Recycling method for barium salt of desulphurization slag produced in wet method desulphurization of barer process

A technology of wet desulfurization and desulfurization slag, which is applied in the removal of solid waste and the preparation of alkaline earth metal aluminate/alumina/aluminum hydroxide, which can solve the problem of high desulfurization cost of barium aluminate and achieve high activity and dispersion Good, good technical and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

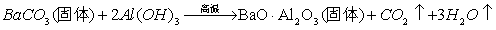

Image

Examples

Embodiment 1

[0019] Example 1: Barium aluminate is used to desulfurize the mother liquor after the high-sulfur bauxite is dissolved to obtain barium salt desulfurization slag, and the barium salt desulfurization slag and aluminum hydroxide are based on the molar ratio of aluminum oxide to barium oxide is 1.1 Mix evenly, place in a roasting furnace at a roasting temperature of 1350°C for 30 minutes to prepare a barium aluminate desulfurizer with a purity of 97.21%, which can be recycled for the desulfurization of seed liquor or causticized liquor.

Embodiment 2

[0020] Example 2: using barium aluminate to desulfurize the causticized solution after the dissolution of high-sulfur bauxite to obtain barium salt desulfurization slag, which is mixed with bauxite according to the ratio that the molar ratio of aluminum oxide to barium oxide is 1.2, Place it in a roasting furnace at a roasting temperature of 1450°C for 60 minutes to prepare a barium aluminate desulfurizer with a purity of 94.33%.

Embodiment 3

[0021] Example 3: The barium aluminate desulfurizer prepared in Examples 1 and 2 is used to desulfurize the causticized liquid after the dissolution of high-sulfur bauxite. When the temperature is 60°C, the time is 25min, and the amount added is When 100%, the desulfurization rate is over 90%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com