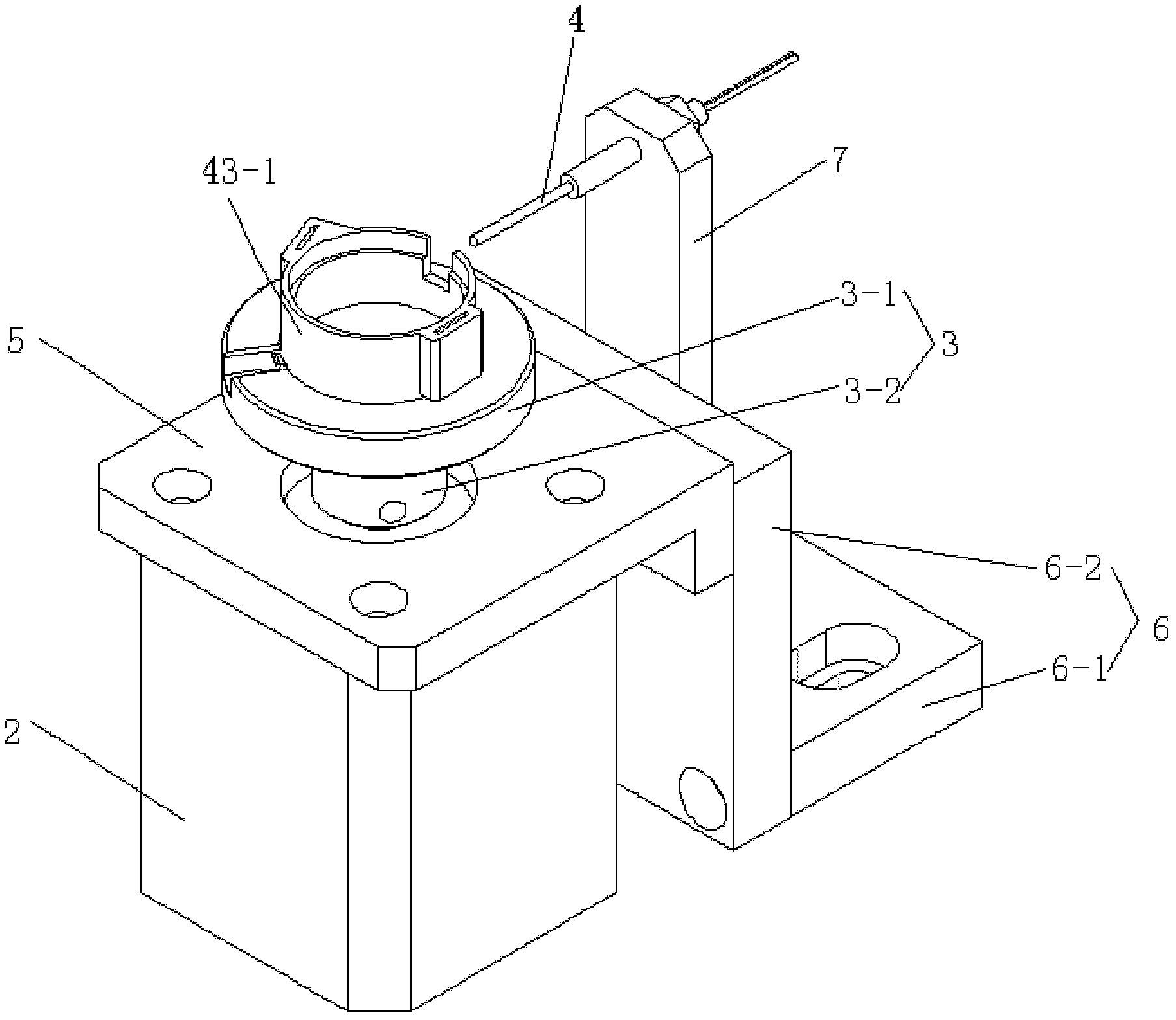

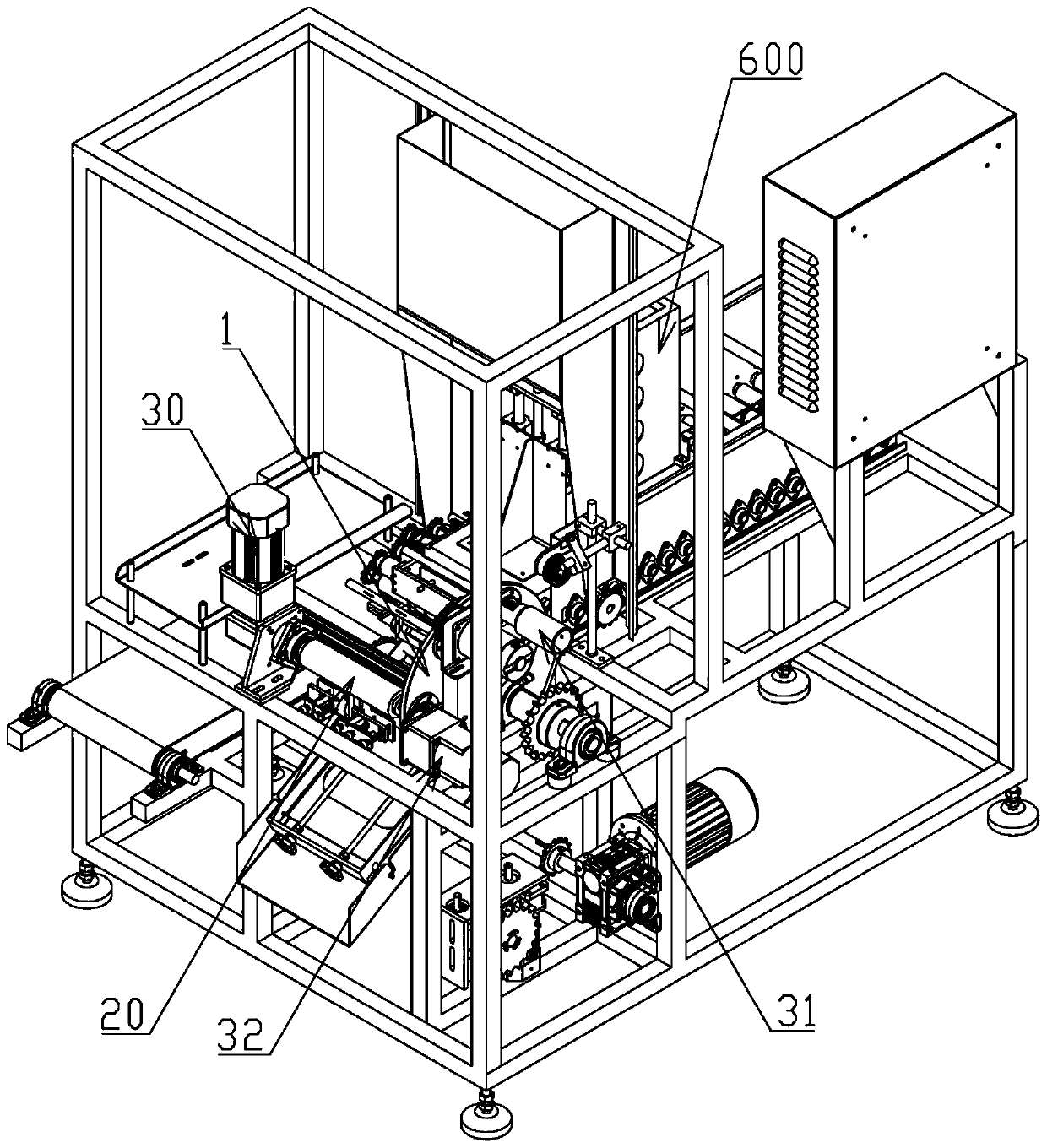

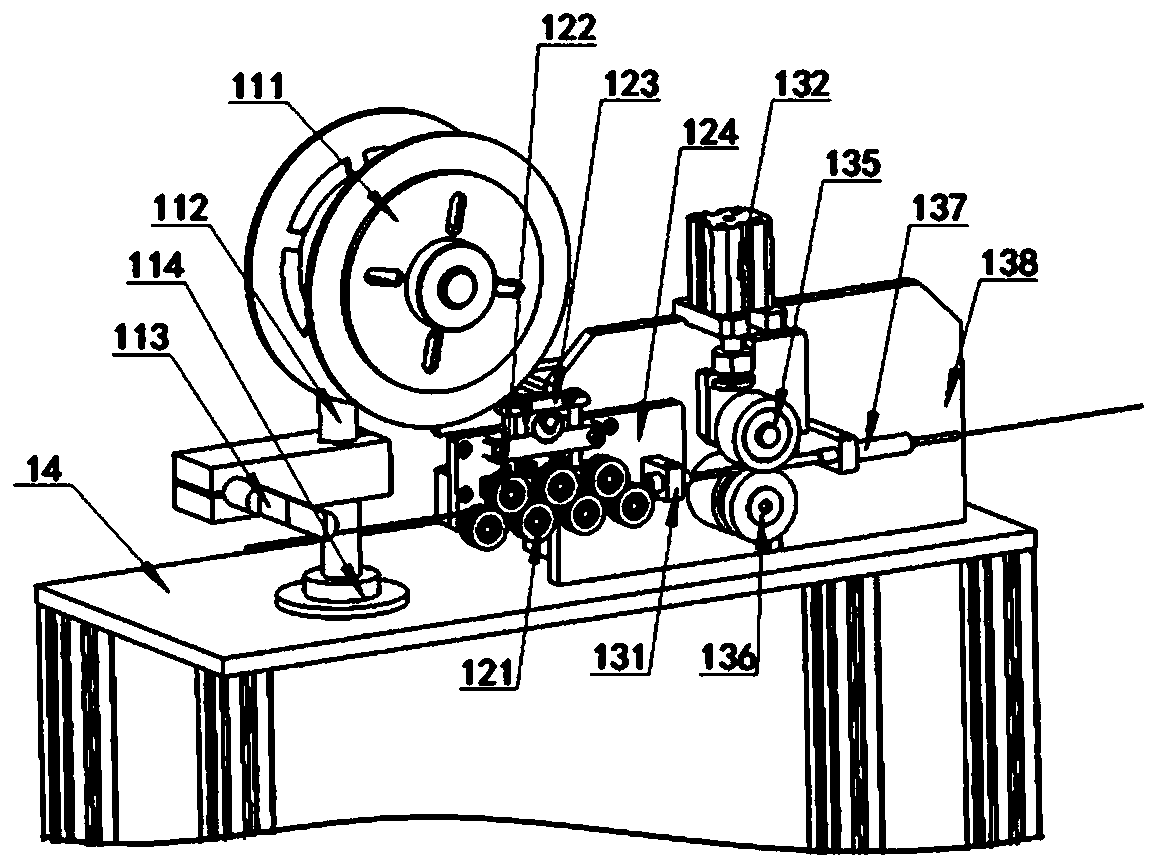

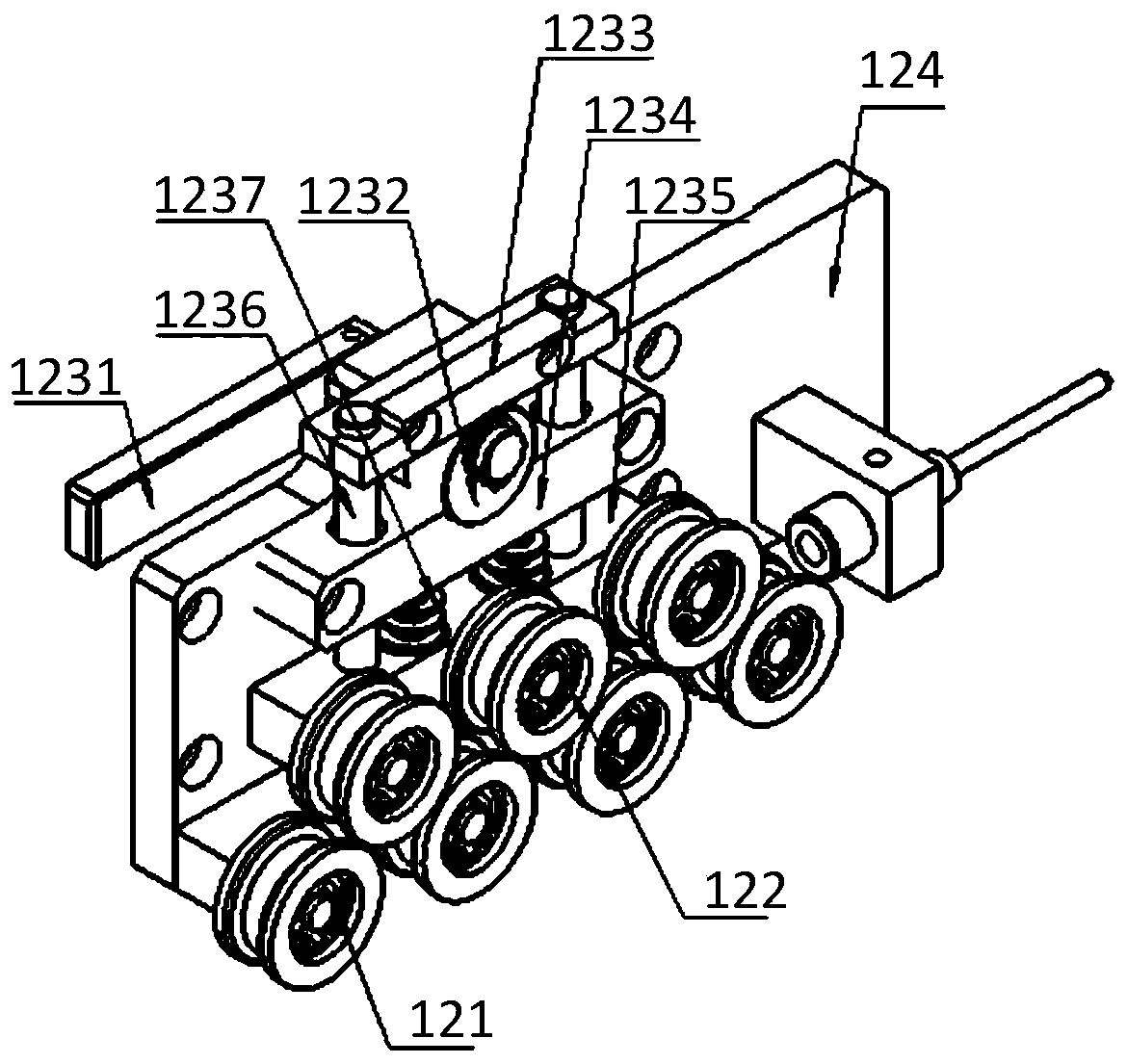

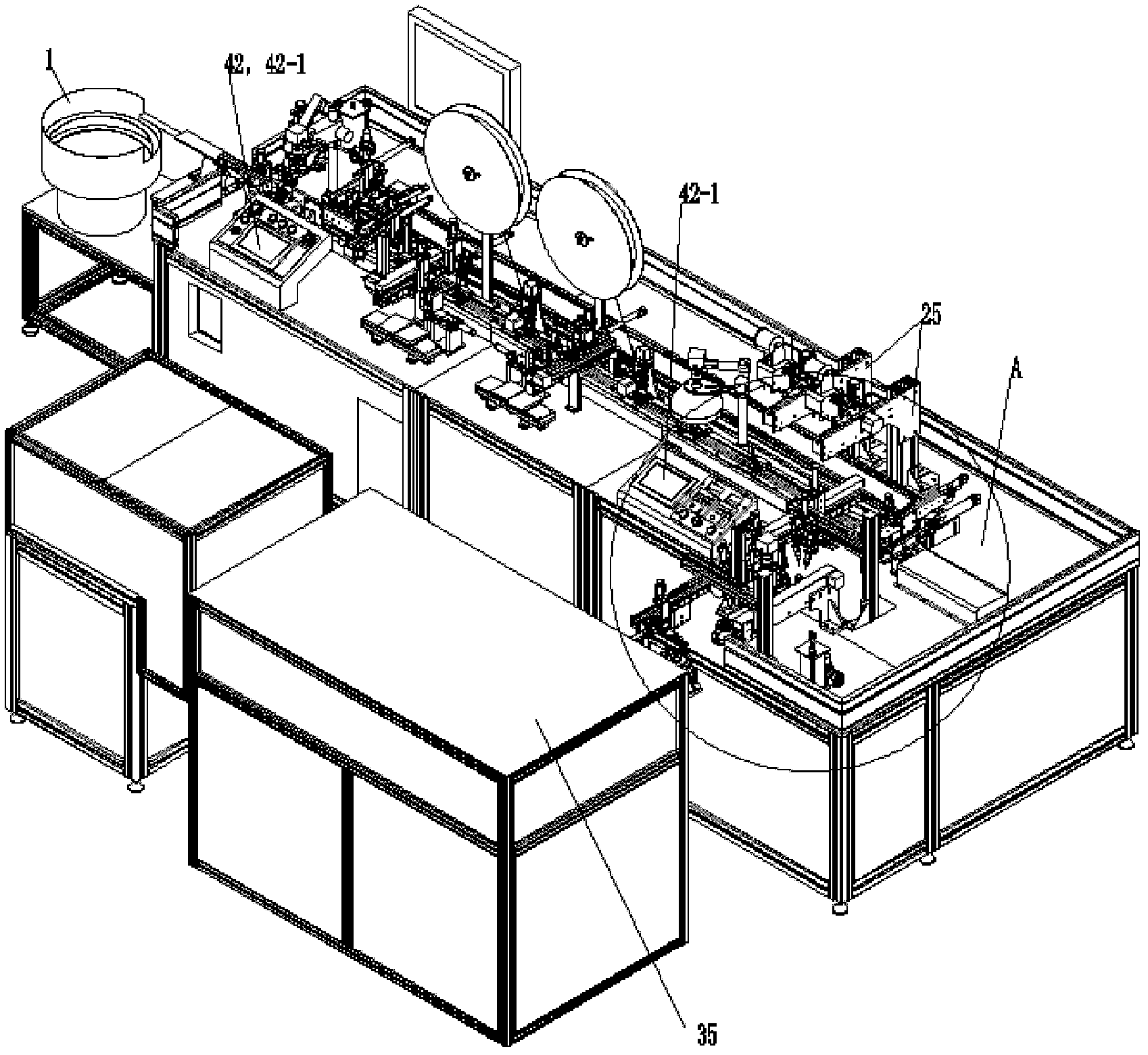

Automatic assembly production line of buzzers

ActiveCN102848187AGuaranteed accuracyRealize automatic feeding processAssembly machinesProduction lineEngineering

The invention discloses an automatic assembly production line of buzzers, which comprises a feeding mechanism, a glue coating mechanism, a buzzer piece placing mechanism, a straight contact pin placing mechanism, a first thermoplastic pipe placing mechanism, an inclined contact pin placing mechanism, a second thermoplastic pipe placing mechanism, a thermoplastic pipe heat sealing mechanism, a contact pin welding mechanism, a dispensing mechanism, a curing mechanism and a detecting and sorting mechanism, which are sequentially arranged on a work table; the glue coating mechanism comprises an automatic shell locating mechanism located behind a glue applicator, and the automatic shell locating mechanism comprises a motor, a rotating jig, an optical fiber sensor, a motor base, a supporting plate and a sensor bracket; the optical fiber sensor is a reflective optical fiber sensor and is arranged to be aligned to the shell; and the optical fiber sensor is installed on the upper part of the sensor bracket, and the lower part of the optical fiber sensor is fixed to the side plate of the supporting plate. The automatic assembly production line disclosed by the invention has the advantages of smart design and simple structure, realizes high level automation, replaces the manual operation, reduces the cost of manpower and physical resources and improves the production efficiency of the assembly line.

Owner:CHANGZHOU MINGSEAL ROBOT TECH CO LTD

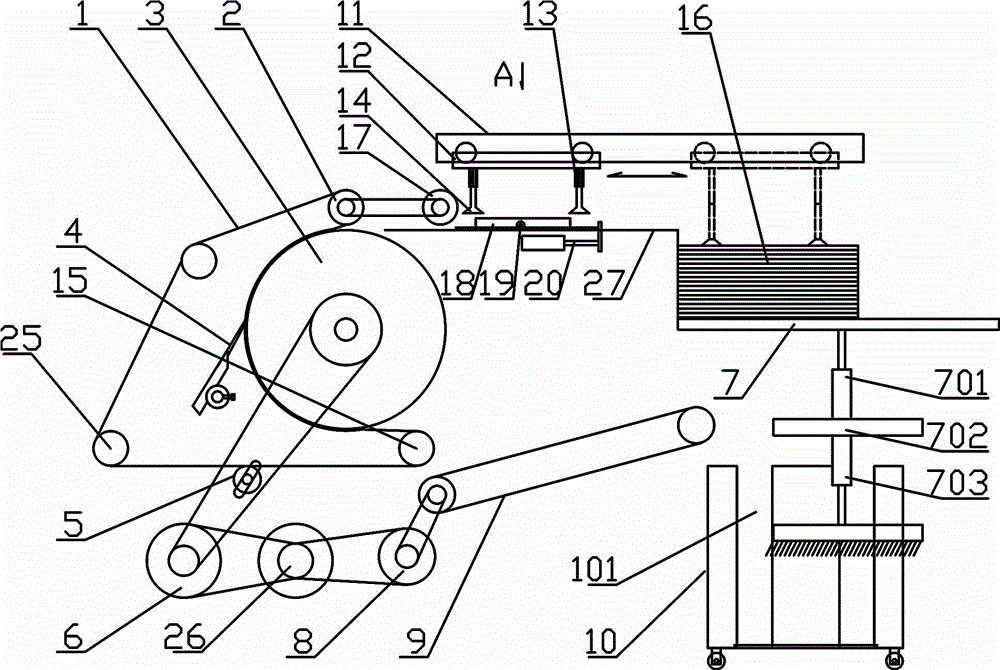

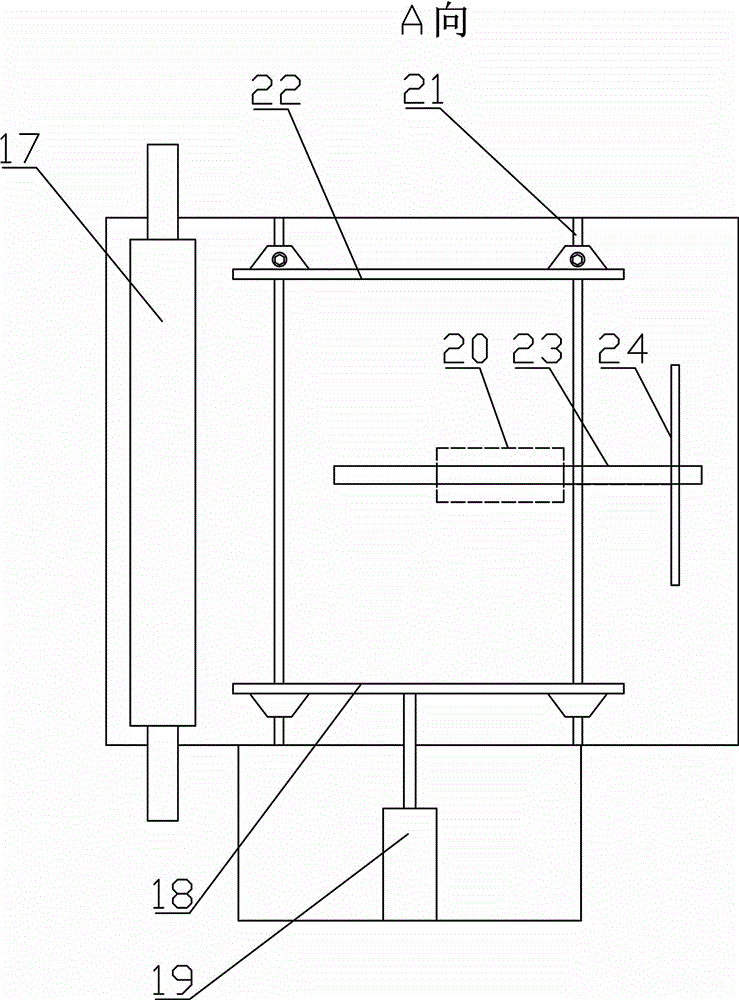

Automatic conveyer device for test cards

ActiveCN104773544AIngenious structural designHigh degree of automationArticle feedersArticle separationTest cardEngineering

The invention provides an automatic conveyer device for test cards. The conveyer device comprises a pushing mechanism, a clamping groove feeding mechanism and a rotary plate mechanism, wherein the pushing mechanism is used for pushing the test cards, the clamping groove feeding mechanism is used for containing and selecting the types of fed test cards, and the rotary plate mechanism is used for carrying and moving the test cards to corresponding operating positions. The conveyer device provided by the invention is smart in structural design, the automatic continuous feeding of the test cards can be realized by the cooperation of the pushing mechanism, the clamping groove feeding mechanism and the rotary plate mechanism, and the possibility can be provided to realize the possibility of testing excrement samples with high efficiency; furthermore, the types of the used test cards can be automatically selected to realize the test for various projects by one analyzer; meanwhile, the device is high in degree of automation, thereby saving the manual cost; in addition, the device is good in sanitary condition, thereby being capable of preventing the cross infection if an operator is careless to be in contact with the sample; and the device is reasonable and smart in structure, reliable to operate and long in service life.

Owner:济南兰洁生物技术有限公司

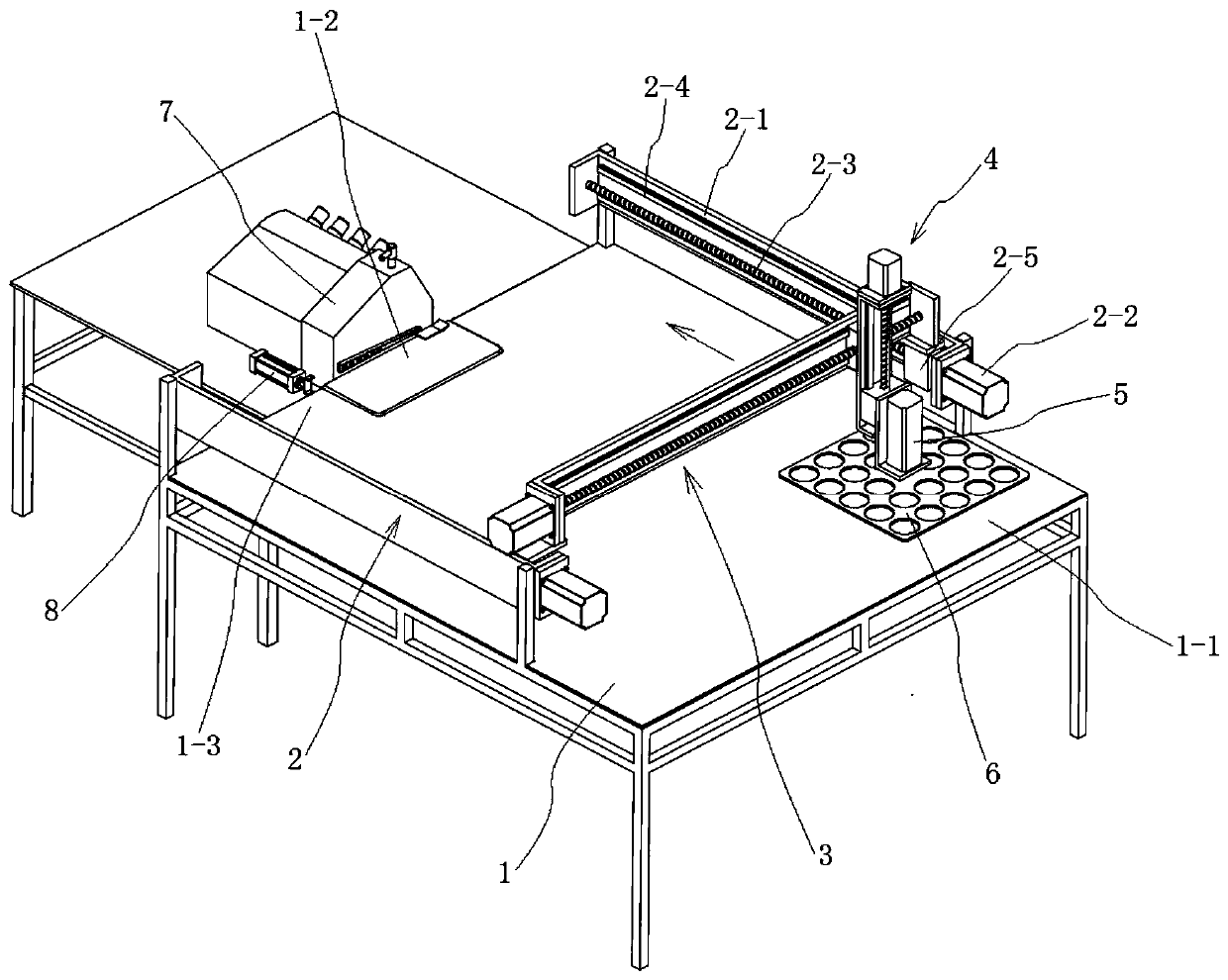

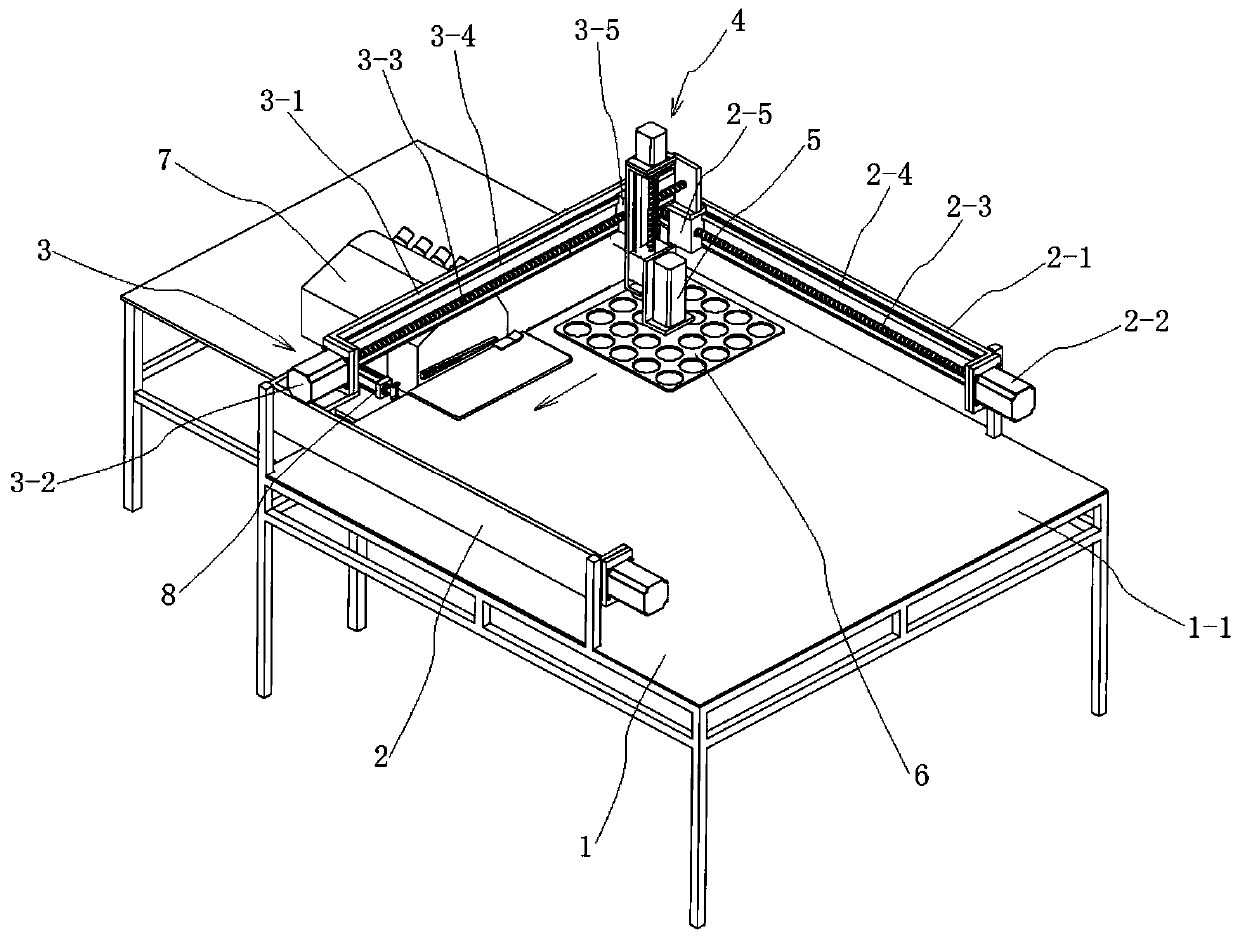

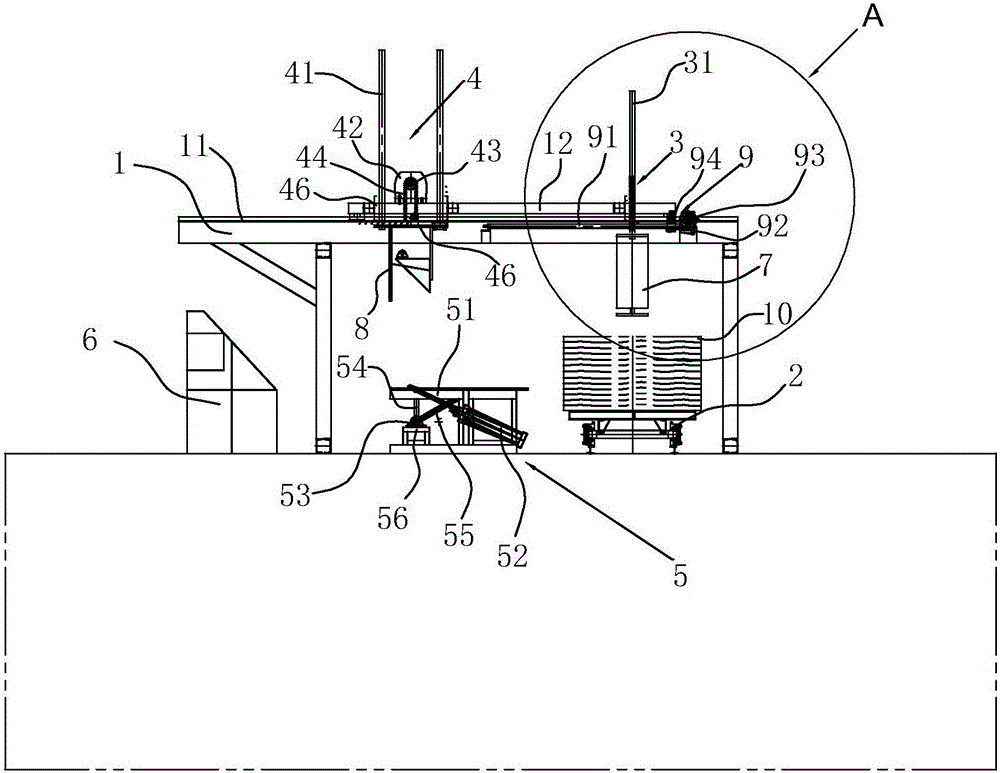

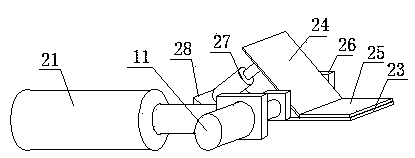

Automatic towel continuous serging device and serging method thereof

ActiveCN110067088AMotor coordination and stabilityHigh movement position accuracyWorkpiece carriersWork-feeding meansTowel clampEngineering

The invention discloses an automatic towel continuous serging device and a serging method thereof, and belongs to the field of towel making equipment. According to the towel continuous serging deviceand the serging method thereof, a pressing plate cooperates with a workbench to press a towel fabric to translate a towel, and the pressing plate is driven to move up and down, rotate, and move horizontally and vertically by a towel clamping and moving mechanism, so that the automatic continuous serging of edge of the towel along the outer contour of the towel on a machine head of a serging machine is realized, and the serging quality and the production efficiency of the towel are improved; in addition, the device is reasonable in structural design, convenient to automatically control, simpleand convenient to operate, and stable and reliable to move. The whole set of towel continuous serging device cooperates with a controller to control the movement process of each part; the serging process is continuous and stable, the connection is in order, and the device can be applied to serging of towels of most sizes, including square towels and towels in other shapes, can replace traditionaltowel serging equipment, and has very high promotion and use values.

Owner:陈建强

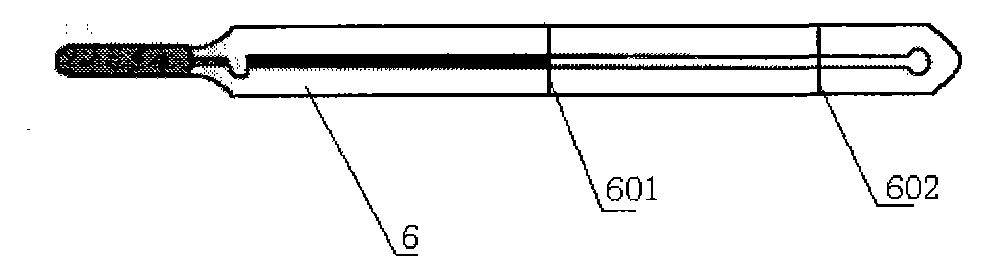

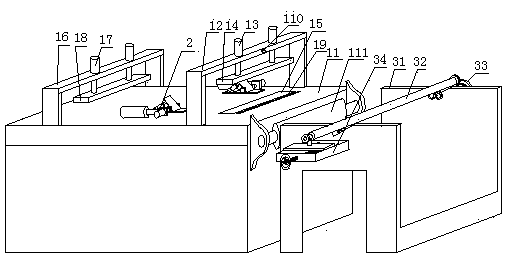

Glass clinical thermometer automatic sorting device

The invention belongs to the technical field of medical apparatus and instruments, and relates to a glass clinical thermometer automatic sorting device which comprises a machine frame and a feeding device, an image acquisition device, a single-chip microcomputer, a push shot device and a material collecting device which are mounted on the machine frame; the feeding device achieves automatic continuous feeding; the image acquisition device shoots and acquires pattern information of glass clinical thermometer tube materials each scratched with a datum line; the single-chip microcomputer divides clinical thermometers into groups according to the datum line separation distance obtained by the image acquisition device, and calculates a conveying position of each tube material on a conveying belt; the push shot device is composed of a plurality of electromagnetic launchers arranged side by side, and each electromagnetic launcher corresponds to a group of image signals; when the glass clinical thermometer tube materials reach corresponding positions of the electromagnetic launchers, the single-chip microcomputer controls the push shot device to push and shoot the glass clinical thermometer tube materials into corresponding material collecting boxes. Through adopting a quite simplified structure, automatic sorting of the glass clinical thermometers is achieved, and the sorting accuracy and the sorting efficiency are effectively improved.

Owner:东阿阿华医疗科技有限公司

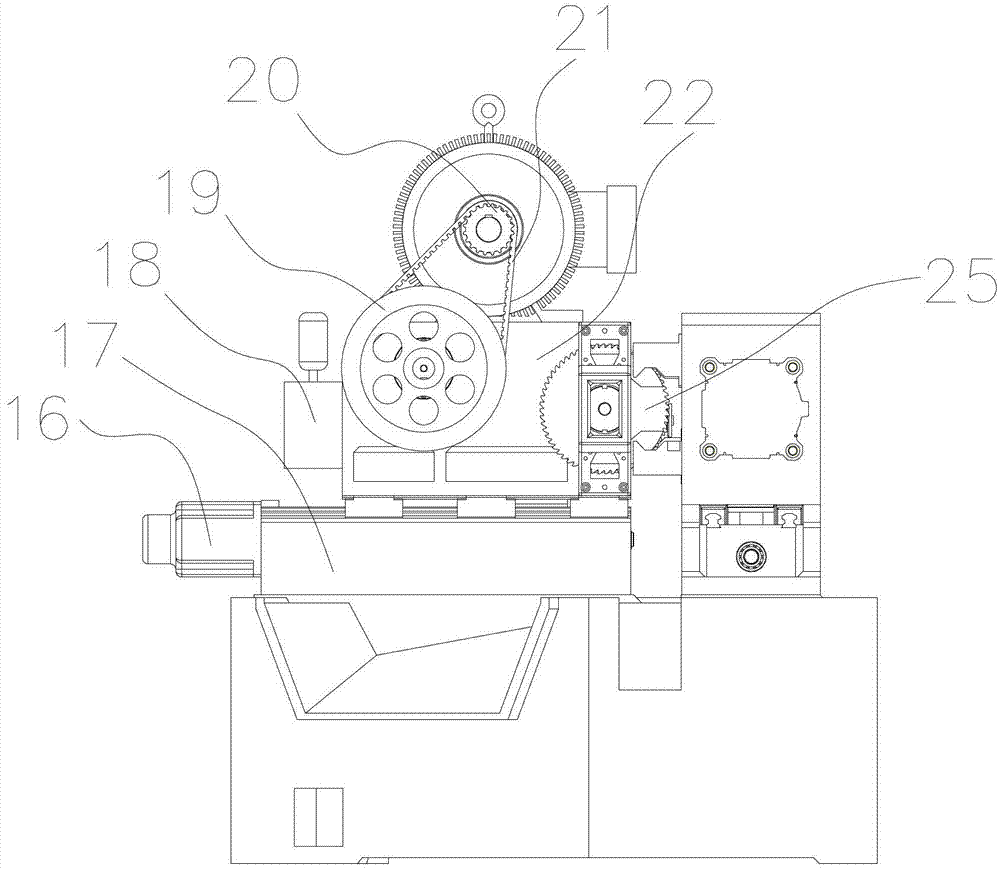

High-speed circular sawing machine

The invention discloses a high-speed circular sawing machine which comprises a lathe bed. A top double-clamping clamping mechanism and a parallel cutting mechanism are arranged at one end of the lathe bed, and a feeding mechanism is arranged at the other end of the lathe bed. The top double-clamping clamping mechanism comprises a front clamping base installed on the lathe bed, and the front clamping base is provided with a clamping frame with an opening arranged at one end. The high-speed circular sawing machine is simple in structure, convenient to install, strong in stability, high in automation degree, high in the running efficiency of the whole machine, low in energy consumption, simple to operate, and fast in cutting speed, and can save labor, and meanwhile high-speed precise cutting off of carbon steel and alloy steel and the like can be carried out, service life of a blade is prolonged, automatic continuous feeding is achieved, clamping efficiency is high, performance is stable, the service lives of main components of the device are improved, the benefit of an enterprise is increased, and labor intensity is reduced.

Owner:HANGZHOU TIANHE COMP NETWORK CO LTD

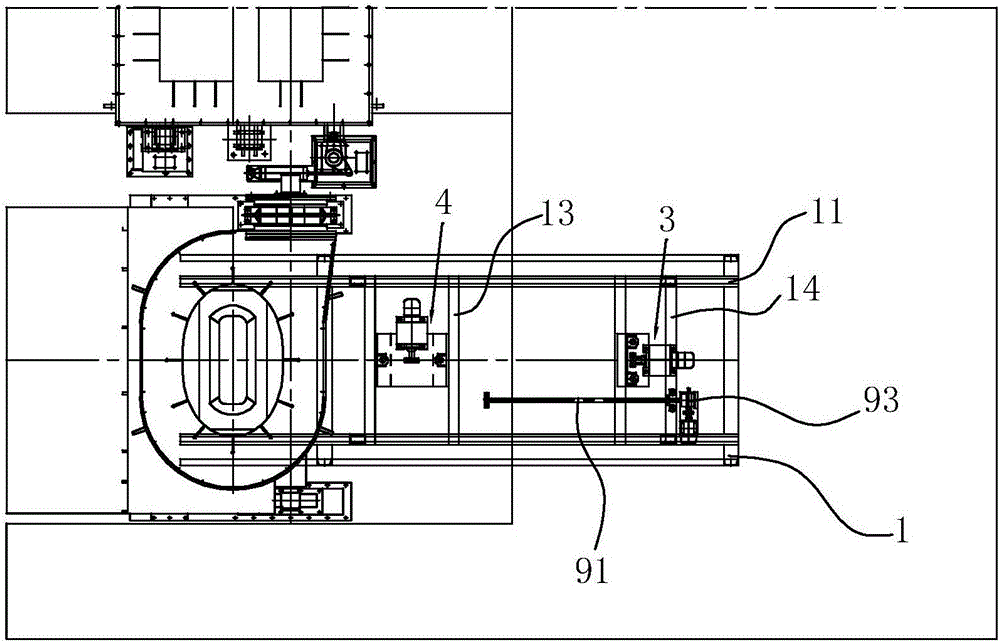

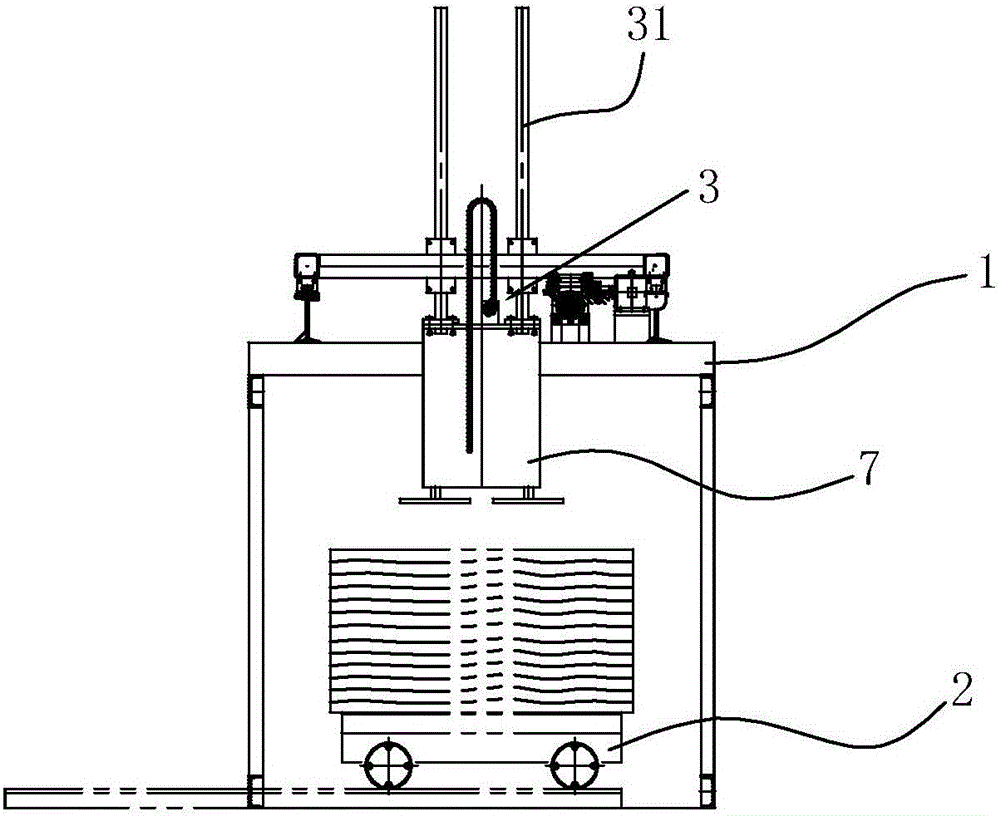

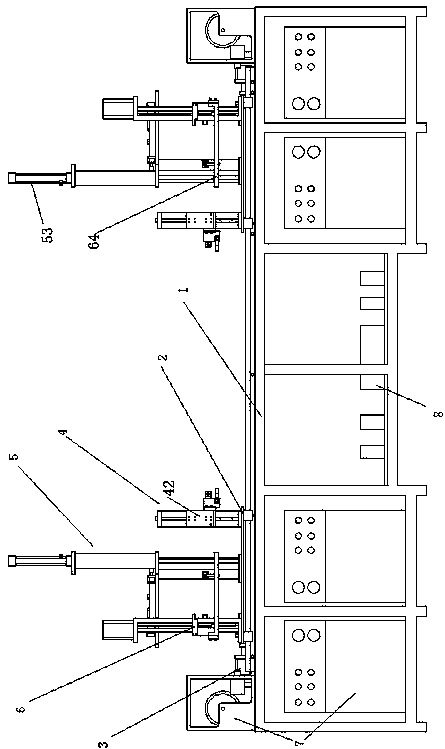

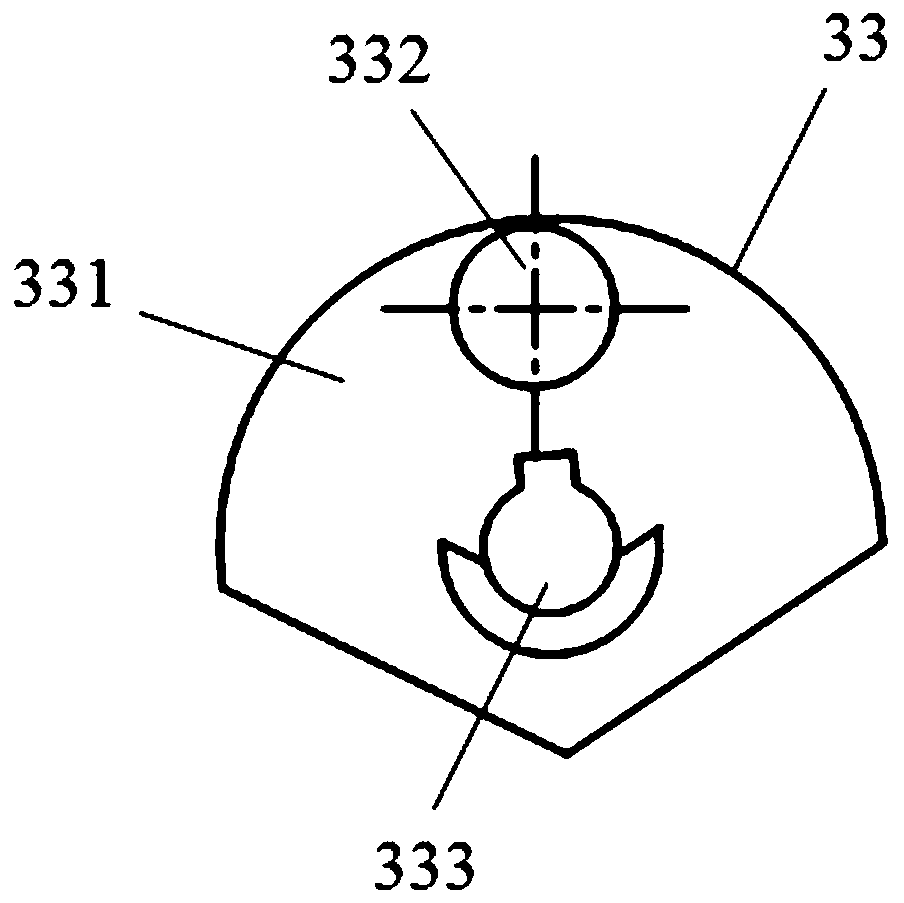

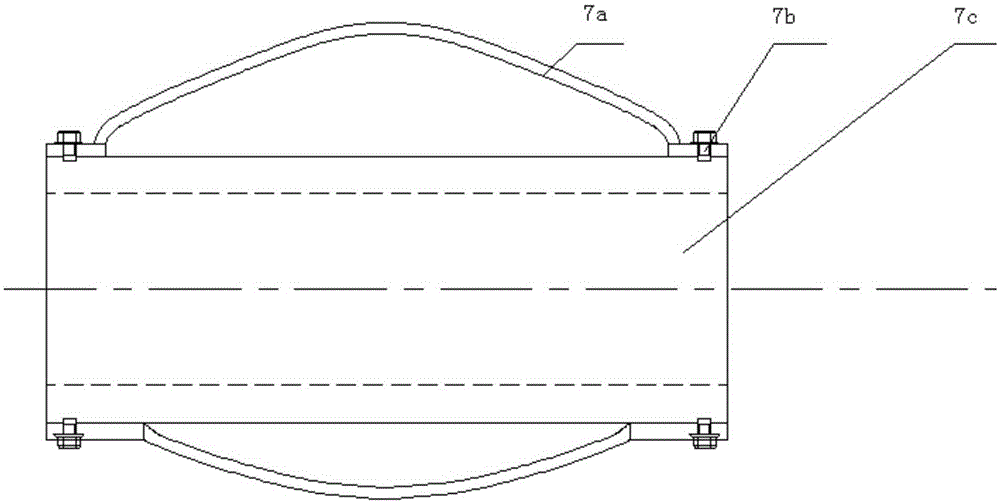

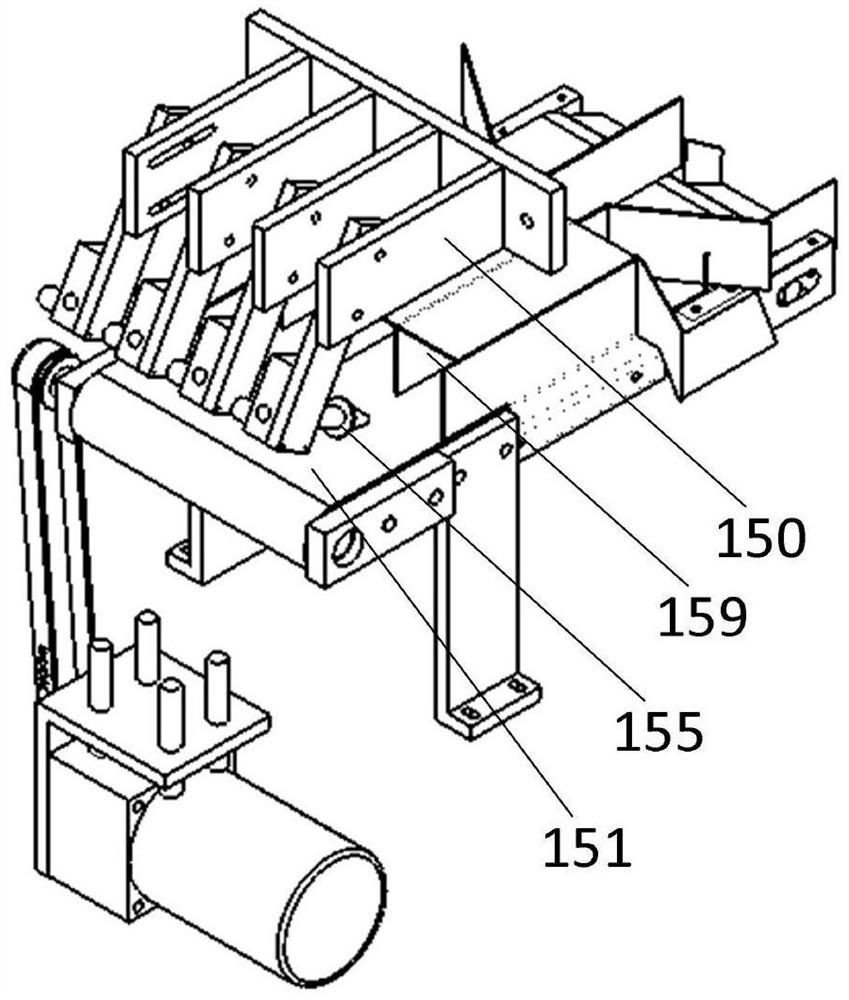

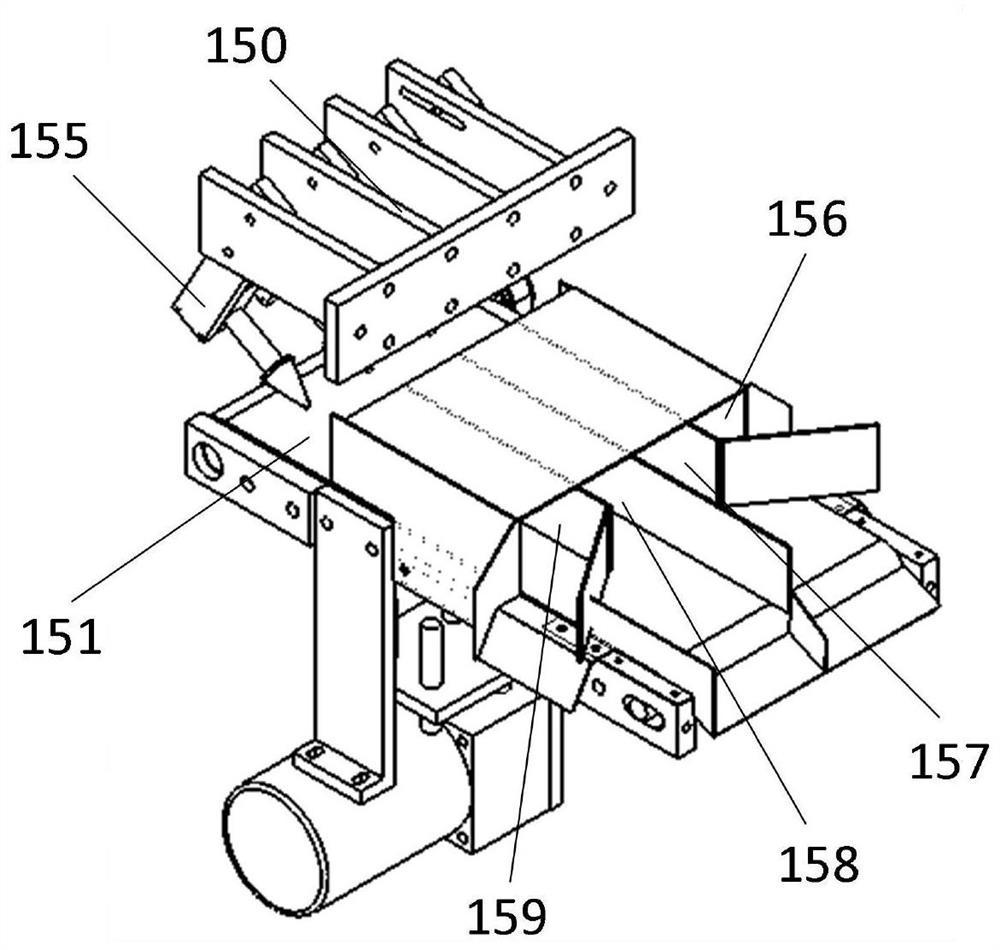

Automatic continuous feeding device for horizontal continuous casting furnace

An automatic continuous feeding device for a horizontal continuous casting furnace, including a gantry frame, a feeding trolley with electrolytic plates laid flat, and an overturning device for vertically turning the flat electrolytic plates. Transport the electrolytic plate on the feeding trolley to the first lift of the turning device and the second lift that transports the electrolytic plate on the turning device to the furnace platform. The feeding trolley is set at the position corresponding to the starting point of the first lift under the gantry, and the turning device is set at The position below the gantry corresponds to the starting point of the second elevator. The lower end of the first elevator is provided with a hoist for lifting the electrolytic plate on the feeding trolley, and the lower end of the second elevator is provided with a clamp for clamping the flipped electrolytic plate. Tongs, the gantry is provided with a transmission mechanism that drives the first elevator and the second elevator to move back and forth. The invention has reasonable structure and convenient operation, not only saves time and labor, but also ensures the personal safety of operators, and at the same time greatly improves work efficiency.

Owner:NINGBO JINTIAN COPPER TUBE

Goods shelf cross beam and hanging piece automatic welding device and application method thereof

ActiveCN109909582AAvoid collisionRealize automatic positioning and clampingWelding accessoriesEngineeringWelding

The invention relates to the technical field of welding, in particular to a goods shelf cross beam and hanging piece automatic welding device and application method of the goods shelf cross beam and hanging piece automatic welding device. Through the cooperation of a movable platform, a clamping air cylinder, a cross beam positioning mechanism, a hanging piece feeding mechanism and a welding mechanism, hanging piece automatic feeding and automatic positioning, cross beam automatic positioning and one-time welding of two ends of the cross beam and four hanging piece welding seams can be realized, the welding operation difficulty is reduced, and the production efficiency is improved.

Owner:常熟市江龙智能科技有限公司 +1

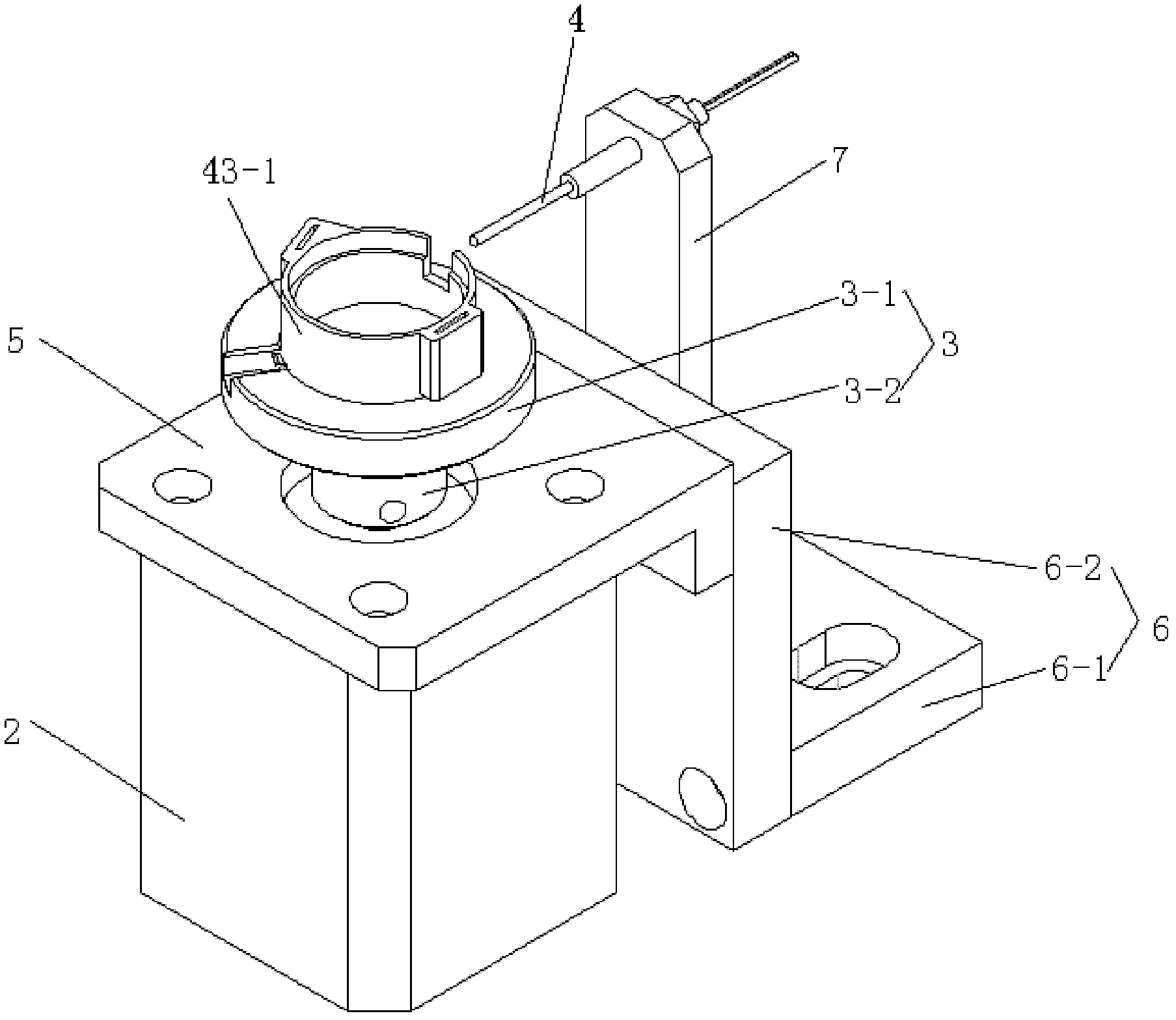

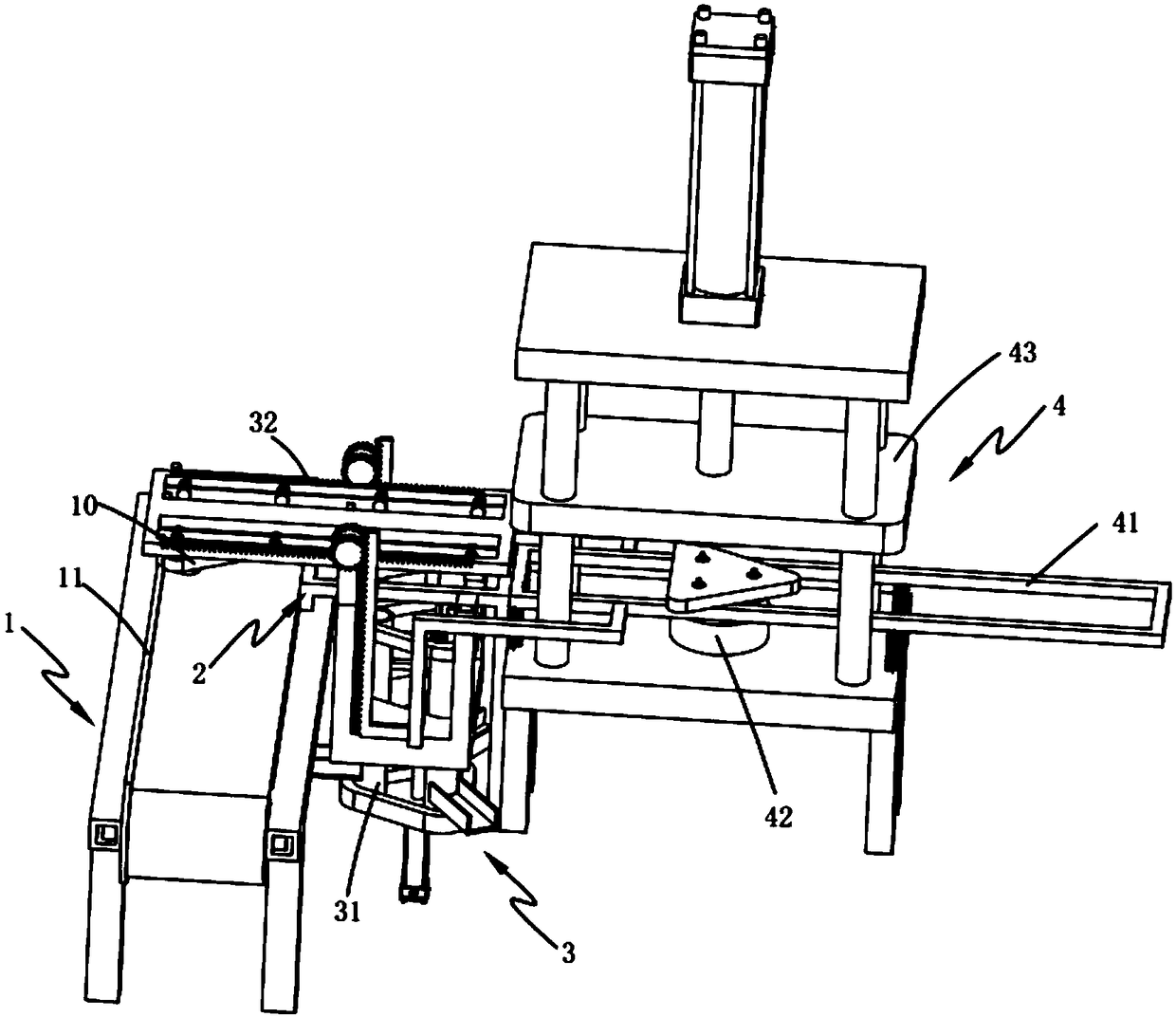

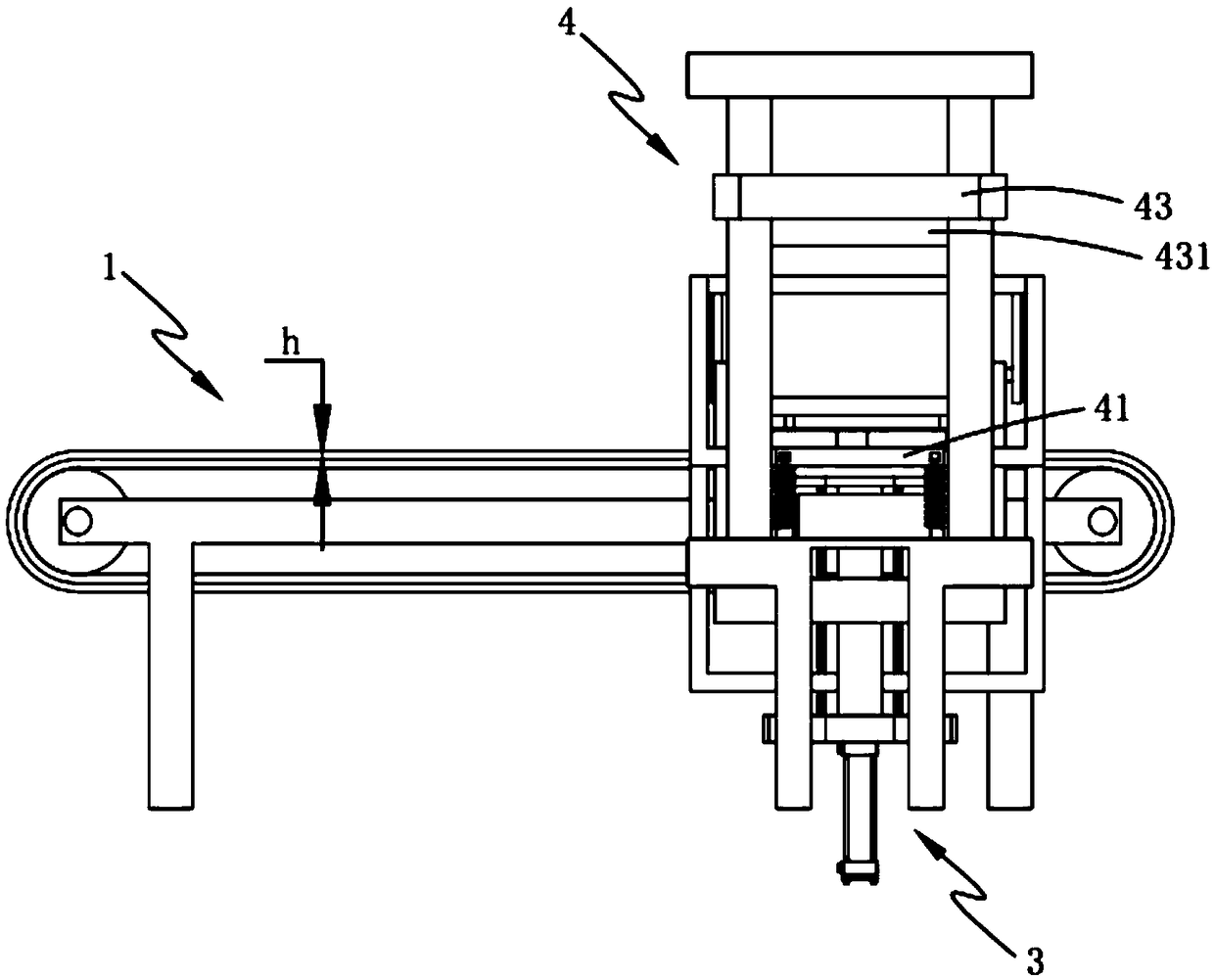

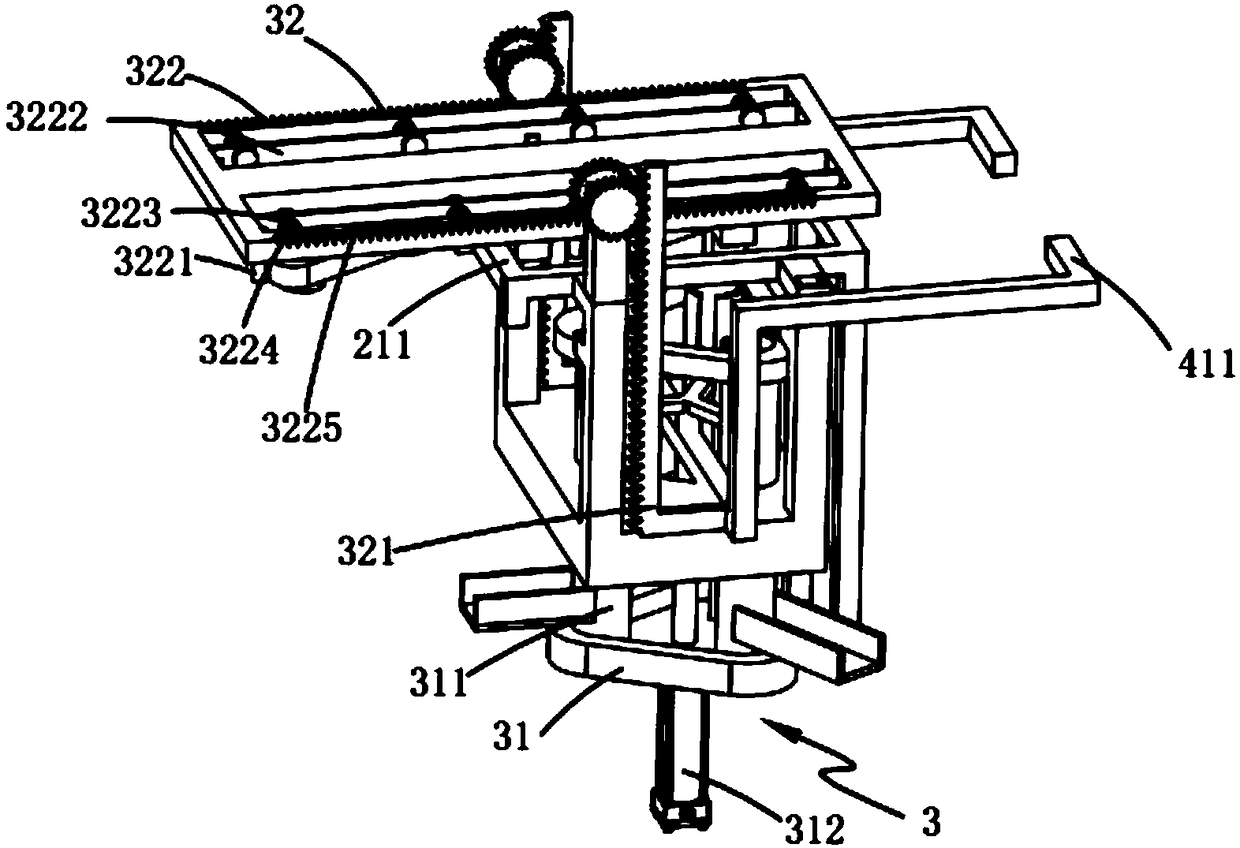

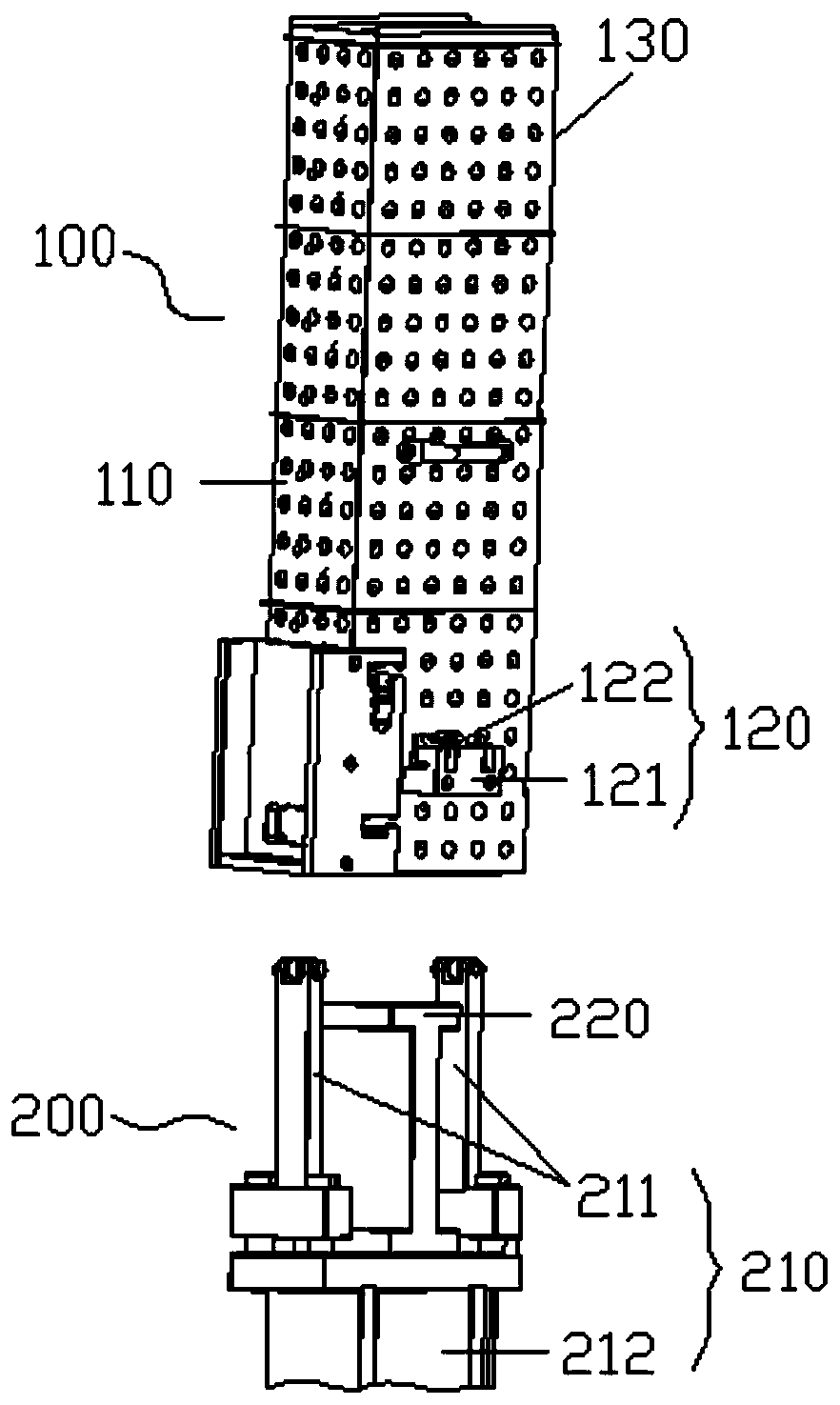

Bearing inner ring supply device

PendingCN110589452ARealize automatic continuous feedingReasonable designBearing componentsConveyor partsEngineeringMaterial supply

The invention provides a bearing inner ring supply device capable of being provided with a plurality of material stringing rods. A plurality of bearing inner rings can be stacked on each material stringing rod, and a large number of bearing inner rings can be stored in the device. Through a pushing device, the supply device has the capability of sequentially discharging the single bearing inner rings, and the enterprise requirement for continuous and uninterrupted large-batch bearing inner ring supply is met. After the bearing inner rings on one material stringing rod are discharged, a rotation shaft driving device is used for driving a rotation shaft to rotate, accordingly, a bearing device is made to rotate, and accordingly automatic material stringing rod replacement for discharging isachieved. Full-automatic continuous discharging of the supply device is achieved, and manual operation for material stringing rod replacement is not needed. The supply device is reasonable in design,the one-time feeding continuous work time is long, the positioning precision is high, and running is stable. The enterprise bearing product preparing efficiency is improved, the labor cost is saved, meanwhile, material supply continuity is guaranteed, and the machine assembling efficiency is improved.

Owner:SUZHOU TIEJIN ELECTROMECHANICAL TECH

Device and method for removing head of freshwater fish by arc cutting

The invention relates to a device for removing the head of a freshwater fish by arc cutting. The device comprises a conveyer belt mechanism, wherein a pressing plate for preventing the fish from jumping is arranged above the conveyer belt mechanism; a positioning frame is arranged at the tail end of the conveyer belt mechanism, and an arc baffle is arranged on the positioning frame; the radian of the arc baffle is consistent with or similar to that of a fish head; automatic expanding and contracting baffles are arranged on two sides of the conveyer belt mechanism; the automatic expanding and contracting baffles and the arc baffle are matched for positioning a fish body; a roller knife rack is mounted behind the arc baffle, and a plurality of arc blades which are arranged at equal angles are mounted on the roller knife rack; the radian of the blades simulates the radian of the operculum of the fish. After the fish head is cut, the baffles, positioned on the fish body pushing-out side, of the automatic expanding and contracting baffles completely contract downwards / upwards, and a rotating dial plate positioned above the fish body rotates so that the fish body is pushed down to a fish body collecting device; an automatic switchover baffle at the bottom of a positioning rack downwards reverses to be opened, and the fish head drops down from the opening to fall into a fish head collecting box below.

Owner:FISHERY MACHINERY & INSTR RES INST CHINESE ACADEMY OF FISHERY SCI

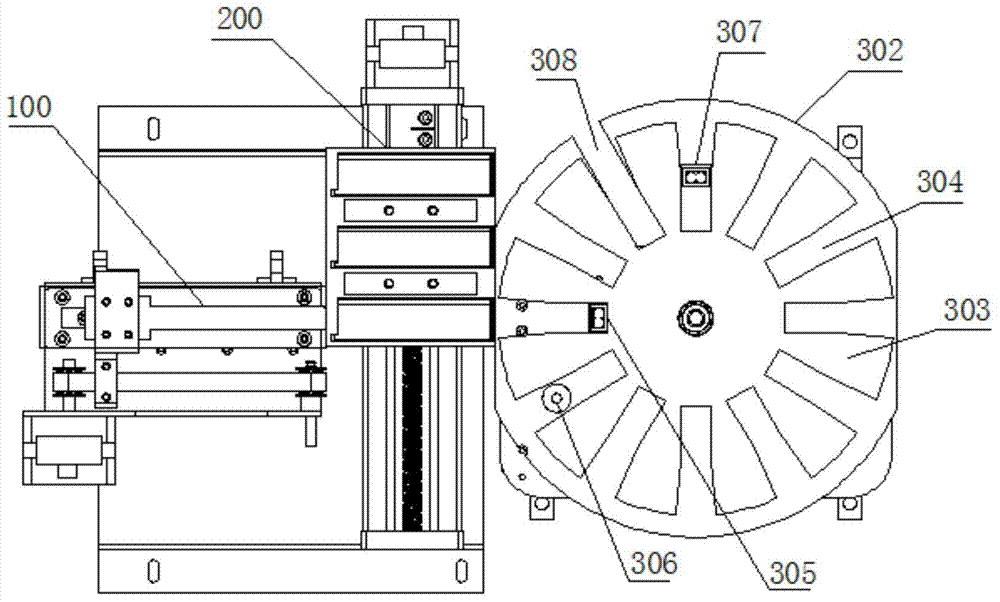

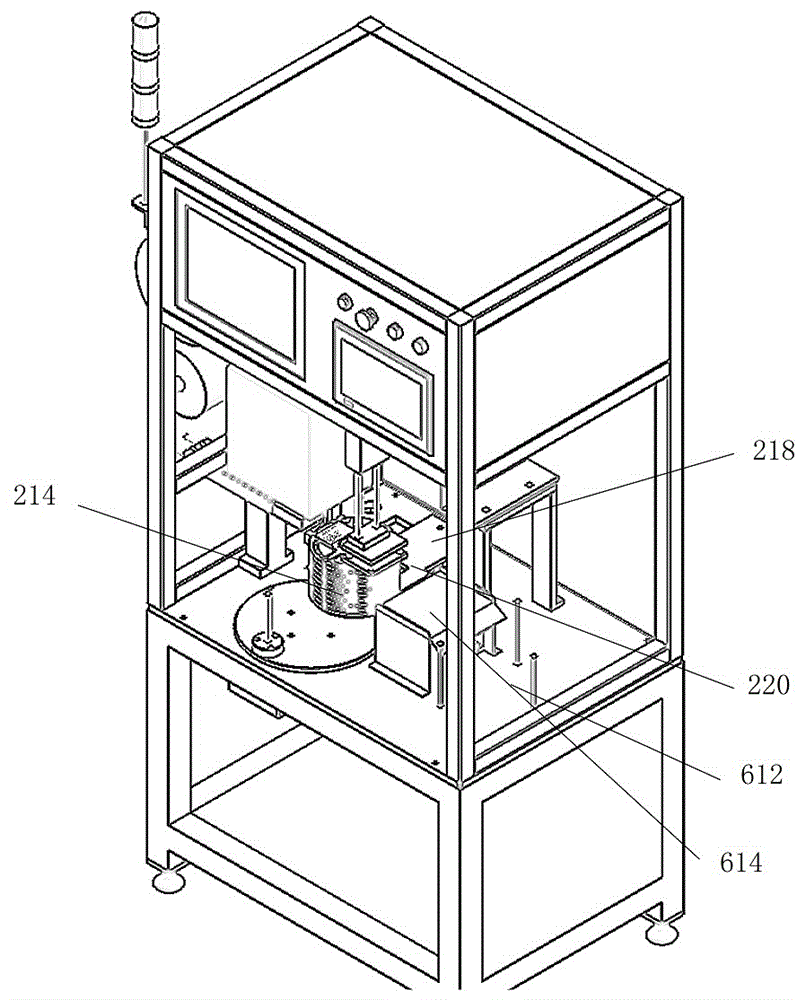

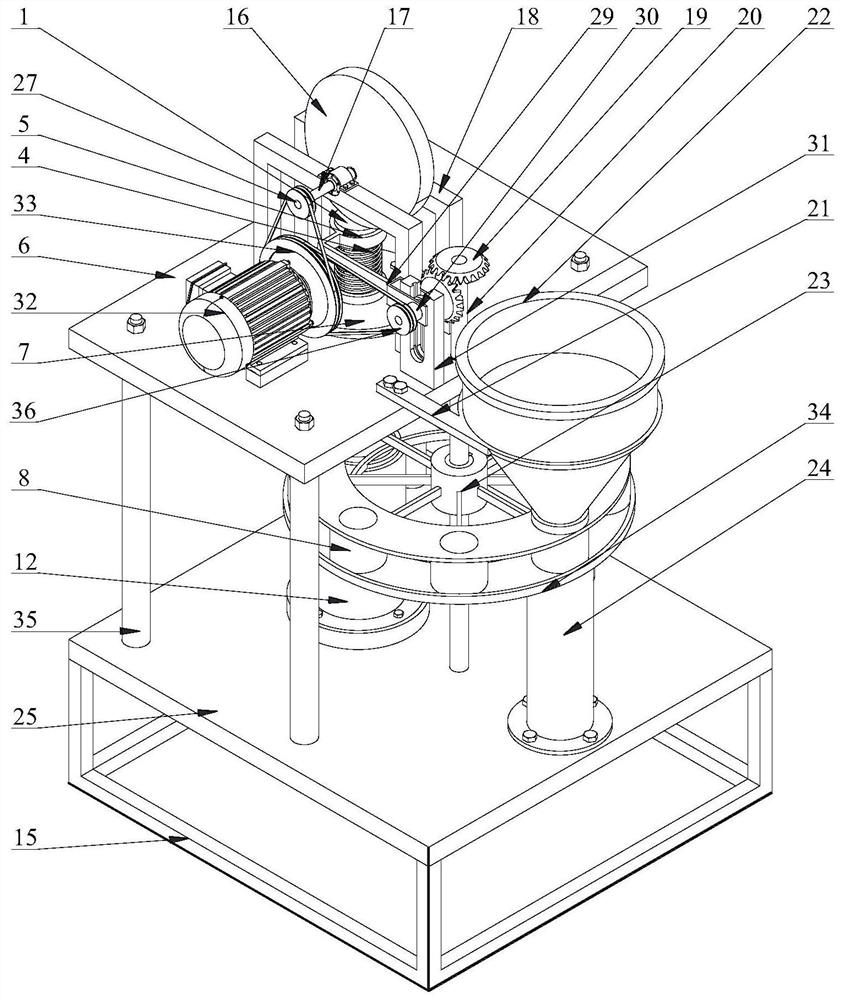

Commutator size and appearance defect detection equipment based on CCD vision

ActiveCN113714143ARealize automatic continuous feedingImprove work efficiencyMaterial analysis by optical meansUsing optical meansDisplay deviceCommutator (electric)

The invention discloses commutator size and appearance defect detection equipment based on CCD vision. The commutator size and appearance defect detection equipment comprises an electrical cabinet, a workbench and a hood, wherein a vibration feeding device is arranged on one side of the workbench, a rotary shifting mechanism connected with a discharging port of the vibration feeding device is arranged on one side of the top surface of the workbench, a glass rotating mechanism connected with a discharging port of the rotary shifting mechanism is arranged in the center of the top surface of the workbench, and a guide mechanism is arranged at the axis of the glass rotating mechanism; a first camera assembly, an optical fiber detection assembly, a second camera assembly, a third camera assembly, a fourth camera assembly, a fifth camera assembly, a sixth camera assembly and a discharging assembly which are located on the outer side of the glass rotating mechanism are sequentially arranged on the top surface of the workbench; and a display is arranged at the top of the outer side wall of the hood. According to the commutator size and appearance defect detection equipment, continuous automatic feeding, placement, positioning, all-dimensional detection and classified discharging of a commutator product to be detected can be realized, appearance detection is comprehensively covered, the detection result is accurate and reliable, and the detection efficiency is high.

Owner:安徽思普泰克智能制造科技有限公司

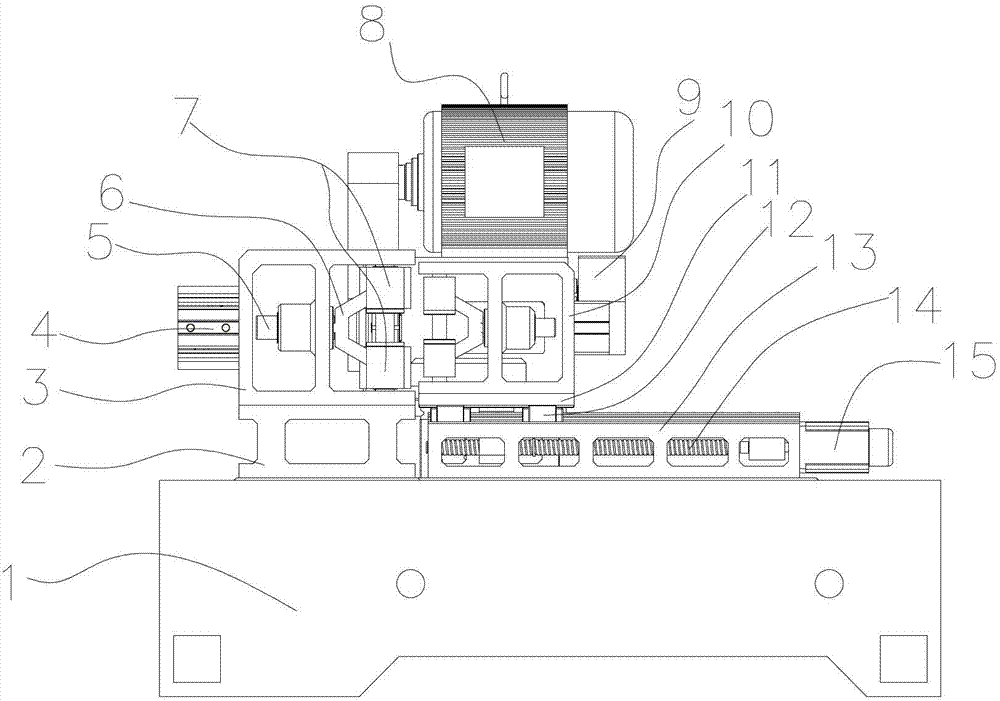

Automatic polishing production line for aluminum alloy profile

InactiveCN110977669AAvoid affecting the dimensional accuracy of grindingRealize automatic continuous feedingEdge grinding machinesGrinding drivesTransmission beltElectric machinery

The invention discloses an automatic polishing production line for an aluminum alloy profile. The automatic polishing production line is characterized by comprising a feeding mechanism, a first belt conveying mechanism, a second belt conveying mechanism and a polishing mechanism. The feeding mechanism comprises a feeding support, multiple rolling shafts and two guide plates. The first belt conveying mechanism comprises a first conveying belt and a first driving assembly used for driving the first conveying belt to conduct feeding in the horizontal direction. The second belt conveying mechanismcomprises a second conveying belt and a second driving assembly used for driving the second conveying belt to conduct feeding in the horizontal direction. The polishing mechanism comprises a fixed seat, a first motor, a first screw rod, a first guide rail, two moving seats and two polishing units. By means of the automatic polishing production line, automatic and assembly line type polishing machining can be conducted on the two ends of the aluminum alloy profile, and the work efficiency can be improved in a multiplied manner.

Owner:重庆新美鱼博洋铝业有限公司

Paperboard V-groove machine

InactiveCN105459442AOvercome the problem of easy skewRealize automatic continuous feedingPaper-makingBox making operationsPaperboardEngineering

A paperboard V-groove machine comprises a main roller driven by a driving device to rotate. A slotting tool is arranged on the portion, wrapped with adhesive tape, of the main roller. A vacuum adsorption feeding device is arranged above a feeding platform. A feeding roller used for feeding is arranged on the feeding platform. The feeding roller is connected with a top roller through a transmission mechanism. An aligning device is arranged on the feeding platform. A fixed baffle is arranged on one side of the feeding platform, and an aligning baffle is arranged on the other side of the feeding platform. The aligning baffle slides along a transverse slide rail on the feeding platform. The aligning baffle is connected with an aligning air cylinder. A feeding baffle is arranged at the other end opposite to the feeding roller. The feeding baffle slides along a longitudinal slide rail on the feeding platform and is connected with a feeding air cylinder. According to the paperboard V-groove machine, automatic continuous feeding is achieved through the vacuum adsorption feeding device and the feeding platform provided with the aligning baffle and the feeding baffle, and the problem that inclination happens easily due to the fact that a top roller is adopted for feeding is solved by arranging the special feeding roller.

Owner:湖北华彩包装有限公司

Automatic seaweed roll machine

PendingCN110122800ARealize automatic continuous feedingShorten transition timeFood coatingFood shapingAutomationCoating

The invention discloses an automatic seaweed roll machine, which comprises a feeding device, a winding device, a coating device and a material taking device; the feeding device has a plurality of conveying rollers for conveying the seaweed pieces to a winding station; the winding device has a rotating table that rotates in a vertical direction and winding rollers that are circumferentially distributed on the rotating table, the winding rollers are all rotated, and the rotating table drives the winding rollers to pass through the winding station, a coating station and a material taking stationin sequence, and the winding rollers can contact the seaweed pieces and roll the seaweed pieces into seaweed rolls during the movement to the winding station; the coating device has a coating bar forrolling the outer peripheral surface of the seaweed rolls on the winding rollers of the coating station; and the material taking device has jaws for taking up the seaweed rolls on the winding rollersof the material taking station. The automatic seaweed roll machine has the characteristics of high integration and automation, high production efficiency and good finished product quality.

Owner:KUNSHAN HENGSHAO FOOD MACHINES CO LTD

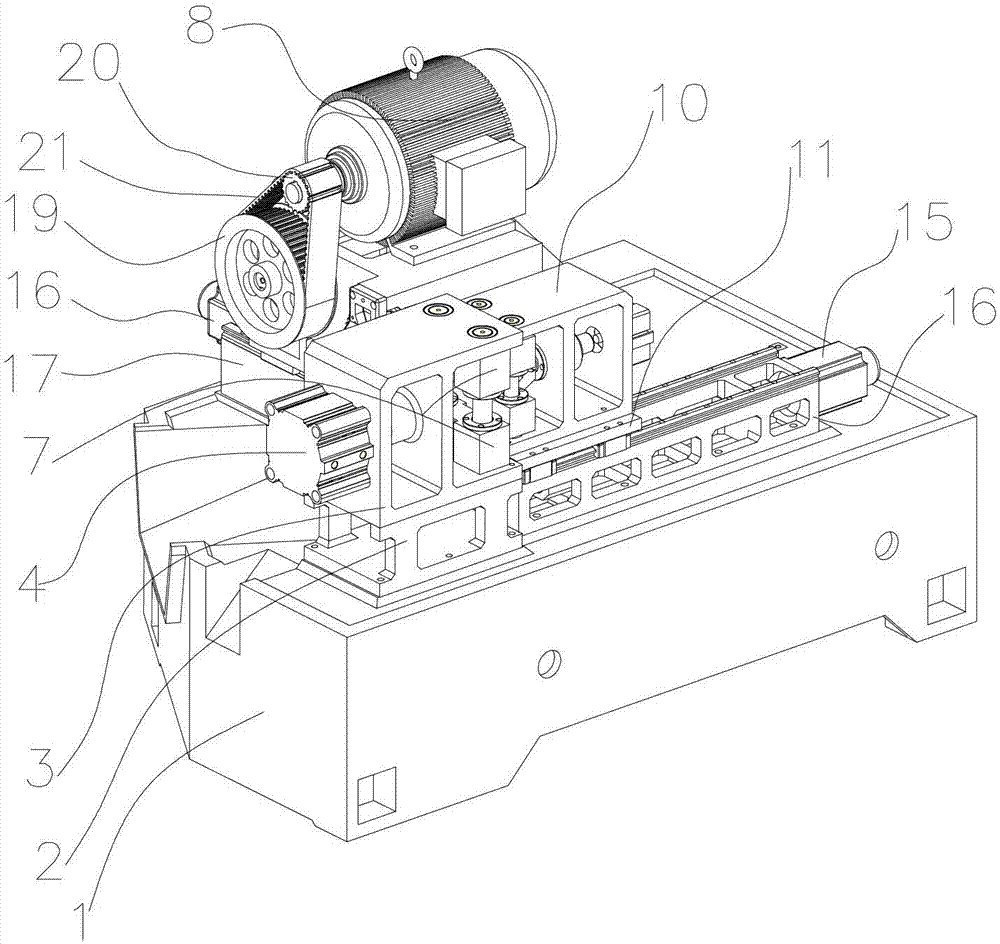

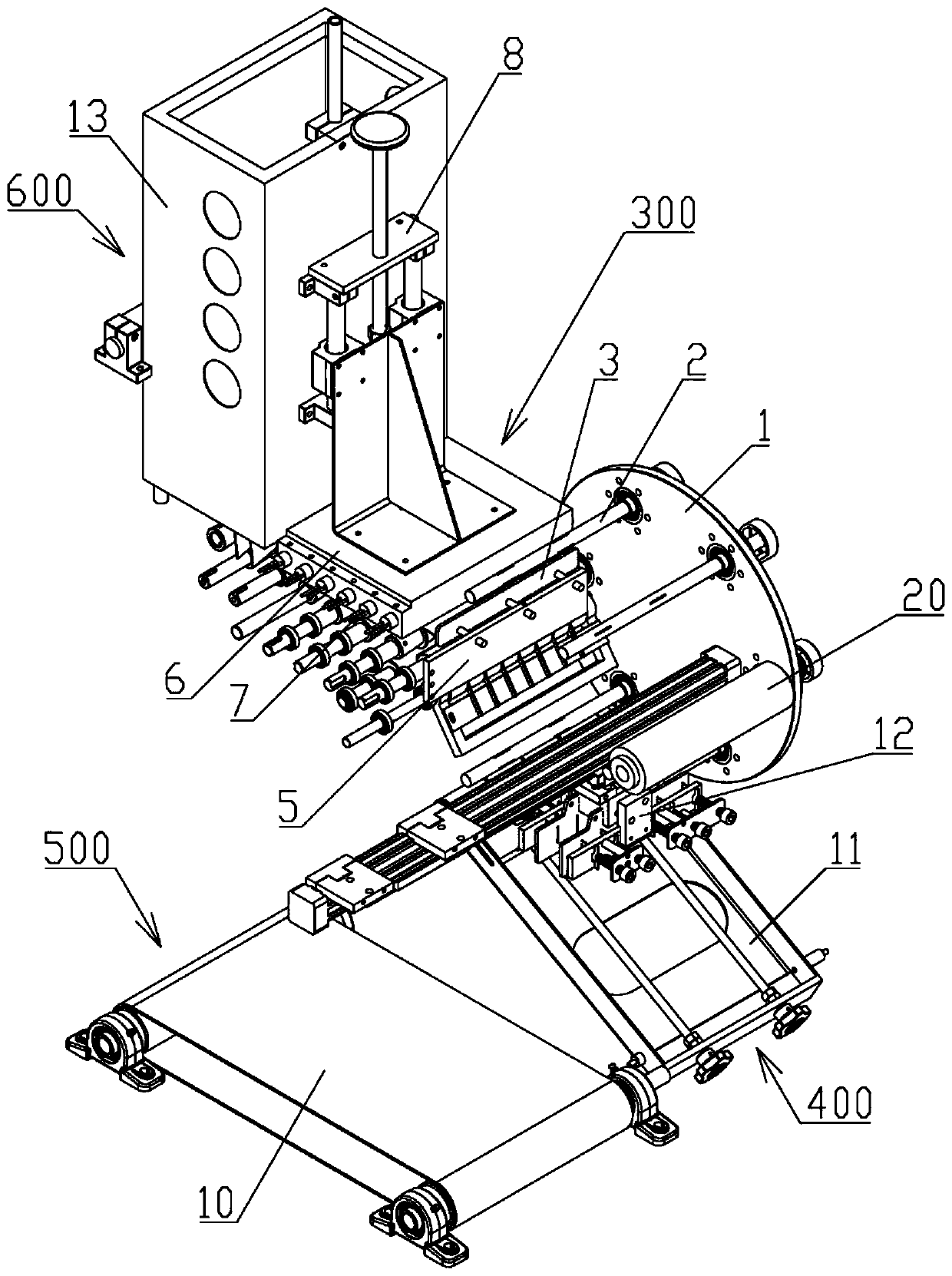

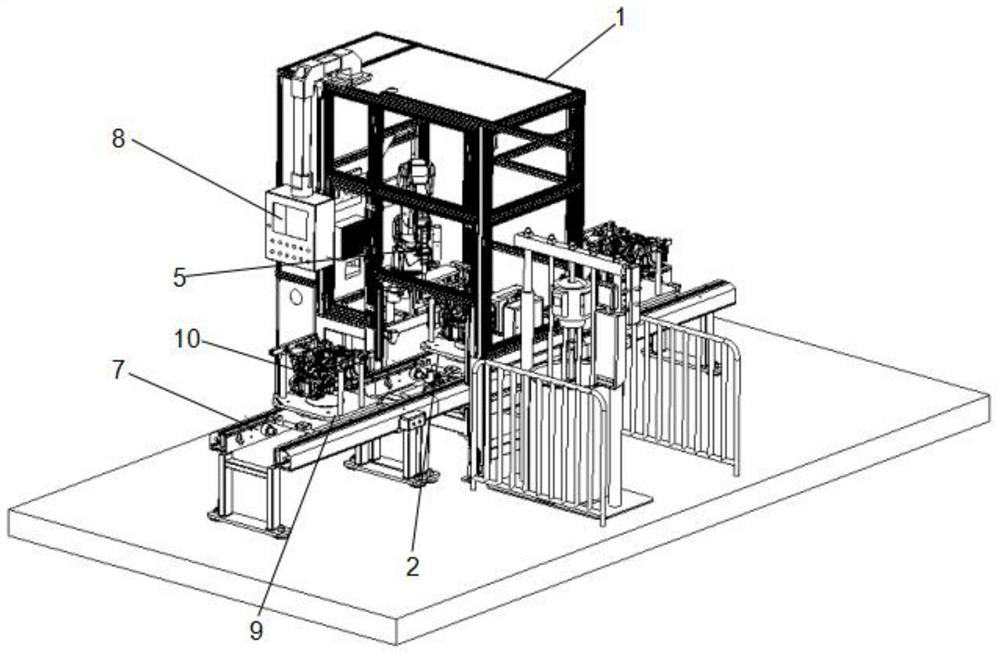

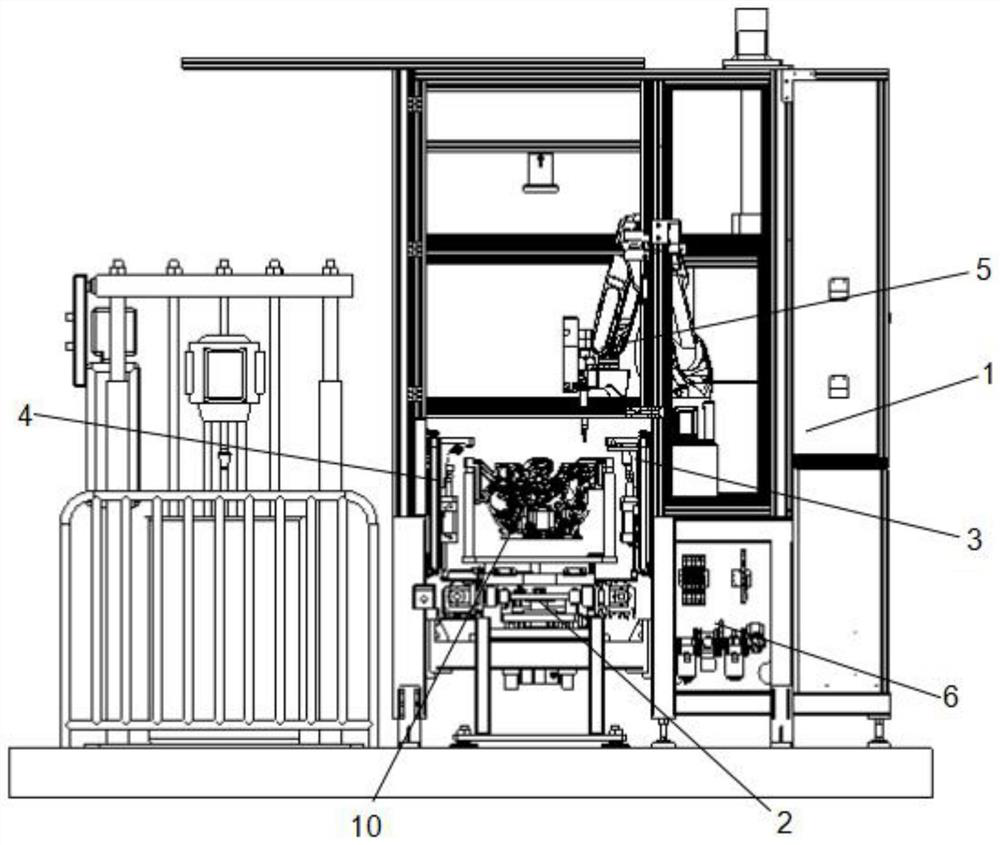

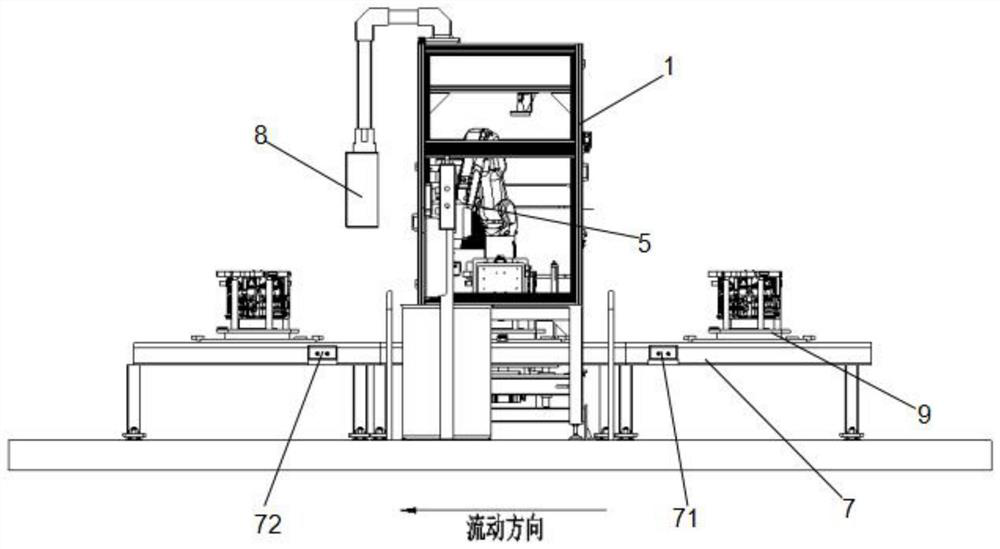

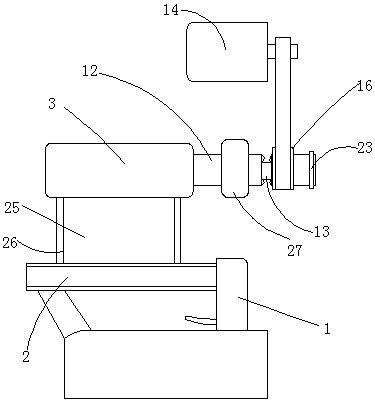

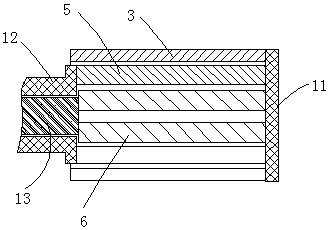

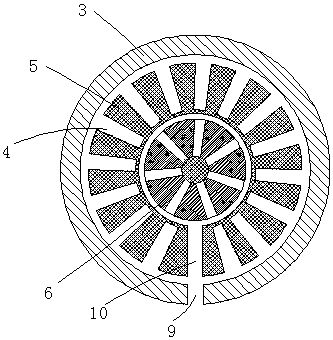

Friction stir welding additive manufacturing device and method capable of continuously feeding rods

ActiveCN114393292ARealize automatic continuous feedingImprove performanceIncreasing energy efficiencyNon-electric welding apparatusEngineeringMaterials science

The invention discloses a friction stir welding additive manufacturing device and method capable of continuously feeding rods. Comprising a welding mechanism, a first feeding mechanism, a second feeding mechanism and a feeding mechanism, wherein the welding mechanism is used for stirring and rubbing an additive position and guiding a bar to axially move towards the additive position; the first feeding mechanism is used for driving the bar to axially move towards the additive position; the second feeding mechanism is used for driving the bar to axially move towards the additive position; the second feeding mechanism is arranged between the welding mechanism and the first feeding mechanism and located on the side of a bar moving in the axial direction, and the feeding mechanism is arranged between the first feeding mechanism and the second feeding mechanism and located on the side of the bar moving in the axial direction. The first feeding mechanism and the second feeding mechanism alternately drive the multiple bars to continuously move towards the material adding position. Automatic continuous feeding of the bars is achieved, and the device does not need to be stopped in the material adding process.

Owner:AEROSPACE ENG EQUIP SUZHOU CO LTD

Continuous production process of waterproof roll

InactiveCN106274002ARealize automatic continuous feedingRealize continuous feedingLaminationLamination apparatusPolyethylene terephthalate glycolPolyethylene terephthalate

The invention provides a continuous production process of a waterproof roll. A base is continuously fed into a coating component by using a rolling and holding mechanism, upper and lower surfaces of the base are coated respectively with asphalt through the coating component, the upper surface of the base is coated with a PET (polyethylene terephthalate) film, and the lower surface of the base is coated with an isolating film; the upper and lower surfaces of the base are coated, the base is then continuously fed into an extrusion component to extrude the redundant asphalt, and a waterproof roll is acquired after the redundant asphalt is extruded, the waterproof roll is passed through a drying component to heat the inner asphalt such that the inner asphalt is applied evenly, the waterproof is then cooled via a cooling component, and the formed waterproof roll is obtained; the continuous production process of the waterproof roll enables the base to be continuously fed such that the coating component is available for continuous production with no interruption, production continuity is guaranteed, and processing efficiency is improved.

Owner:山东安之源防水材料有限公司

Automatic labeling machine

ActiveCN105857806ARealize automatic continuous feedingRealize receiptLabelling machinesElectrical and Electronics engineering

The invention discloses an automatic labeling machine which comprises a machine frame. A start switch and a control panel are arranged on the machine frame. The automatic labeling machine is characterized in that the machine frame is further provided with a feeding mechanism, a label printing and stripping mechanism and a collecting mechanism, wherein the feeding mechanism is used for conveying trays; the label printing and stripping mechanism is used for printing labels, stripping the labels and sticking the labels to the trays; and the collecting mechanism is used for collecting the trays stuck with the labels. By the adoption of the automatic labeling machine, automatic operation of automatically and continuously feeding and collecting the trays and printing and stripping the labels is achieved, and the automatic labeling machine has the advantages of being simple, efficient, accurate, reliable and the like.

Owner:SUZHOU DELTA LOGISTICS

Vapor deposition device and vapor deposition method

PendingCN111270204AWill not pyrolyzeRealize automatic continuous feedingVacuum evaporation coatingSputtering coatingEvaporation (deposition)Molten state

The invention relates to the technical field of thin film forming, in particular to a vapor deposition device and a vapor deposition method. The vapor deposition device comprises a storing mechanism,a conveying mechanism and an evaporation mechanism, the storing mechanism comprises a storing cavity and a storing heating unit, the upper end of the storing cavity is provided with a storing feedinginlet, the lower end of the storing cavity is provided with a storing discharging outlet, and the storing heating unit is used for heating solid materials into a molten state. The conveying mechanismcomprises a communicating device and a conveying heating unit, one end of the communicating device communicates with the storing discharging outlet, and the conveying heating unit heats the molten materials in the communicating device; and the evaporation mechanism comprises an evaporation cavity, the lower end of the evaporation cavity is provided with an evaporation feeding inlet communicating with the other end of the communicating device, and the upper end of the evaporation device is provided with an evaporation discharging outlet. The molten materials are converted into a gaseous state and discharged from the evaporation discharging outlet, in the process, the communicating device is in a dynamic balancing state all the time to guarantee that the materials cannot be pyrolyzed at a high temperature for a long time, and continuous batch production without opening the cavities can be ensured.

Owner:JITRI INST OF ORGANIC OPTOELECTRONICS CO LTD

Oil pan gumming machine

ActiveCN111822250ACompact structureHigh degree of automationLiquid surface applicatorsCoatingsEngineeringMachine

The invention provides an oil pan gumming machine. The oil pan gumming machine comprises a protective machine frame, guide rails are installed on the front side of the protective machine frame, a feeding slide seat is installed on the guide rails, and a workpiece is placed on the feeding slide seat. The oil pan gumming machine further comprises a lifting positioning mechanism which is installed onthe front side of the protective machine frame and located on the lower portions of the guide rails, a gumming mechanism installed on the protective machine frame, a main plug pin mechanism which isinstalled on the protective machine frame and located on the lower portion of the gumming mechanism, an auxiliary plug pin mechanism which is installed on the guide rails and transversely arranged with the main plug pin mechanism side by side in a spaced mode oppositely, and a workpiece recognition sensor is fixed to the auxiliary plug pin mechanism. The oil pan gumming machine is compact in structure and high in automation degree, through automatic cooperation of the feeding slide seat, the lifting positioning mechanism, the main plug pin mechanism, the auxiliary plug pin mechanism and the gumming mechanism, full-automatic continuous feeding, precise positioning, accurate gumming, gumming visual detection and automatic discharging of an engine oil pan can be achieved, the whole working efficiency is high, and the gumming quality is good.

Owner:GUANGZHOU BOYAN ELECTROMECHANICAL EQUIP IND

Shearing and wire tightening device for automatic tying equipment of wine jar

PendingCN111169731AImprove automation and work efficiencyRealize automatic continuous feedingWrapper twisting/gatheringAssembly lineStructural engineering

The invention discloses a shearing and wire tightening device for the automatic tying equipment of a wine jar. The shearing and wire tightening device comprises a tensioning mechanism, a wire tightening mechanism, a wire discharging mechanism and a shearing mechanism, wherein the tensioning mechanism and the wire tightening mechanism are arranged just above a preset position on an assembly line; the wire discharging mechanism and the shearing mechanism are arranged on one side of the preset position on the assembly line; the tensioning mechanism, the wire tightening mechanism, the wire discharging mechanism and the shearing mechanism are all connected with a control system; the wire discharging mechanism and the shearing mechanism are arranged on one side of the preset position on the assembly line; the wire discharging mechanism is provided with the shearing mechanism along a front direction of a wire discharging direction of the wire discharging mechanism; the tensioning mechanism and the wire tightening mechanism are arranged just above the preset position on the assembly line through a second supporting mechanism; an iron wire is automatically and directionally discharged through the wire discharging mechanism; the tensioning mechanism grabs a first positioning position of the iron wire; the shearing mechanism cuts off the iron wire; and the wire tightening mechanism grabsa second positioning position of the iron wire to tighten the iron wire. According to the shearing and wire tightening device, the automatic and continuous loading, the automatic shearing and the automatic tightening work of a bundled material can be realized, manual tying action is replaced, and the automation degree and working efficiency are greatly improved.

Owner:ZHEJIANG COLLEGE OF ZHEJIANG UNIV OF TECHOLOGY

Efficient pulverizer

InactiveCN108236998AAvoid insecurityRealize automatic continuous feedingGrain treatmentsAgricultural engineeringPulverizer

The invention relates to an efficient pulverizer. The pulverizer comprises a propelling part and a pulverizing tank, wherein the propelling part comprises a big propelling device and a small propelling device; and the pulverizing tank comprises an inclined multi-disc pulverizing device, a spiral split pulverizing device and a tank body. The efficient pulverizer has the advantages of automatic feeding, double propelling, multi-stage pulverizing, high pulverizing speed and good pulverizing effect.

Owner:长沙仁之德自动化设备有限公司

Continuous production process of waterproof coiled material

InactiveCN105365339AContinuous feedingReturn to normal feedingLamination ancillary operationsLaminationEngineeringAsphalt

The invention provides a continuous production process of a waterproof coiled material. The process includes: sending a substrate into a covering component continuously by a winding temporary storage mechanism, coating the upper surface and lower surface of the substrate with asphalt respectively by the covering component, covering the upper surface of the substrate with a PET film, and covering the lower surface of the substrate with an isolating film; then letting the substrate covered with a film on the upper and lower surface respectively enter a rubber extrusion component continuously to conduct excess asphalt extrusion so as to obtain a waterproof coiled material, and passing the waterproof coiled material through a drying component, heating the inner layer asphalt to make the inner layer asphalt coated evenly, and subjecting the waterproof coiled material to cooling molding by a cooling component, thus obtaining the molded waterproof coiled material. The continuous production process of the waterproof coiled material can realize continuous feeding of the substrate, so that the covering component can achieve continuous production without interruption, thus ensuring production continuity and improving the processing efficiency.

Owner:安徽五星凯虹防水建材科技有限公司

Charging process and device of corner reinforcing separation plate of carton box

ActiveCN105857750ARealize automatic continuous feedingPrecise positioningPackagingElectrical and Electronics engineeringCarton

The invention relates to a charging process and device of a corner reinforcing separation plate of a carton box and belongs to the field of carton box package. The charging device of the corner reinforcing separation plate of the carton box, provided by the invention, comprises a separation plate charging and molding structure and a feeding structure, wherein the separation plate charging and molding structure is used for charging and molding the separation plate; the feeding structure is arranged on the outer side of the separation plate charging and molding structure and is used for pushing the separation plate to one side of the separation plate charging and molding structure; the separation plate charging and molding structure comprises at least one group of molding plates which are vertically arranged; a lifting air cylinder is arranged on the inner side of each molding plate and a charging air cylinder is arranged at the bottom of the lifting air cylinder; a charging clamping claw is arranged on one side, located on the corresponding molding plates, of the charging air cylinder; and the feeding structure is arranged on the outer sides of the molding plates. With the adoption of the charging process and device, provided by the invention, automatic and continuous charging of the separation plate is realized, automatic production is realized and the working efficiency is greatly improved.

Owner:SHINVA MEDICAL INSTR CO LTD

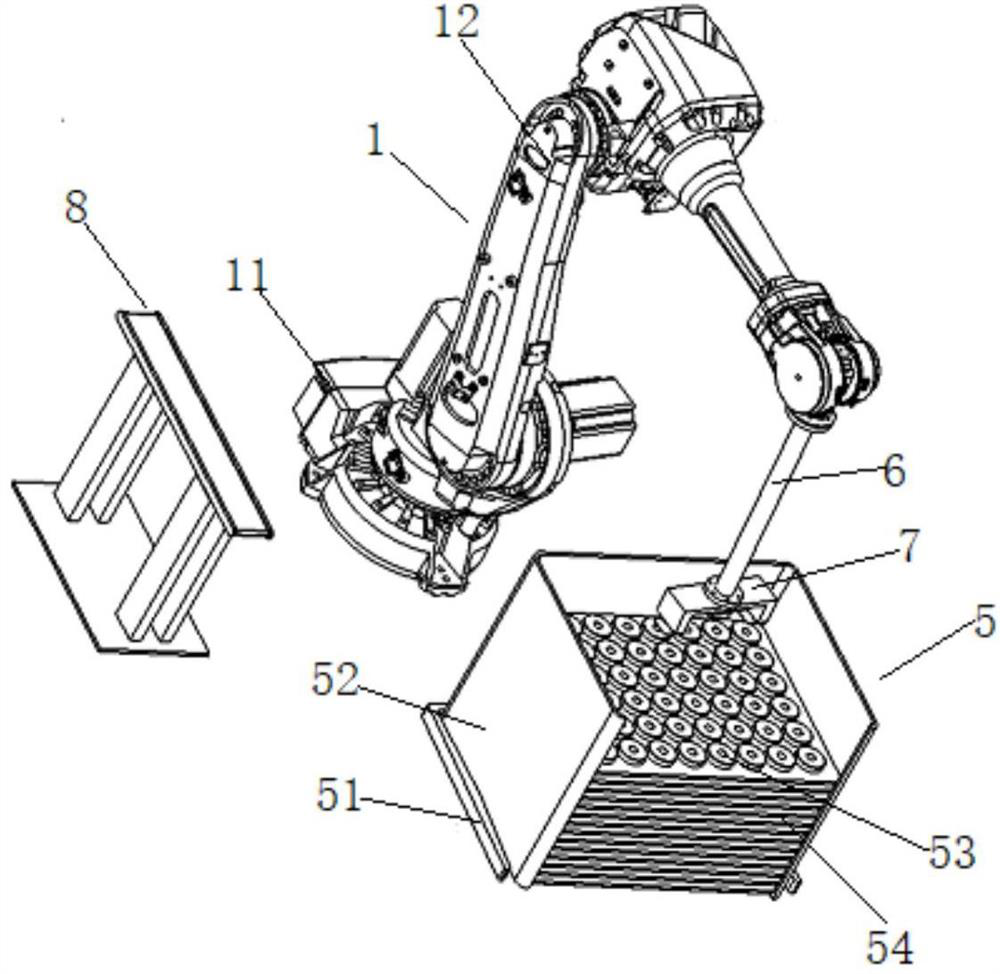

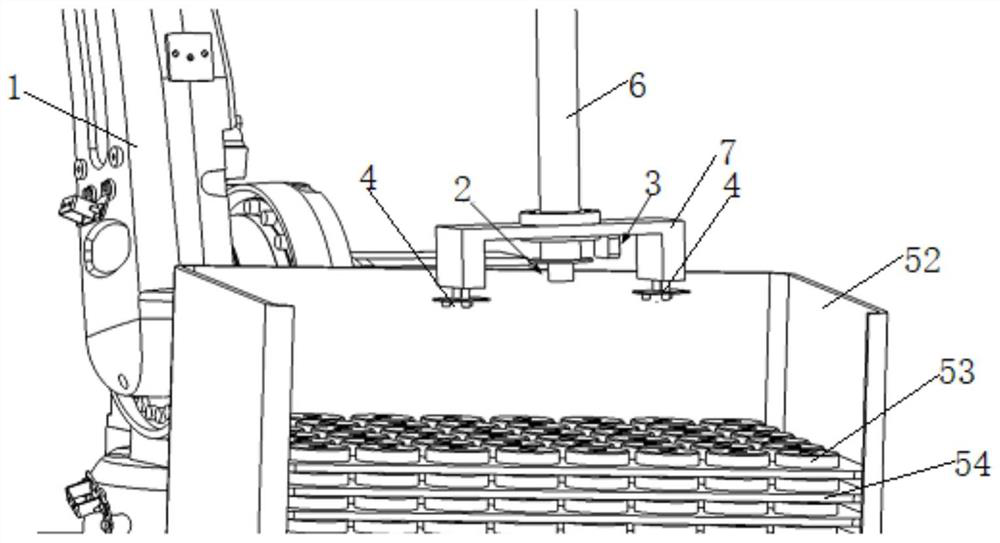

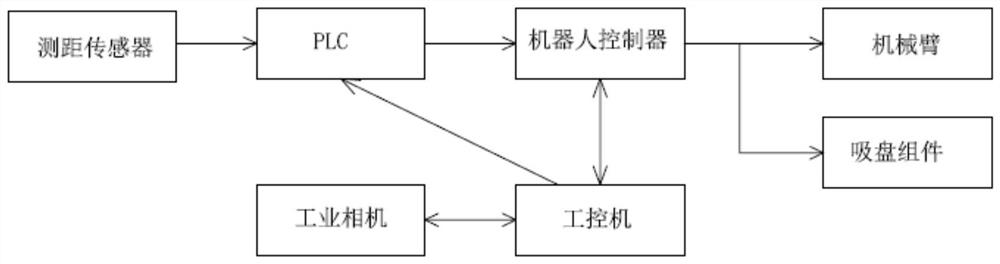

Automatic workpiece unstacking and feeding system and method

PendingCN114249135ASimple structureLow running costVacuum gaugesControl devices for conveyorsControl engineeringProcess engineering

The invention relates to an automatic workpiece unstacking and feeding system and method, and belongs to the technical field of automatic workpiece feeding, the automatic workpiece unstacking and feeding system comprises an industrial robot, the industrial robot comprises a robot controller and a mechanical arm, and the execution end of the mechanical arm is provided with an industrial camera, a distance measuring sensor and a suction cup assembly; the distance measuring sensor is connected with the robot controller through the PLC to determine the photographing height of the industrial camera and the material taking height of the suction cup assembly, and the industrial camera is connected with the robot controller and the suction cup assembly through the PLC to determine the material taking position of the suction cup assembly and then take materials. According to the stacking type workpiece unstacking and feeding device, the mode that visual positioning and sensor distance measurement are combined is adopted, automatic unstacking and feeding of the stacking type workpieces can be achieved through the industrial robot, the labor intensity of workers is relieved, the production efficiency is improved, and the feeding safety is improved.

Owner:WUHU HIT ROBOT TECH RES INST

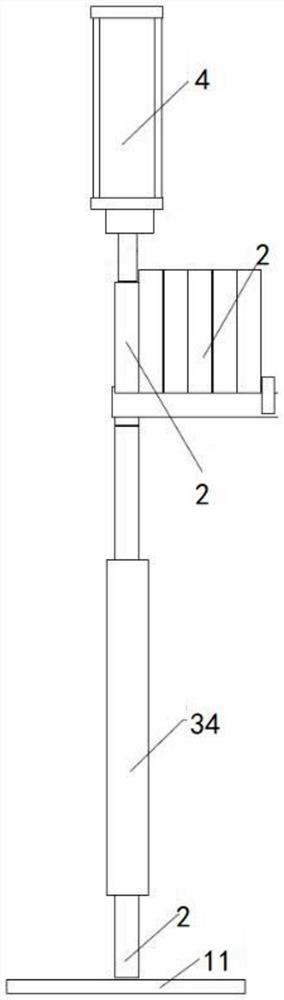

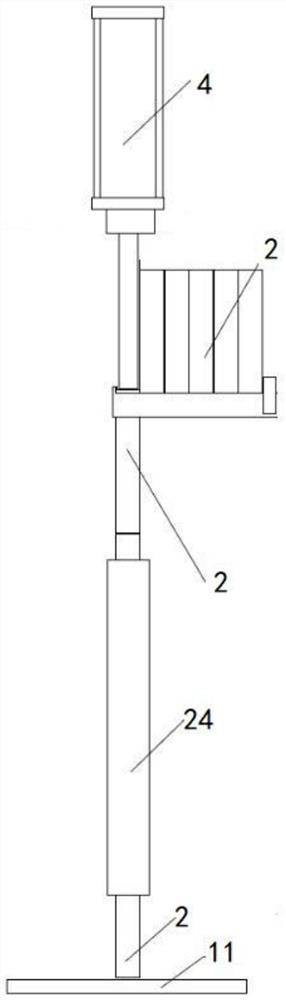

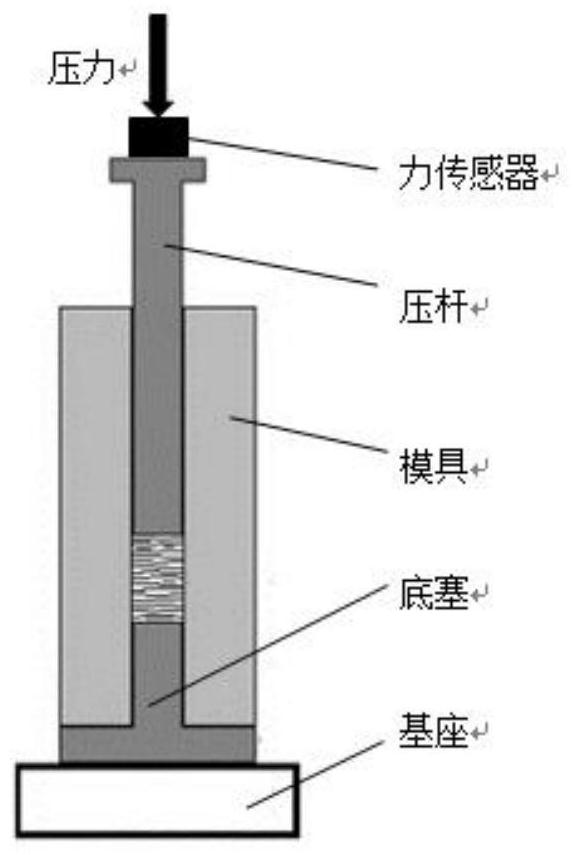

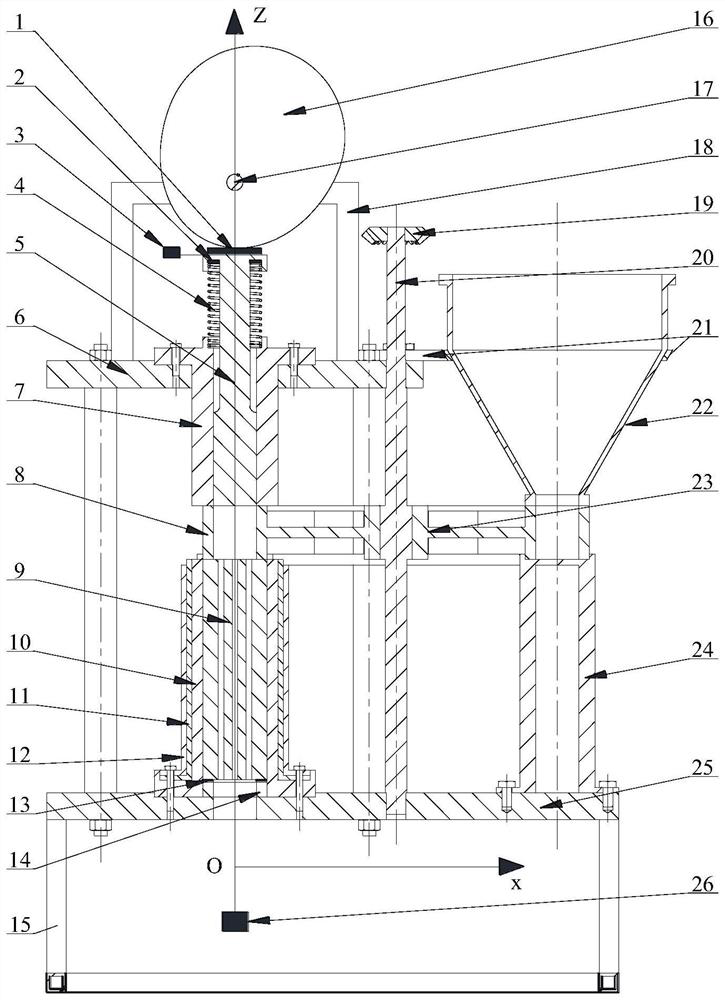

Compression molding mechanical property testing device for loose materials

ActiveCN113405904ARealize automatic continuous feedingFeeding without stoppingMaterial strength using tensile/compressive forcesUnit/actuationCam

The invention discloses a compression molding mechanical property testing device for a loose material. The device comprises a rack; a hopper used for applying materials into a feeding unit; the feeding unit provided with a plurality of loading rings for receiving materials; a cam used for rotating under the driving of a driving unit to apply pressure to a pressing unit, wherein a gap for accommodating the loading rings is formed between the pressing unit and a mold unit; the pressing unit used for pressing materials in the loading rings into the mold unit; the driving unit connected with the cam and the feeding unit through a first transmission mechanism and a second transmission mechanism respectively; the second transmission mechanism enabling the feeding unit to be separated from the driving unit in the downward moving process of the pressing unit, so that the loading ring located between the pressing unit and the mold unit is in a static state; when the pressing unit moves upwards to the highest position, the second transmission mechanism enabling the feeding unit to be connected with the driving unit so as to complete sequential conveying of the loading rings, so that one-by-one conveying of the loading rings is achieved; a measuring unit used for measuring mechanical parameters. The device is consistent with actual working conditions.

Owner:NANJING UNIV OF SCI & TECH

Automatic assembly production line of buzzers

ActiveCN102848187BGuaranteed accuracyRealize automatic feeding processAssembly machinesProduction lineEngineering

The invention discloses an automatic assembly production line of buzzers, which comprises a feeding mechanism, a glue coating mechanism, a buzzer piece placing mechanism, a straight contact pin placing mechanism, a first thermoplastic pipe placing mechanism, an inclined contact pin placing mechanism, a second thermoplastic pipe placing mechanism, a thermoplastic pipe heat sealing mechanism, a contact pin welding mechanism, a dispensing mechanism, a curing mechanism and a detecting and sorting mechanism, which are sequentially arranged on a work table; the glue coating mechanism comprises an automatic shell locating mechanism located behind a glue applicator, and the automatic shell locating mechanism comprises a motor, a rotating jig, an optical fiber sensor, a motor base, a supporting plate and a sensor bracket; the optical fiber sensor is a reflective optical fiber sensor and is arranged to be aligned to the shell; and the optical fiber sensor is installed on the upper part of the sensor bracket, and the lower part of the optical fiber sensor is fixed to the side plate of the supporting plate. The automatic assembly production line disclosed by the invention has the advantages of smart design and simple structure, realizes high level automation, replaces the manual operation, reduces the cost of manpower and physical resources and improves the production efficiency of the assembly line.

Owner:CHANGZHOU MINGSEAL ROBOT TECH CO LTD

Nail gun with automatic nail supply device

PendingCN107825360ASimple structureEasy to manufacture and installStapling toolsNailing toolsNail plateNail gun

The invention discloses a nail gun with an automatic nail supply device. The nail gun comprises a nail gun body, a clip feeding device, a conveying device and a transmission device. The nail gun bodycomprises a gun body and a main nail bin for containing nail plates. The clip feeding device comprises a plurality of clip barrels and a fixed shell, and the multiple clip barrels are each arranged tobe of a hollow barrel-shaped structure, are sequentially fixed to each other in a sleeved mode from inside to outside and are coaxially arranged; each clip barrel is internally provided with a plurality of branched nail bins for containing the nail plates; the multiple clip barrels are driven by the transmission device and freely rotate relatively; the clip barrels are arranged in the fixed shell, the lower portion of the shell is provided with a first discharging outlet, and the clip barrels are provided with second discharging outlets matched with the first discharging outlet; and the nailplates flow out from the discharging outlets and are conveyed into the main nail bin through the conveying device. Through the nail gun with the automatic nail supply device, the storage quantity of the nail plates is increased to a great extent, the continuous nailing sustainability of the nail gun is improved, the nailing efficiency is improved, and the practicality is high.

Owner:彭方

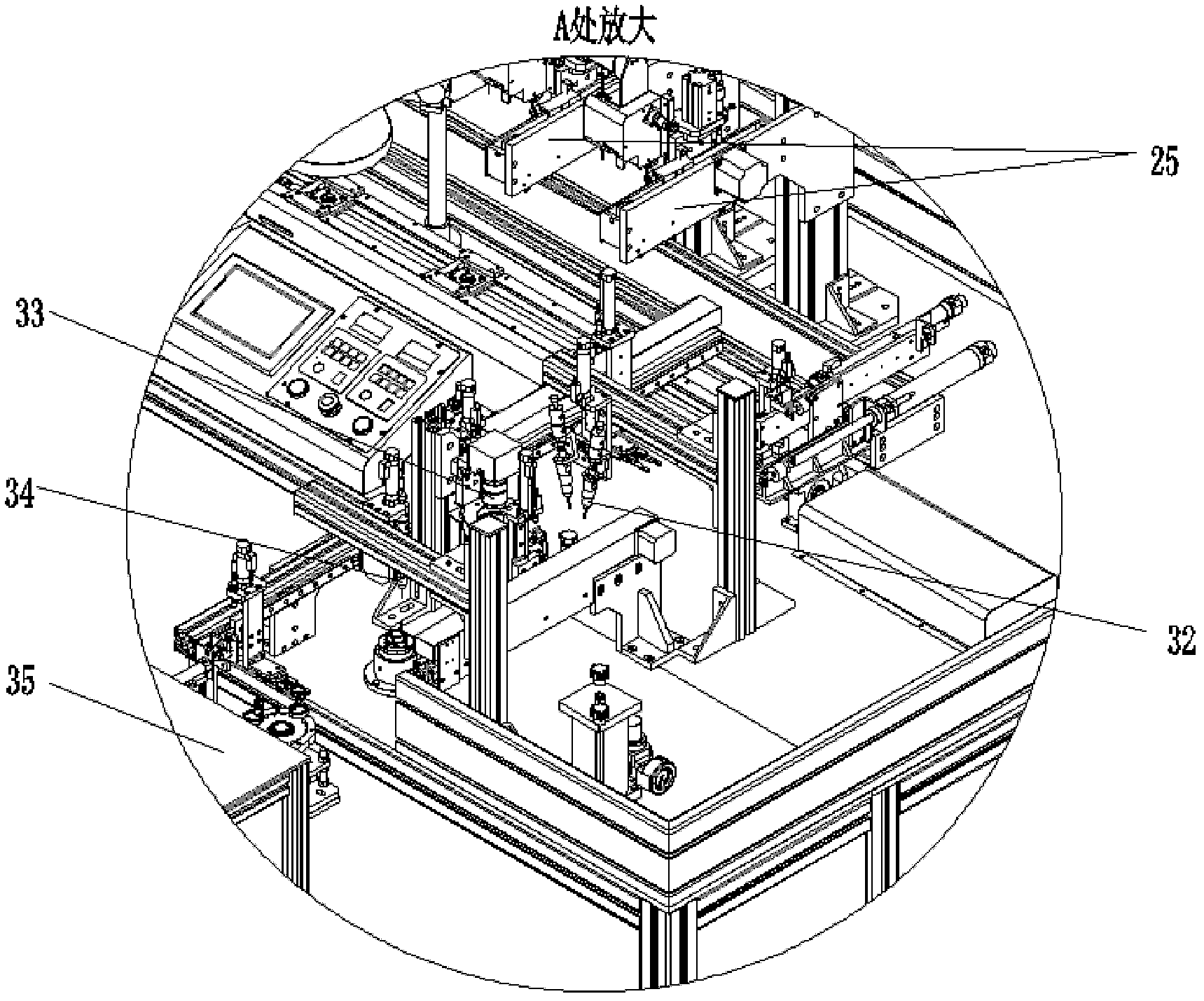

Semiautomatic continuous assembly machine for electromagnetic clutches

ActiveCN108972452ARealize automatic forward conveyingRealize automatic continuous feedingMetal-working hand toolsElectromagnetic clutchEngineering

The invention provides a semiautomatic continuous assembly machine for electromagnetic clutches, comprising a triangular baseplate conveying mechanism, a triangular baseplate conveying rail, a cap laying mechanism and an assembly compressing mechanism. The cap laying mechanism includes a cap feeding component and a triangular baseplate pushing component; the cap feeding component includes three groups of conveying barrels; the assembly compressing mechanism includes an elastic rail, a limiting platform and a compressing component; when the cap feeding component conveys a cap to a triangular baseplate, the cap laying mechanism arranged herein drives the triangular baseplate pushing mechanism to synchronously push the triangular baseplate forward, and under the cooperation of the elastic rail linked to the cap feeding component, the triangular baseplate is limited on the limiting platform when the elastic rail presses down and is compressed and fitted via the compressing component; feeding, pushing and limiting automation is achieved for the assembly process; the technical problems of the prior art, such as low working efficiency, low automation level and high error rate are solved.

Owner:ZHEJIANG HANGTAI AUTO PARTS

Feeding device and feeding method

InactiveCN111807065AFully automatedRealize automatic continuous feedingDe-stacking articlesControl theoryIndustrial engineering

The invention provides a feeding device and a feeding method. The feeding device comprises a limiting mechanism and a jacking mechanism, and a limiting part of the limiting mechanism is used for limiting a feeding box arranged above a feeding box at the bottommost layer to descend; and a driving part of the jacking mechanism abuts against the bottom of the bottommost-layer feeding box. According to the feeding device, through supporting and limiting of the limiting mechanism, the bottommost-layer feeding box in the multiple layers of feeding boxes arranged longitudinally can be used for feeding independently, meanwhile, through cooperation of the limiting mechanism and the jacking mechanism, automatic and continuous feeding of the feeding boxes is achieved, manpower is released, and the feeding efficiency is improved.

Owner:BOZHON PRECISION IND TECH CO LTD

Automatic food material loading device

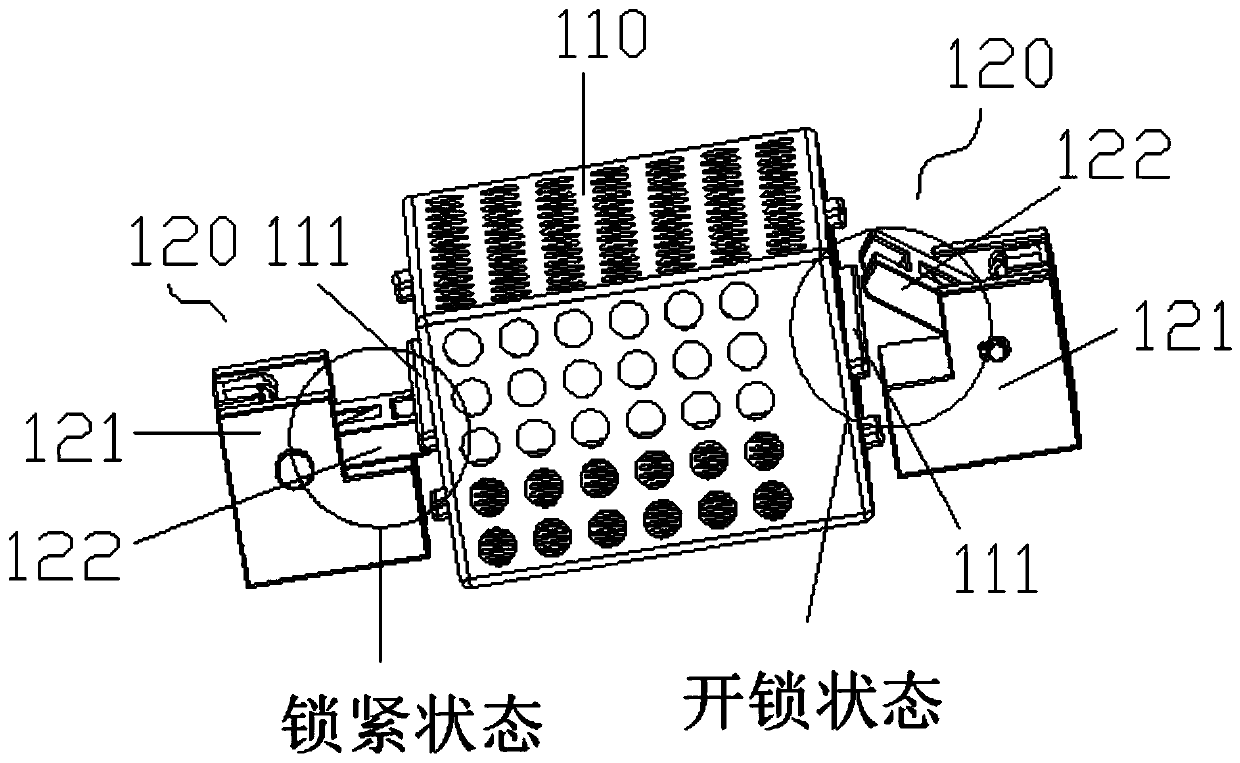

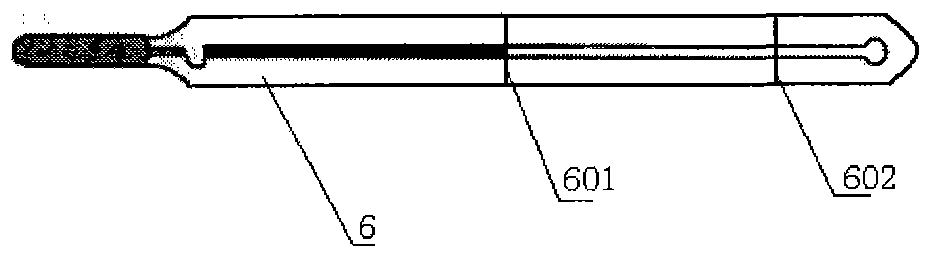

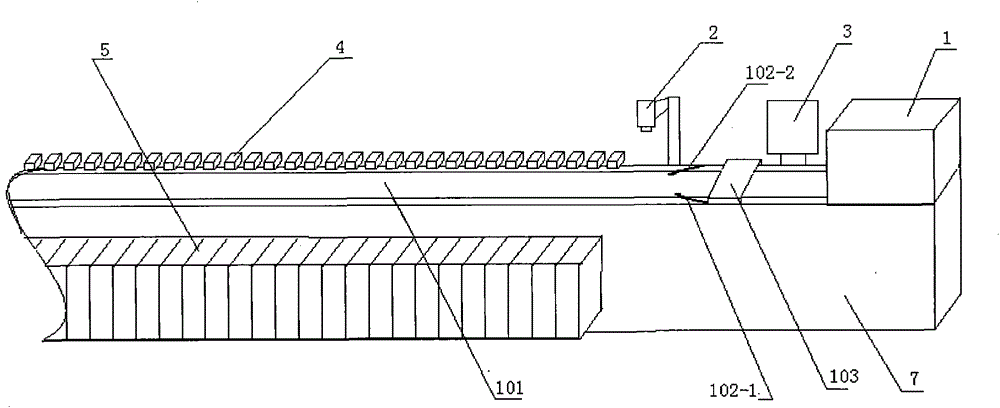

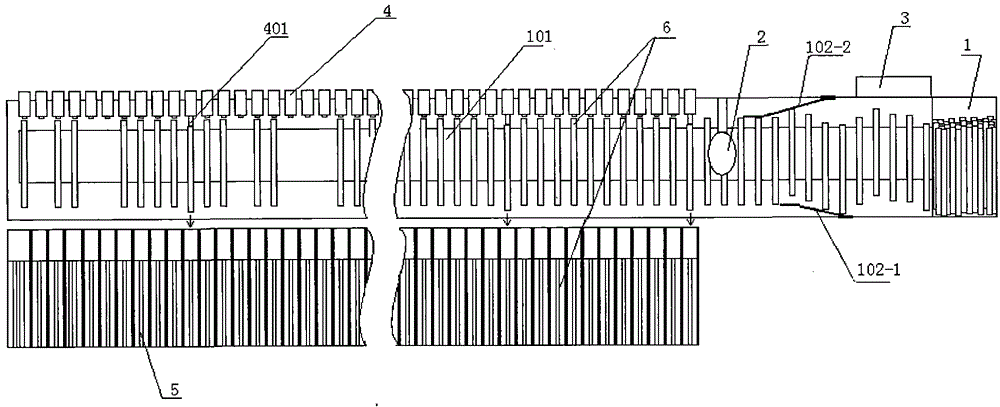

PendingCN110127359ARealize automatic continuous feedingAchieve unlockStorage devicesConveyor partsHigh humidityLocking mechanism

The invention relates to the technical field of food processing equipment, in particular to an automatic food material loading device. The automatic food material loading device comprises a material storage mechanism, an unlocking mechanism and a material pickup mechanism, wherein the material storage mechanism comprises overlapped material frames for containing food material, and a locking mechanism which locks the material frame at the bottom layer, the unlocking mechanism comprises an unlocking structure which completes unlocking action for the locking mechanism and a material receiving platform for receiving the material frames after being unlocked, and the material pickup mechanism is used for moving the material frames on the material receiving platform into a device in a next working process. The invention aims as providing the automatic food material loading device. By adopting the technical scheme, the automatic food material loading device solves the technical problems that in the prior art, the food material is loaded by using manual labor, and therefore automatic degree in low, loading efficiency is low, loading accuracy is hugely influenced by workers, and high temperature and high humidity work environment brings disadvantages to body health of the workers.

Owner:GUANGDONG LYRIC ROBOT INTELLIGENT AUTOMATION CO LTD

Glass thermometer automatic sorting device

ActiveCN103977961BRealize automatic sortingRealize automatic continuous feedingSortingMicrocontrollerMicrocomputer

Owner:东阿阿华医疗科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com