Method for preparing gamma'-Fe4N soft magnetic material by utilizing liquid nitrogen via high-speed ball milling

A soft magnetic material, -fe4n technology, applied in the direction of magnetic materials, magnetic objects, metal processing equipment, etc., can solve the problems that it is difficult to achieve pure phase, low N purity, affecting soft magnetic properties, etc., and achieve the goal of overcoming solid solubility Confinement, homogeneity of elements and structures, effect of reduced size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The starting material was pure iron with a purity of 99% (Alfa Aesar); liquid nitrogen was provided by PRAXAIR; a high energy ball milling system CM5100 (Luomen) was operated in planetary rotation mode.

[0035] Wear-resistant stainless steel balls are used as the grinding medium with a mass-to-sample ratio of 10:1. The tank is continuously cooled with liquid nitrogen from the integrated cooling system before and during the grinding process, making the samples brittle and retaining their volatility Nitrogen. Liquid nitrogen circulates in the system and is continuously replenished from the external filling system, which is precisely controlled to keep the temperature at -196°C;

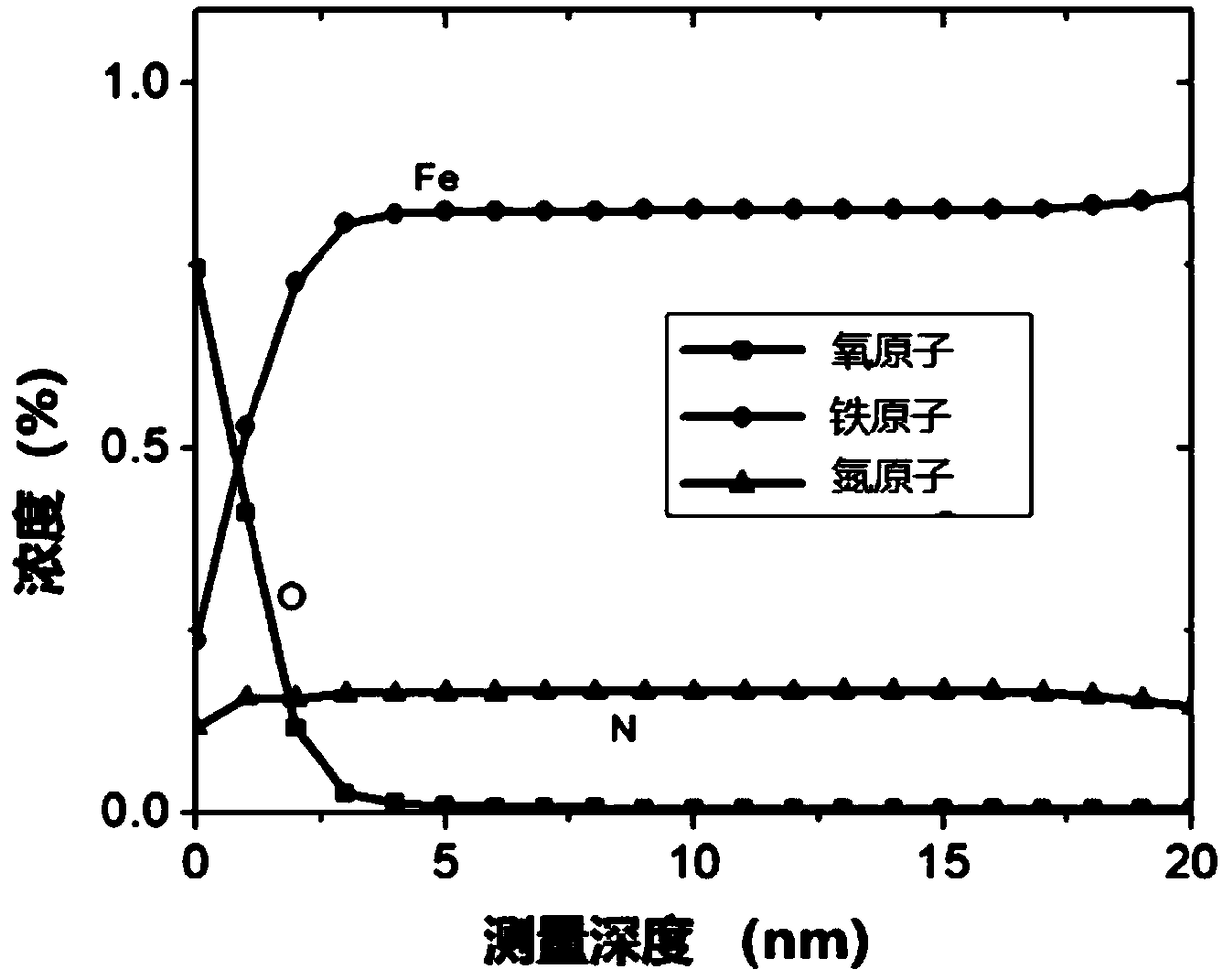

[0036] The iron feedstock and ball milling product were handled in a nitrogen atmosphere inside a glove box, which protected the particles from oxidation. The milling time was 90 hours and the rotational speed was 3000 rpm. The mill run was stopped for 5 minutes every hour. The direction of r...

Embodiment 2

[0043] Referring to the method conditions of Example 1, the annealing temperature is replaced by 200°C or 250°C, and other conditions remain unchanged, the prepared γ'-Fe 4 N material.

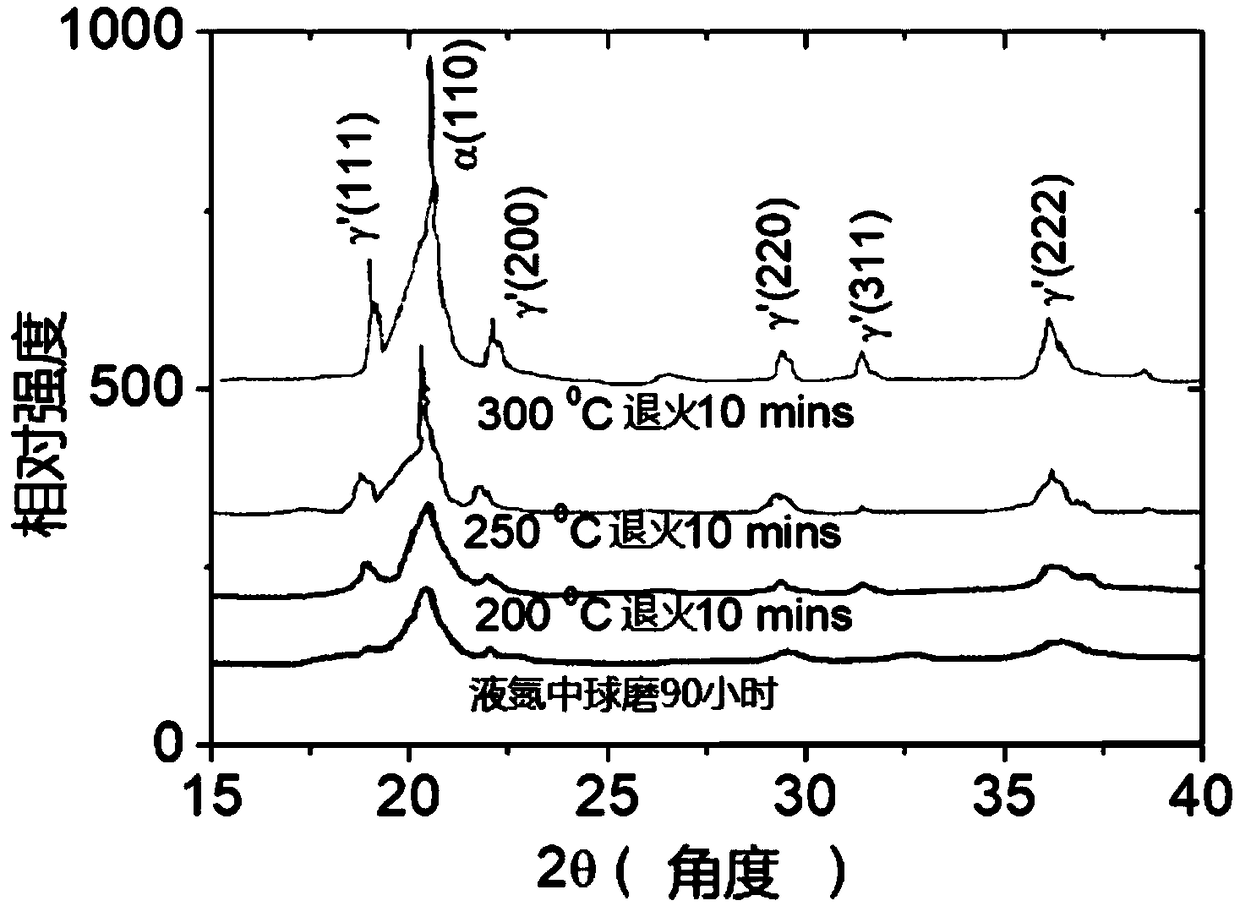

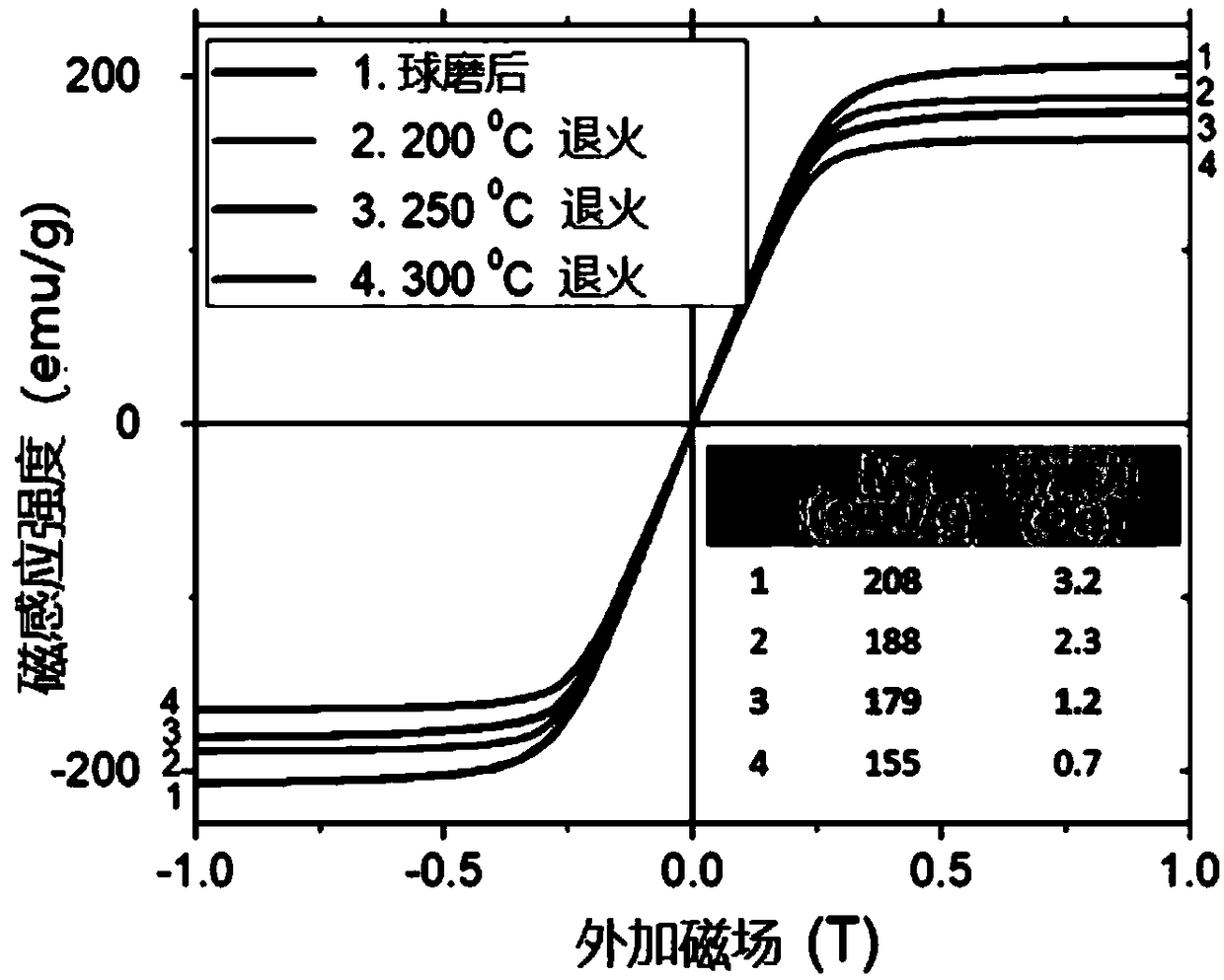

[0044] The resulting material was characterized by XRD spectroscopy, as figure 2 As shown, for the sample prepared after freeze-milling, it exhibits a broad bcc Fe peak, consistent with the metastable supersaturation of N conversion to Fe. Annealing at 200°C for 10 minutes resulted in a slight change in the powder, γ'-Fe 4 Slight sharpening of the N peak. Annealing at 250 °C for 10 min resulted in sharp bcc Fe and γ′-Fe4N peaks. Annealing at 300 °C results in more γ'-Fe 4 N peak and sharper bcc Fe. Furthermore, further increasing the annealing temperature, slightly above 300 °C, had no significant effect on the XRD peaks; indicating that the high-energy cryogenic cooling process produces broad BCC Fe with nitrogen supersaturation, and short post-annealing can lead to sharp BCC and γ′-Fe ...

Embodiment 3

[0048] Referring to Example 1, the weight ratio of the ball and the iron powder material was replaced from 10:1 to 30:1, and other conditions remained unchanged, and the iron-nitrogen material was prepared. The magnetic properties of the obtained iron-nitrogen material are similar to those obtained in Example 1, and the yield is about 30% of that of the material in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com