Degradable resin coated slow release fertilizer and preparation method thereof

A coating slow-release and degradable resin technology, applied in layered/coated fertilizers, fertilization devices, fertilizer mixtures, etc., can solve problems such as high production costs, difficult degradation of coating materials, environmental hazards, etc., and improve fertilizer utilization rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

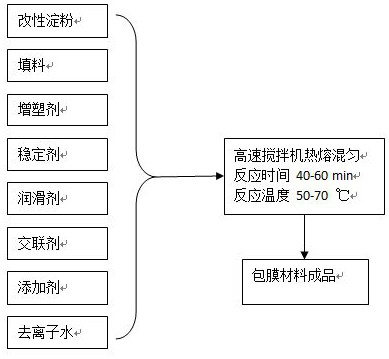

Method used

Image

Examples

Embodiment 1

[0026] A degradable resin-coated slow-release fertilizer, comprising the following components by weight:

[0027] 60 parts of modified starch, 1 part of gelatinizer, 1 part of oxidizing agent, 4 parts of filler, 10 parts of plasticizer, 0.1 part of stabilizer, 1 part of lubricant, 1 part of crosslinking agent, 1 part of additive, Na 2 S 2 O 3 1 serving.

[0028] A preparation method of a degradable resin-coated slow-release fertilizer, comprising the following steps:

[0029] a) Preparation of modified starch: Add 60 parts of commercially available starch and 60 parts of deionized water to a high-speed mixer to mix, heat to 50°C, stir for 5 minutes, add 1 part of NaOH, H 2 O 2 1 part, Na was added after 50min of reaction 2 S 2 O 3 1 part, stir at high speed for 3 minutes to stop oxidation, then add deionized water to wash, dehydrate and dry to obtain finished modified starch;

[0030] b) Preparation of coating material: 60 parts of modified starch, 300 parts of deioni...

Embodiment 2

[0033] A degradable resin-coated slow-release fertilizer, comprising the following components by weight:

[0034] 70 parts of modified starch, 1.5 parts of gelatinizer, 1.5 parts of oxidant, 5 parts of filler, 12 parts of plasticizer, 0.15 parts of stabilizer, 1.5 parts of lubricant, 1.5 parts of crosslinking agent, 1.5 parts of additives, Na 2 S 2 O 3 1.5 servings.

[0035] A preparation method of a degradable resin-coated slow-release fertilizer, comprising the following steps:

[0036] a) Preparation of modified starch: add 70 parts of commercially available starch and 70 parts of deionized water to a high-speed mixer and mix, heat to 60°C, stir for 8 minutes, add 1.5 parts of NaOH, H 2 O 2 1.5 parts, Na was added after 55min of reaction 2 S 2 O 3 1.5 parts, stirred at high speed for 6 minutes, terminated oxidation, then added deionized water to wash, dehydrated and dried to obtain the finished product of modified starch;

[0037] b) Preparation of coating material:...

Embodiment 3

[0040] A degradable resin-coated slow-release fertilizer, comprising the following components by weight:

[0041] 80 parts of modified starch, 2 parts of gelatinizer, 2 parts of oxidizing agent, 6 parts of filler, 15 parts of plasticizer, 0.2 part of stabilizer, 2 parts of lubricant, 2 parts of crosslinking agent, 2 parts of additives, Na 2 S 2 O 3 2 servings.

[0042] A preparation method of a degradable resin-coated slow-release fertilizer, comprising the following steps:

[0043] a) Preparation of modified starch: Add 80 parts of commercially available starch and 80 parts of deionized water to a high-speed mixer to mix, heat to 70°C, stir for 10 minutes, add 2 parts of NaOH, H 2 O 2 2 parts, Na was added after 60min of reaction 2 S 2 O 3 2 parts, high-speed stirring for 10min, termination of oxidation, then adding deionized water for washing, dehydration and drying to obtain the finished modified starch;

[0044] b) Preparation of coating material: 80 parts of modif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com