Water-soluble rolling liquid composition and application thereof

A technology of composition and rolling fluid, which is applied in the direction of lubricating composition and petroleum industry, can solve the problems of poor emulsification stability of emulsified rolling fluid, poor cooling performance and poor cleanliness of pure oil-type rolling fluid, and achieve good Cleanliness, excellent cooling, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

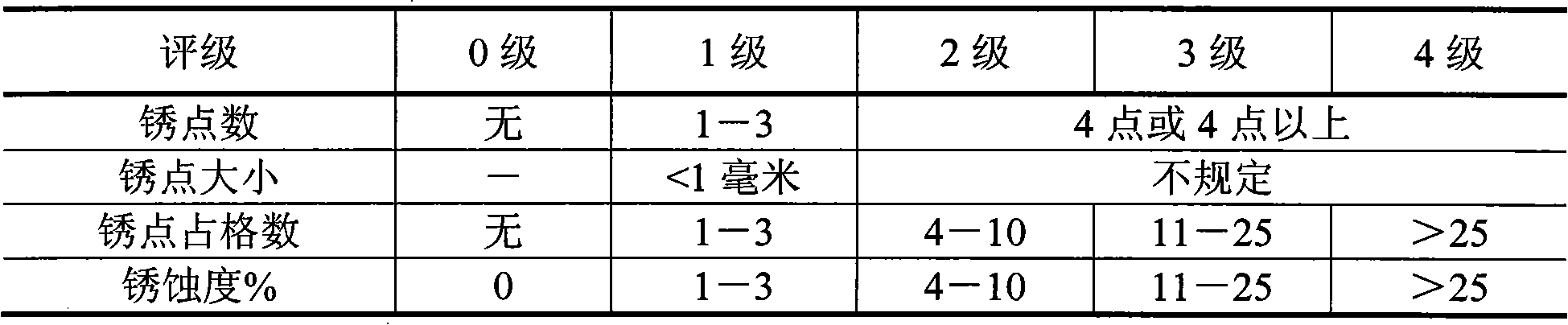

Examples

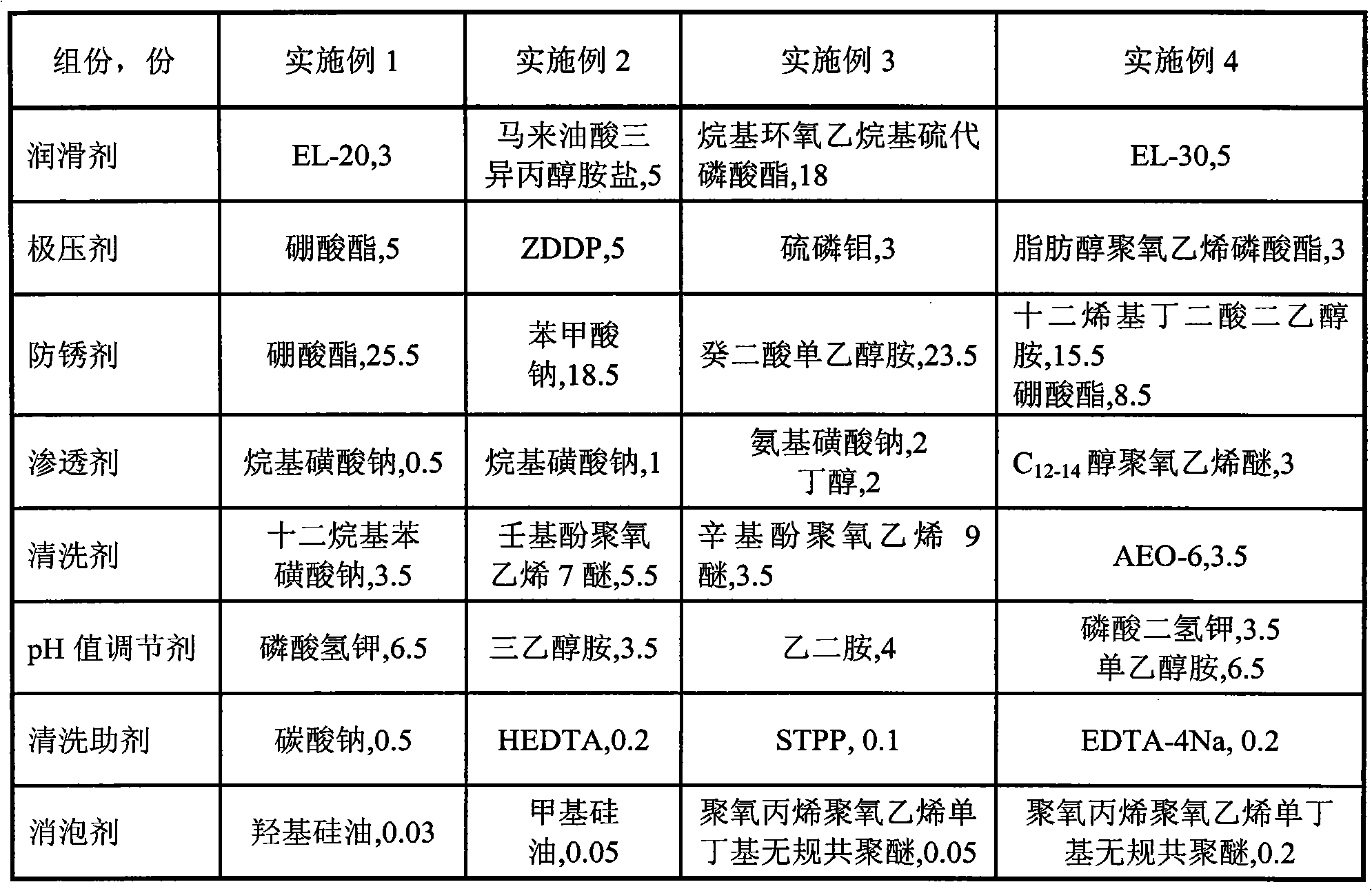

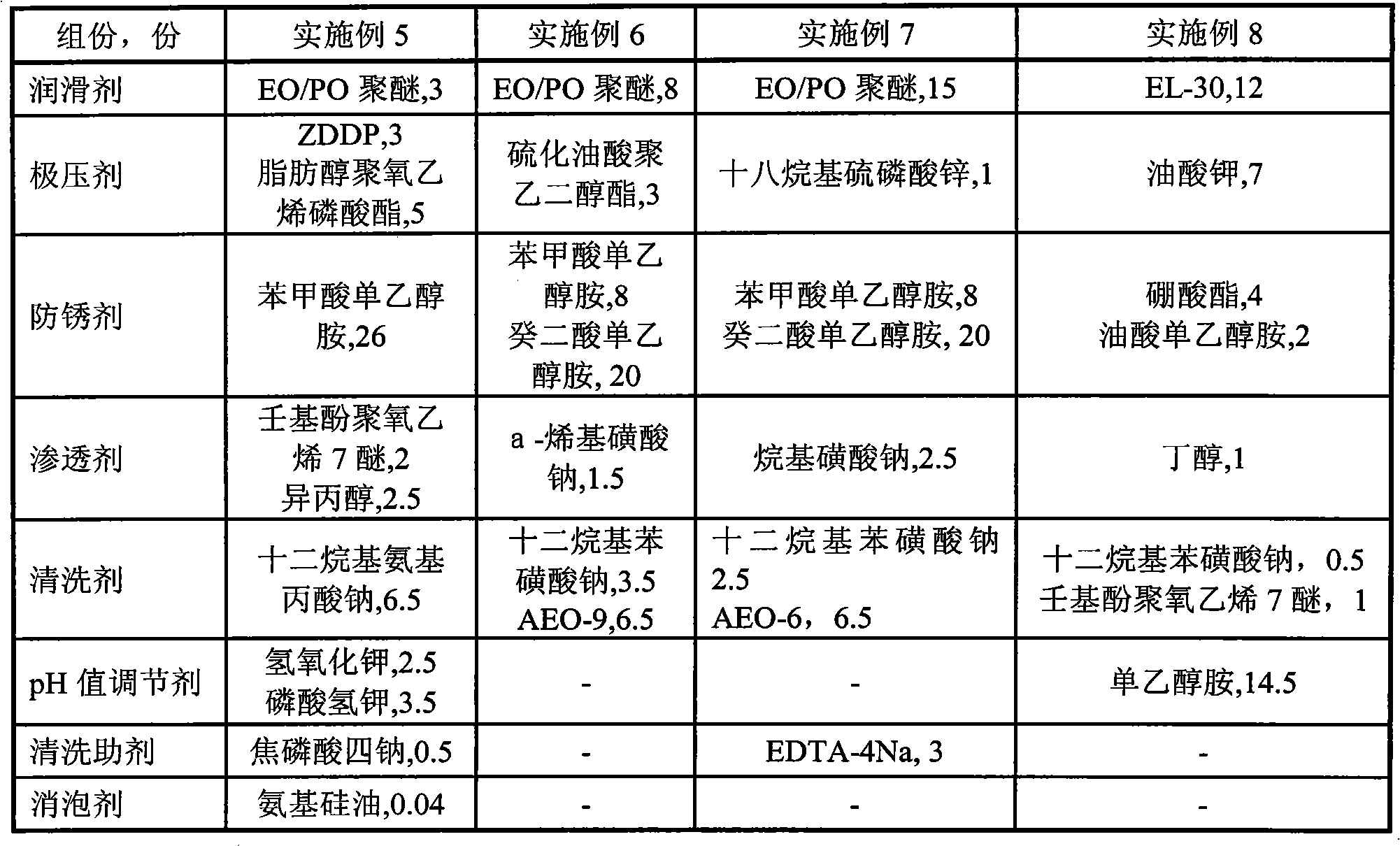

Embodiment 1~12

[0032]Heat the water to 35°C, and add the required amount of lubricant, extreme pressure agent, rust inhibitor, penetrant, pH value regulator, cleaning agent, cleaning aid and defoamer in turn while stirring, and adjust the pH value to 10 ~11, stop stirring and heating after fully stirring for 1.5 hours, filter and fill after standing for 2 hours.

[0033] The specific components and their contents in each composition are shown in Table 2-Table 4. Wherein, the content of each component is the number of parts. In each embodiment, deionized water is used to supplement 100 parts, and the content of component water is omitted.

[0034] In Table 2 to Table 4, EL-20 is castor oil polyoxyethylene 20 ether, EL-30 is castor oil polyoxyethylene 30 ether, HEDTA is sodium diamine triacetic acid, STPP is sodium tripolyphosphate, EDTA-4Na Tetrasodium edetate, EO / PO polyether is ethylene oxide / propylene oxide copolymer, AEO-6 is fatty alcohol polyoxyethylene 6 ether, AEO-9 is fatty alcohol ...

Embodiment 13

[0047] The compositions of [Examples 1 to 12] were diluted with water and used in the rolling lubrication process of cold-rolled steel sheets. When rolling a medium and narrow strip with a minimum rolling thickness greater than 0.4 mm, the dilution concentration is 4% by weight; when rolling a medium and narrow strip with a minimum rolling thickness of less than 0.4 mm, the dilution concentration is 7% by weight. During the rolling process, it is convenient to use, there is no maintenance in the stable state during the use process, and the steel plate is clean after rolling.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com