Rare earth doped scandium barium aluminate up-conversion luminescent material and preparation method thereof

A luminescent material, rare earth doping technology, applied in luminescent materials, chemical instruments and methods, sustainable manufacturing/processing, etc., can solve the problems of low controllability, low repeatability, low preparation yield, etc. The effect of good performance, simple preparation process and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] What this example prepares is Ba 2 sc 0.67 Yb 0.3 Er 0.03 AlO 5Powder, prepared as follows:

[0034] Calculate 0.01976mol of barium carbonate, 0.00255mol of scandium oxide, 0.00114mol of ytterbium oxide, and 0.00011mol of erbium oxide according to the molar ratio of elements Ba, Sc, Yb, Er, and Al: 2.6:0.67:0.3:0.03:1 and 0.00760mol of aluminum hydroxide quality, and accurately weighed. Put all the raw materials into a beaker, and add 25 ml of absolute ethanol as a dispersion medium, stir with a glass rod to make the suspension fully uniform, let it stand for 4 minutes, put the beaker into a drying oven, and set the drying temperature to 80°C , record the initial drying time, and dry for 10 hours to completely evaporate the water vapor and absolute ethanol in the sample. Take out the beaker, roughly divide the precursor powder into 4 parts, press the divided sample powder into a disc shape with a tablet press, and keep the pressure gauge at 16Mpa for about ten min...

Embodiment 2

[0038] Prepare Ba according to the steps of Example 1 2 sc 0.67 Yb 0.3 Er 0.03 AlO 5 For the powder, only the sintering step in Example 1 is first kept at 1200°C for 20 minutes, then at 1700°C for 90 minutes, adjusted to first at 1200°C for 20 minutes, then at 1500°C for 90 minutes, and other steps remain unchanged. The purpose is to repeat the test to verify the feasibility of the present invention under different high temperature conditions.

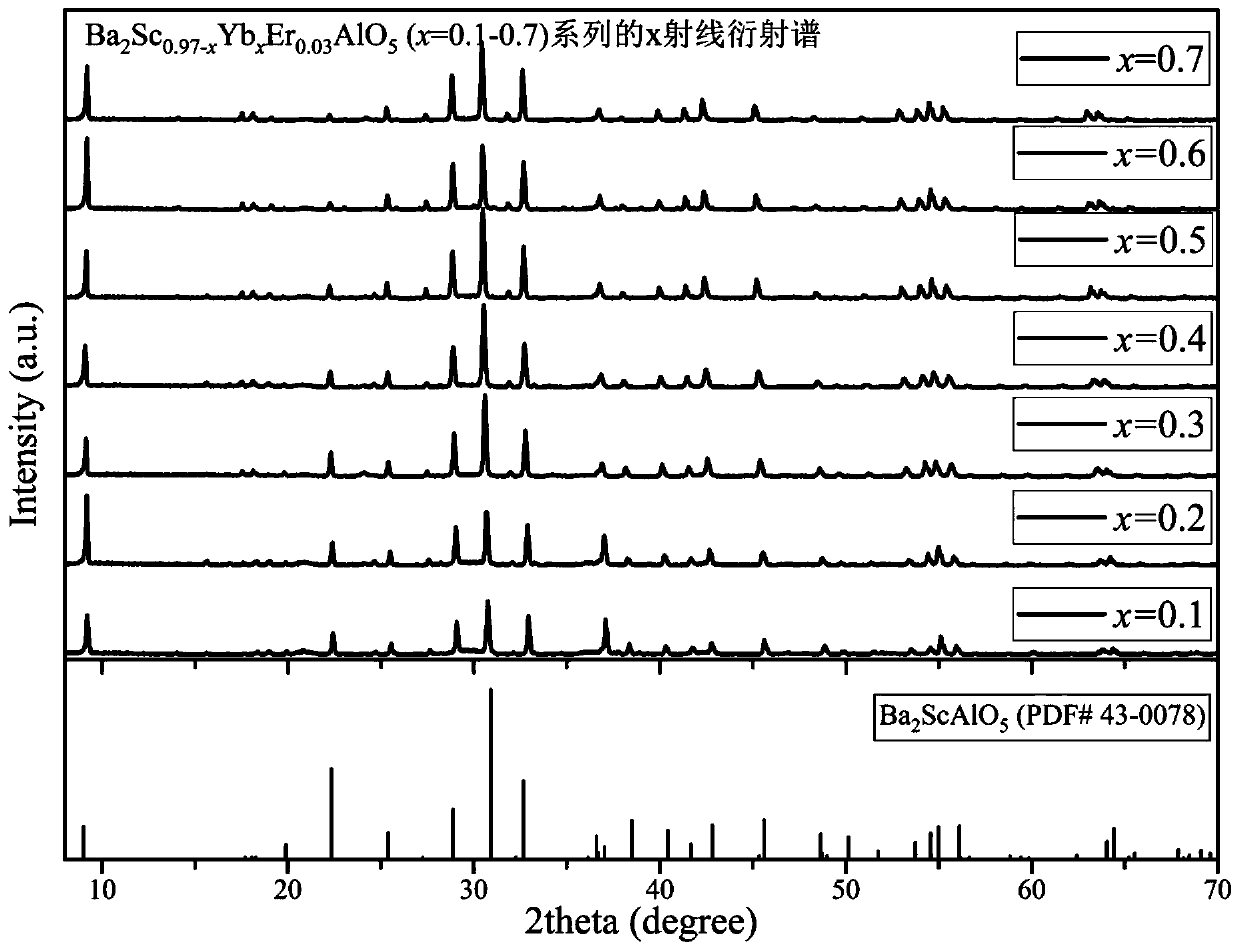

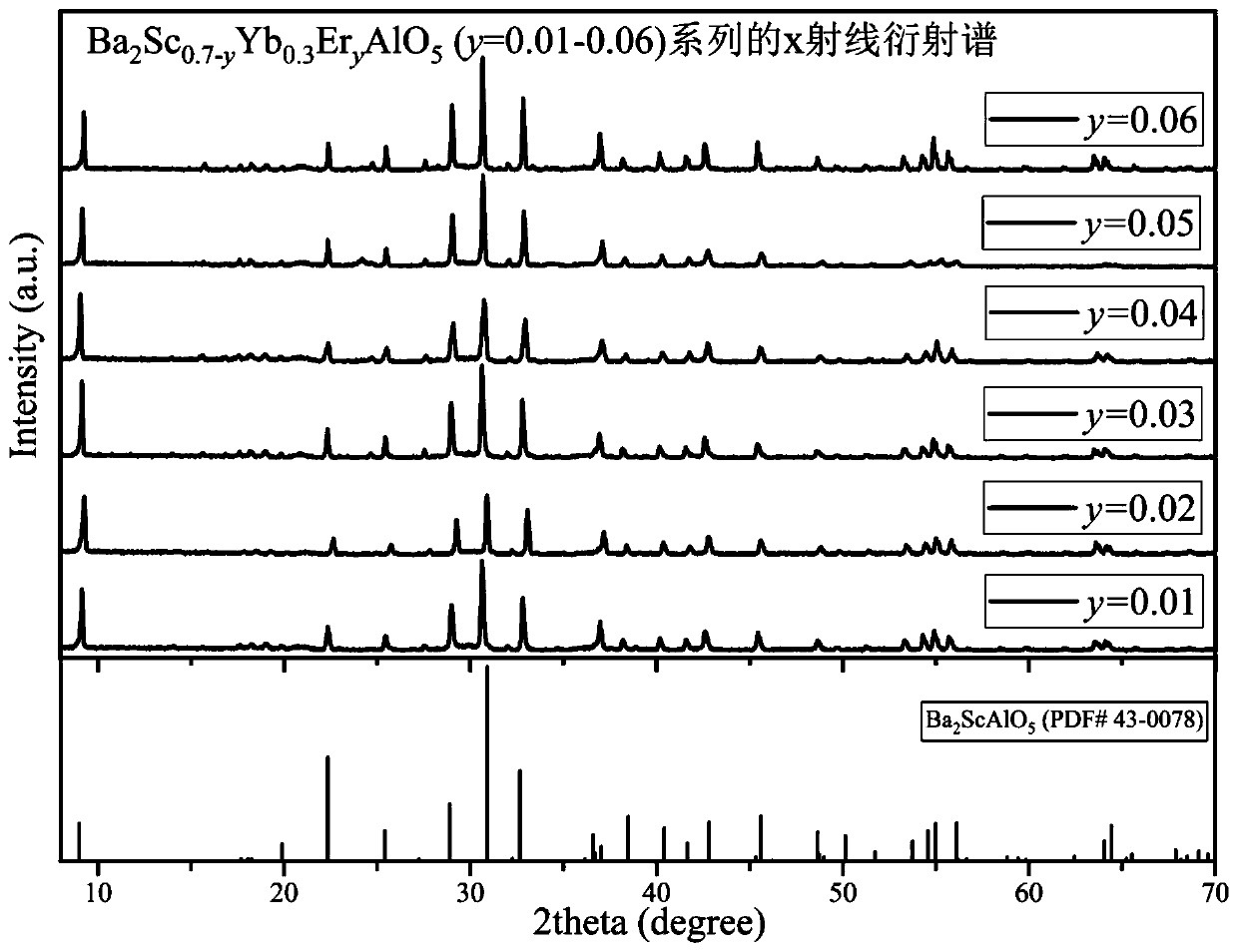

[0039] Figure 7 The X-ray diffraction results showed that the crystal structure of the sample conformed to the Ba 2 ScAlO 5 Crystal structure (PDF card number 43-0078), indicating that the product is a single-phase Ba that also has a hexagonal close-packed structure 2 ScAlO 5 (beta phase).

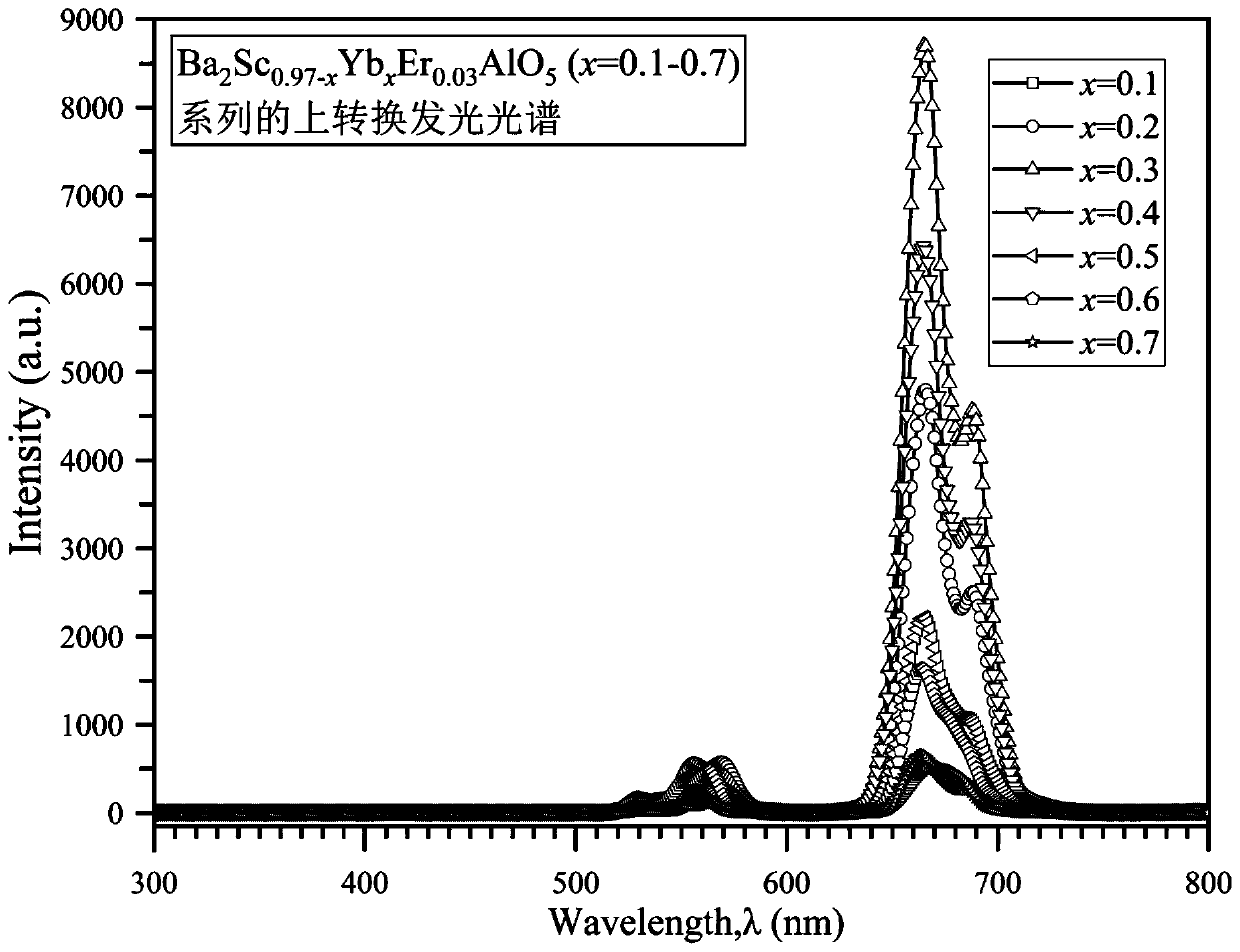

[0040] Depend on Figure 8 It can be seen from the wavelength-luminous intensity relationship diagram that, also excited by a 980nm infrared laser, the red light wavelength at 666nm has a maximum luminous intensity of 8858.63, and the ex...

Embodiment 3

[0042] What this example prepares is Ba 2 sc 0.68 Yb 0.3 Er 0.02 AlO 5 Powder, the difference between this embodiment and embodiment 1 is that the content of erbium oxide is adjusted from 0.00011 mol to 0.00007 mol, and other steps remain unchanged. The purpose is to verify the stability of the present invention in regulating raw material composition and manufacturing process after regulating the ratio of rare earth oxides.

[0043] Figure 9 The X-ray diffraction results showed that the crystal structure of the sample conformed to the Ba 2 ScAlO 5 Crystal Structure (PDF Card No. 43-0078).

[0044] Depend on Figure 10 The wavelength-luminous intensity relationship diagram shows that Ba 2 sc 0.68 Yb 0.3 Er 0.02 AlO 5 The powder is also excited by a 980nm infrared laser. The red light wavelength at 667nm has a maximum luminous intensity of 8061.92, and the excited secondary maximum wavelength of 689nm has a light intensity of 4003.3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Light intensity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com