Two-component aqueous antirust quick-drying paint

A rust-resistant, two-component technology, applied in anti-corrosion coatings, coatings, etc., can solve problems such as poor adhesion, poor water resistance, salt water resistance and salt spray resistance, and high cost of water-based anti-rust paint , to achieve the effect of excellent water resistance, good salt water resistance and strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A two-component water-based anti-rust quick-drying paint with rust, its two components are as follows:

[0023] Powder composition:

[0024] name

Dosage (unit: %)

30

Wuhan Solid Technology Co., Ltd.

Compound Latex Powder

30

Wuhan Solid Technology Co., Ltd.

Iron Oxide Red

12

Shijiazhuang Schindler Technology Co., Ltd.

Composite iron titanium powder

15

Wuxi Wanda Technology

iron oxide black

2

Anhui Fanchang Sihuan Pigment Company

[0025] Liquid components:

[0026] name

Dosage (unit: %)

Styrene Acrylic Emulsion 1001-A

20

Hengshui Xinguang Chemical Company

Thixotropic agent B216

1

Wuhan Solid Technology Co., Ltd.

Defoamer 090

1.2

Anti-flash rust agent ZT708

1.5

Beijing Zhitu Chemical Company

water

76.3

[0027] ...

Embodiment 2

[0031] A two-component water-based anti-rust quick-drying paint with rust, its two components are as follows:

[0032] Powder composition:

[0033] name

[0034] Liquid components:

[0035] name

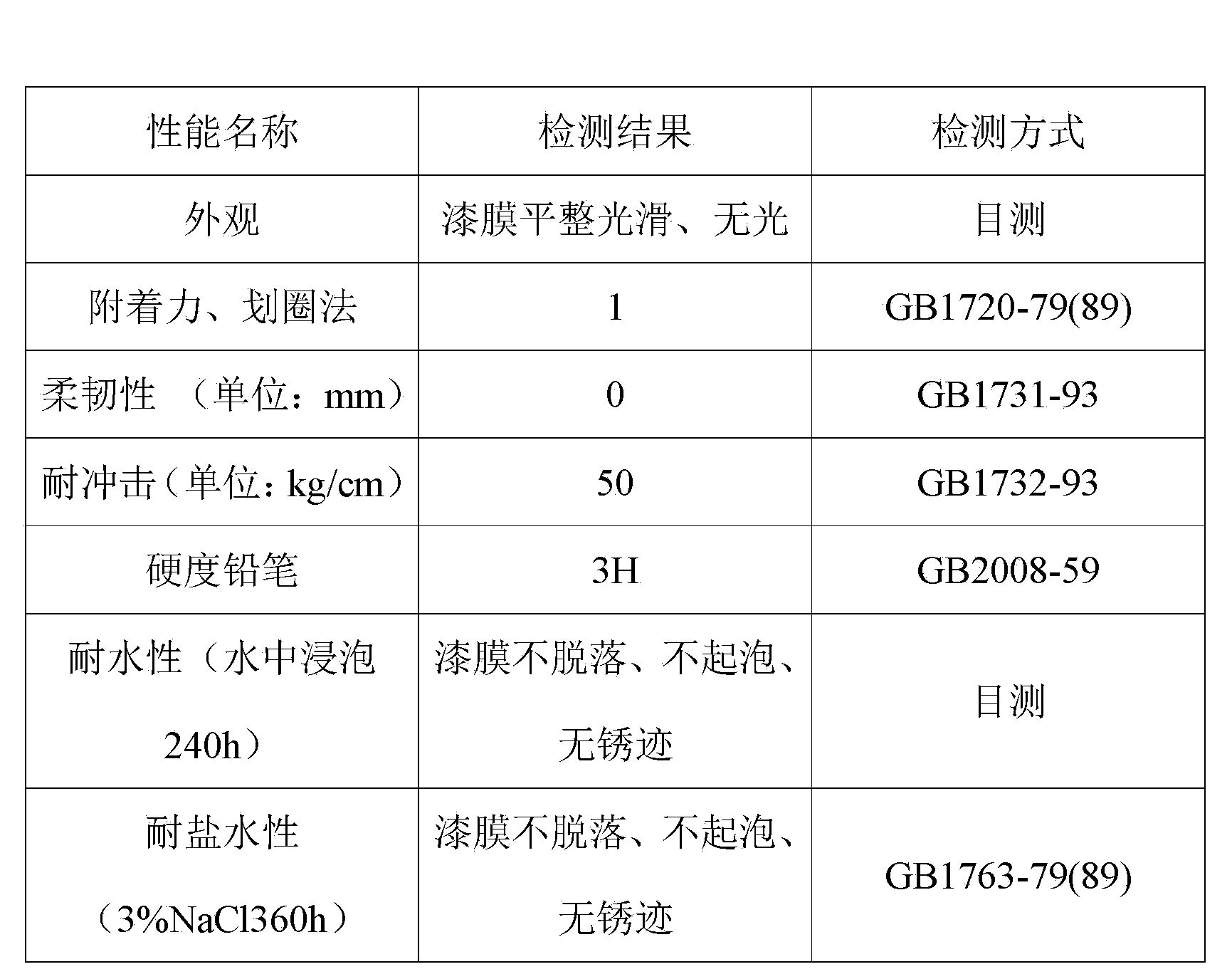

[0036] The above two components are mixed uniformly according to the aforementioned method and then used for later use. When using, mix the powder component: liquid component = 1: 2.1 and spray it on the test board. Put the test board in a closed 40 ℃ electric water bath (not soaked in water). The drying time of the paint film was 150 minutes, and the main conventional technical indicators of the coating were tested after the test panel was placed for seven days, and the results were the same as in Example 1.

Embodiment 3

[0038] A two-component water-based anti-rust quick-drying paint with rust, its two components are as follows:

[0039] Powder composition:

[0040] name

[0041] Liquid components:

[0042] name

[0043] The above two components are mixed uniformly according to the aforementioned method respectively and then used for later use. When using it, mix it evenly according to the ratio of powder component: liquid component = 1:1.9, and then brush it on the test board. After seven days, after removing the paint film, the original old rust on the floor is completely gone, and it is bright and passivated. Test the main routine technical index of its coating, the result is identical as example one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com