Compression molding mechanical property testing device for loose materials

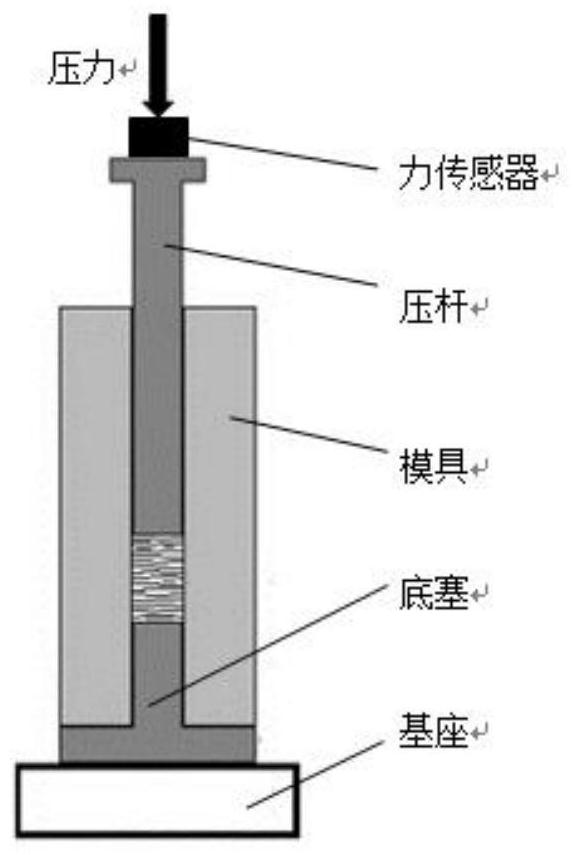

A technology for pressing and forming loose materials. It is used in measuring devices, using stable tension/pressure to test the strength of materials, scientific instruments, etc. It can solve the problem of inability to measure the stress-strain relationship of materials, low pressing speed, and inability to run continuously, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

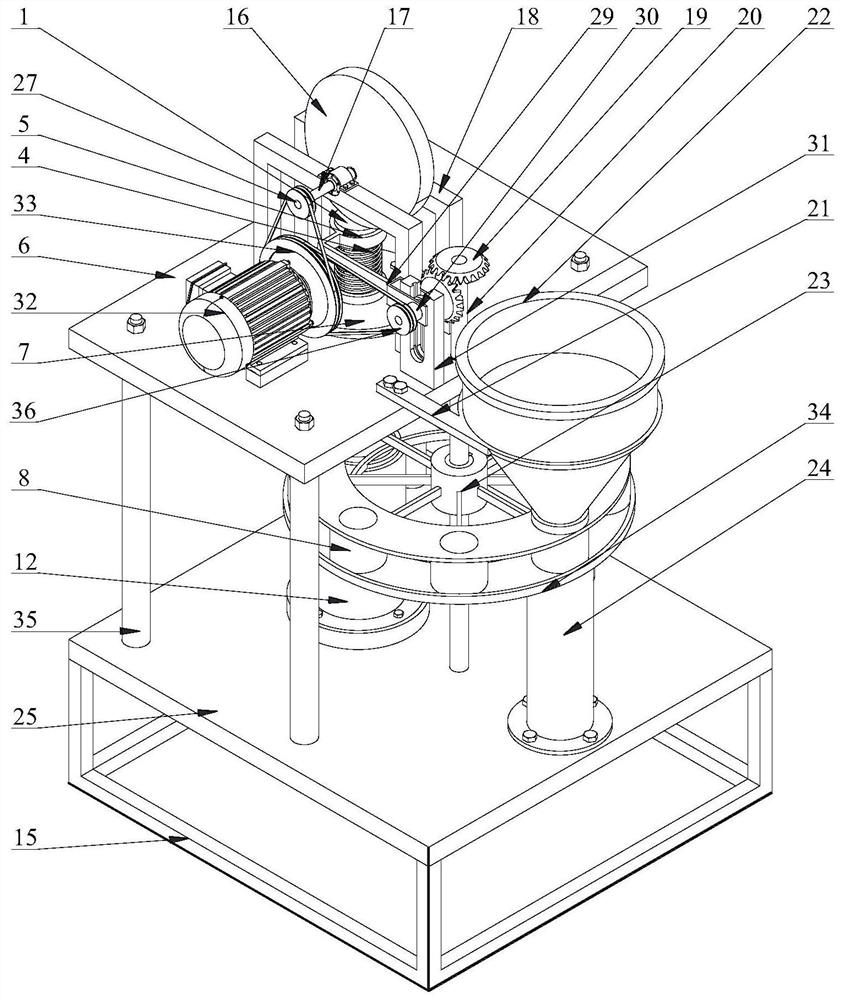

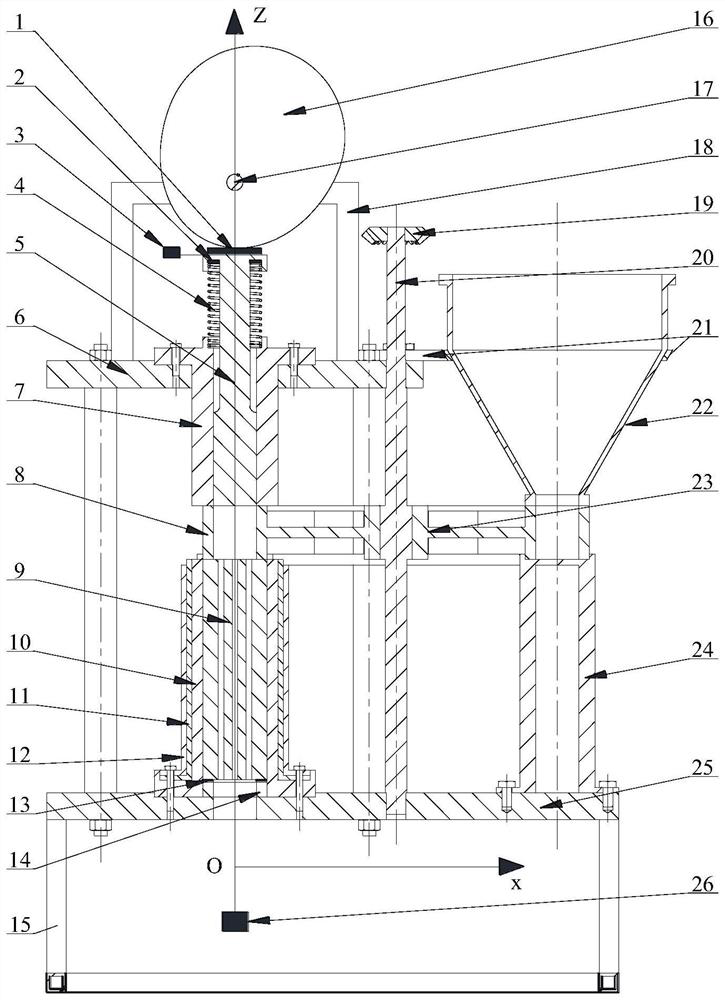

[0027] The present invention will be further introduced below in conjunction with the accompanying drawings and specific embodiments.

[0028] combine Figure 2-Figure 4 , a loose material compression molding mechanical performance testing device of the present embodiment includes a frame, a driving unit, a pressing unit, a feeding unit, a mold unit, and a cam.

[0029] Described driving unit adopts motor 32, and described pressing unit comprises spring 4, pressing shaft 5, upper base plate 6, upper sleeve 7; Described frame comprises upper base plate 6, upper frame 18, lower frame 15, lower base plate 25.

[0030] A synchronous belt is used for transmission between the motor 32 and the cam 16. The cam 16 is connected to the upper frame 18 by the camshaft 17. The upper base plate 6 and the lower base plate 25 are connected and fixed by a plurality of support columns 35 to ensure that the upper sleeve 7 The coaxiality with the lower sleeve 10 is within a certain range.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com