Aqueous asphalt imitation anticorrosion coating for container chassis and preparation method thereof

A technology of anti-corrosion coatings and containers, applied in anti-corrosion coatings, coatings, etc., can solve problems such as environmental pollution and affecting the health of construction workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

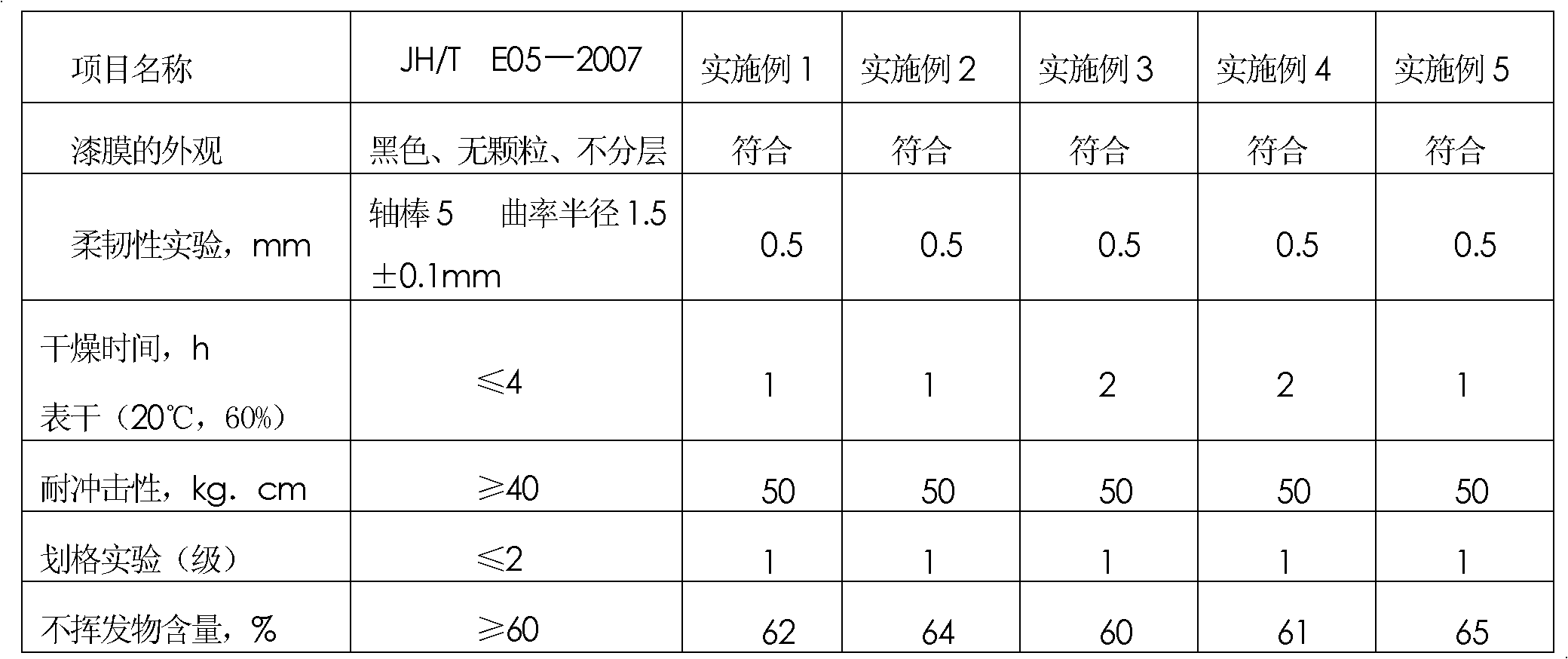

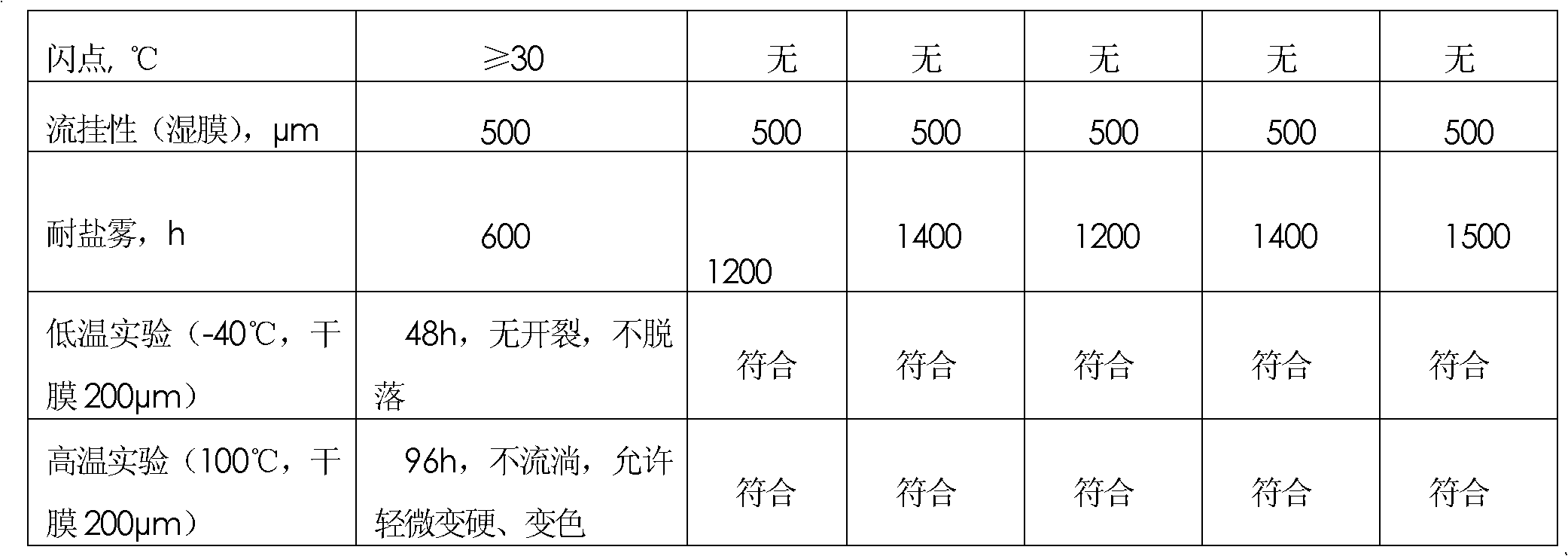

Examples

Embodiment 1

[0038] Under the rotating speed of 200r / min, add 50 parts of tap water, 0.5 parts of wetting and dispersing agent A (Disperbyk180, German BYK chemical company), 2 parts of wetting and dispersing agent B (X-405, American Rohm and Haas Company), prevent 1 part of flash rust agent (SER-AD FA 179, Zhongshan Yongfeng Chemical Co., Ltd.), 2 parts of pH regulator (AMP-95, Dow Chemical), 1 part of defoamer (Foamex815N, German Tego Chemical), After stirring for 5 minutes, adjust the rotating speed to 2500r / min, add 6 parts of dustproof agent (A200, Germany Degussa Company) successively, 50 parts of antirust pigment (iron black, Lockwood Pigment Co., Ltd.), disperse at high speed for 30 minutes, and prepare Get paint paste.

[0039] At 800r / min, add 620.5 parts of water-based acrylic emulsion (CN-18, BASF Emulsion Co., Ltd.), 1 part of defoamer (Defom W-0505, Deqian Chemical), barium sulfate (800 mesh, jade Feng Powder Material Co., Ltd.) 60 parts, talcum powder (800 mesh, Guangfu Fuji...

Embodiment 2

[0041] At a speed of 400r / min, 60 parts of tap water, 2 parts of wetting and dispersing agent A (Orotan 731A, Rohm and Haas, USA), 2 parts of wetting and dispersing agent B (AP-560, Shenzhen Giyadh Industrial Co., Ltd.) were added successively. ) 2 parts, anti-flash rust agent (raybo60-NoRμst, U.S. Ruibao Auxiliary Company) 2 parts, pH regulator (ammonia water, Dow Chemical) 2 parts, defoamer (Foamex K3, German Tego Chemicals) 1 part , after stirring for 5 minutes, adjust the rotating speed to 2000r / min, add 10 parts of dustproof agent (A200, Germany Degussa Company) successively, 80 parts of antirust pigment (iron black, Lockwood Pigment Co., Ltd.), disperse at high speed for 30 minutes, Pigment paste is prepared.

[0042]At a speed of 700r / min, add 603 parts of water-based acrylic emulsion (AP-6750, Shanghai Showa Polymer Co., Ltd.), 50 parts of barium sulfate (800 mesh, Yufeng Powder Material Co., Ltd.), talc to the above-mentioned pigment slurry 40 parts of powder (800 me...

Embodiment 3

[0044] Under the rotating speed of 600r / min, add 130 parts of tap water, 1 part of wetting and dispersing agent A (SN-5027, Shenzhen Haichuan Chemical Co., Ltd.), 10 parts of wetting and dispersing agent B (Hydropalat 436, Shenzhen Haichuan Chemical Co., Ltd.), prevent 2 parts of flash rust agent (SER-ADFA379, Zhongshan Yongfeng Chemical Co., Ltd.), 4 parts of pH regulator (dimethylethanolamine, Haiyutian Chemical Industry), 1 part of defoamer (Foamex 8050, German Tego Chemicals), Add 10 parts of dustproof agent ((N-20), Wacker Company, Germany), and after stirring for 15 minutes, add 112 parts of barium sulfate (800 mesh, Yufeng Powder Material Co., Ltd.) and talcum powder (800 mesh, Guangzhou Fujian Material (Jiaoling) Refining Chemical Co., Ltd.) 100 parts, antirust pigment (iron black, Lockwood Pigment Co., Ltd.) 80 parts, antirust pigment (zinc phosphate, Shijiazhuang Xinsheng Chemical Co., Ltd.) 20 parts, antirust pigment ( Aluminum tripolyphosphate, Guangzhou Zhengtong ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com