A kind of composite gas generating agent with Maisa combustion effect and its preparation method

A gas generating agent and combustion effect technology, which is applied in the generation of compressed gas, attack equipment, explosives, etc., can solve the problems of high combustion temperature, poor thermal stability, high burning rate and pressure index, and achieve good application prospects and stable thrust performance , The effect of chemical combustion stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

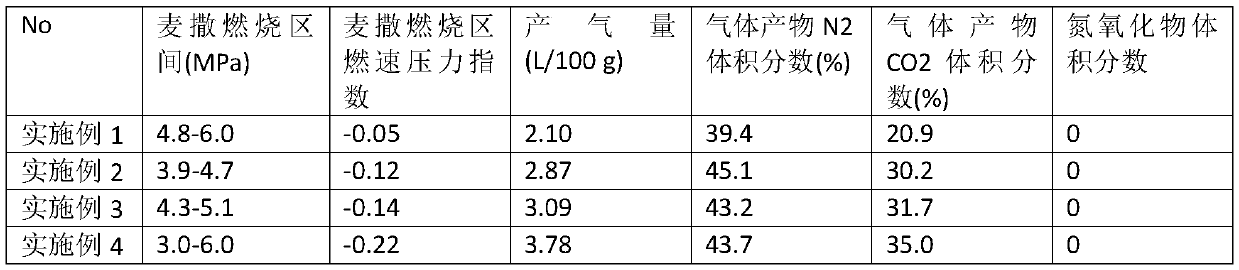

Examples

preparation example Construction

[0036]

[0037] (1) 17.1 grams of 5-aminotetrazole and 18.02 grams of guanidine carbonate were placed in an incubator at 80°C for drying for 8 hours; (2) after drying, 5-aminotetrazole was added to 500ml of ethanol solution and stirred slowly Slowly add guanidine carbonate simultaneously; (3) place on the constant temperature magnetic stirrer after putting into magnetic stirrer, temperature is set to 50 ℃, and rotating speed is set to 500rpm, and stirring time is set to 12 hours; (4) stops after stirring After 3 hours, the product with reaction gas escapes completely, and the reaction solution is added to a suction filtration device for suction filtration; (5) collect the solid matter obtained after suction filtration, and place it in a constant temperature drying oven at 80° C. for drying for 24 hours to obtain Pentaaminotetrazolium guanidine salt.

Embodiment 1

[0039] A composite gas generating agent, based on the mass of the gas generating agent as 100%, its composition and mass fraction are 24.9% of 5-aminotetrazole, 20.1% of strontium nitrate, 2% of copper oxide, and 1% of zinc oxide %, calcium carbonate 30%, magnesium carbonate 20%, epoxy resin 2%;

[0040] A kind of preparation method of above-mentioned composite type gas generant composition is as follows:

[0041] (1) 5-aminotetrazole and strontium nitrate were ball milled in a ball mill at 100rpm for 1.5 hours respectively, and repeatedly passed through a 200 mesh sieve for 2 times to obtain 5-aminotetrazole and strontium nitrate with a particle diameter≤75 μm; (2) Place calcium carbonate and magnesium carbonate in an incubator at 80°C to dry for 12 hours, repeat passing through a 200-mesh sieve 4 times to obtain calcium carbonate and magnesium carbonate with a particle size of ≤75 μm; (3) mix 24.9g of 5-aminotetrazole, 20.1g of strontium nitrate, 30g of calcium carbonate an...

Embodiment 2

[0043] A composite gas generating agent, based on the mass of the gas generating agent as 100%, its composition and mass fraction are 25.8% of 5-aminotetrazole, 21.5% of nitroguanidine, 26.7% of strontium nitrate, copper oxide 2%, zinc oxide 2%, calcium carbonate 20%, epoxy resin 2%;

[0044](1) 5-aminotetrazole, nitroguanidine and strontium nitrate were ball milled in a ball mill at 100rpm for 1.5 hours respectively, and passed through a 200 mesh sieve twice to obtain 5-aminotetrazole and nitroguanidine with a particle size≤75 μm. Guanidine and strontium nitrate; (2) place calcium carbonate in an incubator at 80°C to dry for 12 hours, repeat passing through a 200-mesh sieve 4 times to obtain calcium carbonate with a particle size of ≤75 μm; (3) mix 25.8g of 5-aminotetrazole , 21.5g nitroguanidine, 26.7g strontium nitrate and 20g calcium carbonate were mixed, after adding 2g copper oxide, 2g zinc oxide, ball milled again in the ball mill of 100rpm for 0.5 hour to obtain a unif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com