Barium containing sulpho- ferro- aluminate cement

A technology of aluminate cement and ferroaluminate, which is applied in the field of cement materials, can solve the problems of limiting the application of barium-containing sulfoaluminate cement, unstable strength in the later stage, and high raw material costs, and achieves fast setting and hardening speed and high strength in the later stage. Increase, improve the effect of building quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Numbering

[0040] Numbering

[0041] In the laboratory, the above clinker is fired in a silicon-molybdenum rod furnace at 1800°C, and the firing temperature is 1200°C-1280°C. The physical properties of cement are listed in Table 3.

[0042]

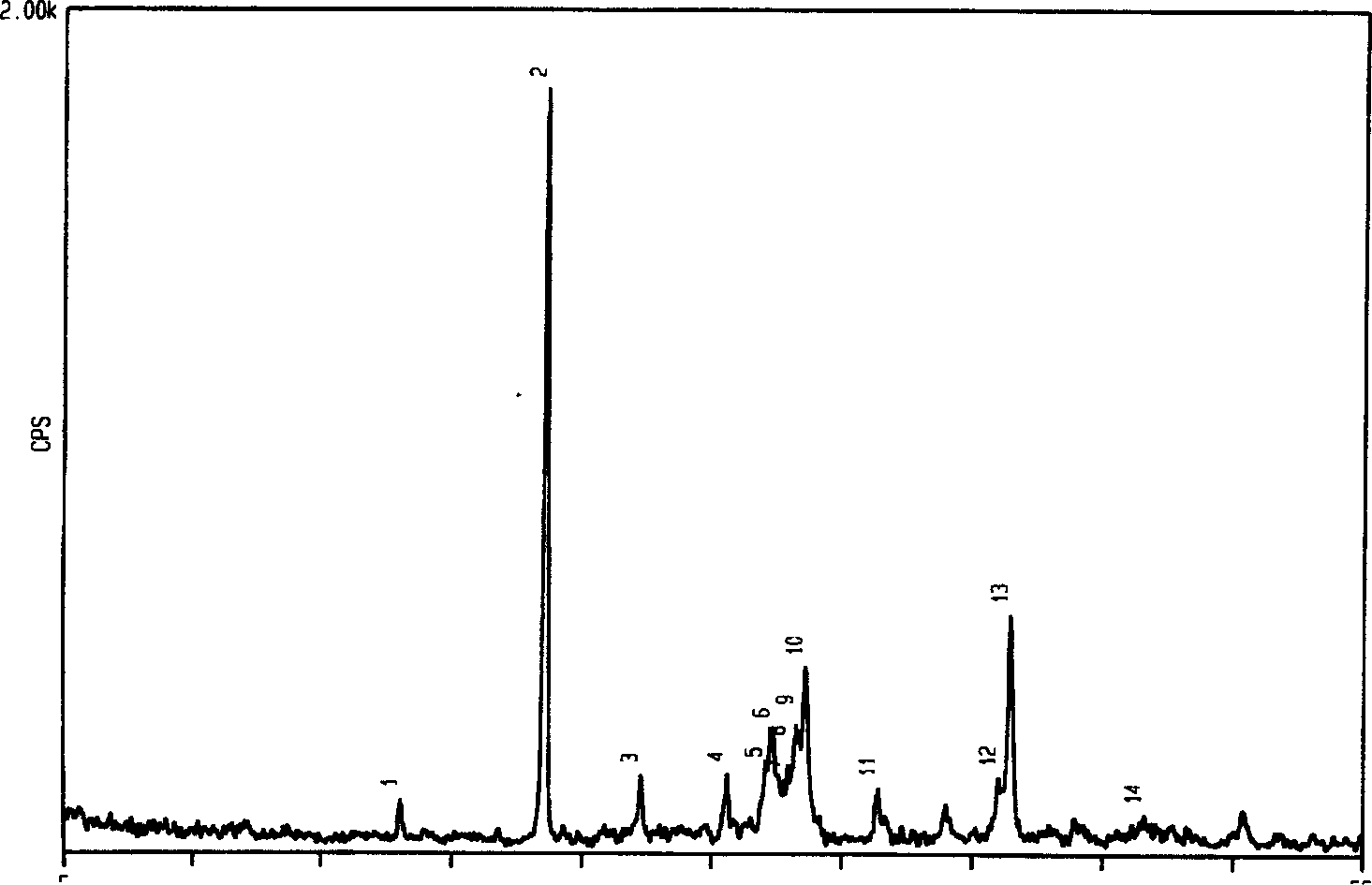

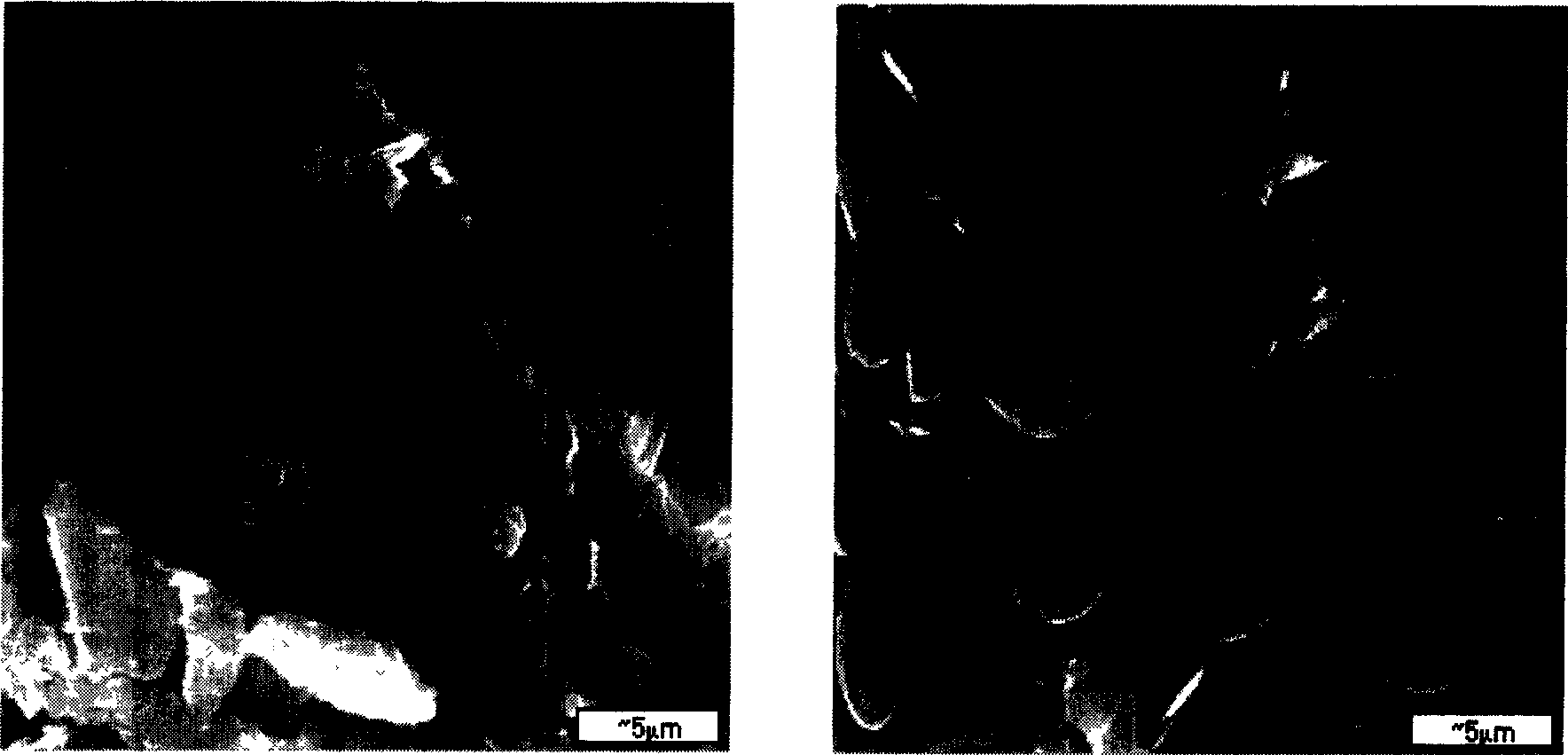

[0043] Carried out XRD and SEM analysis to 1# clinker wherein, see figure 1 and figure 2 . It can be seen that in the barium-containing sulfoaluminate cement clinker mineral system, a certain amount of barium-containing calcium sulfoaluminate minerals and dicalcium silicate minerals coexist.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com