Method for producing protein feed material by utilizing food wastes

A protein feed and kitchen waste technology, applied in the molding or processing of animal feed, animal feed, animal feed, etc., can solve the problems of hidden safety hazards, neglect of the risk of food waste, etc., to remove peculiar smell, reduce homologous phase The effect of the risk of eating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

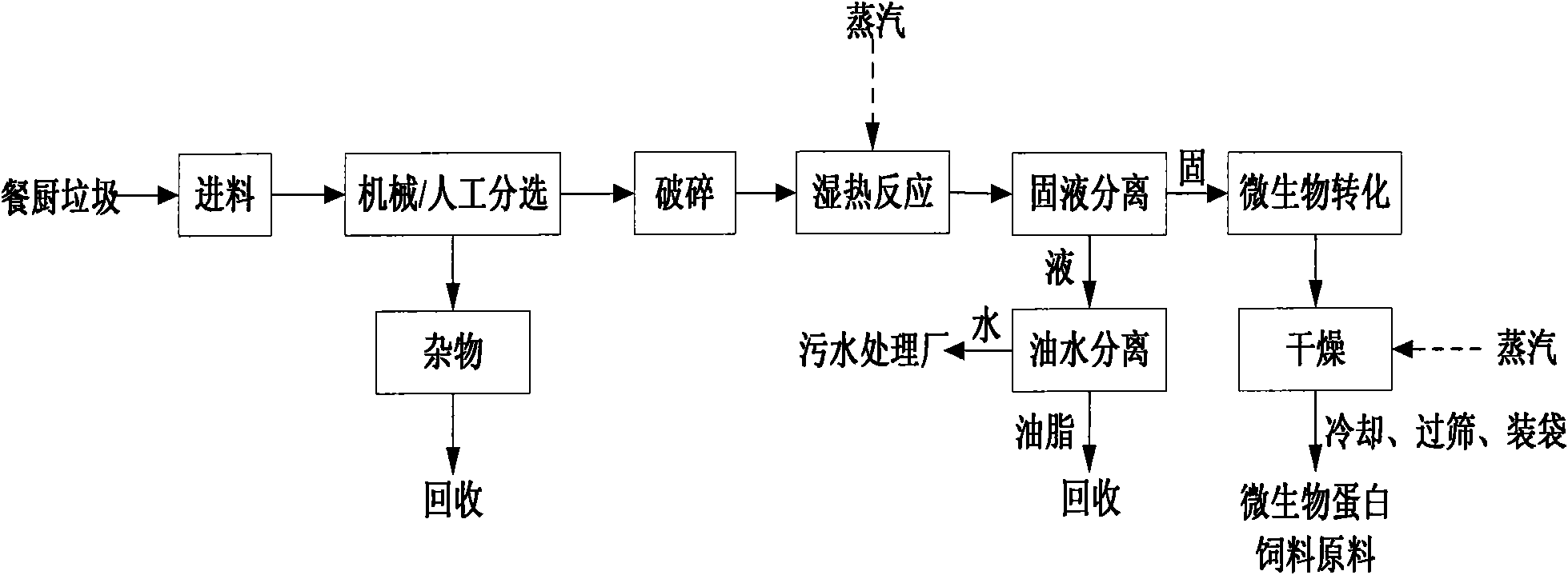

Method used

Image

Examples

Embodiment 1

[0023] A food waste treatment plant has a daily processing capacity of 50 tons. The collected food waste is discharged into the hopper and sent to the mechanical sorting machine by the scraper conveyor. After sorting, it is manually sorted to further separate plastic bags, chopsticks, The sundries such as bottle caps are cleaned and recycled; the sorted food waste is crushed to 1-10mm, and sent to the damp heat reactor through a rotary piston pump into the pipeline; the moisture content of the material is adjusted to 80%, and the indirect steam Heating, when the temperature reaches 135°C, continue to cook for 80 minutes; the cooked material is separated from the solid and liquid by a plate and frame filter press, and the moisture content of the solid after the filter is 40-50%; the liquid after the oil-water separation is separated by a disc filter. Centrifuge for oil-water separation, oil recovery, waste water into the sewage pipe network into the sewage treatment plant; solid...

Embodiment 2

[0025] A food waste treatment plant has a daily processing capacity of 100t. The collected food waste is discharged into the hopper and sent to the mechanical sorting machine by the scraper conveyor. After sorting, it is manually sorted to further separate plastic bags, chopsticks, The sundries such as bottle caps are cleaned and recycled; the sorted food waste is crushed to 1-10mm, and sent to the damp heat reactor through a rotary piston pump; the moisture content of the material is adjusted to 85%, and the steam is used for indirect Heating, when the temperature reaches 145°C, continue to cook for 70 minutes; the cooked material is separated from the solid and liquid by a plate and frame filter press, and the moisture content of the solid after the filter is 40-50%; the liquid after the oil-water separation is separated by a disc filter. The centrifuge performs oil-water separation, oil recovery, and waste water is discharged into the sewage pipe network and enters the sewag...

Embodiment 3

[0027] A food waste treatment plant has a daily processing capacity of 100t. The collected food waste is discharged into the hopper and sent to the mechanical sorting machine by the scraper conveyor. After sorting, it is manually sorted to further separate plastic bags, chopsticks, The sundries such as bottle caps are cleaned and recycled; the sorted food waste is crushed to 1-10 mm, and sent to the damp heat reactor through a rotary piston pump; the moisture content of the material is adjusted to 90%, and the steam is used for indirect Heating, when the temperature reaches 160°C, continue to cook for 60 minutes; the cooked material is separated from solid and liquid by plate and frame filter press, and the moisture content of solid after filter press is 40-50%; the liquid after oil-water separation is separated by disc filter Centrifuge for oil-water separation, oil recovery, waste water into the sewage pipe network into the sewage treatment plant; solid matter into the biolog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com