Interface binder used for steel and concrete, and production method thereof

A technology of interface adhesives and production methods, applied in the direction of adhesive types, hydrocarbon copolymer adhesives, non-polymer adhesive additives, etc., can solve problems such as short life, decomposition, etc., to avoid corrosion, Produce simple, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

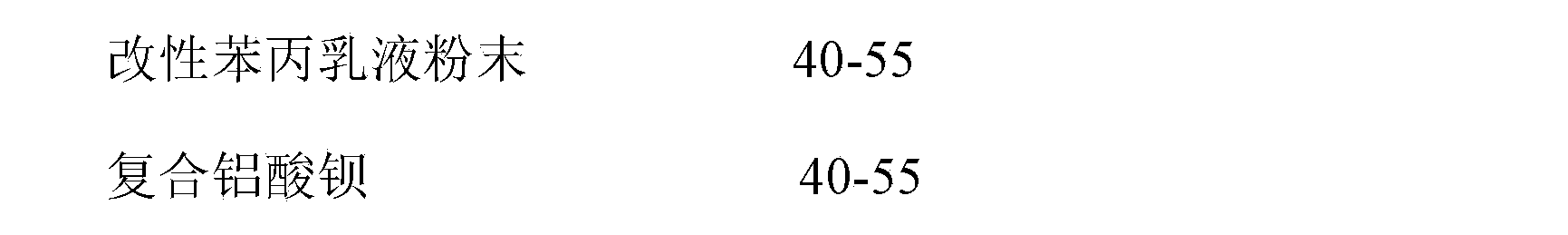

[0015] An interface binder between steel and concrete, its composition percentage is:

[0016] Name

[0017] Put the above components into a cone mixer in turn, mix for one hour and then grind to 400 mesh in a ball mill to obtain the product interface binder. When it is bonded to the steel plate and cement board, the bonding fastness is measured as 22 megapoise.

Embodiment 2

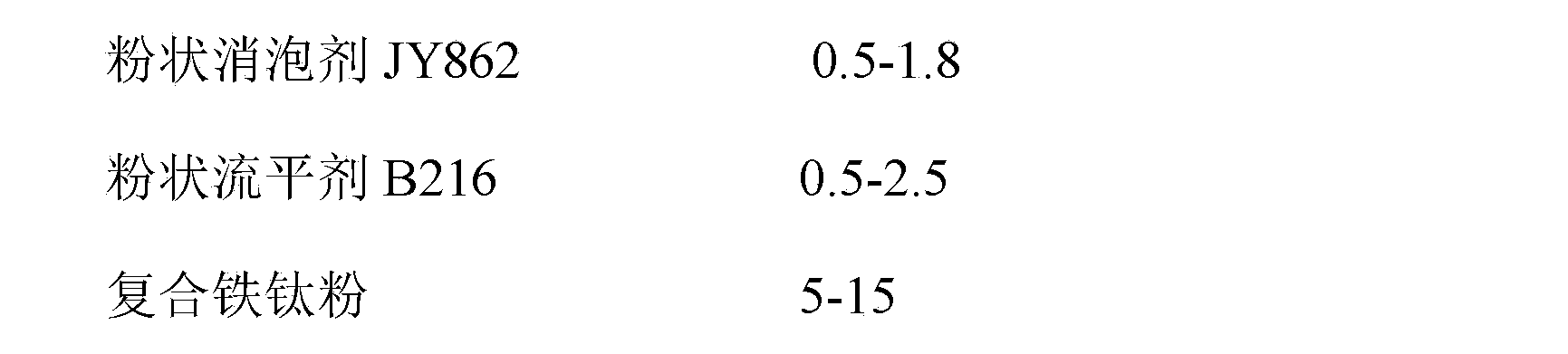

[0019] An interface binder between steel and concrete, its composition percentage is:

[0020] Name

[0021] Put the above components into a cone mixer in turn, mix for one hour and grind it to 500 mesh in a ball mill, add water according to 1:1 and mix evenly and brush on the steel plate, then grouting ordinary cement on the steel plate, and curing for 27 days. After breaking the cement with a steel hammer, the interface adhesive still adheres to the steel plate.

Embodiment 3

[0023] An interface binder between steel and concrete, its composition percentage is:

[0024] Name

[0025] Put the above components into a cone mixer in turn, mix for one hour and grind to 400 mesh in a ball mill, add water in the same amount and mix thoroughly, when iron red appears. This time it is suitable for the requirements when the cement color needs to be adapted. It needs to be replaced with other color powders instead of iron oxide red powder, and its bonding strength is 18 megapoise.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com