Strong-pressure resisting water-based insulting paint for electric steel and preparation method thereof

An insulating coating, electrical steel technology, applied in polyester coatings, epoxy resin coatings, coatings, etc., can solve the problem of poor adhesion of coatings and steel sheets, uneven brown appearance, poor corrosion resistance of coatings, etc. problems, to achieve the effects of excellent insulation and anti-rust performance, high creep resistance and strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

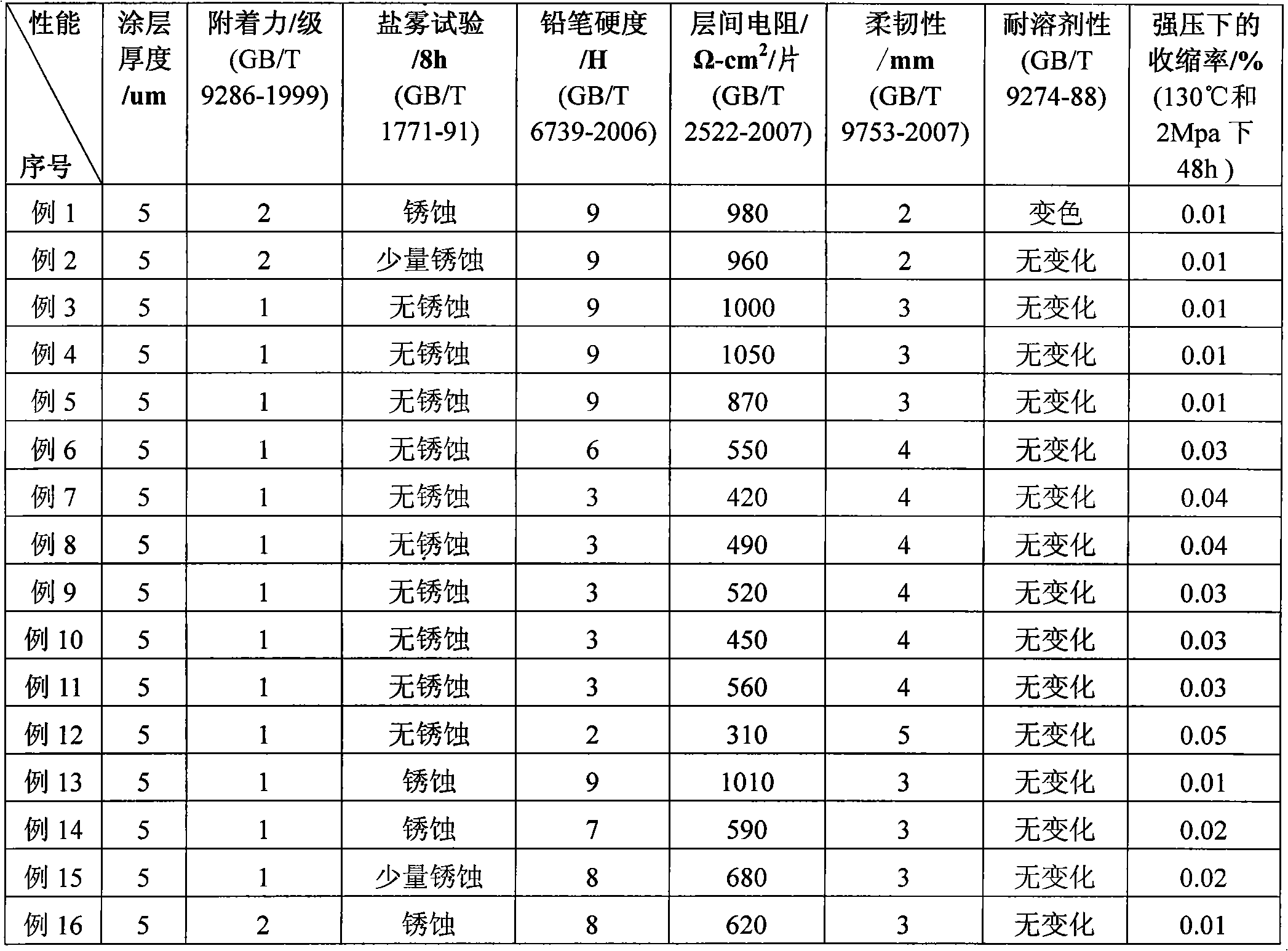

Examples

Embodiment 1

[0028] A high-pressure resistant water-based insulating coating for electrical steel and a preparation method thereof. 10-15wt% water-based acrylic modified epoxy resin, 2-5wt% methanol-etherified melamine formaldehyde resin, 55-60wt% pigment, 8-10wt% additive, 0.1-0.2wt% p-toluene The sulfonic acid, 4-5wt% of anthranilic acid and 5-10wt% of deionized water are mixed, ground in a sand mill until the fineness is below 15 microns, and then packed.

[0029] Among the pigments: 35-40wt% of group A, 10-15wt% of group B, 5-10wt% of group C and 1-5wt% of group D;

[0030] The auxiliary agent is a mixture of wetting and dispersing agent, defoaming agent, leveling agent, coupling agent, thickener, preservative and pH regulator.

Embodiment 2

[0032] A high-pressure resistant water-based insulating coating for electrical steel and a preparation method thereof. 15-20wt% water-based acrylic modified alkyd resin, 5-10wt% ethanol-etherified melamine formaldehyde resin, 53-56wt% pigment, 4-8wt% additive, 0.2-0.3wt% p-toluene The sulfonic acid, 4-5wt% of anthranilic acid and 10-15wt% of deionized water are mixed, ground in a sand mill until the fineness is below 15 microns, and then packed.

[0033] Among the pigments: 35-45wt% of group A, 5-10wt% of group B, 5-10wt% of group C and 1-5wt% of group D;

[0034] The auxiliary agent is a mixture of wetting and dispersing agent, leveling agent, coupling agent, thickener, preservative and pH regulator.

Embodiment 3

[0036] A high-pressure resistant water-based insulating coating for electrical steel and a preparation method thereof. 18-22wt% water-based acrylic modified resin, 2-5wt% propanol etherified melamine formaldehyde resin, 40-45wt% pigment, 5-7wt% additive, 0.3-0.4wt% p-toluenesulfonate acid, 2-3wt% m-aminobenzoic acid and 25-30wt% deionized water are mixed, ground in a sand mill until the fineness is below 15 microns, and then packed.

[0037] Described water-based acrylic modified resin is the mixture of water-based acrylic modified epoxy resin and water-based acrylic modified alkyd resin;

[0038] Among the pigments: 30-35wt% of group A, 5-10wt% of group B and 5-10wt% of group C;

[0039] The auxiliary agent is a mixture of wetting and dispersing agent, defoamer, thickener, preservative and pH regulator.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com