Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33 results about "CALCIUM CARBONATE/MAGNESIUM CARBONATE" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Calcium carbonate with magnesium overdose occurs when someone takes more than the normal or recommended amount of medicine that contains these ingredients. The overdose may be by accident or on purpose.

Additive for plastic and plastic

InactiveUS20060188428A1Small amountCalcium/strontium/barium carbonatesMagnesium carbonatesCALCIUM CARBONATE/MAGNESIUM CARBONATEMagnesium carbonate / Magnesium Oxide

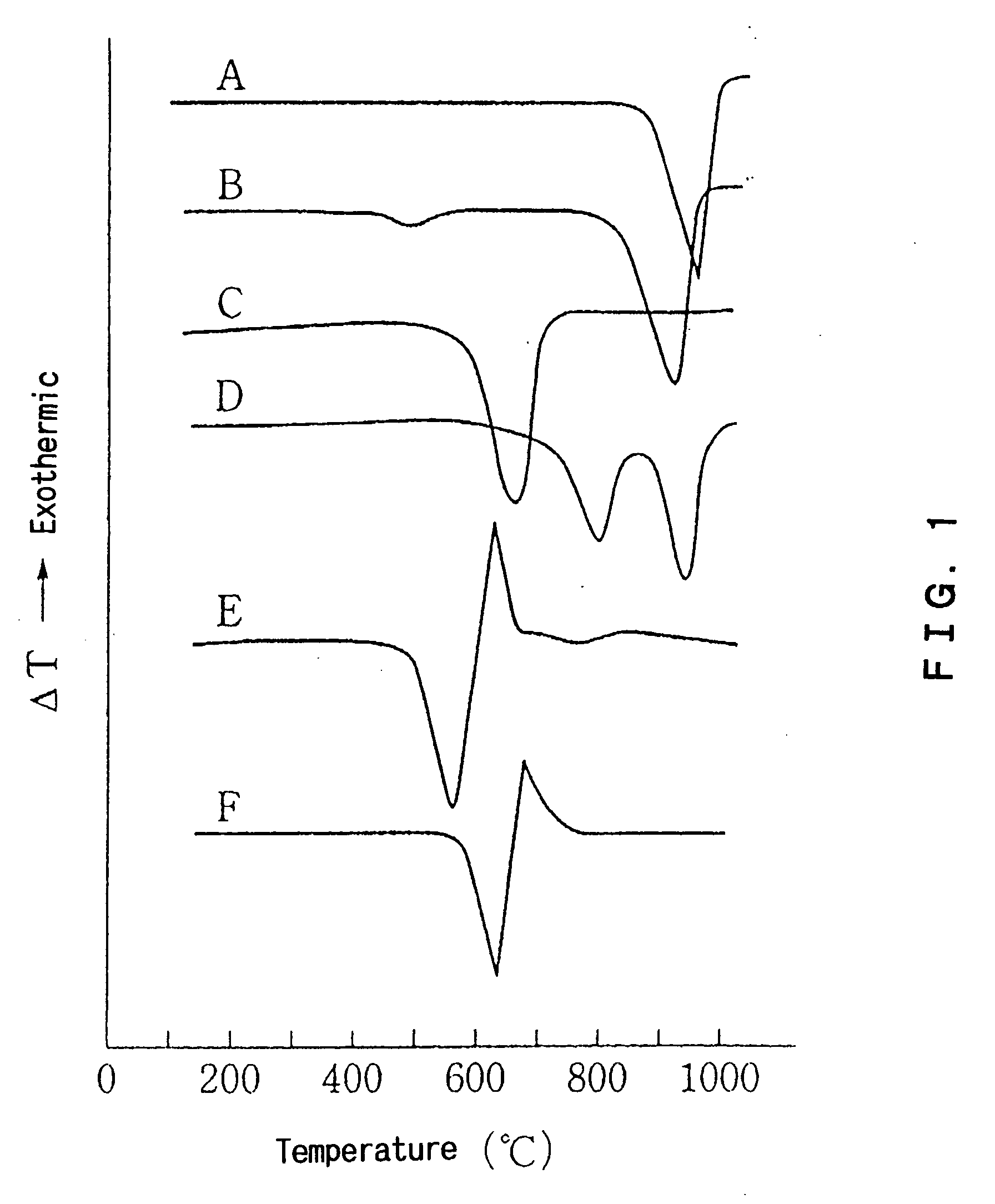

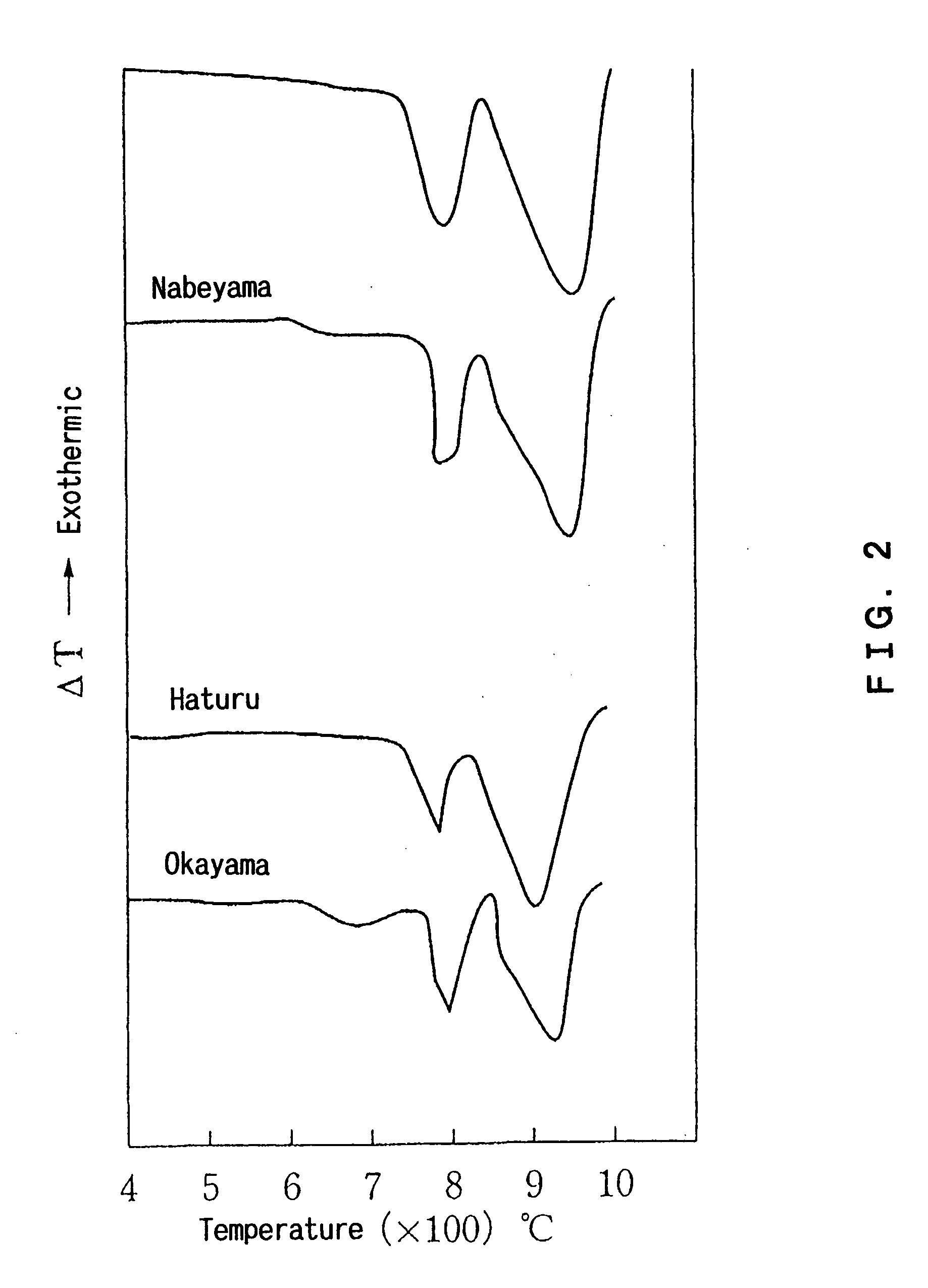

Disclosed is an additive for a plastic, comprising fine particles obtained by calcination and slaking of a dolomite which exhibits two endothermic peaks in the differential thermal analysis, said fine particles containing calcium carbonate, magnesium carbonate, magnesium oxide, calcium hydroxide and magnesium hydroxide as main chemical components and also containing an ignition loss component in an amount of 10 to 40% by weight based on the weight of said fine particles. A plastic hating hydrogen chloride scavenging properties and antimicrobial properties imparted by incorporating the additive for a plastic is also disclosed.

Owner:OSAKA MUNICIPAL TECHN RES INST +2

Method for producing and using water-preserving agent used in desert

InactiveCN1465650APrevent leakageImprove survival rateOrganic fertilisersSoil conditioning compositionsCALCIUM CARBONATE/MAGNESIUM CARBONATEPhosphate

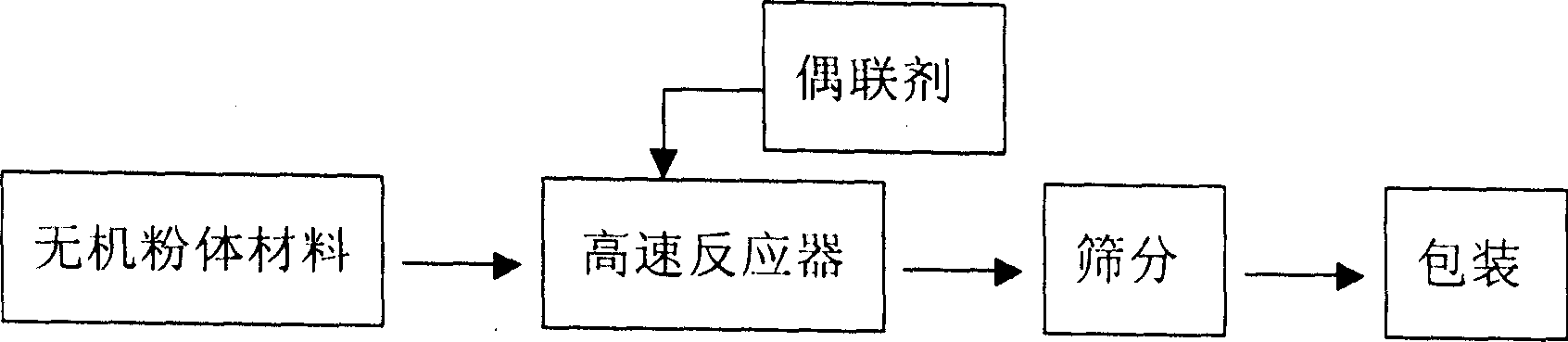

The water-preserving agent for desert zone is made of inorganic powder material and coupling agent according to the weight ratio of 100:0.5-2.5, the described inorganic powder body material is any one of calcium carbonate, magnesium carbonate, talcum powder, pottery clay, wollastonite, coal gangue, flyash, diatomaceous earth or desulfurized gypsum or their any combination, and the described coupling agent is any one of coupling agent of organic titanate, RCA modifying agent, aluminate coupling agent, phosphate coupling agent or silane coupling agent.

Owner:曾敦华

Healthy common salt and production process thereof

The invention provides a healthy common salt which is prepared by crude salt, calcium carbonate, magnesium carbonate, propylene glycol, potassium iodate, ferric citrate, ferric ammonium citrate, sodium selenite and zinc sulfate according to weight ratio; the invention further provides a production process of the healthy common salt: dissolving the propylene glycol, the ferric citrate and the ferric ammonium citrate in water, and dissolving the potassium iodate, the sodium selenite and the zinc sulfate in another water; respectively continuously spraying the two types of solution on the crude salt distributed on a conveyor belt through a nozzle; continuously feeding the crude salt into a boiling drying bed, drying at the temperature of 75-85 DEG C, leading the water to be not more than 0.2%, and feeding into the conveyor belt; mixing the calcium carbonate with the magnesium carbonate, and adding on the crude salt which is distributed on the conveyor belt and fed onto the conveyor belt after drying through a quantitative feeder; feeding the crude salt with auxiliary materials into a rotary mixer, and fully mixing; and packaging, and warehousing after passing the detection. The healthy common salt has good loose effect, convenient storage and transportation, difficult deliquescence and consolidation and high nutritional value, thereby being consistent with the declaration of national green food certification and meeting the requirements on foreign foods and domestic green foods.

Owner:宋秀成 +1

Beauty dispersible tablet compound preparation for helping woman delay senescence and preparation method thereof

InactiveCN104621431AFood ingredient as antioxidantVitamin food ingredientsLycoperseneCALCIUM CARBONATE/MAGNESIUM CARBONATE

The present invention discloses a beauty dispersible tablet compound preparation for helping woman delay senescence and a preparation method thereof. The beauty dispersible tablet compound preparation includes the following active ingredients: collagen, a variety of antioxidants, composite vitamins, composite mineral substances and auxiliary materials. A variety of the antioxidants include grape seed extract (anthocyanin), lycopene, vitamin E and vitamin C. The composite vitamins include beta-carotene, vitamin A, vitamin D3, lutein, folic acid, vitamin B1, vitamin B2, vitamin B6 and vitamin B12 (1%). The composite mineral substances include zinc gluconate, calcium carbonate, magnesium carbonate, ferrous fumarate and selenium yeast. The auxiliary materials include an excipient, a disintegrating agent, a lubricant, a sweetener, a colouring agent and an essence.

Owner:JIANGSU ALAND NOURISHMENT

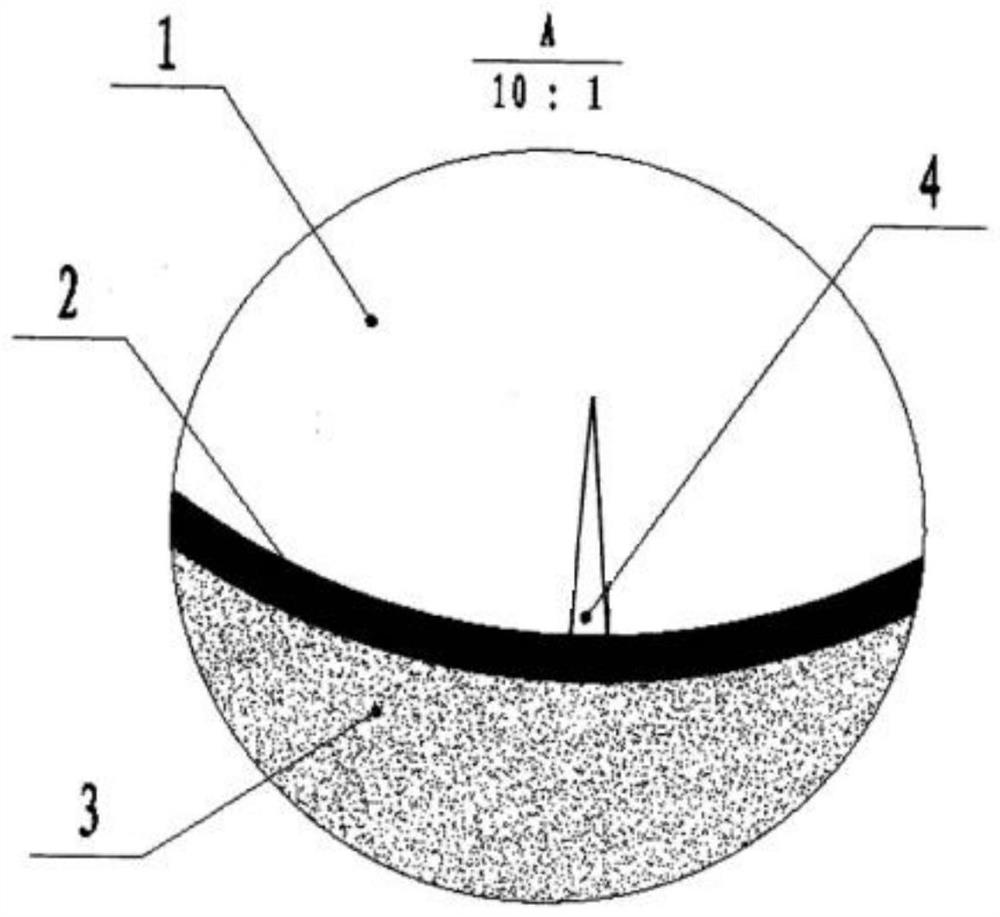

Composite sphere for outside-stove refining dephosphorization, removing fine foreign matter and its manufacturing method

The invention relates to an external refining method for microalloy steel and special steel, in particular to a compound sphere for external refining desulphurization and fine inclusion removal and a preparation method thereof. The compound sphere is the preferred compound sphere for refining desulphurization and fine inclusion removal of various microalloy steel or special steel. The compound sphere consists of a spherical core and a shell, wherein, the spherical core mainly comprises low melting point premelting slag powder, calcium carbonate, magnesium carbonate or a mixture of the calcium carbonate and the magnesium carbonate; and the shell mainly comprises one of calcium oxide or magnesium oxide or a mixture of the calcium oxide and the magnesium oxide. The method has scientific formula and simple and reasonable process, can effectively remove inclusions in molten steel, can realize the quick refining desulphurization of the molten steel until the content of sulfur is lower than 0.0030 percent proven by application, is high in efficiency, steady and short in time, can meet the requirements of different molten steel on the content of the sulfur, greatly improves the quality of refining steel, and reduces smelting cost.

Owner:ANGANG STEEL CO LTD

Energy-saving sulfur-reducing dust removal concentration liquid

The invention discloses an energy-saving, eliminating sulfur and falling dust concentrated liquid, which comprises the following steps: choosing kalii permangana, thyronorman, sodium nitrate, common salt, rare earth chloride, calcium carbonate, calcia, magnesium carbonate, potassium bichromate, boric oxide and borax as raw material; grinding calcium carbonate, magnesium carbonate and calcia to powder with grain size smaller than 1mm; mixing the raw material; adding into water; stirring evenly; getting the product. This concentrated liquid can be mixed into coal, which can increase the temperature of fire box and the heating efficiency of high boiler.

Owner:XINJIANG TIANRONG ENVIRONMENT PROTECTION SCI & TECH DEV

Low-cost environmentally-friendly interior wall paint

ActiveCN102382573AMeet the needs of useWide variety of sourcesLignin material coatingsSodium BentoniteCarbonate

The invention discloses low-cost environmentally-friendly interior wall paint which comprises the following components by weight percent: 30-40% of straw powder, 10-15% of calcium carbonate, 10-15% of magnesium carbonate, 10-15% of bentonite, 2-3% of hydroxyethylcellulose, 3-5% of white latex and the balance of water. Because used raw materials are wide in sources and low in cost, and particularly regenerative straw powder has large proportion, the cost of the paint can be greatly reduced, and the paint is environmentally-friendly.

Owner:5ELEM HI TECH CORP

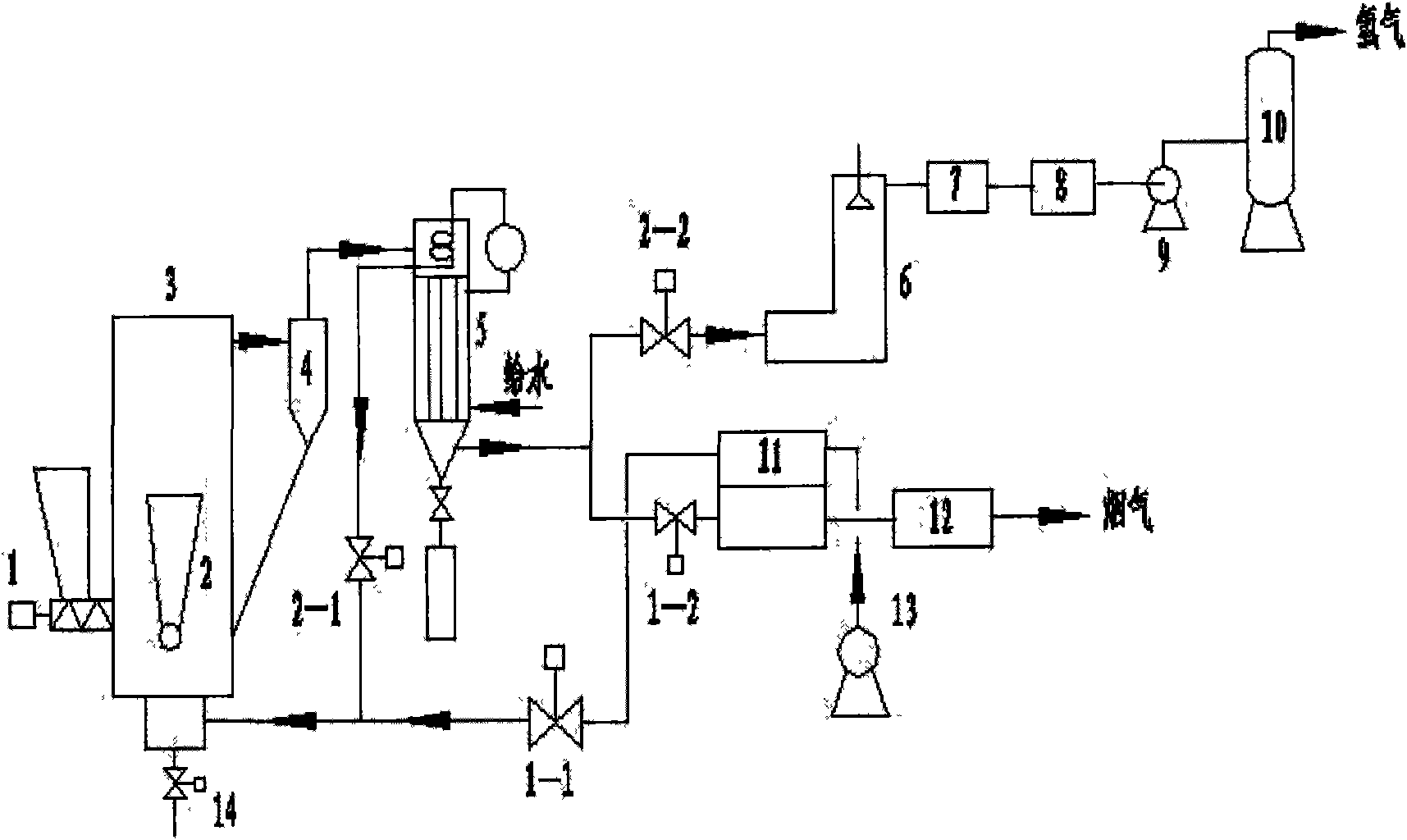

Method and device for producing hydrogen through biomass gasification by using single fluidized bed and two-step method

InactiveCN101570315BQuality improvementLess investmentHydrogen separationEnergy inputCALCIUM CARBONATE/MAGNESIUM CARBONATEFluidized bed gasifier

The invention belongs to the field of energy. Biomass is used as a raw material, and is added with catalyst calcium carbonate / magnesium carbonate of a carbonate system to react in a fluidized bed; a biomass gasification process is divided into two processes, namely a biomass burning process and a biomass pyrolysis and gasification process, and the two processes work alternately in turn, wherein the burning process comprises that catalyst calcium carbonate / magnesium carbonate granules are added into the fluidized bed, simultaneously air is supplied to the fluidized bed, the air supply to the furnace is stopped when the temperature of the bed layer is raised to a predetermined temperature, and the burning process is finished; then the biomass burning process turns to the gasification process, namely vapor and biomass are supplied to the fluidized bed to obtain hydrogen-rich gas with extremely low tar content; and after the hydrogen-rich gas is washed and purified by coal gas, the hydrogen-rich gas is converted into H2 and CO2 in a CO conversion device, then the gas is desulfurized and compressed, and the H2 is extracted from the gas in a variable pressure adsorption device. The method achieves that the gasification and burning two processes and the cyclic regeneration of a catalyst are finished in the same fluidized bed gasification furnace, the investment is saved, and the running cost is low.

Owner:JIANGSU UNIV

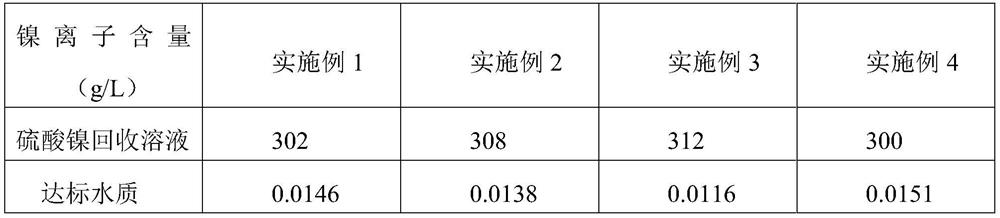

Electroplating nickel-containing wastewater treatment and recovery method

PendingCN112010454AReduce the content of nickel ions in water qualityEfficient removalSpecific water treatment objectivesWater contaminantsCALCIUM CARBONATE/MAGNESIUM CARBONATECalcium bicarbonate

The invention discloses an electroplating nickel-containing wastewater treatment and recovery method, and relates to the field of wastewater treatment. According to the method, carbon dioxide is introduced; on one hand, carbon dioxide and water are mixed to generate bicarbonate ions; the carbonate ions are weak acid, the pH value of the electroplating nickel-containing wastewater can be adjusted to be neutral to weakly acidic; on the other hand, the generated bicarbonate ions react with calcium ions, magnesium ions and aluminum ions to generate calcium bicarbonate, magnesium bicarbonate and aluminum carbonate respectively; calcium bicarbonate and magnesium bicarbonate are hydrolyzed into calcium carbonate, magnesium carbonate and carbon dioxide gas under high temperature; calcium carbonateand magnesium carbonate precipitates are hydrolyzed immediately to generate aluminum hydroxide and carbon dioxide and aluminum hydroxide precipitates due to too weak chemical bonds among aluminum, carbon and oxygen so that calcium ions, magnesium ions and aluminum ions in the electroplating nickel-containing wastewater are removed, and the content of other ions in the recovered nickel solution and the content of metal ions in water after wastewater treatment are reduced.

Owner:上海顺樊环保科技有限公司

Novel aluminum oxide metal ceramic sealing element and preparation method thereof

The invention relates to a novel aluminum oxide metal ceramic sealing element and a preparation method thereof. The novel aluminum oxide metal ceramic sealing element is composed of aluminum oxide, cerium oxide, aluminate, calcium carbonate, magnesium carbonate, wax emulsion, poly(ammonia methacrylate) and kaolin. The novel aluminum oxide metal ceramic sealing element composed of the previous ingredients is improved in both material toughness and uniformity.

Owner:NINGBO DONGLIAN MECHANICAL SEAL

Impurity removal process for lithium sulfate purified liquid

InactiveCN113072081AGuarantee product qualityImprove product qualityLithium carbonates/bicarbonatesLithium sulfates/sulfitesCALCIUM CARBONATE/MAGNESIUM CARBONATELithium sulphate

The invention discloses an impurity removal process for a lithium sulfate purified liquid, belongs to the technical field of lithium sulfate preparation, and aims to provide an impurity removal process for a lithium sulfate purified liquid to solve the problem that the existing lithium sulfate purified liquid contains small-particle impurities and Ca<2+> impurities of insoluble substances such as calcium carbonate and magnesium carbonate and slightly soluble substances such as calcium sulfate and the quality of subsequent lithium carbonate products is poor. The method comprises the following steps of: (1) filtering by adopting a precision filter, and filtering and intercepting insoluble substances such as calcium carbonate and magnesium carbonate and slightly soluble substances such as calcium sulfate in the lithium sulfate purified liquid; and (2) selectively adsorbing soluble Ca<2+> impurities in the lithium sulfate solution through an ion exchange resin column to finish deep purification of the lithium sulfate purified solution. The method is suitable for impurity removal of the lithium sulfate purification completion liquid.

Owner:四川恩特普环保科技有限公司

Production method capable of improving surface roughness of float glass

The invention relates to a production method capable of improving the surface roughness of float glass. After uniformly mixing quartz sand, aluminum oxide, soda ash, calcium carbonate, magnesium carbonate and lithium carbonate, they are sent into a float glass melting furnace, and the float glass The molten glass is melted at high temperature in the melting furnace, and the molten glass flows into the working pool after being clarified and homogenized. The molten glass enters the forming tin tank from the launder in the working pool to form a strip-shaped continuous glass plate. The strip-shaped continuous glass plate is annealed. , Cutting process to make finished glass. The method replaces part of the quartz sand with lithium carbonate and reduces the content of magnesium carbonate by half to overcome and solve the problem of poor flatness in the process of polishing and edge drawing; The reaction process inside the tin bath prevents micro-wrinkles on the surface of the finished glass. The surface roughness of the float glass produced by the above-mentioned production method can reach below 0.004 μm, and the flatness is high.

Owner:TG ANHUI GLASS

Mouldproof maintenance spray for wicker artware

InactiveCN107267015AHas bactericidal and anti-mildew effectImprove mildew resistanceWax coatingsAntifouling/underwater paintsCALCIUM CARBONATE/MAGNESIUM CARBONATEPotassium persulfate

The invention discloses mouldproof maintenance spray for a wicker artware and relates to the field of wicker product daily maintenance. The mouldproof maintenance spray is prepared from beeswax, nano-silver, styrene, butyl acrylate, litsea cubeba oil, cassia bark oil, white mineral oil, potassium persulfate, a level dyeing agent, beta-cyclodextrin, sodium alginate, water, montmorillonite, ammonium polyacrylate, inorganic salt copper sulfate, mercuric chloride, sodium fluoride, calcium carbonate-magnesium carbonate powder and a mouldproof aid. The mouldproof maintenance spray is used for daily maintenance of a wicker product, prevents wicker product mildew, realizes high mouldproof efficiency, can repair fine scratch and can effectively protect wicker products.

Owner:阜南县铭钰柳木工艺品有限公司

Power plant boiler desulfurization and denitrification long-life self-cleaning section steel bottom surface primary glaze

InactiveCN112876074AHigh temperature resistanceImprove corrosion resistanceCALCIUM CARBONATE/MAGNESIUM CARBONATEManganese oxide

The invention relates to a power plant boiler desulfurization and denitrification long-life self-cleaning section steel bottom surface primary glaze which comprises the following components in percentage by weight: 55-90% of a main material, and 10-45% of an auxiliary material, the main material comprises the following components in percentage by weight: 50-60 percent of at least one of quartz sand or zircon sand, 10-30 percent of at least one of Fe3Al, FeAl, Fe2Al5 and FeAl3, and 3.2 to 5.2 percent of lithium nickelate; the auxiliary material comprises the following components in percentage by weight: 9.5-11.5 percent of sodium carbonate, 10.22 -12.25 percent of borax, 1-1.6 percent of ice crystal, 5-8 percent of titanium dioxide, 0.3-0.35 percent of manganese oxide, 0.56-0.8 percent of ferric oxide, 1.2-2.6 percent of calcium carbonate, 1-1.6 percent of magnesium carbonate and 0.8-1.2 percent of zinc oxide. According to the power plant boiler desulfurization and denitrification long-life self-cleaning section steel bottom surface primary glaze, fire-resistant and antioxidant components are added so that high-temperature resistance and corrosion resistance are obtained.

Owner:江阴市全达实业有限公司

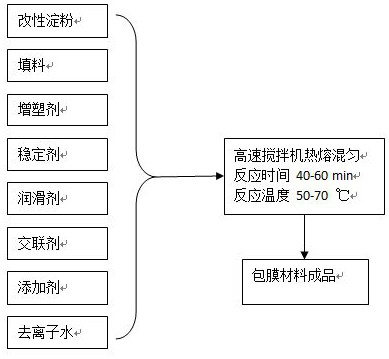

Degradable resin coated slow release fertilizer and preparation method thereof

PendingCN114591119ASlow release of nutrientsIncrease profitAgriculture gas emission reductionLayered/coated fertilisersEpoxySodium bicarbonate

The invention discloses a degradable resin coated slow release fertilizer and a preparation method thereof. The preparation method is characterized by comprising the following steps: selecting materials such as diatomite, wood flour, phthalic ester, epoxy resin, grease amide, a cross-linking agent, calcium carbonate, magnesium carbonate, sodium bicarbonate and modified starch, and performing hot melting, uniform mixing and processing to obtain a coating material; materials such as urea particles, a compound fertilizer and a granular potash fertilizer are used as core materials to prepare the degradable resin coated slow-release fertilizer. The production process is simple in method and low in production cost. The degradable resin is selected to coat fertilizer particles, so that fertilizer nutrients can be slowly released, and the utilization rate of the fertilizer is improved; after the nutrients are completely released, the residual coating material in the soil can be completely degraded to become nutrients which can be absorbed by plants, so that the environment is not polluted, and the fertilizer is an environment-friendly fertilizer.

Owner:TIANJIN AGRICULTURE COLLEGE

Composite dephosphorizing agent for tapping after furnace, preparation method and application

InactiveCN112961962AImprove dephosphorization efficiencyPhosphorus fixation effect is remarkableCALCIUM CARBONATE/MAGNESIUM CARBONATEIron(II) oxide

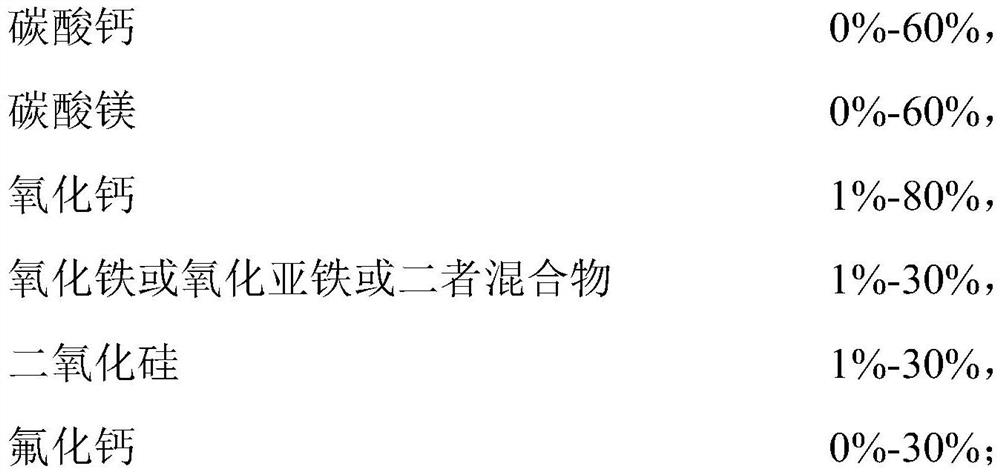

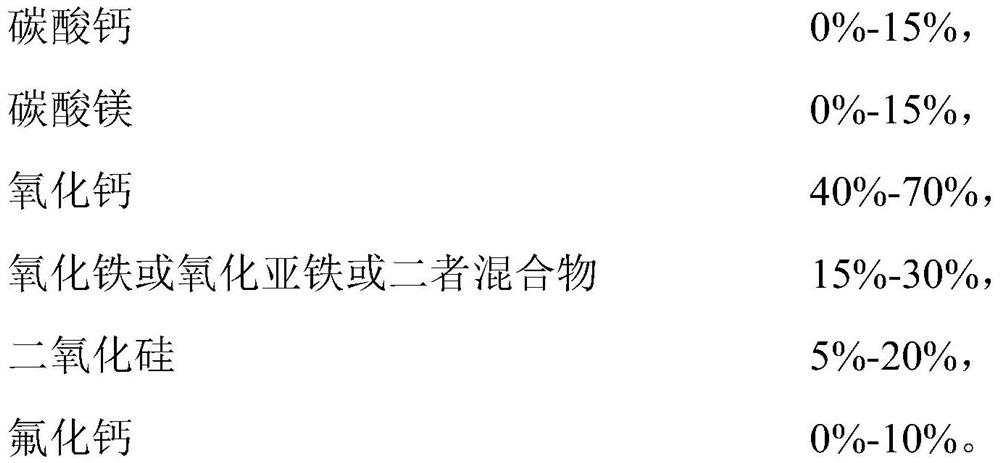

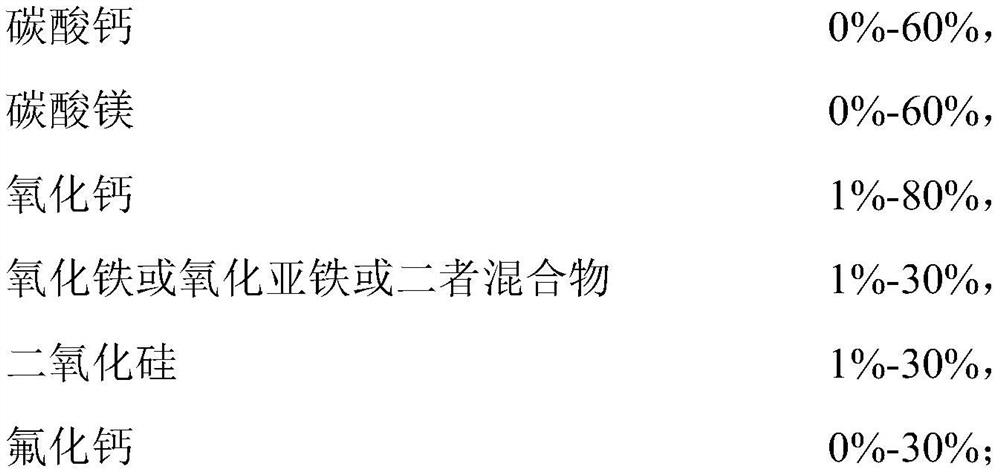

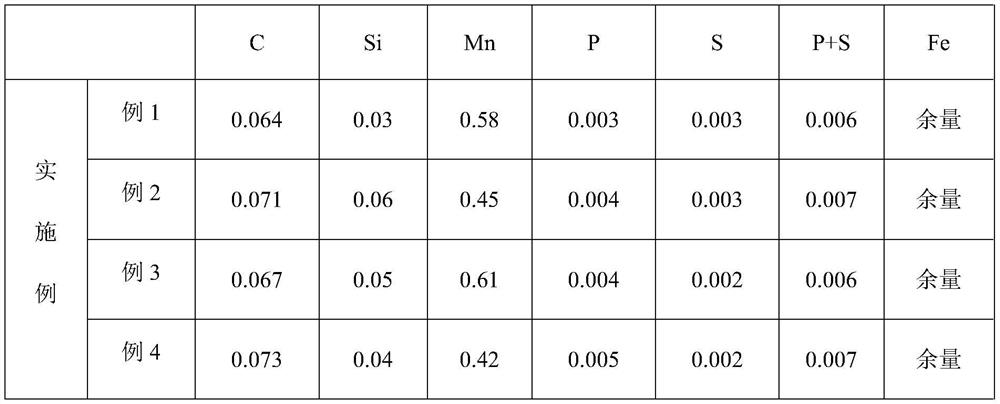

The invention belongs to the technical field of metallurgy, and discloses a composite dephosphorizing agent for tapping after a furnace, a preparation method and application. The composite dephosphorizing agent is powdery and is divided into a sintering powder form and a mechanical mixed powder form; and the raw materials in the two forms comprise, by weight, 0%-60% of calcium carbonate, 0%-60% of magnesium carbonate, 1%-80% of calcium oxide, 1%-30% of ferric oxide or ferrous oxide or a mixture of the ferric oxide and the ferrous oxide, 1%-30% of silicon dioxide and 0%-30% of calcium fluoride. In the tapping process of a converter or an electric furnace, composite dephosphorization powder is added, good reaction kinetics and thermodynamics conditions are utilized, the purpose of deep dephosphorization is achieved, the technology for producing ultra-low phosphorus steel through a single-slag method is improved, and the smelting cost is reduced.

Owner:NORTHEASTERN UNIV

Method for preparing cleaning agent for eliminating downhole polymer micelle

InactiveCN109913190AGood thermal stabilityUse safety and environmental protectionCleaning apparatusDrilling compositionChemistryWater soluble

The invention discloses a method for preparing a cleaning agent for eliminating downhole polymer micelle. The method is characterized by comprising the following steps: preparing an emulsion A from amixed liquid of water and oleyl alcohol in the presence of a surfactant; preparing a liquid B from water, water-soluble ammonium polyphosphate, ammonium chloride and triisopropanolamine; preparing a liquid C from water, maleic acid, ethanediamine, potassium chloride and terephthalaldehyde; preparing a liquid D from water, sucrose ester, nonylphenol polyoxyethylene ether and lauryl sodium sulfate.The pH value of the neutral slow-speed unblocking descaling agent prepared by using the method is within 6.0-7.5; the cleaning agent and a waste cleaning liquid are both neutral, no acid mist is generated, ironic equipment structures are not corroded, and corrosion-free safe unblocking descaling can be achieved; the unblocking descaling agent is capable of both eliminating polymer material scale and asphaltene scale of a rod pumped well and a screw pump well, and eliminating inorganic scale such as calcium carbonate, magnesium carbonate, calcium sulfate and ferric oxide, is good in thermal stability, safe and environmentally friendly to use and applicable to popularization.

Owner:UNIV OF JINAN

Fluoride-free molten steel purifying agent and preparation method thereof

ActiveCN112981043AReduce manufacturing costReduce phosphorus contentProcess efficiency improvementCALCIUM CARBONATE/MAGNESIUM CARBONATESteelmaking

The invention discloses a fluoride-free molten steel purifying agent and a preparation method thereof, and relates to the technical field of steelmaking. The fluoride-free molten steel purifying agent is a composite sphere, the composite sphere is composed of an inner core and an outer shell, the inner core is composed of diatomite, aluminum nitride, Ba-Ti alloy and a silane coupling agent, the outer shell is composed of calcium carbonate, magnesium carbonate and a composite binder, and the mass ratio of the inner core to the outer shell is (1-2): (0.5-2). According to the fluoride-free molten steel purifying agent, raw materials are easy to obtain, the preparation method is simple and easy to operate, the cost is low, inclusions in molten steel can be quickly removed, the functions of slagging, deoxidation, desulfurization and dephosphorization are achieved, and the purification degree of the molten steel is greatly improved; and the diatomite is effectively utilized to purify the molten steel, the production cost is greatly reduced, and the purposes of energy conservation and environmental protection are achieved.

Owner:湖南紫荆新材料科技有限公司

A low-cost and environment-friendly interior wall paint

ActiveCN102382573BMeet the needs of useWide variety of sourcesLignin material coatingsCALCIUM CARBONATE/MAGNESIUM CARBONATECellulose

The invention discloses low-cost environmentally-friendly interior wall paint which comprises the following components by weight percent: 30-40% of straw powder, 10-15% of calcium carbonate, 10-15% of magnesium carbonate, 10-15% of bentonite, 2-3% of hydroxyethylcellulose, 3-5% of white latex and the balance of water. Because used raw materials are wide in sources and low in cost, and particularly regenerative straw powder has large proportion, the cost of the paint can be greatly reduced, and the paint is environmentally-friendly.

Owner:5ELEM HI TECH CORP

Metallurgical solid waste steel slag cement manufacturing method

The invention relates to a metallurgical solid waste steel slag cement manufacturingmethod. Metallurgical solid waste steel slag is immersed into a certain amount of water (or other liquid), and the obtained mixture is put into a pressure container, heated and pressurized, and subjected to heat preservation and pressure maintaining for a certain period of time, so that the water (or other liquid)permeates into dicalcium silicate and tricalcium silicate dense crystals in the steel slag, the pressure container is instantly opened to release pressure, so that the air pressure is rapidly reduced.Due to the fact that the water permeates into the overburnt dicalcium silicate and tricalcium silicate in the steel slag, water molecules are rapidly vaporized and expanded under the huge pressure difference, the crystallization density of the dicalcium silicate and tricalcium silicate is reduced, the specific surface area is increased, the hydration speed of the overburnt dicalcium silicate, tricalcium silicate and other substances is increased, and the early hardness of steel slag cement is improved. Free calcium oxide and magnesium oxide completely react to generate calcium carbonate through pressurization release of carbon dioxide and a catalyst. Due to stable components of magnesium carbonate, later magnesium oxide of the steel slag cement can be avoided. Due to the unstable expansion of the calcium oxide, a great amount of magnetically-separable iron alloy powder can be obtained through reduction.

Owner:BEIJING ZHONGKE JINTENG TECH

Phillipsite-containing heat preservation brick and preparation method thereof

InactiveCN107266124AWide variety of sourcesLow costConstruction materialCeramic materials productionCALCIUM CARBONATE/MAGNESIUM CARBONATEBrick

The invention discloses a phillipsite-containing heat preservation brick and a preparation method thereof and belongs to the field of heat preservation bricks. The heat reserving brick is prepared from 60-80 parts by weight of iron ore tailings, 30-50 parts by weight of phillipsite, 25-35 parts by weight of phosphogypsum, 20-30 parts by weight of glass fibers, 15-25 parts by weight of modified diatomite, 10-20 parts by weight of aerated aluminum powder, 5-15 parts by weight of calcium carbonate-magnesium carbonate powder, 10-20 parts by weight of white latex, 8-12 parts by weight of silicon-calcium slag, 1-5 parts by weight of a water reducing agent, 1-5 parts by weight of a hydrophobic agent, 1-3 parts by weight of a foaming agent and 1-3 parts by weight of a foam stabilizer. The preparation method comprises carrying out ball milling on iron ore tailings to obtain powder, mixing all the raw materials, adding water into the mixture, carrying out uniform stirring to obtain slurry, press-molding the slurry, carrying out natural curing, carrying out drying and carrying out high temperature calcination. The preparation method realizes a low heat preservation production cost. The heat preservation brick has good compressive strength, frost resistance, weather resistance, small dry density, strong practical durability, environmental friendliness and broad market prospect.

Owner:安徽睿智检验检测服务有限公司

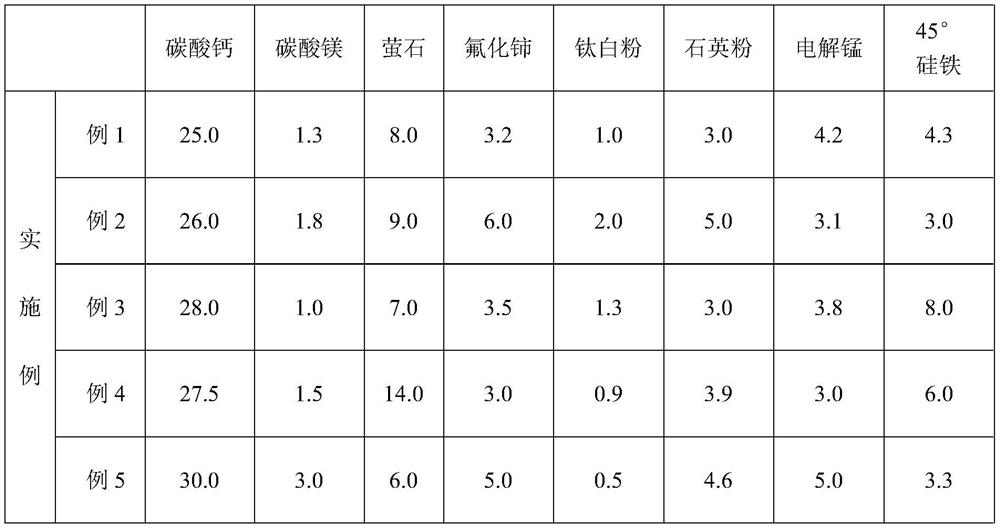

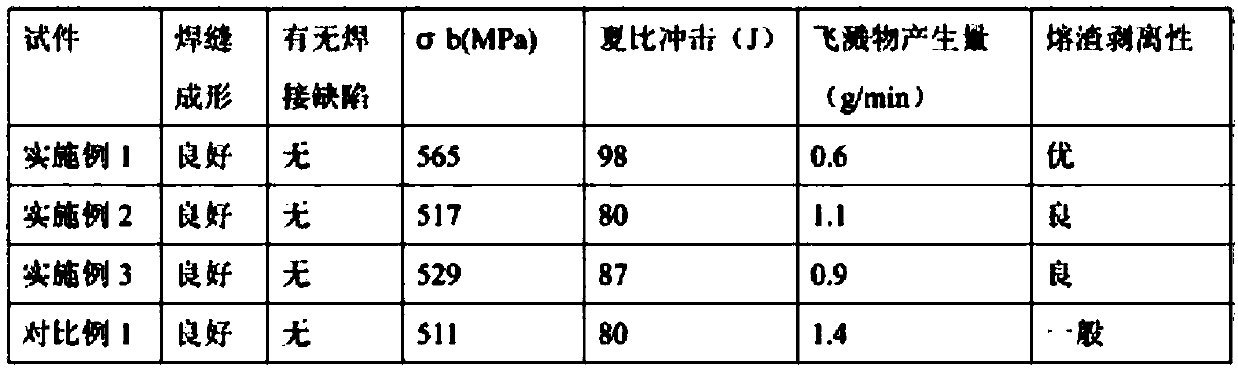

Welding rod for 07MnNiMoDR steel spherical tank and preparation method of welding rod

ActiveCN113458648AImprove toughnessImprove crack resistanceWelding/cutting media/materialsSoldering mediaCALCIUM CARBONATE/MAGNESIUM CARBONATECrack resistance

The invention discloses a high-efficiency, high-crack-resistance high-strength welding rod for a 07MnNiMoDR steel spherical tank. A coating of the high-strength welding rod comprises calcium carbonate, magnesium carbonate, fluorite, cerium fluoride, titanium dioxide, quartz powder, electrolytic manganese, 45-degree ferrosilicon, ferromolybdenum, metal nickel, ferrotitanium, ferroboron, atomized iron powder, rare earth alloy, alginate and a binder. The welding rod is wide in adaptability, can resist long-time heat treatment and can be used for ultra-large heat input welding, the welding seam metal deposition efficiency reaches up to 120%, the melting coefficient is larger than 11 g / A.h, and the welding efficiency of a construction site can be remarkably improved. And deposited metal has high strength, high toughness, ultralow diffusible hydrogen and excellent crack resistance.

Owner:KUSN GINTUNE WELDING

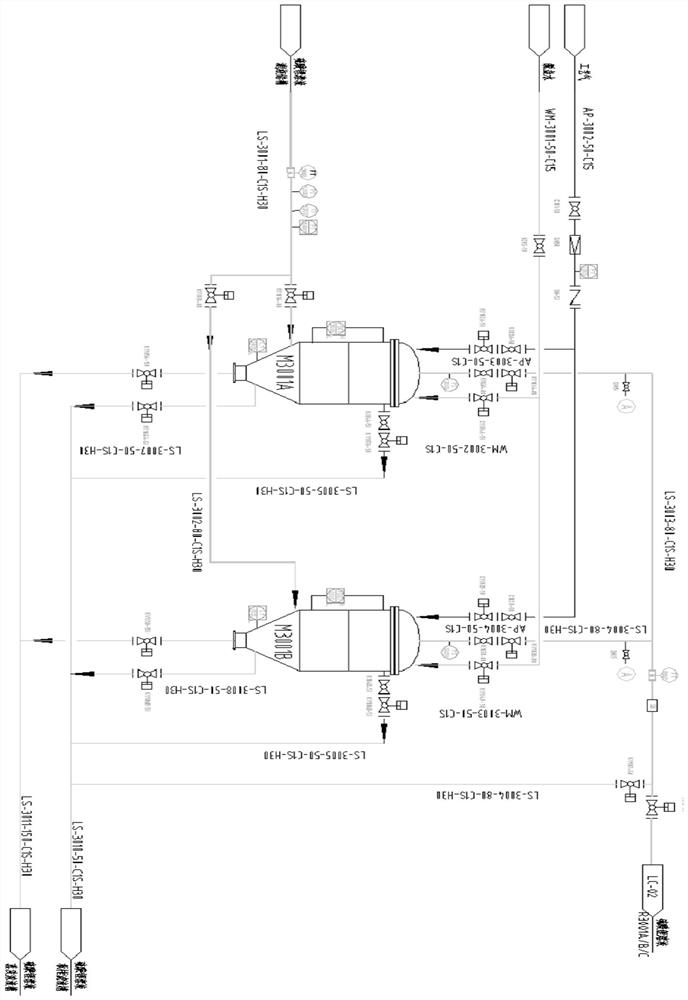

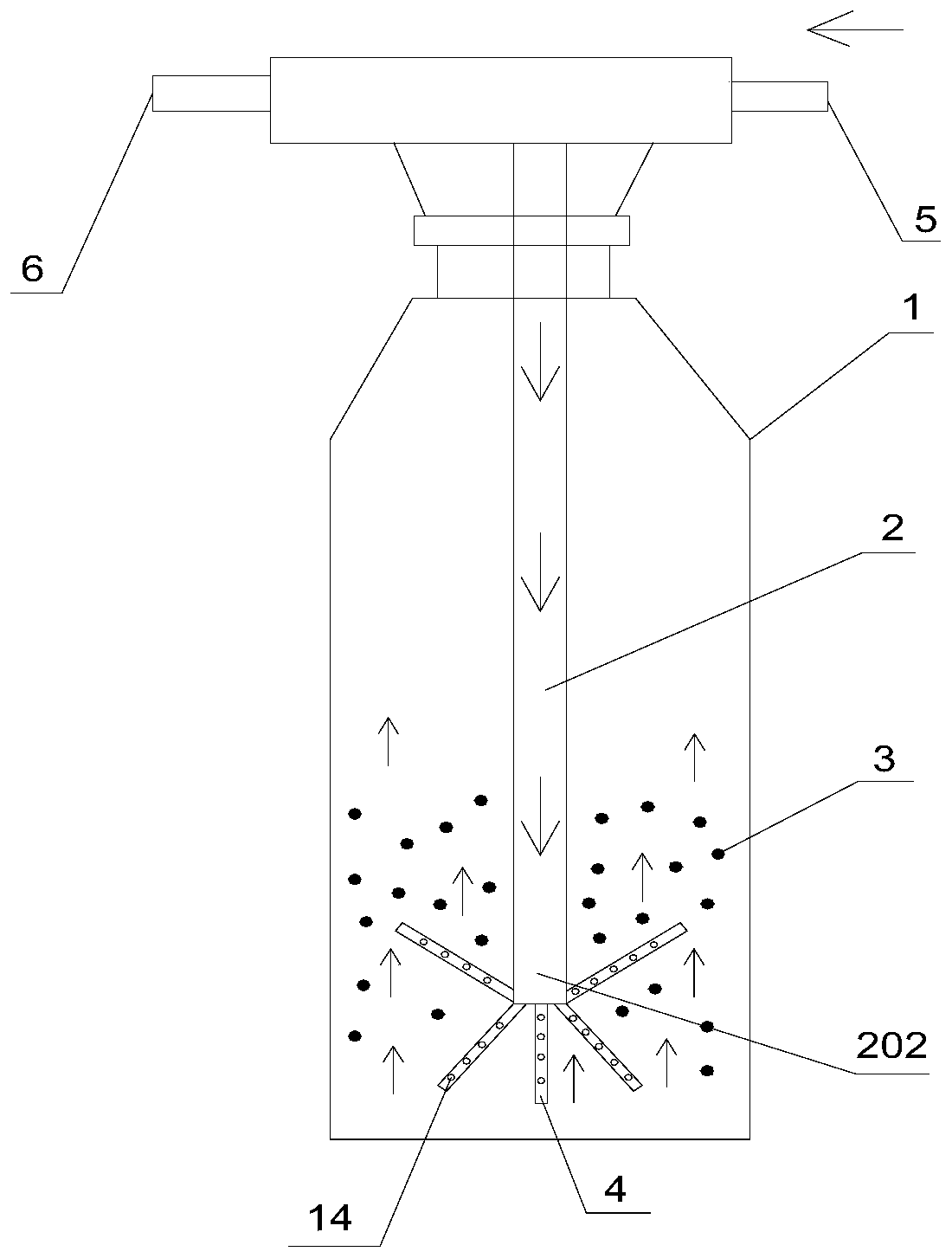

Water softening device

PendingCN111547869AFully contactedReduce concentrationTreatment using complexing/solubilising chemicalsCALCIUM CARBONATE/MAGNESIUM CARBONATEWater softening

The invention relates to the technical field of de-scaled softened water, and discloses a water softening device. The device comprises a reaction tank in a closed state and a flow guide pipe, the reaction tank communicates with a water inlet and a water outlet; a filter material for modifying the lattice structure of ores is arranged in the reaction tank; the first end of the flow guide pipe is positioned outside the reaction tank; the second end of the flow guide pipe penetrates through the water inlet and extends to the bottom of the reaction tank, raw water flows in from the first end and flows out from the second end, the pressure in the reaction tank is increased, the filter material moves upwards under the action of pressure, the raw water is in full contact with the filter material,and calcium ions and magnesium ions in the raw water are converted into calcium carbonate and magnesium carbonate crystals that suspend in the raw water under the catalytic action of the filter material. Through the technical scheme, the calcium and magnesium ions are converted into insoluble micro crystals, the temporary hardness of water is converted into stable calcium carbonate crystals, theformed crystals are stable, and scale accumulation is avoided. The filter material is not needed to be continuously added, equipment cannot be corroded, the service life of the equipment is not shortened, and operators cannot be hurt.

Owner:李冰

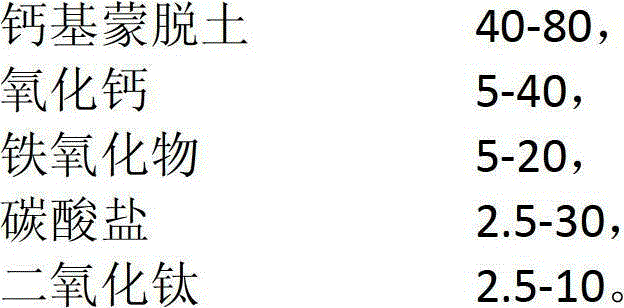

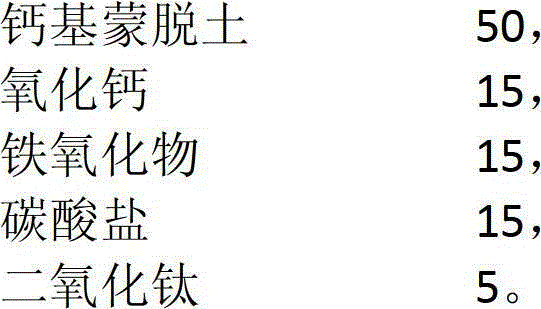

Desulfurizing and denitrifying agent for smoke gas

InactiveCN102179164BImprove desulfurization and denitrification effectEasy doseDispersed particle separationAir quality improvementCALCIUM CARBONATE/MAGNESIUM CARBONATEIron(II) oxide

The invention discloses a smoke gas catalyst capable of simultaneously realizing desulfurization and denitrification, which aims to provide a desulfurizing and denitrifying agent for CTR-ultraviolet radiation smoke gas capable of reducing the investment and operation costs of the device and simultaneously efficiently removing the NO, NO2 and SO2 in the smoke gas. The moke gas desulfurizing and denitrifying catalyst provided by the invention may comprise the following components according to fractional ratio: 40-100% of calcium-based imvite, 0-40% of calcium oxide, 0-20% of iron oxide, 0-30% of carbonate and 0-10% of titanium dioxide, wherein the iron oxide is one or more types of ferrous oxide, iron sesquioxide and ferroferric oxide, and the carbonate is one or more types of calcium carbonate and magnesium carbonate. The desulfurizing and denitrifying agent for CTR-ultraviolet radiation smoke gas is not only suitable for the flue gas desulfurization of a new boiler but also particularly suitable for the improvement in order to construct a combustion device.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

Composite sphere for outside-stove refining desulfurization, removing fine foreign matter and its manufacturing method

ActiveCN100543153CStrong desulfurization abilityRealize refining desulfurizationCALCIUM CARBONATE/MAGNESIUM CARBONATESteelmaking

Owner:ANGANG STEEL CO LTD

A kind of fe-a12o3 cermet sealing ring and preparation method thereof

ActiveCN108425059BImproved toughnessGood high temperature and wear resistanceCALCIUM CARBONATE/MAGNESIUM CARBONATEAluminate

The invention relates to a Fe-Al2O3 metal ceramic sealing ring with excellent wear resistance and toughness and uniform microscopic structures, and a preparation method thereof. The Fe-Al2O3 metal ceramic sealing ring is composed of, by weight, 40 to 60% of alumina, 2 to 4% of iron oxide, 1 to 3% of zirconia, 3 to 5% of cerium oxide, 0.1 to 1% of LaNbO4, 1 to 2% of an aluminate, 0.1 to 1% of calcium carbonate, 0.2 to 0.8% of magnesium carbonate, 0.02 to 0.5% of a wax emulsion, 0.3 to 1.2% of ammonium polymethacrylate, 0.5 to 3% of a binder, 0.2 to 1% of a dispersant, and the balance clay and inevitable impurities. The composition of the Fe-Al2O3 metal ceramic sealing ring is reasonable; and the Fe-Al2O3 metal ceramic sealing ring with excellent performance is prepared through strict preparation technology.

Owner:NINGBO DONGLIAN MECHANICAL SEAL

A stainless steel electrode that resists redness and cracking of the drug skin

InactiveCN111112882BSmall volume expansionReduce the amount of expansion deformationWelding/cutting media/materialsSoldering mediaCALCIUM CARBONATE/MAGNESIUM CARBONATECellulose

The invention belongs to the field of welding materials, in particular to a stainless steel welding rod resistant to redness and cracking of the drug skin, comprising a stainless steel welding core with a longitudinal V-shaped groove on the outer peripheral surface, a copper plating layer and a drug layer, and the dry powder component in the drug layer For: Rutile 10%‑12%, Mica 8%‑10%, Calcium Carbonate 8%‑10%, Magnesium Carbonate 8%‑10%, Nickel Carbonate 5%‑7%, White Clay 3%‑5%, Zirconia 2%‑4%, 8%‑10% fluorite, 1%‑3% spodumene, 4%‑6% ferromanganese, 2%‑4% ferrotitanium, 5%‑7% ferrosilicon, sodium alginate 0.2%-0.3%, carboxymethyl cellulose 0.15%-0.25%, nano-cerium oxide and / or nano-yttrium oxide and / or nano-lanthanum oxide 1.5%-2%, and the rest is feldspar. The welding core of the invention has small volume expansion after being heated, high strength of the coating, high welding arc voltage, joint transition of molten droplet in the form of slag wall and jet, and strong resistance to redness and cracking of the coating.

Owner:ZHENGZHOU UNIV

A kind of flux-cored welding wire for underwater welding and preparation method

ActiveCN108296667BArc stabilizationReduce splashWelding/cutting media/materialsSoldering mediaCALCIUM CARBONATE/MAGNESIUM CARBONATEManganese

The invention discloses a flux-cored wire for underwater welding and a preparation method. The flux-cored wire is composed of outer skin and a flux core. The flux-cored wire is characterized in that the outer skin is made from low-carbon steel, the flux core is prepared from oxide, carbonate, fluoride and metal powder, the oxide is the mixture of calcium oxide, magnesium oxide, titanium oxide, iron oxide and silicon oxide, the fluoride is the mixture of calcium fluoride, lithium fluoride and barium fluoride, the carbonate is the mixture of calcium carbonate, magnesium carbonate and barium carbonate, and the metal powder is the mixture of silicon, aluminum, titanium, magnesium, nickel, iron, manganese and boron. The flux-cored wire enables underground wet welding to have the advantages thatelectric arc is stable, less splash is produced, molten slag stripping performance is excellent, welding seam forming performance is good, and welding seam structure performance is excellent.

Owner:QINGDAO RUNQIAN HI TECH CO LTD

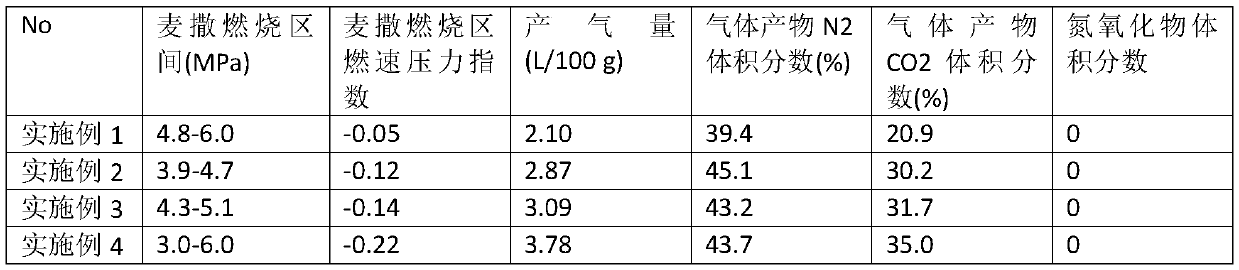

A kind of composite gas generating agent with Maisa combustion effect and its preparation method

ActiveCN108752154BStable combustionStable thrust performanceExplosivesPressure gas generationCALCIUM CARBONATE/MAGNESIUM CARBONATEEngineering

Owner:UNIV OF SCI & TECH OF CHINA

Composite molten steel purifying agent and preparation method thereof

ActiveCN113151638AWide variety of sourcesReduce phosphorus contentProcess efficiency improvementSteelmakingCALCIUM CARBONATE/MAGNESIUM CARBONATE

The invention discloses a composite molten steel purifying agent and a preparation method thereof, and relates to the technical field of steelmaking. The composite molten steel purifying agent is a composite sphere, wherein the composite sphere is composed of an inner core and a shell, the inner core is composed of aluminum ash, barium oxide, titanium dioxide and water glass, the shell is composed of calcium carbonate, magnesium carbonate and a composite binder, and the mass ratio of the inner core to the shell is (1-2):(0.5-2). According to the composite molten steel purifying agent, the raw materials are easy to obtain, the preparation method is simple and easy to operate, the cost is low, inclusions in molten steel can be rapidly removed, the functions of slag making, deoxidation, desulfurization and dephosphorization are achieved, and the purification degree of the molten steel is greatly improved. The solid waste slag aluminum ash is effectively utilized, so that the production cost is greatly reduced, and the purposes of energy conservation and environmental protection are achieved while the purification effect is guaranteed.

Owner:湖南紫荆新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com