Combustion method with integrated CO2 separation by means of carbonation

a technology of combustion method and carbonation, which is applied in the direction of combustible gas purification/modification, separation process, other chemical processes, etc., can solve the problems of large-scale and very costly installations, large amount of energy, and reduce the yield of generating useful electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

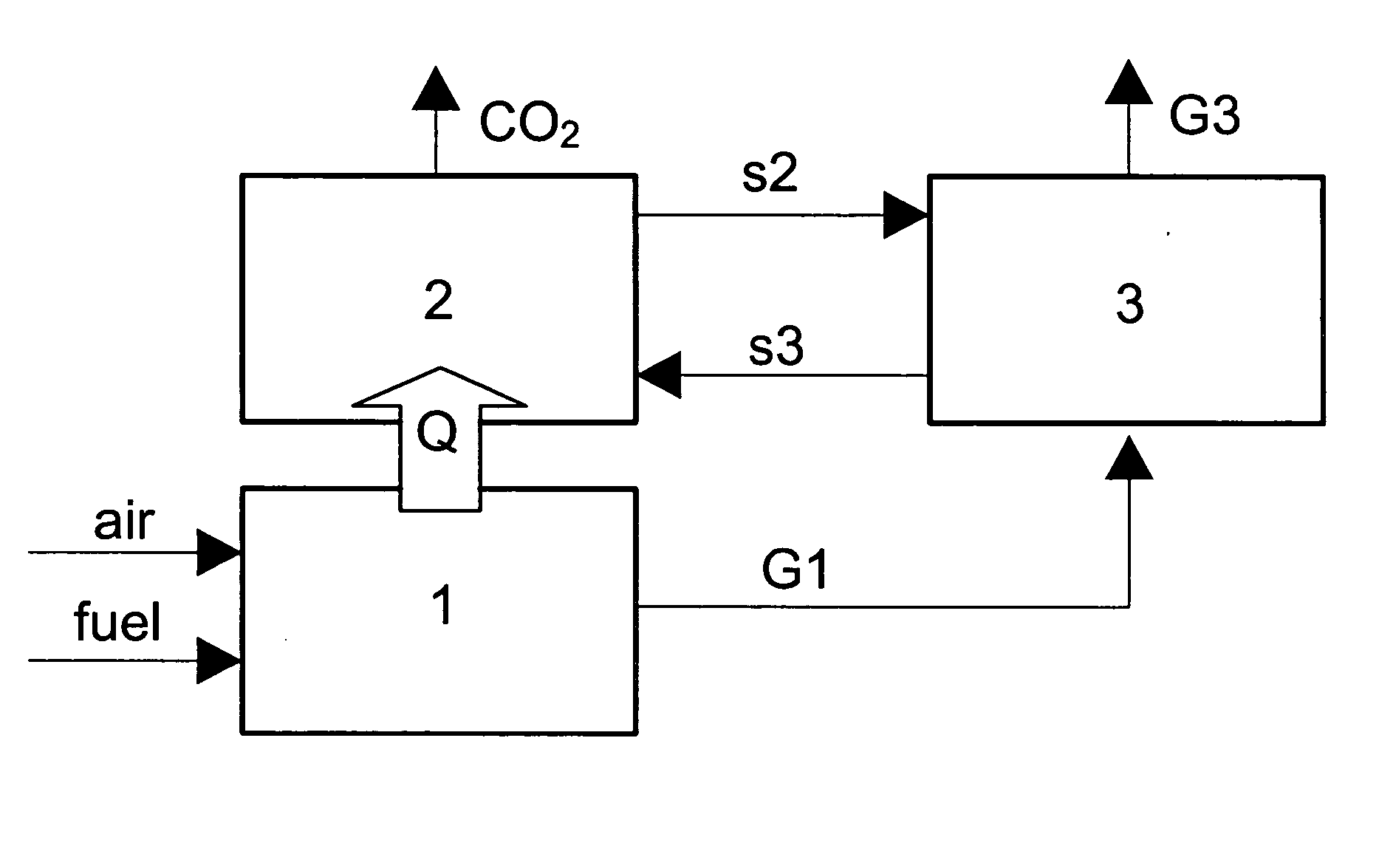

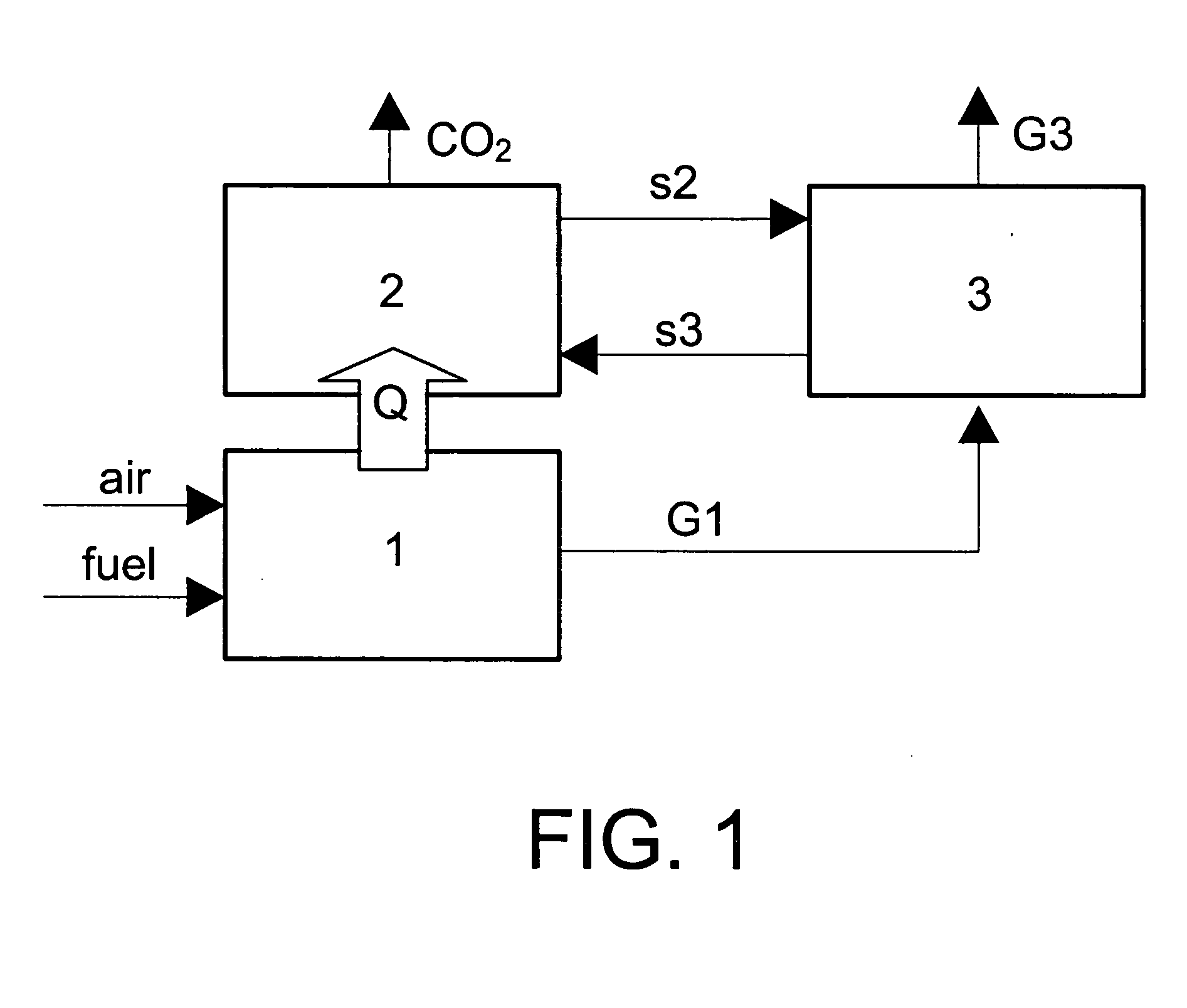

It describes a new combustion method with integrated CO2 separation by means of carbonation based on the use of part of the heat generated in the combustion chamber by the calciner in order to maintain the endothermic reaction of calcination and to regenerate the sorbent, without the need to use an air separating plant; in combination with a carbonator to treat the hot gases and which in turn generate energy during carbonation.

The object of the invention comprises a combustion chamber (1) wherein any type of fuel is burnt with air, preferably at temperatures higher than 1,000° C. generating heat and a stream of combustion gases at a high temperature with a CO2 content between 3 and 17% by volume depending on the fuel and the excess air used in the combustion. The combustion chamber may be of any type, a fluidized bed, a conventional powdered carbon combustion boiler, or natural gas burner or burner of other liquid fuels. Combustion can be done at atmospheric pressure or at a high...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperatures | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com