Barium aluminate concrete swelling agent and preparation method thereof

A technology of barium aluminate and expansion agent, which is applied in the field of building materials, can solve problems such as poor control of expansion concrete preparation and failed engineering cases, and achieve the effects of increased compactness, improved strength, and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

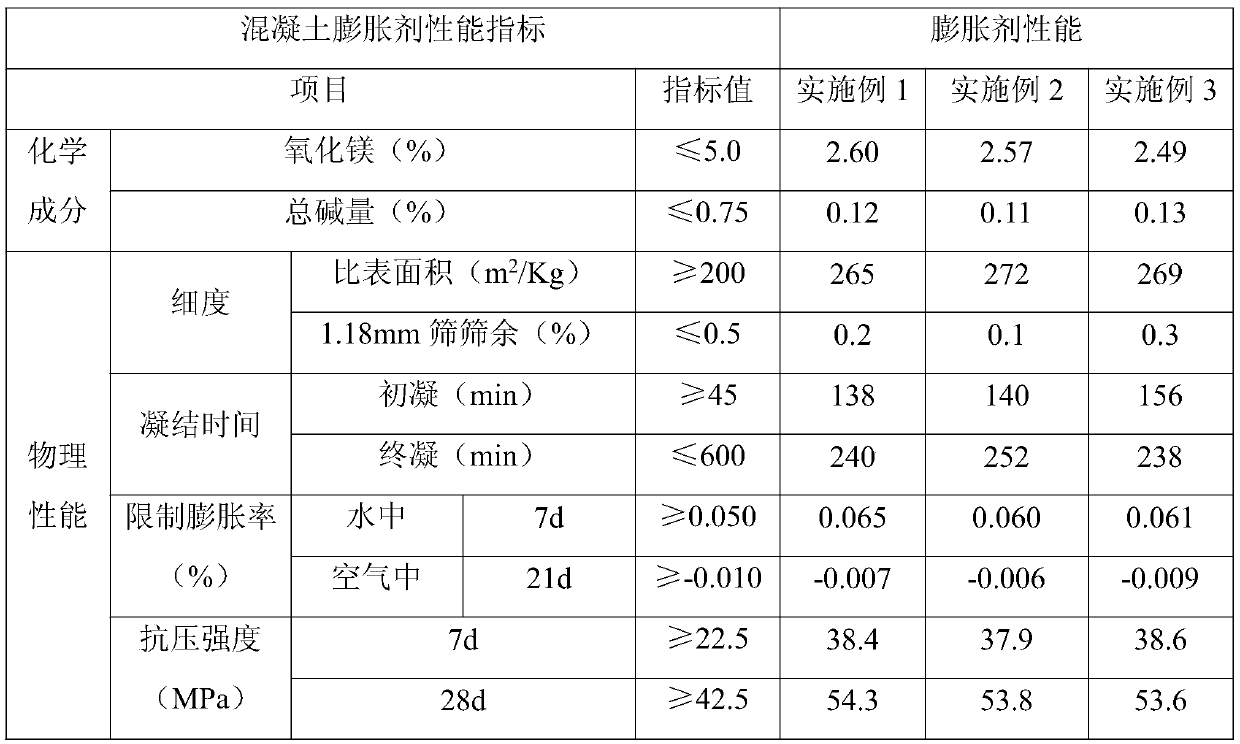

Examples

Embodiment 1

[0039] A kind of barium aluminate concrete expansion agent of the present invention, its preparation method is as follows:

[0040] Step 1. Take an appropriate amount of barium carbonate and alumina, and dry them at a temperature of 110±5°C; according to BaCO 3 :Al 2 o 3 = 2:1 weight percentage Weigh and mix each material, and then grind to 4.6% of 0.08mm square hole sieve to obtain raw meal, set aside;

[0041] Step 2. Add 2% soluble starch and an appropriate amount of water to the raw meal prepared in step 1. The amount of water added is based on the amount of water that can be pressed into shape. Stir evenly, then press into shape, and dry;

[0042] Step 3. Put the raw material dried in step 2 into a high-temperature furnace, and heat it at 1300°C for 120 minutes, and then burn it into barium aluminate clinker A; after the heat preservation is completed, take out the material and cool it to room temperature;

[0043] Step 4: Do batching according to the ratio of barium a...

Embodiment 2

[0046] A kind of barium aluminate concrete expansion agent of the present invention, its preparation method is as follows:

[0047] Step 1. Take an appropriate amount of barium carbonate and alumina, and dry them at a temperature of 110±5°C; according to BaCO 3 :Al 2 o 3 = 2:1 weight percentage Weigh and mix each material, and then grind to 4.6% of 0.08mm square hole sieve to obtain raw meal, set aside;

[0048] Step 2. Add 2% soluble starch and an appropriate amount of water to the raw meal prepared in step 1. The amount of water added is based on the amount of water that can be pressed into shape. Stir evenly, then press into shape, and dry;

[0049] Step 3. Put the raw material dried in step 2 into a high-temperature furnace, and keep it warm at 1400°C for 60 minutes, and then burn it into barium aluminate clinker B; after the heat preservation is over, take out the material and cool it to room temperature;

[0050] Step 4, batching according to the ratio of barium alumi...

Embodiment 3

[0053] A kind of barium aluminate concrete expansion agent of the present invention, its preparation method is as follows:

[0054] Step 1. Take an appropriate amount of barium carbonate and alumina, and dry them at a temperature of 110±5°C; according to BaCO 3 :Al 2 o 3 = 2:1 weight percentage Weigh and mix each material, and then grind to 4.6% of 0.08mm square hole sieve to obtain raw meal, set aside;

[0055] Step 2. Add 2% soluble starch and an appropriate amount of water to the raw meal prepared in step 1. The amount of water added is based on the amount of water that can be pressed into shape. Stir evenly, then press into shape, and dry;

[0056] Step 3. Put the raw material dried in step 2 into a high-temperature furnace, and heat it at 1350°C for 90 minutes to produce barium aluminate clinker C; after the heat preservation is completed, take out the material and cool it to room temperature;

[0057] Step 4, batching according to the ratio of barium aluminate clinker...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com