Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

87 results about "Waste treatment plant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

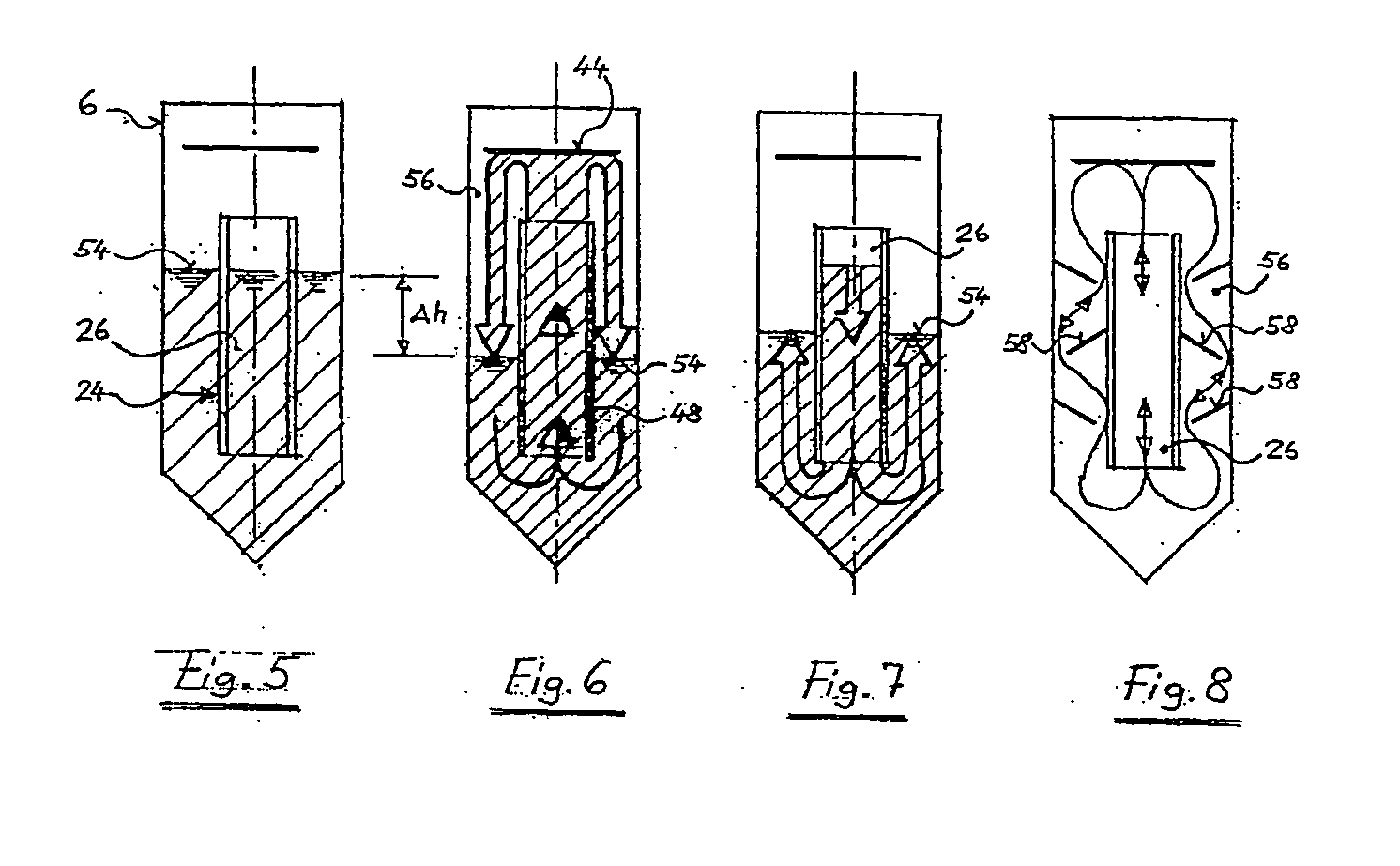

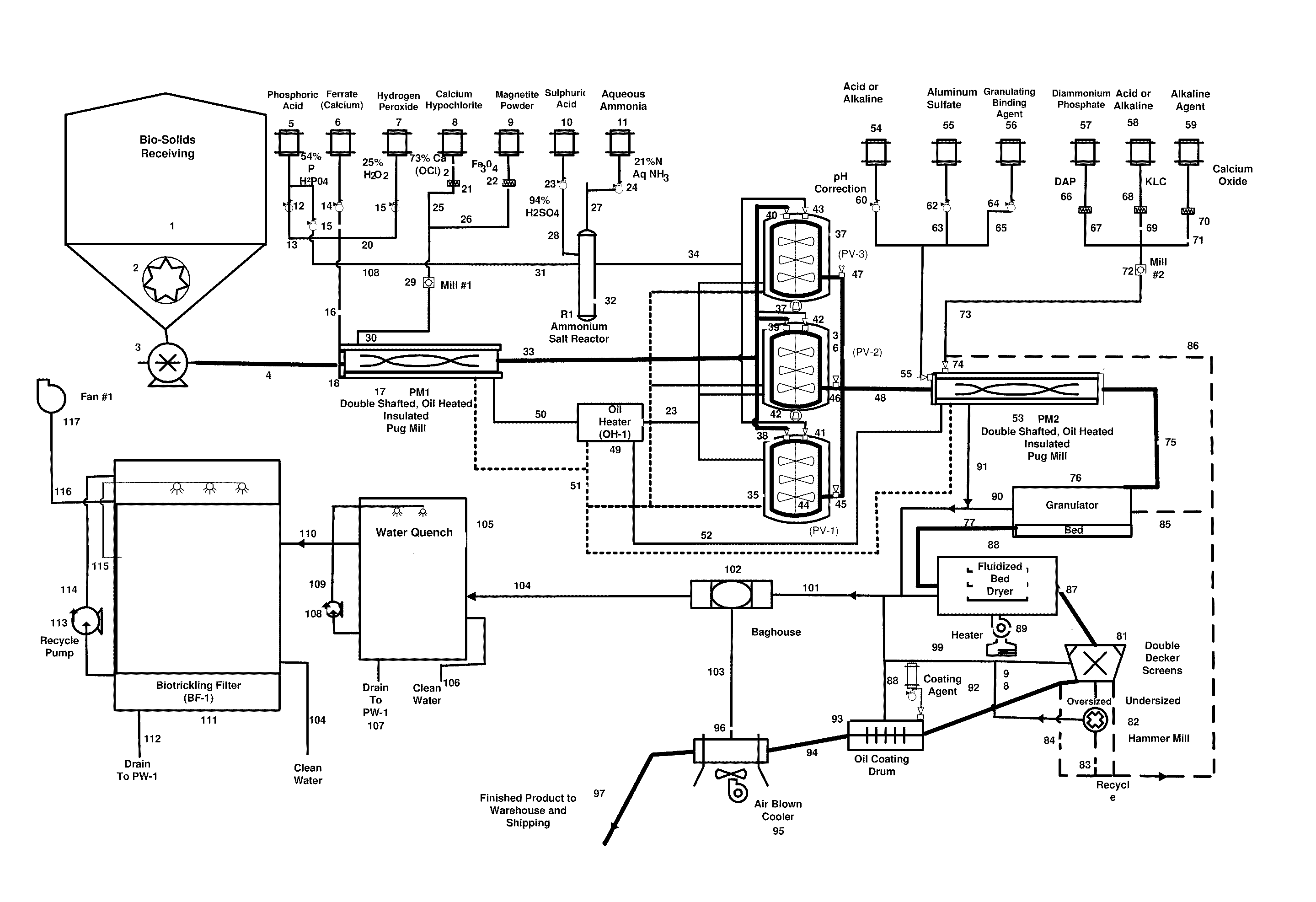

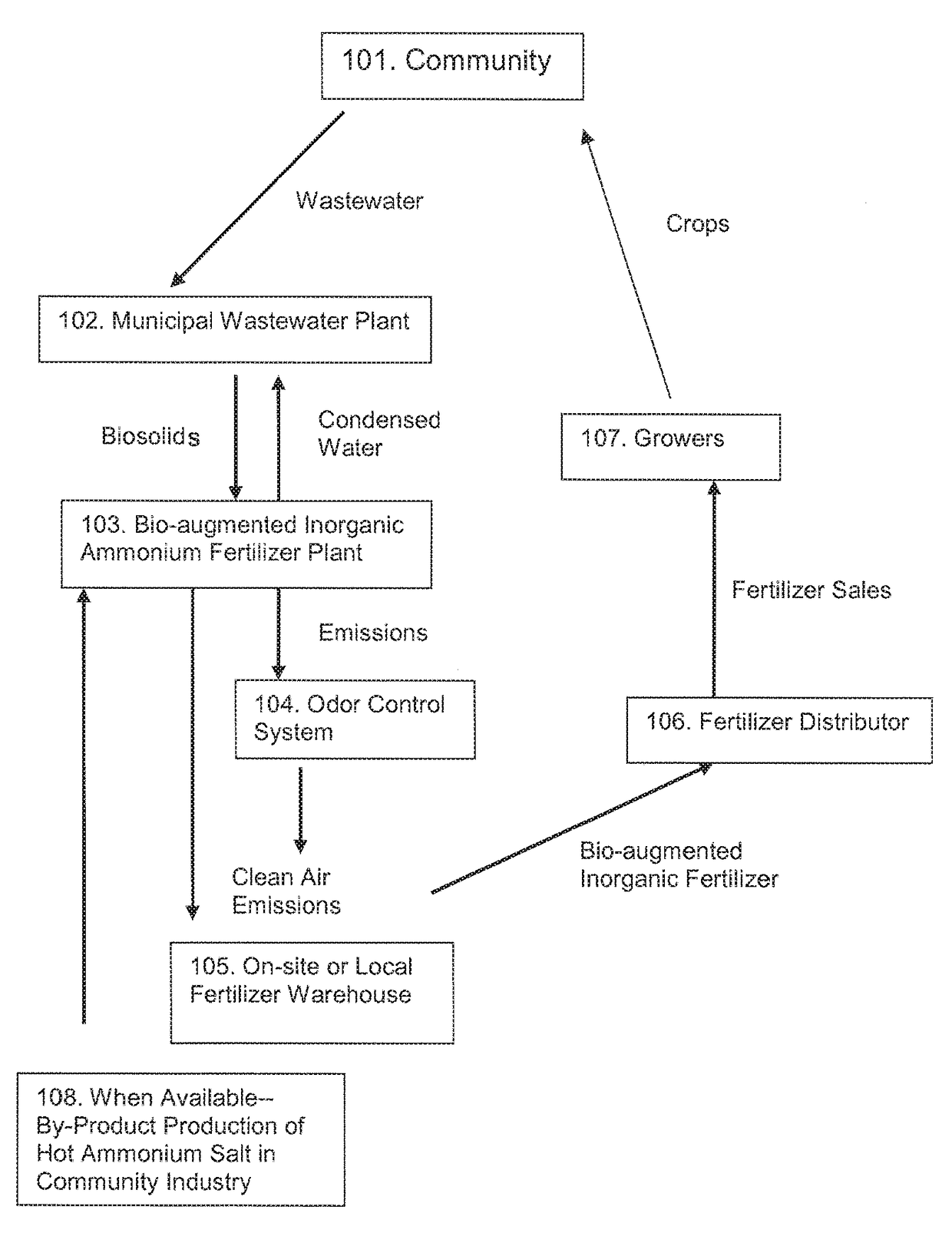

Process for treating sludge and manufacturing bioorganically-augmented high nitrogen-containing inorganic fertilizer

ActiveUS20080230484A1Reduce logisticsReduces liabilityByproduct vaporizationExcrement fertilisersPhosphateRetention time

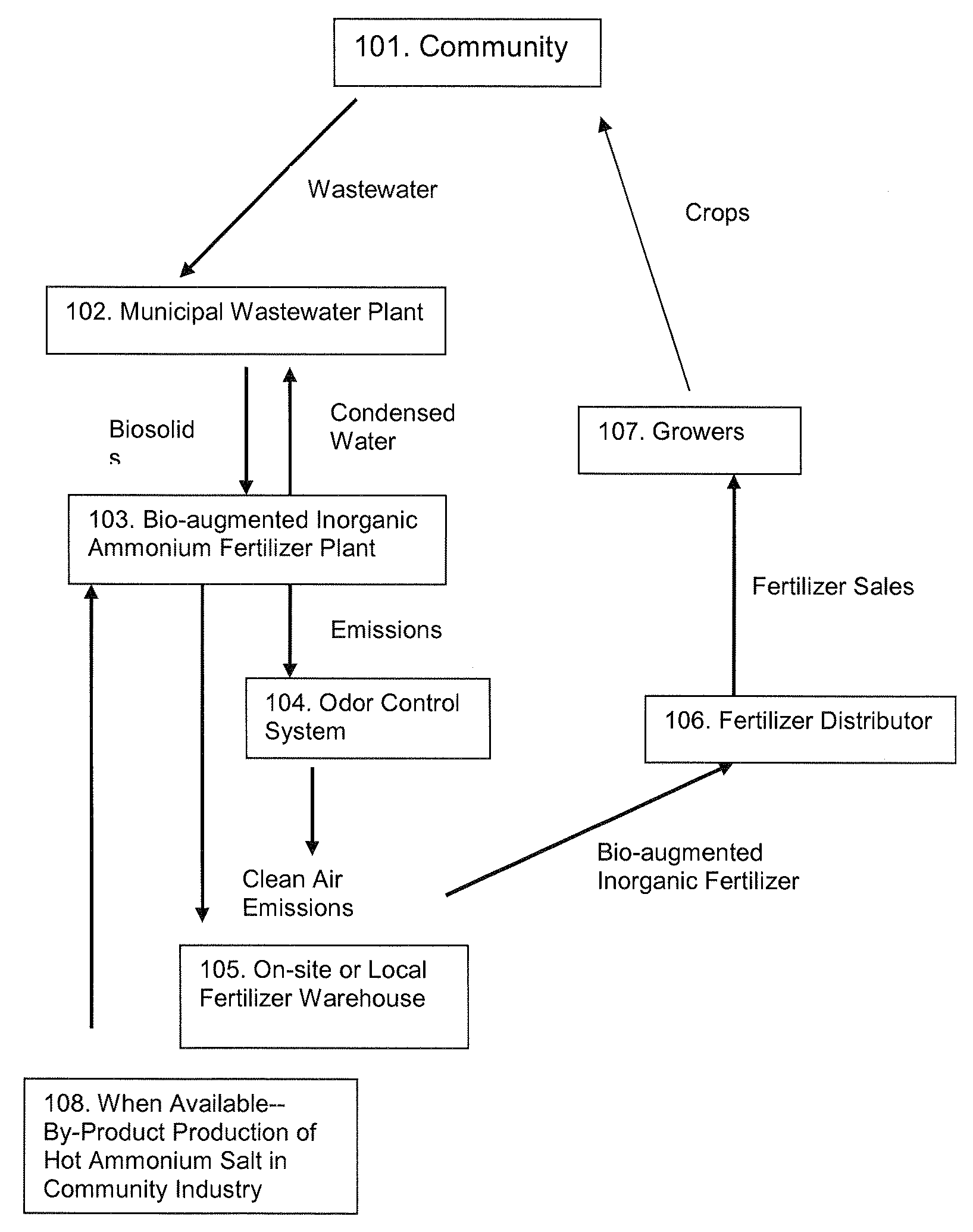

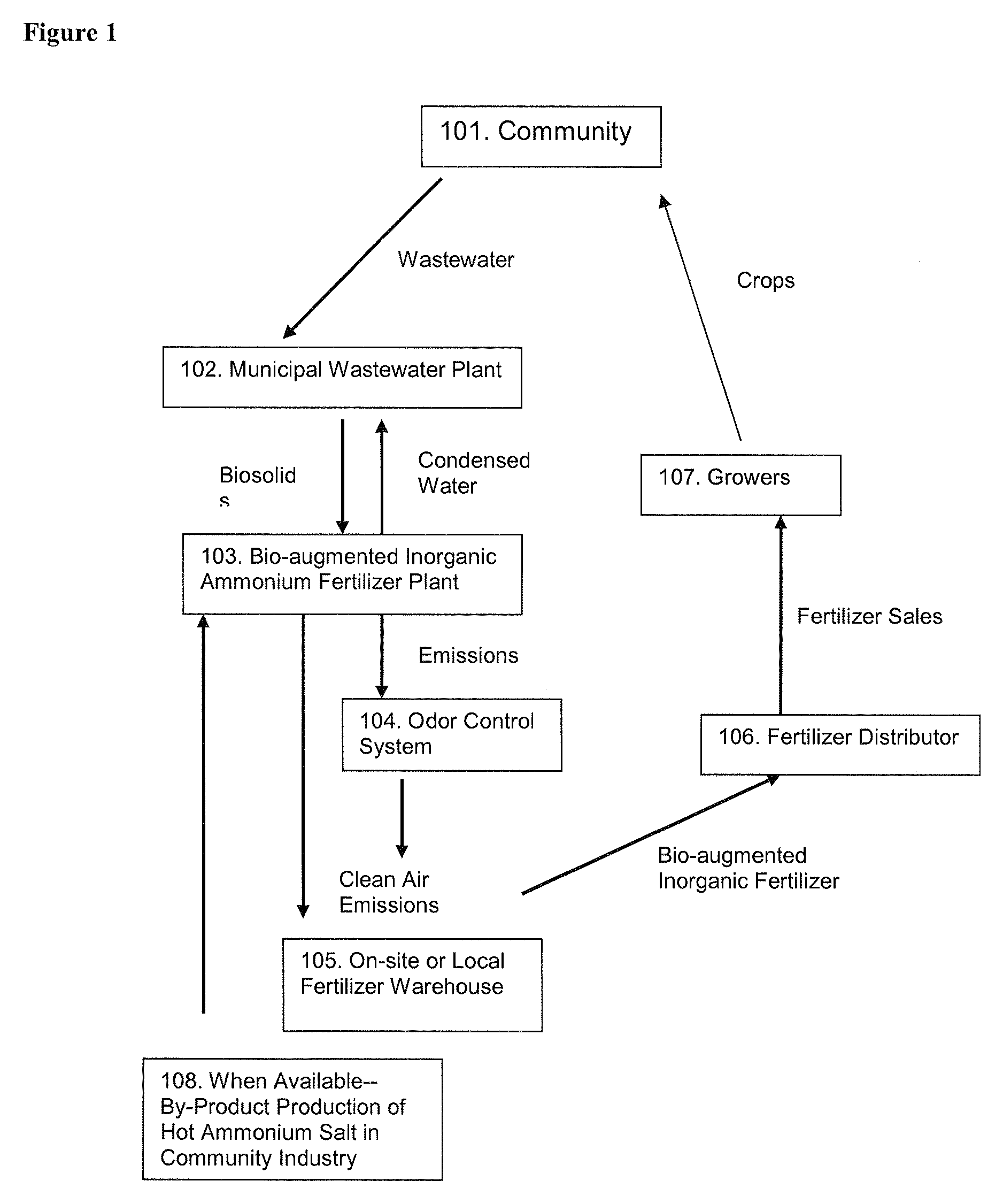

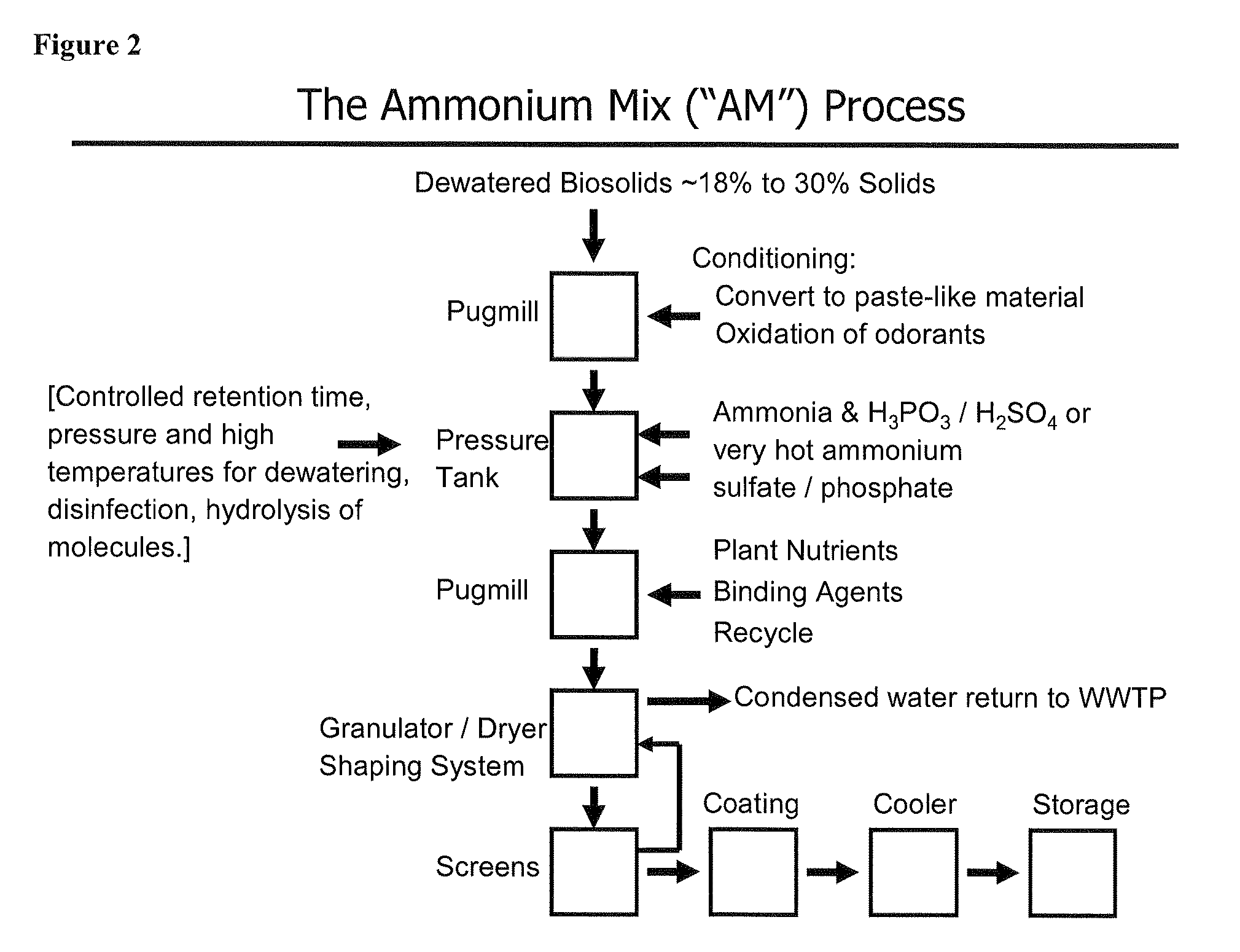

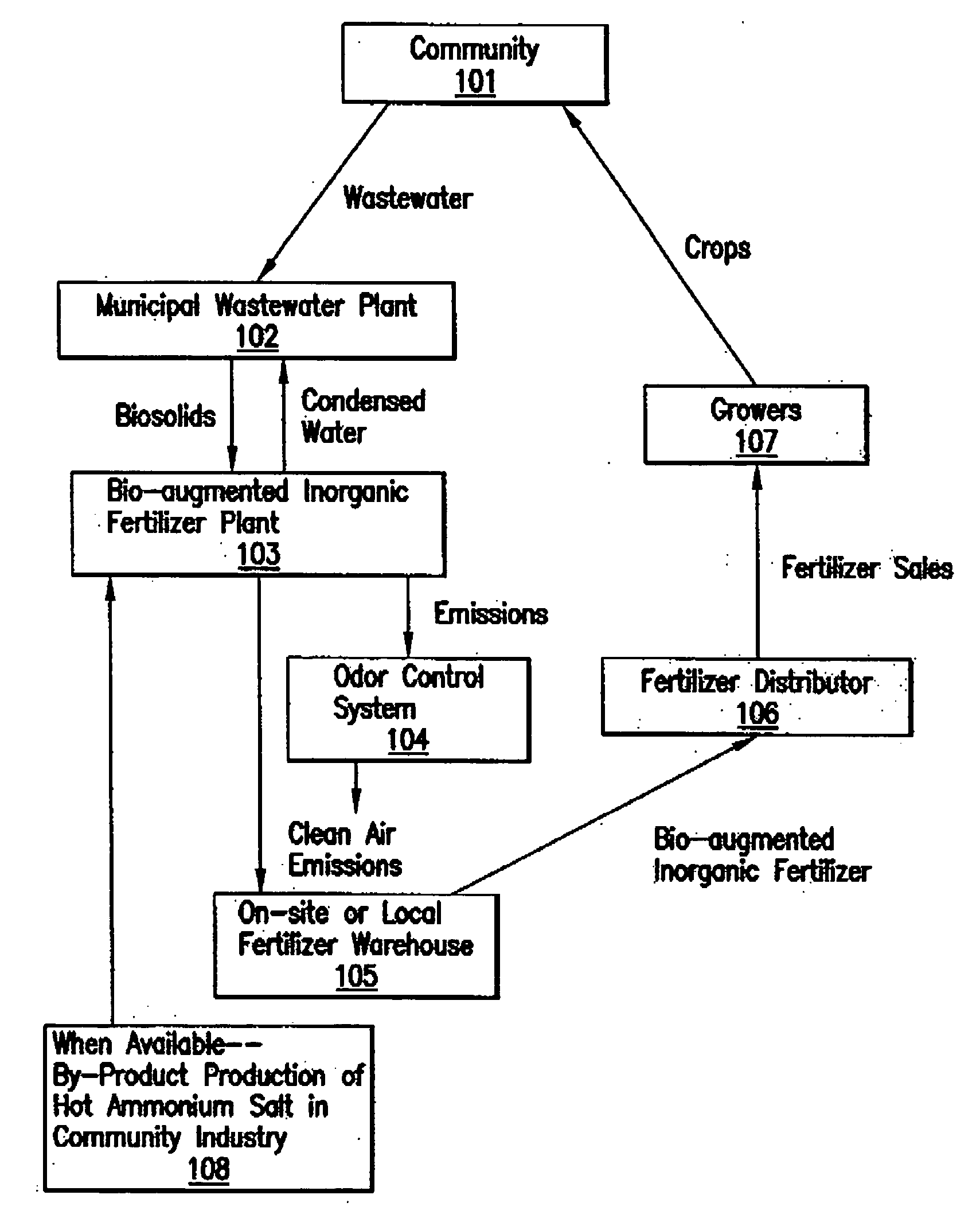

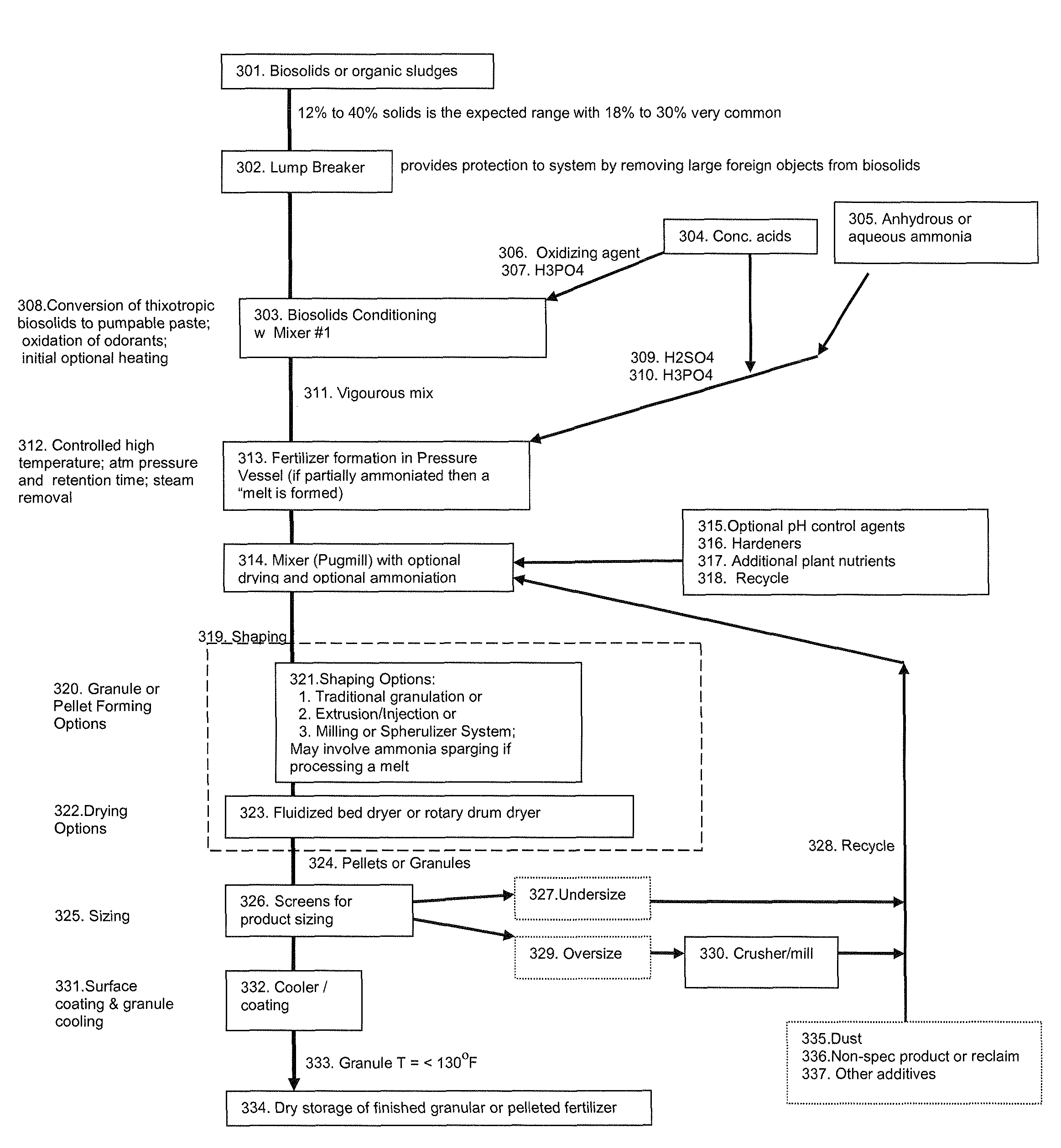

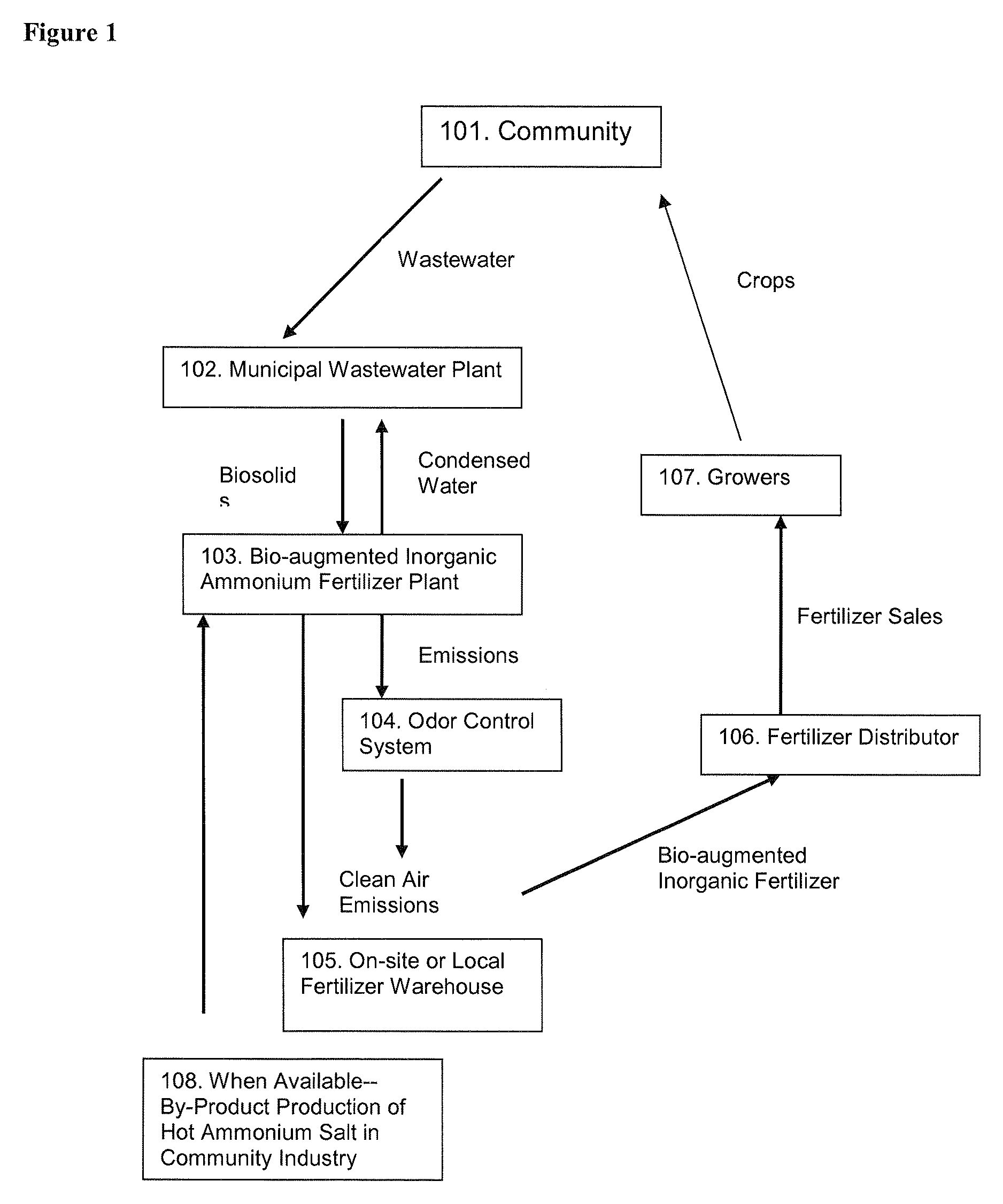

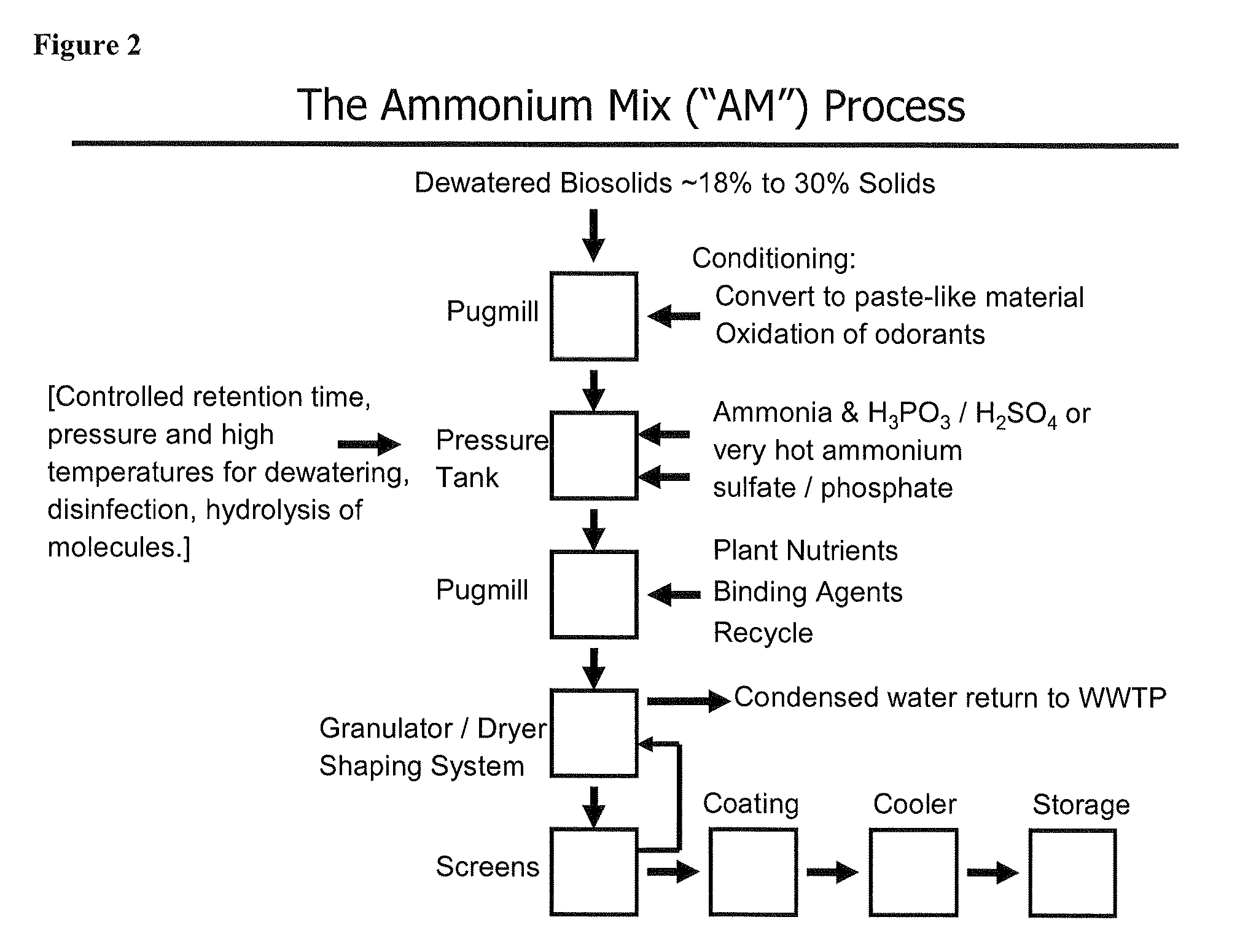

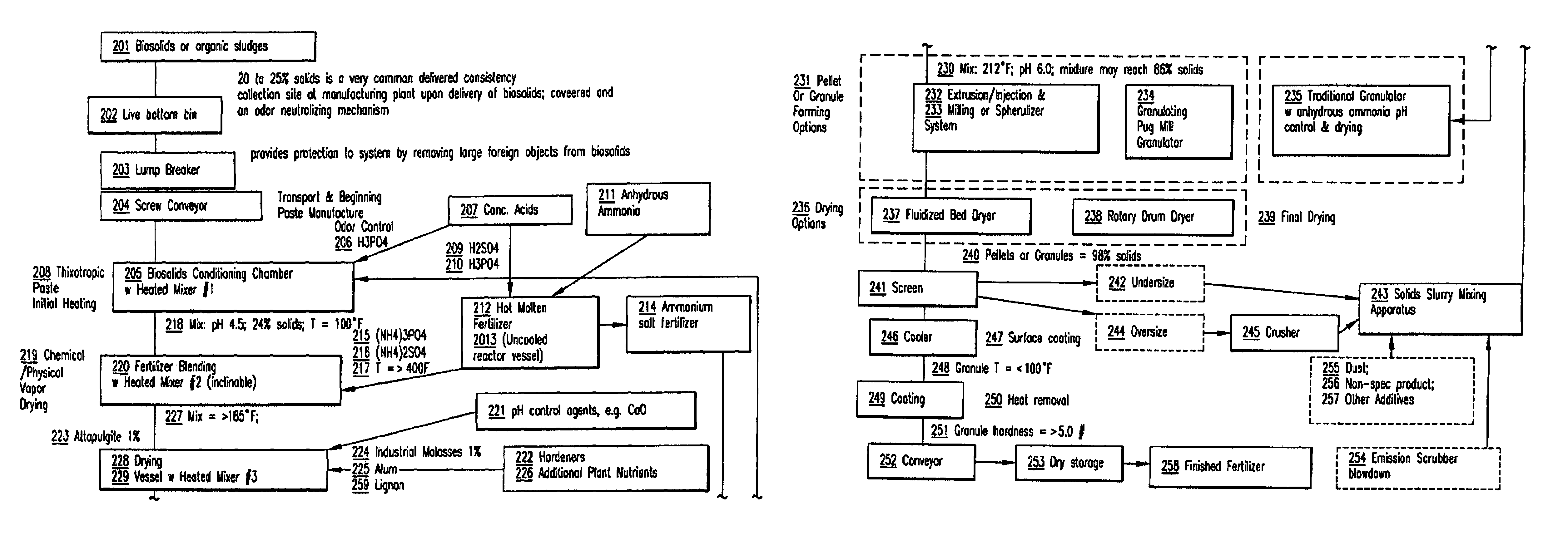

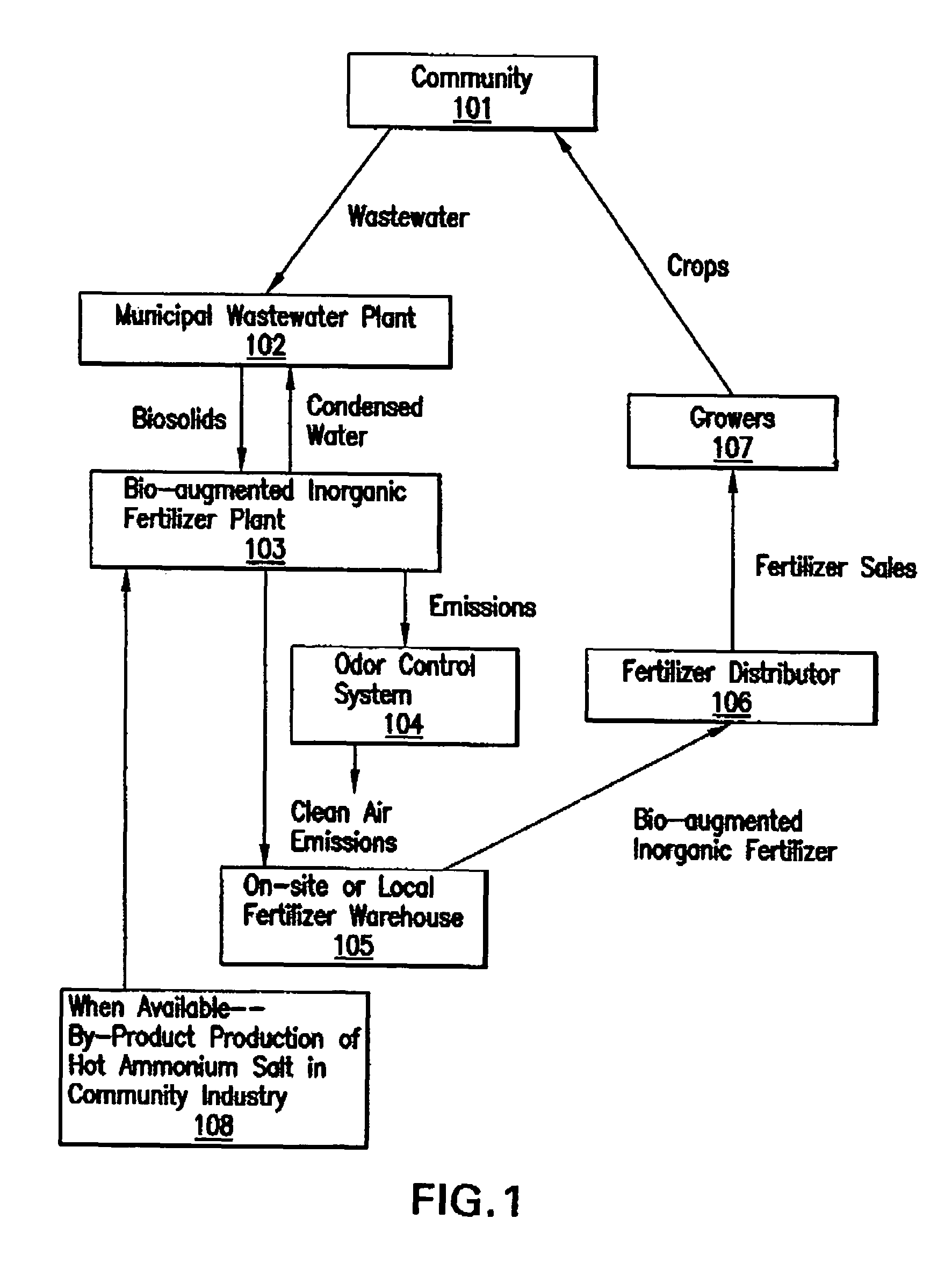

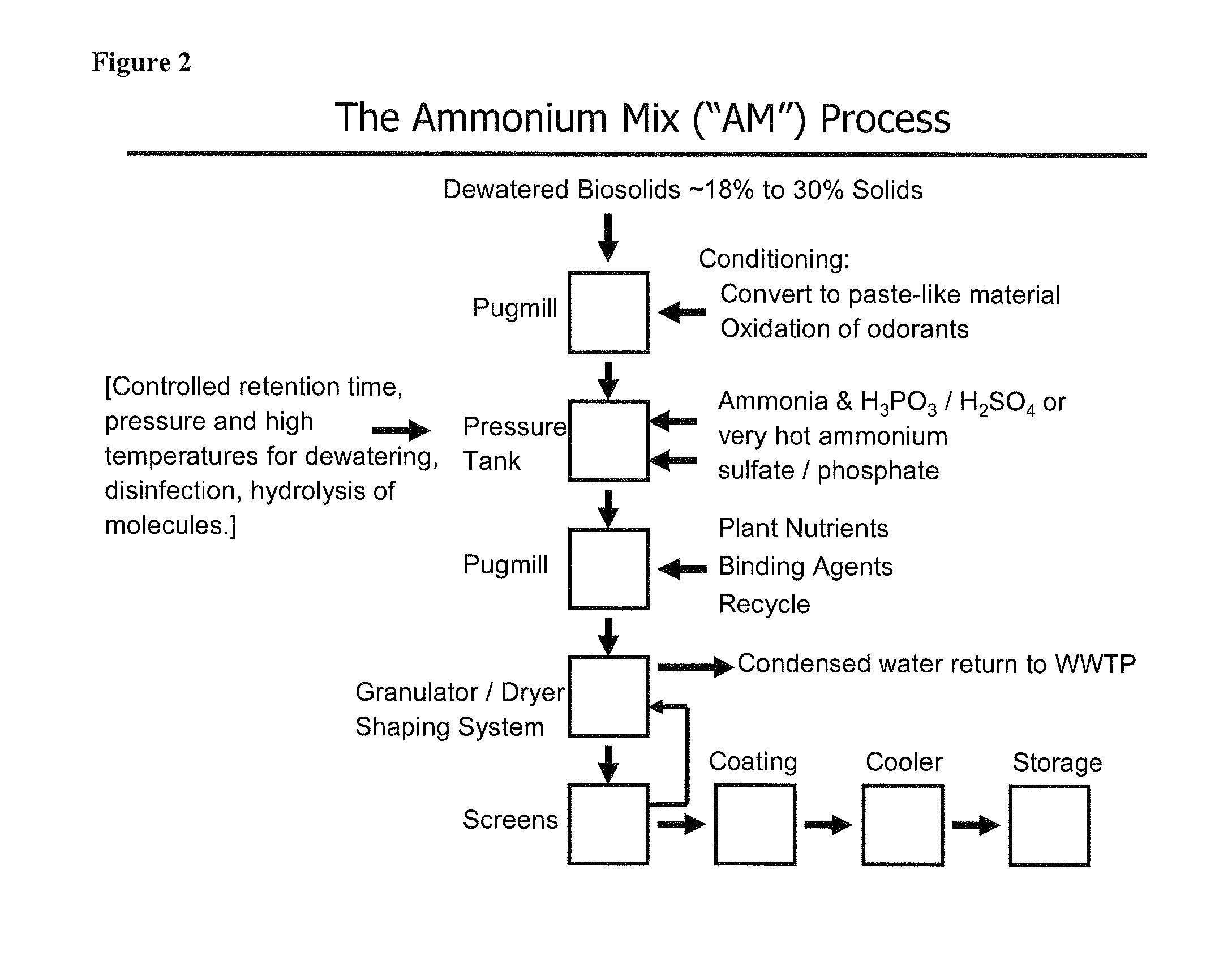

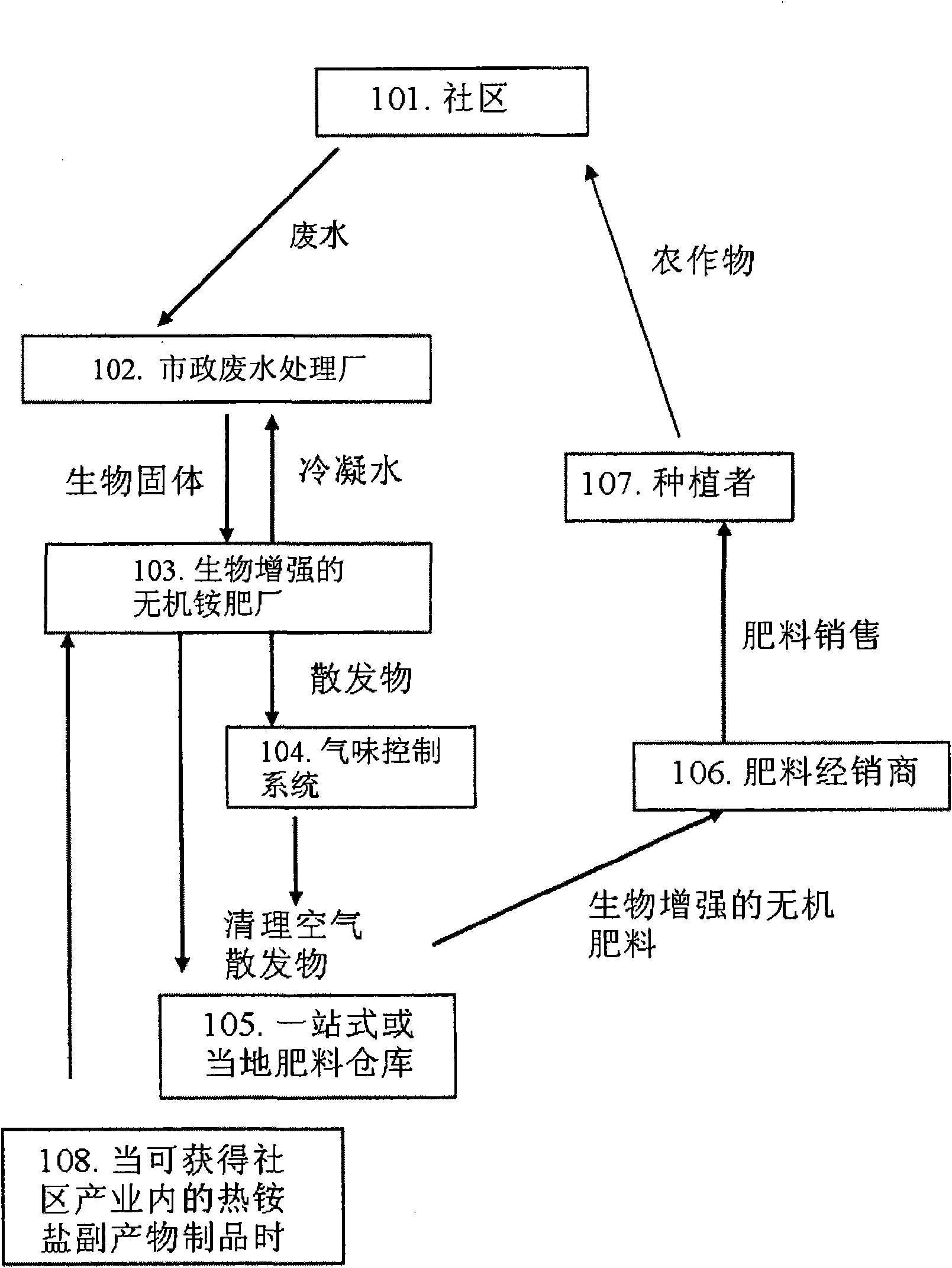

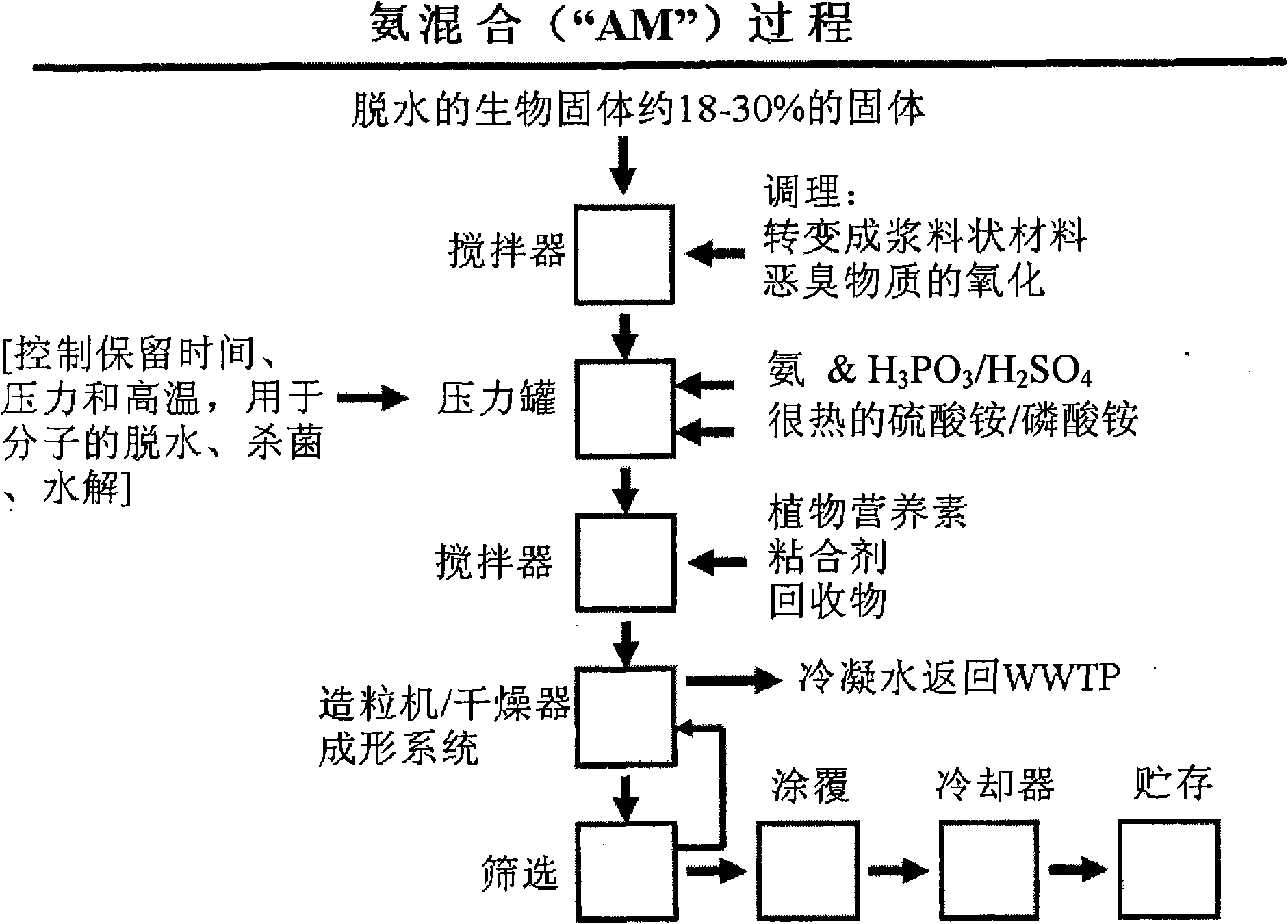

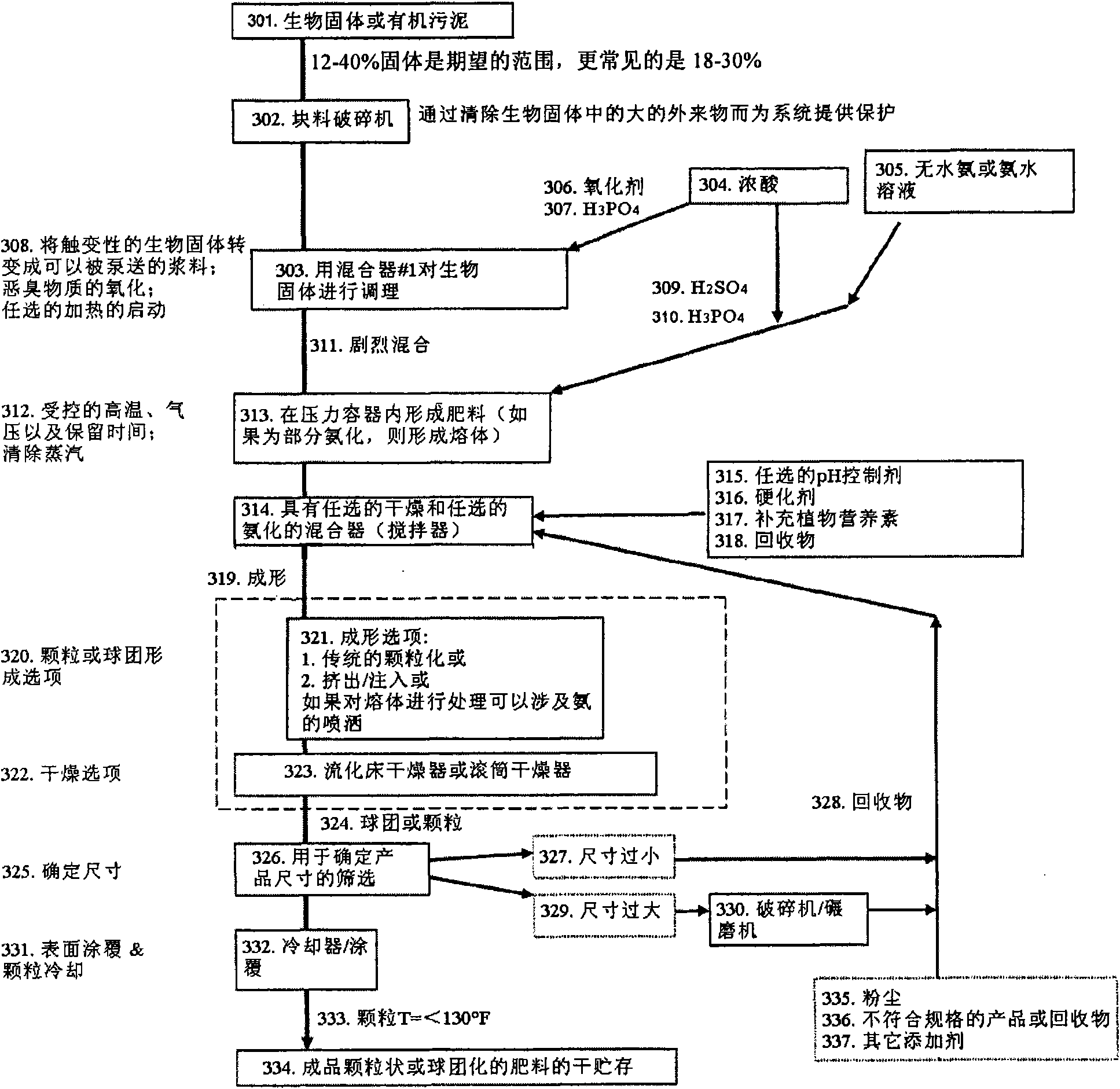

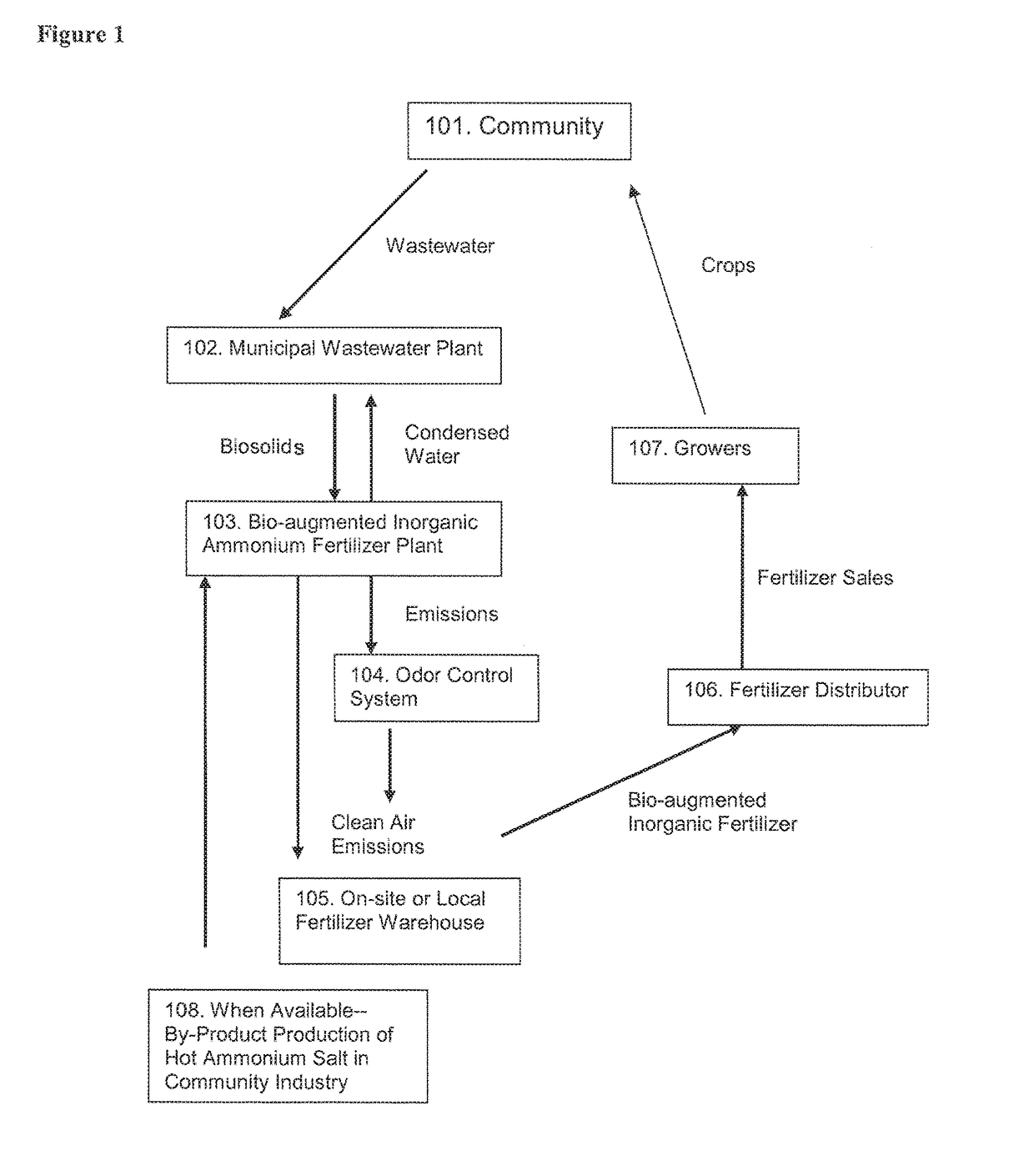

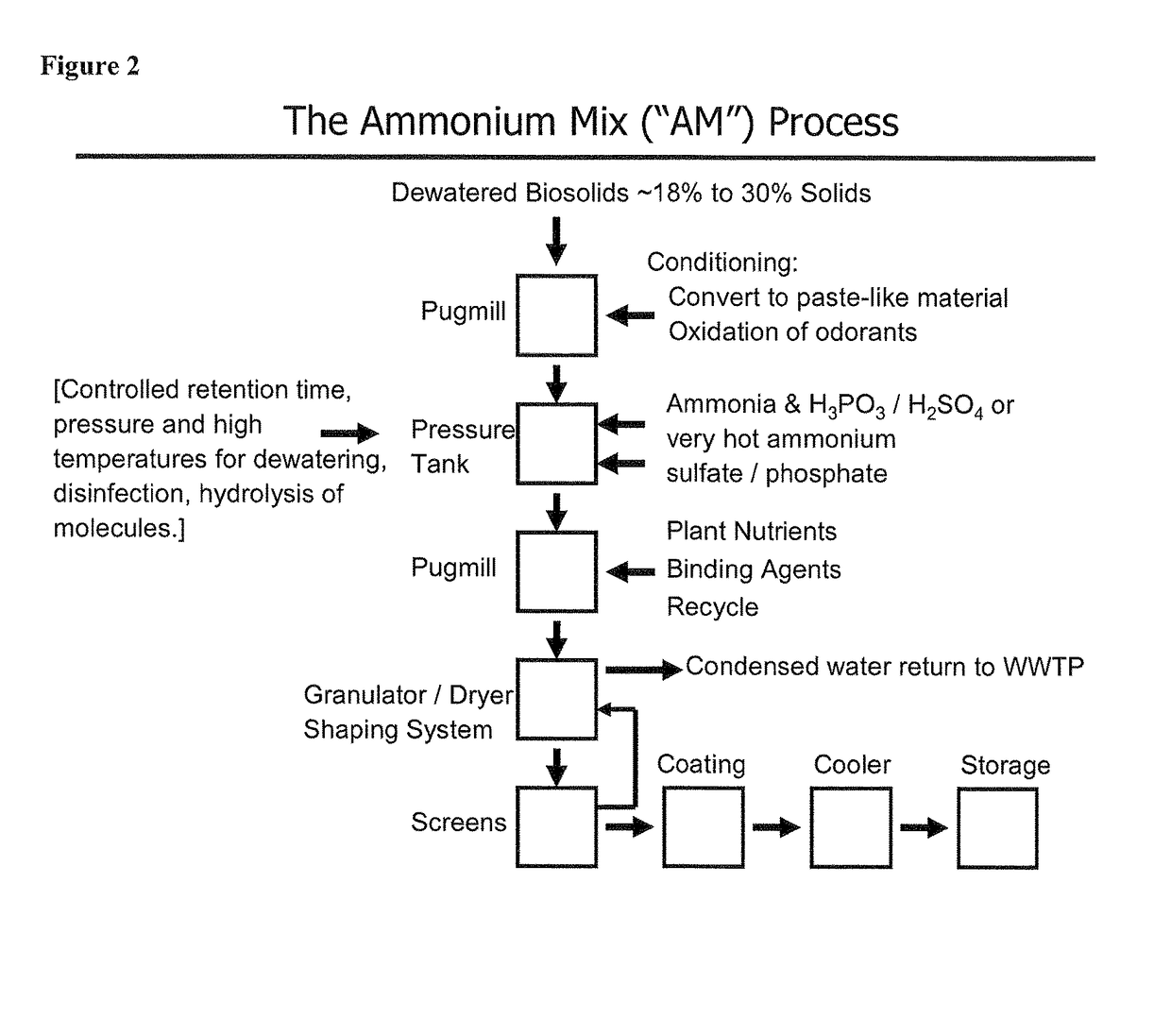

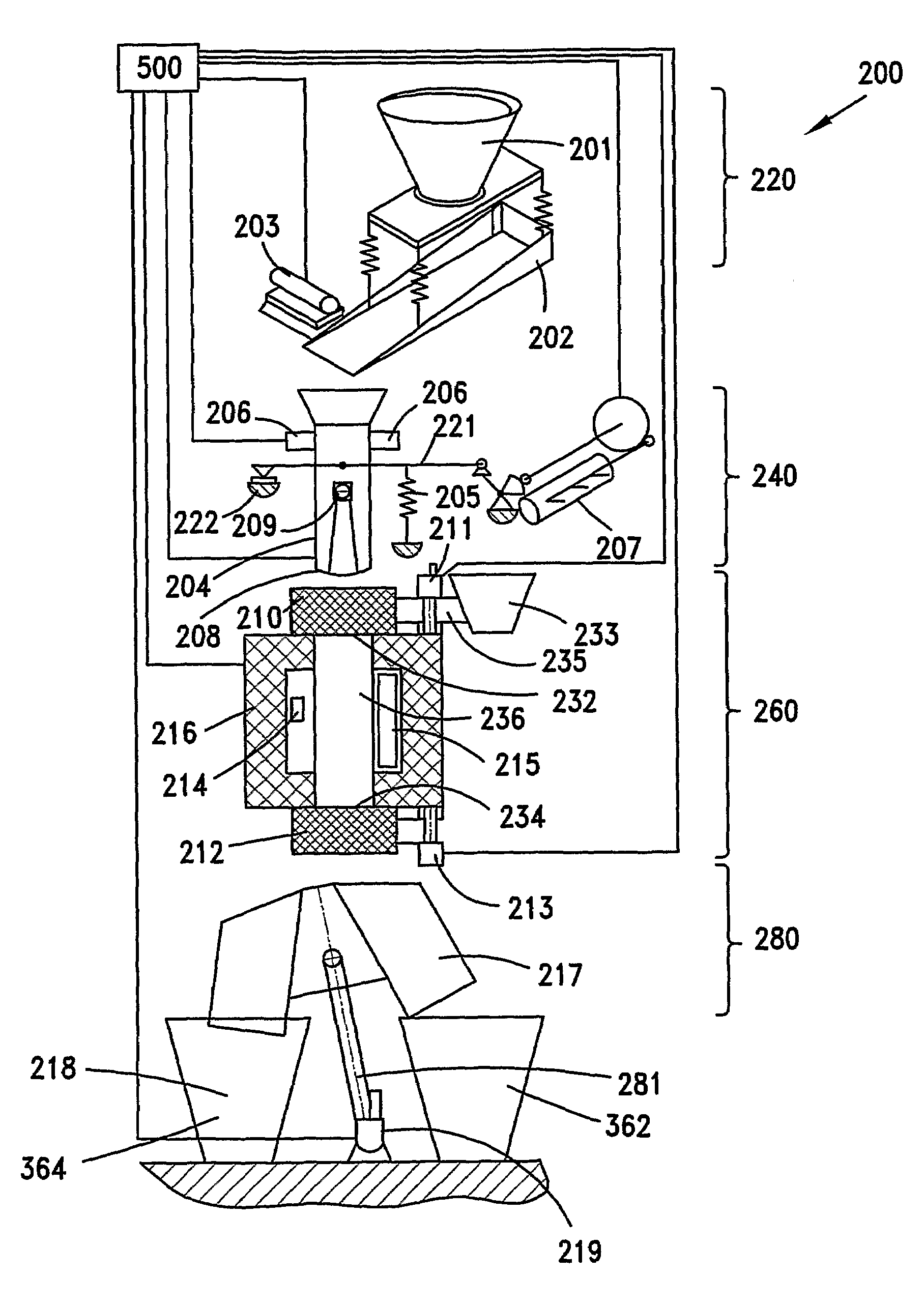

The invention describes a new method for treating sludge, which can result in the production of high nitrogen organically-augmented inorganic fertilizer that incorporates municipal sludges or biosolids or organic sludges that can compete with traditional fertilizers such as ammonium phosphate, ammonium sulfate and urea on the commodity fertilizer marketplace. The method takes advantage of the thixotropic property of dewatered biosolids or organic sludge to create a pumpable paste-like material from the biosolids or organic sludge that is then treated with an oxidizer to reduce odorant effects and an acid. This mix is then interacted with concentrated sulfuric and or phosphoric acids and an ammonia source or alternatively a hot or molten melt or salt of ammonium sulfate / phosphate to form a fertilizer mix. The present invention controls the heat, atmospheric pressure and retention time of the fertilizer mix in the reaction vessel. When a fertilizer melt is formed ammoniation is subsequently completed by the specific use of vaporized ammonia. The invention can also be an add-on to commercial production of ammonium salts. The fertilizer produced by the present invention contains more than 8 wt. % nitrogen and preferably 15 wt. % nitrogen. The invention is oriented to be tailored to the biosolids production for individual municipal waste treatment plants in order to keep the fertilizer manufacturing plants of the present invention small with a minimization of logistics and liability.

Owner:GENERATE LENDING LLC +1

Manufacturing of bioorganic-augmented high nitrogen-containing inorganic fertilizer

The invention describes a new method for the production of high nitrogen organically-augmented inorganic fertilizer that incorporates municipal biosolids or organic sludges that can compete with traditional fertilizers such as ammonium phosphate, ammonium sulfate and urea on the commodity fertilizer marketplace. The method creates a thixotropic paste-like material from the biosolids or organic sludge that is blended with hot or molten ammonium salts, especially a mixture of ammonium phosphate and ammonium sulfate. The invention can be an add-on to commercial production of ammonium salts or it can stand alone by manufacturing ammonium salts prior to their introduction to the conditioned biosolids. The invention is oriented to be tailored to production facilities for individual municipal waste treatment plants in order to keep manufacturing plants small with a minimization of logistics and liability.

Owner:GENERATE LENDING LLC +1

Process for treating sludge and manufacturing bioorganically-augmented high nitrogen-containing inorganic fertilizer

ActiveUS7947104B2Reduce responsibilityEliminate needByproduct vaporizationExcrement fertilisersRetention timePhosphate

The invention describes a new method for treating sludge, which can result in the production of high nitrogen organically-augmented inorganic fertilizer that incorporates municipal sludges or biosolids or organic sludges that can compete with traditional fertilizers such as ammonium phosphate, ammonium sulfate and urea on the commodity fertilizer marketplace. The method takes advantage of the thixotropic property of dewatered biosolids or organic sludge to create a pumpable paste-like material from the biosolids or organic sludge that is then treated with an oxidizer to reduce odorant effects and an acid. This mix is then interacted with concentrated sulfuric and or phosphoric acids and an ammonia source or alternatively a hot or molten melt or salt of ammonium sulfate / phosphate to form a fertilizer mix. The present invention controls the heat, atmospheric pressure and retention time of the fertilizer mix in the reaction vessel. When a fertilizer melt is formed ammoniation is subsequently completed by the specific use of vaporized ammonia. The invention can also be an add-on to commercial production of ammonium salts. The fertilizer produced by the present invention contains more than 8 wt. % nitrogen and preferably 15 wt. % nitrogen. The invention is oriented to be tailored to the biosolids production for individual municipal waste treatment plants in order to keep the fertilizer manufacturing plants of the present invention small with a minimization of logistics and liability.

Owner:GENERATE LENDING LLC +1

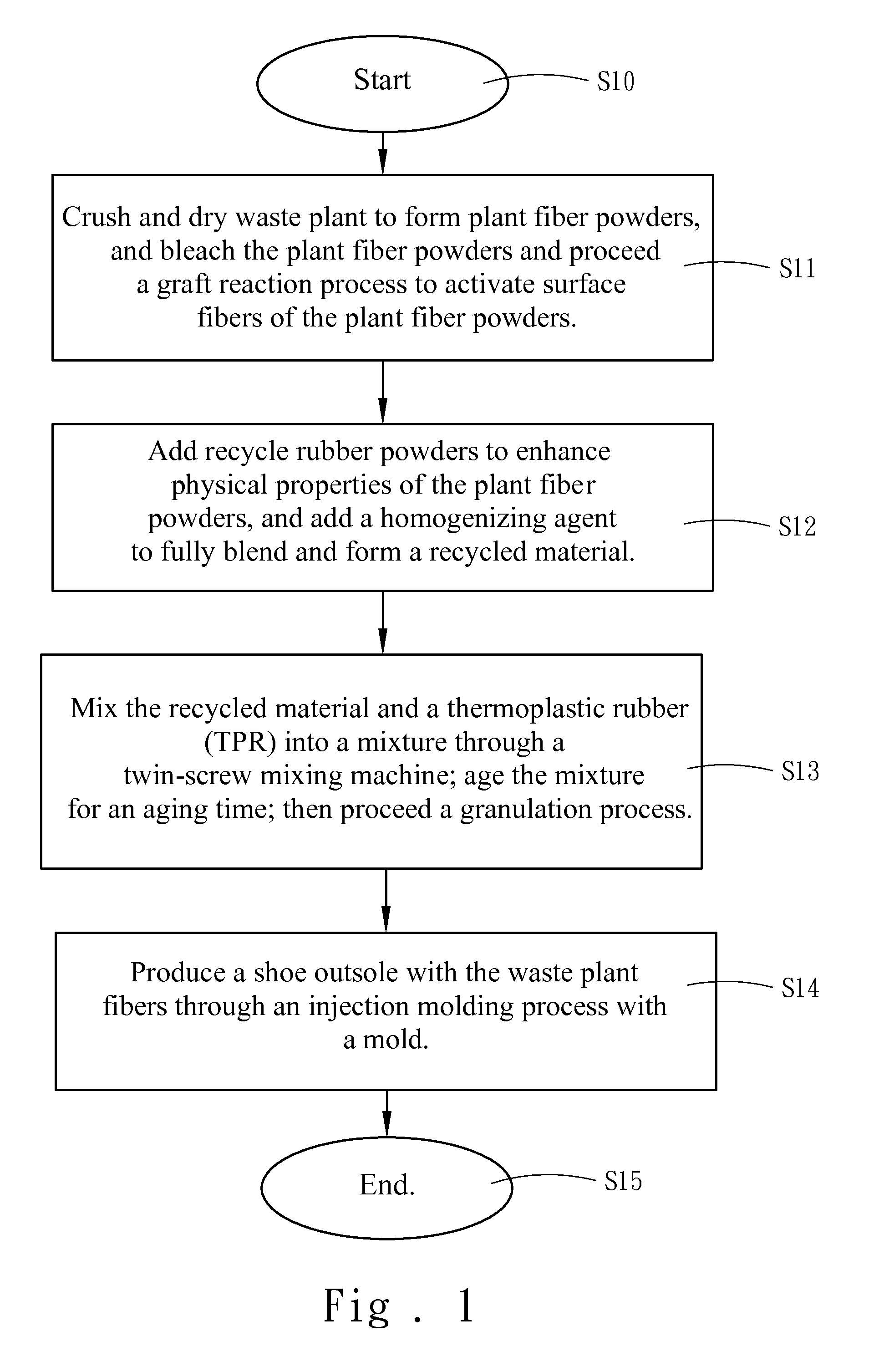

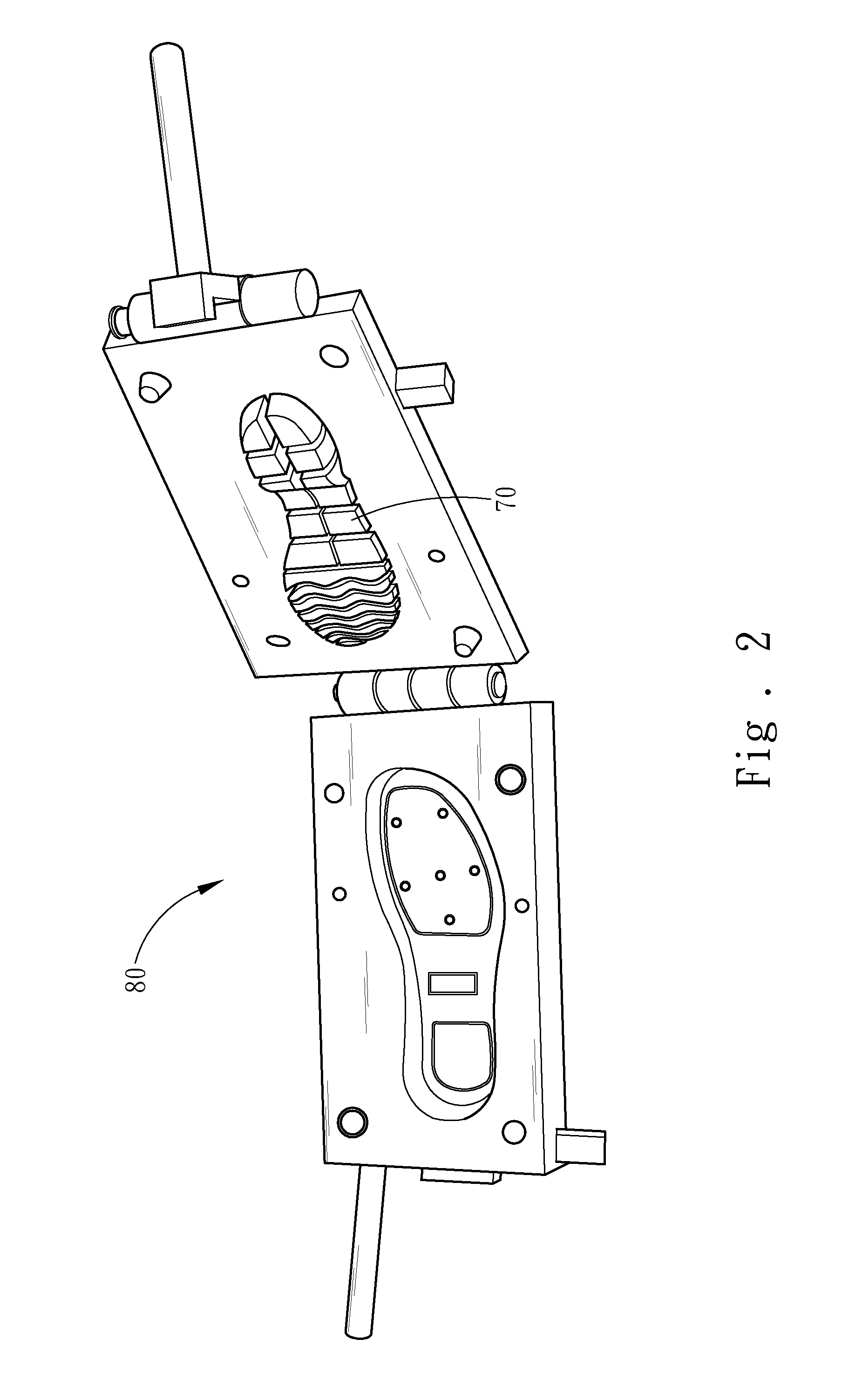

Method of manufacturing shoe outsoles from waste plant fibers

InactiveUS7785521B1Good physical propertiesUndesirable physical propertySolesPlastic recyclingGraft reactionPlant fibre

A method of manufacturing shoe outsoles from waste plant fibers includes steps of: bleaching plant fiber powders; activating the plant fiber powders through a graft reaction process; mixing the plant fiber powders and recycle rubber powders to enhance physical properties of the plant fiber powders; adding a homogenizing agent to fully blend the hydrophilic plant fiber powders and the lipophilic recycle rubber powders to form a recycled material; mixing the recycled material and thermoplastic rubber into a mixture; aging the mixture for an aging time; granulating the mixture; and producing a shoe outsole through an injection molding process. Thus a novel approach is provided to produce shoe products. Waste plants or rubber can be recycled to improve environmental conservation and protection.

Owner:CHEN SUNG HO

Garbage percolate treatment technique

ActiveCN101234836AOptimizing Process ParametersImprove water qualityWater/sewage treatment bu osmosis/dialysisTreatment with aerobic and anaerobic processesSludgeLitter

The invention discloses a technology for treating landfill leachate, which comprises the steps of pretreatment, upflow type sludge bed reaction, nitrification and denitrification reaction, mud-water separation and membrane treating. The technology for treating landfill leachate treats the landfill leachate by comprehensively using physics and biochemistry method, which largely reduces the cost for treating the leachate, simultaneously promotes effluent water quality at large amplitude, and can be widely used for treating landfill leachate in a waste treatment plant.

Owner:CHONGQING GROUP SANFENG TECH

Manufacturing of bioorganic-augmented high nitrogen-containing inorganic fertilizer

The invention describes a new method for the production of high nitrogen organically-augmented inorganic fertilizer that incorporates municipal biosolids or organic sludges that can compete with traditional fertilizers such as ammonium phosphate, ammonium sulfate and urea on the commodity fertilizer marketplace. The method creates a thixotropic paste-like material from the biosolids or organic sludge that is blended with hot or molten ammonium salts, especially a mixture of ammonium phosphate and ammonium sulfate. The invention can be an add-on to commercial production of ammonium salts or it can stand alone by manufacturing ammonium salts prior to their introduction to the conditioned biosolids. The invention is oriented to be tailored to production facilities for individual municipal waste treatment plants in order to keep manufacturing plants small with a minimization of logistics and liability.

Owner:GENERATE LENDING LLC +1

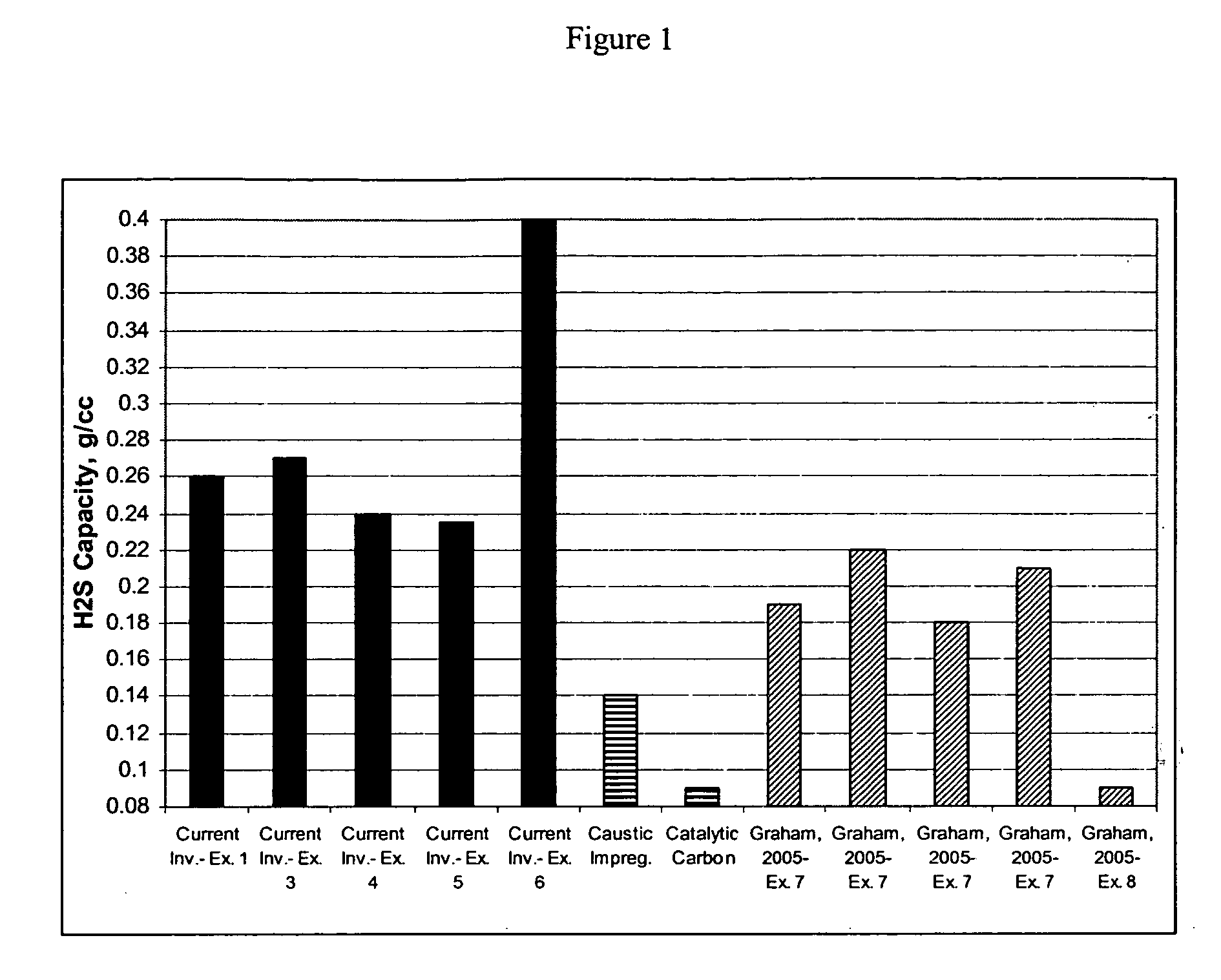

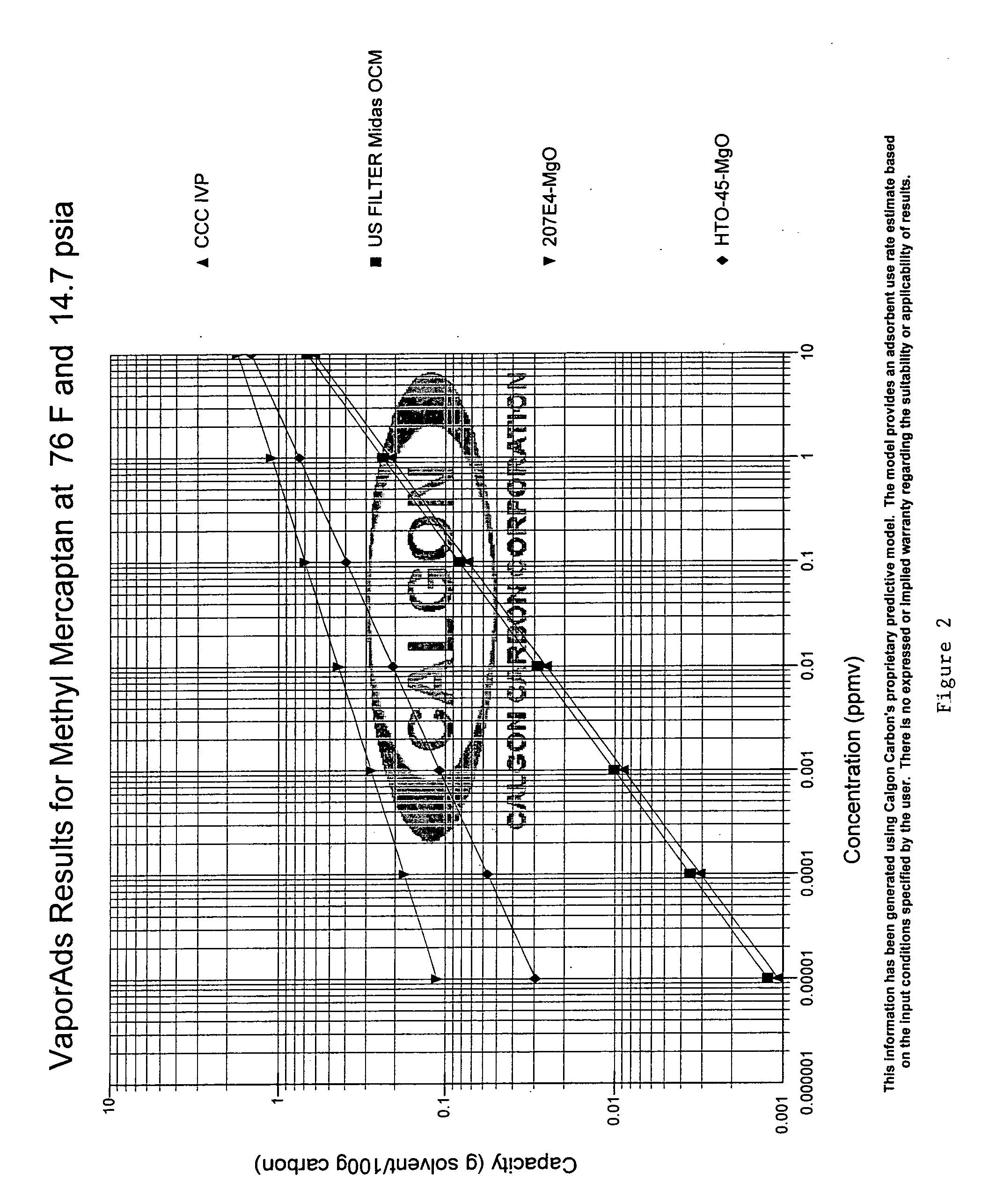

Adsorbents for removing H2S, other odor causing compounds, and acid gases from gas streams and methods for producing and using these adsorbents

Adsorbents for removing H2S, other odor-causing compounds, and other acid gases from gas streams, as well as methods for manufacturing and using adsorbents, are provided. Adsorbents comprise a porous media in which at least one metal oxide is primarily distributed on or over the surface of the pores of the media. In an example, the porous media is activated carbon and the metal oxide is magnesium oxide. The adsorbents of the present invention are particularly useful for removing odor caused by hydrogen sulfide and organic sulfinur compounds that are common at municipal waste treatment plants, paper mills and industrial plants.

Owner:CALGON CARBON

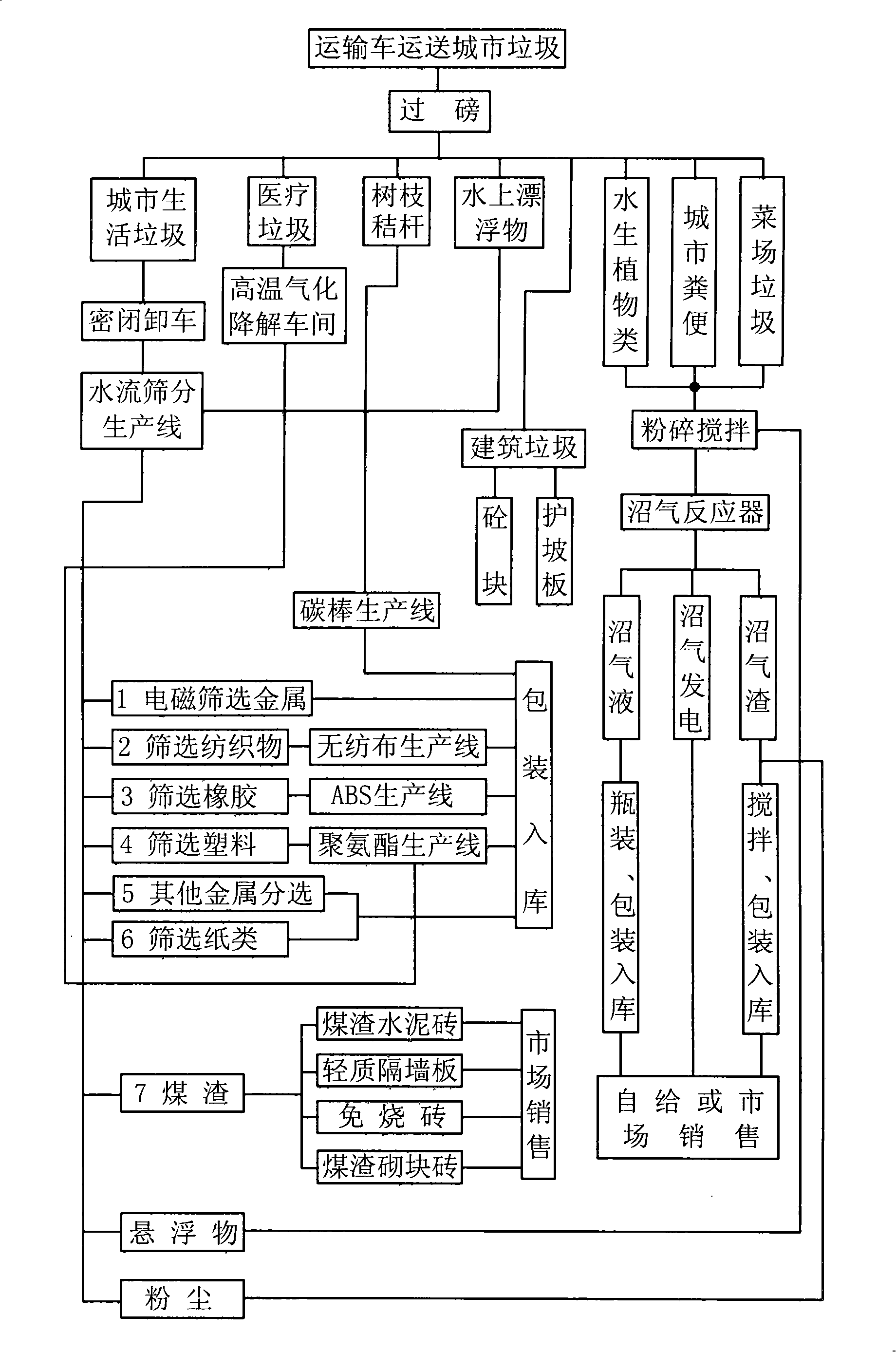

Comprehensive treatment and utilization technique for urban domestic garbage

InactiveCN101318192AAvoid occupyingAvoid pollutionBio-organic fraction processingSolid waste disposalMedical treatmentNight soil

The invention relates to a comprehensive treatment utilization technology for municipal domestic waste, which belongs to the technical field of treating and recycling municipal waste; the technology is as follows: the municipal waste is transported to a waste treatment plant so as to carry out harmless treatment, then is classified into eight kinds, that is, the municipal domestic waste, medical waste, branches and straws, floater on water surface, construction waste, aquatic plant, urban night soil and market waste, and is transported to a department belonging to one kind so as to be treated and recycled. The technology of the invention solves the problems of occupying a lot of lands, and polluting environment and groundwater resources caused by the landfill mode which is adopted to treat the municipal waste for a long time, solves the problems in municipal solid waste incineration that dioxin, a carcinogenesis gas, is released into air and 40 percent of waste residues still need to be land-filled, so that lands still needs to be occupied; therefore, the technology can change the municipal waste into valuables, recycle natural resources, give full play to the value of resource recycling, and realize the measures advocated by the country such as 'waste reduction', 'resource recycling' and 'harmlessness', thus being suitable for waste treatment in different cities.

Owner:武汉生宝丰泽环保科技有限公司

Method for treating atrazine-containing pesticide wastewater

ActiveCN101734821ASolve processing problemsEnsure safetyMultistage water/sewage treatmentWater/sewage treatment by neutralisationSlagEvaporation

The invention relates to a method for treating atrazine-containing pesticide wastewater, which is characterized by comprising: pumping pesticide wastewater into a neutralization pool; adding inorganic acid to regulate pH between 7 and 8; allowing the obtained product to enter a coagulation-sedimentation pool; putting in coagulant for coagulation; allowing the obtained product to enter a sand filter; performing filtration; allowing the obtained product to enter a reduced-pressure evaporation system of a water-collecting pool; discharging condensate which is repeatedly evaporated and concentrated and then is subjected to activated carbon adsorption into a recycled-water storage pool; allowing reactor-bottom residual liquid of evaporated and concentrated under reduced pressure to enter a salting-out tank and cooling the reactor-bottom residual liquid to form salt; and periodically transporting salt slag to a solid waste treatment plant for final treatment. The method has the advantages of realizing the zero wastewater discharge of pesticide production processes, performing safe disposal on solid pollutants, ensuring environmental safety, effectively solving the problem that the wastewater produced during pesticide production is difficult to treat, saving a large amount of cost for pollution discharge, reducing environmental pollution and having high economic and environmental benefit.

Owner:PETROCHINA CO LTD

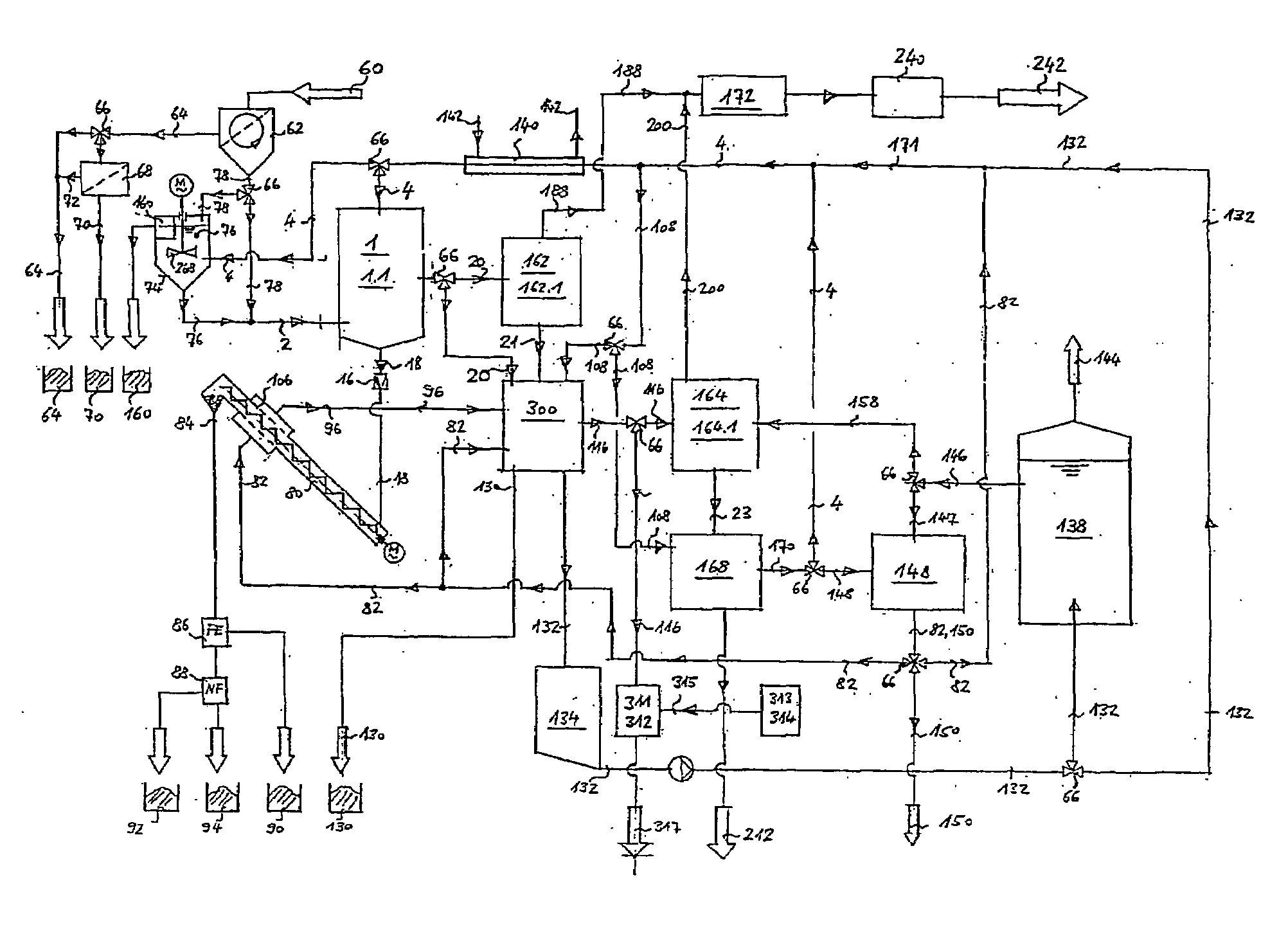

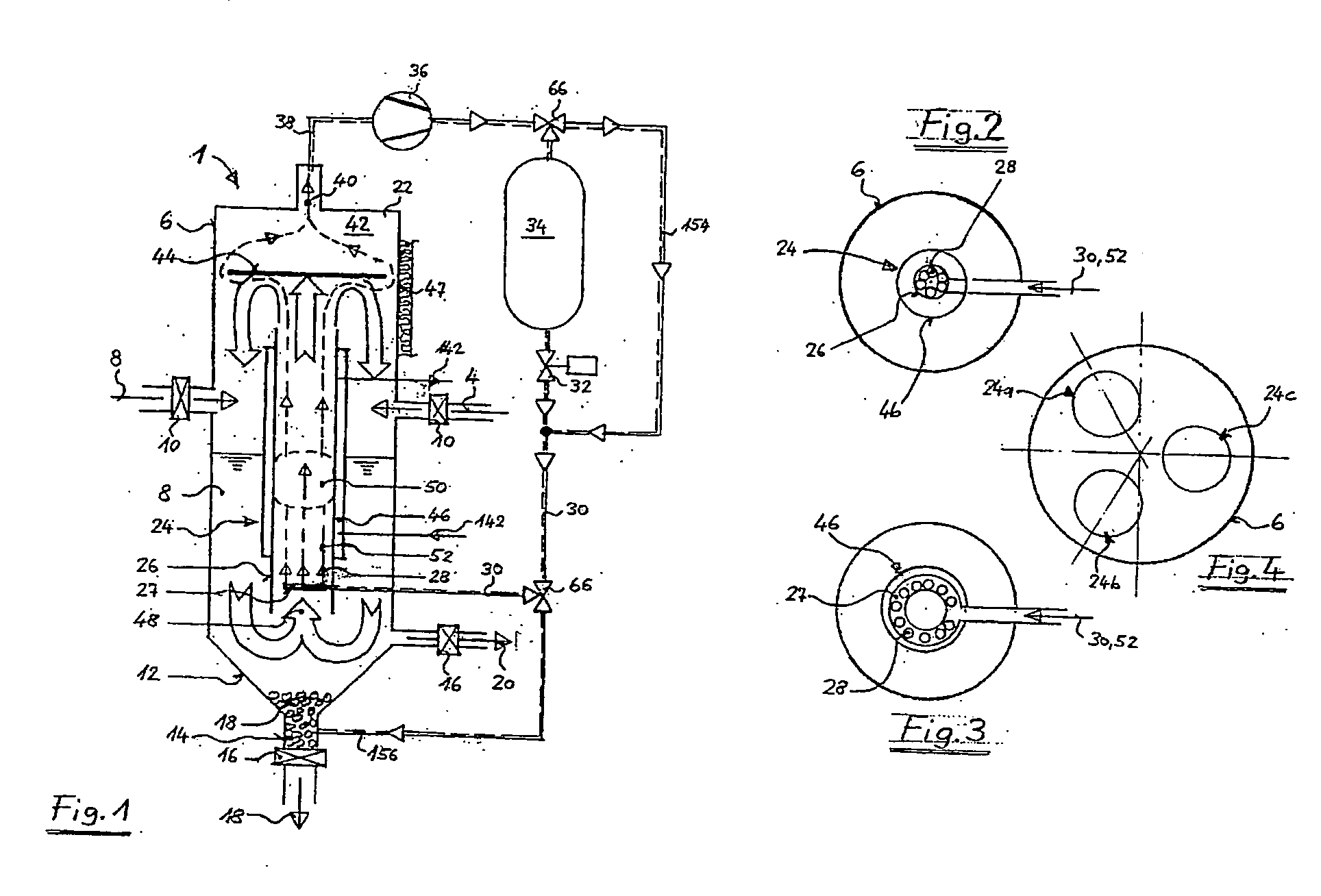

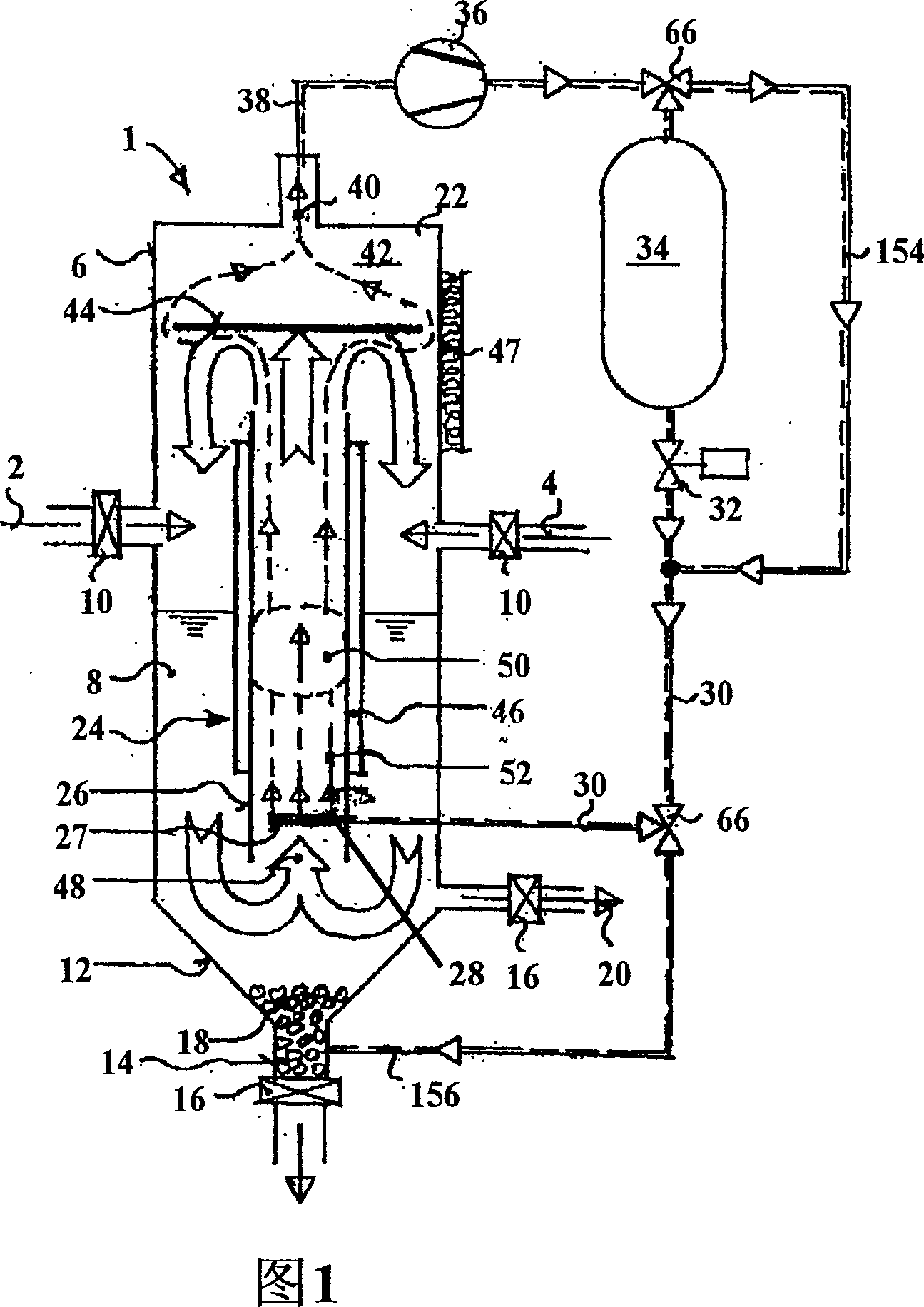

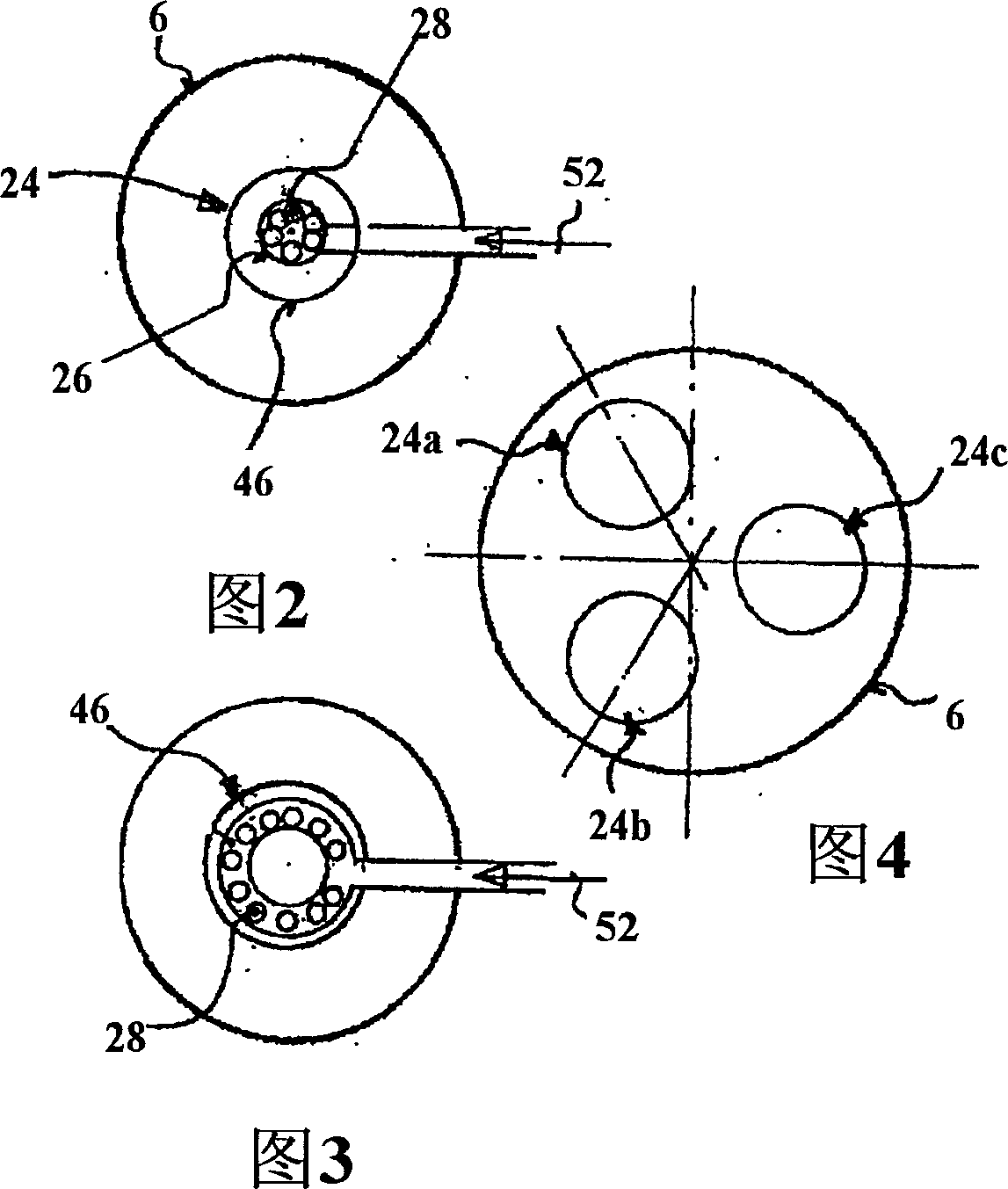

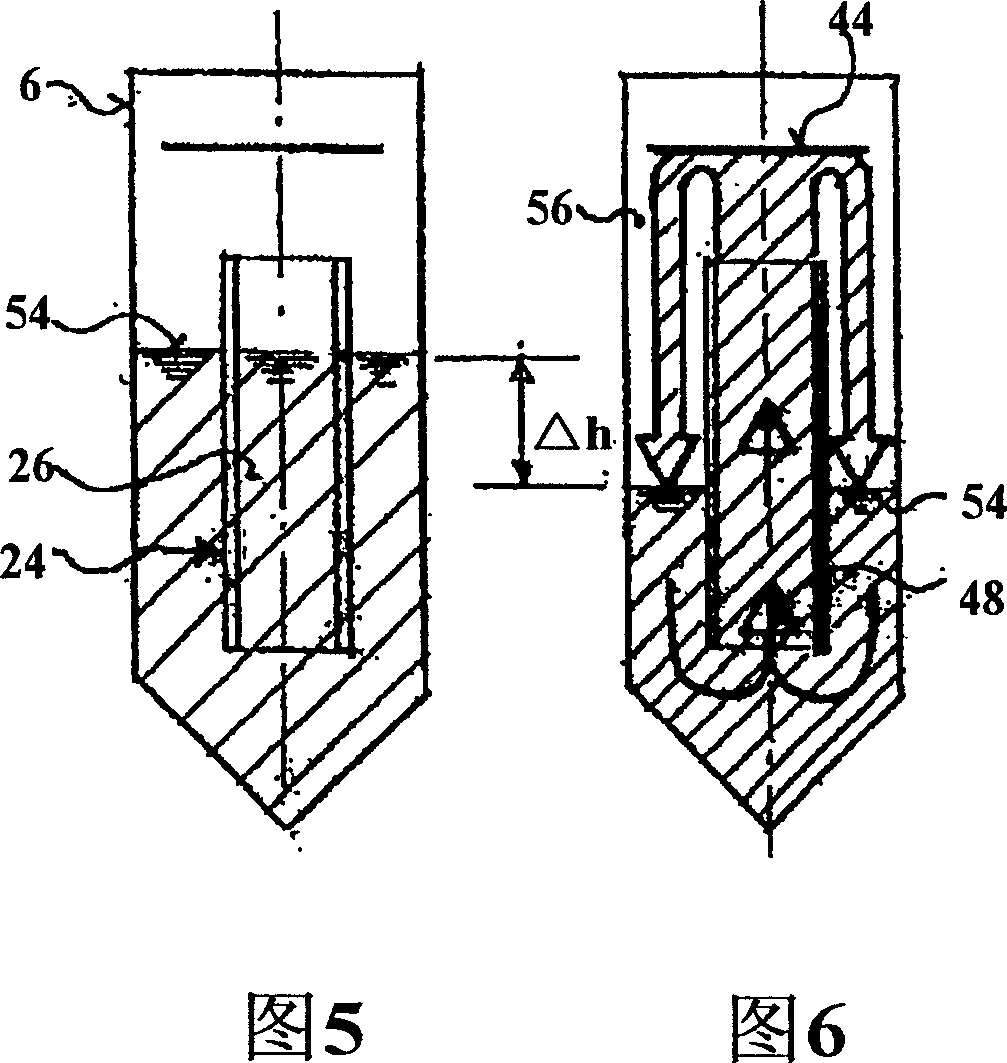

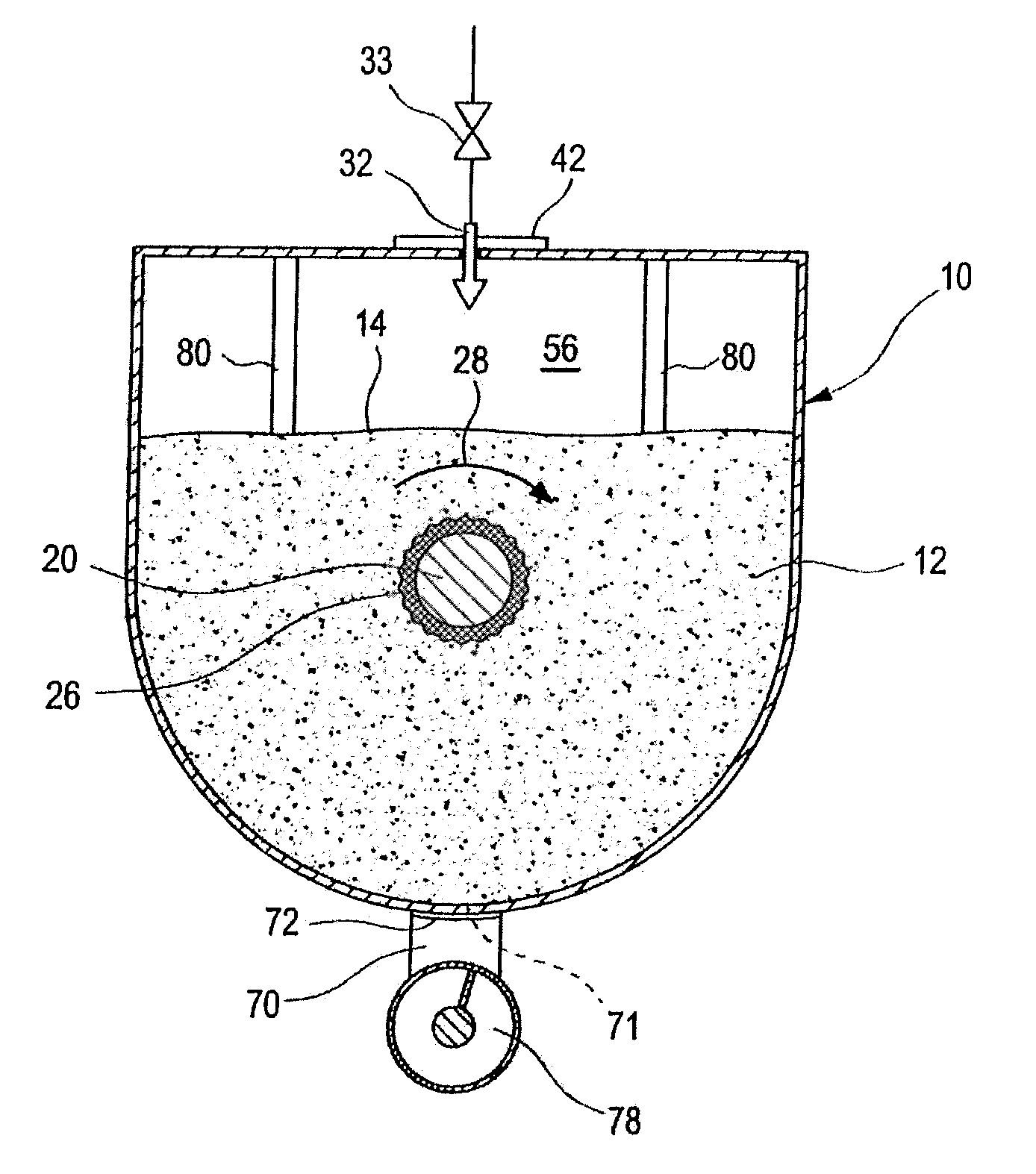

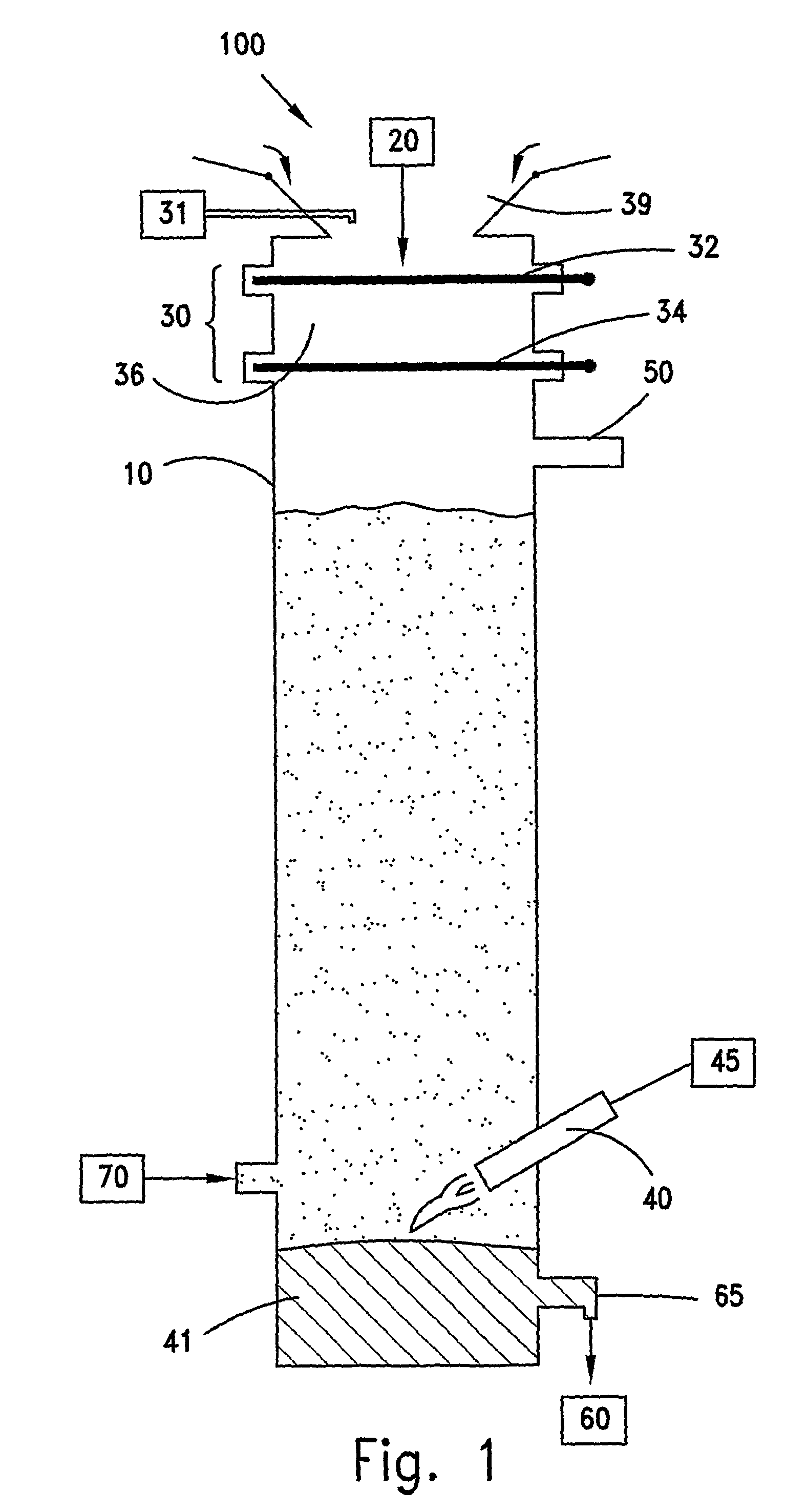

Material Solubiliser Reactor For Hydrolysis and/or Wet Fermentation and Waste Treatment Plant With Such a Solubiliser and Reactor

InactiveUS20080199943A1Short timeReduce spendingBioreactor/fermenter combinationsBio-organic fraction processingSolventHydrolysis

The invention relates to a method for the treatment of waste with organic components, whereby in standardized method steps, various material solubilisers, for dissolving the organic material in a solvent and various reactors for carrying out a hydrolysis and / or a wet fermentation are used depending on the particle size and suitable solubilisers and reactors. A suitable waste treatment plant is also disclosed.

Owner:WIDMER CHRISTIAN

Process for Treating Sludge and Manufacturing Bioorganically-Augmented High Nitrogen-Containing Inorganic Fertilizer

ActiveUS20110265532A1Reduce logisticsReduces liabilityCalcareous fertilisersClimate change adaptationRetention timePhosphate

The invention describes a new method for treating sludge, which can result in the production of high nitrogen organically-augmented inorganic fertilizer that incorporates municipal sludges or biosolids or organic sludges that can compete with traditional fertilizers such as ammonium phosphate, ammonium sulfate and urea on the commodity fertilizer marketplace. The method takes advantage of the thixotropic property of dewatered biosolids or organic sludge to create a pumpable paste-like material from the biosolids or organic sludge that is then treated with an oxidizer to reduce odorant effects and an acid. This mix is then interacted with concentrated sulfuric and or phosphoric acids and an ammonia source or alternatively a hot or molten melt or salt of ammonium sulfate / phosphate to form a fertilizer mix. The present invention controls the heat, atmospheric pressure and retention time of the fertilizer mix in the reaction vessel. When a fertilizer melt is formed ammoniation is subsequently completed by the specific use of vaporized ammonia. The invention can also be an add-on to commercial production of ammonium salts. The fertilizer produced by the present invention contains more than 8 wt. % nitrogen and preferably 15 wt. % nitrogen. The invention is oriented to be tailored to the biosolids production for individual municipal waste treatment plants in order to keep the fertilizer manufacturing plants of the present invention small with a minimization of logistics and liability.

Owner:GENERATE LENDING LLC

Process for treating sludge and manufacturing bioorganically-augmented high nitrogen-containing inorganic fertilizer

The invention describes a new method for treating sludge, which can result in the production of high nitrogen organically-augmented inorganic fertilizer that incorporates municipal sludges or biosolids or organic sludges that can compete with traditional fertilizers such as ammonium phosphate, ammonium sulfate and urea on the commodity fertilizer marketplace. The method takes advantage of the thixotropic property of dewatered biosolids or organic sludge to create a pumpable paste-like material from the biosolids or organic sludge that is then treated with an oxidizer to reduce odorant effectsand an acid. This mix is then interacted with concentrated sulfuric and or phosphoric acids and an ammonia source or alternatively a hot or molten melt or salt of ammonium sulfate / phosphate to form afertilizer mix. The present invention controls the heat, atmospheric pressure and retention time of the fertilizer mix in the reaction vessel. When a fertilizer melt is formed ammoniation is subsequently completed by the specific use of vaporized ammonia. The invention can also be an add-on to commercial production of ammonium salts. The fertilizer produced by the present invention contains more than 8 wt. % nitrogen and preferably 15 wt. % nitrogen. The invention is oriented to be tailored to the biosolids production for individual municipal waste treatment plants in order to keep the fertilizer manufacturing plants of the present invention small with a minimization of logistics and liability.

Owner:ANUVIA PLANT NUTRIENTS HLDG INC

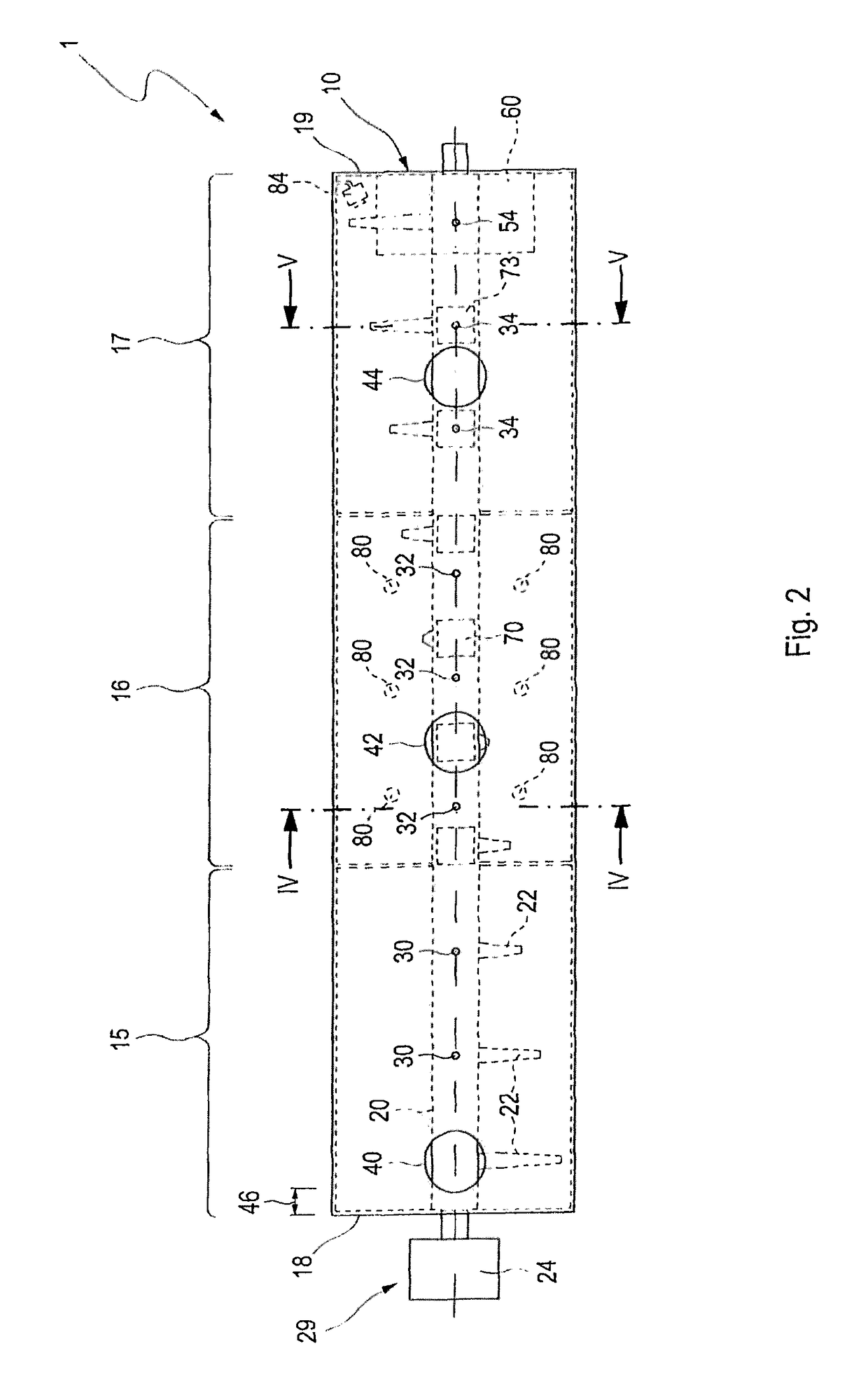

Plant for waste disposal and associated method

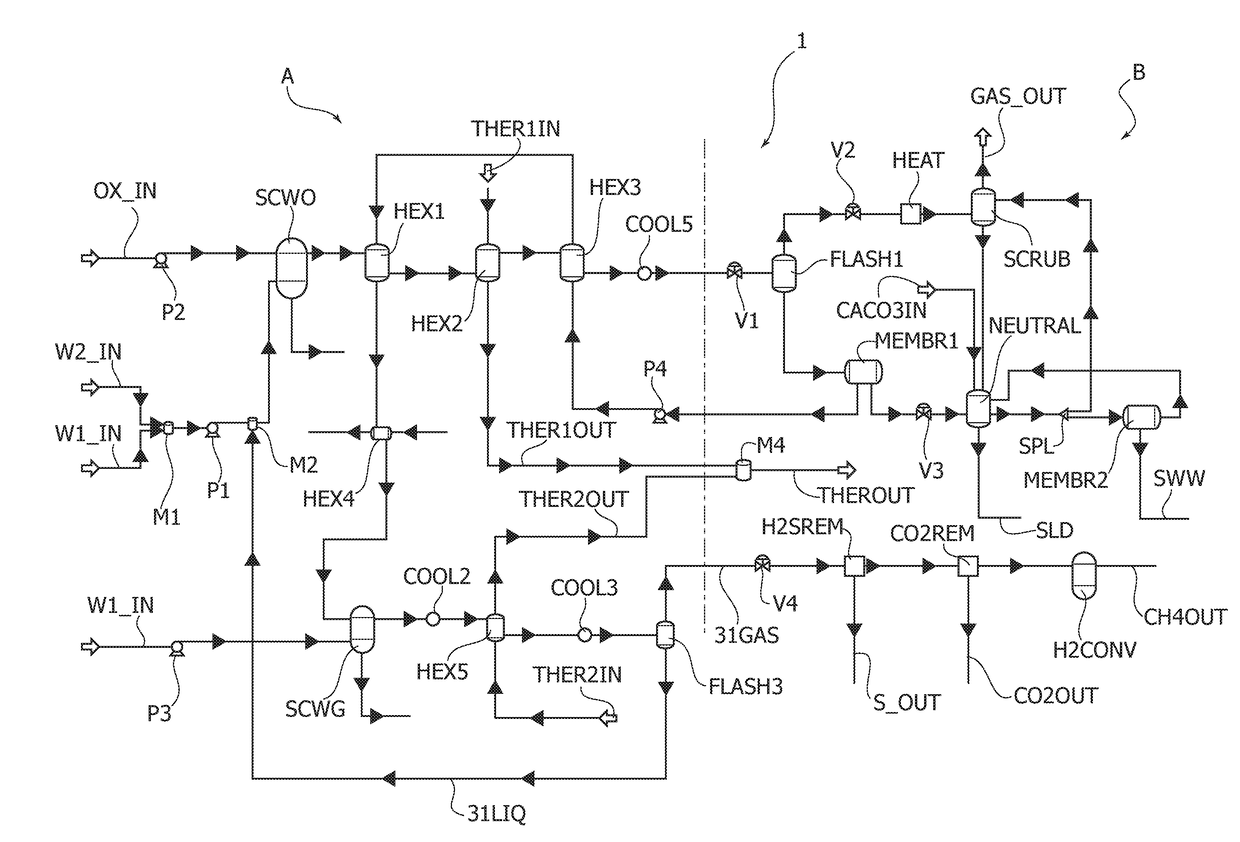

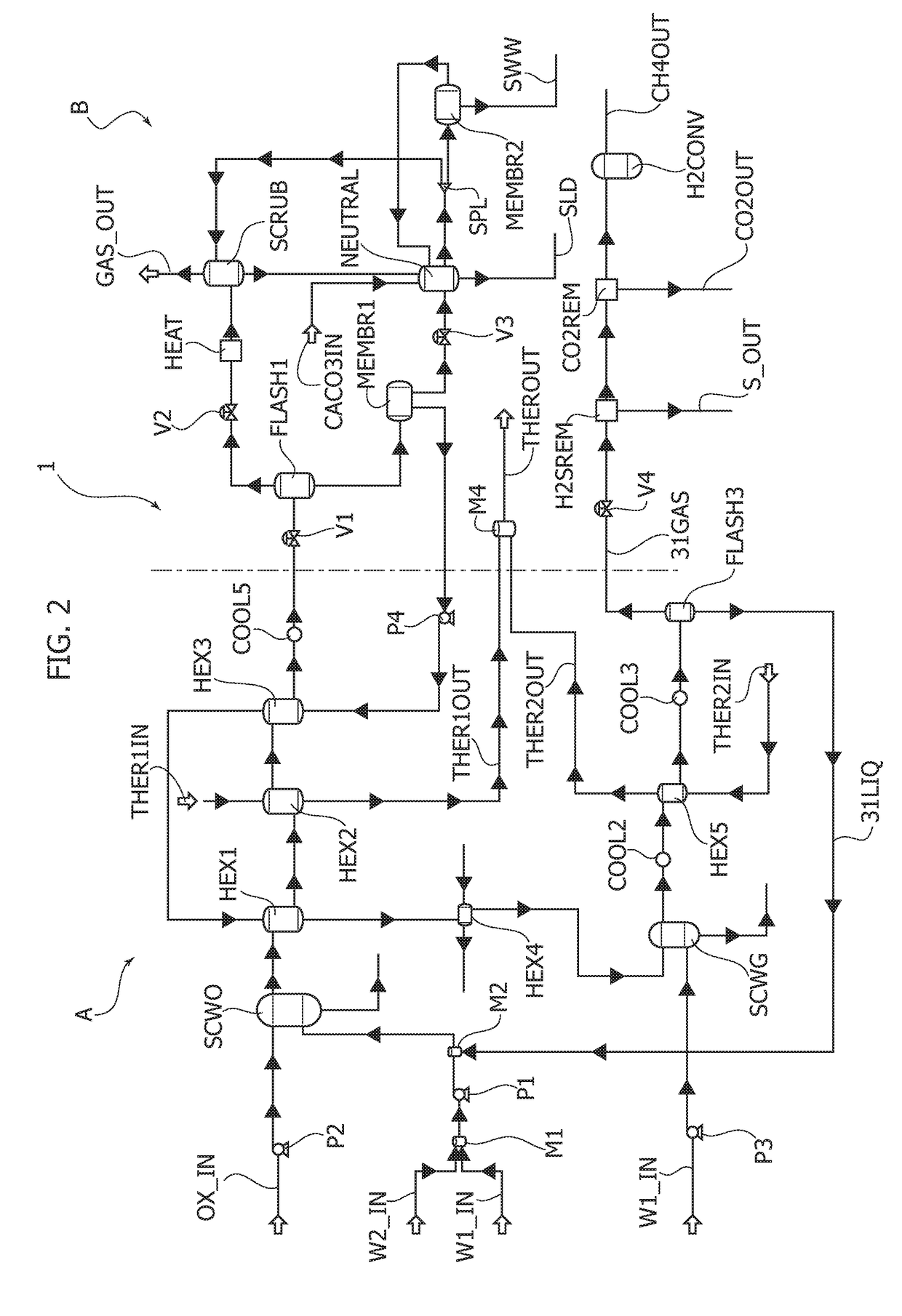

ActiveUS20180117561A1Improve energy efficiencyMinimal environmental impactWaste water treatment from quariesLiquid degasificationEnvironmental engineeringSupercritical water oxidation

A plant for the disposal of wastes includes a supercritical water oxidation reactor, a supercritical water gasification reactor, and a feeding system configured for feeding at least two organic currents of wastes to the supercritical water oxidation reactor and supercritical water gasification reactor and configured for feeding at least one aqueous flow within said plant. The feeding system is configured for feeding the at least one aqueous current with a series flow through the supercritical water oxidation reactor and supercritical water gasification reactor. The feeding system is configured for feeding the at least two organic currents of wastes with a parallel flow through the supercritical water oxidation reactor and supercritical water gasification reactor and so as to selectively feed each of the organic currents of wastes to the supercritical water oxidation reactor or to the supercritical water gasification reactor.

Owner:ARCHIMEDE

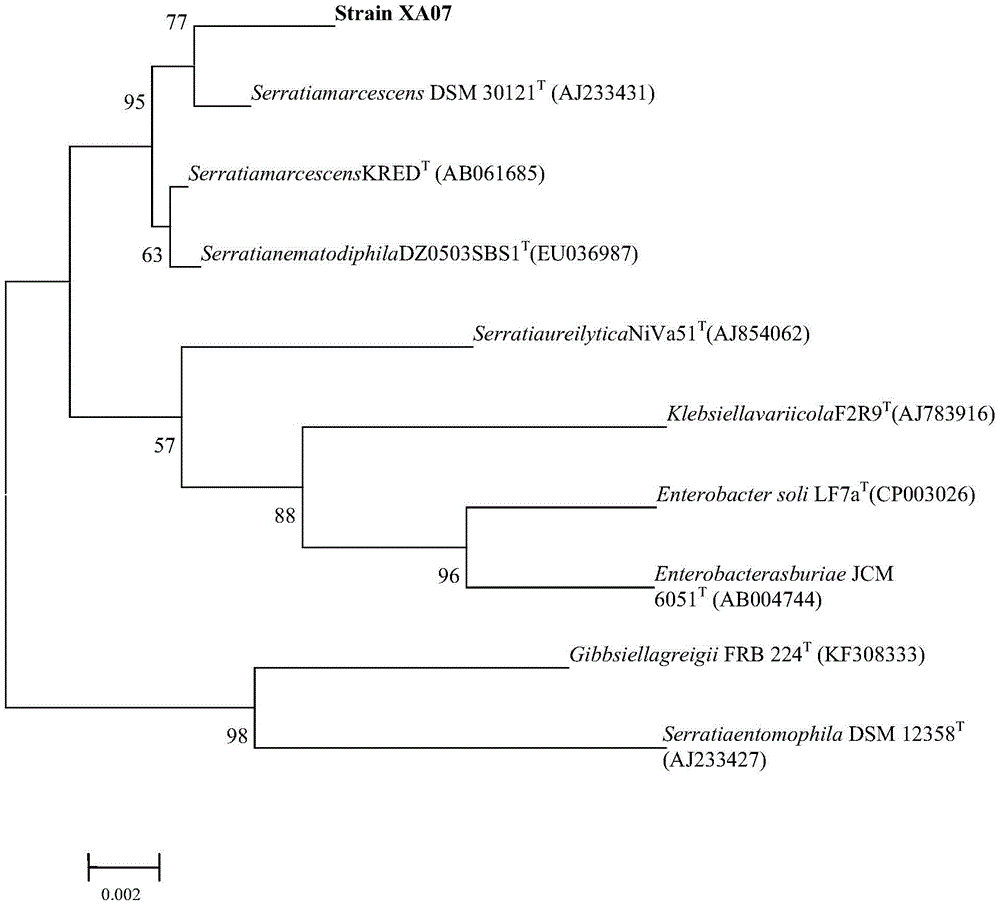

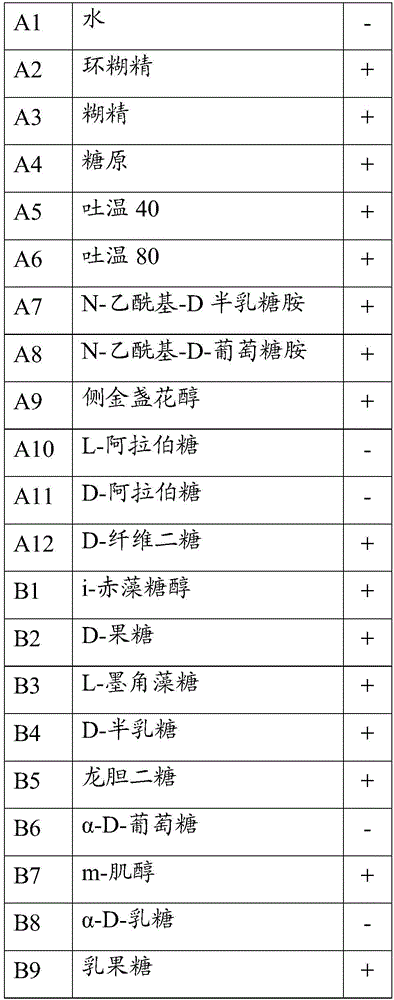

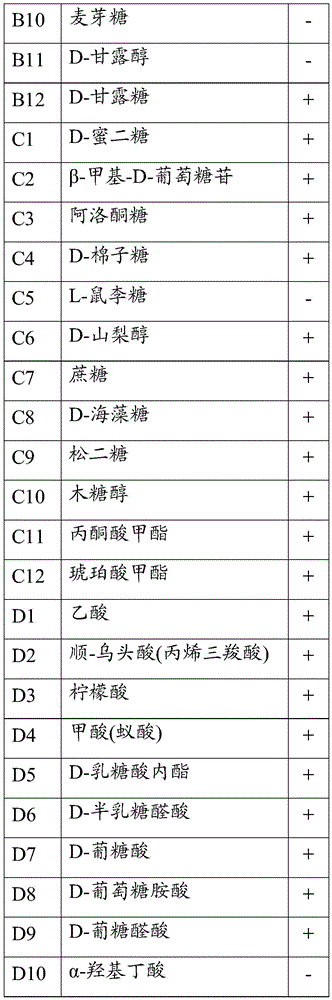

Serratia marcescens and preparation method and application thereof

InactiveCN105483036AImprove adsorption capacityBacteriaContaminated soil reclamationMicroorganismSerratia species

The invention belongs to the field of microorganisms and discloses serratia marcescens and a preparation method and application thereof. A sequence of the serratia marcescens is shown as SEQ IN NO:1 in a sequence table. The preparation method includes: extracting a soil sample from the periphery of a waste battery and heavy metal landfill of a solid waste treatment plant, adding into sterile water, vibrating completely, standing to obtain supernatant, diluting the supernatant into different times, respectively spreading onto a culture medium, adding heavy metal ions to the culture medium to carry out culturing, selecting ingle colonies from the culture medium, inoculating to a slant culture medium to obtain original strains; inoculating the original strains to a liquid culture medium, performing constant-temperature shake culturing, standing overnight to obtain a bacterial liquid, diluting the bacterial liquid, respectively putting in sterilization plates, performing ultraviolet radiation, spreading to a solid culture medium, and performing constant-temperature static culturing and enriched heavy metal analysis to obtain the serratia marcescens. The serratia marcescens has an excellent performance in adsorption of Cr2+, Cd2+ and Pb2+ and is an excellent biosorption material.

Owner:THE FIRST AFFILIATED HOSPITAL OF XIAN JIAOTONG UNIV

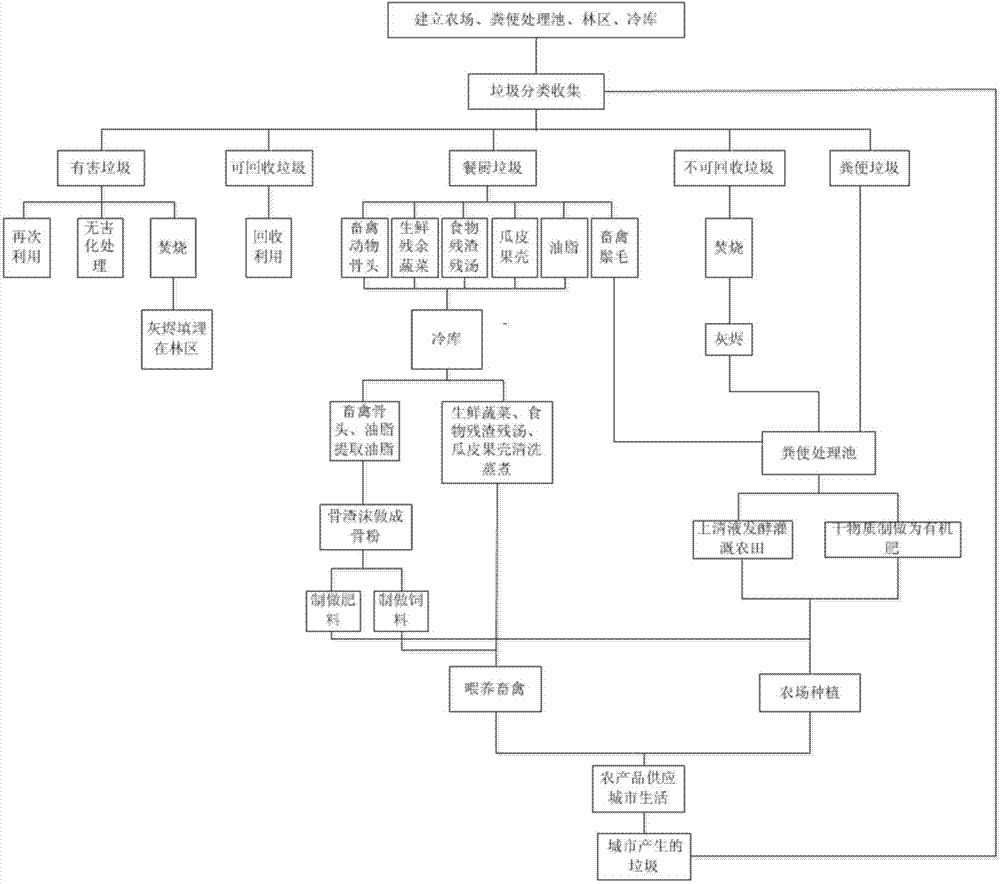

Comprehensive cyclic utilization and treatment method for municipal waste

The invention discloses a comprehensive cyclic utilization and treatment method for municipal waste, belonging to the technical fields of comprehensive treatment of municipal refuse and cyclic reutilization of resources. The comprehensive cyclic utilization and treatment method comprises the following steps: (1) building a farm, an excrement treatment pond, a forest zone and a refrigeration house; (2) collecting waste in a classifying manner; (3) transporting the classified and collected kitchen waste to the refrigeration house for centralized treatment, particularly transporting classified and collected recyclable waste, unrecyclable waste and harmful waste to a waste treatment plant for sorting; (4) extracting grease from bones and grease of livestock, and making squeezed bone dreg into bone meal; (5) transporting fresh residual vegetables, food residues and soup, melon shells and fruit shells in the refrigeration house to the farm for use; (6) transporting excrement waste and livestock bristles to the excrement treatment pond built in the farm; and (7) transporting agricultural products produced in the farm to a city to meet city living needs, and cyclically treating and utilizing the produced waste according to the previous steps.

Owner:CHONGQING YURUN FOOD CO LTD

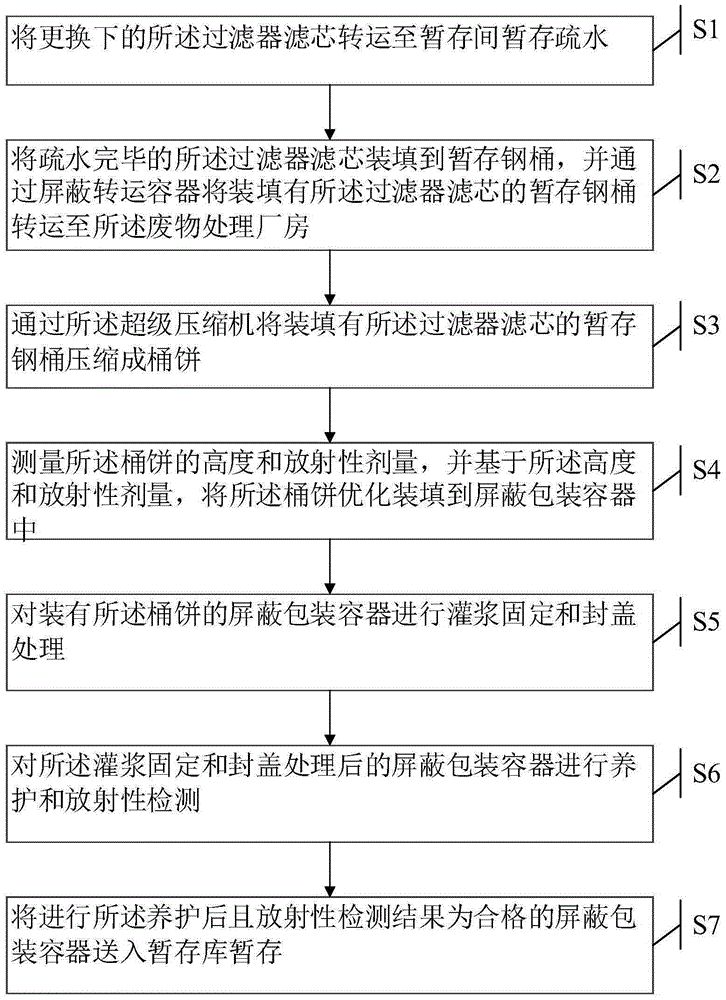

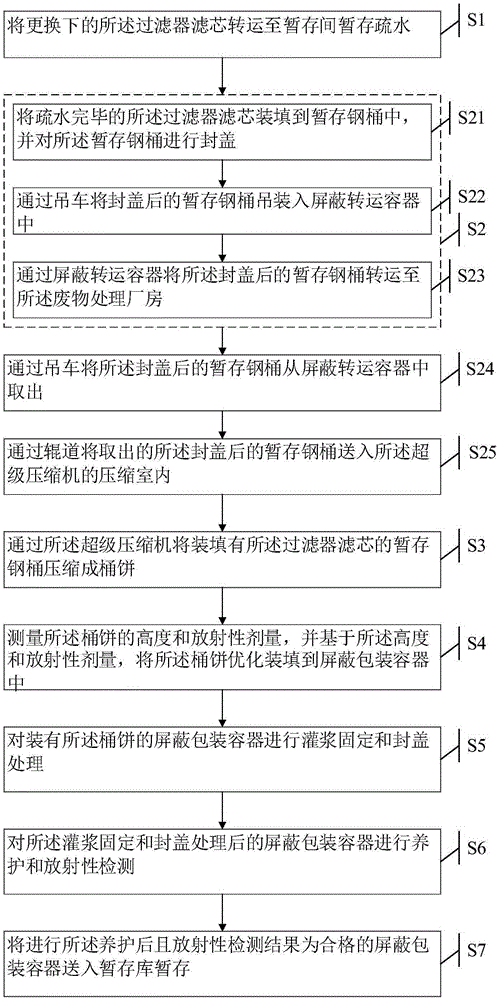

Method and system for treating low-medium radioactive level filter core of filter in nuclear power station

ActiveCN105355252AReliable handlingMeet packaging requirementsRadioactive decontaminationNuclear powerNuclear power plant

The invention discloses a method and system for treating a low-medium radioactive level filter core of a filter in a nuclear power station, and solves a technical problem in the prior art that a waste package is large in size after the filter core is treated and the treatment cost is high. The method for treating the filter core comprises following steps: S1, transferring a replaced filter core of the filter to a temporary storage room for temporary storage and drainage; S2, putting the drained filter core of the filter into a temporary storage steel barrel, and transferring the temporary storage steel barrel to a waste treatment factory through a shield transferring container; S3, compressing the temporary storage steel barrel into a barrel cake through a super compressor; S4, measuring the height of the barrel cake and the radioactive dosage, and loading a shield packing container with the barrel cake according to the measured values in an optimization manner; S5, grouting, fixing and capping the shield packing container; S6, maintaining the shield packing container and performing radioactivity detection on the shield packing container; and S7, conveying the shield packing container to a temporary storage house for temporary storage. According to the invention, the filter core can be efficiently reduced in volume, the size of the waste package is decreased, and the waste treatment cost is reduced.

Owner:中广核工程有限公司 +1

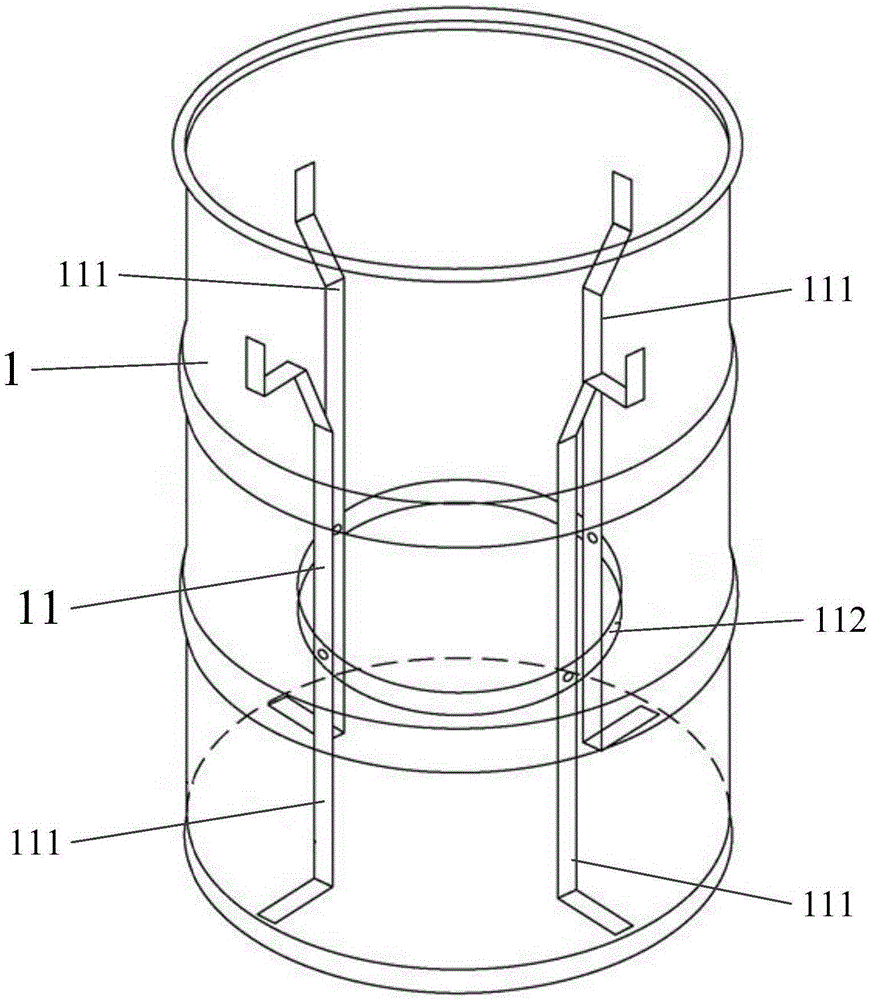

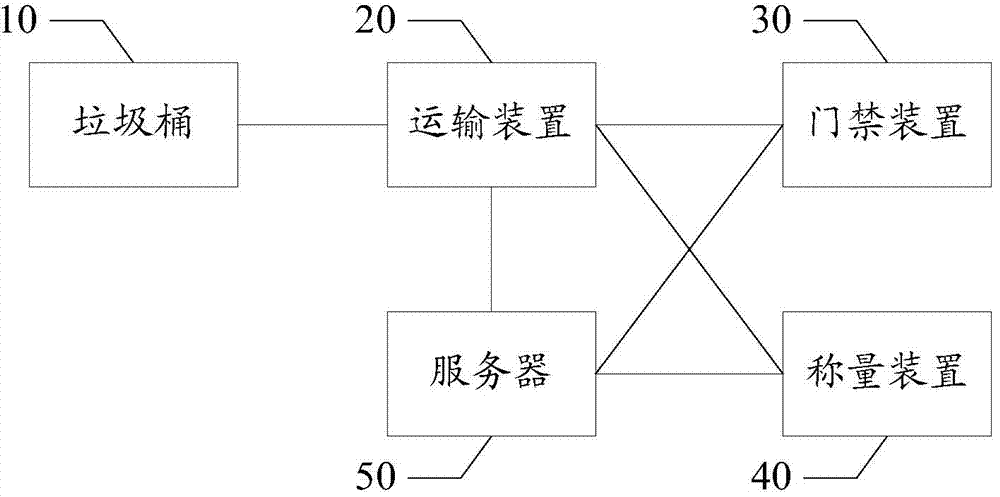

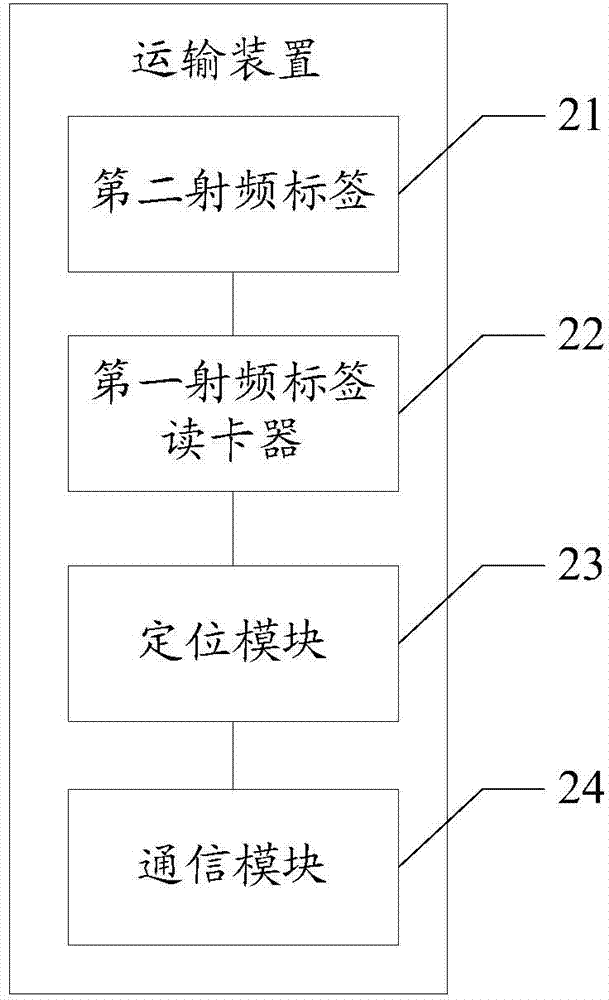

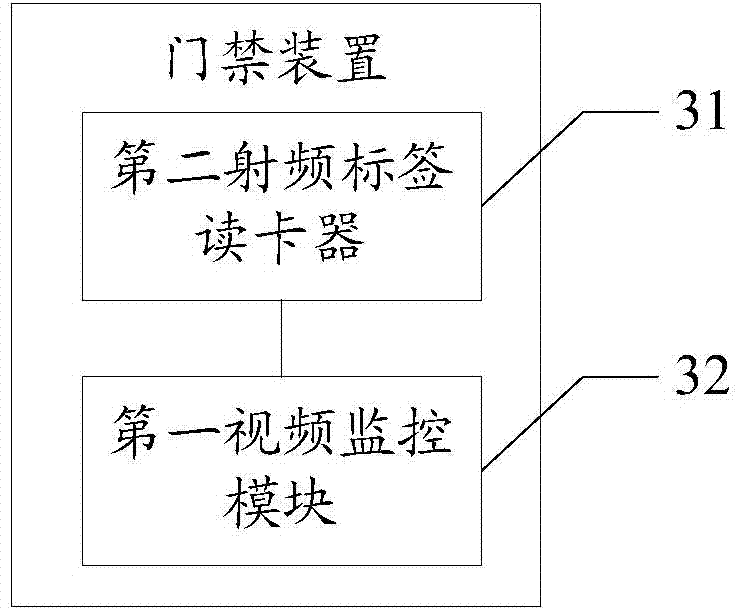

Real-time monitoring and management system for waste collection

InactiveCN103617587ARealize real-time monitoringTake advantage ofData processing applicationsSensing record carriersWaste collectionRead through

The invention discloses a real-time monitoring and management system for waste collection. A first radio frequency tag is arranged on a dustbin, information of the dustbin is read through a first radio frequency tag card reader on a transporter, then, the information of the dustbin is stored in a second radio frequency tag, and the information of the dustbin is read through a second radio frequency tag card reader on an entrance guard device or a third radio frequency tag card reader on a weighing device and uploaded to a server to be inquired and called. The dustbin can be monitored in real time, the information of the dustbin is related to the transporter, the entrance guard device and the weighing device, and thus the transporter can be deployed reasonably, and transportation resources can be fully utilized. Besides, the waste output and the transportation process can be monitored and managed throughout the process in cooperation with the waste treatment capacity, the waste treatment process and environmental protection networked monitoring and management of a waste treatment plant, the effectiveness and the quality of waste treatment and transportation can be guaranteed, and a scientific reference basis is provided for government decision making.

Owner:深圳市英尔科技有限公司

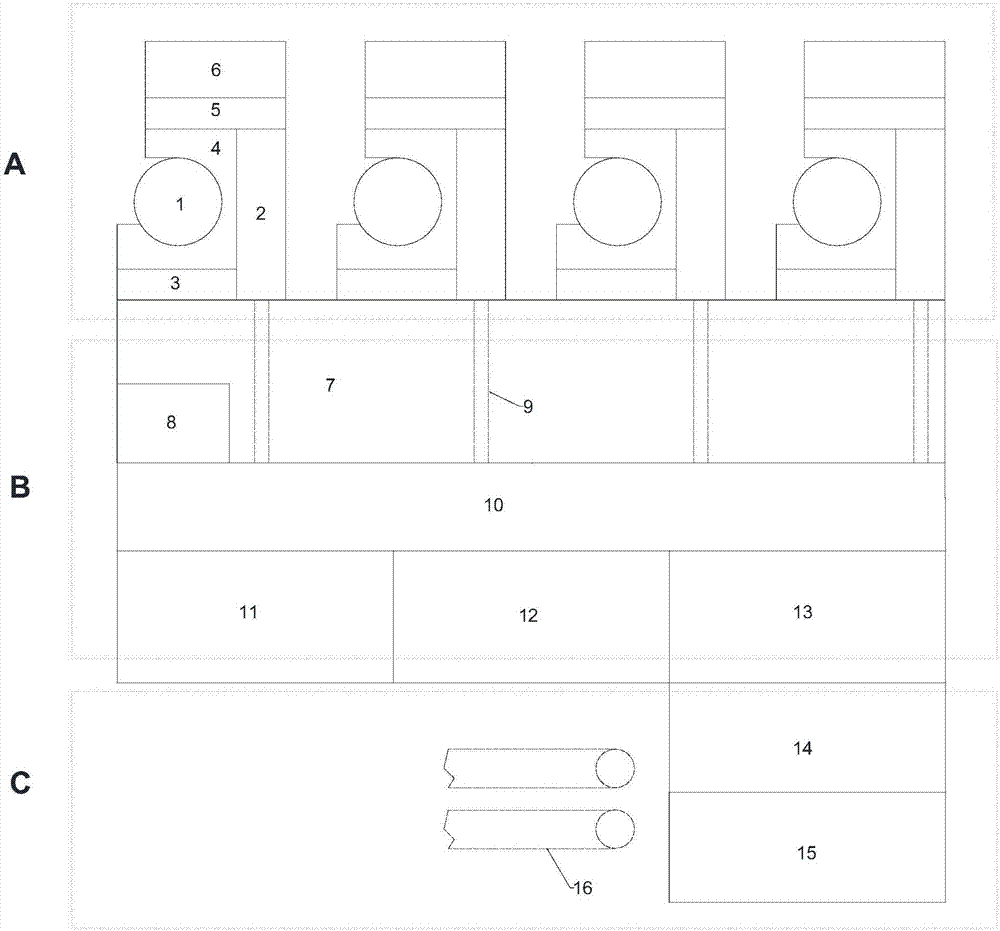

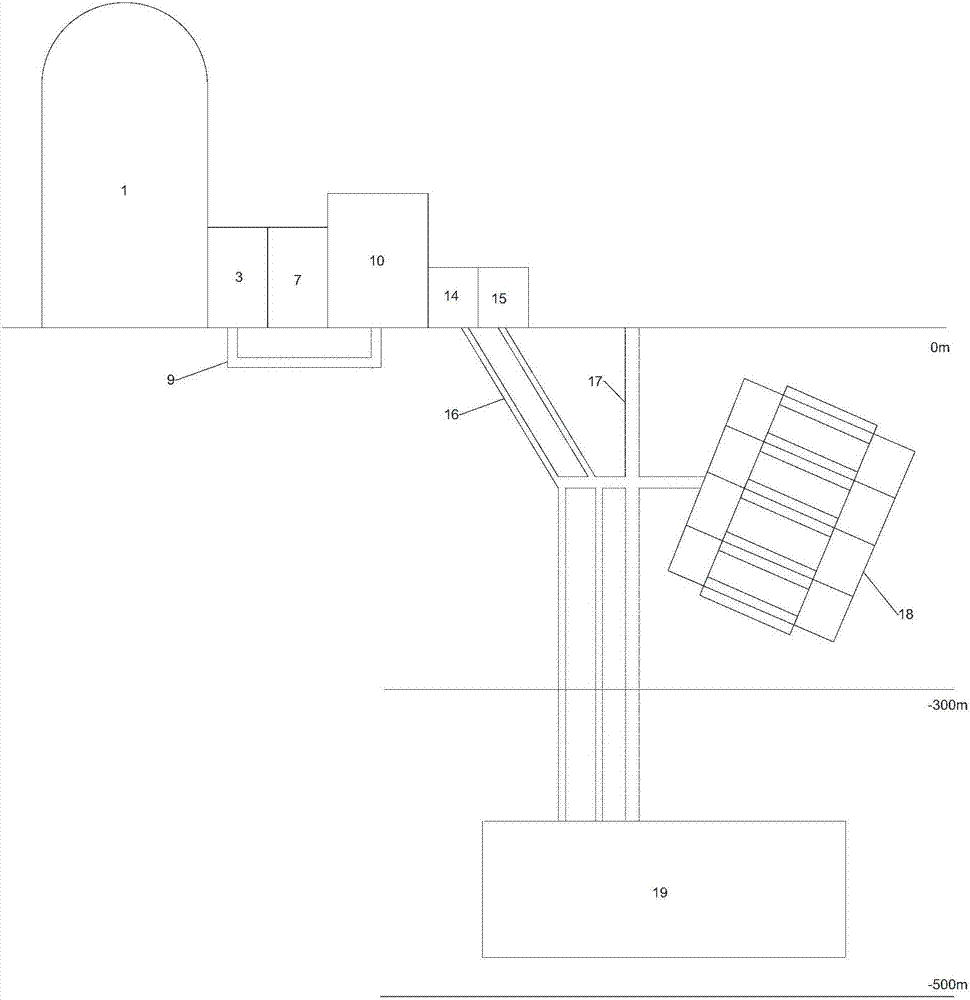

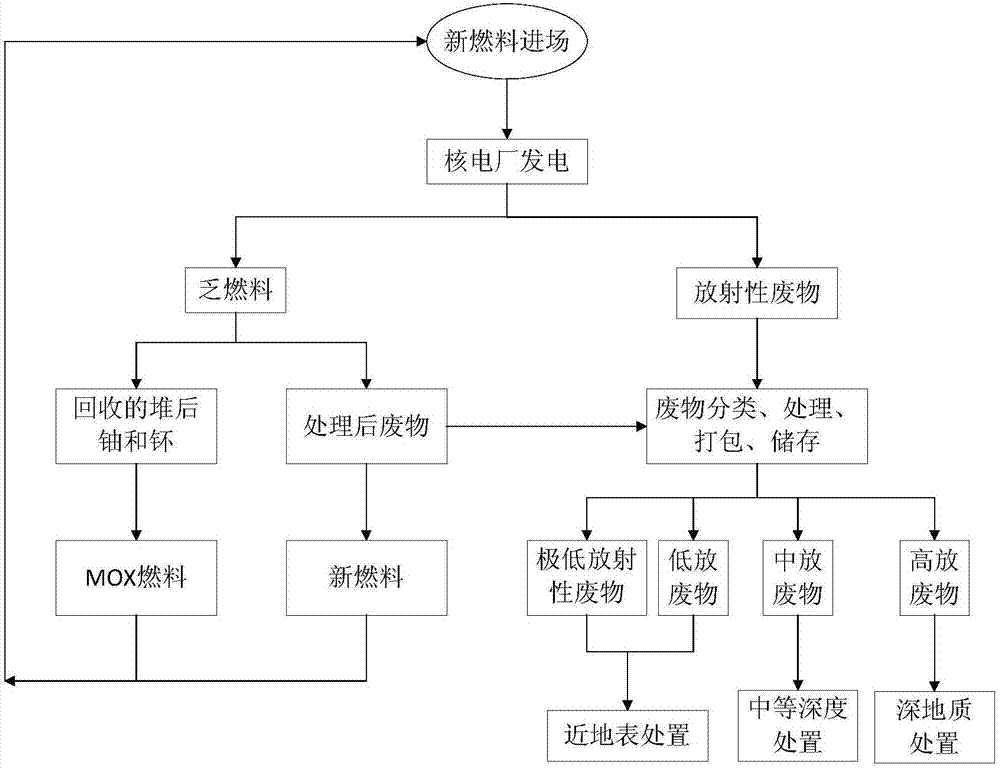

Power generation and nuclear fuel processing disposal integrated nuclear energy base based on closed cycle

PendingCN107039095ASave resourcesMeeting Disposal NeedsNuclear energy generationReactor fuel elementsFuel reprocessingDeep geological repository

The invention discloses a power generation and nuclear fuel processing disposal integrated nuclear energy base based on closed cycle. The power generation and nuclear fuel processing disposal integrated nuclear energy base comprises a nuclear energy power generation area, a spent fuel and waste disposal area, and a waste final disposal area. The nuclear energy power generation area comprises a reactor workshop, a nuclear auxiliary workshop, and a fuel workshop. The spent fuel and waste disposal area comprises a spent fuel and waste disposal workshop and a waste processing workshop. The waste disposal area comprises a commissioned near surface disposal warehouse, a decommissioned near surface disposal warehouse, a middle depth disposal warehouse, and a deep geological disposal warehouse. The nuclear energy base is divided into the power generation area, the fuel and waste disposal area, and the waste final disposal area according to functions, and the planning, the siting, and the investment of the whole nuclear energy base are realized in a unified manner, and therefore planning is facilitated, and factory site resources are saved. The spent fuel and the wastes are processed and disposed in the neighborhood, and therefore radiation risks caused by long distance transport are prevented.

Owner:CHANGJIANG SURVEY PLANNING DESIGN & RES

Environment-friendly monitoring system for flue gas pollutants

The invention discloses a continuous monitoring system for flue gas pollutants. The system is used for monitoring contents of elementary mercury, mercury ions and total mercury in flue gas. By arrangement of a sampling channel and a detection system, the influence of adsorbent particles of a particle filter in the channel on a detection result can be reduced. The continuous monitoring system for the flue gas pollutants can be applied to precisely continuous monitoring for mercury discharging of a fixed pollution source such as a chemical plant, a coal-fired power plant and a waste treatment plant, so as to realize discharge control over the pollution source and provide real-time and reliable data for environmental monitoring and environmental protection.

Owner:南京泷逸环保科技有限公司

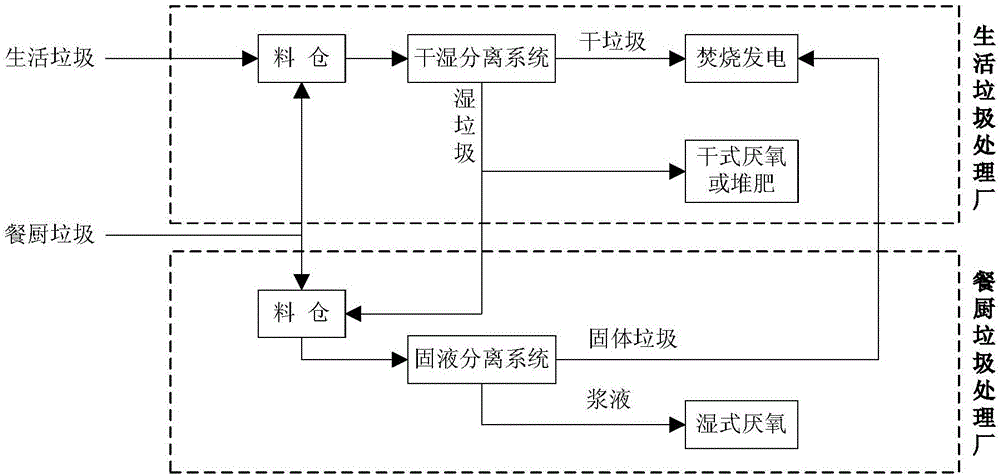

Synergic treatment method for household garbage and kitchen wastes

The invention discloses a synergic treatment method for household garbage and kitchen wastes. The household garbage can be treated and the kitchen wastes can be further synergically treated in a household garbage treatment plant or a kitchen waste treatment plant. The method comprises the following steps: after mixing the household garbage and the kitchen wastes in a stock bin in the household garbage treatment plant, separating the two into dry garbage and wet garbage through a dry and wet separating system, using the separated dry garbage as a raw material for incineration power generation, and using the separated wet garbage as a raw material for dry anaerobic biogas preparation or compost preparation; and after mixing the kitchen wastes in the kitchen waste treatment plant with wet garbage separated from the household garbage treatment plant through the dry and wet separating system in the stock bin, separating the two into solid garbage and slurry through a solid-liquid separation system, using the separated solid garbage as a raw material for incineration power generation of the household garbage treatment plant and using the separated slurry as a raw material for wet anaerobic biogas preparation. The method disclosed by the invention makes full use of process equipment of an existing garbage treatment plant, and has the advantages of high efficiency, simple treatment process, low treatment cost and the like.

Owner:SOUND ENVIRONMENTAL RESOURCES +1

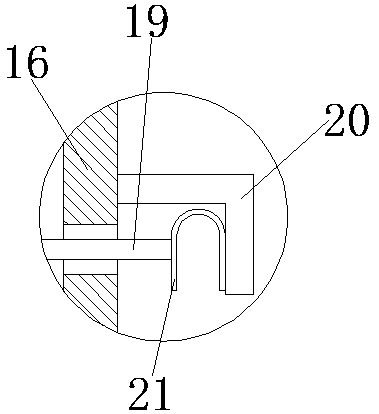

Material solubiliser reactor for hydrolysis and/or wet fermentation and waste treatment plant with such a solubiliser and reactor

InactiveCN101065188ADissolve fastAvoid overall overheatingBio-organic fraction processingClimate change adaptationHydraulic cylinderEngineering

To provide an arm device for bedsides which fixes the angle between arms regardless of a torque which is applied to the connected section between the arms to hold the posture of the arms. For this arm device 1 for bedsides, a base 2, a first arm 10, a second arm 20 and a head mount 30 are connected by first to third turning shafts 13, 23 and 33. A first electromagnetic valve 80 is provided in a bypass 45 which communicates two liquid chambers 44a and 44b of a doubly acting type first hydraulic cylinder 40 provided between base 2 and the first arm 10. A second electromagnetic valve 90 is provided in a bypass 55 which communicates two liquid chambers 54a and 54b of a doubly acting type second hydraulic cylinder 50 provided between the first arm 10 and the second arm 20. The first electromagnetic valve 80 and the second electromagnetic valve 90 are operated by buttons 85 and 95 which are arranged on the head mount 30, and thus, the posture of the arm device 1 is changed.

Owner:克里斯蒂安·威德默

Process for preparing biomass fuel by using rural town domestic waste and agricultural and forestry waste

ActiveCN108435754ALess investmentLow costSolid waste disposalExcrement fertilisersLiquid wasteSludge

The invention discloses a process for preparing biomass fuel by using rural town domestic waste and agricultural and forestry waste. The process comprises the steps of step one, waste leachate treatment and foul smell deodorization; step two, waste screening, sorting and coarse crushing; step three, non-organic matter magnetic separation, winnowing and fine crushing; step four, agricultural and forestry waste crushing and screening; step five, stirring of waste combustible materials, agricultural and forestry waste, sludge and water, compression molding, airing and biomass fuel obtaining; andstep six, waste organic matter adding of livestock and poultry manure, and organic fertilizer obtaining. According to the process, the biomass fuel can be directly used in a boiler, and the problem that the livestock and poultry manure pollutes the environment in a livestock farm is solved through the organic fertilizer; for the construction of waste treatment plants, the investment is small, thecost is low, and implementation is easy; the agricultural and forestry waste is collected with paying performed, so that the income of farmers is increased, and the pollution is reduced; the profit rate is high, and operating can last without government subsidy; the waste gas, the waste liquid and the waste residue are subjected to the environmental protection treatment so that new pollution can be avoided.

Owner:于继林

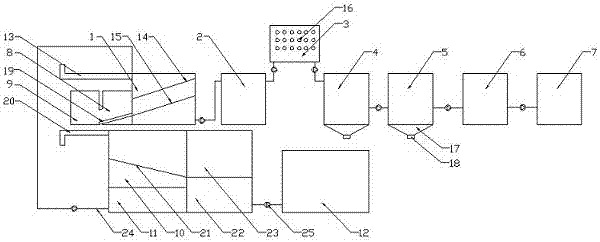

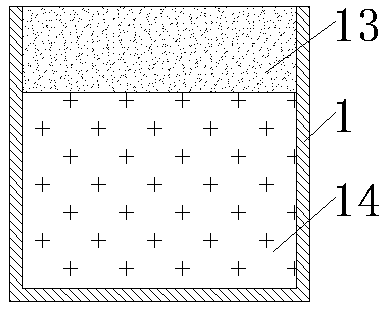

Treatment system for community domestic wastewater

InactiveCN107459218AComplete and compact structural designIncrease dissolved oxygenTreatment using aerobic processesExcrement fertilisersGratingTreatment pond

The invention discloses a treatment system for community domestic wastewater. The treatment system comprises a grating tank, a first water collecting tank, an aeration tank, a primary settling tank, a second settling tank, a disinfecting tank and a clean water tank which are connected with each other in turn through the connecting pipelines. The excrement and urine and the washing water for daily life are separately treated; the water for daily life is grated by a grating plate; the waste residue enters into a waste residue treating tank, is dried and then enters into a crushing chamber for crushing and is transferred as a solid waste into a solid waste treatment plant for treating; the excrement and urine enter into a primary treating tank for treating through a sewage feeding pipeline, the excrement enters into an excrement drying chamber for drying, the dried excrement enters into a fermenting tank and is fermented with the other materials and the fermented mixture enters into a fertilizer collecting chamber for collecting and storing under the effect of a lifting pump, so that the fermented mixture can be used as the fertilizer for farmland and greening or can be sold to the needing people.

Owner:卓辉(福建)建设工程有限公司

Kitchen waste treatment method capable of improving capacity of treatment system and hydrolysis tank

The invention relates to the technical field of kitchen waste treatment, in particular to a method for improving the capacity of a kitchen waste anaerobic treatment system and a hydrolysis tank. According to the kitchen waste treatment method capable of improving the capacity of the treatment system and the hydrolysis tank, kitchen waste slurry is fed from 1 / 2 or above height of the tank wall of the hydrolysis tank and is synchronously stirred, so that the kitchen waste slurry can be fully mixed with original kitchen waste slurry in the hydrolysis tank from top to bottom; the temperature of the kitchen waste slurry in the hydrolysis tank is kept at 35+ / -3 DEG C by monitoring and interfering the environment in the hydrolysis tank, the average concentration of dissolved oxygen is kept at 0.5-1.0 mL / L, the pH value is kept at 3-5, the hydrolysis conversion rate can be remarkably increased, and therefore the treatment load of the treatment system is improved, by means of the method, the treatment load of the treatment system can be improved to be 4.5-6.5 kgVS / m<3>*d, the treatment residence time can be saved by about 40%, and the occupied space of an anaerobic tank can be saved by 25%or above; and the method has great application significance in increasing the treatment amount of the kitchen waste under the condition that an original kitchen waste treatment plant is not expanded.

Owner:广州市朗坤环境科技有限公司

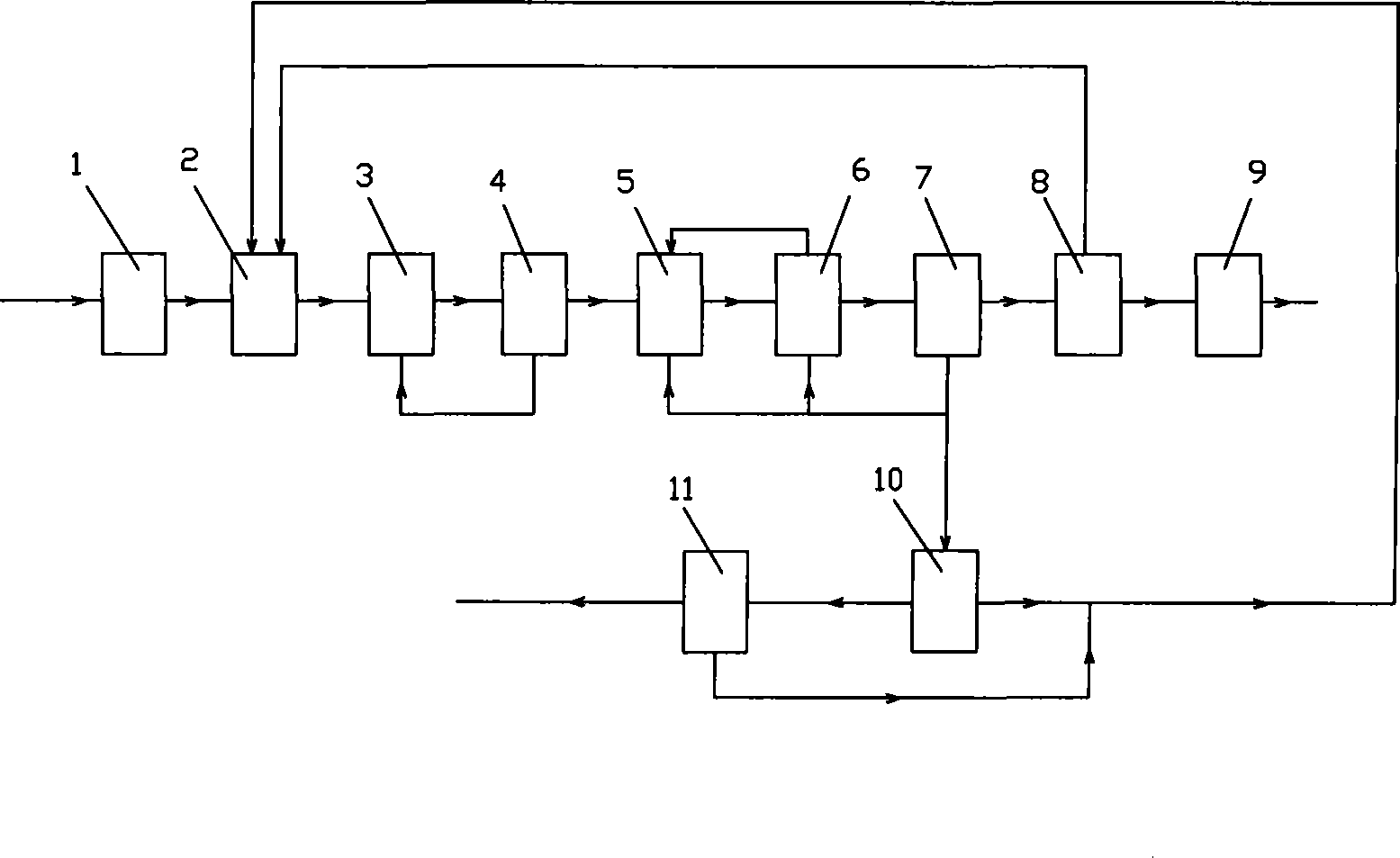

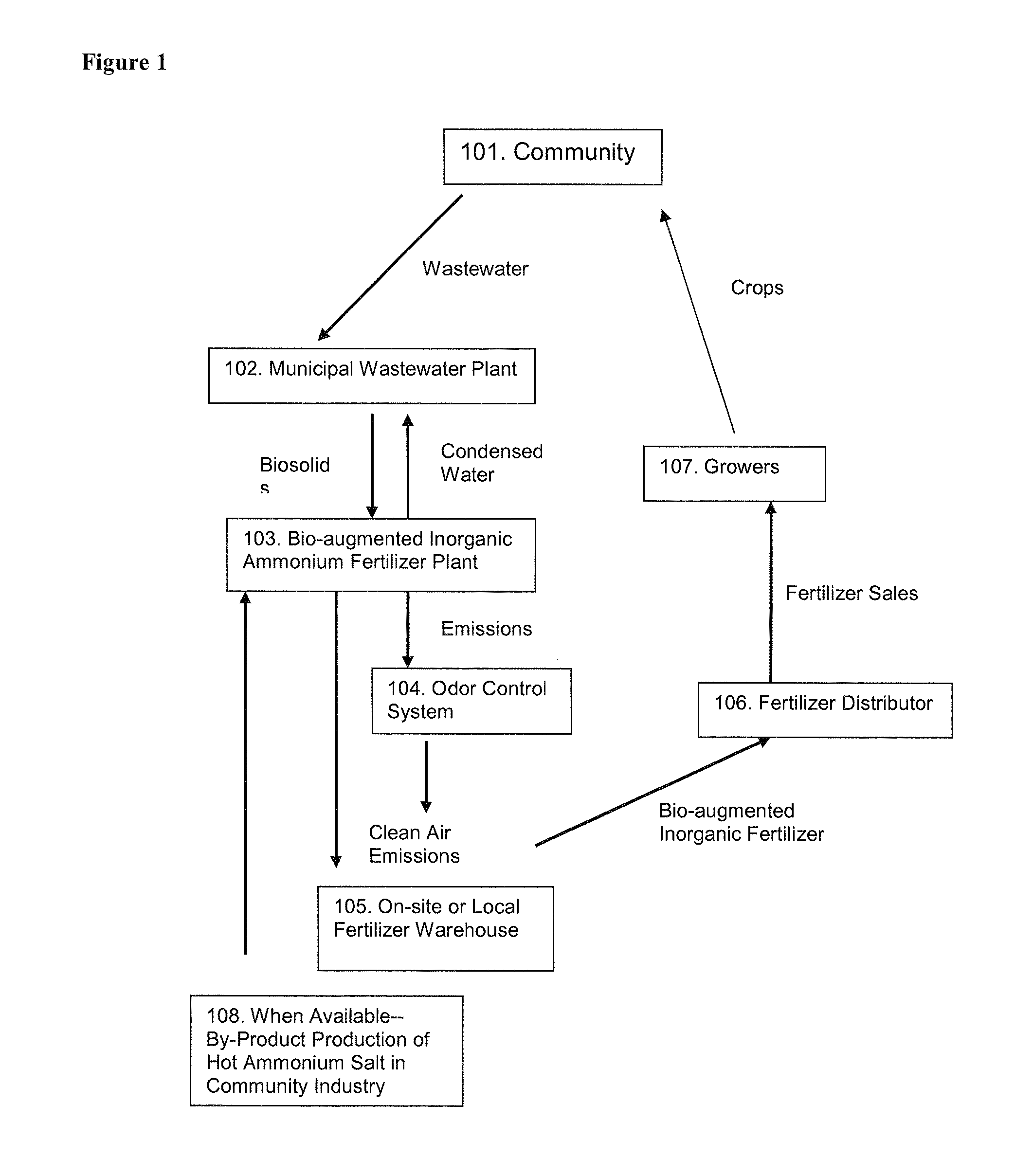

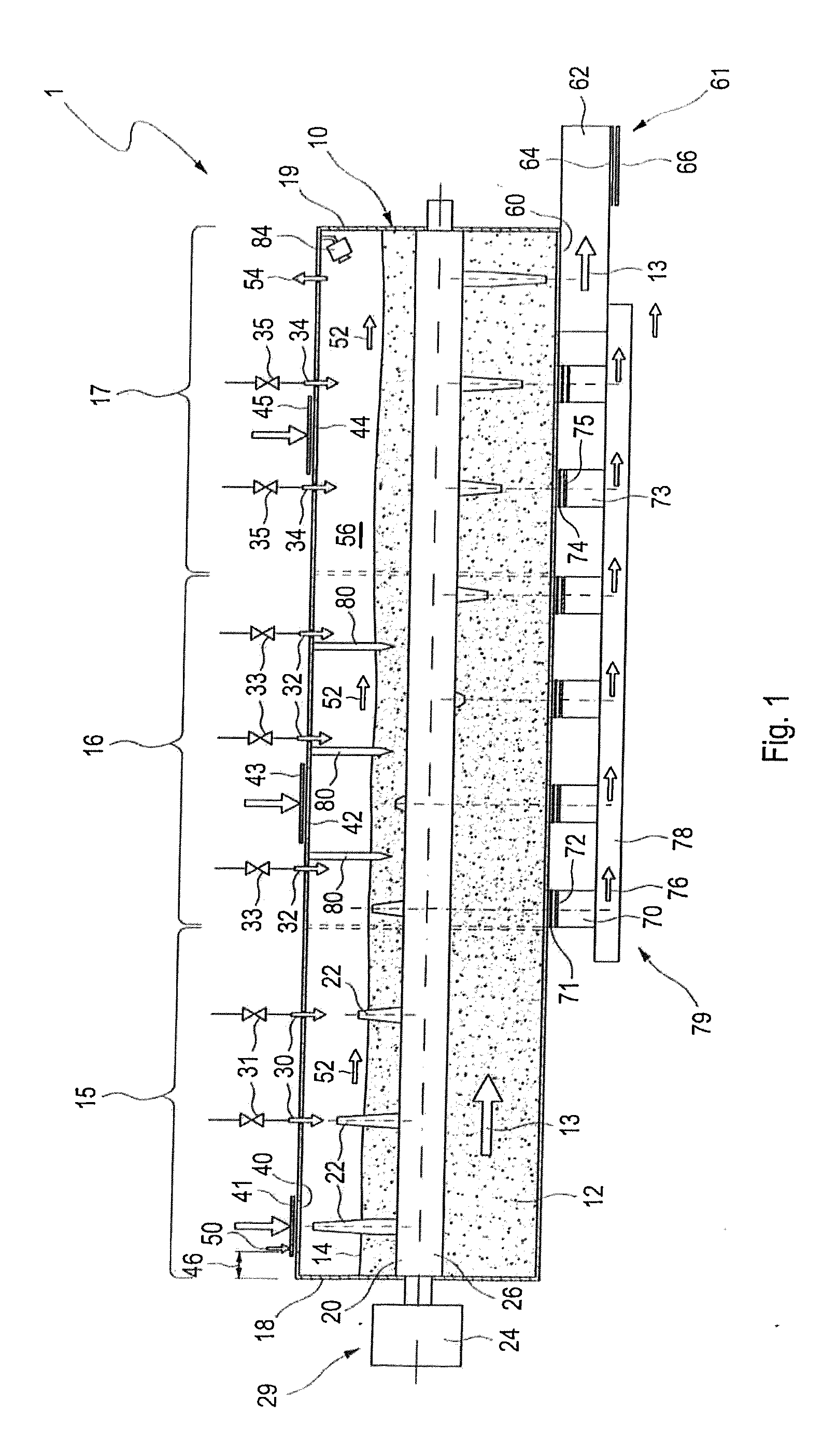

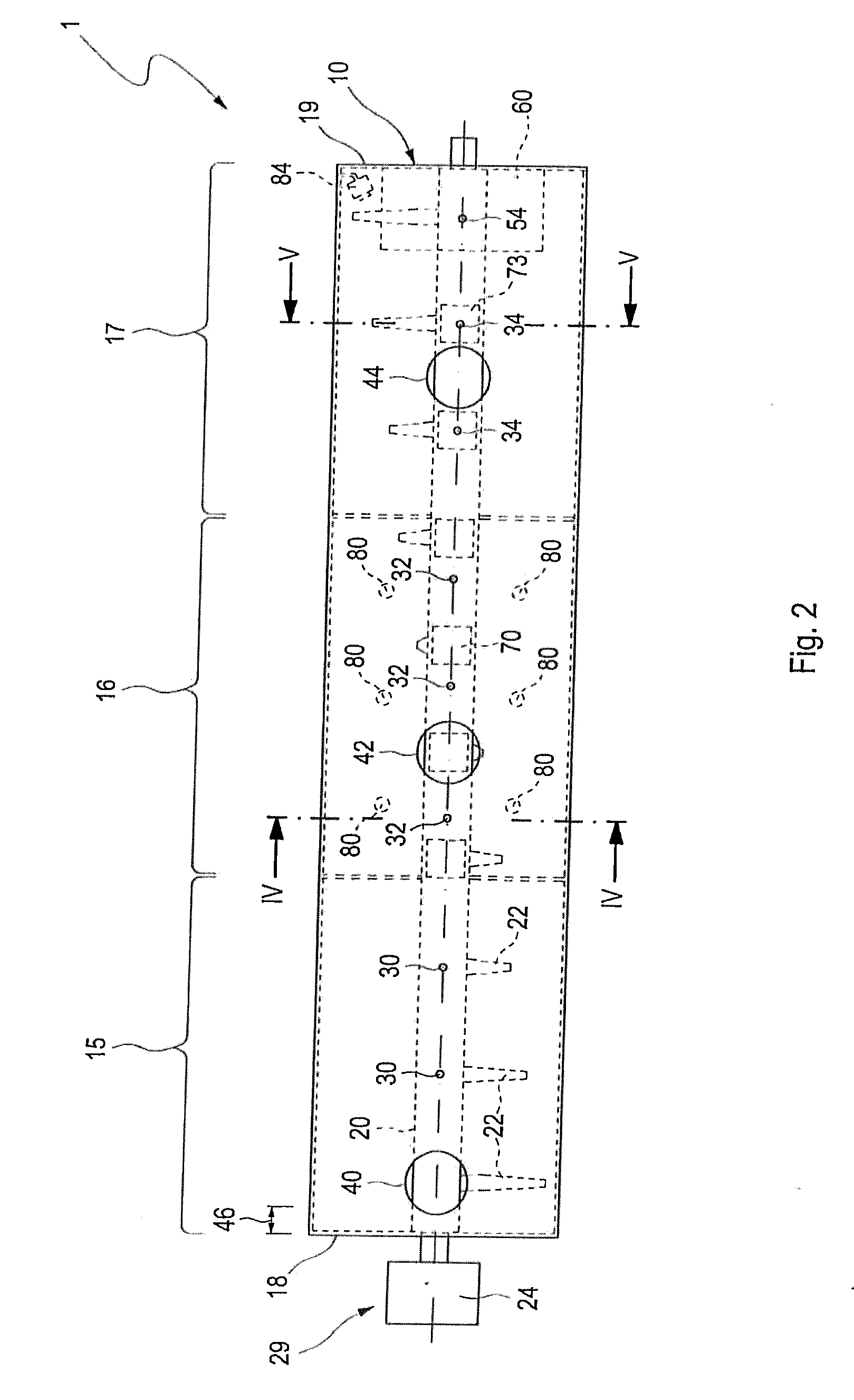

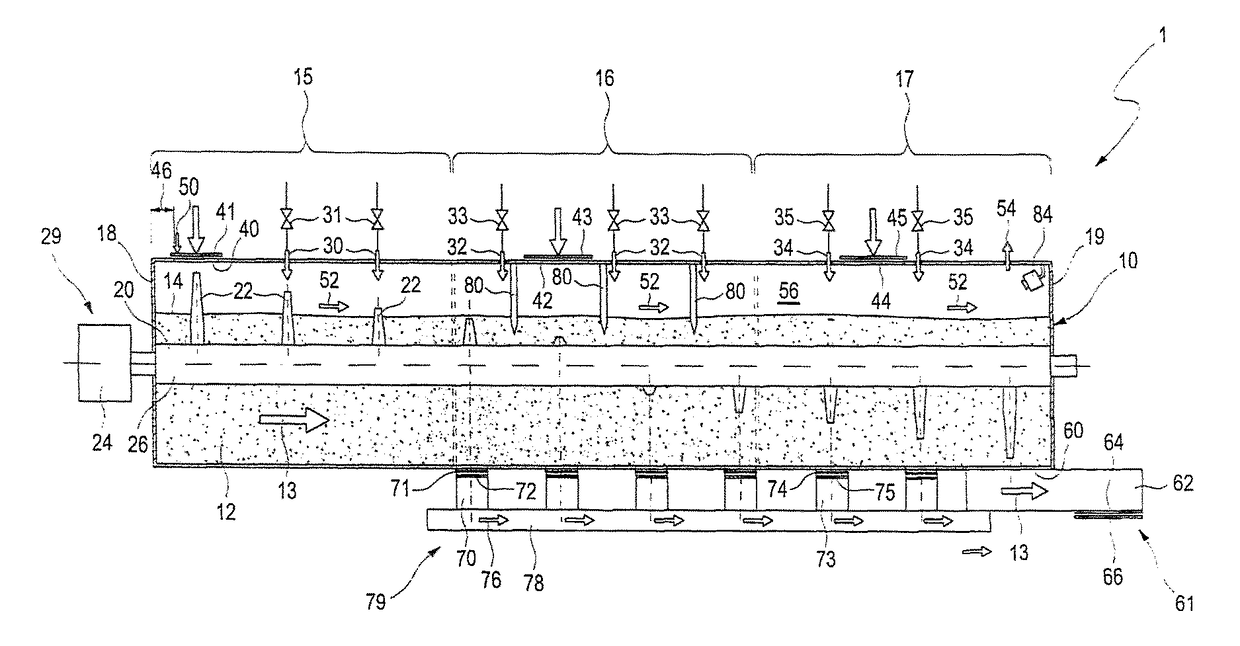

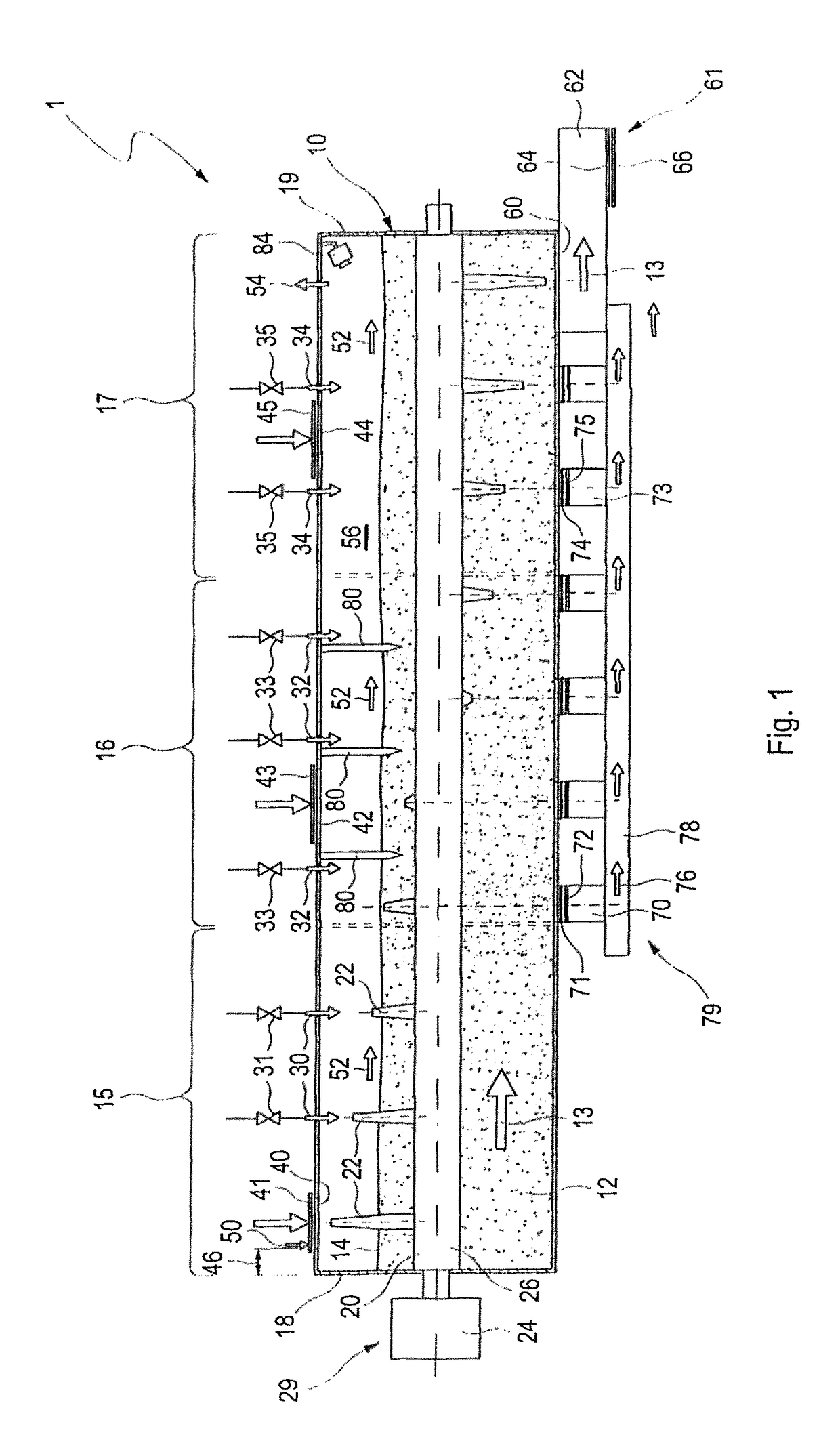

Method and Device for the Mechanical or Mechanical-Biological Treatment of Waste

ActiveUS20140203120A1Keep for a long timeReduce throughputBiofuelsSolid fuelsEnvironmental engineeringHigh water content

The invention relates to a method for treating waste in a mechanical or mechanical-biological waste treatment plant, comprising the following steps of:introducing waste-into the waste treatment plant at least one input point,homogenizing the waste by way of at least one agitator,determining the consistency of the waste in the waste treatment plant,adding water or waste which has a higher water content than the waste in the waste treatment plant in a first scenario, or removal of water or addition of waste having a lower water content in another scenario,transporting the introduced waste to at least one output point,removing the waste. The waste treatment plant is subdivided into at least two zones and in each zone the consistency of the waste is regulated separately by the input of waste and / or addition or removal of water.

Owner:ZWECKVERBAND ABFALLBEHANDLUNG KAHLENBERG

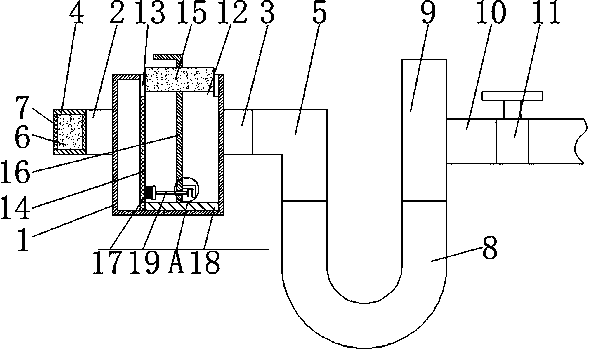

Sewage treatment device for kitchen sink

InactiveCN107754430AAvoid cloggingRelieve pressureSpecific water treatment objectivesTreatment involving filtrationActivated carbonWastewater

The invention discloses a sewage treatment device for a kitchen pool, comprising a box body, a water outlet, a water inlet, a filter pipe, a first connecting pipe, an activated carbon layer, a baffle, a U-shaped pipe, a drain pipe, a second connecting pipe, and a valve , round hole, ring, curved filter screen, rubber plug, first connecting rod, brush, piston disc, second connecting rod, fixed block and spring leaf. The invention is reasonable in structure and novel in design, and can prevent a large amount of vegetable leaves and rice grains from accumulating in the sewer to cause sewer blockage. For gathering, the vegetable leaves and rice grains accumulated in the box can be quickly taken out through the piston plate and the first connecting rod. At the same time, the arc-shaped filter can be cleaned by the brush to prevent the sieve holes on the arc-shaped filter from clogging, which can effectively Reduce the pressure on the wastewater treatment station.

Owner:哈建薇

Method and device for the mechanical or mechanical-biological treatment of waste

ActiveUS9708559B2Keep for a long timeReduce throughputBiofuelsSolid fuelsEnvironmental engineeringHigh water content

A method for treating waste in a mechanical or mechanical-biological waste treatment plant is provided. Waste is introduced into the waste treatment plant at at least one input point, the waste is homogenized by way of at least one agitator and the consistency of the waste in the waste treatment plant is determined. Water or waste which has a higher water content than the waste in the waste treatment plant is added in one scenario. Water is removed or waste having a lower water content is added in another scenario. Further, the method involves transporting the introduced waste to at least one output point, and removing the waste. The waste treatment plant is subdivided into at least two zones and in each zone the consistency of the waste is regulated separately by the input of waste and / or addition or removal of water.

Owner:ZWECKVERBAND ABFALLBEHANDLUNG KAHLENBERG

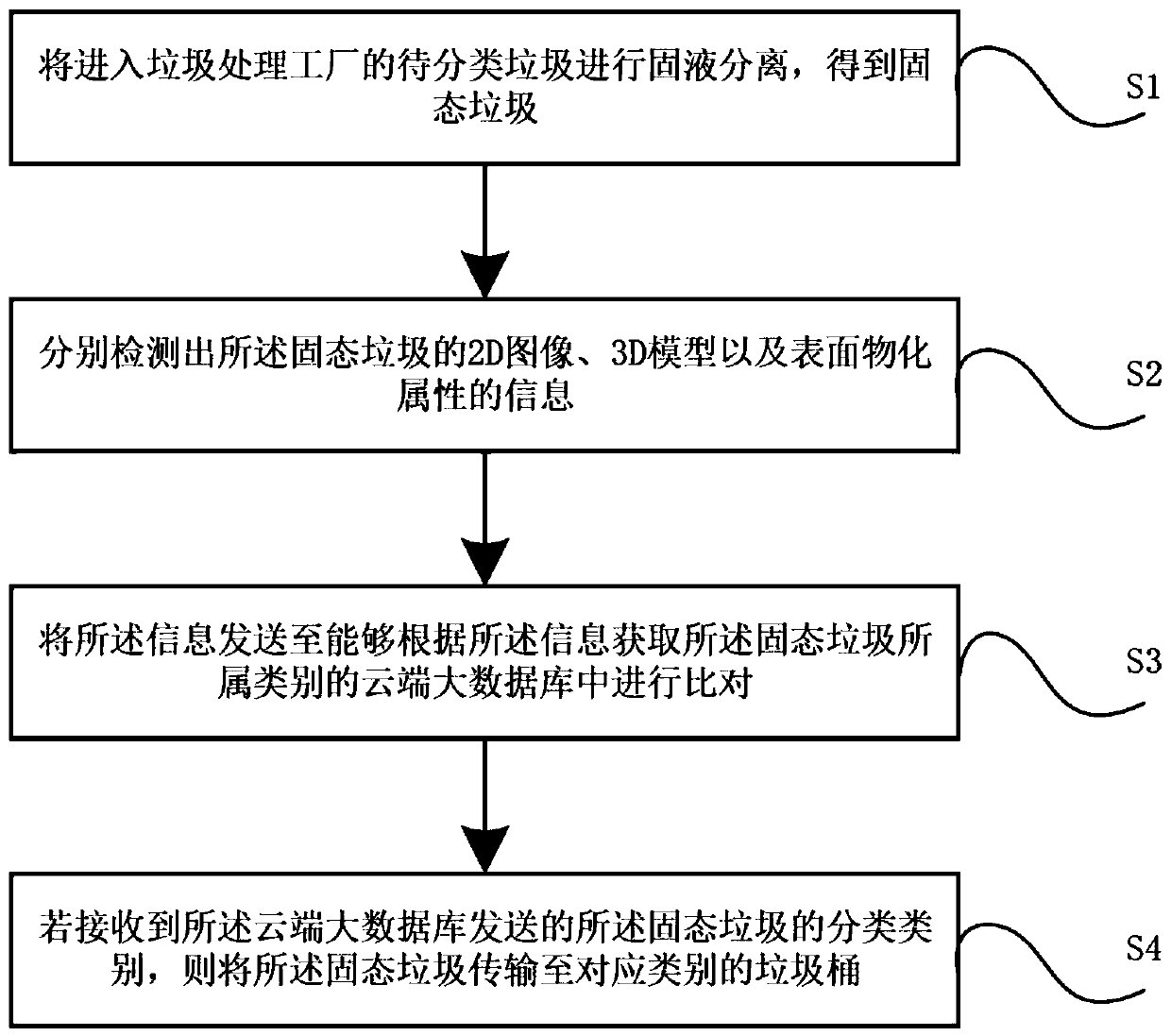

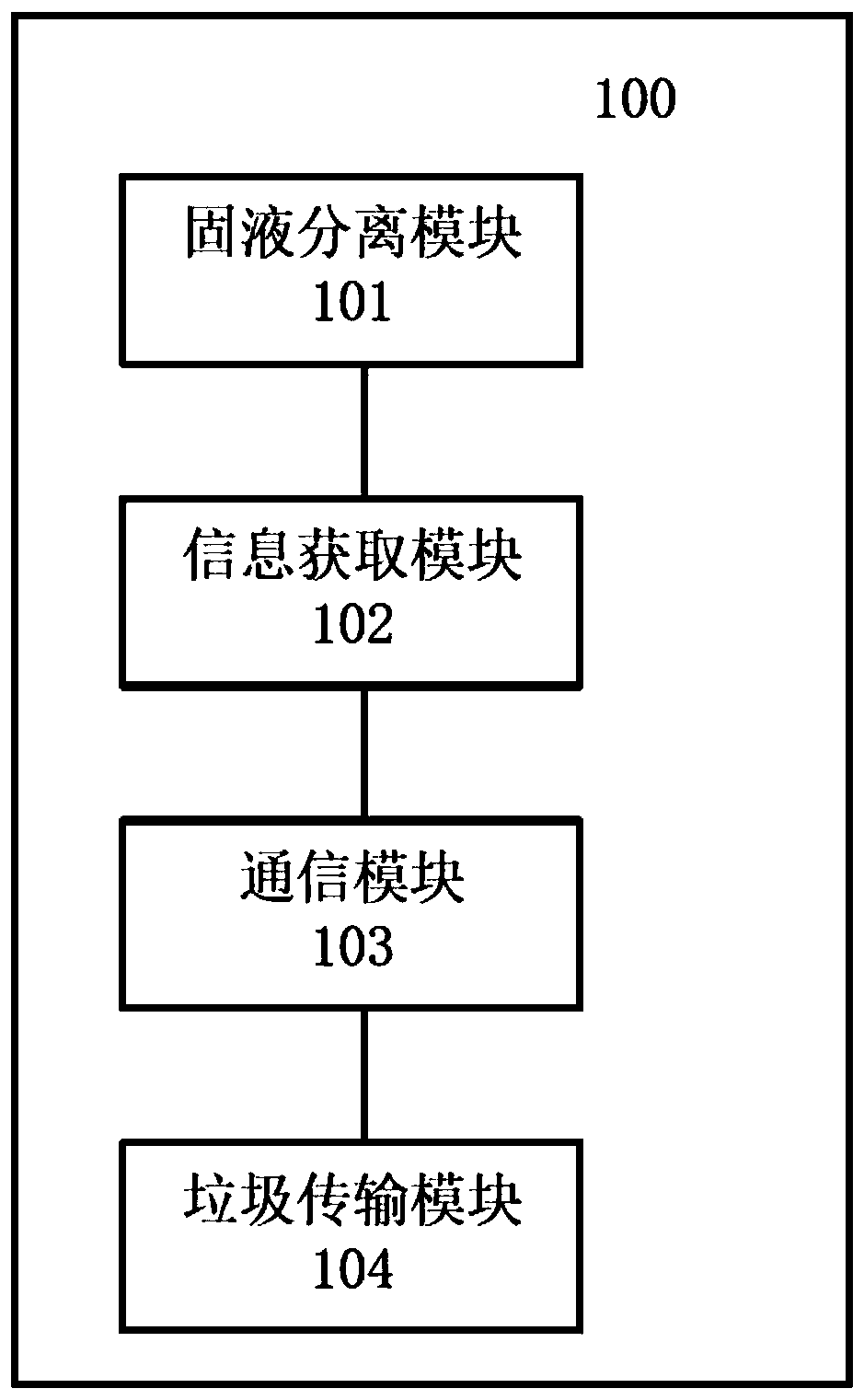

Household waste sorting method and system based on Internet big data and image treatment technology

InactiveCN110921146ARaise classification awarenessHigh precisionWaste collection and transferRefuse receptacles3d imageThe Internet

The invention discloses a household waste sorting method and a household waste sorting system based on Internet big data and an image treatment technology. The household waste sorting method comprisesthe following steps of: carrying out solid and liquid separation on to-be-sorted wastes which are sent to a waste treatment plant to obtain solid wastes; correspondingly detecting a 2D image, a 3D model and surface materialization attribute information of the solid wastes; sending the information to a cloud big database which can acquire the type of the solid wastes according to the information and then carrying out comparison; and sending the solid wastes to the corresponding type of garbage can after receiving the classification type of the solid wastes from the cloud bid database. The household waste sorting method disclosed by the invention improves the garbage sorting accuracy by virtue of the 2D image, the 3D image and physical material molecule analysis, and realizes great improvement of the garbage sorting accuracy in comparison with a method which implements garbage identification and sorting by using images only.

Owner:BENGBU COLLEGE

Process for treating sludge and manufacturing bioorganically-augmented high nitrogen-containing inorganic fertilizer

ActiveUS9695092B2Reduce responsibilityEliminate needCalcareous fertilisersAlkali orthophosphate fertiliserPhosphateRetention time

The invention describes a new method for treating sludge, which can result in the production of high nitrogen organically-augmented inorganic fertilizer that incorporates municipal sludges or biosolids or organic sludges that can compete with traditional fertilizers such as ammonium phosphate, ammonium sulfate and urea on the commodity fertilizer marketplace. The method takes advantage of the thixotropic property of dewatered biosolids or organic sludge to create a pumpable paste-like material from the biosolids or organic sludge that is then treated with an oxidizer to reduce odorant effects and an acid. This mix is then interacted with concentrated sulfuric and or phosphoric acids and an ammonia source or alternatively a hot or molten melt or salt of ammonium sulfate / phosphate to form a fertilizer mix. The present invention controls the heat, atmospheric pressure and retention time of the fertilizer mix in the reaction vessel. When a fertilizer melt is formed ammoniation is subsequently completed by the specific use of vaporized ammonia. The invention can also be an add-on to commercial production of ammonium salts. The fertilizer produced by the present invention contains more than 8 wt. % nitrogen and preferably 15 wt. % nitrogen. The invention is oriented to be tailored to the biosolids production for individual municipal waste treatment plants in order to keep the fertilizer manufacturing plants of the present invention small with a minimization of logistics and liability.

Owner:GENERATE LENDING LLC +1

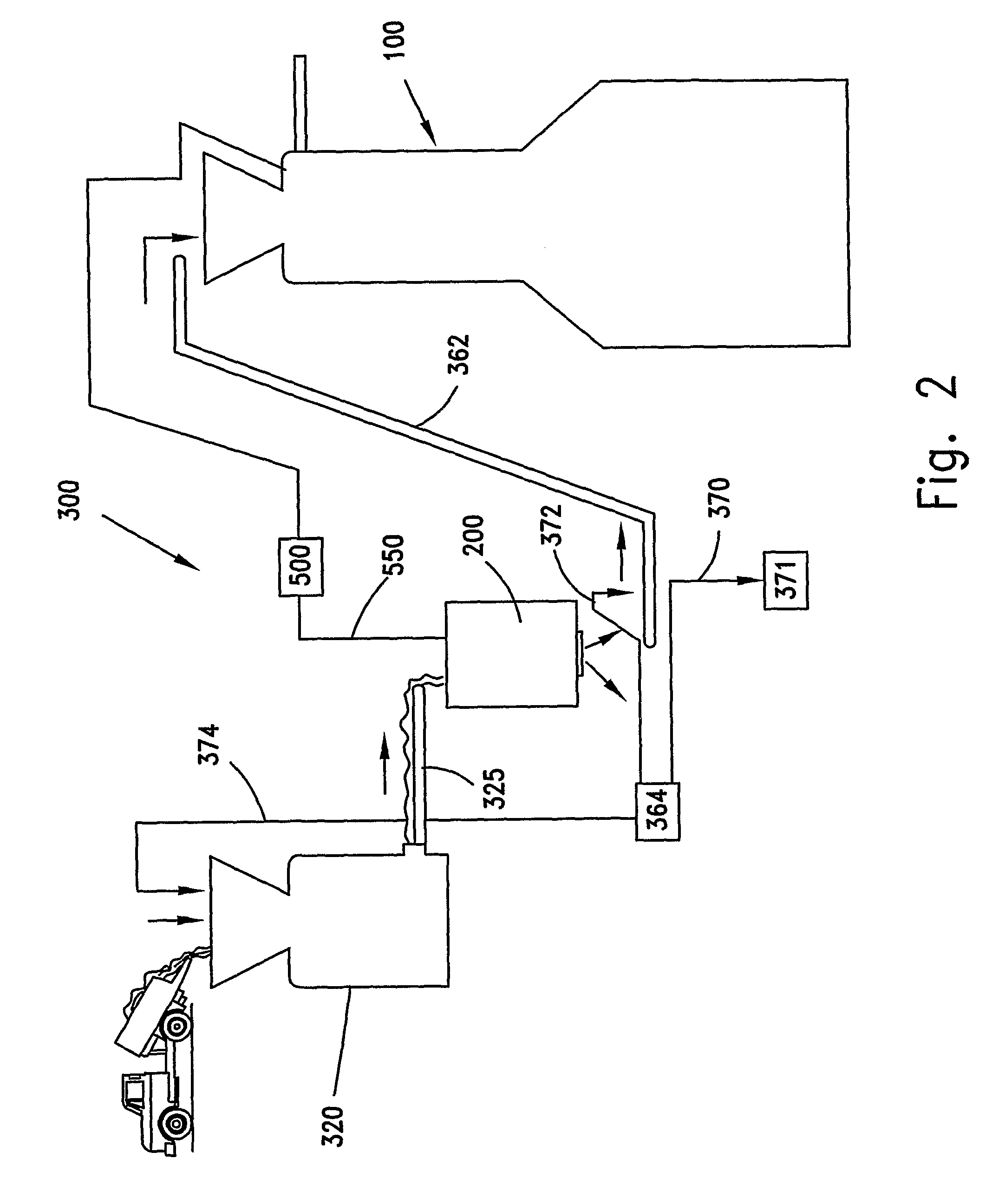

System for controlling the level of potential pollutants in a waste treatment plant

InactiveUS7513371B2Material analysis using wave/particle radiationConversion outside reactor/acceleratorsCompound (substance)Neutron

The invention is an apparatus and method for on-line sorting of waste matter, at the entrance to a waste processing plant, according to the level of specific chemicals, typically chlorine detected therein. The apparatus comprises a waste matter inlet that provides waste matter to a weighing module, preferably until a preset limit is reached. Then, this control volume of waste is introduced into a pulsed neutron material analyzer that is optimized for the determination of the content of the specific chemical in the control volume. A control means such as a computer then decides whether the level of the chemical in the waste control volume is above or below a preset threshold, and accordingly channels the waste into one or another of two channels. One of these channels accepts waste with low content of the given chemical, for introduction into the waste processing chamber. The other channel stores the waste until, for example, it may be mixed with other waste having a sufficient low content such that the overall amount of the chemical is still below the threshold value.

Owner:E E R ENVIRONMENTAL ENERGY RESOURCES (ISRAEL) LTD (IL)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com