Rotary sucrose-6-ester continuous production equipment and production method

A production equipment and a rotary technology, which are applied in the preparation of sugar derivatives, sugar derivatives, sugar derivatives, etc., can solve the problems of shortening the production process of sucrose-6-ester and low production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

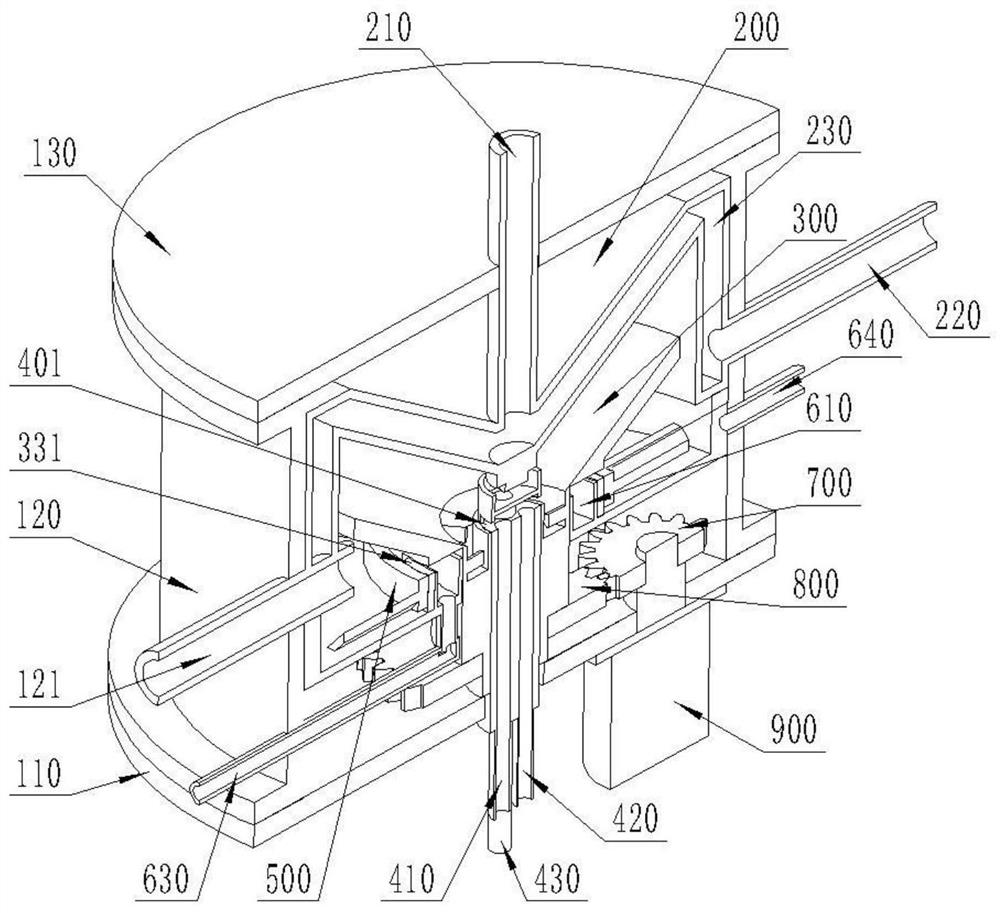

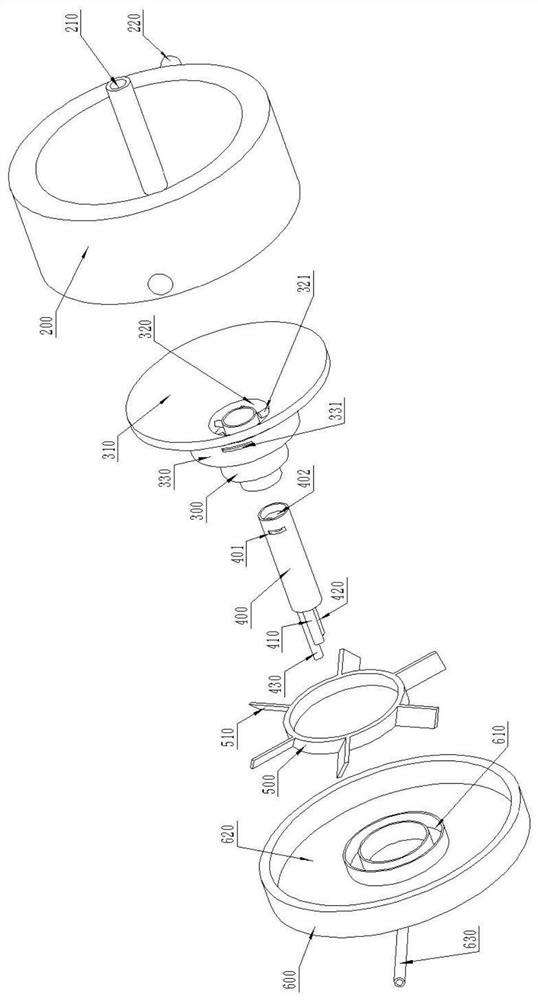

[0039] Preferred embodiments of the present invention will be described in detail by reference to the accompanying drawings However, the present invention can also be implemented in various forms, and thus the present invention is not limited to the embodiments described hereinafter, and the present invention is described in order to more clearly describe the present invention. The connected components will be omitted from the drawings;

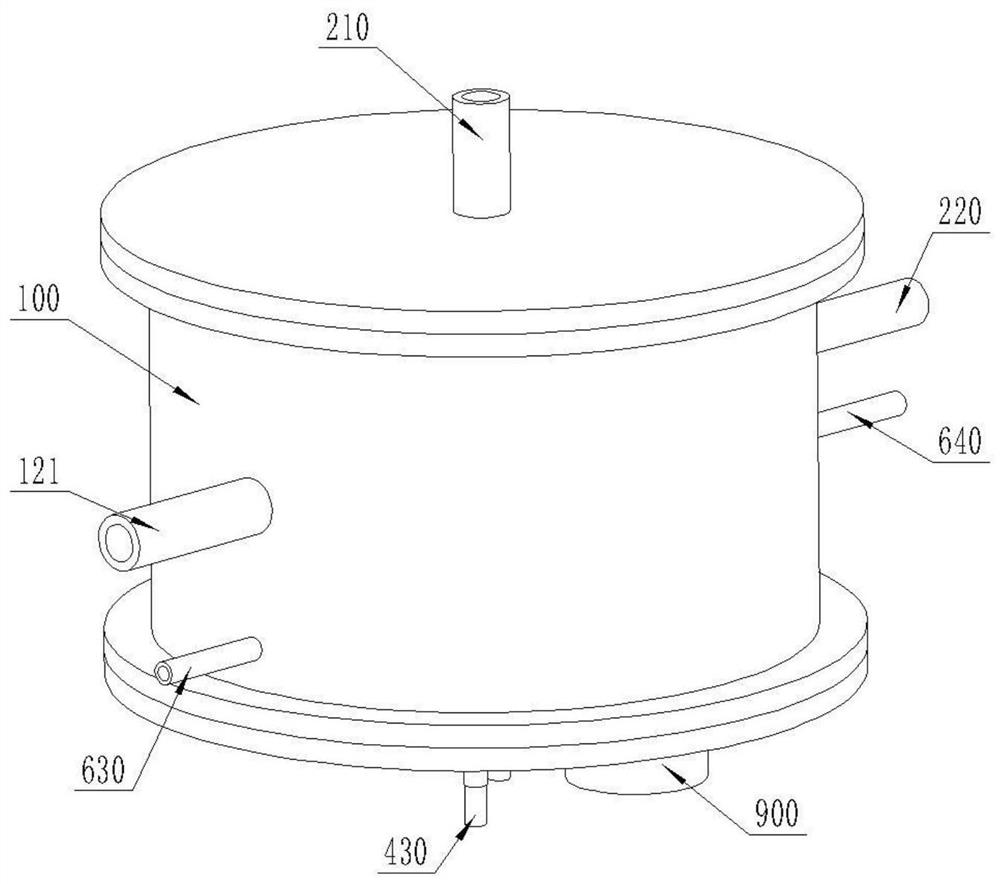

[0040] For 1 to 1 Figure 6 As shown, a rotary sucrose-6-ester continuous production apparatus includes: tank 100, cooling body 200, cone heating plate 300, nozzle tube 400, agitator 500, liquid disc 600, pinion 700, large Gear 800, drive motor 900;

[0041] The tank 100 is composed of three parts of the lower can 110, the main tank 120 and the upper canister 130, and can be removed from the can cover 130 when installing or disassembling, facilitating the installation and maintenance, the lower can cover 110 The drive motor 900 is fixedly mounted ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com