Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

63 results about "Barium aluminate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Barium Aluminate is generally immediately available in most volumes. Aluminates are compounds with a negatively-charged alumina ion and a metallic oxide with various industrial applications such as water treatment and ceramics manufacturing.

Method for preparing silicon-free or low-silicon acidproof ceramic fracturing propping agent

The invention discloses a method for preparing a silicon-free or low-silicon acidproof ceramic fracturing propping agent, which comprises the following steps of: (1) preparing the following raw materials in percentage by weight: 30 to 95 percent of alumina, 5 to 70 percent of barium carbonate and 0 to 10 percent of sintering aid, wherein the sintering aid is one or more of titanium dioxide, boric acid, calcium carbonate, magnesium oxide and dolomite; (2) performing ball milling on the raw materials in the step (1) in a ball mill for 24 to 48 hours; (3) preparing the raw materials obtained in the step (2) into semi-finished product particles; and (4) sintering the semi-finished product particles obtained in the step (3) at the temperature of between 1,500 and 1,800 DEG C for 1 to 3 hours, and cooling to the room temperature. The method has simple process; the barium carbonate is decomposed at high temperature to generate barium oxide, and the barium oxide is fully reacted with alumina to generate stable barium aluminate; and the barium aluminate has strong acidproof performance and protects other components in the finished product against corrosion of acid liquor, so the acidproof performance of the finished product is greatly improved.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Composite combining corundum based refractory materials

ActiveCN101423401AImprove high temperature resistanceStrong thermal shock resistanceSuperplasticizerMaterials science

The invention relates to a composite sialon-corundum fire-resisting material, which is characterized in that the formulation of the fire-resisting material comprises the following: 30 to 54 percent of corundum or aluminum oxide hollow sphere the diameter of which is between 3 and 1 millimeter, 7 to 30 percent of the corundum or the aluminum oxide hollow sphere the diameter of which is between 1 and 0.0088 milliliter, 16 to 30 percent of corundum powder the diameter d90 of which is less than 0.088 millimeter, 3 to 10 percent of alpha aluminum oxide micro powder, 2 to 8 percent of hydrated aluminum oxide, 0.2 to 2 percent of siliceous dust, 0 to 2 percent of barium aluminate cement, 0.05 to 0.4 percent of efficient water reducing agent (which is prepared from polycarboxylic acid, sulfonated naphthaldehyde polymer and sulfonated melamine polymer), 1 to 6 percent of polyacrylic acid emulsion, and 1 to 6 percent of water. The composite sialon-corundum fire-resisting material obviously has the advantages of coagulation, hardening, demolding, drying and heating performances remarkably similar to a low cement casting material, and good high-temperature resistant performance, and can be made into various products or be used as an unshaped material.

Owner:RUITAI MATERIALS TECHNOLOGY CO LTD

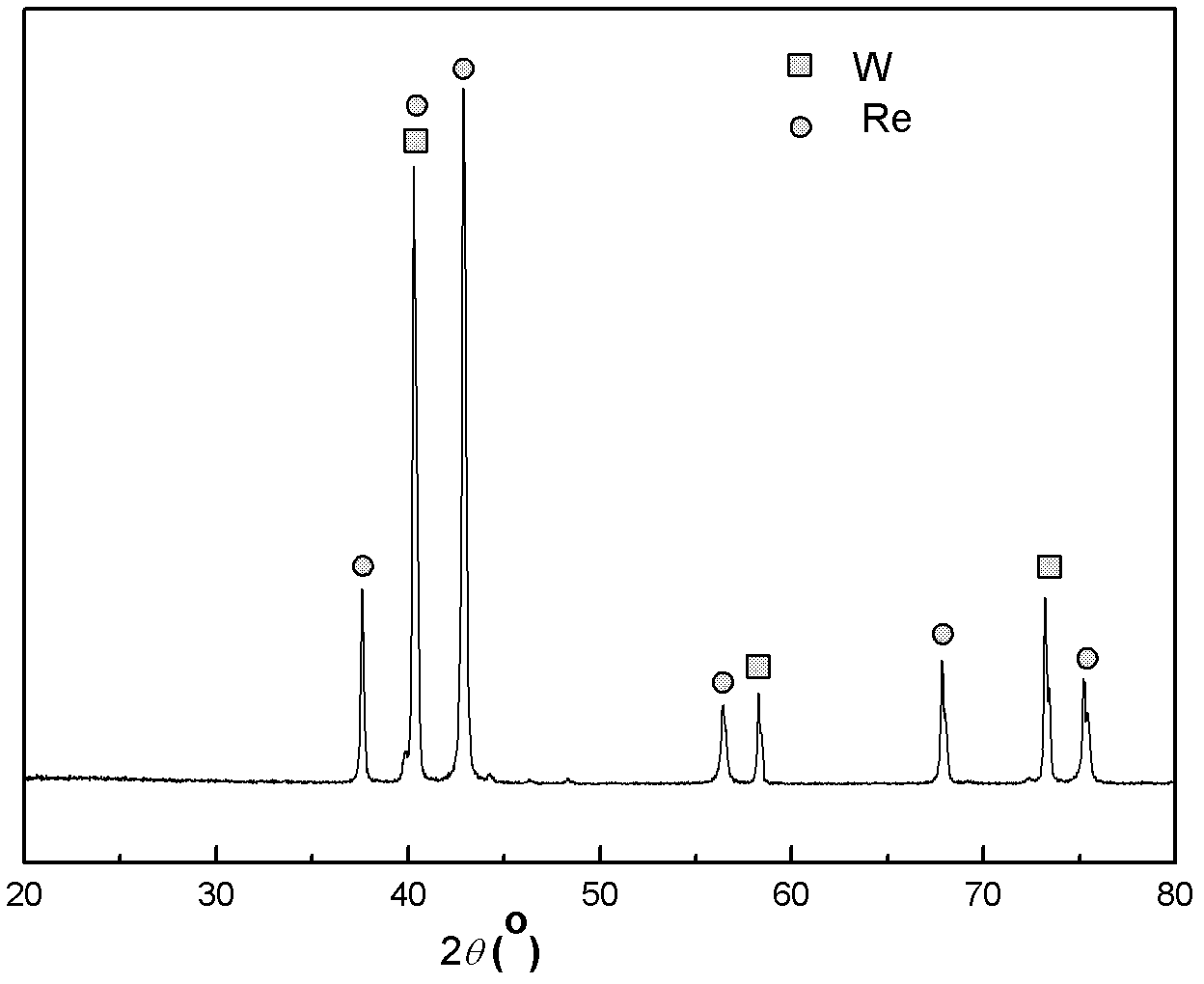

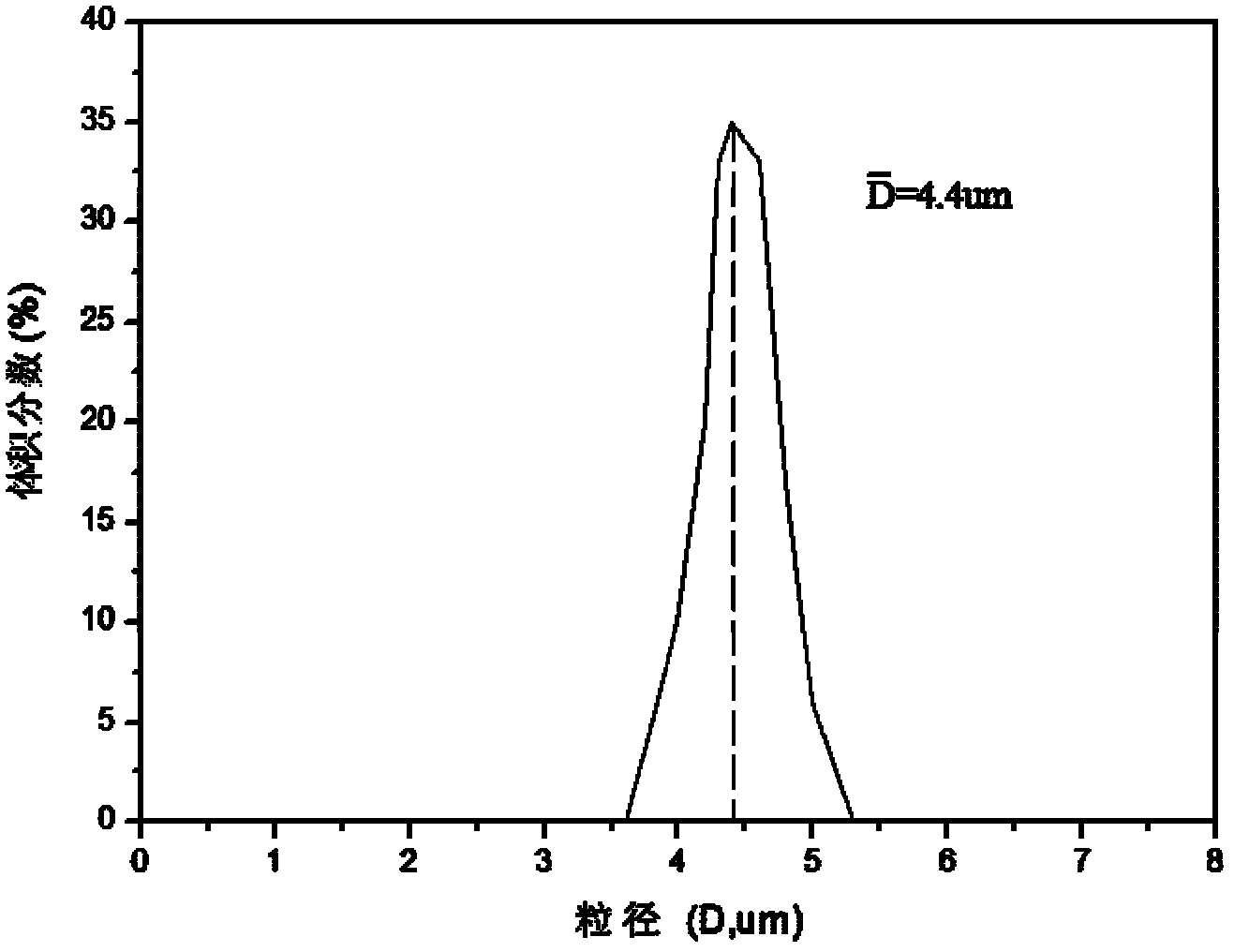

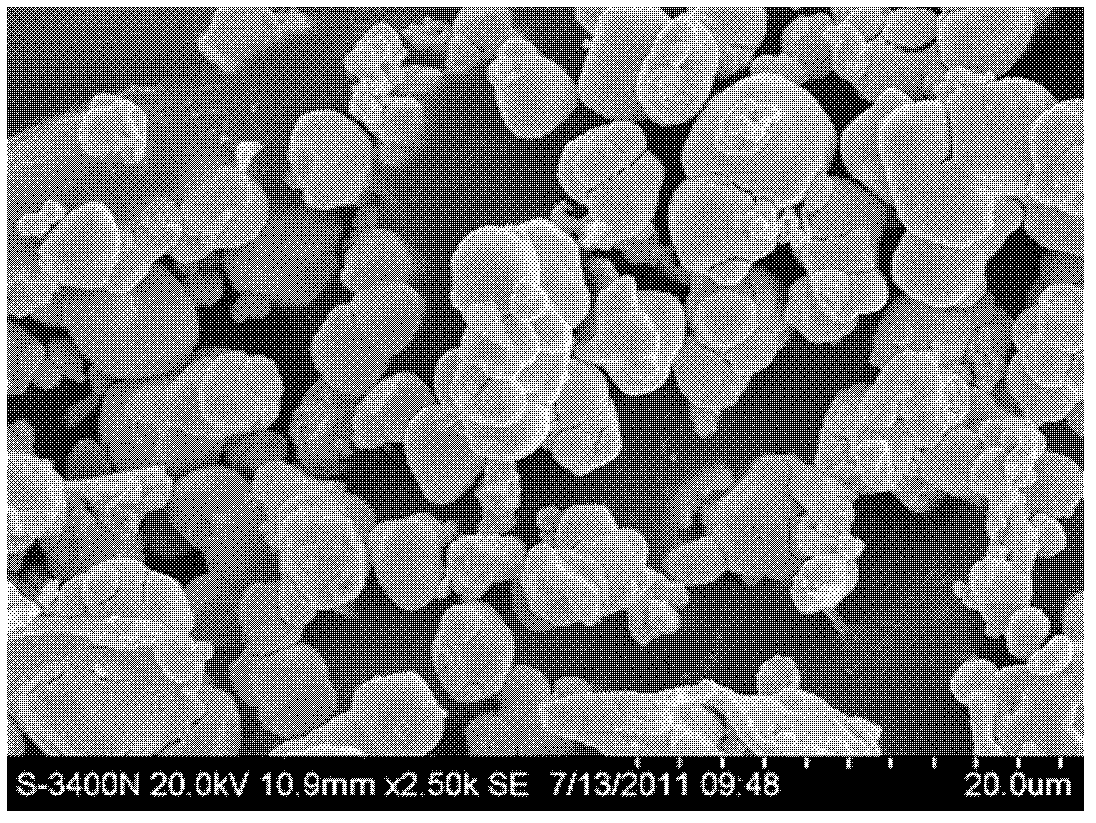

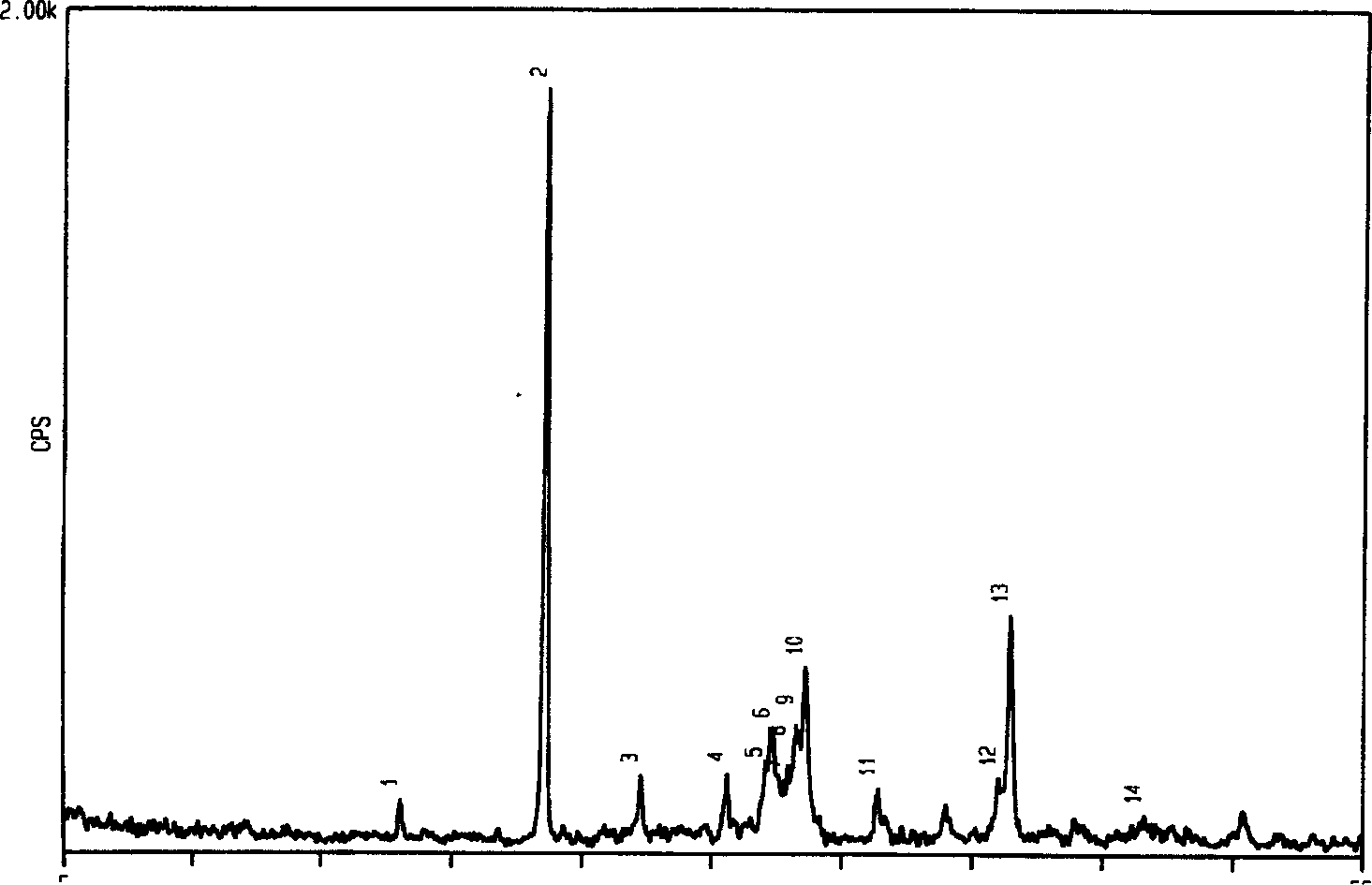

Rhenium tungsten based cathode material and preparation method thereof

The invention relates to a rhenium tungsten based cathode material and a preparation method thereof and belongs to the technical field of a refractory metal thermal cathode material. BaO, CaO and Al2O3 are loaded in pores of a porous rhenium tungsten base; the rhenium tungsten base is formed by coating tungsten grains by rhenium. The preparation method comprises the following steps: dissolving ammonium perrhenate in water, thereby preparing into a solution; adding tungsten powder into the ammonium perrhenate solution and stirring; drying; resolving and reducing in two steps under the hydrogen atmosphere, thereby obtaining rhenium tungsten powder; and pressing and sintering the rhenium tungsten powder under the hydrogen atmosphere, thereby obtaining a rhenium tungsten base and steeping into a molten barium aluminate calcium salt. The preparation method provided by the invention has the advantages that the preparation process is simple, the introduction of impurity element during the preparation process is avoided, the repeatability is strong, the prepared cathode material is excellent in emitting property, and the ion bombardment resistance of a traditional barium tungsten cathode is enhanced.

Owner:BEIJING UNIV OF TECH

Barium containing sulpho- ferro- aluminate cement

The invention relates to a barium containing sulfur ferrum aluminate cement with sulfur ferrum calcium barium aluminate and dicalcium silicate as the primary minerals, wherein the cement clinker contains 5-80% (weight) of sulfur ferrum calcium barium aluminate, the molecular formula of sulfur ferrum calcium barium aluminate (abbreviated as C4-xBxA3-yF-yS) is (3-X)CaO*XbaO*9(3-Y)Al2O3*Fe2O3*CaSO4 (X, Y=0.10-3). The beneficial effects of the invention are, the burning temperature is higher than that of the sulphoaluminate early strength cement, and the cost is low.

Owner:UNIV OF JINAN

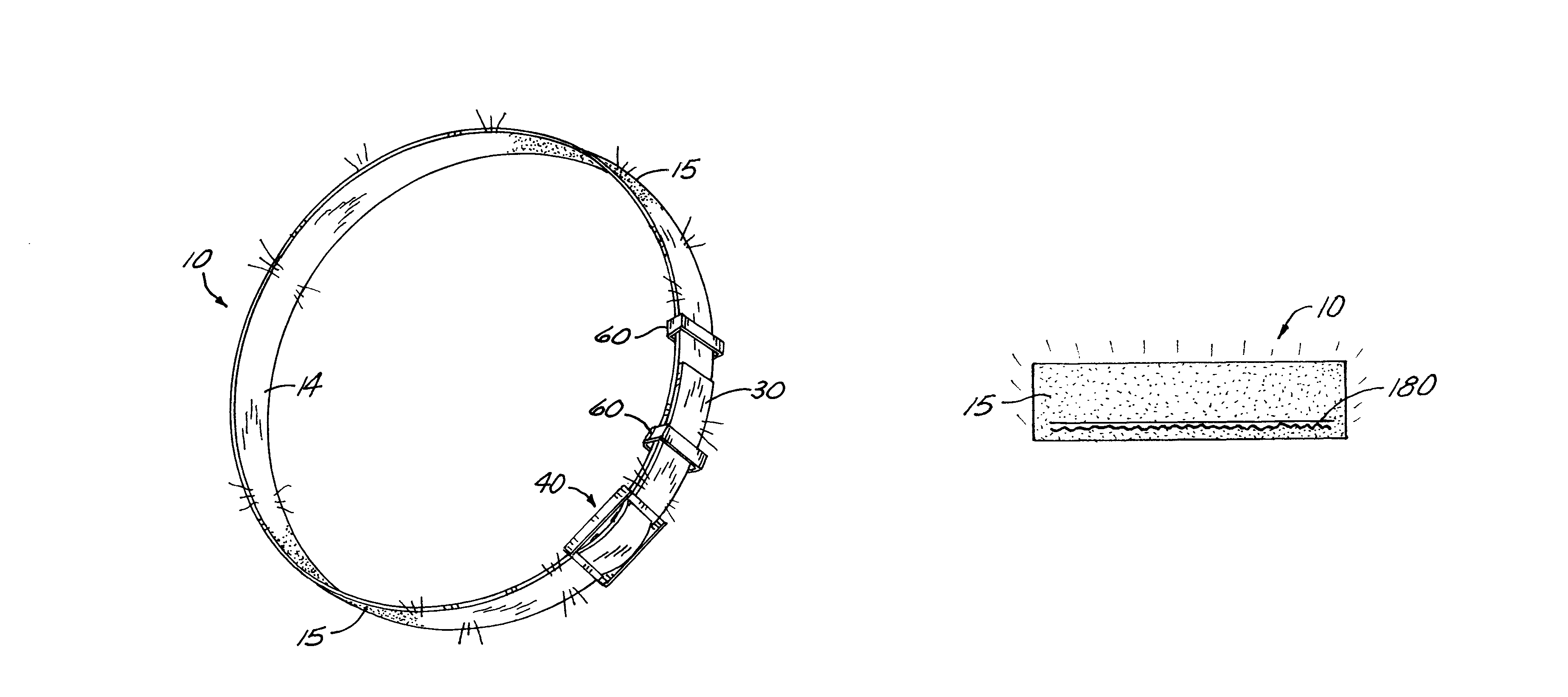

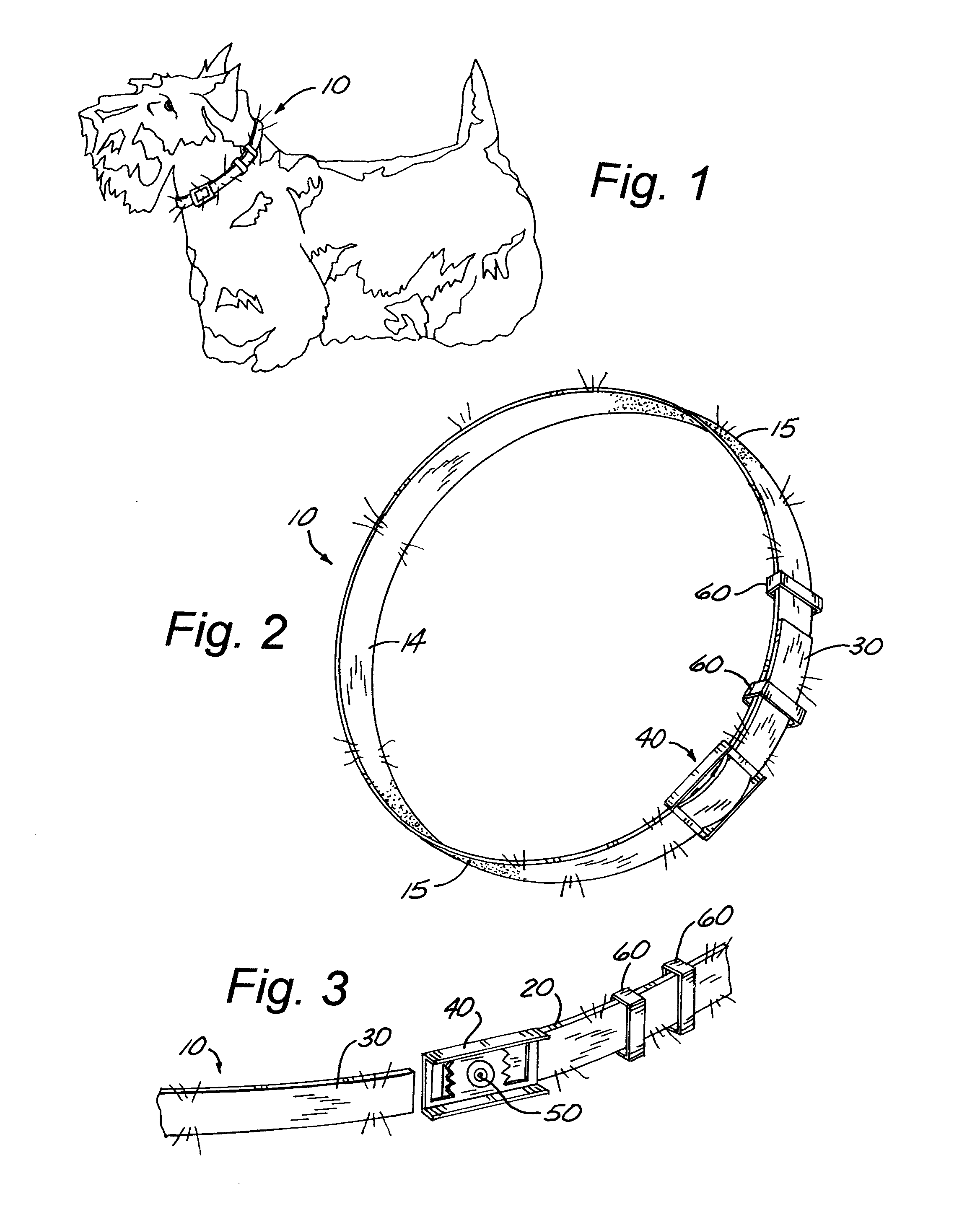

Glow in the dark pet strap

InactiveUS7980203B1Improve performanceSafety beltsTaming and training devicesElastomerPhotoluminescence

A pet strap formed of a transparent material, such as plastic or synthetic rubber, with photoluminescent or phosphorescent colored pigment homogeneously dispersed within and incorporated into the elastometric material. The preferred photoluminescent is strontium oxide aluminate or strontium barium aluminate, which emit a yellow-green light. The strap may be disposed to encircle the neck of the pet as a conventional collar with a buckle and strap end retainers. The strap may also be made in various dimensions suitable for pets of all sizes, and may be configured to be trimmed to the desired size. Another embodiment of the pet strap includes a light reversion strip and an underlying or encased fabric reinforcing strip encased within the elastomeric strap adjacent the bottom side of the strap that contacts the pet. The light reversion strip will allow available light to charge the luminescents more proficiently for better performance.

Owner:ORME DANIEL C

High-temperature-resistant methanation catalyst and preparation method thereof

ActiveCN104907075AThe humidity gradient decreasesAvoid crackingGaseous fuelsMetal/metal-oxides/metal-hydroxide catalystsAlkaline earth metalPtru catalyst

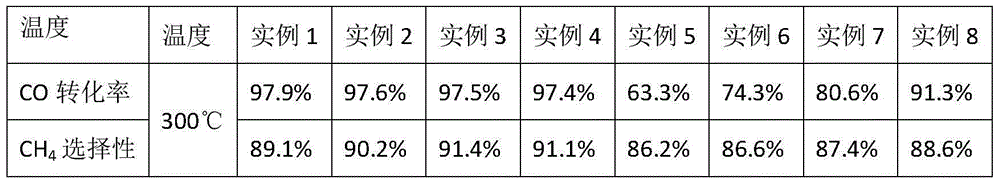

The invention relates to a high-temperature-resistant methanation catalyst and a preparation method thereof. The preparation method comprises the following steps: by taking nickel as a main active ingredient, hexa-aluminate barium as a carrier and rare earth metals as a cocatalyst, preparing a hexa-aluminate barium carrier by virtue of a precipitation method combined with a microwave drying technology; then introducing an active ingredient nickel oxide to prepare a catalyst semi-finished product; then adding anti-sintering components such as kaolin, potassium carbonate, alkaline-earth metals and the like; and finally adding calcium aluminate cement and mixing, roasting and grinding the mixture together and slicing and forming the mixture to prepare the methanation catalyst. The methanation catalyst comprises the following components in percentage by mass: 5-15% of NiO, 5-30% of SiO2, 2-30% of BaO, 7-12% of K2CO3, 5-30% of CaO, 0.5-5% of La2O3, 5-15% of MgO and 30-65% of Al2O3. The methanation catalyst maintains relatively good methanation activity in a using temperature range form 300 DEG C to 700 DEG C and has good stability and anti-carbon performance.

Owner:HUANENG CLEAN ENERGY RES INST +1

Europium-activated barium magnesium aluminate phosphor

InactiveUS7014792B2Reduce probabilityImprove performanceCathode ray tubes/electron beam tubesLuminescent compositionsBarium aluminateEuropium

A europium-activated barium aluminate phosphor is described wherein the phosphor is doped with tetravalent ions of Hf, Zr, or Si. Preferably, the phosphor is represented by (Ba1−xEux)MgAl10O17:(Hf,Zr,Si)y where 0.05≦x≦0.25 and 0<y≦0.05. The tetravalent dopant ions are shown to enhance the stability of the phosphor in UV / VUV applications.

Owner:OSRAM SYLVANIA INC

Cement-free high strength unshaped refractory

Disclosed is a cement-free high strength unshaped refractory in which barium aluminate and a dispersant are further added to a refractory which includes a refractory material containing Al2O3 and SiC and an alumina sol binder to largely improve handling strength of the unshaped refractory. The unshaped refractory according to the present invention is usefully applicable to lining which contacts slag in a blast furnace or a gasifier.

Owner:KOREA INST OF SCI & TECH

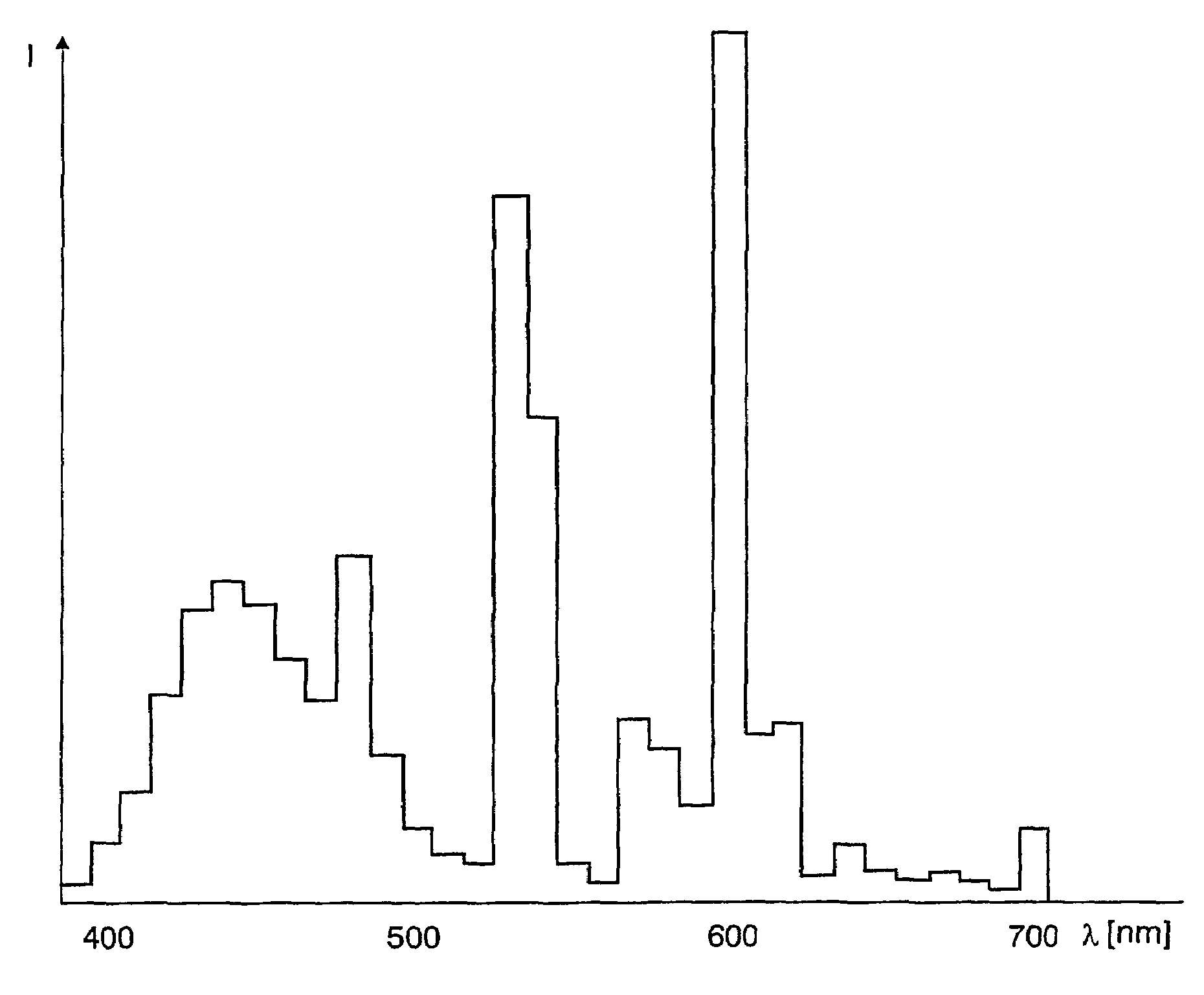

Phosphor composition for a low-pressure discharge lamp with high color temperature

InactiveUS7670507B2Physical improvementEnhances spiritual well-beingDischarge tube luminescnet screensLamp detailsPhosphoric acidManganese

A phosphor composition for a low-pressure discharge lamp with a high light yield and a high color temperature contains phosphors which emit in the red wavelength region, including yttrium oxide doped with europium or gadolinium-zinc-magnesium pentaborate doped with cerium and manganese, phosphors which emit in the green wavelength region including lanthanum phosphate doped with cerium and terbium and / or cerium-magnesium aluminate doped with terbium and / or cerium-magnesium pentaborate doped with terbium, and optionally a phosphor which emits in the blue wavelength region of the barium-magnesium aluminate doped with europium type. The phosphor composition additionally contains at least one phosphor which emits in the blue or blue-green wavelength region selected from the group consisting of manganese-strontium-barium-magnesium aluminate doped with manganese and europium or barium-magnesium aluminate doped with europium and manganese and strontium aluminate doped with europium and strontium-barium-calcium chloroapatite doped with europium and strontium borophosphate doped with europium.

Owner:LEDVANCE GMBH

Impregnated Re3W-Sc2O3 mixed base cathode material and preparation method thereof

InactiveCN104299869AExcellent pulse electron emission performanceTransit-tube cathodesDischarge tube/lamp detailsBarium saltRare earth

Owner:BEIJING UNIV OF TECH

New method for removing fluorine in zinc solution through sodium aluminate

InactiveCN106521186ARaw materials are easy to getLower the purification temperaturePhotography auxillary processesProcess efficiency improvementBarium aluminateSlag

The invention relates to a new method for removing fluorine in a zinc solution through sodium aluminate, and belongs to the field of zinc hydrometallurgy. The new method comprises the specific operation steps that 1, industrial grade sodium aluminate powder and water are mixed to prepare a mixed solution with the concentration of 5%-50%, the solution is sufficiently stirred for use, and the mixed solution has no obvious agglomeration phenomenon after being sufficiently mixed; 2, the sodium aluminate solution is gradually added into the fluorine-containing zinc solution (with the fluorine content being 100-600 mg / L), sufficient stirring is carried out for removing fluorine, the fluorine removing temperature is controlled to be 15-50 DEG C, and the fluorine removing time is controlled to be 0.5-2 h; and 3, after the reaction in the step 2 is finished, a zinc solution with fluorine removed and fluorine-removed slag are obtained through solid-liquid separation. According to the method, the industrial grade sodium aluminate powder is adopted for the first time in the technology of removing fluorine in the zinc solution, the fluorine-removed slag amount is reduced, the filter performance of the solution with fluorine removed is improved, the industrial grade sodium aluminate powder is easy to obtain, the purification temperature is low, purification time is short, the fluorine removing technology is simplified, and economic benefits of enterprises are improved.

Owner:YUNNAN CHIHONG ZINC & GERMANIUM

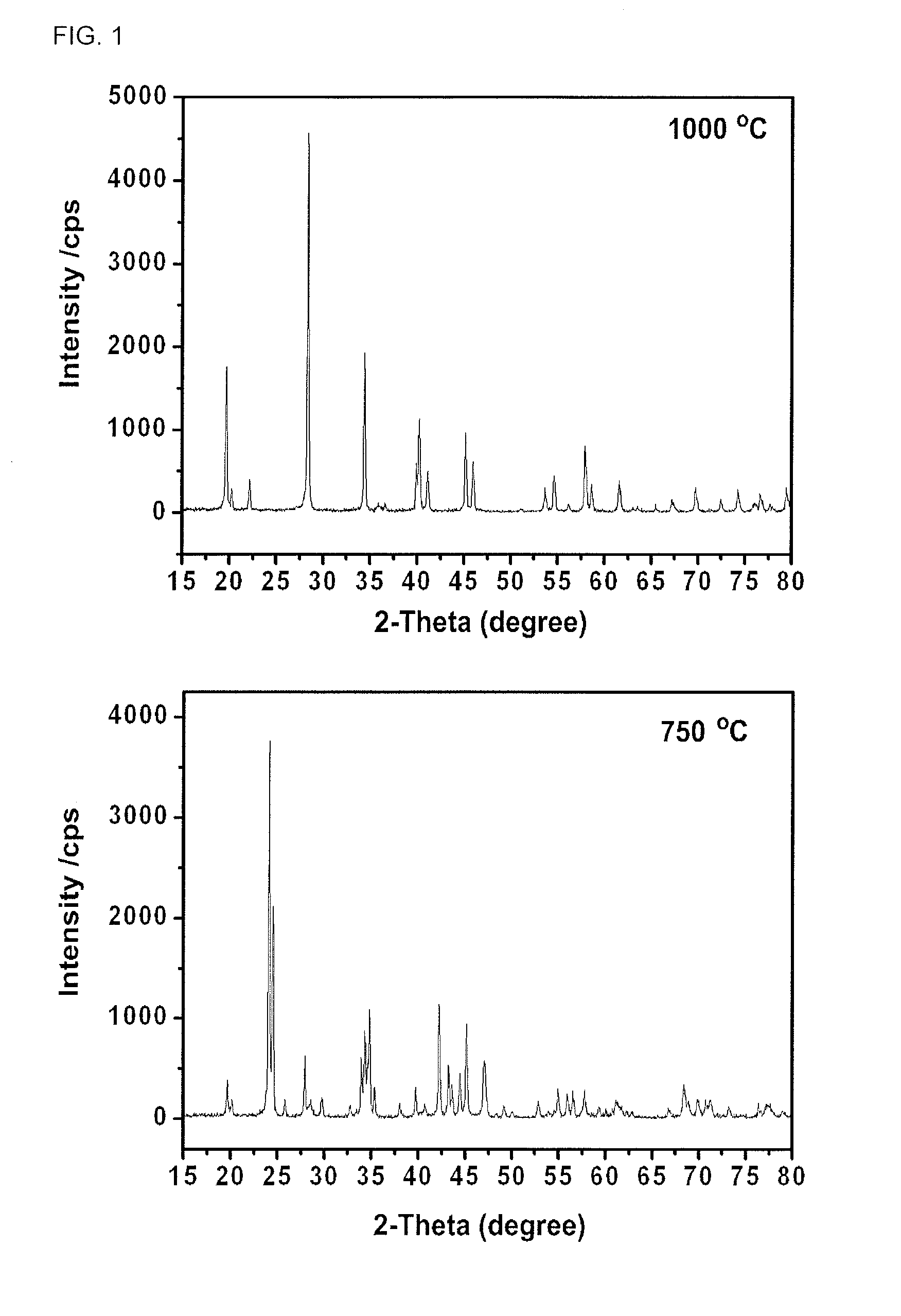

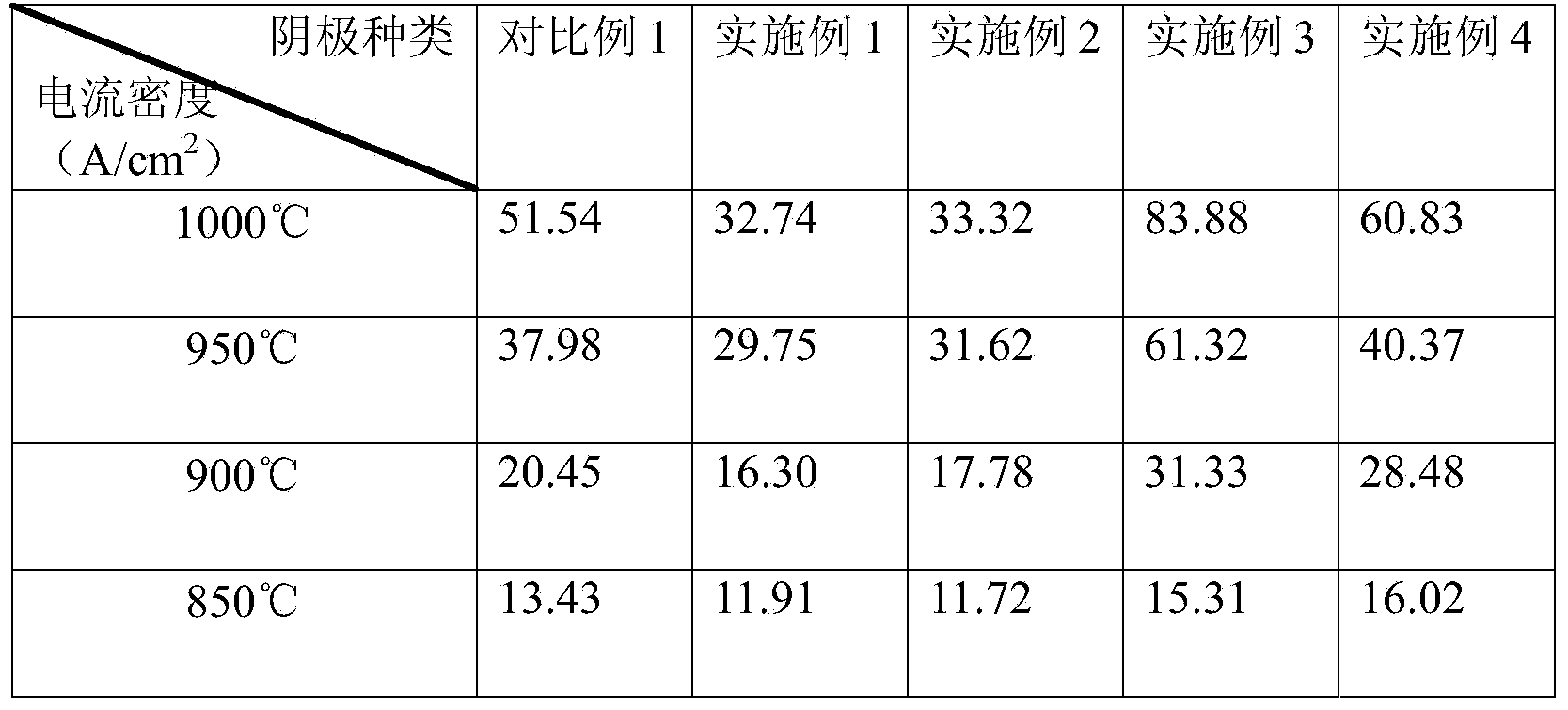

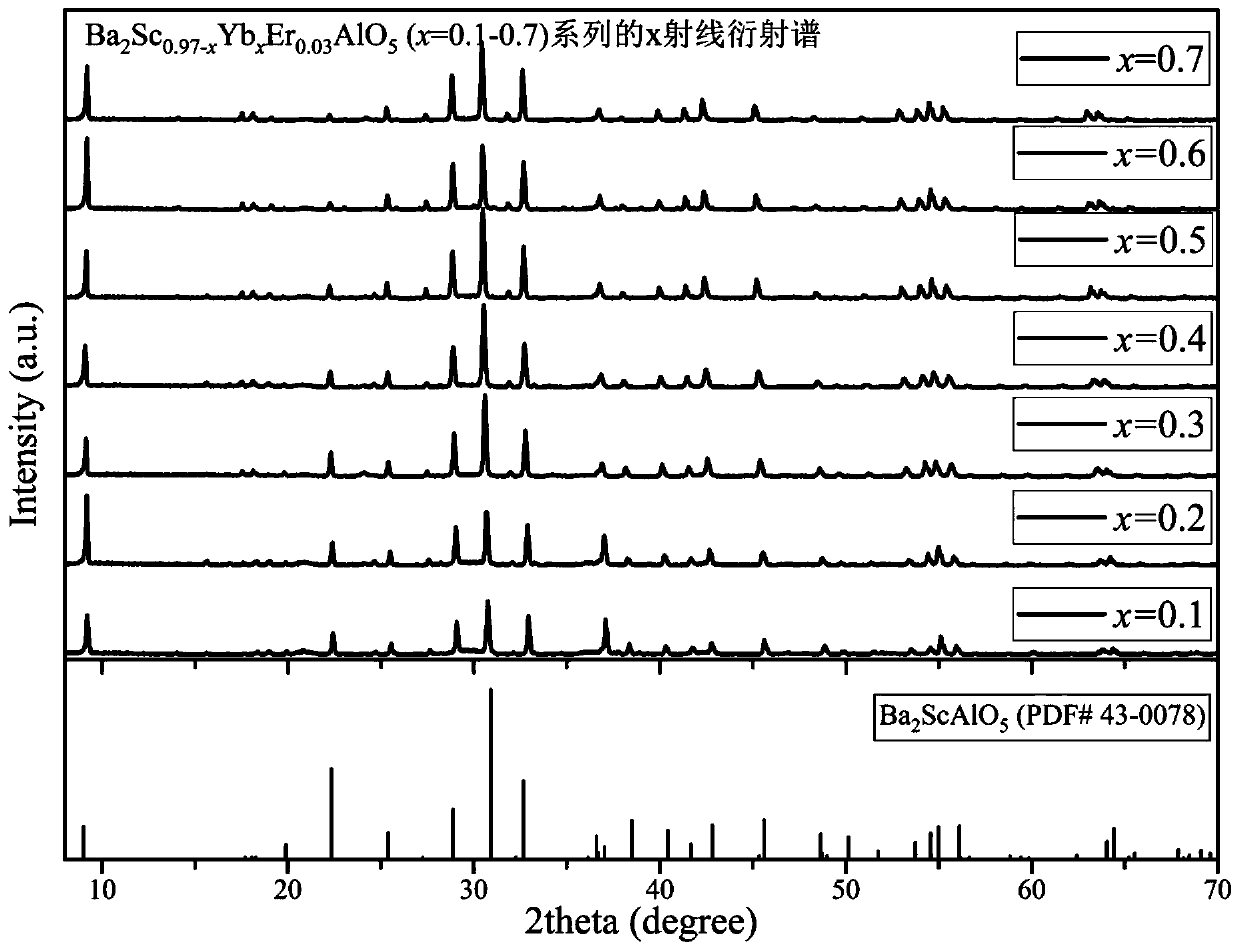

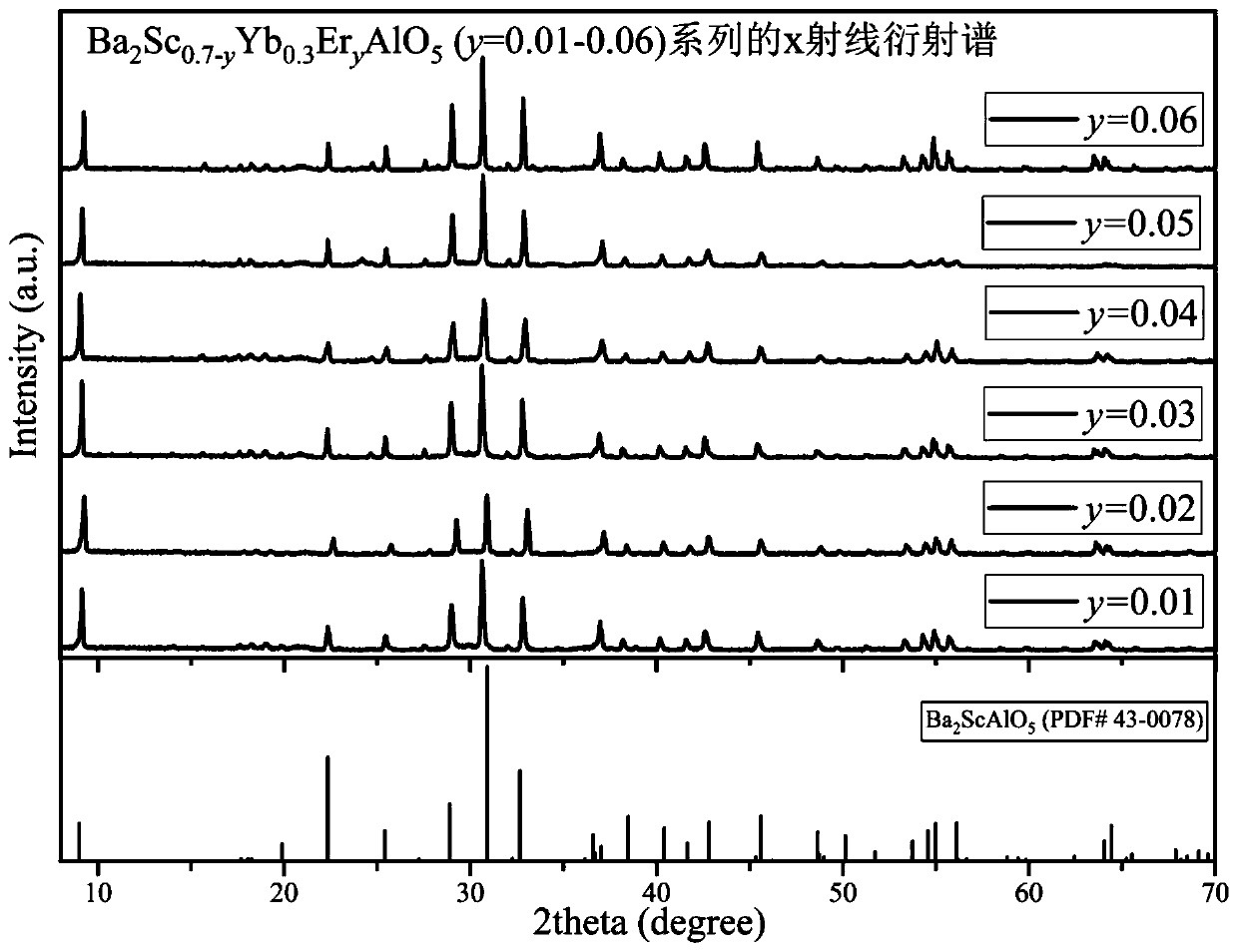

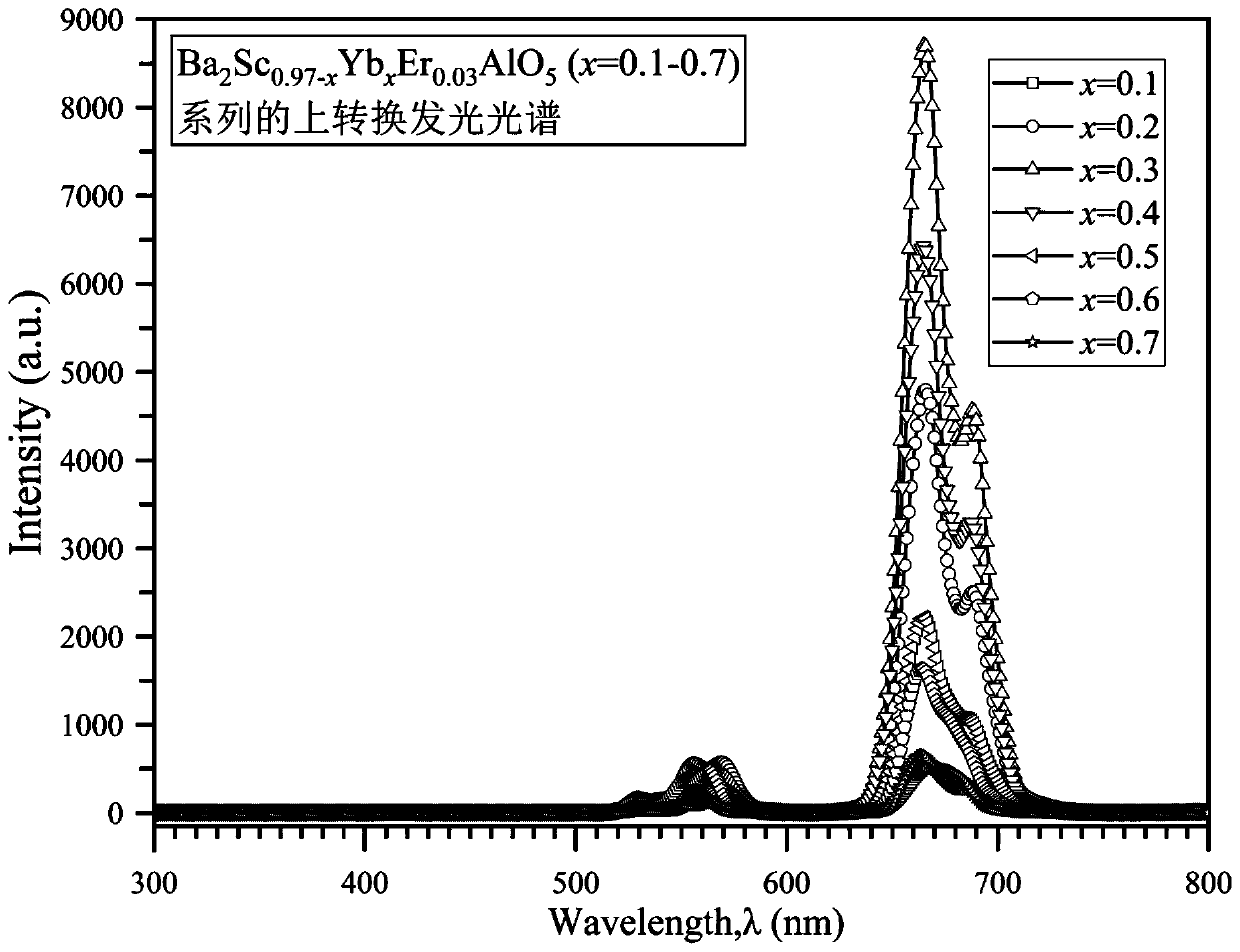

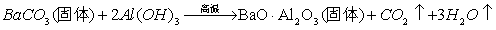

Rare earth doped scandium barium aluminate up-conversion luminescent material and preparation method thereof

ActiveCN110885684AGood repeatabilityImprove luminosityChemical industryLuminescent compositionsYTTERBIUM OXIDEAluminium hydroxide

The invention discloses a rare earth doped scandium barium aluminate up-conversion luminescent material and a preparation method thereof, and belongs to the technical field of luminescent materials. The up-conversion luminescent material provided by the invention has the structural formula of Ba2Sc(1-x-y)YbxEryAlO5, wherein x is equal to 0.1 to 0.6, and y is equal to 0.01 to 0.07. The preparationmethod is a high-temperature solid-phase method, and comprises the steps: by taking barium carbonate, scandium oxide, ytterbium oxide, erbium oxide and aluminum hydroxide as raw materials, uniformly mixing the raw materials by using absolute ethyl alcohol, drying, pressing into pieces, and carrying out high-temperature solid-phase sintering in a hydrogen furnace at the temperature of 1500 DEG C-1700 DEG C. The prepared rare earth doped scandium barium aluminate up-conversion luminescent material has excellent luminescent property, the highest relative luminescent intensity can reach 8701.14, the corresponding red light wavelength is 665 nm, and the luminescent intensity can be regulated and controlled by adjusting the proportion of doped rare earth. Meanwhile, the preparation method is good in repeatability, high in yield, simple and feasible in preparation process, more energy-saving and environment-friendly in preparation process and suitable for industrial popularization.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Exhaust gas sulphur removal agent

InactiveCN105854511AReduce consumptionEasy to recycleDispersed particle separationSilicon compoundsCelluloseBarium aluminate

The invention relates to the technical field of fuel combustion exhaust gas purification, in particular to an exhaust gas sulphur removal agent. The exhaust gas sulphur removal agent comprises, by mass, 3.8-8.8 parts of N, N-lupetazin, 10-18 parts of silica micro powder, 6-12 parts of carboxyl methyl cellulose, 3.8-5.8 parts of barium aluminate, 0.8-2.4 parts of sulphur-removal synergist, 0.8-2.4 parts of sodium dodecylsulphate and 50-60 parts of water, wherein the pH value of the exhaust gas sulphur removal agent ranges from 5 to 7. By means of the exhaust gas sulphur removal agent, sulfur dioxide can be efficiently adsorbed and removed, in addition, after being desorbed, sulfur dioxide can be regenerated and reutilized, consumption of adsorbent is greatly reduced, and at the same time, through the penetrating adsorption-desorption process of the adsorbent, industrial sulfur dioxide can be recycled conveniently.

Owner:NANJING HUADIAN ENERGY SAVING & ENVIRONMENTAL PROTECTION EQUIP

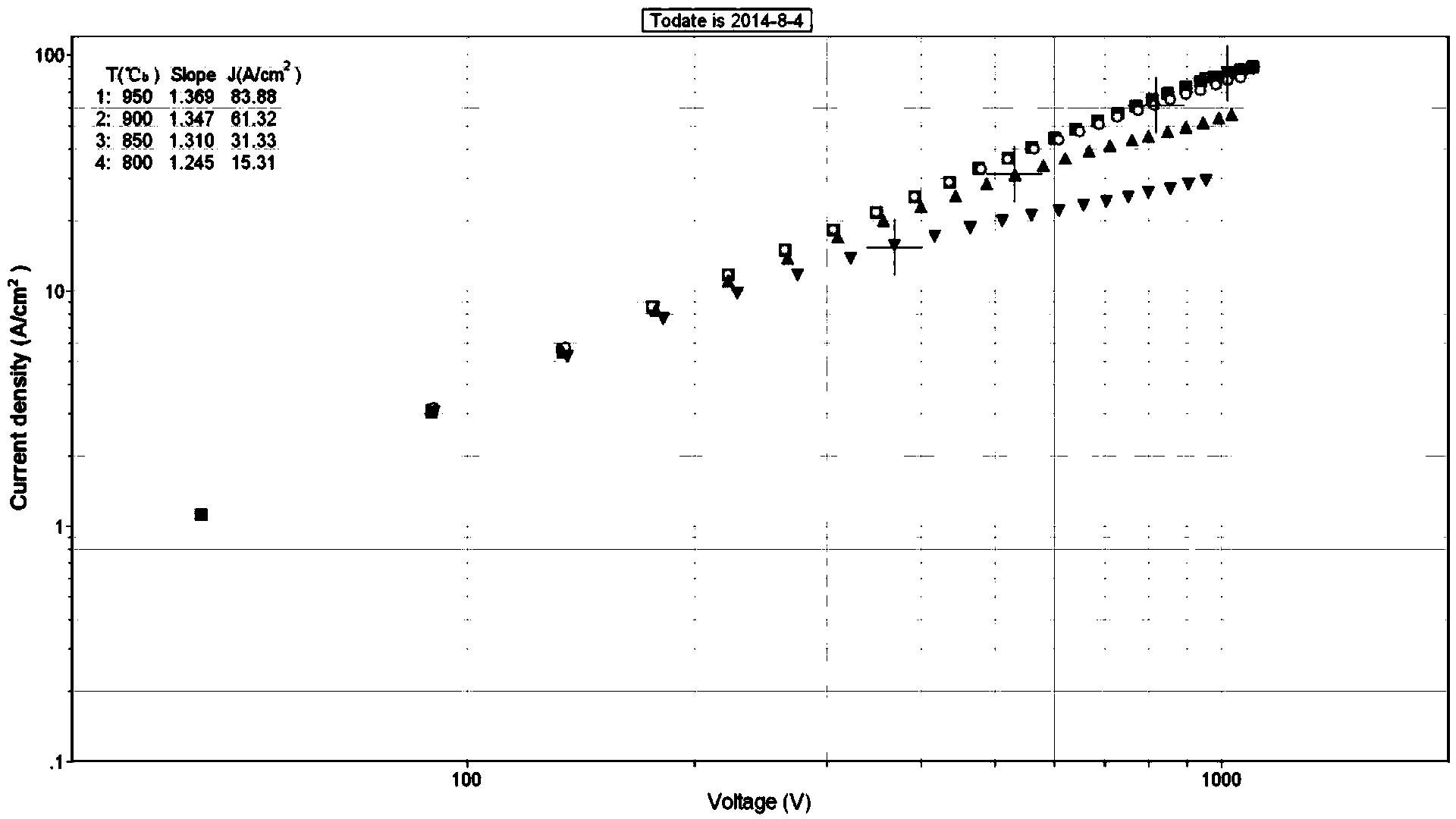

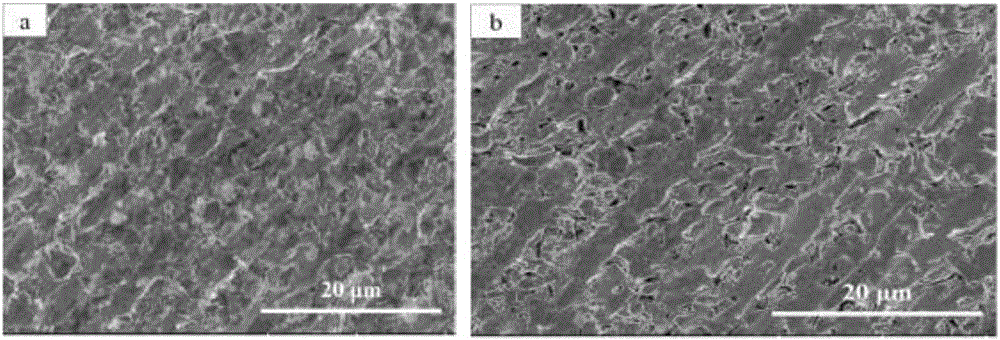

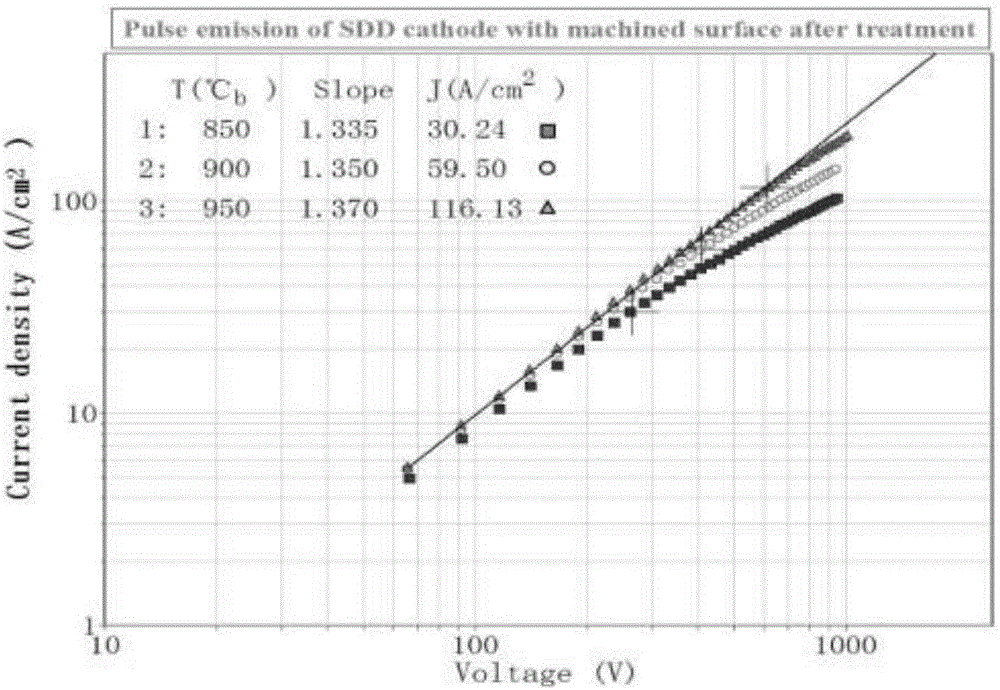

Preparation method of scandia-doped dispenser cathode material with turned surface

ActiveCN105810531AGood surface morphologyThermionic cathode manufactureCold cathode manufactureHydrogen atmosphereSurface cleaning

The invention provides a preparation method of a scandia-doped dispenser cathode material with a turned surface, and belongs to the field of rare-earth refractory metal cathode materials. Cathode matrixes are dipped with a cathode emission active salt, are turned and are subjected to surface cleaning; the cathode matrixes are Sc2O3 and W; the Sc2O3 accounts for 1wt%-10wt% of the total weight of a cathode and the rest is W; and the dipping cathode emission active salt is calcium barium aluminate. The method comprises the following steps: firstly, turning the cathode dipped with the cathode emission active salt into the cathode with the specified dimension, then putting the cathode into an acid solution with the concentration of 0.5wt%-10wt% and keeping the cathode for 10-60 seconds; cleaning the cathode with deionized water and absolute ethyl alcohol respectively; and finally heating the cathode in a hydrogen atmosphere to 830-860 DEG C, carrying out heat preservation for 20-30 minutes and then cooling the cathode. The current density of the cathode subjected to secondary treatment in a pulse voltage test can reach 116A / cm<2> at 950 DEG C.

Owner:BEIJING UNIV OF TECH

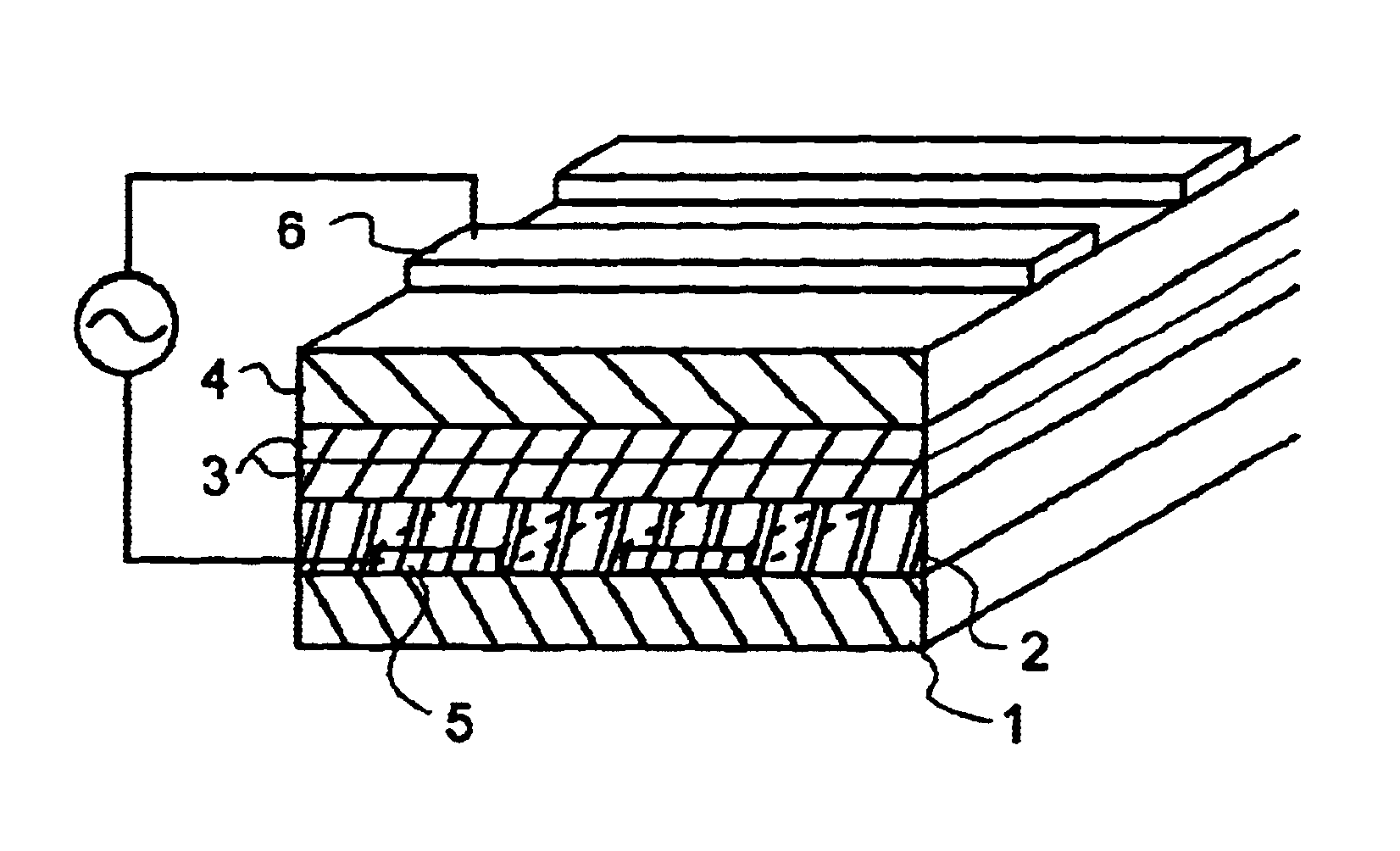

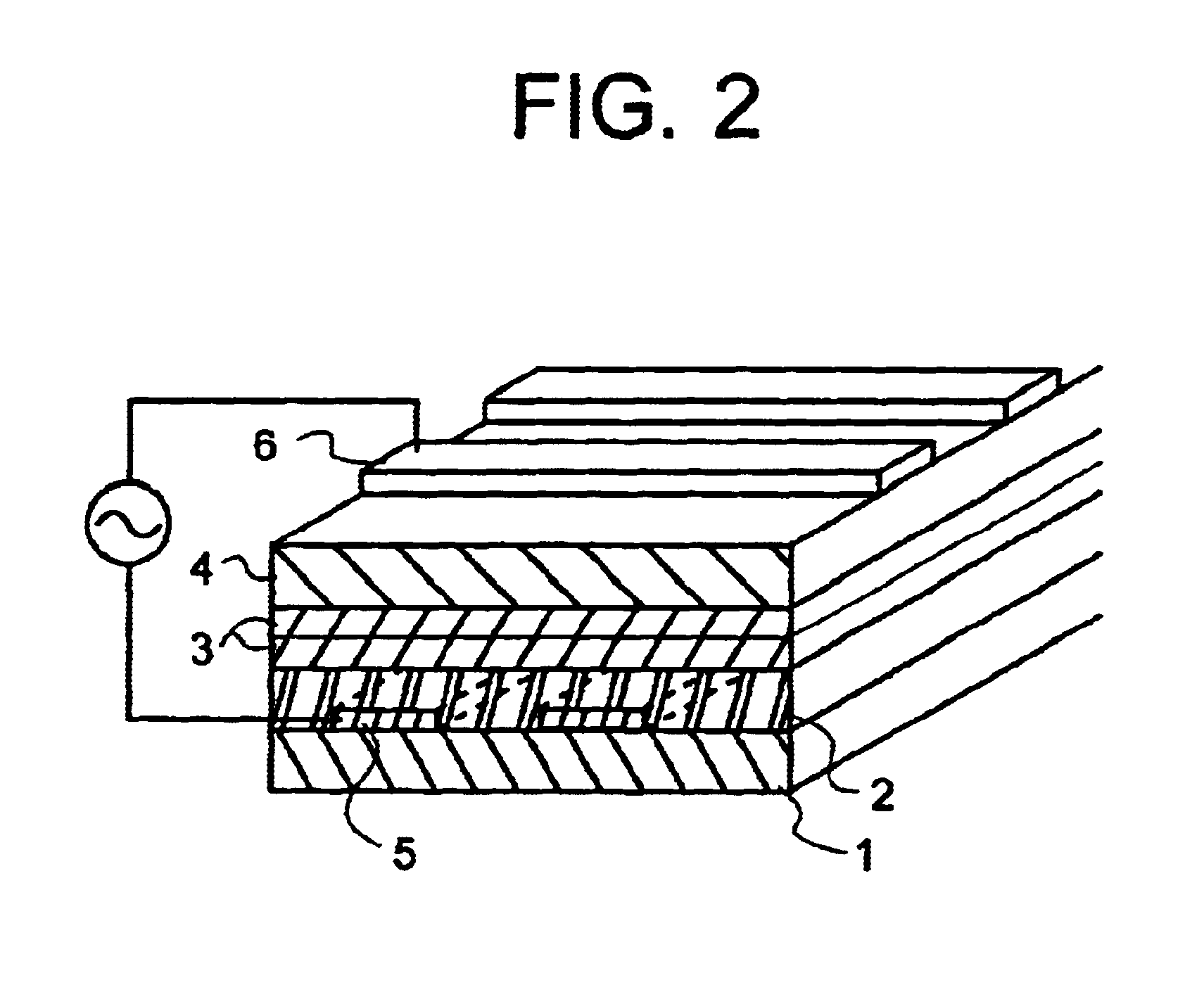

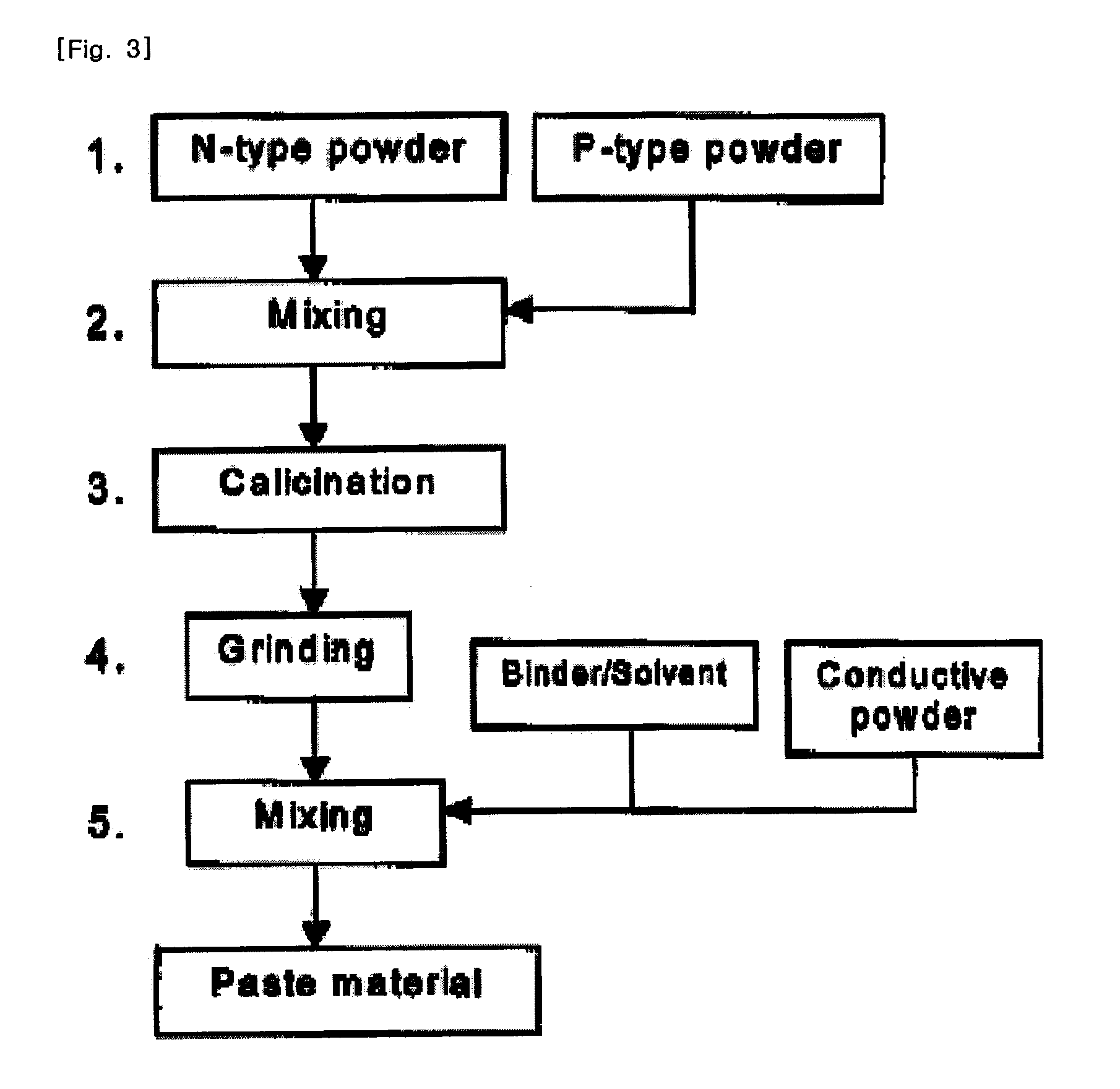

Phosphor multilayer and EL panel

InactiveUS6761835B2Discharge tube luminescnet screensElectroluminescent light sourcesBarium aluminatePhosphor

The invention aims to provide a phosphor multilayer eliminating a need for filters, having a satisfactory color purity and useful in white monochromatic EL devices, and an EL panel. Such objects are achieved by a phosphor multilayer comprising at least a first thin film and a second thin film wherein the first thin film is formed of a matrix material comprising barium aluminate as a main component, containing sulfur element and further containing Eu as a luminescent center, and the second thin film is formed of a matrix material comprising zinc sulfide as a main component, and an EL panel using the same.

Owner:IFIRE IP CORP

Preparation method of high-strength nanoscale building material

The invention discloses a preparation method of a high-strength nanoscale building material. The building material contains the following components according to the weight formula: 20-30 parts of barium aluminate cement, 20-40 parts of nano-silicon nitride, 14-30 parts of carbon fiber powder, 30-45 parts of an ethyl silicate solution, 40-50 parts of an ethanol water solution, 3-10 parts of a dispersing agent, 10-18 parts of nano-kaolinite and 15-20 parts of nano-silica sol. The building material provided by the invention has a relatively high bonding effect, compressive strength and shock strength, so that the problems that a traditional building material is easily cracked and hollowed are effectively solved.

Owner:SHAOXING UNIVERSITY

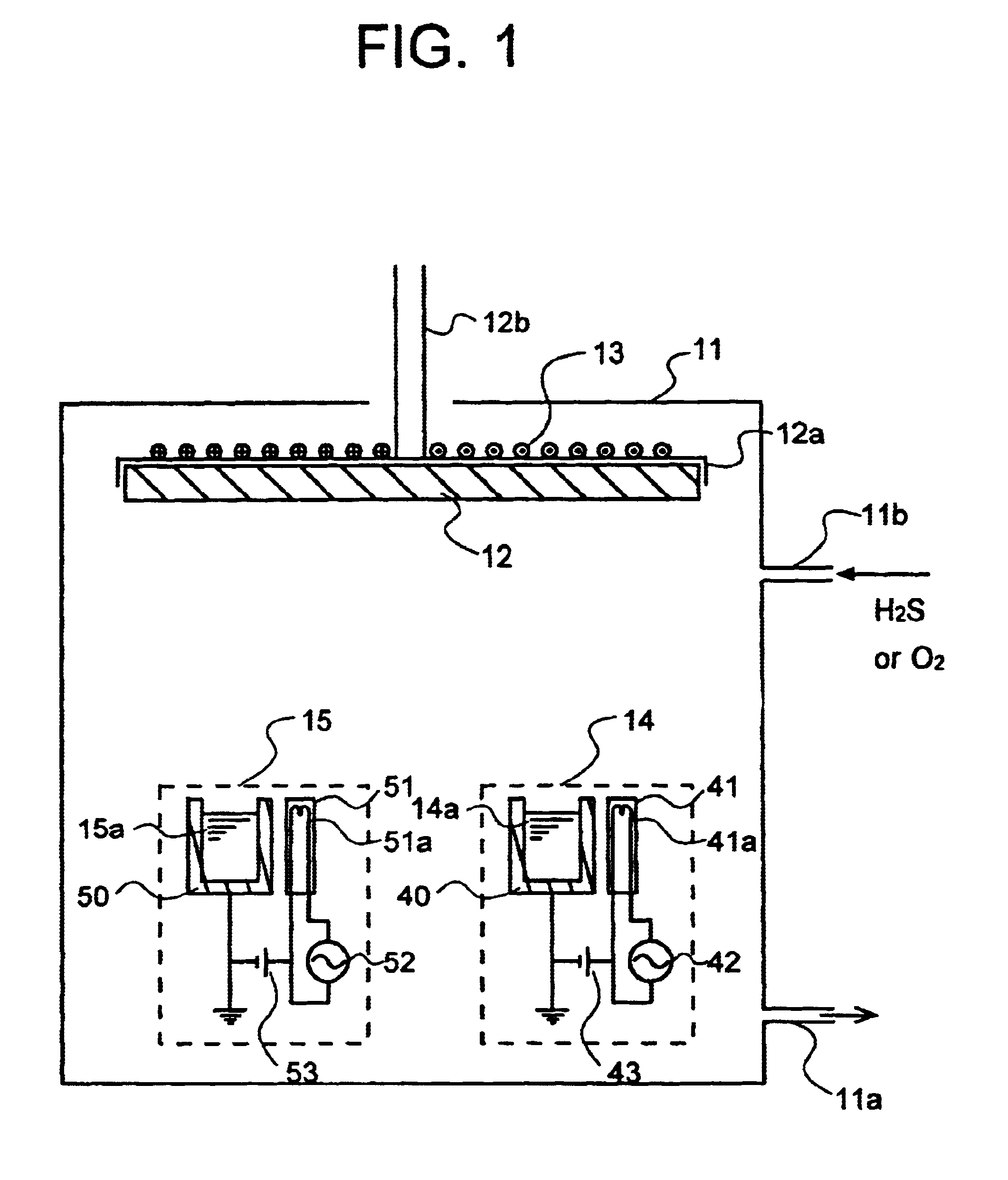

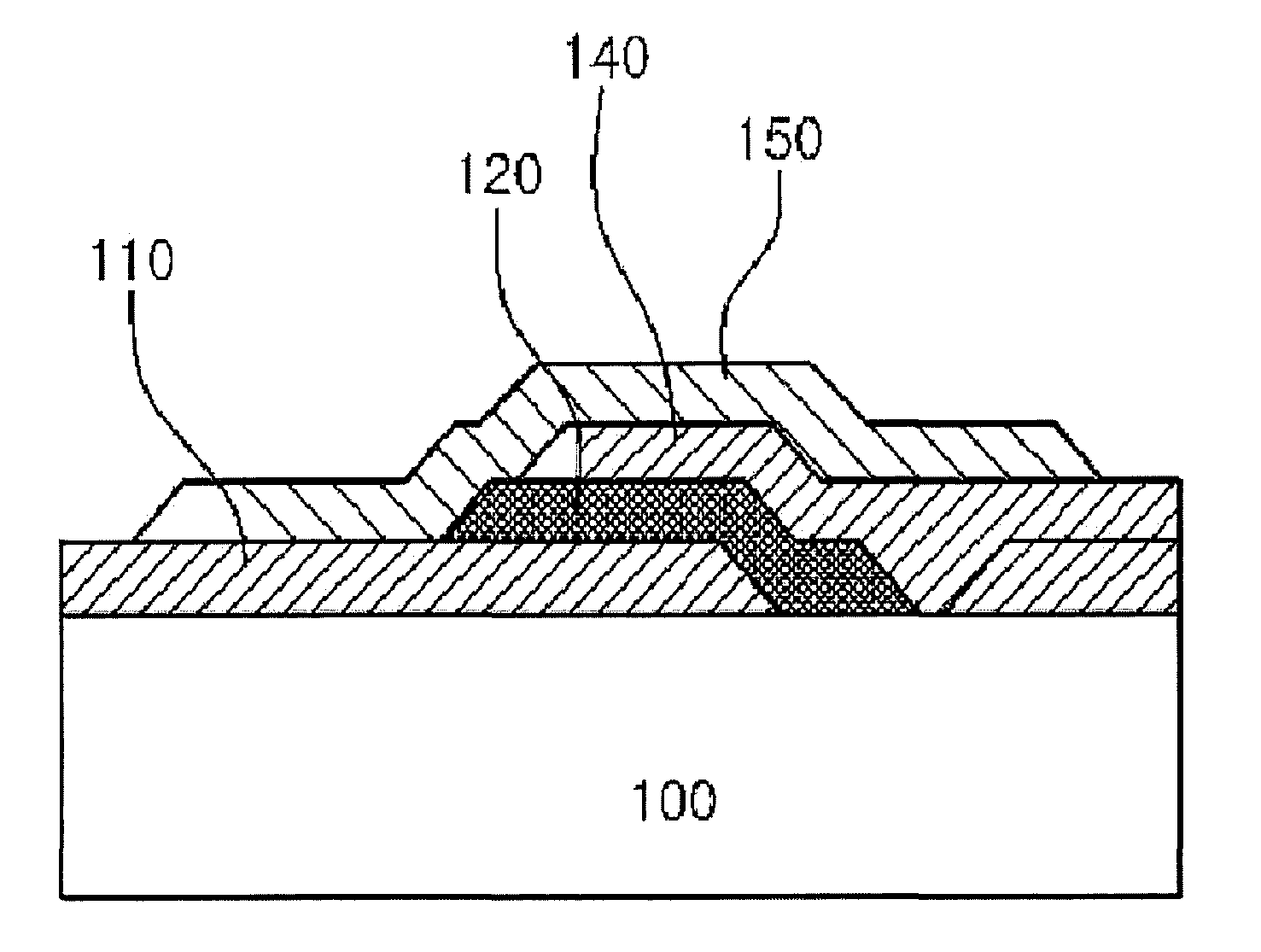

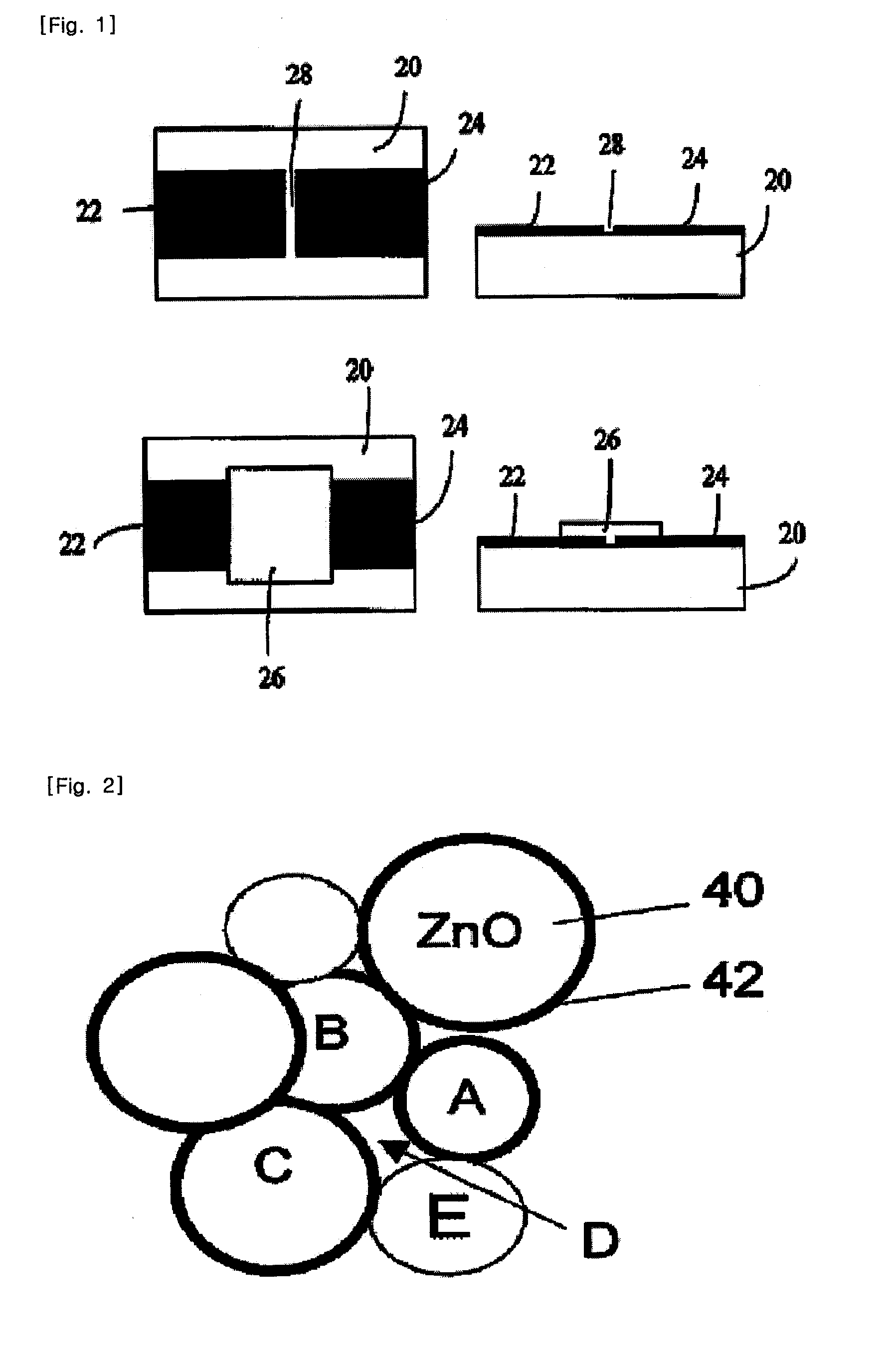

ESD protective device having low capacitance and stability and a preparing process thereof

InactiveUS20110032649A1Reduce capacitanceLow stability characteristicSemiconductor/solid-state device detailsSolid-state devicesSignal waveCapacitance

An ESD protective device having a low capacitance and stability characteristics constructed by installing a voltage sensitive material between electrodes. The voltage sensitive material comprises a fluorescent substance. The voltage sensitive material may be barium aluminate. The voltage sensitive material may be zinc silicate. The voltage sensitive material may be zinc sulfide. The voltage sensitive material is doped with a metal atom such as Mn, Cu and Eu. The device does not distort a signal wave pattern and have low capacitance of 0.5 pF or lower.

Owner:LATTRON

Recycling method for barium salt of desulphurization slag produced in wet method desulphurization of barer process

InactiveCN102838150AReduce dosageHigh activitySolid waste disposalAlkaline-earth metal aluminates/aluminium-oxide/aluminium-hydroxide preparationBarium aluminateSulfur

The invention discloses a recycling method for barium salt desulphurization slag produced in wet method desulphurization of barer process. Barium aluminate desulfurizer is obtained by mixing aluminium-containing materials with the barium salt desulphurization slag, and roasting at a temperature of 1000-1700 DEG C. the obtained barium aluminate desulfurizer is used in the wet method desulphurization of barer process for recycle. The recovery and recycle of the barium salt desulphurization slag greatly reduce the raw material consumption in the production of desulfurizer by using original method, and the desulphurization cost is substantially decreased. The barium aluminate desulfurizer prepared by the method of the invention has a bulk density of about 1.5g / cm3, a volume average particle diameter of about 89.808 [mu]m, and purity of more than 95%; and has a desulfurization rate of 69-85% in a spent liquor, and a desulfurization rate of 70-95% in a causticized liquor, with high purity and activity, and good dispersibility and desulphurization effect; and establishes a more favorable economic foundation for industrial applications of high-sulfur bauxite, and enables the high-sulfur bauxite to be an available resource with good technical and economic benefits.

Owner:GUIYANG AL-MG DESIGN & RES INST

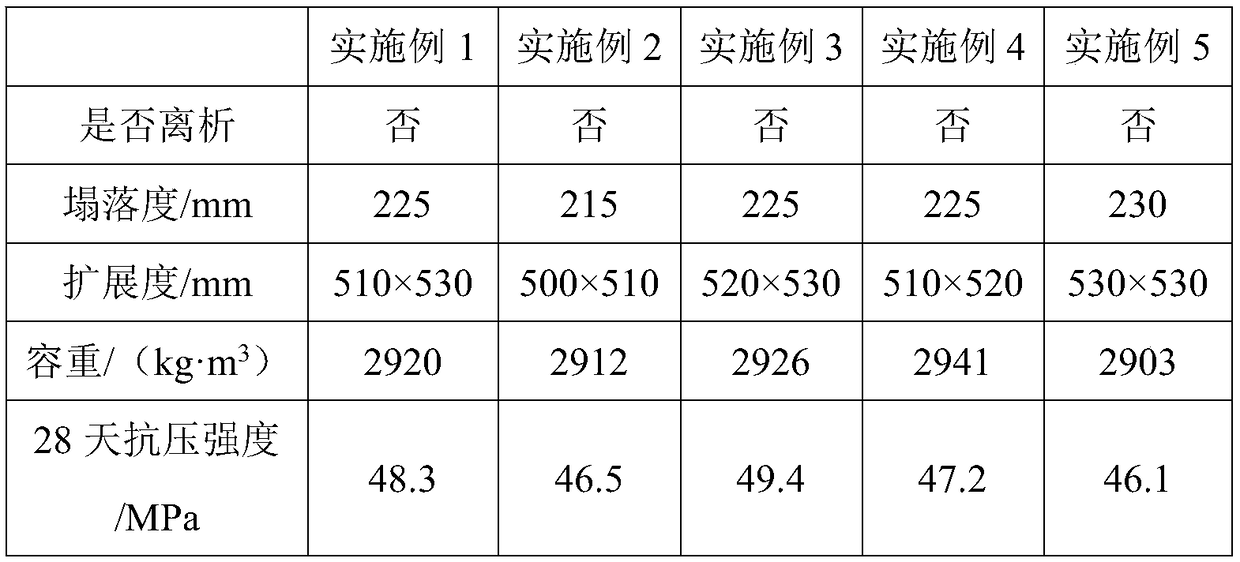

Barium aluminate cement-based radiation shielding concrete and preparation method thereof

InactiveCN109231932AReduce the chance of segregationImprove homogeneityBarium aluminateUltimate tensile strength

The invention belongs to the field of concrete, and particularly discloses barium aluminate cement-based radiation shielding concrete and a preparation method thereof. The concrete is prepared from the following materials in parts by weight: 300 to 350 parts of cement, 900 to 1200 parts of fine aggregate, 1200 to 1500 parts of coarse aggregate, 10 to 20 parts of neutron absorbent, 0.4 to 0.6 partof a water reduction agent, and 140 to 160 parts of water. The prepared barium aluminate cement-based radiation shielding concrete has the characteristics that the strength requirement of C40 concreteis met, the segregation is avoided, the collapsing degree and extendibility are good, the volume weight is 2900 to 2950kg.m<3>, and the volume weight requirements of the radiation shielding concreteare met; the working property is excellent, the anti-radiation property is good, the cost is low, the fire-refractory property is realized, and the like; the problems of easiness in segregation, poorhomogenizing property, poor construction property and the like in the traditional radiation shielding concrete, and the problem of application difficulty in fire-resistant environments are solved.

Owner:成都宏基建材股份有限公司

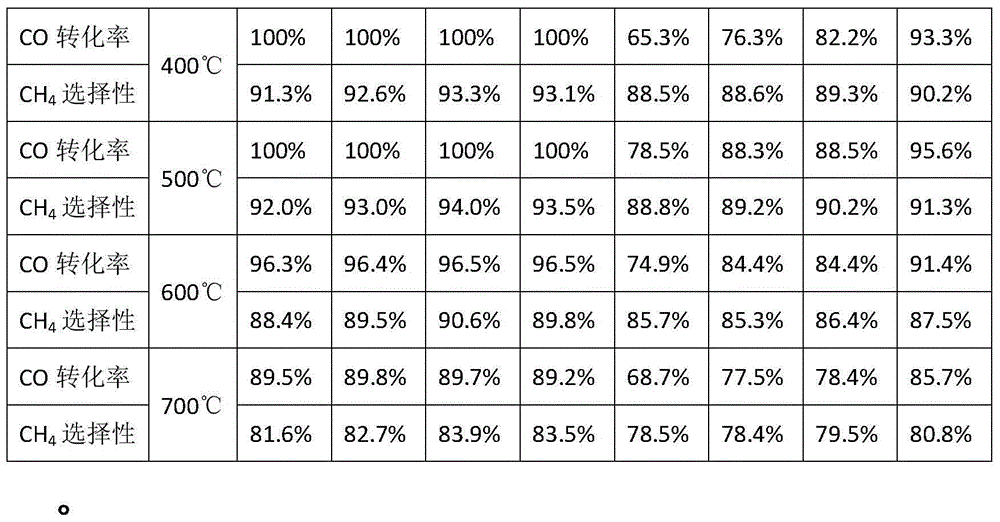

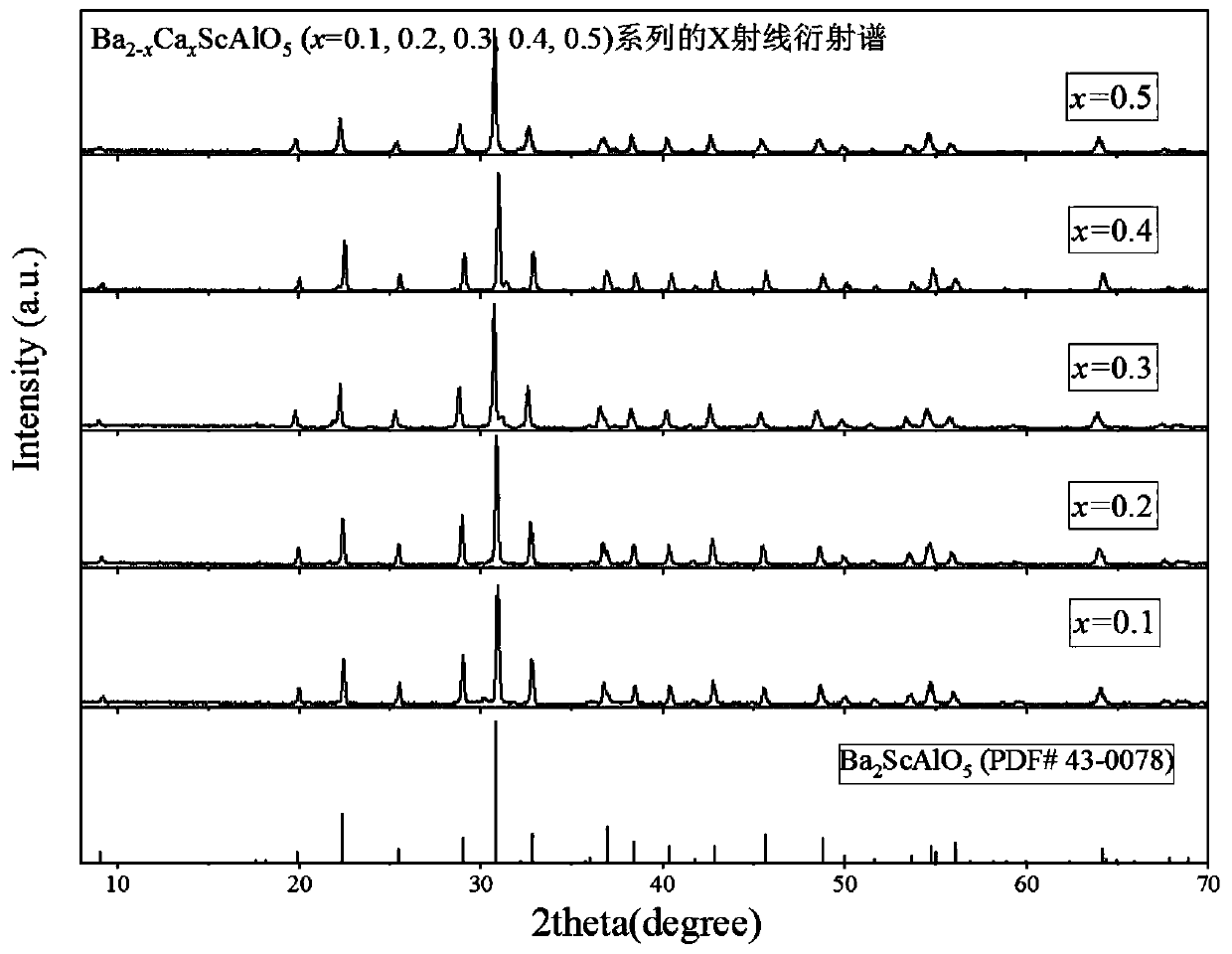

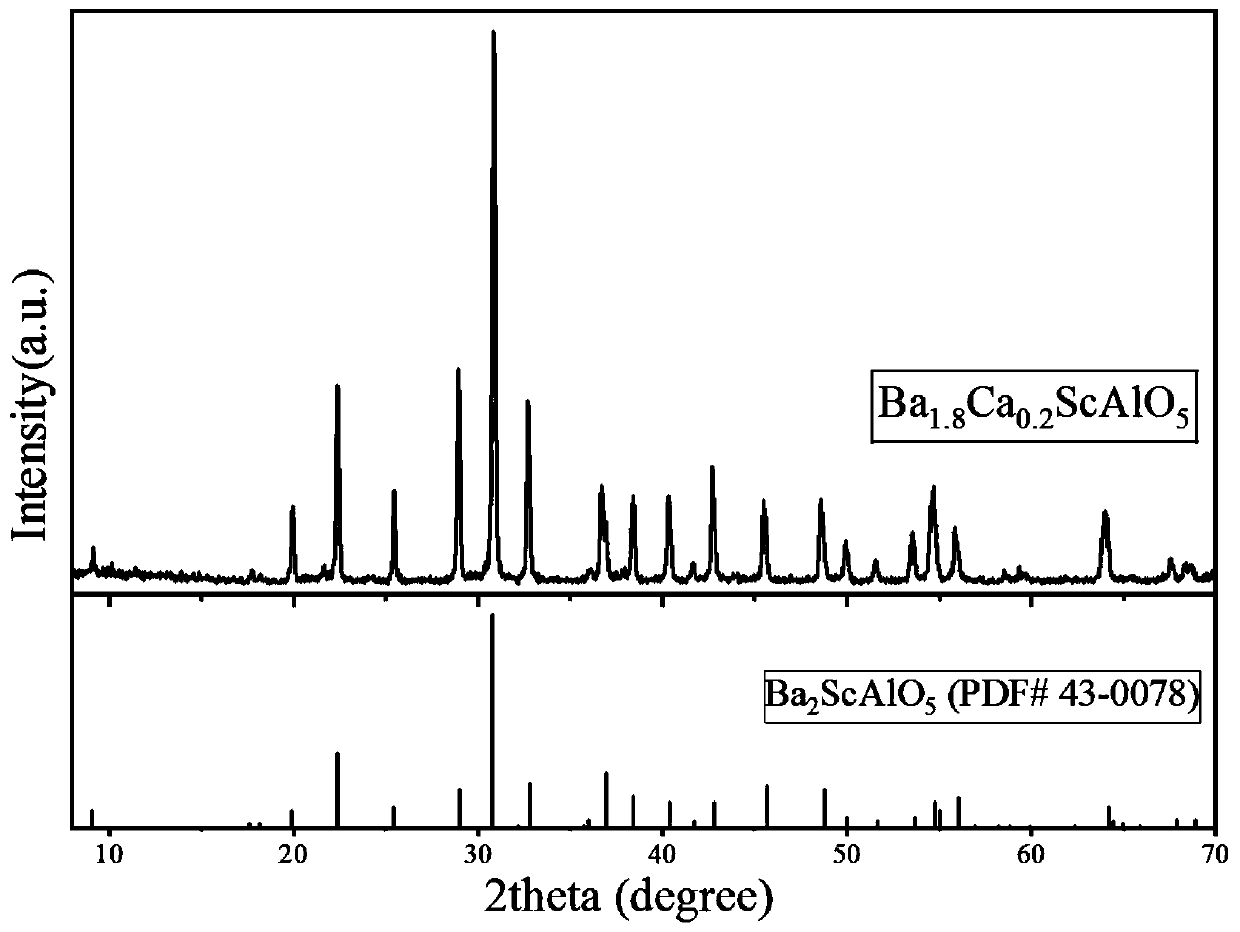

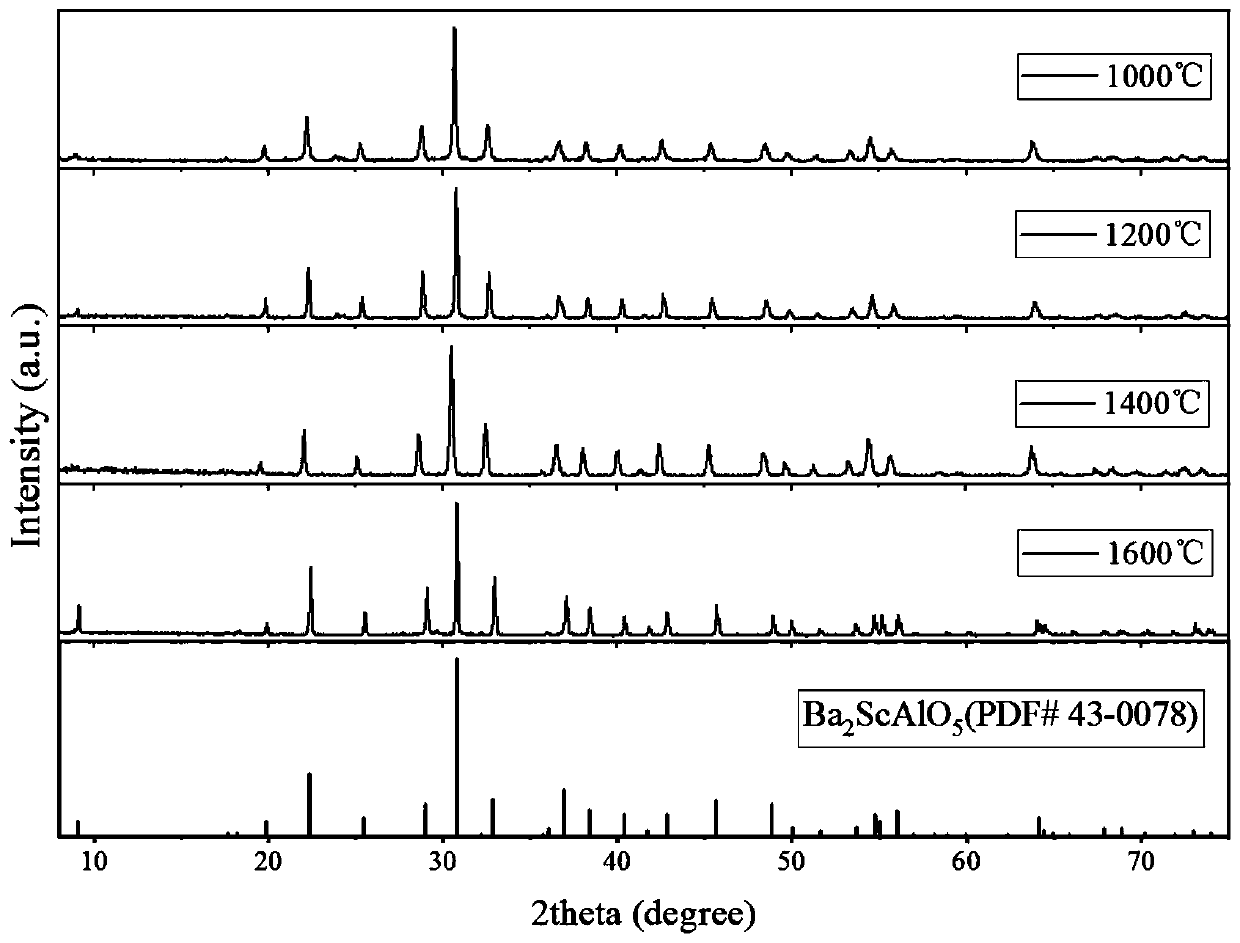

Calcium-containing barium scandium aluminate for impregnated diffusion cathode and preparation method thereof

ActiveCN111269012AAchieve low temperature and high current density characteristicsGood repeatabilityDischarge tube/lamp detailsRare earth metal compoundsBarium aluminateBarium salt

The invention discloses calcium-containing barium scandium aluminate for dipping a diffusion cathode and a preparation method thereof, and belongs to the field of manufacturing of vacuum electronic devices. The structural formula of the calcium-containing barium scandium aluminate is Ba<2-x>Ca<x>Sc<Al>O<5>, wherein x is greater than or equal to 0.1 and less than or equal to 0.5. The preparation method is a liquid-phase coprecipitation method and comprises the following steps: dissolving water-soluble barium salt, calcium salt, scandium salt and aluminum salt in deionized water, mixing and stirring the solution with an ammonium carbonate solution, filtering and cleaning the solution to obtain a precursor, tabletting the precursor, and sintering the precursor in a muffle furnace at 1000-1600DEG C for 4-5 hours to obtain calcium-containing barium scandium aluminate. The prepared calcium-containing barium scandium aluminate has a single Ba2ScAlO5 close-packed hexagonal crystal structure,a cathode impregnated with the active substance can provide direct-current emission current density close to 11.51 A / cm2 at 1000 DEG C, and the low-temperature high-current density characteristic of an impregnated diffusion cathode is achieved. The preparation method of the calcium-containing barium scandium aluminate is good in repeatability, high in yield, simple in preparation process and suitable for industrial popularization.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Corundum-mullite castable for zinc oxide rotary kiln and preparation method of corundum-mullite castable

ActiveCN113999027AEnvironmentally friendlyLow thermal conductivityProcess efficiency improvementSilicon oxideWater reducer

The invention relates to a corundum-mullite castable for a zinc oxide rotary kiln and a preparation method of the corundum-mullite castable. According to the technical scheme, the preparation method comprises the following steps: firstly, taking 40 to 60 weight percent of porous corundum-barium aluminate particles, 10 to 20 weight percent of mullite particles, 5 to 15 weight percent of zirconium mullite fine powder, 5 to 15 weight percent of white corundum fine powder, 5 to 15 weight percent of sillimanite fine powder, 5 to 10 weight percent of silicon oxide micro powder, 1 to 5 weight percent of samarium oxide fine powder, 1 to 5 weight percent of barium sulfate fine powder, 1 to 5 weight percent of sialon fine powder and 1 to 2 weight percent of titanium silicon carbide fine powder as raw materials; and adding 0.02-0.08 wt% of a water reducing agent, 1-4wt% of calcium aluminate cement and 7-15wt% of water into the raw materials, uniformly stirring, and carrying out vibration molding, thereby obtaining the corundum-mullite castable for the zinc oxide rotary kiln. The corundum-mullite castable for the zinc oxide rotary kiln prepared by the invention has the characteristics of environmental friendliness, low heat conductivity coefficient, good wear resistance, high thermal shock resistance and excellent erosion resistance.

Owner:湖南立达高新材料有限公司

Method for preparing alumina through bauxite containing sulphur

InactiveCN102718237AMeet the requirements of whiteness indexSimple processAluminium oxides/hydroxidesBarium aluminateIron removal

The invention discloses a method for preparing alumina through bauxite containing sulphur, and relates to a method adopting a normal Bayer process for processing high-sulphur bauxite to prepare alumina. The preparation process adopts the Bayer process. The method is characterized in that barium aluminate is added in the preparation process. The method provided by the invention adopts the normal Bayer process for processing the high-sulphur bauxite to prepare the white alumina. Slurry containing sulphur is obtained by pulverizing, dissolving out and diluting the high-sulphur bauxite. The while alumina which satisfies the index requirement of the white degree of metallurgical-grade alumina is obtained by adding 0.01 to 1 percent by weight of the barium aluminate for removing sulphur and iron removal and decolorizing processing through decomposition and calcinations. The method has a simple technical flow and a low production cost.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

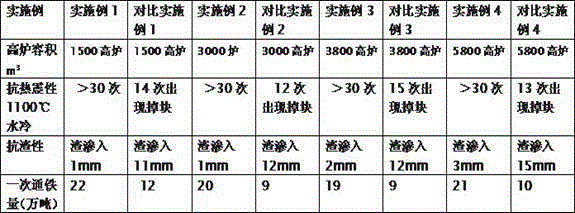

Castable

InactiveCN105330311AImprove corrosion resistanceImprove thermal shock resistanceCobaltMolybdenum trioxide

The invention relates to castable. The castable is prepared from a main material and additives. The main material is prepared from, by weight, 5-8 parts of 8-5 mm barium aluminate, 15-20 parts of 5-3 mm chromium mononitride, 10-15 parts of 3-1 mm sillimanite, 8-15 parts of 1-0 mm calcium chromite, 2-5 parts of clay-like powder, 3-7 parts of cobalt aluminum oxide powder, 5-10 parts of cutting powder, 3-8 parts of amorphous graphite, 1-2 parts of composite powdered carbon, 0-3 parts of molybdenum trioxide powder, 3-5 parts of alumina micro powder, 1-5 parts of magnesium oxide iron powder, 1-3 parts of rho aluminum oxide and 0-5 parts of electric-smelted pure calcium aluminate cement. With the main material accounting for 100% by weight in total, the additives are prepared from, by weight, 0.1-0.2 part of calcium lignosulfonate, 0.01-0.05 part of nanometer dried potato powder, 0.01 part of malic acid and 0.01 part of C12H14N4O5S2. A blast furnace iron runner made of the castable has the advantages of being good in thermal shock resistance, high in corrosion resisting performance, large in iron exchanging amount and long in service life.

Owner:山国强

Iron trough castable

The invention relates to iron trough castable. The castable comprises a main material and additives, wherein the main material is prepared from, by weight, 5-8 parts of 5-8 mm barium aluminate, 15-20 parts of 3-5 mm barium aluminate, 10-15 parts of 1-3 mm andalusite, 8-15 parts of 0-1 mm calcium chromite, 2-5 parts of partical clay powder, 3-7 parts of cobalt-aluminum oxide powder, 5-10 parts of cutting powder, 3-8 parts of amorphous graphite powder, 1-2 parts of composite carbon powder, 0-3 parts of molybdenum trioxide powder, 3-5 parts of aluminum oxide micro powder, 1-5 parts of magnesium oxide powder, 1-3 parts of rho-aluminum oxide, and 0-5 parts of electric smelted pure calcium aluminate cement; based on the fact that the total weight part of the main material is 100%, the additives are prepared from, by weight, 0.1-0.2 part of calcium lignosulphonate, 0.01-0.05 part of nanometer potato powder,< 0.01 part of malic acid and 0.1 part of C<12>H<14>N<4>O<5>S<2>. A blast furnace iron trough prepared from the castable has the advantages of being good in thermal shock resistance, great in anti-erosion performance, large in iron exchanging amount and long in service life.

Owner:山国强

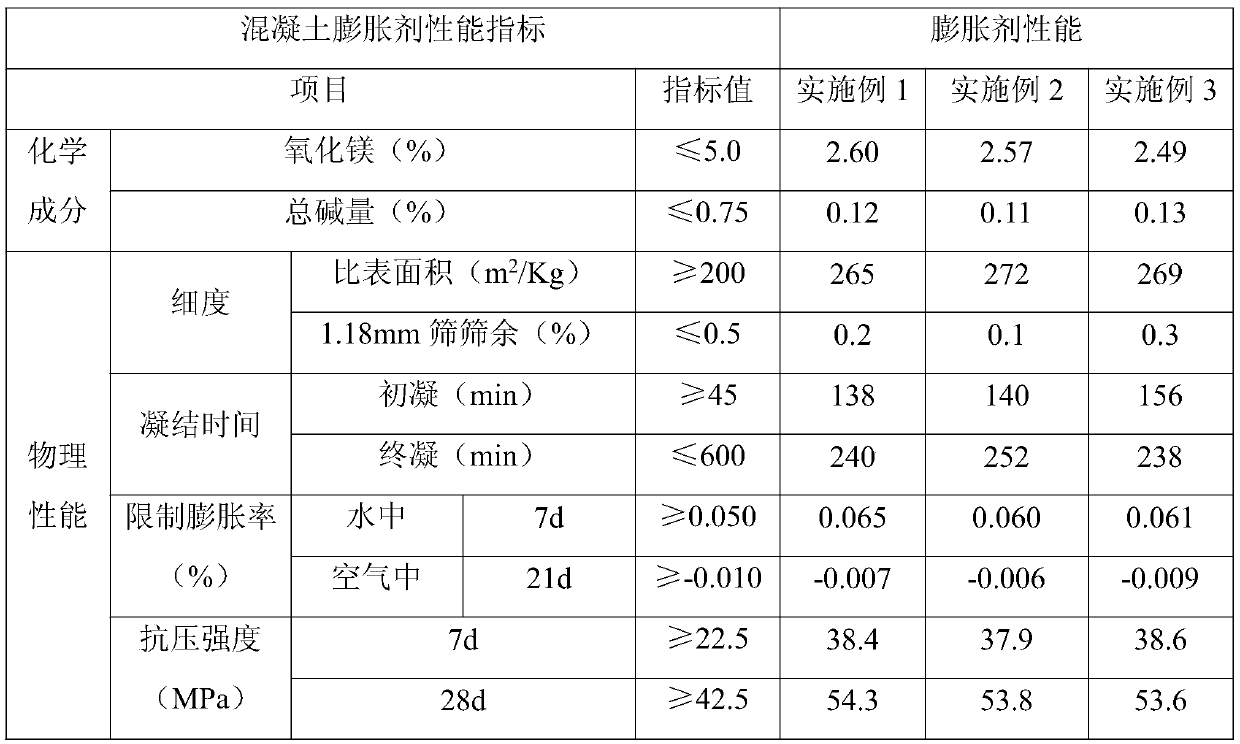

Barium aluminate concrete swelling agent and preparation method thereof

ActiveCN110451836AImprove compactnessFlexible adjustment of expansion timeAluminium sulfateSwelling capacity

The invention discloses a barium aluminate concrete swelling agent. The barium aluminate concrete swelling agent is prepared from, by weight, 50-60% of a barium aluminate clinker, 40-50% of anhydriteand anhydrous aluminum sulfate with the weight accounting for 0-5.0% of the total weight of the barium aluminate clinker and the anhydrite, wherein the barium aluminate clinker is formed by mixing, forming and calcining a raw material, soluble starch and water in sequence; the raw material is prepared by mixing and grinding barium carbonate and aluminum oxide in a weight ratio of 2:1. The preparation method comprises the following steps that the barium carbonate and the aluminum oxide are prepared into the raw material; the soluble starch and a proper amount of water are added to the raw material for uniform stirring, and then, the mixture is compressed, formed and dried; the dried mixture is calcined at the temperature of 1350+ / -50 DEG C, the temperature is maintained for 60-120 minutes,and then the barium aluminate clinker is obtained; the clinker is taken out and cooled to room temperature; the anhydrite, the anhydrous aluminum sulfate and the barium aluminate clinker are mixed andground, and then the swelling agent is prepared. The total swelling capacity of the swelling agent is high, the swelling time can be flexibly adjusted, along with the generation of a barium sulfate precipitate, the compactness of the concrete is increased, and the strength of the concrete is easily improved.

Owner:合肥净龙环保科技有限公司

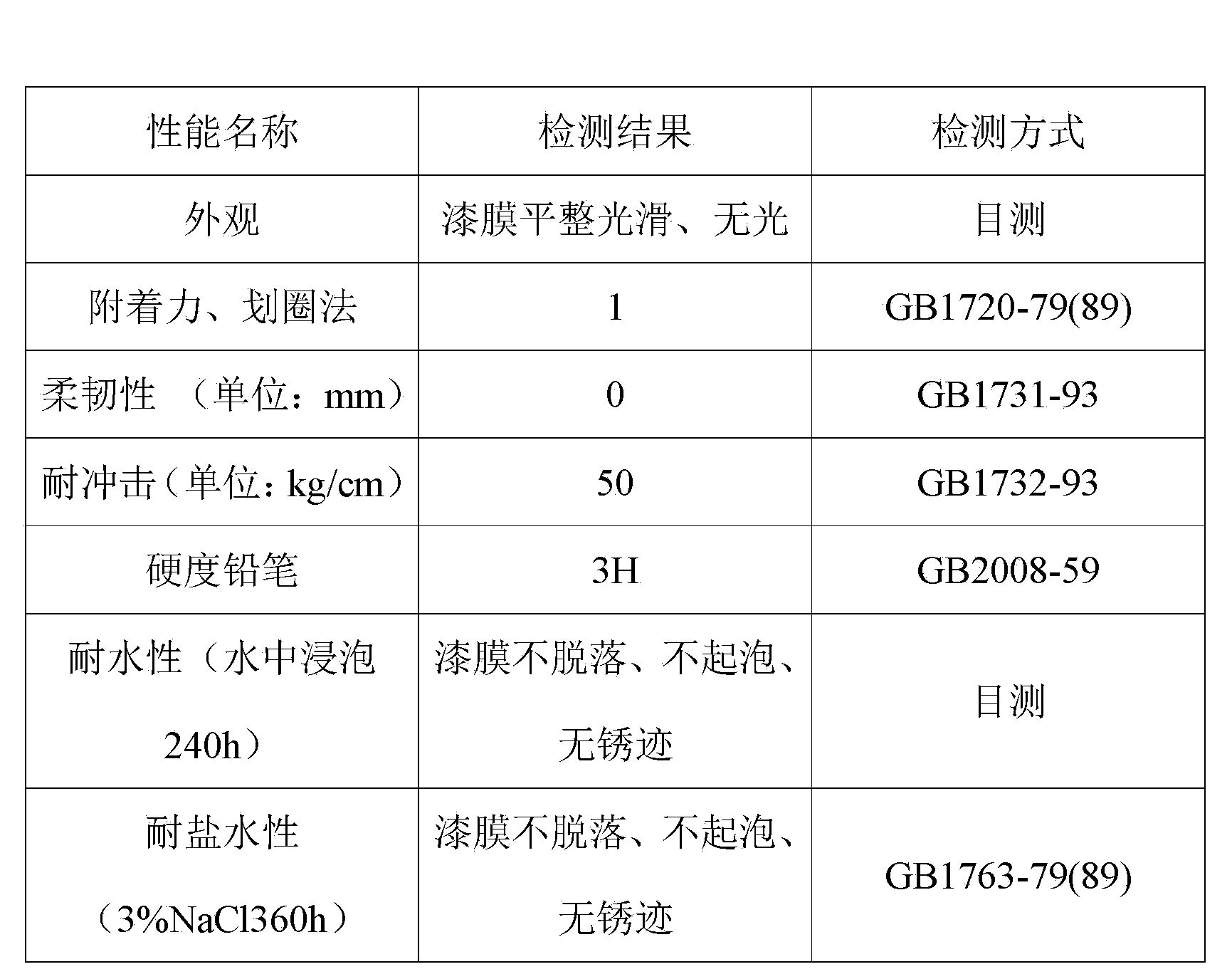

Two-component aqueous antirust quick-drying paint

ActiveCN103694804AImprove rust resistanceStrong adhesionAnti-corrosive paintsBarium aluminateMaterials science

A two-component aqueous antirust quick-drying paint is made by using new products composite barium aluminate and composite latex powder produced by Wuhan Shuolide Company as main materials. The paint has the advantages of strong adhesion, excellent water resistance, good brine resistance, antirust, and rapid drying in wet environment. Industrial antirust paints produced by using the two-component aqueous antirust quick-drying paint are further better than products of a same kind in China, and a film formed by the two-component aqueous antirust quick-drying paint has the characteristics of water resistance, rapid drying in the wet environment, and antirust, so the two-component aqueous antirust quick-drying paint has a very high cost performance because of the above comprehensive characteristics and the low cost.

Owner:永城青山环保科技有限公司

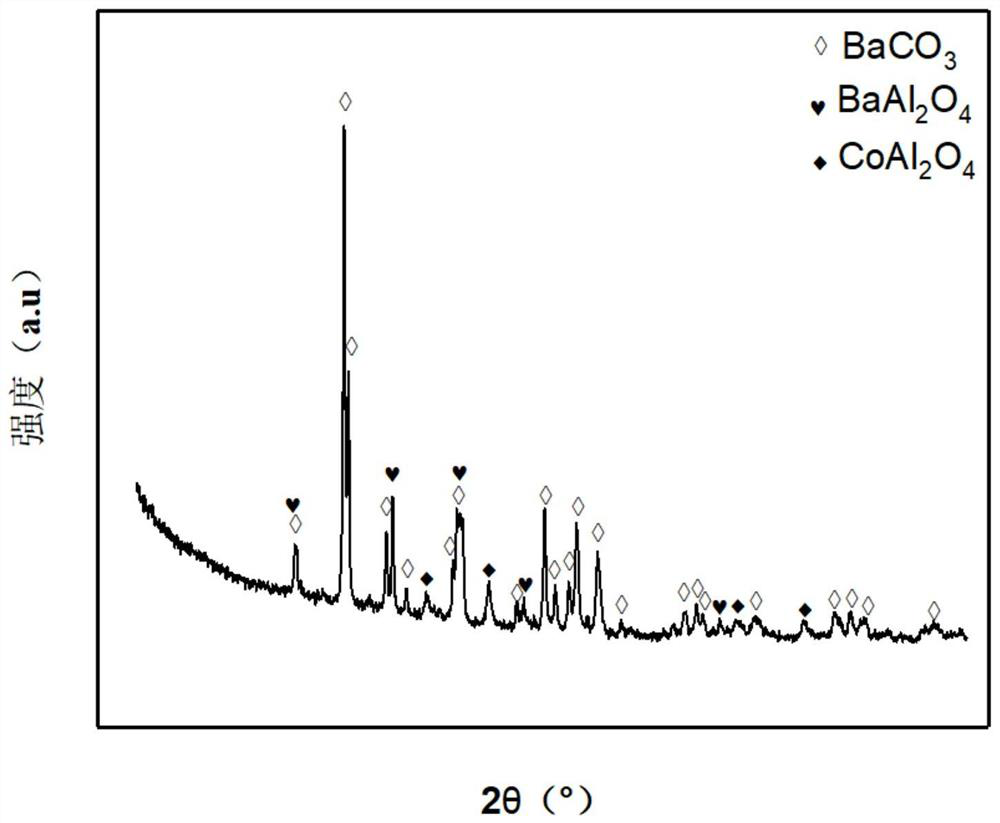

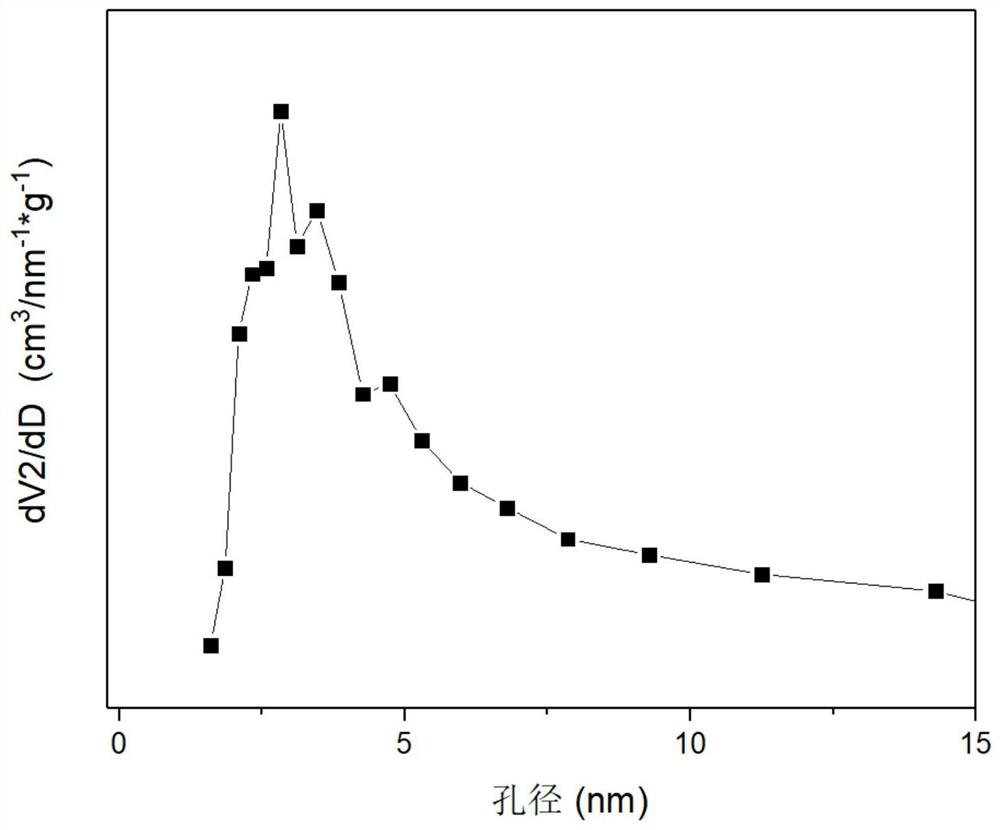

Barium aluminate spinel composite oxide cobalt-based catalyst for hydrogen production by autothermal reforming of acetic acid

ActiveCN112892542ASimple structureGood for adsorption and activationHydrogenHydrogen/synthetic gas productionPtru catalystComposite oxide

The invention relates to a barium aluminate spinel composite oxide cobalt-based catalyst for hydrogen production by autothermal reforming of acetic acid. The invention provides a novel catalyst which is stable in structure, resistant to sintering, resistant to carbon deposition, resistant to oxidation and high in activity aiming at the problem that the catalyst is inactivated due to the change of the catalyst structure and the oxidation and sintering of active components in the autothermal reforming process of acetic acid in the existing catalyst, the molar composition of the catalyst is (BaO) a (AlO1.5) b (CoO1.5) c, wherein a is 0.285-0.588, b is 0.269-0.599, and c is 0.102-0.165; in terms of oxide, the weight percentage of the barium oxide is 52.0-78.0%, the weight percentage of the aluminum oxide is 12.0-36.0%, and the weight percentage of the cobalt oxide is 10.0-12.0%. The catalyst is prepared by adopting a sol-gel method, and the barium-aluminum composite oxide cobalt-based catalyst which takes Co-Ba-Al-O as an active center and BaCO3 as a framework and contains BaAl2O4 and CoAl2O4 spinel structures is formed after roasting, so that the oxidation resistance and the dispersity of active components are improved, and meanwhile, the hydrogen yield, the sintering resistance and the carbon deposition resistance in the acetic acid autothermal reforming process are improved.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

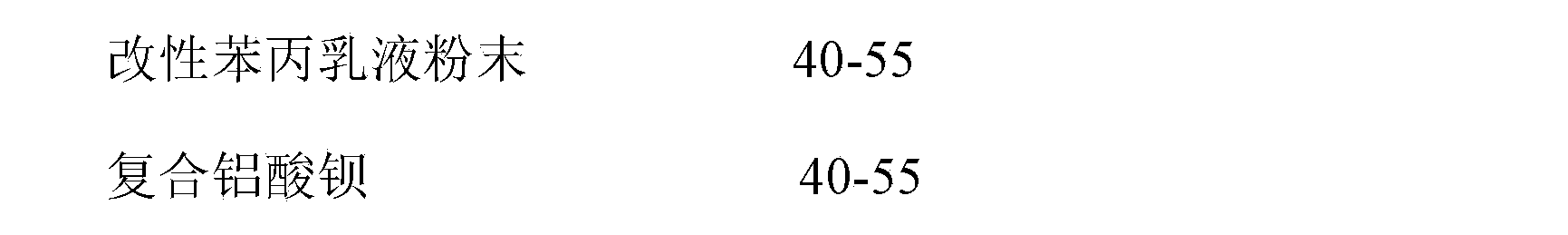

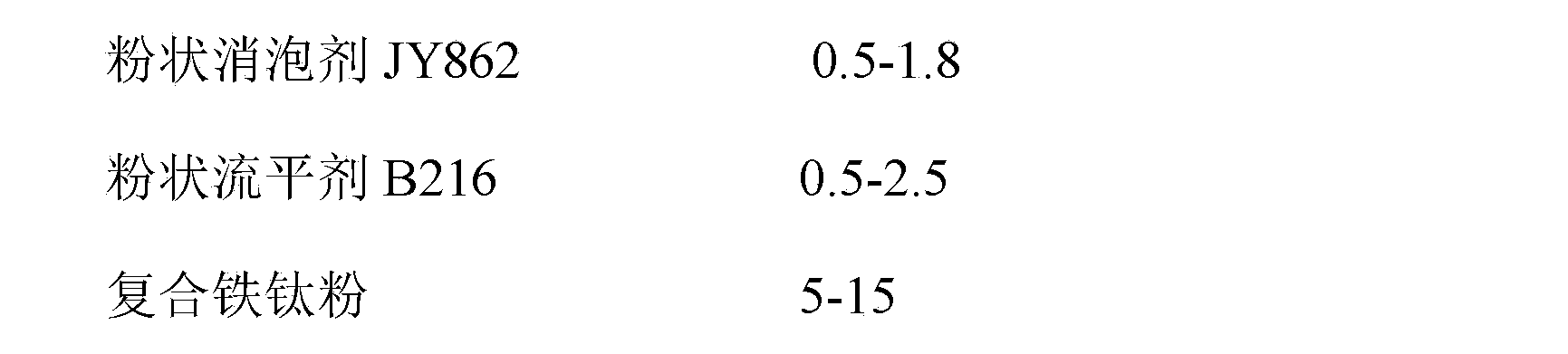

Interface binder used for steel and concrete, and production method thereof

InactiveCN103694927AAvoid corrosionEasy to produceNon-macromolecular adhesive additivesHydrocarbon polymer adhesivesBarium aluminateEmulsion

An interface binder used for steel and concrete is composed of modified styrene acrylic emulsion powder, composite barium aluminate, composite iron titanium powder and an assistant. The interface binder is produced by mixing the above components, and carrying out ball milling of the components. The interface binder used between a steel plate and cement makes the steel plate and the cement bonded, no slits generated permanently and the steel plate contacting with the cement not corroded. The interface binder has the advantages of simple production, use convenience, no toxicity or pollution, one-time construction, and permanent effect.

Owner:湖北中科博策新材料研究院

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com